Hydraulic follow-up rotating mechanism

A slewing mechanism and follow-up technology, which is applied in the direction of fluid pressure actuators, mechanical equipment, servo motors, etc., can solve difficulties, limit the output power and application range of hydraulic follow-up slewing mechanisms, and cannot realize high output torque of slewing mechanisms, etc. problem, to achieve the effect of wide range of use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

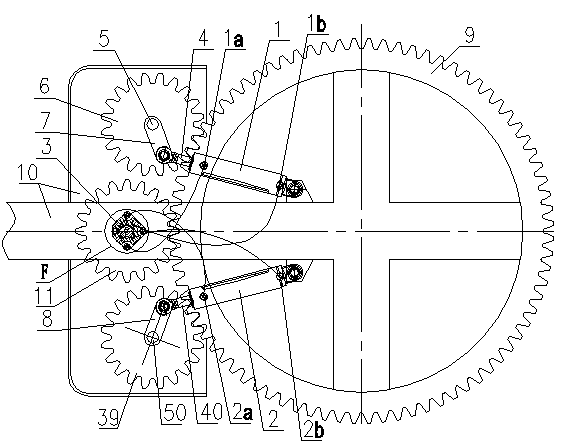

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

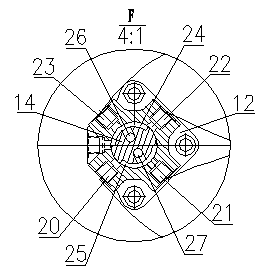

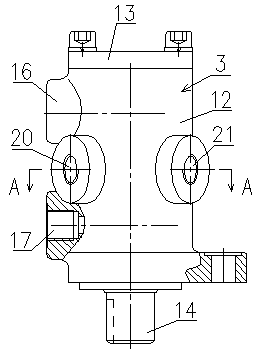

[0023] like figure 1 As shown, the hydraulic follow-up slewing mechanism includes a fixed frame 10, two mandrels 5 and 50 arranged on the frame 10 through bearings, and a structure that can transmit torque through keys or welding is arranged on each mandrel. The pinion 6 or 39 on the 5 or 50, the two double-acting oil cylinders 1 and 2 hinged with the frame 10 at the bottom, and the fixed rotary valve 3, the piston rods 4 or 40 of the two double-acting oil cylinders 1 and 2 It is hinged with one end of the corresponding connecting rod 7 or 8, and the other end of each connecting rod 7, 8 is connected with the corresponding mandrel 5 or 50 by welding, and the two small gears 6, 39 are meshed with the large gear 9 , the large gear 9 is also meshed with a follower gear 11, such as Figure 2 to Figure 11 As shown, the rotary valve 3 includes a valve body 12, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com