Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

77 results about "Friction tape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Friction tape is a type of adhesive tape made from cloth impregnated with a rubber-based adhesive, mainly used to insulate splices in electric wires and cables. Because the adhesive is impregnated in the cloth, friction tape is sticky on both sides. The rubber-based adhesive makes it an electrical insulator and provides a degree of protection from liquids and corrosion. In the past, friction tape was widely used by electricians, but PVC electrical tape has replaced it in most applications today. The frictional properties of the tape come from the cloth material, which is usually made from cotton, while the fabric base protects electrical splices against punctures and abrasion.

Friction electrostatic painting infrared ray cured powder paint for electromagnetic wire and lacquered wire, preparation and use thereof

InactiveCN101469147AWill not polluteImprove labor productivityPlastic/resin/waxes insulatorsPretreated surfacesInfraredResource saving

The invention relates to a functional coating, in particular to a friction electrostatic spraying infrared curing powder coating for an electromagnetic wire and an enamelled wire. The powder coating consists of a resin, a curing agent, a pigment, a filler and an additives; the powdery coating comprises the following compositions by mass percentage: 33 to 62 percent of the thermosetting resin, 5 to 33 percent of the curing agent, 1 to 29 percent of the pigment and the filler, 0.5 to 1 percent of triboelectric additive, 0.5 to 1 percent of powder loosening additive and 1 to 5 percent of other additives; a preparation process comprises: the compositions of a formula are subjected to premixing and melt extrusion and mixing, are cooled to room temperature and are broken into a sheet material; the sheet material is pulverized to ultrafine powder and is separated to obtain a semifinished product of powder coating with less than 160 meshes; and the semifinished product is demagnetized to obtain a finished product. The friction electrostatic spraying infrared curing powder coating for the electromagnetic wire and the enamelled wire does not produce wastewater, waste gas and waste residue in the production process, does not produce any pollution to environment, has high utilization rate and belongs to a resource-saving type product.

Owner:JIANGSU LANLING POLYMER MATERIAL CO LTD

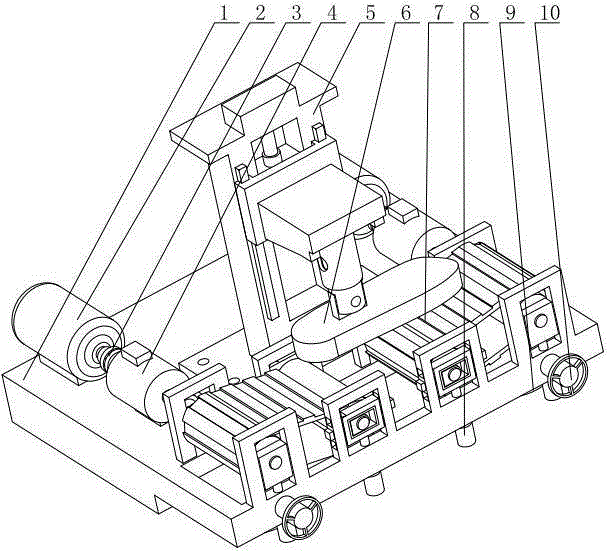

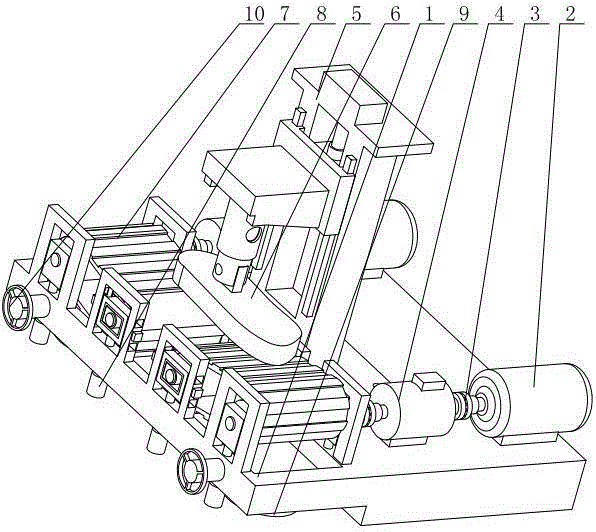

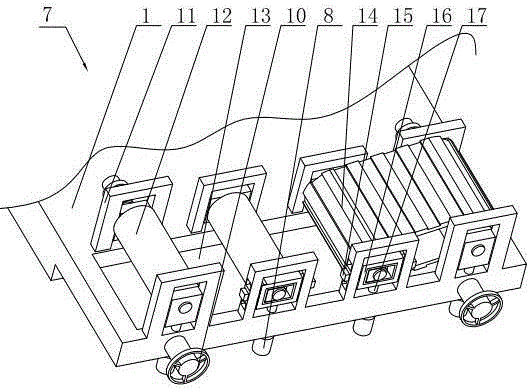

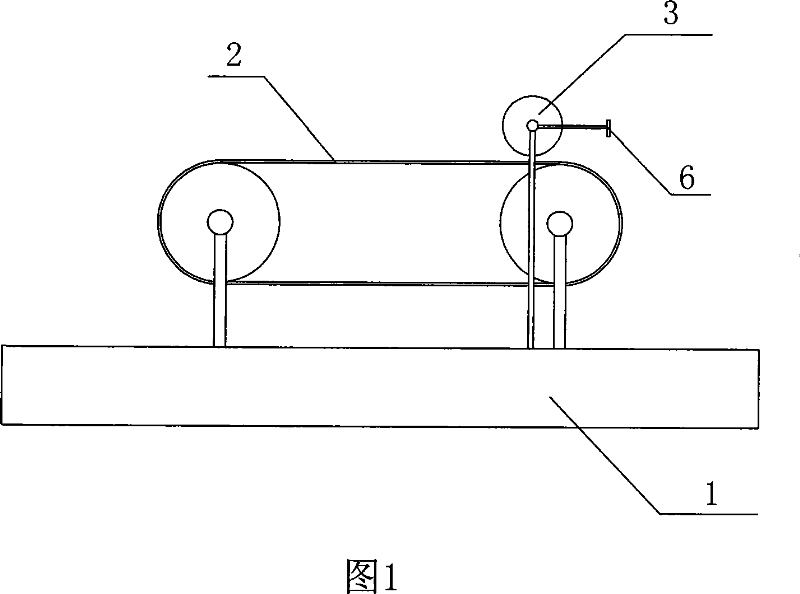

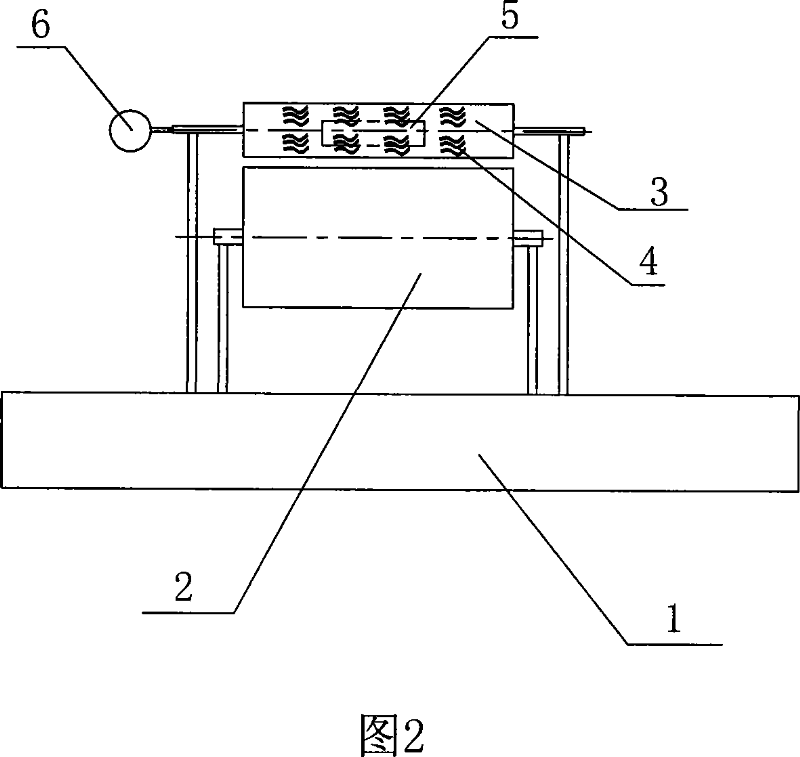

Sole abrasion resistance testing device capable of simulating various environments

ActiveCN105193003ACompact structureReasonable structureFoot measurement devicesEngineeringDrive motor

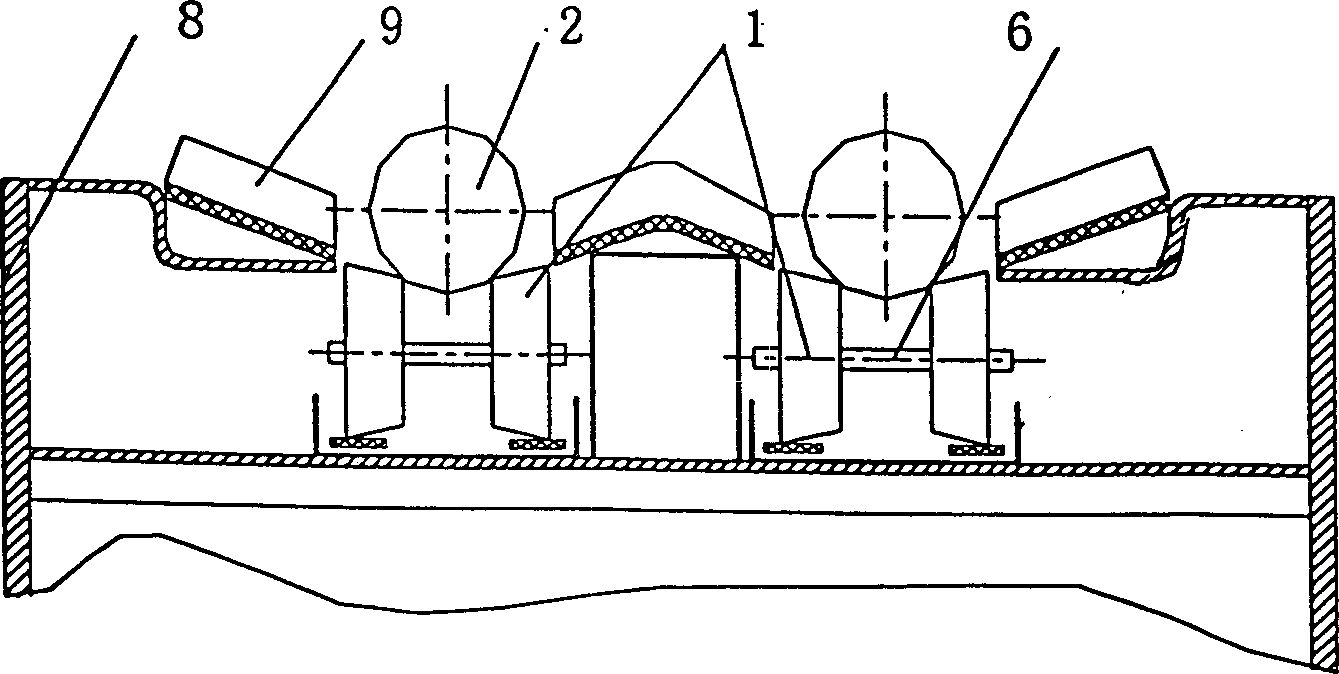

A sole abrasion resistance testing device capable of simulating various environments comprises an experiment table base; two friction experiment devices are arranged at the front end of the experiment table base and mounted at an interval; driving motors used for controlling the movement of the experiment table base, couplers and torque sensors are mounted at two ends of the experiment table base respectively; a hydraulic pressurizing device is mounted in the middle of the experiment table base; a foot model device is connected to the output end of the hydraulic pressurizing device and arranged at the tops of the friction experiment devices. Due to up-down movement of transmission rollers in the friction experiment devices, discontinuous friction of two friction tapes on a shoe, gap between the friction tapes, and replaceability of the friction tapes, the front and back soles of the shoe are abraded by the two friction experiment devices respectively; due to the pressure control of the hydraulic stress application device, and replaceability of a foot model, the walking rules of people can be well simulated; due to torque change measurement of the torque sensors, change of friction coefficient can be obtained indirectly to reflect abrasion degree, so that the obtained data are more direct and accurate.

Owner:JIANGNAN UNIV

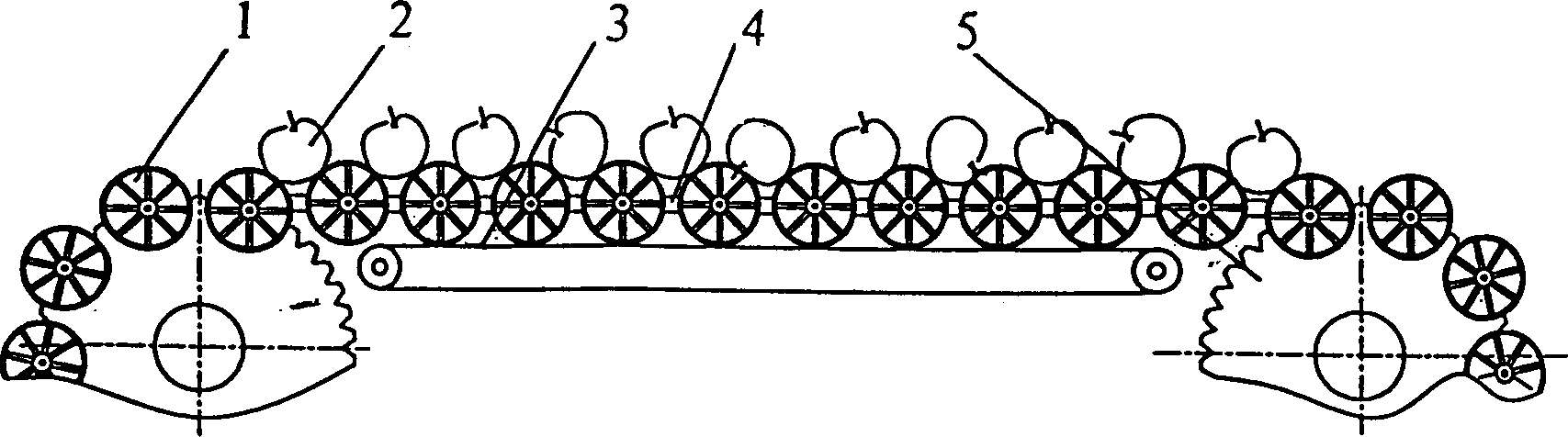

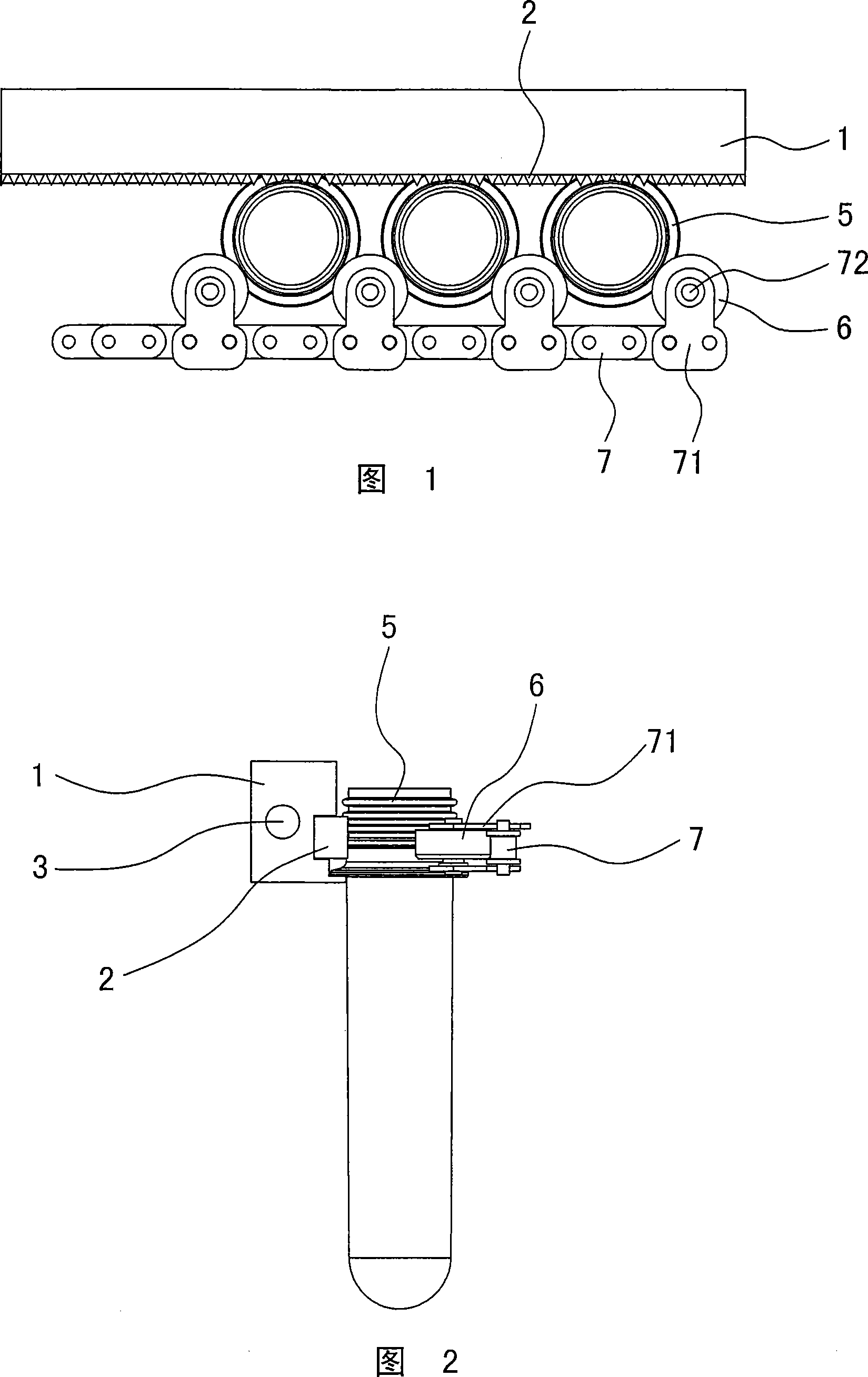

Equipment capable of implementing automatic single-line conveyance of quasi-spherical fruits and uniformly turning them

Double-cone rollers are uniformly mounted on the chain at a certain interval by means of mutually-parallel horizontal small shafts, and can be rotated around the small shaft, when the large chain wheel is driven by motor and is used for driving chain to make it rotate, the double-cone roller can be moved with horizontal small shaft, tow sides of every line of double-cone rollers is equipped with slope board respectively, under the auxiliary action of slope board the quasi-spherical fruits can be automatically arranged into single line and come into between rollers, a friction tape mounted under the double-cone rollers is driven by another motor and rotated, the quasi-spherical fruits can be turned on the rollers. Said ivnention is reliable in operation, can be used for wax-spraying, polishing and sorting fruits.

Owner:ZHEJIANG UNIV

Power-Transmitting Friction Belt and Method for Manufacturing Same

ActiveUS20170009847A1Excellent abrasion resistanceImprove transmission performanceV-beltsOrnamental textile articlesFriction tapeSurface cover

The present invention relates to a frictional power transmission belt having a frictional power transmission surface covered with a warp knitted fabric, in which the warp knitted fabric contains a water absorptive thread in a proportion of 30% by mass or more based on the total amount of threads constituting the warp knitted fabric and a wale direction of the warp knitted fabric is substantially parallel to a belt longitudinal direction.

Owner:MITSUBOSHI BELTING LTD

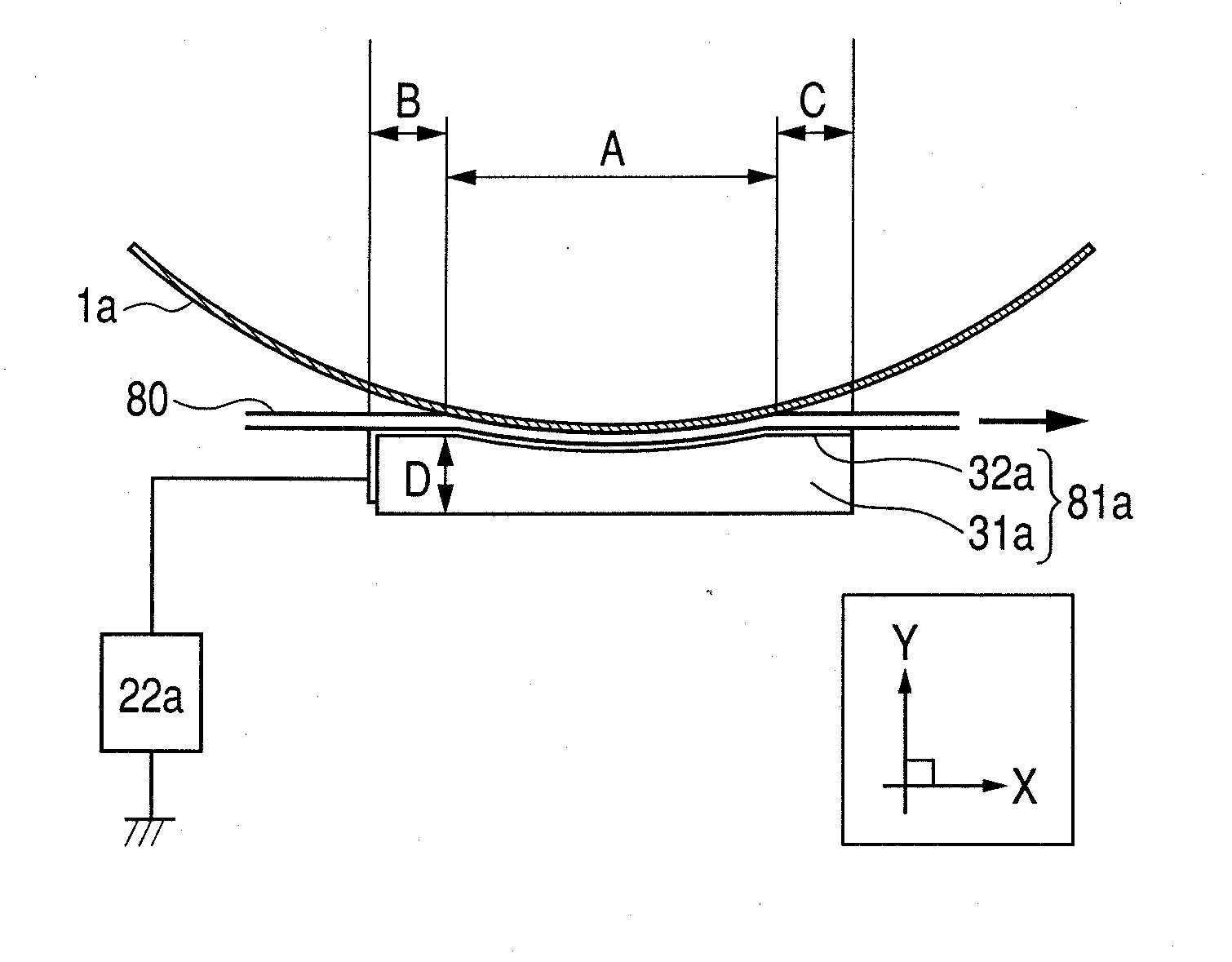

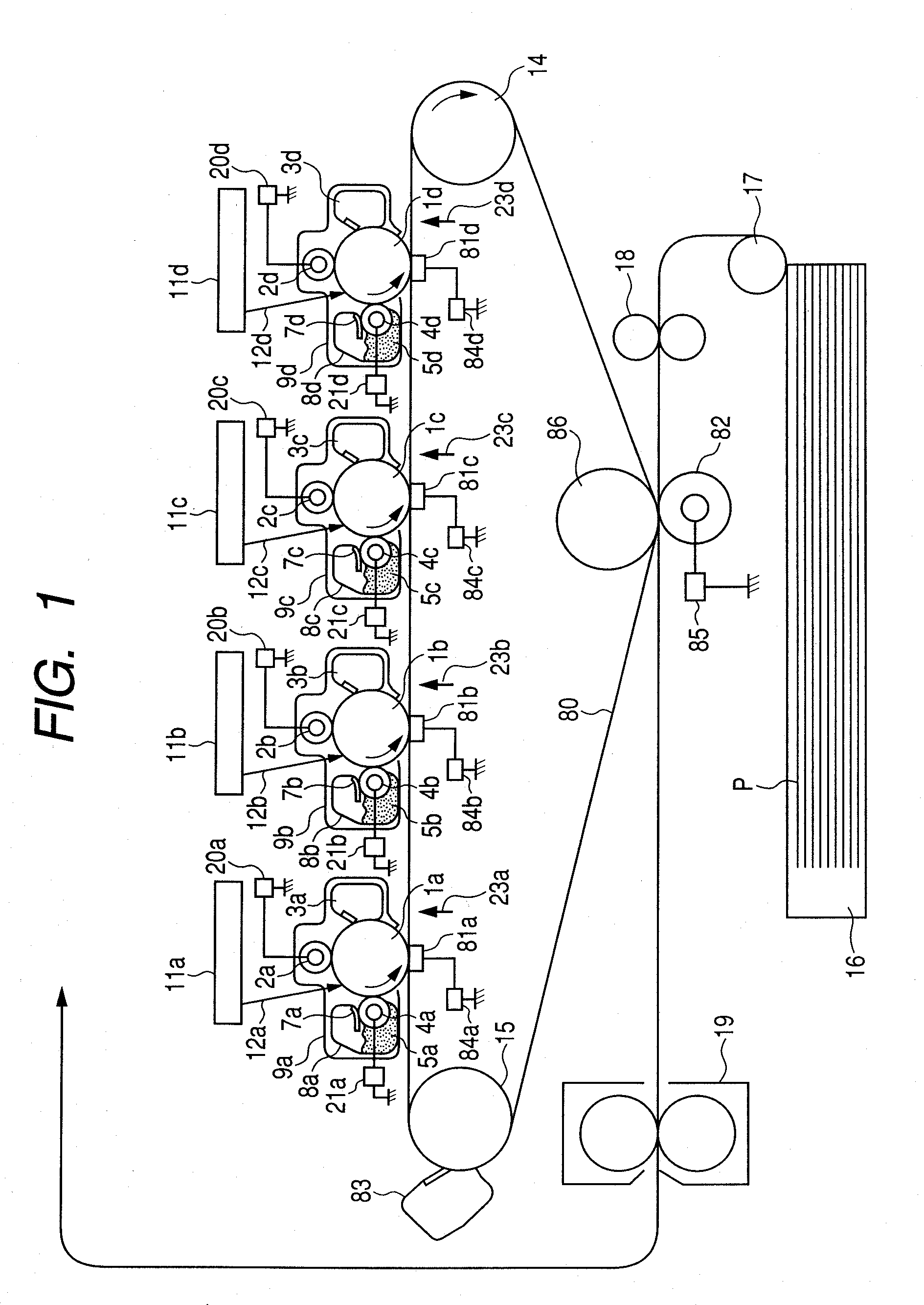

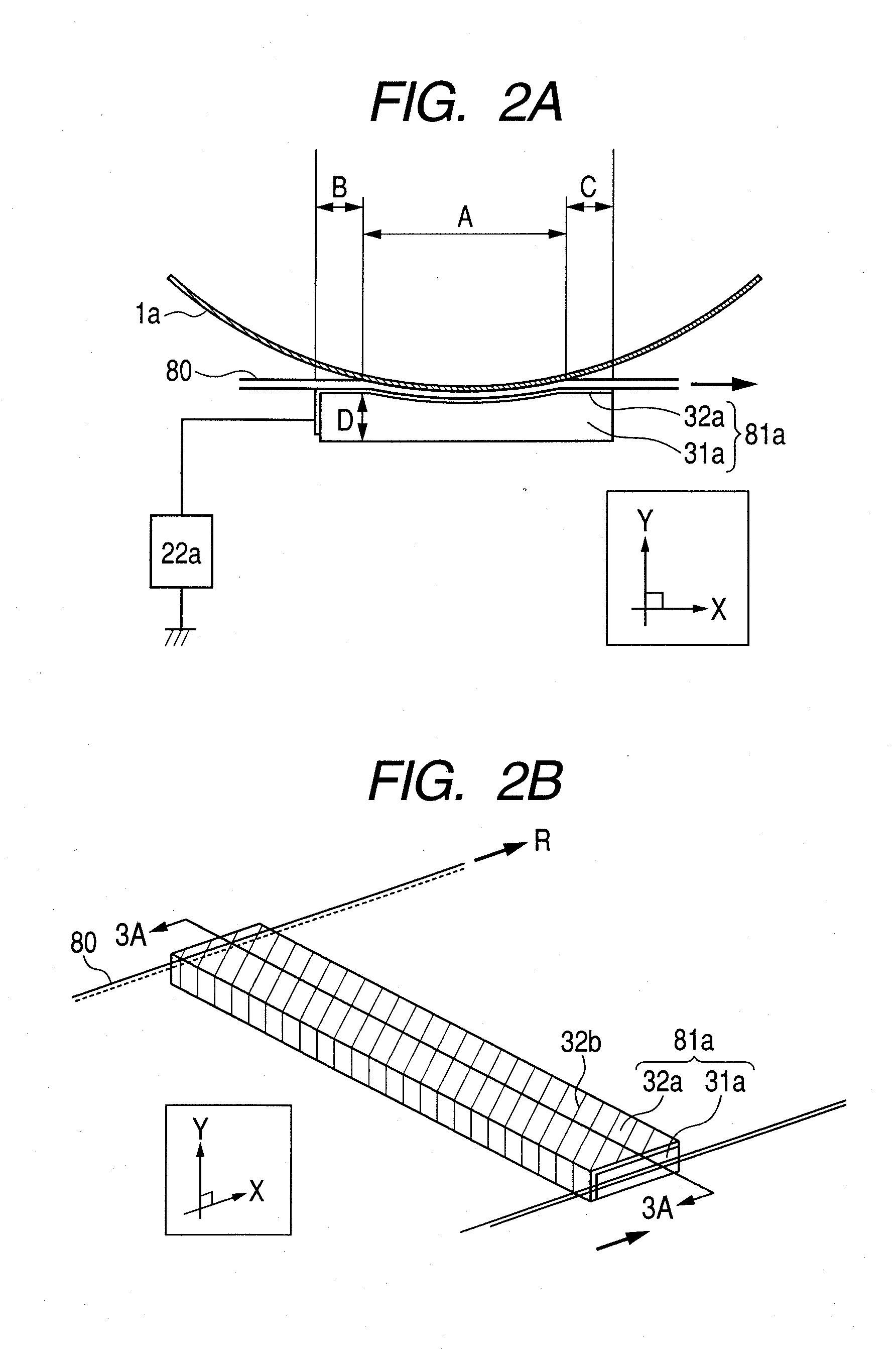

Image forming apparatus

ActiveUS20090202281A1Increase frictionSuppressing increase in drive torque of the beltElectrographic process apparatusImage formationEngineering

An image forming apparatus includes: an image bearing member for bearing a toner image; a belt for conveying the toner image; and a transfer device for rubbing the belt, and a surface of the transfer device, which is brought into contact with the belt includes linear concave portions or linear convex portions. The image forming apparatus of the present invention prevents a friction force between the belt and the transfer device rubbing the belt from increasing and brings a transfer member into a stable contact with the belt for conveying the toner image, thereby suppressing increase in drive torque of the belt which rubs the transfer device and suppressing occurrence of image failure.

Owner:CANON KK

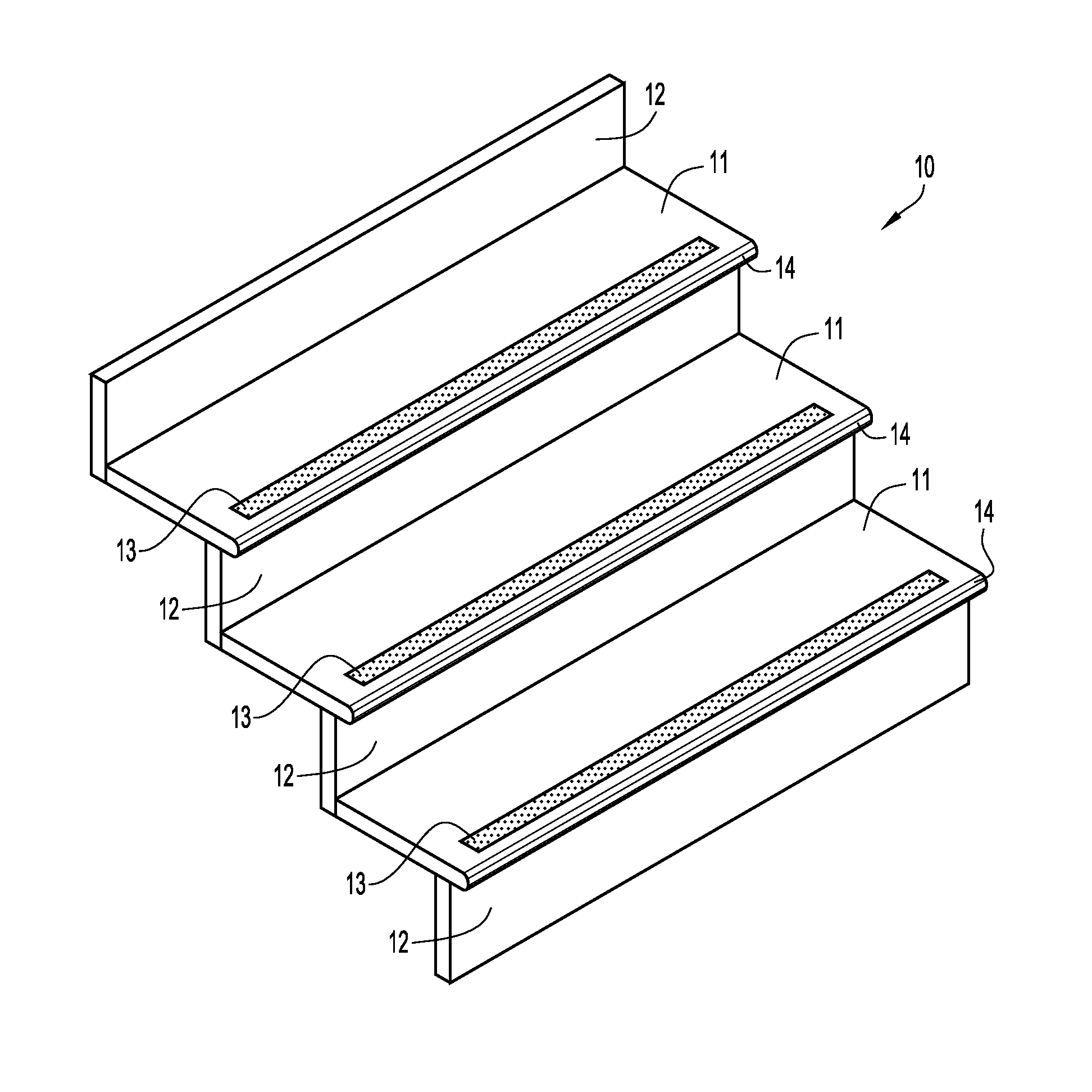

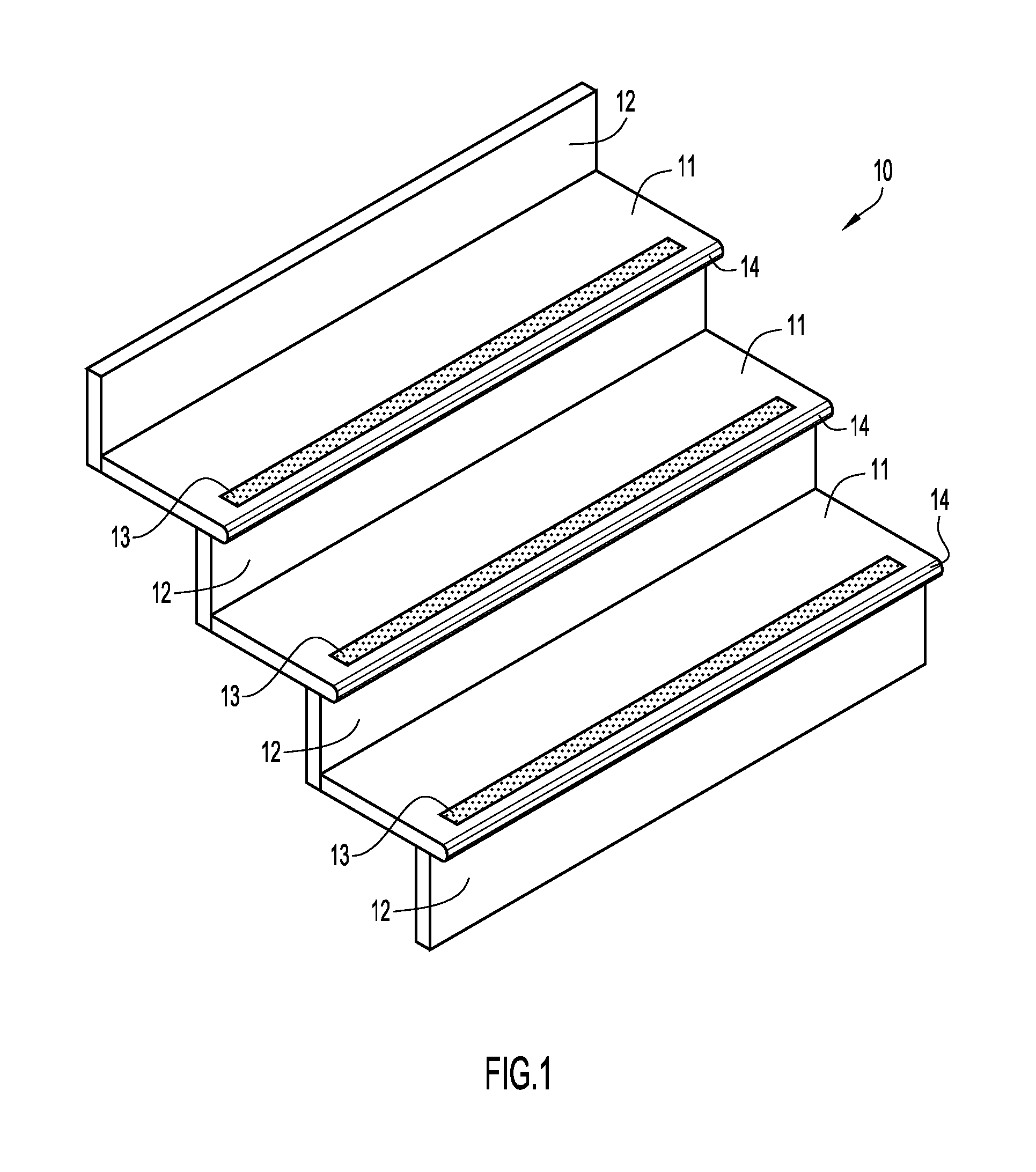

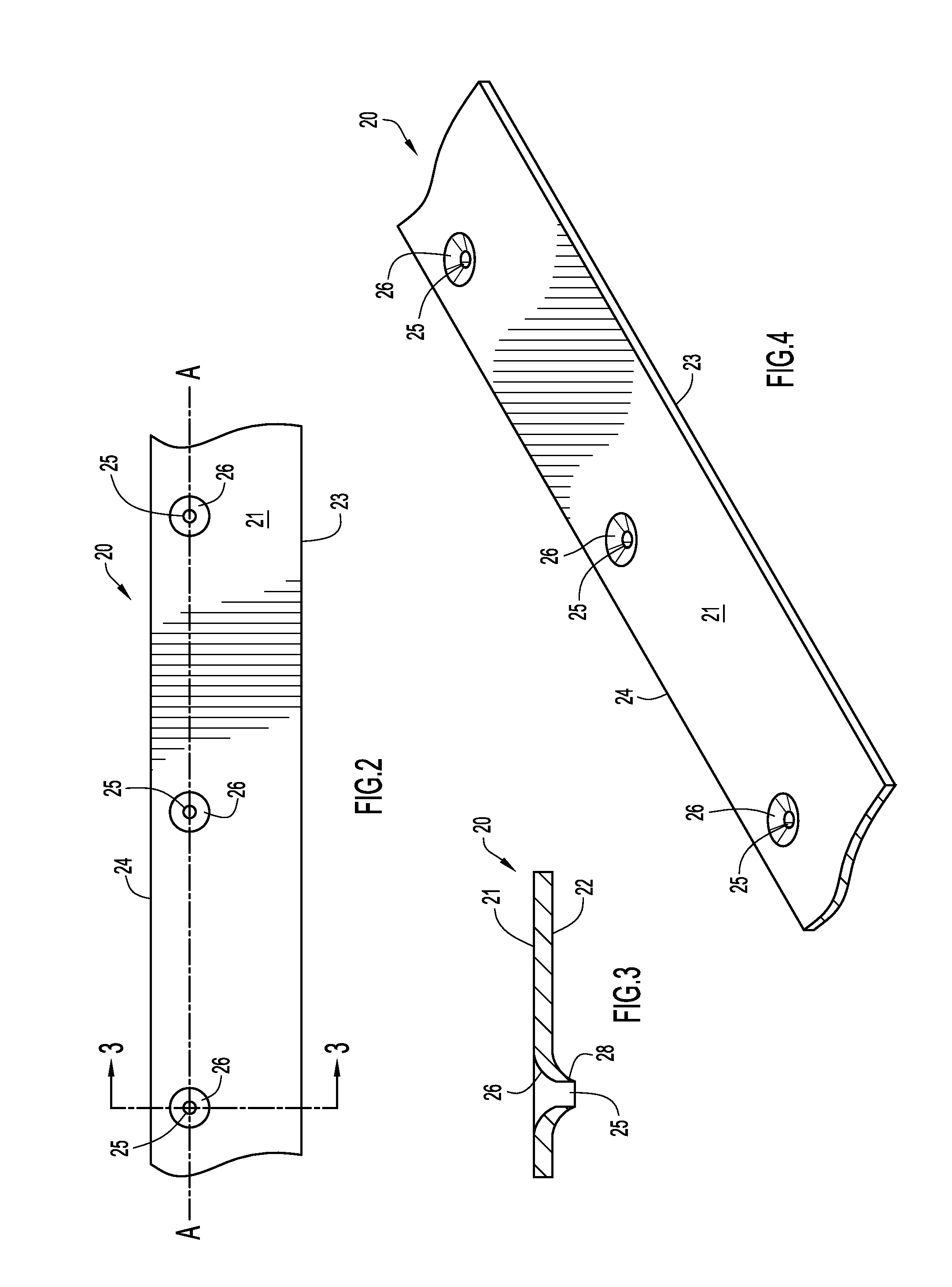

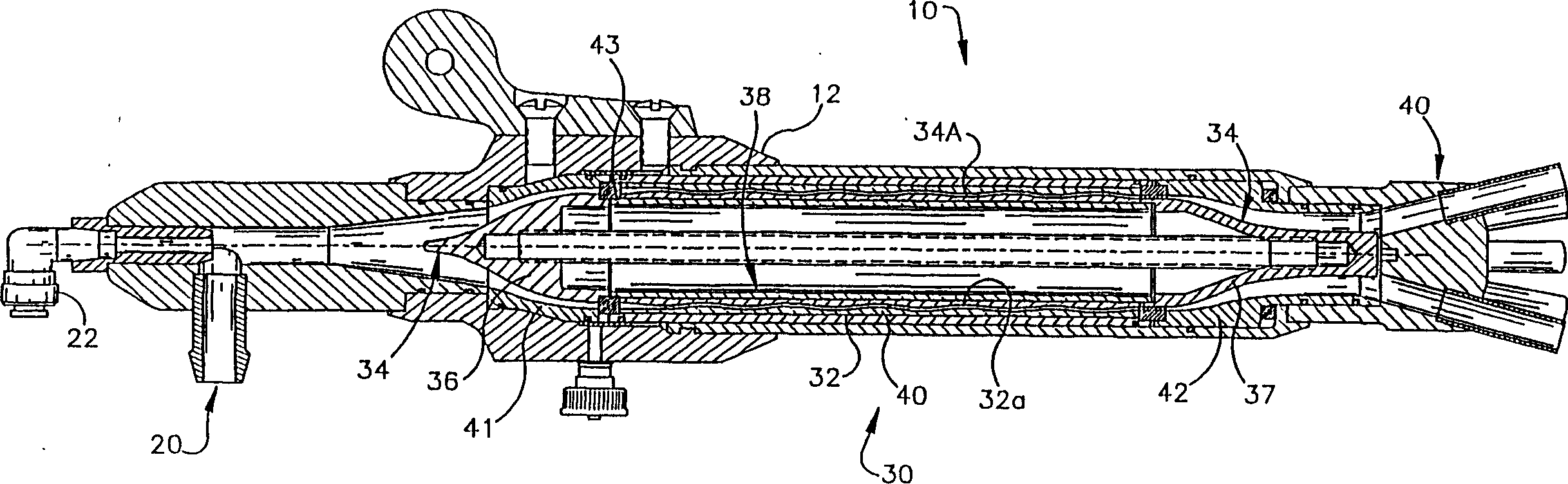

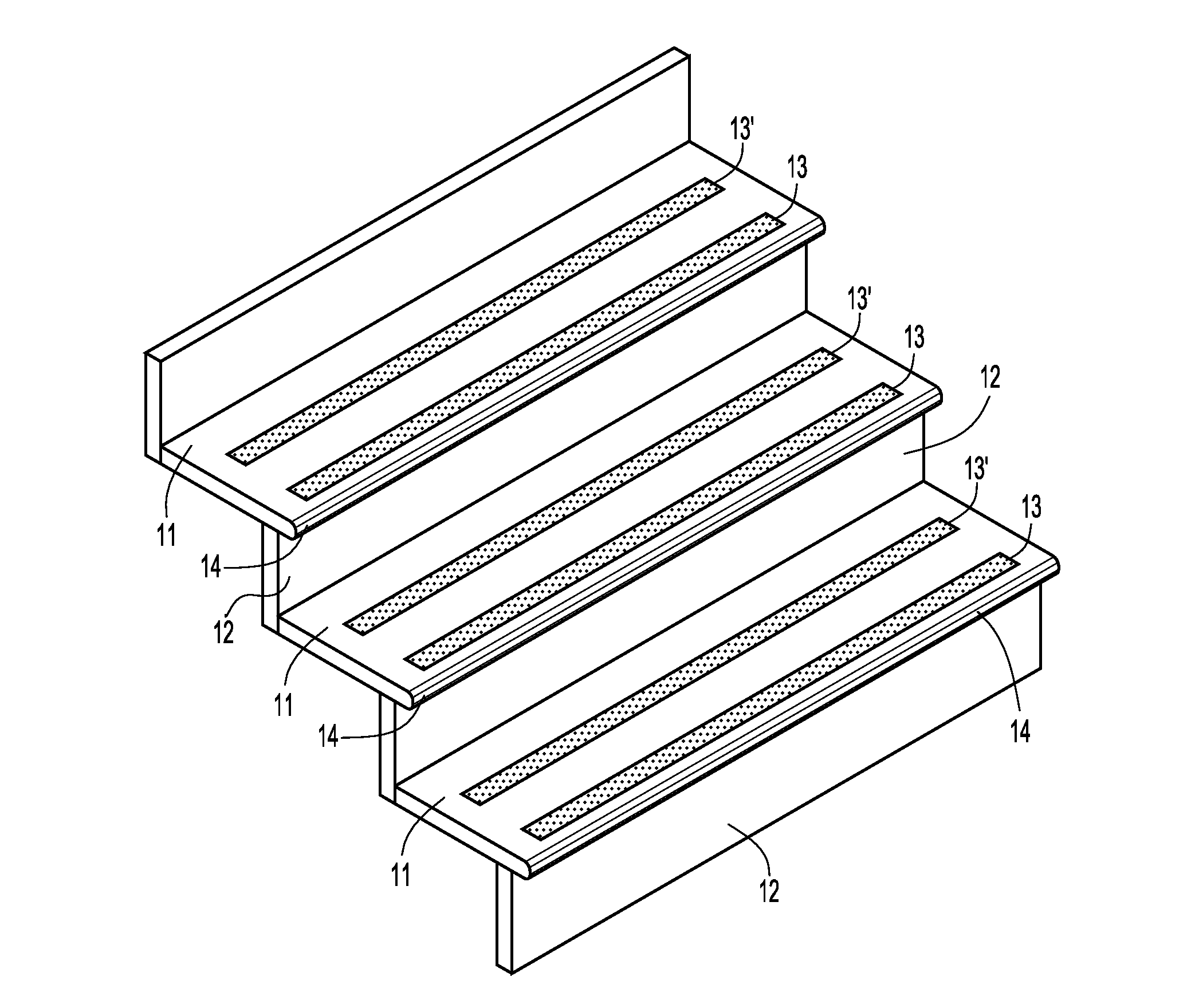

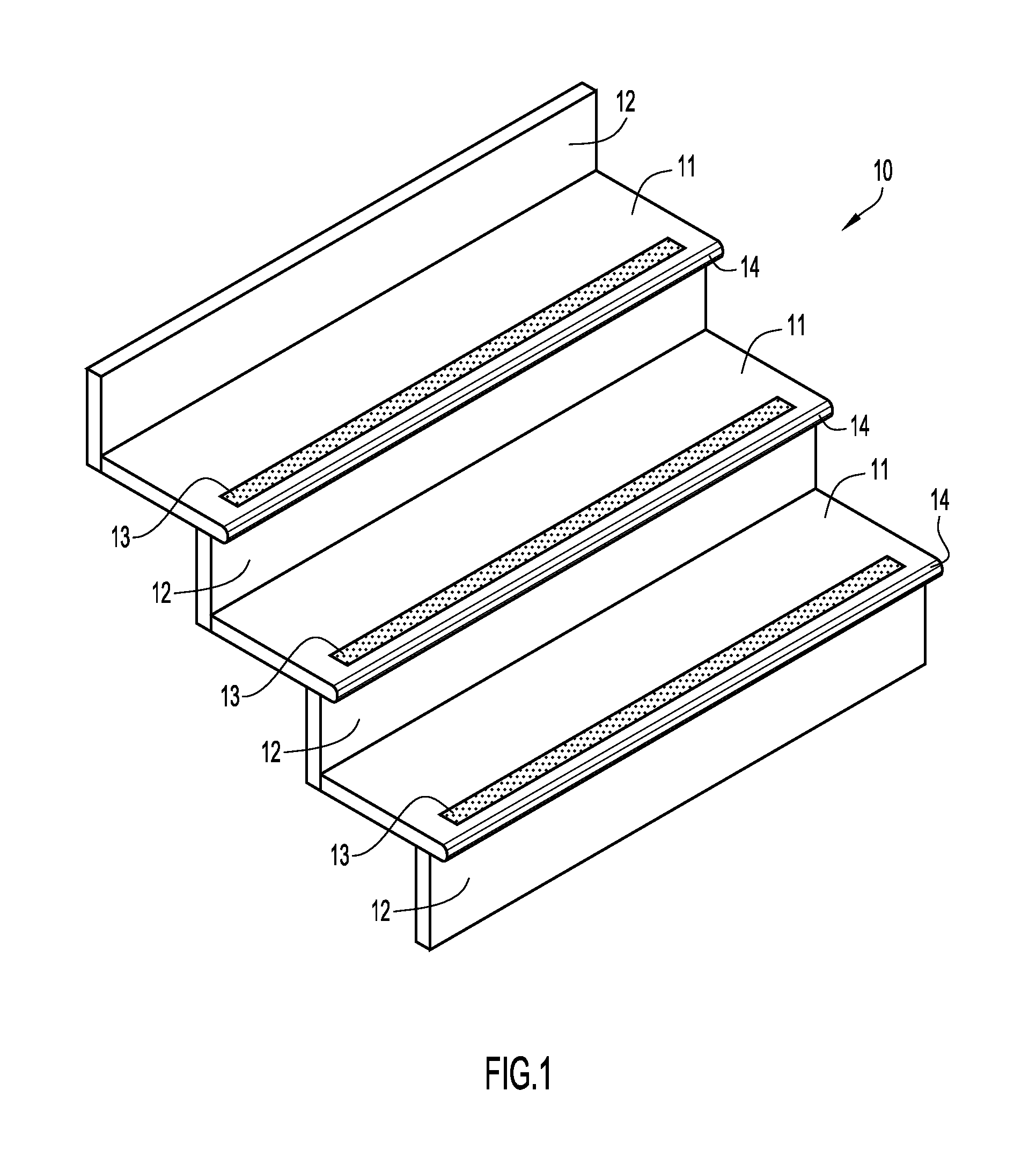

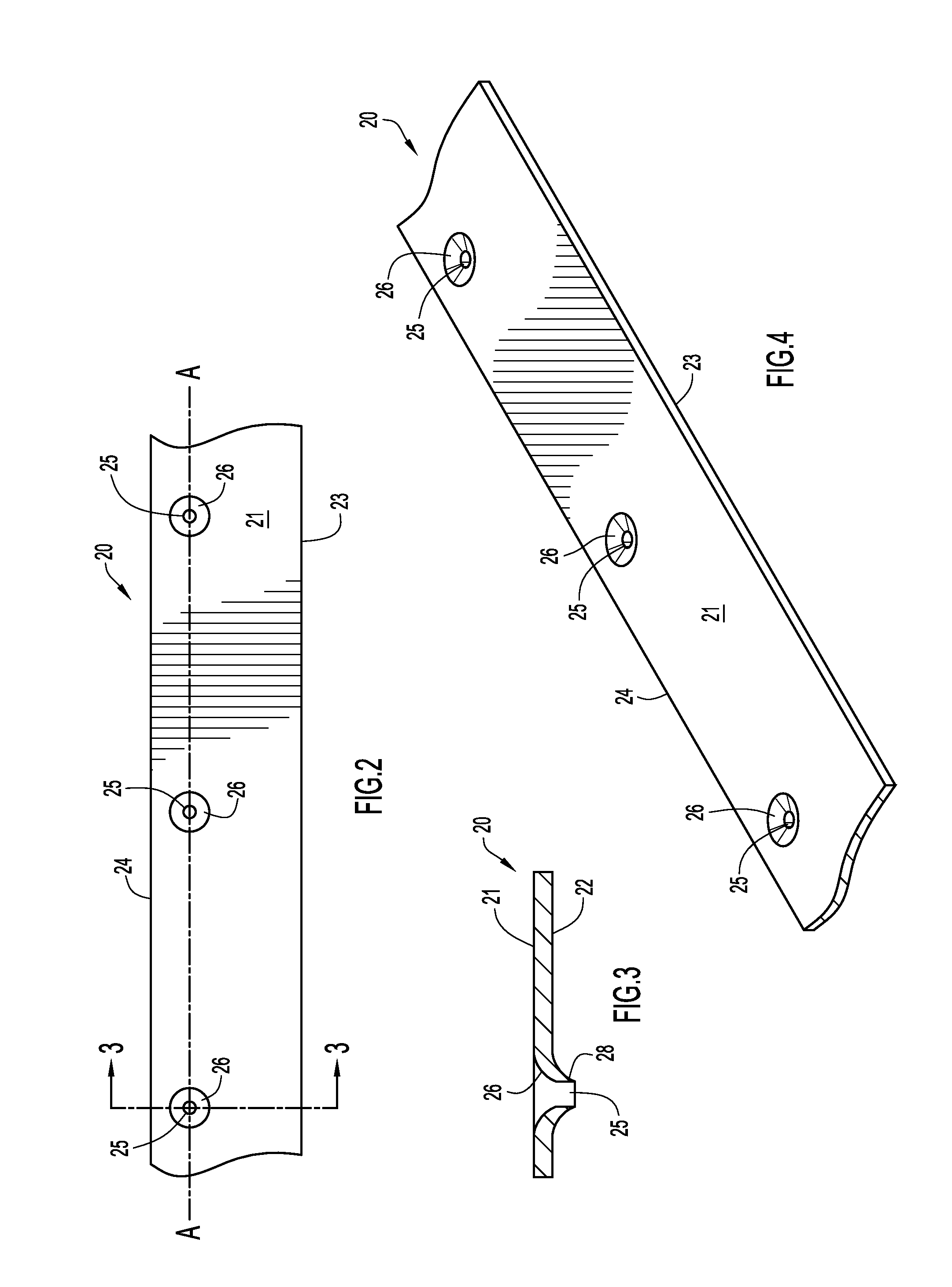

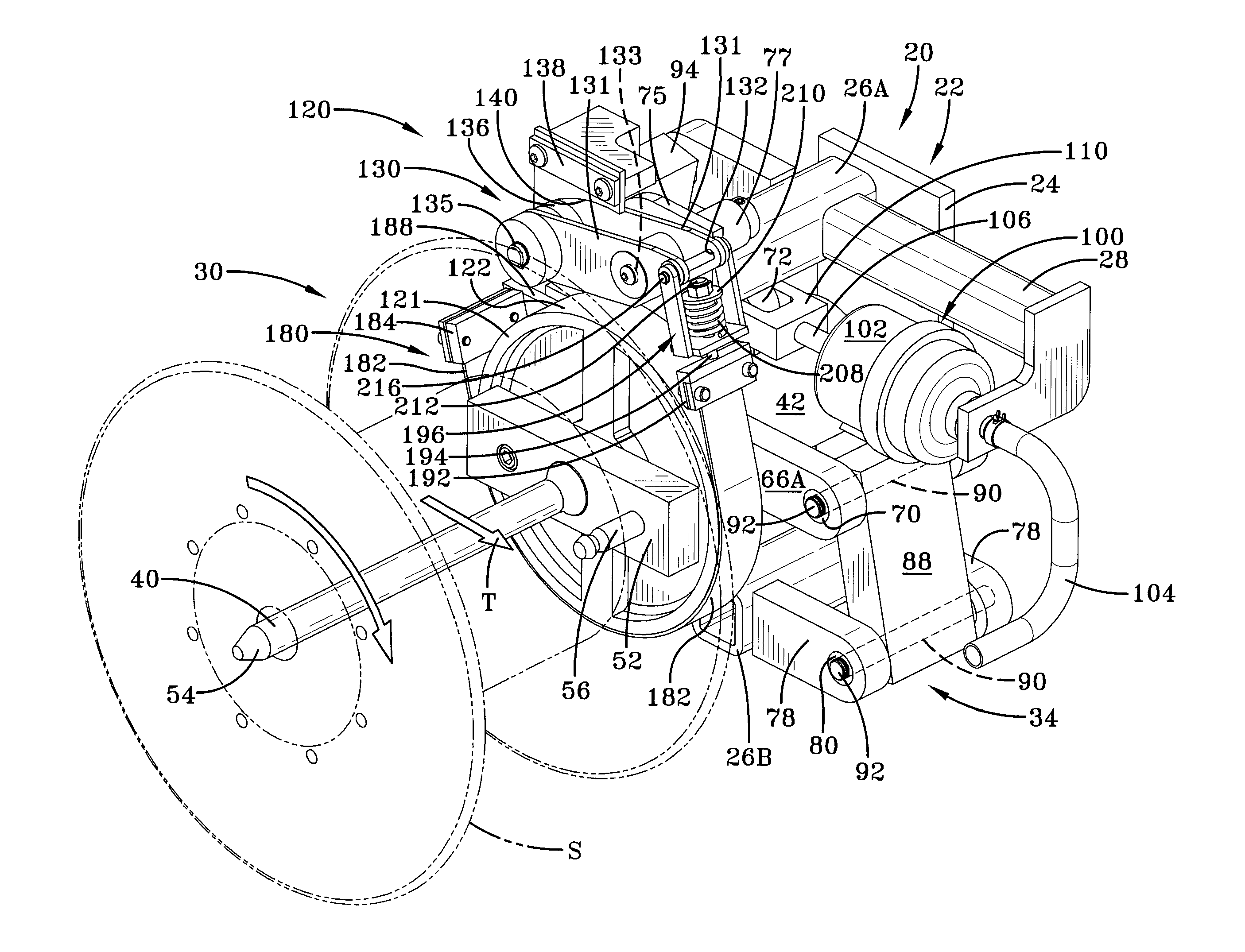

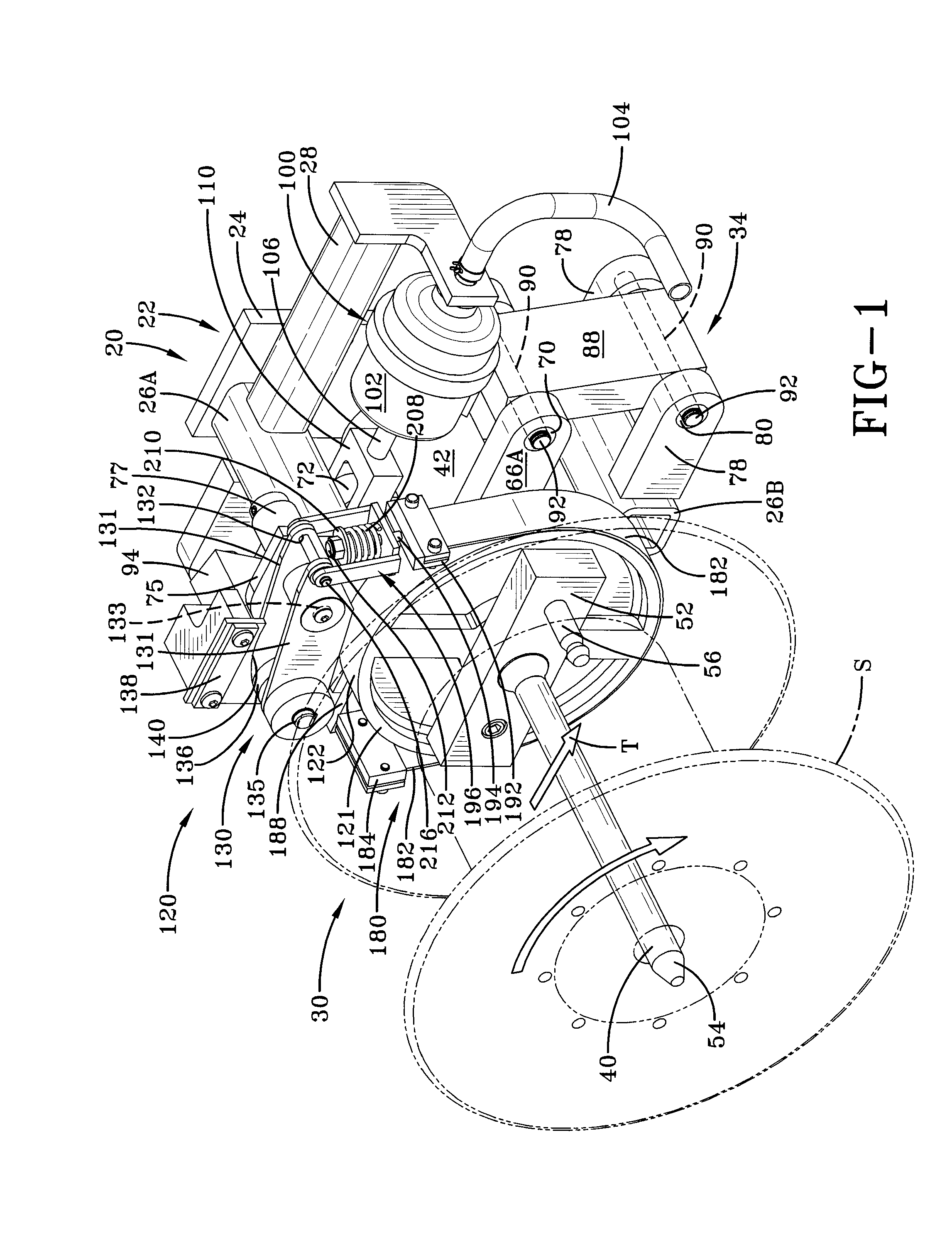

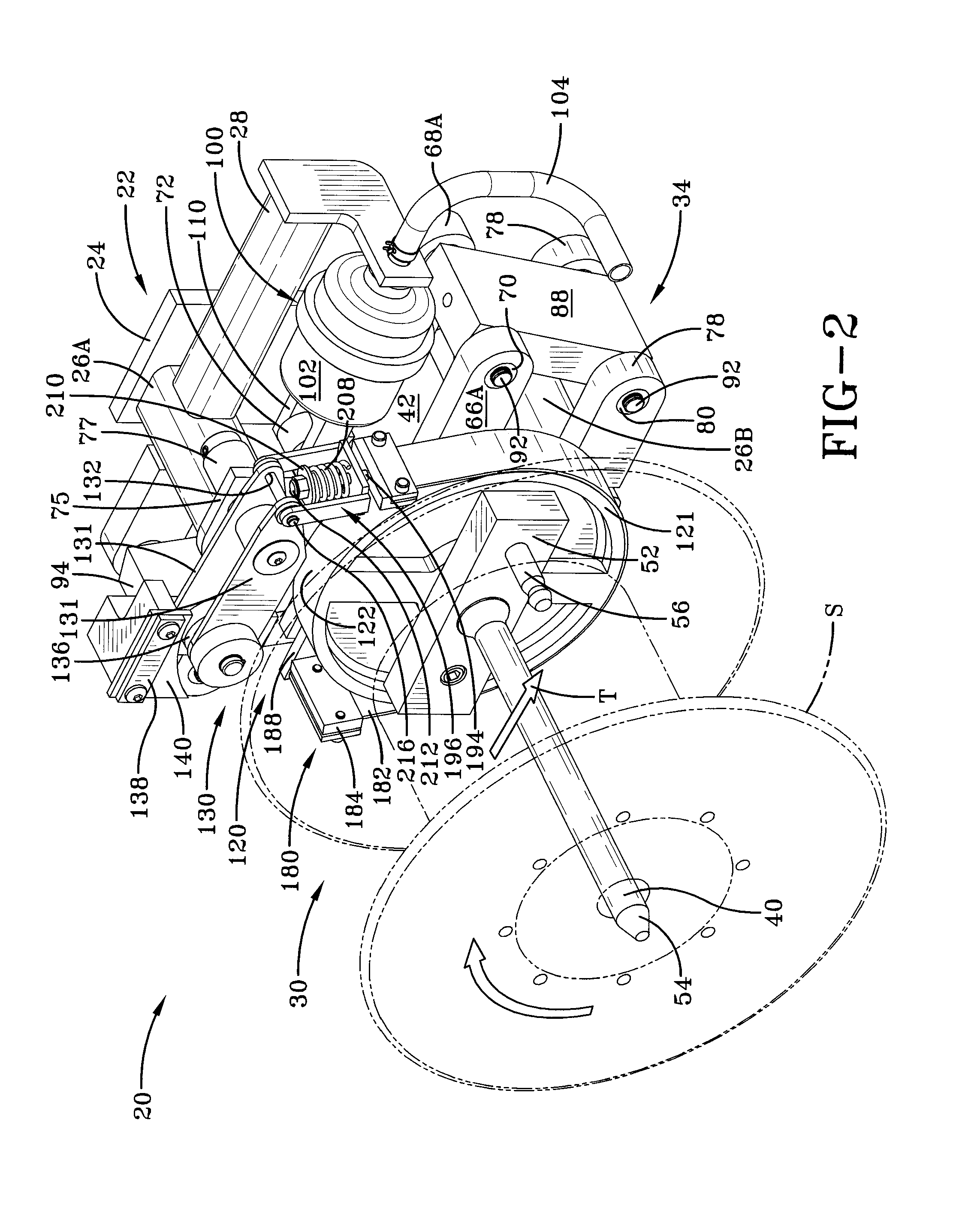

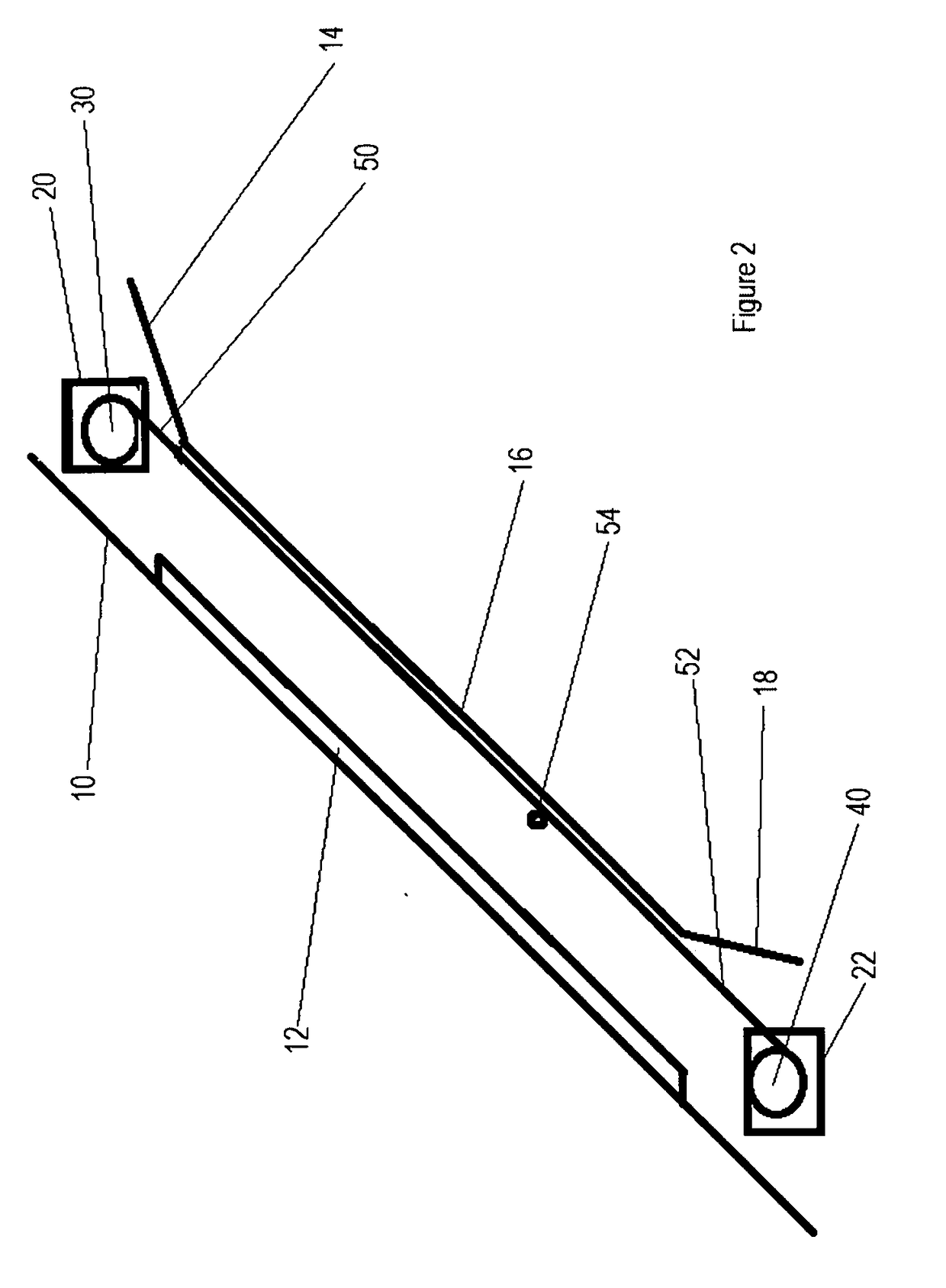

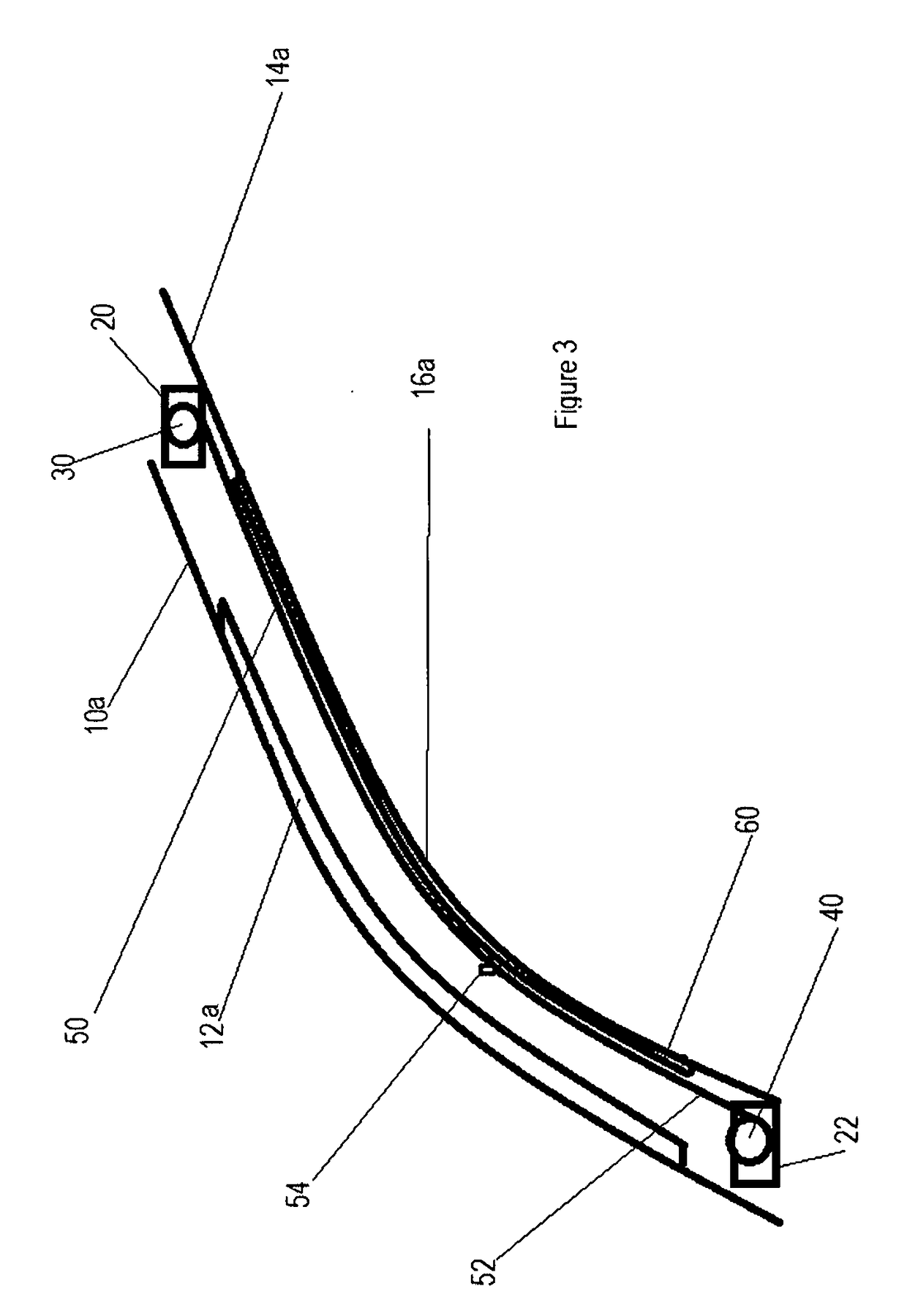

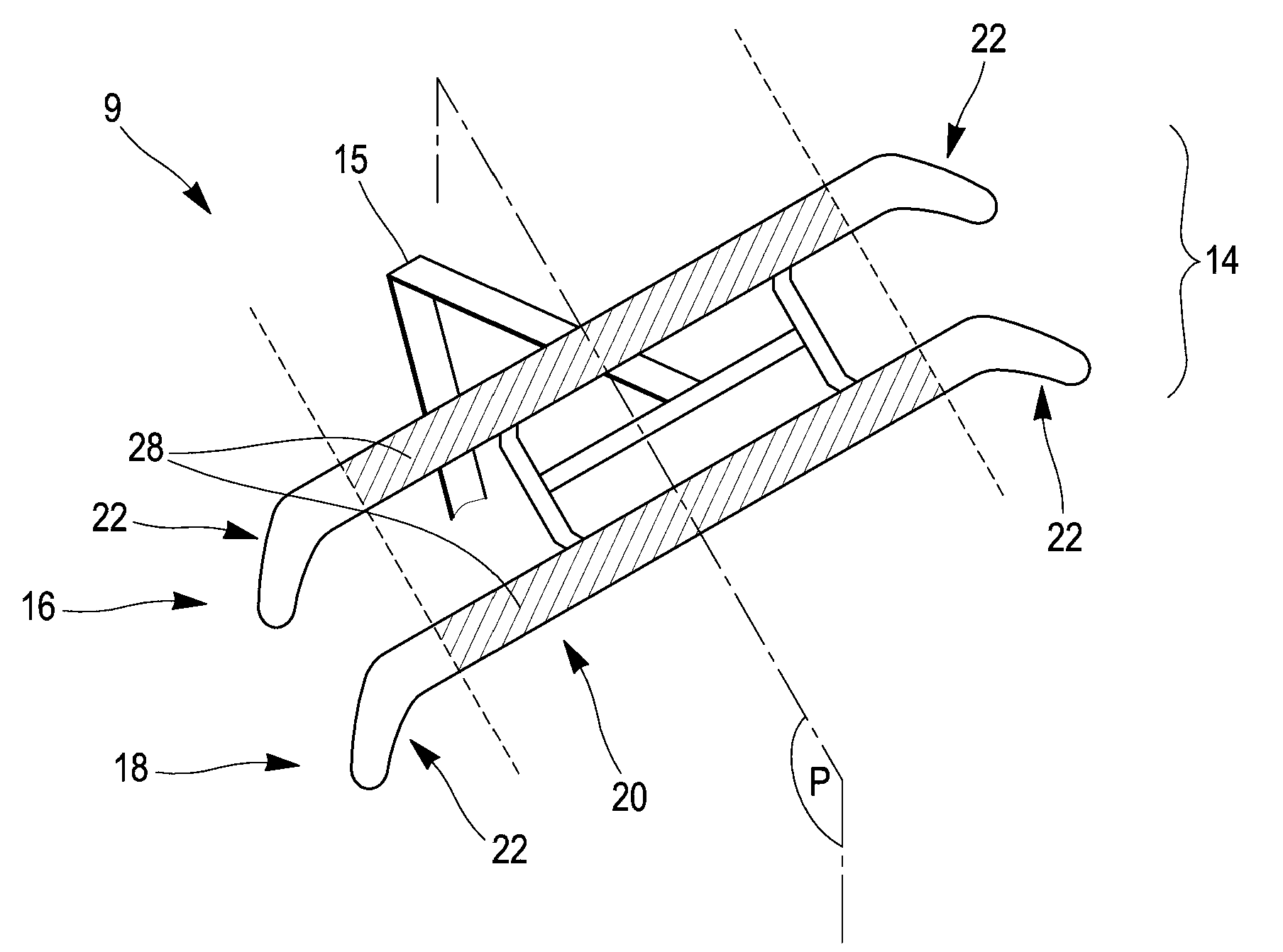

Method and apparatus for enhancing traction on stair treads

ActiveUS9121186B2Increase frictionInexpensive and easily and quicklyTreadsThin material handlingLeading edgeEngineering

A traction element for carpeted stair treads or other flooring includes a deformable substrate secured by screws to the tread that is vertically aligned with the top edge of a riser and slightly rearward of the tread leading edge. The substrate is covered with adhesive backed friction tape. The screws extend through respective apertures centered in respective concave tapered annular recesses defined in the substrate. The apertures are in a linear array defining a bend axis along the substrate length and the tread width and about which the substrate deforms as it is being threadedly attached to the tread. When thusly bent the substrate top surface becomes concave such that its forward edge is higher than its rearward edge, thereby establishing a slight forwardly extending incline. The tape strip conforms to the bent substrate and its exposed top surface comprises a high friction or abrasive substance.

Owner:MENSAH BROBBEY

Rubber band filter

InactiveCN107398111AImprove the environmentAchieve continuous processMembrane filtersMoving filtering element filtersEngineeringFriction tape

The invention provides a rubber band filter. A rubber band is mounted on a rack through a driving roller, a driven roller and a tensioning roller; filter cloth is mounted above the rubber band; a filter cloth pressing roller is arranged at the upper part of the filter cloth; a discharging hopper is mounted above the left side of the filter cloth; isolators are uniformly distributed on the filter cloth; vertical roll devices are arranged on side surfaces of the rubber band; a rinsing hopper is arranged above the filter cloth; lifting devices, rubber band bearings, rubber band carrier rollers and a friction tape are arranged at the lower part of the rubber band; a bend roller and a scraping device are arranged on the right side of the rubber band bearings; vacuum boxes are connected with the rubber band through pipelines; automatic liquid discharging tanks are arranged on one side surface of the rack; a washing tank is arranged on the right side of the rubber band; an automatic filter cloth rectifying device is arranged on the rack and connected with a control cabinet. The rubber band filter has the advantages that the equipment is combined with a precipitation method preparation process, the goal of continuity and automation of the process is achieved, the production quality and the yield are substantially improved, the equipment utilization rate and the production efficiency are improved, and the rubber band filter has innovativeness in preparation of a catalyst with a precipitation method and other aspects.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for preventing honeycomb from sliding

The invention belongs to the technical field of composite manufacturing and relates to a method for preventing a honeycomb from sliding. An anti-slide band is pasted to a tool and is made from a high-friction material. The periphery of each layer of prepreg cloth is closely attached to the friction band, and during the part curing process, the relative position of each layer of the prepreg cloth is ensured through the anti-slide band, so that relative motion of an upper skin prepreg of a sandwich structure and a lower skin prepreg of a sandwich structure is prevented, and the honeycomb is prevented from sliding. The anti-slide band method does not need to change the curing mode of materials and has no special limit to the materials, so that the method is suitable for various prepreg materials. In addition, the operation method is simple and convenient and easy to realize. The sliding problem of the honeycomb in the curing process is effectively solved, and the position and size of a formed part honeycomb meet the requirement of a design drawing.

Owner:HARBIN

Intelligent belt pulley

InactiveCN101205969ARealize the deceleration functionRealize overload skidding protection functionGearingPortable liftingGear wheelReduction drive

The invention relates to a belt pulley in a belt driving mechanism, in particular to an intelligent belt pulley for walking beam type pumping unit in oil fields. The invention solves the problems that: the prior speed reducer and belt driving mechanism for walking beam type pumping unit can not meet the requirements of long-stroke low-frequency pumping units and the energy-saving requirements of a matched low power motor. The intelligent belt pulley comprises a planet gear mechanism consisting of a sun wheel, an annular gear, a planet carrier and a planet gear, and a belt pulley consisting of a belt pulley core and a belt pulley, wherein the belt pulley core is axially fixed on a planet carrier shaft through a bearing, the sun wheel is in floating connection with the belt pulley core, the annular gear is surrounded by an external friction tape, one end of the friction tape is fixed on a connecting plate on the body of the speed reducer, the other end of the friction end is fixed on a screw which passes through the connecting plate and is fixed through a nut. The invention which has reasonable and simple structure, high mechanical efficiency and lower power consumption can meet the requirements of long-stroke low-frequency pumping units in various types of oil fields and is also applicable to other universal machines.

Owner:樊世耀 +1

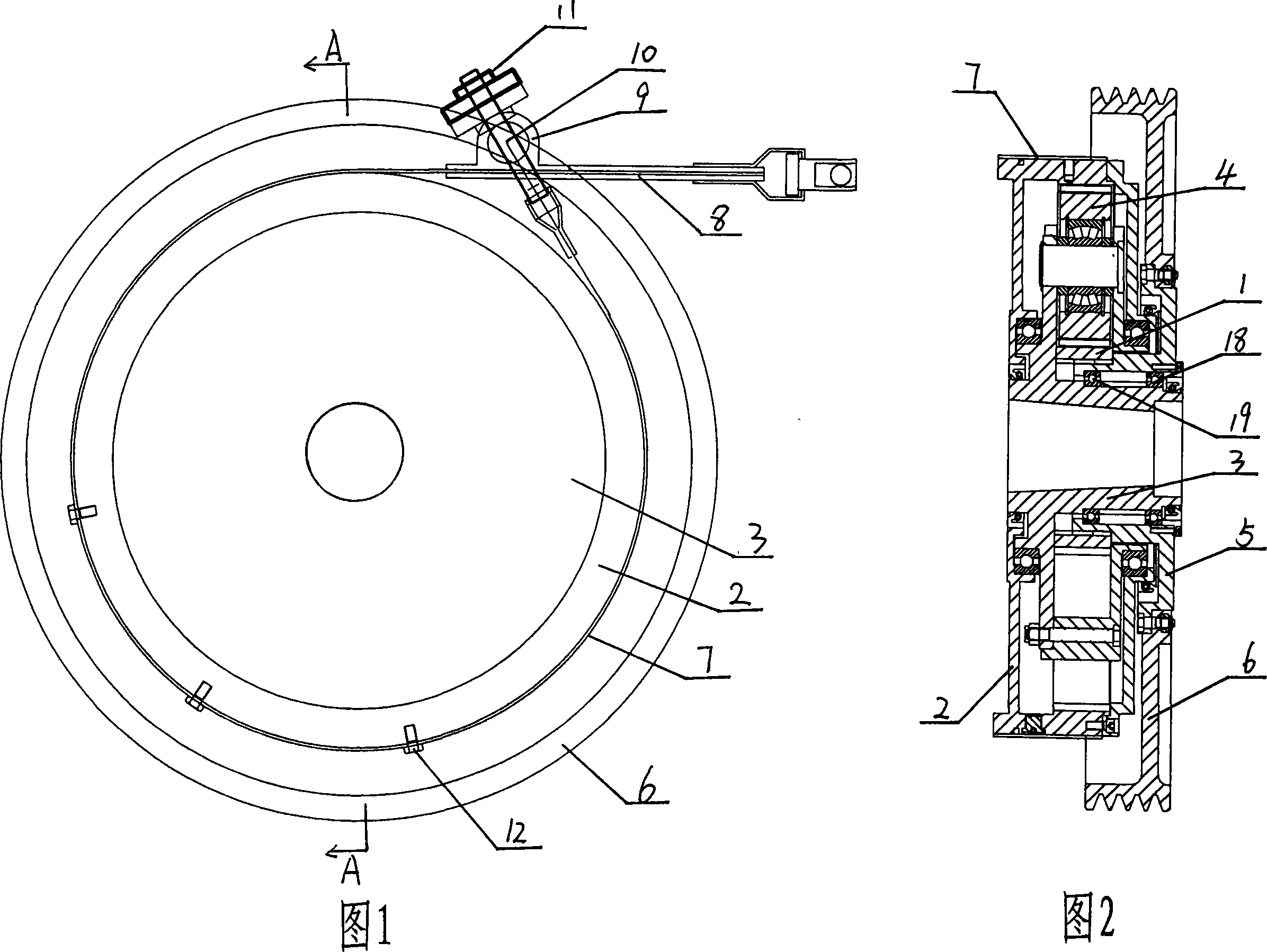

Polishing machine for pot body

InactiveCN103350395AReduce manual labor intensityIncrease productivityPolishing machinesSlide plateBody positions

Disclosed is a polishing machine for a pot body. A sliding plate is sleeved on a linear sliding rail in an inserting mode, a piston rod of an air cylinder is fixed with the sliding plate, a guide pillar is fixed on the sliding plate, a lifting platform is sleeved in the guide pillar in an inserting mode, a rotary motor is fixed on the lifting platform and drives a friction tape to rotate, a workpiece frame is fixed on the sliding plate, and a pulley is installed on the workpiece frame. A pot body frame is composed of a shaft, a friction disc, a bearing and a pot body positioning mould, wherein the friction disc is fixed on the shaft, an inner ring of the bearing is fixed on the shaft, an outer ring of the bearing is fixed on the pot body positioning mould, a pot body workpiece is sleeved in the pot body positioning mould in an inserting mode, the shaft is arranged on the pulley and located between two baffles, the two baffles are both fixed on the workpiece frame, the friction tape faces the friction disc, a polishing motor is fixed on a machine frame, and a polishing brush wheel is fixed on a rotation shaft of the polishing motor. The polishing machine for the pot body relieves the labor intensity for workers, improves production efficiency, and does not need a person to hold the pot body by hand for polishing.

Owner:吴江红蔷薇纺织有限公司

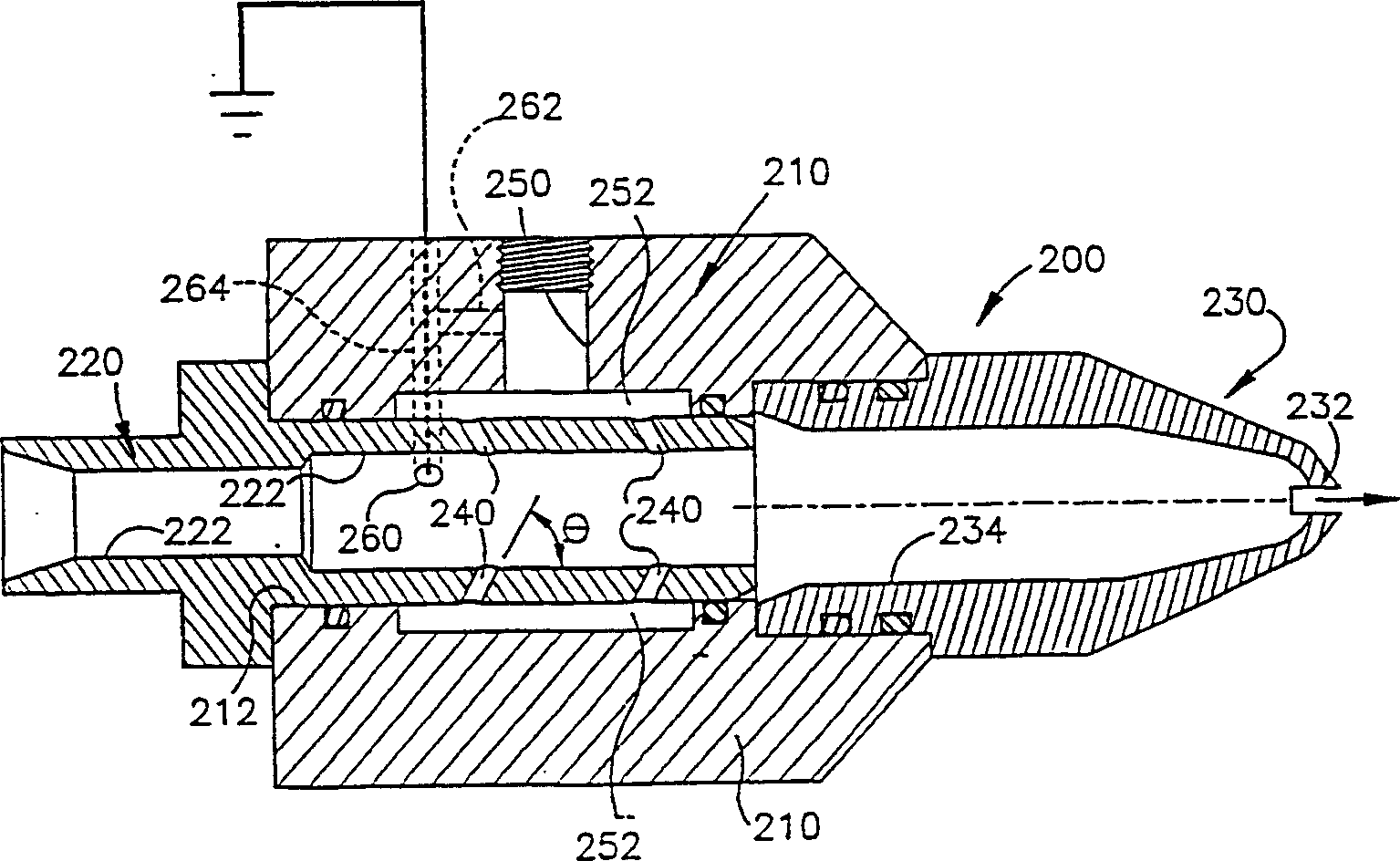

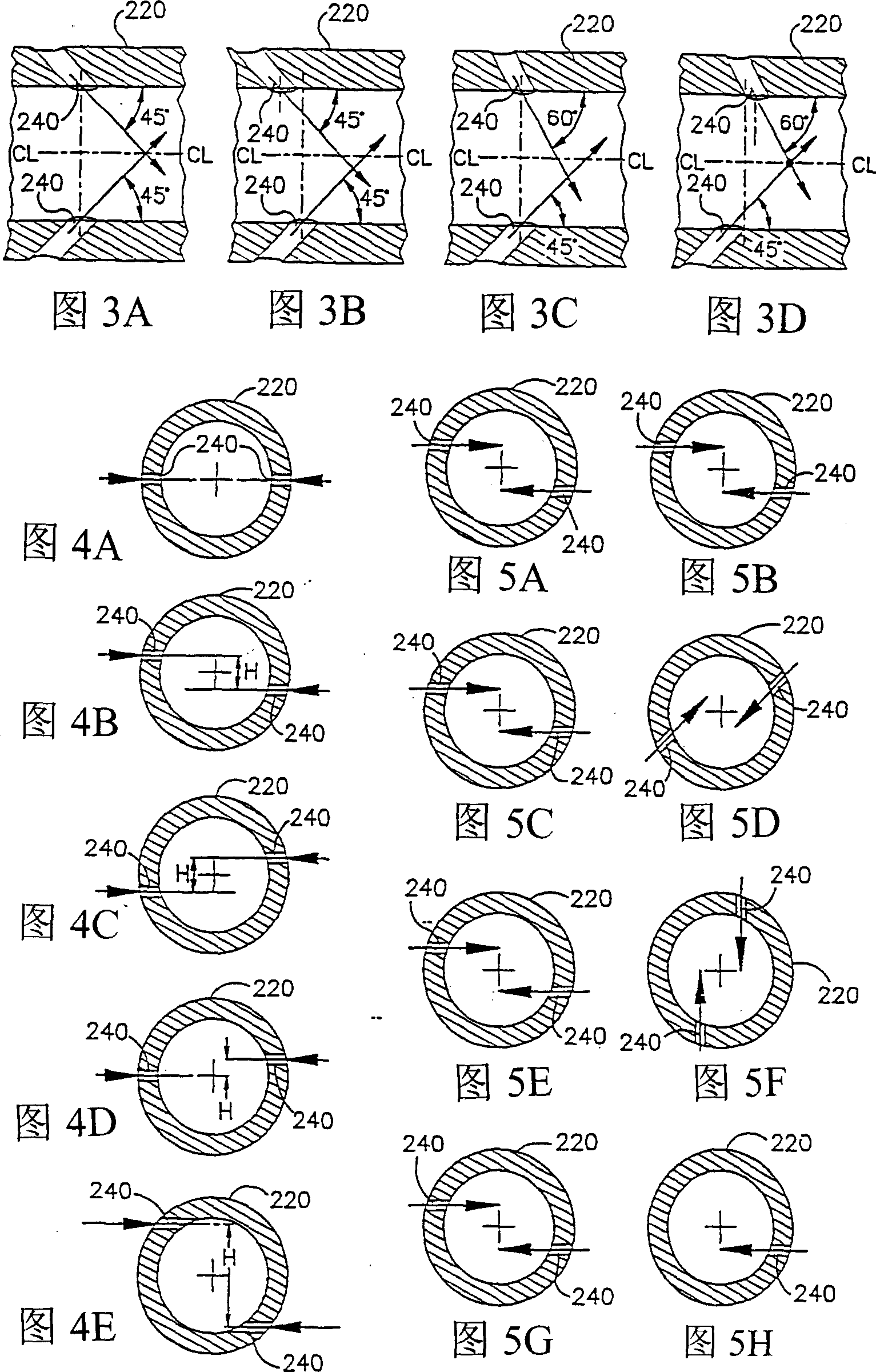

Unipolarity powder coating systems including improved tribocharging and corona guns

The present invention describes a variety of unconventional tribo-negative materials for use as powder contact surfaces in tribo- and corona powder spray guns, in-gun components, and powder delivery system components. The present invention also provides a short barrel triboelectric powder spray gun having interchangeable powder contact inserts and nozzles. The present invention further provides a new type of friction electrification and corona gun structure. The improved powder coating system allows the use of a triboelectric negative gun with a negative corona gun to coat different parts of the same part in the powder coating system. The present invention also provides an inside-out structure in which pressurized air directs the powder coating to the charged surface. In other configurations of the present invention, the air nozzle-induced triboelectric charging and conventional triboelectric charging parts are also combined in a single gun.

Owner:NORDSON CORP

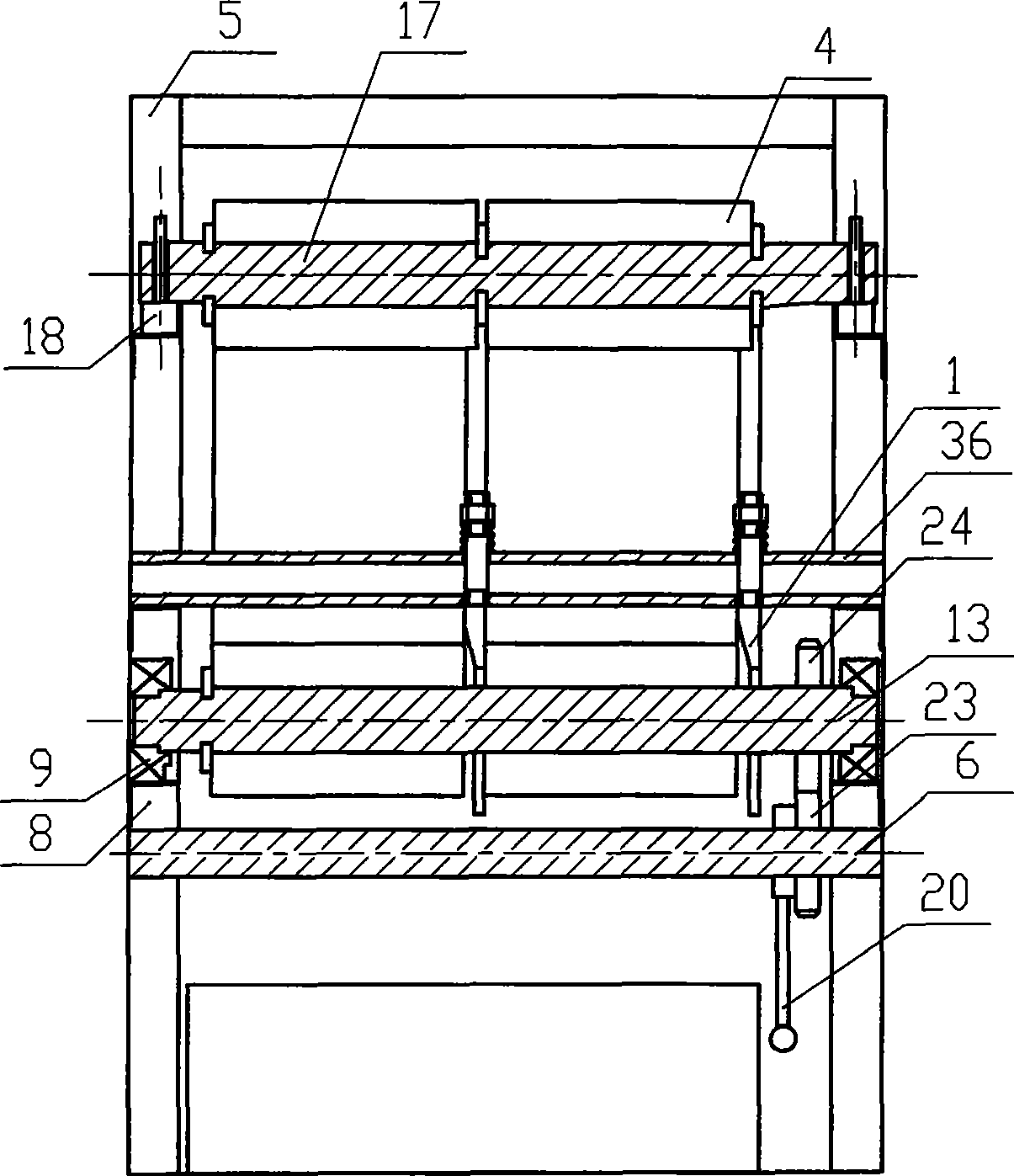

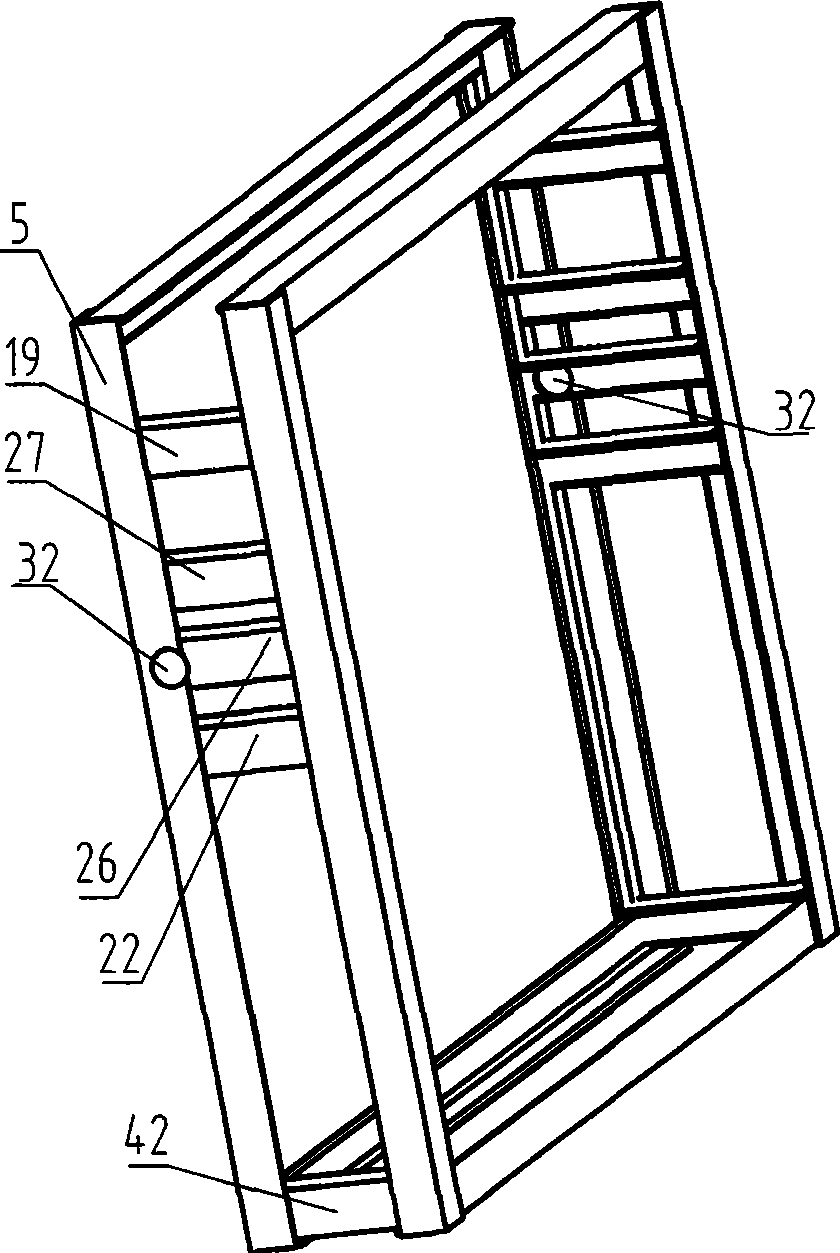

Notice board with recoverable notice paper

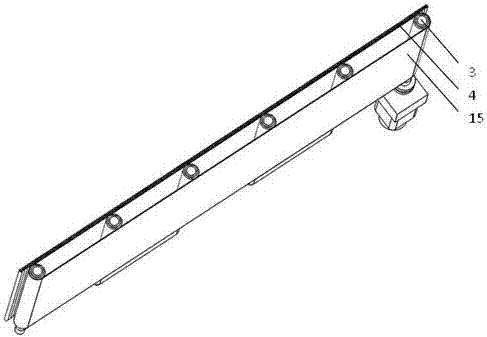

The invention provides a notice board with recoverable notice paper. Two ends of an upper main shaft (17) are arranged on an upper-main-shaft installation beam; two ends of a crossbeam (36) are fixed on a crossbeam installation beam (27); two ends of a lower main shaft (13) are arranged on a lower-main-shaft installation beam (26); two ends of a power shaft (6) are fixed on a power-shaft installation beam (22); two ends of a turning-plate supporting shaft (33) penetrate into a mounting hole (32) of the lower-main-shaft installation beam (26); the outer circumference of a roller of an upper main shaft component and a lower main shaft component is sleeved with a friction tape (3); a recovering box (29) is positioned on a recovering-box installation beam (42); and the front of a bracket is provided with glass clinging to the friction tape. When the notice board is in use, power is input through a handle, and then the friction tape can drive notice paper to move upwards; and after the handle is no longer turned, the notice paper can be clamped between the glass and the friction tape, thus the notice board is convenient to use. As the recovering box is arranged on the bracket, managers can open the recovering box regularly to recover the notice paper.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

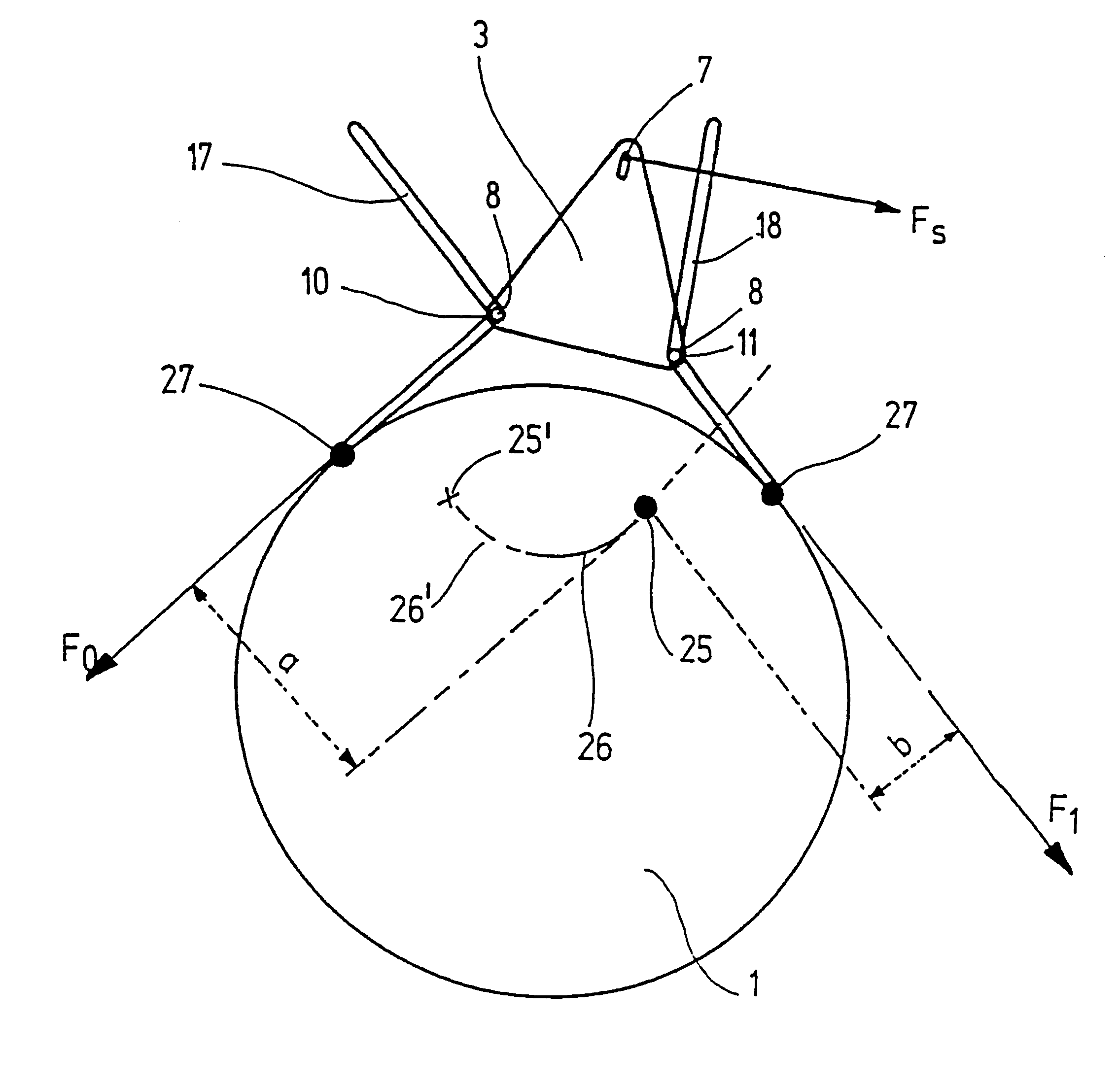

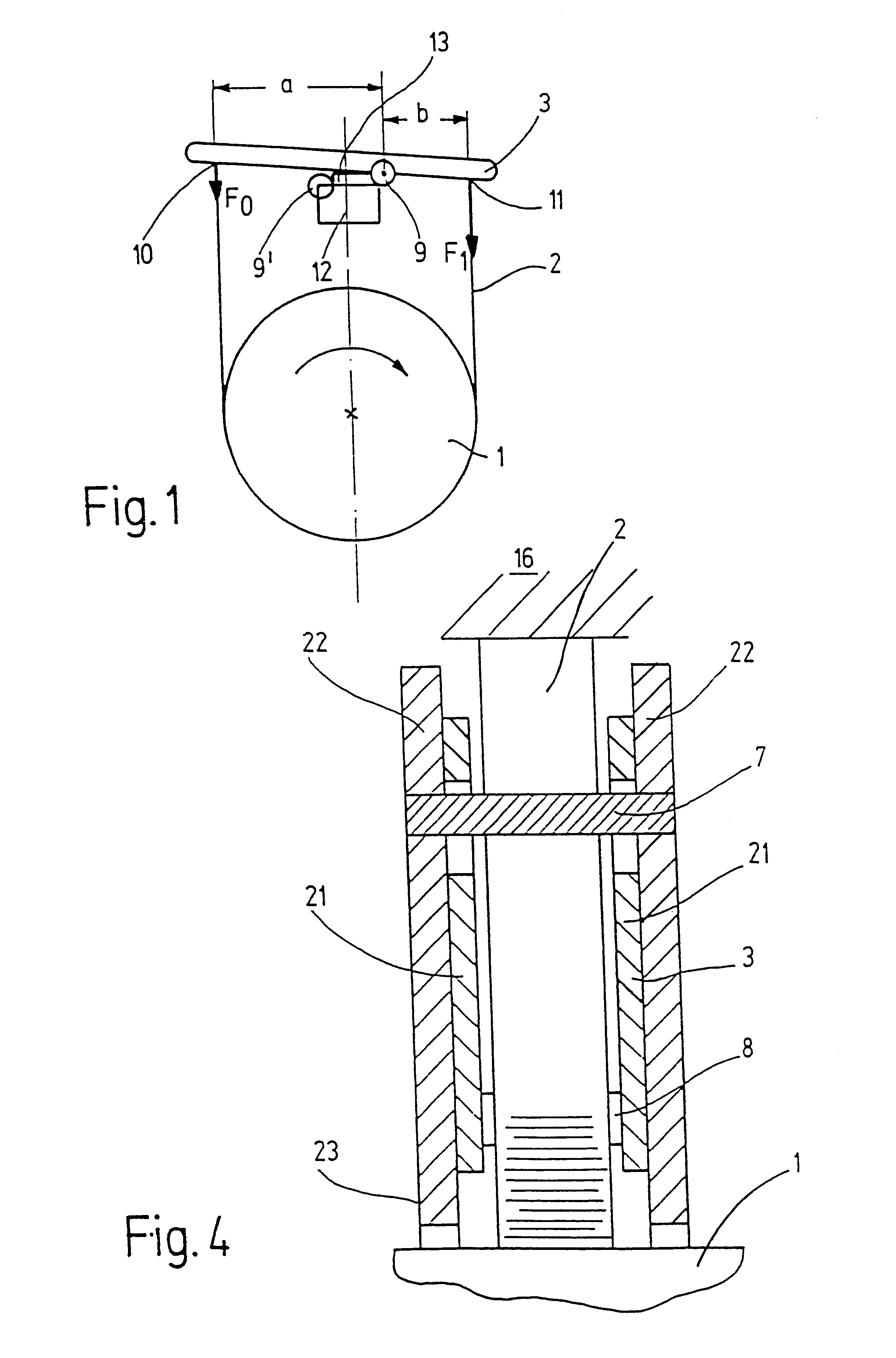

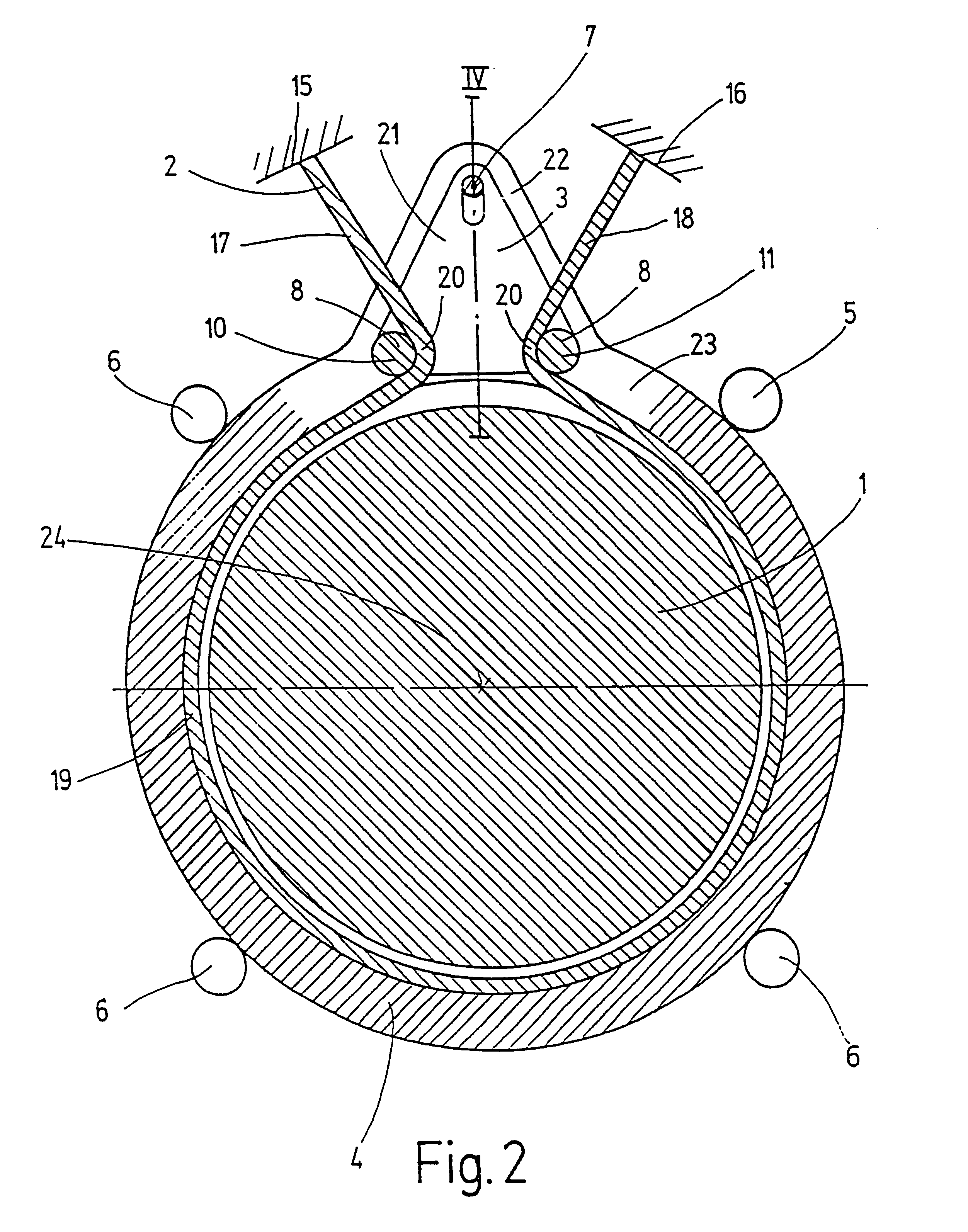

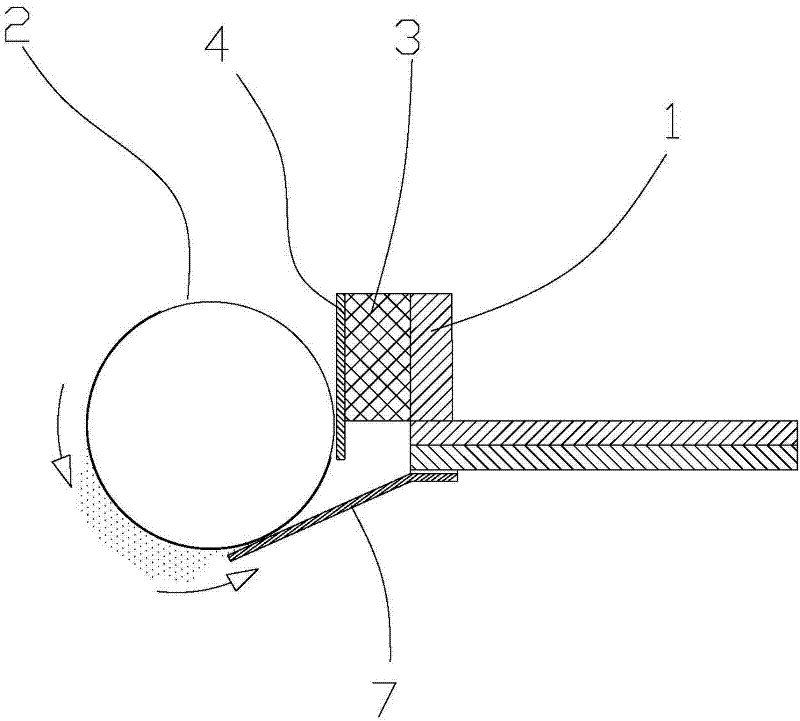

Friction-band brake

In a friction belt brake with a rotary cylinder (1), which is wound around at least a part of its circumference by a friction belt (2), and with a support (3) for the friction belt, which in a first braking position, can be pivoted around a first axis (9; 25) and two securing points (10, 11) for respectively opposite end sections of the friction belt, wherein a first of the two securing points has a longer lever arm (a) in relation to the first axis than the second securing point (11), the provision is made that in a second braking position, the support (3) can be pivoted around a second axis with regard to which the second securing point has a longer lever arm than the first.

Owner:ROBERT BOSCH GMBH

Self-adjusting static friction type vehicle stopping mechanism

ActiveCN106758964APrevent forward rollStabbed smoothlyTraffic restrictionsStatic frictionFriction tape

The invention belongs to the technical field of vehicle stopping and particularly relates to a self-adjusting static friction type vehicle stopping mechanism. The self-adjusting static friction type vehicle stopping mechanism comprises a plurality of wheel constraint mechanisms, wherein each wheel constraint mechanism comprises a friction belt, a balance block, spiked nails, a force applying board, resistance wheels and a friction wheel and can constrain the wheel of a running vehicle. After the wheels are constrained by the wheel constraint mechanisms, the car drags the wheel constraint mechanisms to move forwards along with the vehicle, static friction force between the ground each friction belt is generated to drive the friction belt to rotate due to the fact that the friction belt is arranged on the bottom surface of the wheel constraint mechanism, and the resistance wheels on the friction belt generate appropriate resistance to allow the resistance of the resistant wheels to constantly keep the static friction state between the ground the friction belt. In addition, the balance block is added into each wheel constraint mechanism, the positions of the balance body in the wheel constraint mechanism are adjusted according to vehicle speed, the faster the vehicle is, the more rear the balance block is, forward turning, driven by the vehicle, of the wheel constraint mechanism is prevented, fast vehicle braking is achieved, and a good use effect is achieved.

Owner:HEBEI ZONGSHEN GEMEILI AGRI MACHINERY MFG CO LTD

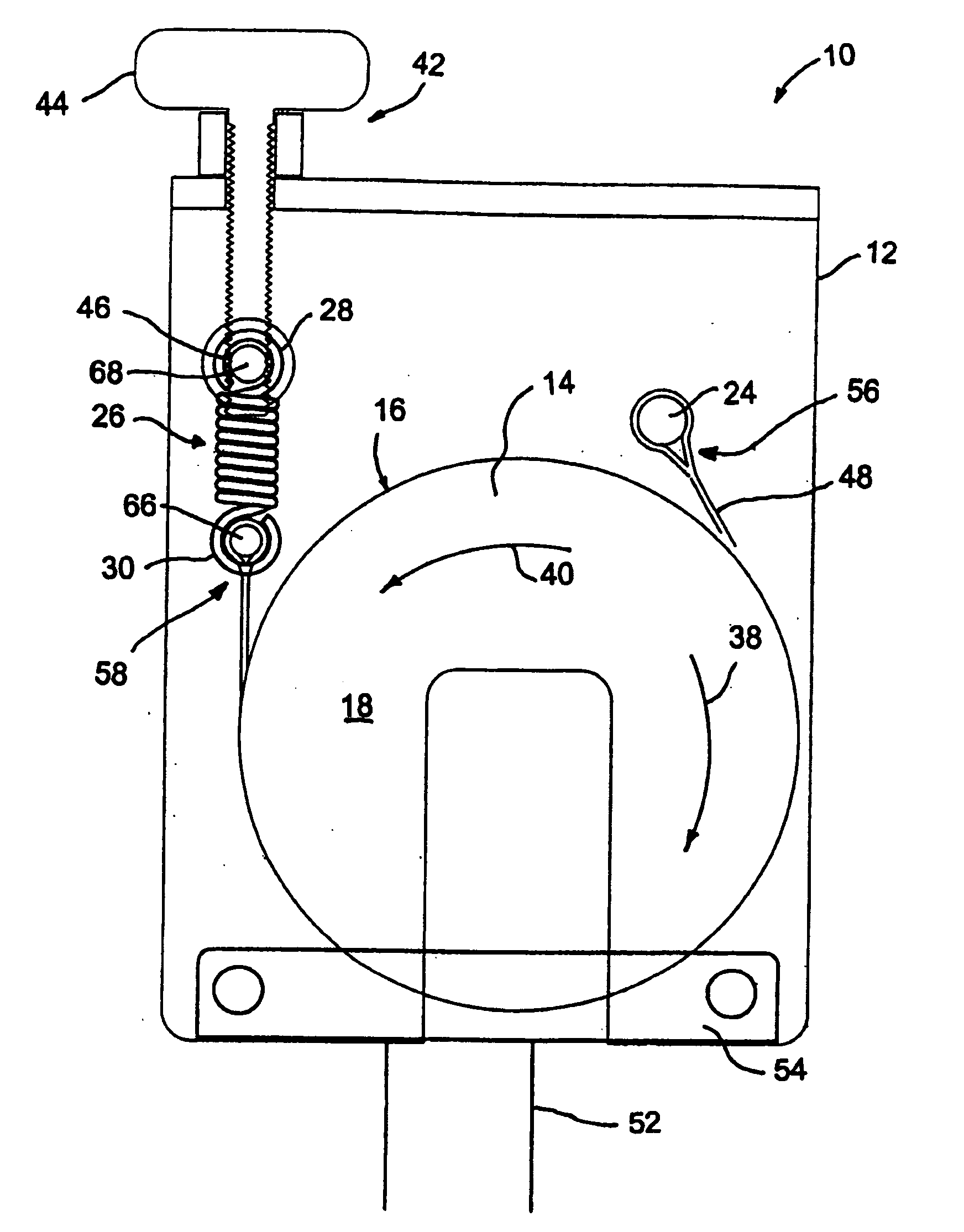

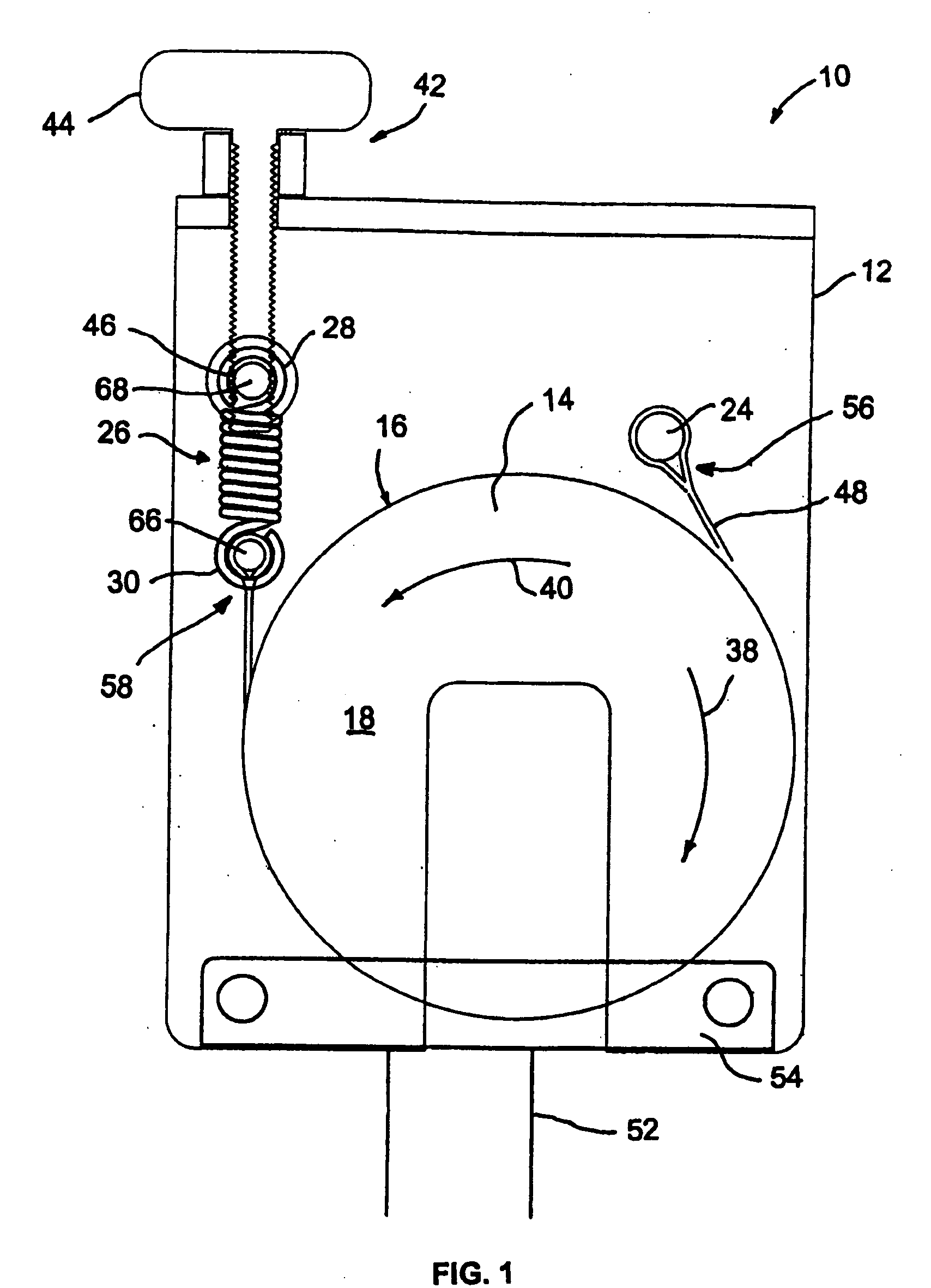

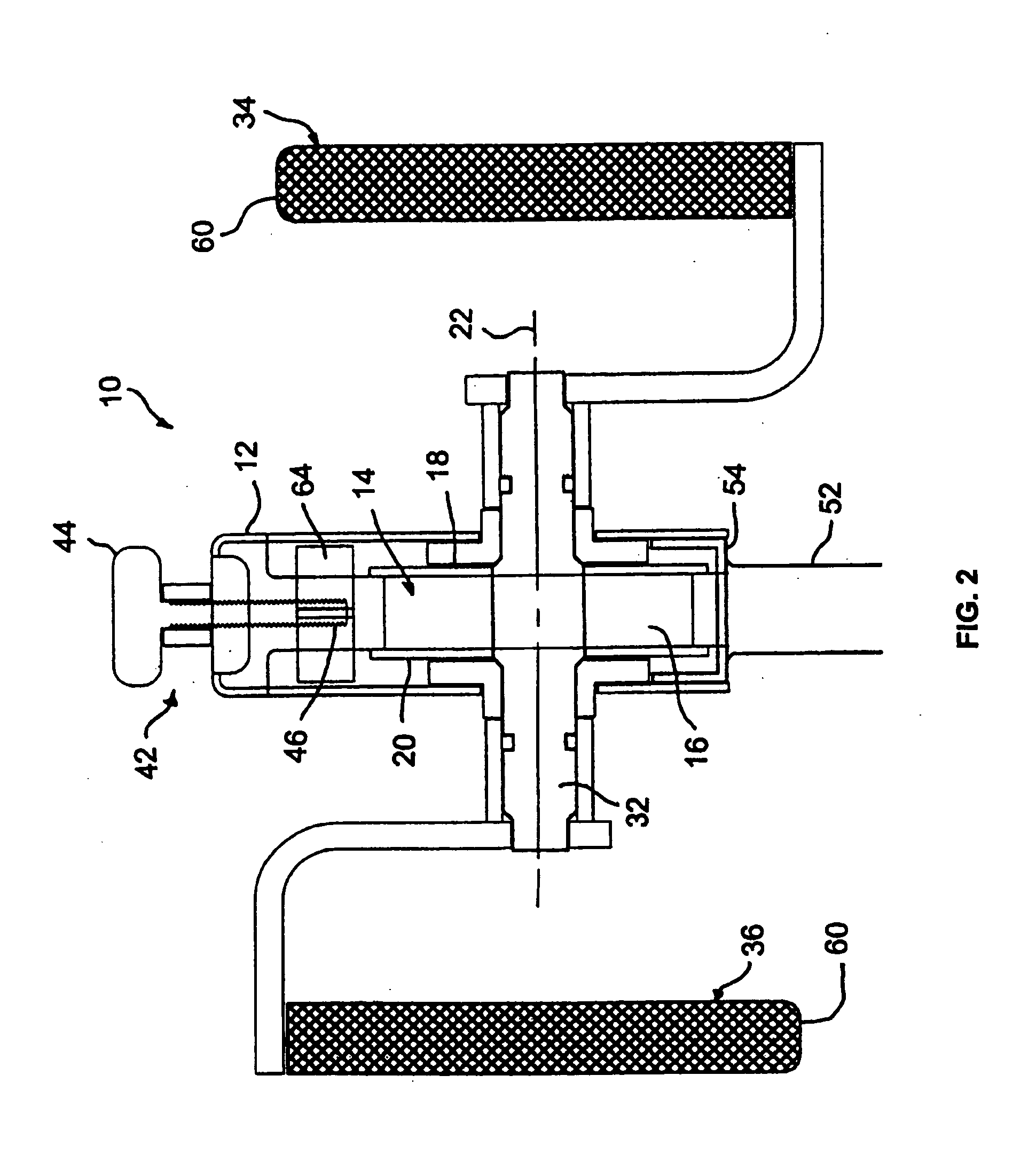

Adjustable linear friction device

InactiveUS20070010379A1Muscle strengtheningImprove abilitiesFrictional force resistorsCircular discPronations

An adjustable linear friction device for exercising the forearm, wrist and hand, comprising: a disc rotatably mounted on a housing, with a circumferential edge and opposed faces; a friction band extending between an anchor and biasing means, the friction band disposed against the circumferential edge of the disc; a shaft extending outwardly from the opposed faces, with handles on the shaft for rotating the shaft to effect rotation of the disc. Rotating the disc in a first direction results in a first normal friction between the friction band and the circumferential edge, and rotating the disc in a second and opposite direction results in a second, different normal friction. The device can be used to exercise the forearm and wrist joint in supination / pronation, extension / flexion, and radial / ulnar deviation motions through the full range of motion.

Owner:CHRISTENSEN BYRON

Method and apparatus for enhancing traction on stair treads

A traction element for carpeted stair treads or other flooring includes a deformable substrate secured by screws to the tread that is vertically aligned with the top edge of a riser and slightly rearward of the tread leading edge. The substrate is covered with adhesive backed friction tape. The screws extend through respective apertures centered in respective concave tapered annular recesses defined in the substrate. The apertures are in a linear array defining a bend axis along the substrate length and the tread width and about which the substrate deforms as it is being threadedly attached to the tread. When thusly bent the substrate top surface becomes concave such that its forward edge is higher than its rearward edge, thereby establishing a slight forwardly extending incline. The tape strip conforms to the bent substrate and its exposed top surface comprises a high friction or abrasive substance.

Owner:MENSAH BROBBEY

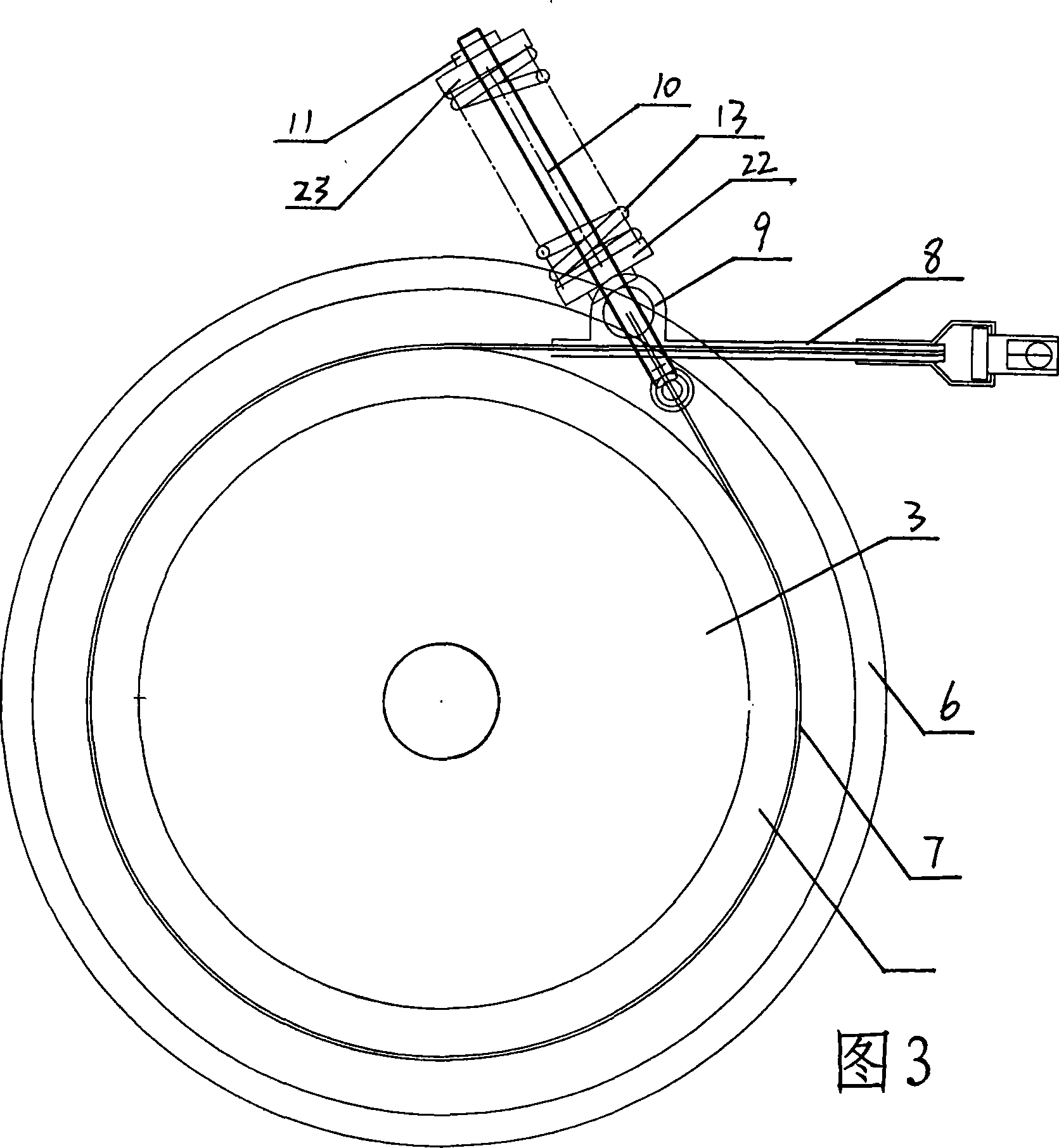

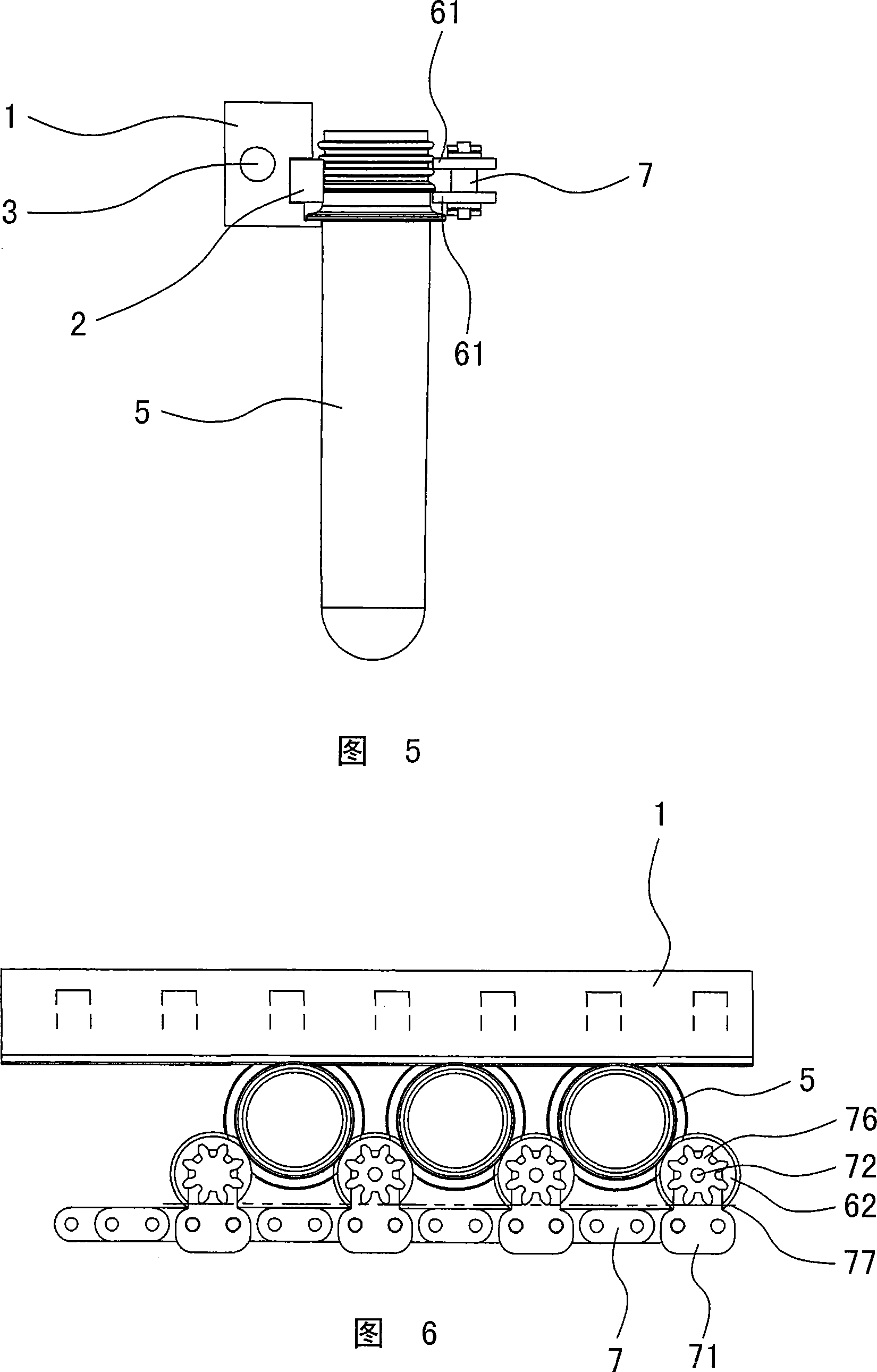

Plastic bottle pipe heater locating friction-conveying chain

The present invention relates to a device for positioning, frictionating and transmitting chain of plastic bottle-tube heater. The device is arranged on a friction bracket and a chain bracket on the heater; a friction tape is arranged on the friction bracket; a drive chain is arranged on the chain bracket; the plastic bottles are transmitted between the friction tape and the chain; the invention is characterized in than a rotary position friction pulley is arranged on the chain; the rotary position friction pulley is inserted between the plastic bottle-tubes and contacted with heads of the plastic bottle-tubes. According to the technical proposal, the rotary position friction pulley is arranged on the chain (can be one side); the rotary position friction pulley extends (is inserted) between each plastic bottle-tube in operation (the plastic bottle-tubes import into the heater one by one in discontinuous arrangement); the plastic bottle-tube is positioned to maintain a certain spacing distance in heating operation; friction on the bottle-tube can generate rotation while the bottle-tube moves forward (revolution); the device is good in heating effect and conducive for entering a subsequent stretch and blow processing.

Owner:ZHEJIANG HONGZHEN MASCH MOULD GRP CO LTD

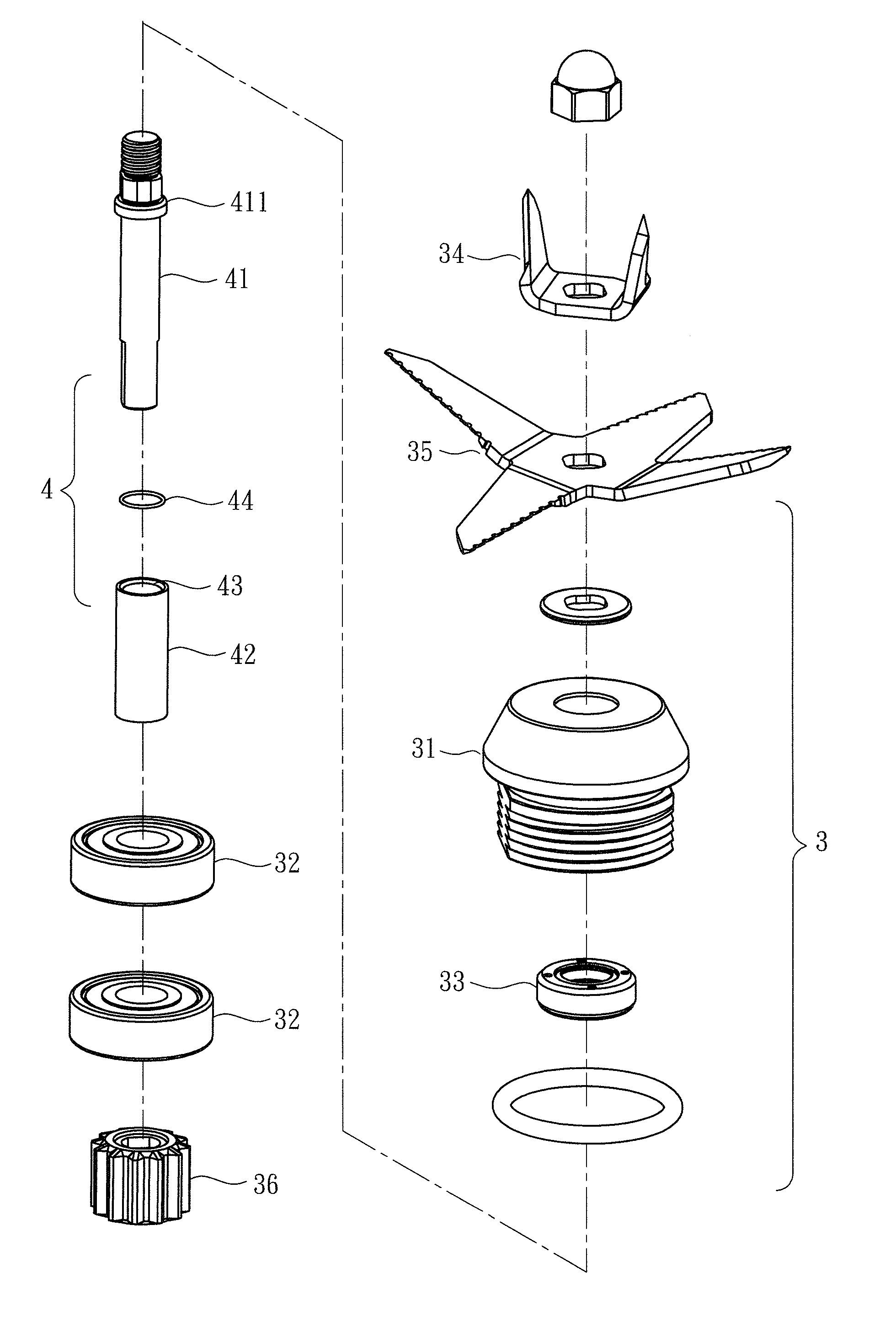

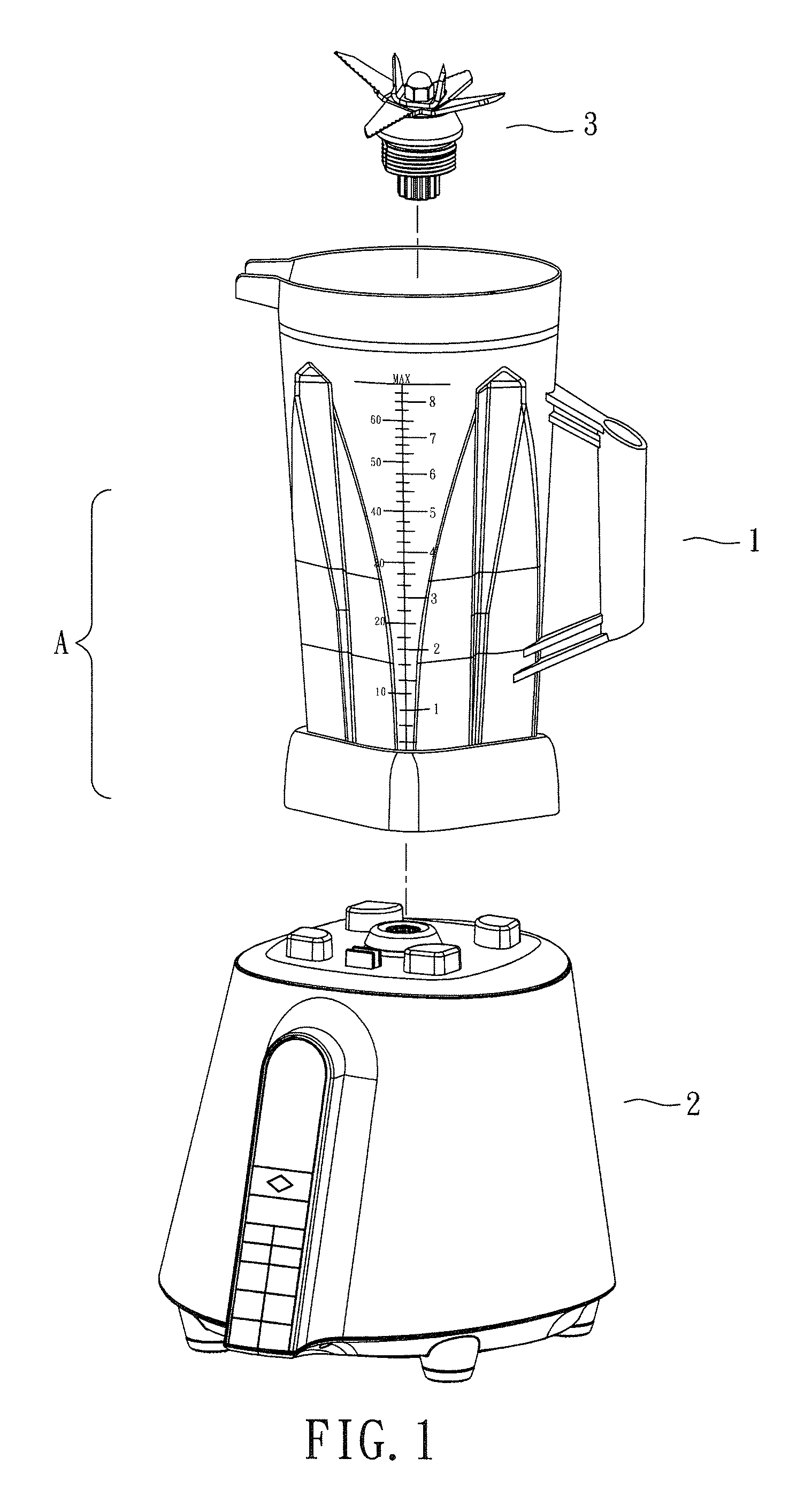

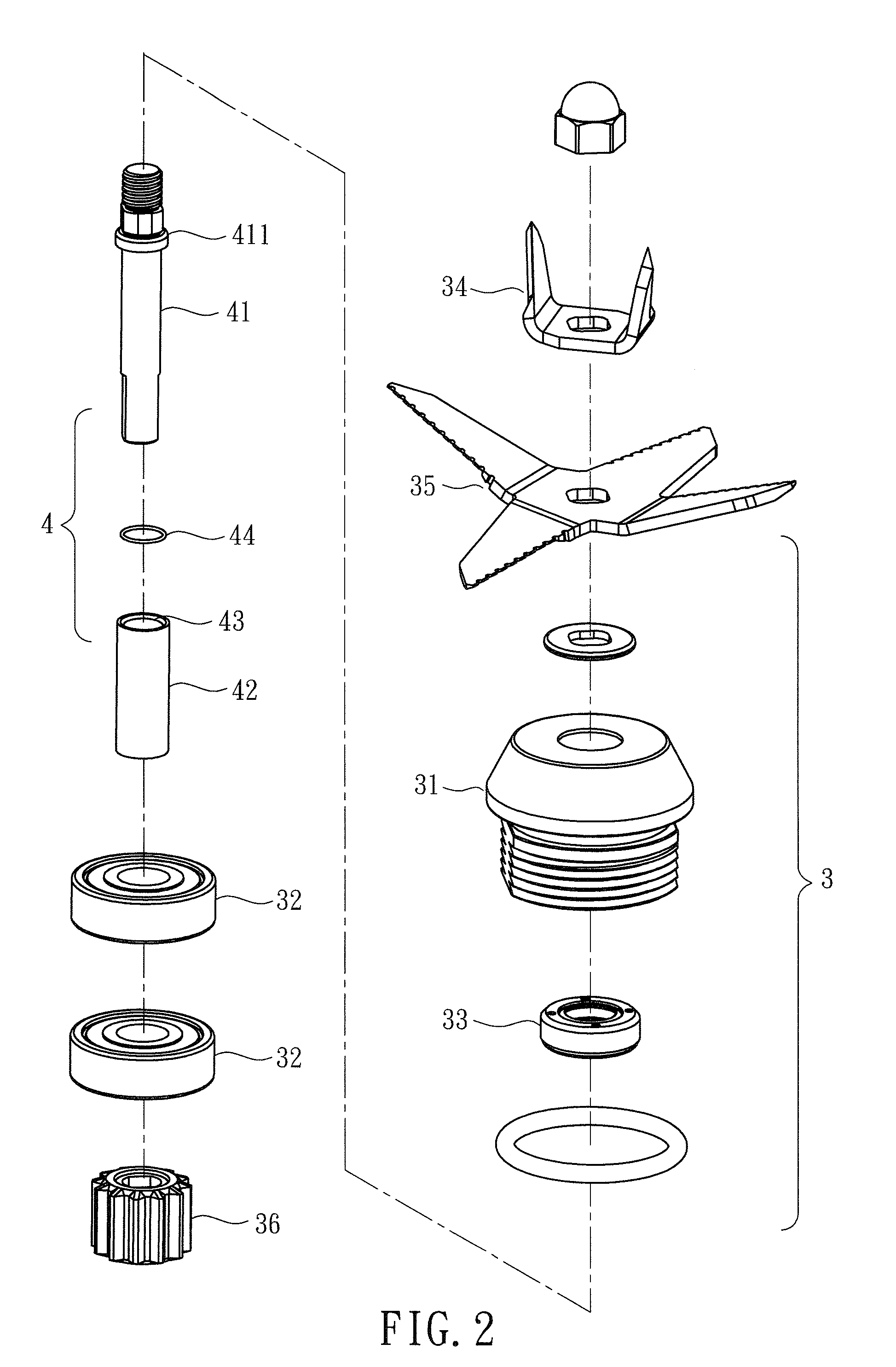

Blenderblade assembly and shaft assembly thereof

A shaft assembly (4) of a blender blade device (3) is provided. The blender blade device (3) is penetrated by the shaft assembly (4) and disposed in a blender container (1) and penetratingly disposed at the bottom of the blender container (1) to operably connect with a blender base (2). The shaft assembly (4) comprises a shaft body (41) and a wear-resistant sleeve (42). A stop ring (411) is disposed at the upper segment of the shaft body (41) and axially protrudes outward from the circumferential wall of the shaft body (41). The wear-resistant sleeve (42) axially fits around the outer wall of the shaft body (41) and has the top rim abutting against the bottom rim of the stop ring (411). The outer circumferential wall of the shaft body (41) is protected against direct contact and friction. With the wear-resistant sleeve (42) being wear-resistant and the shaft body (41) being immune to friction-induced damage, the shaft body (41) is unlikely to get spaced apart from watertight rings (44) even after long use, thereby waterproofing the shaft assembly (4).

Owner:LEE MING HSIEN

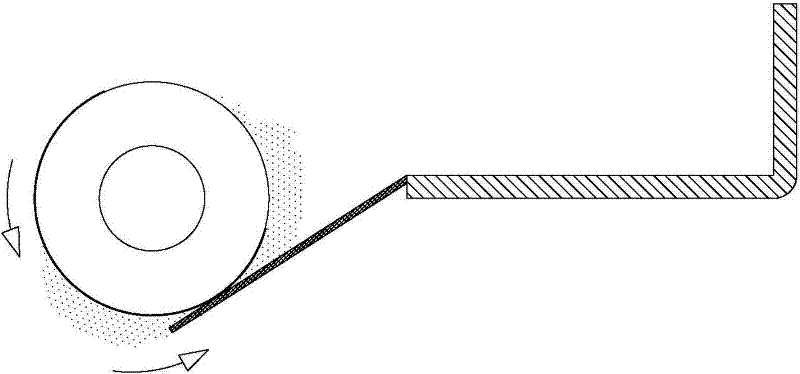

Self-compensating filament tension control device with friction band braking

A self-compensating tension control device for regulating the withdrawal of filamentary material from a spool includes a fixed support that maintains an inverted cam surface and a spindle assembly rotatably carrying the spool. A tension force applied to the filamentary material, in opposition to a biasing force, moves the spindle assembly linearly in relation to the fixed support. A braking mechanism includes a brake drum rotatable with the spindle assembly, a friction band adapted to engage the brake drum and a rocker arm that engages the cam surface. When the tension force applied to the filamentary material is reduced and unable to overcome the biasing force, the cam roller engages the cam surface and causes the friction band to generate a braking force on the brake drum.Withdrawal of the filamentary material at a regular rate occurs when the biasing force is balanced with the tension force.

Owner:RJS

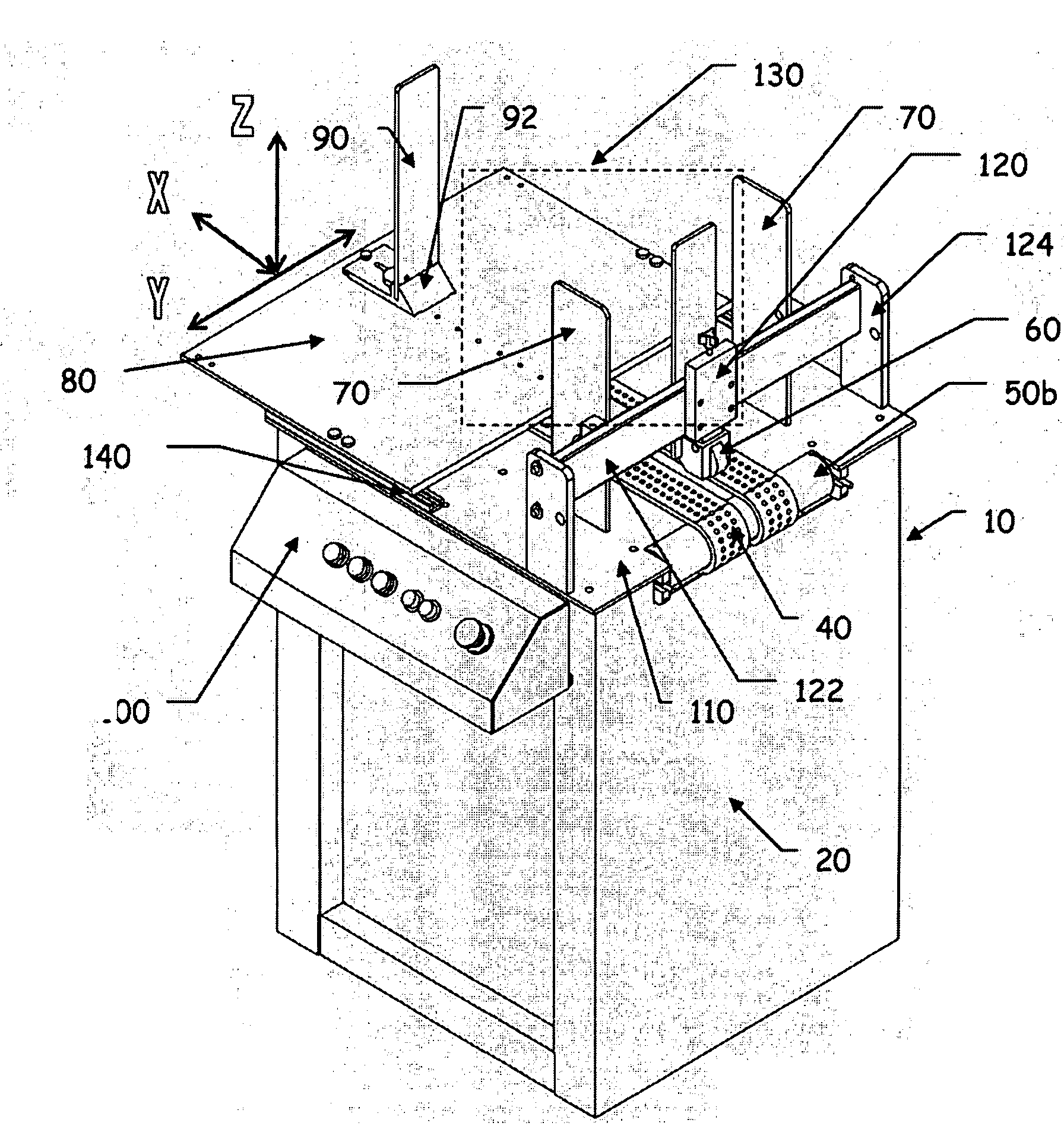

Vacuum friction feeder

A vacuum friction feeder including at least one vacuum friction belt provided with a plurality of holes, a pair of rollers, a table top provided with at least one suction port, an exposure table having a substantially horizontal top surface and a separator. The at least one vacuum friction belt is adapted to rotate around the table top while supported by the rollers such that a suction pressure can be drawn through the plurality of holes provided in the at least one vacuum friction belt as the plurality of holes pass over the suction port. The exposure table is operatively associated with the table top and is adapted to be movable relative to the table top in a plane defined by the substantially horizontal top surface to adjust the portion of the bottommost product in the stack of products exposed to the at least one vacuum friction belt.

Owner:WALLACE ROBERT BRIAN

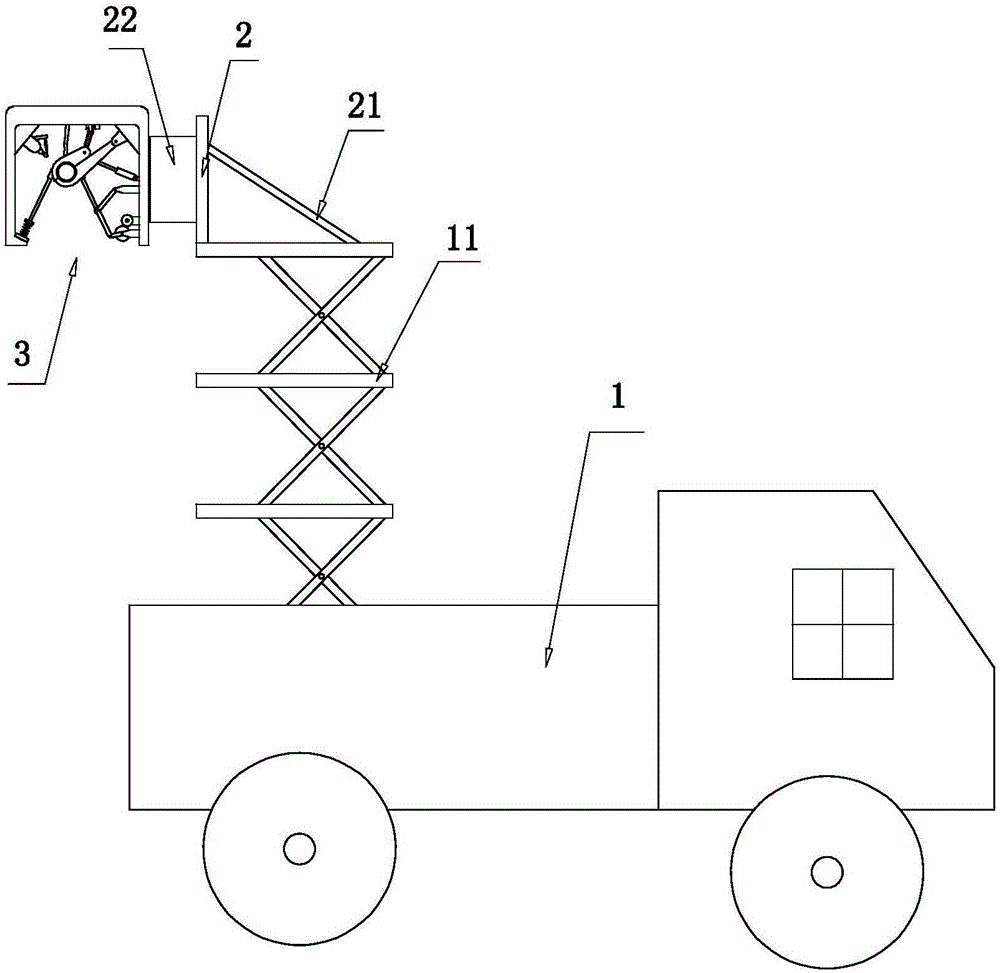

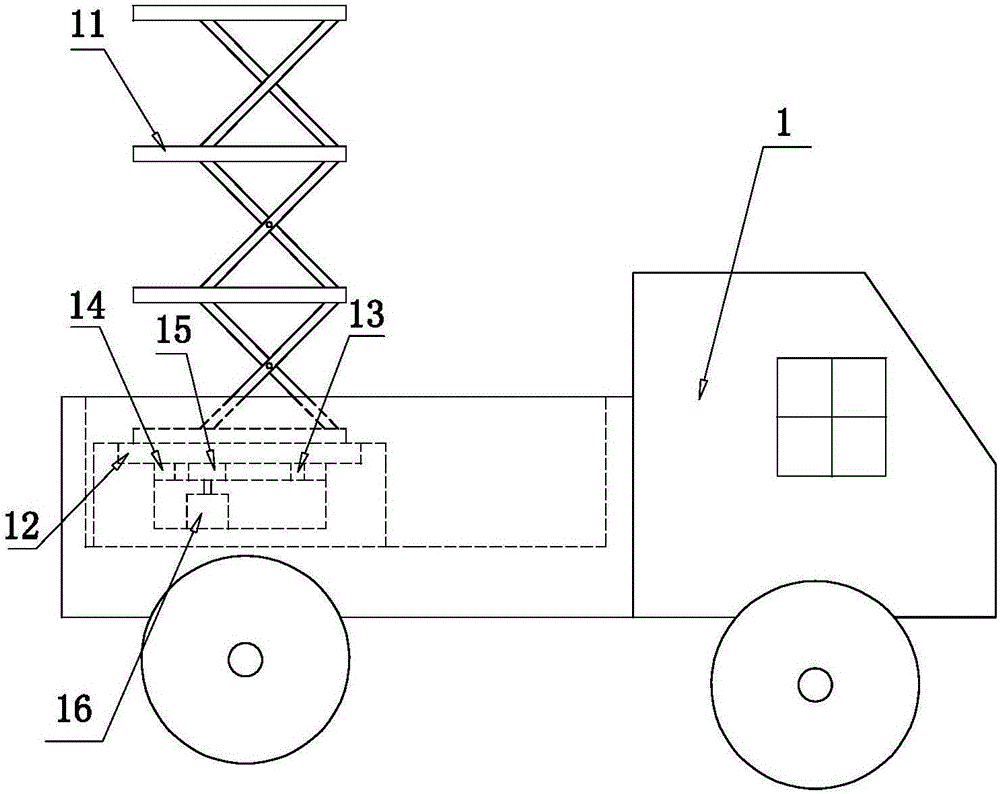

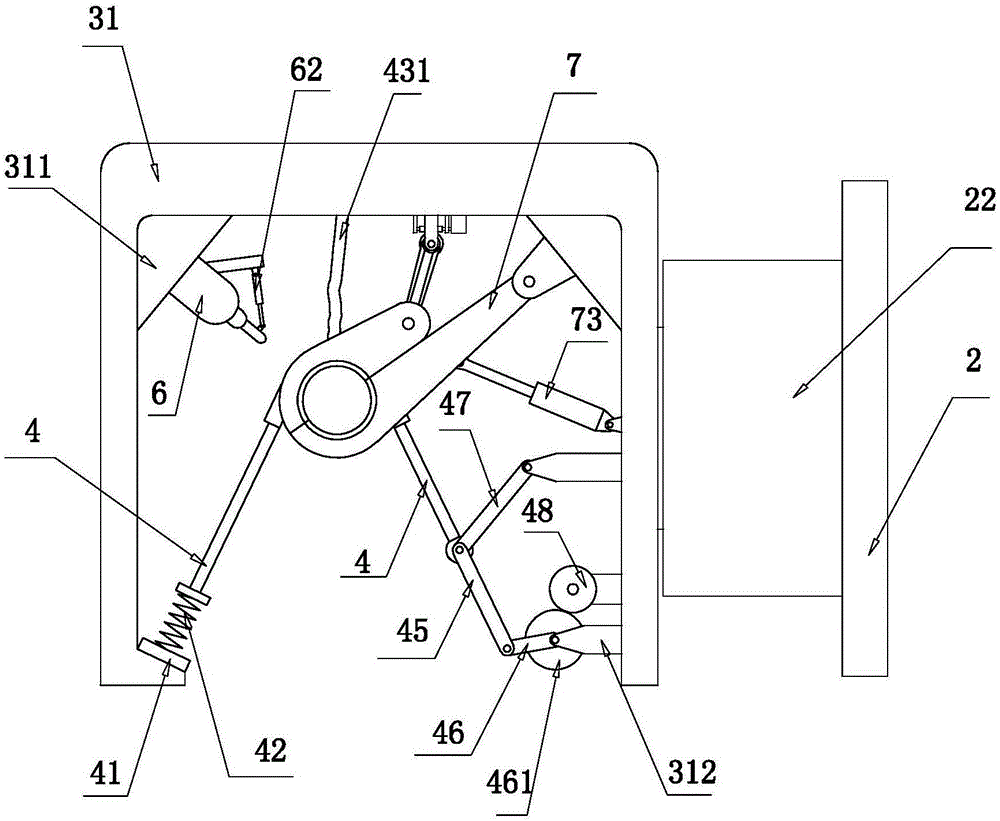

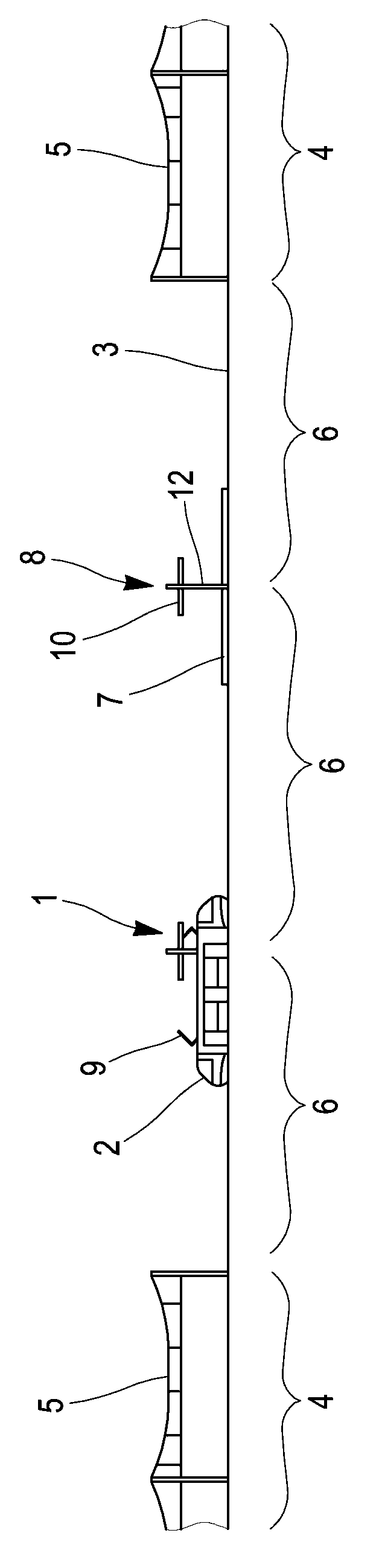

Middle and low voltage distribution line defroster

InactiveCN106486953APlay a supporting roleHigh degree of intelligenceOverhead installationTrailing armLow voltage

The invention relates to a middle and low voltage distribution line defroster which is used for improving deicing efficiency of distribution line. The defroster comprises a vehicle body, an elevator, an elevator rotation mechanism and a deicing assembly, the elevator is arranged on the vehicle body, and the elevator rotation mechanism for driving the elevator to rotate is arranged on the vehicle body; a mounting plate is arranged on the top of the elevator, the deicing assembly is arranged on the mounting plate, the deicing assembly mainly comprises a rack, a rack rotation mechanism, a friction mechanism, a heating mechanism, a pair of lifting mechanisms and a removing mechanism, and the rack rotation mechanism for driving the rack to rotate is arranged on the mounting plate; the friction mechanism is arranged on the inner side of the rack, and the friction mechanism can break the ice on the distribution line through a drawstring to drive a friction tape to move; the pair of lifting mechanisms are arranged on the inner side of the rack, and the lifting mechanisms can lift the distribution line through trailing arms; the heating mechanism is arranged on the rack and can thaw the ice on the distribution line; and the removing mechanism is used for removing the ice on the distribution line. According to the invention, the degree of automation is high, and the deicing efficiency is high.

Owner:STATE GRID SHANDONG ELECTRIC POWER CO LONGKOU POWER SUPPLY CO

Powder control structure of novel printer

Owner:ZHUHAI BENMA PRINTMAX IMAGINE

Board material of charing heat-pringting pattern and the method and device for producing the same

InactiveCN101037063ASave veneer costSave paper and glueBranding equipmentAblative recordingHot stampingEngineering

The invention discloses a method of carbonizing hot stamping pattern and a device designed for the method, the steps of method are as follows: 1) preparing a device of carbonizing hot stamping pattern which includes a machine foundation, a conveying device is provided on the machine foundation, a heating drum is provided on the upper of the conveying device, the protruding pattern is provided on the surface of the heating drum and the clearance is remained between the upper surface of the conveying device and the heating drum; 2) placing the board of the hot stamping pattern to be carbonized on the clearance between the upper surface of the conveying device and the heating drum, adjusting space of the clearance between the upper surface of the conveying device and the heating drum to contact the protruding pattern of the surface of the heating drum with the upper surface of the board; 3) driving the board to move by the conveying device, when the board moves, driving the heating drum to roll with rotation by friction to hot stamp the protruding pattern on the surface of the heating drum on the upper surface of the board and to hot stamp with carbonizing the corresponding pattern on the upper surface of the board, so as to obtain the board with the carbonizing hot stamping pattern.

Owner:唐邦元

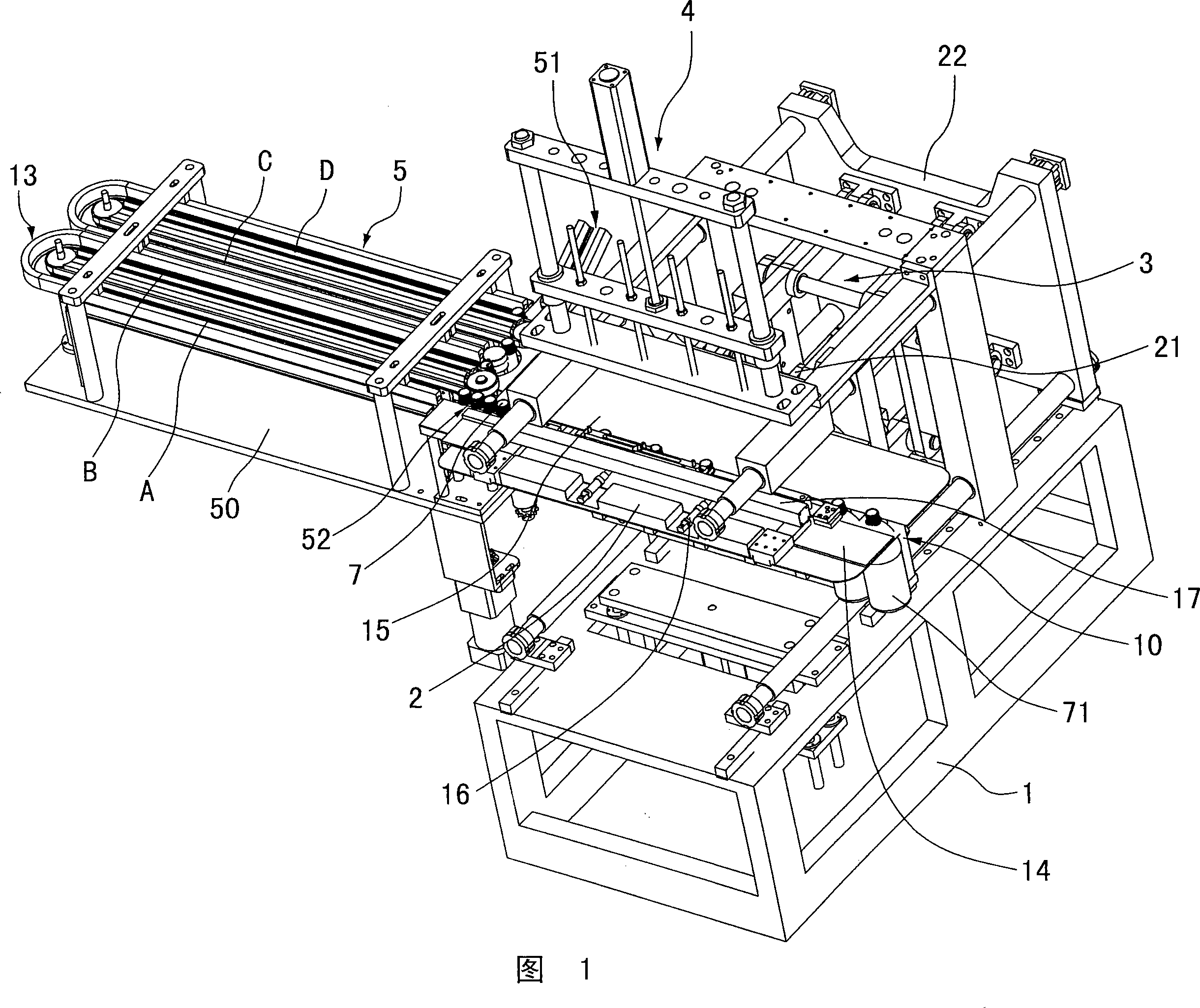

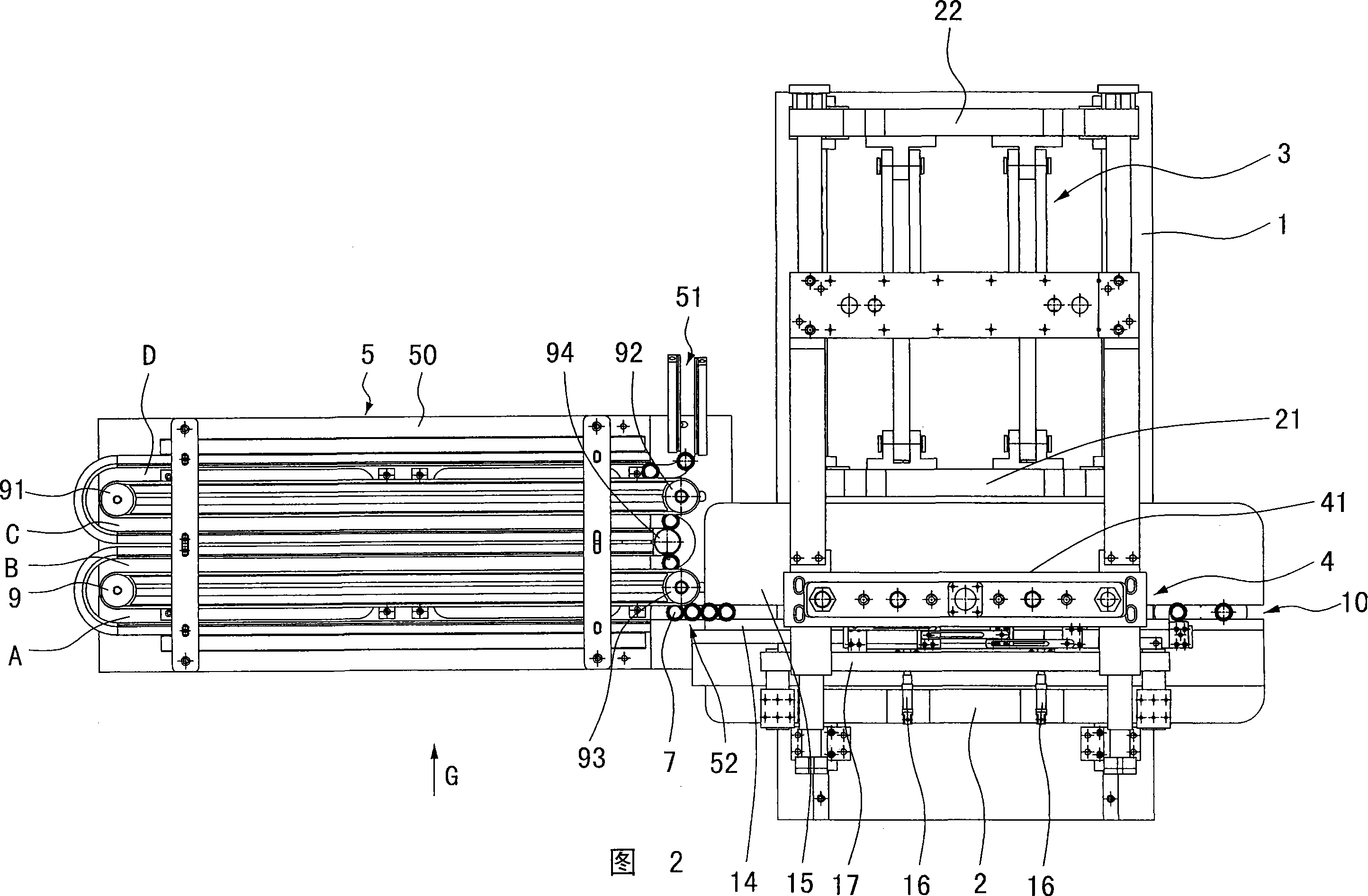

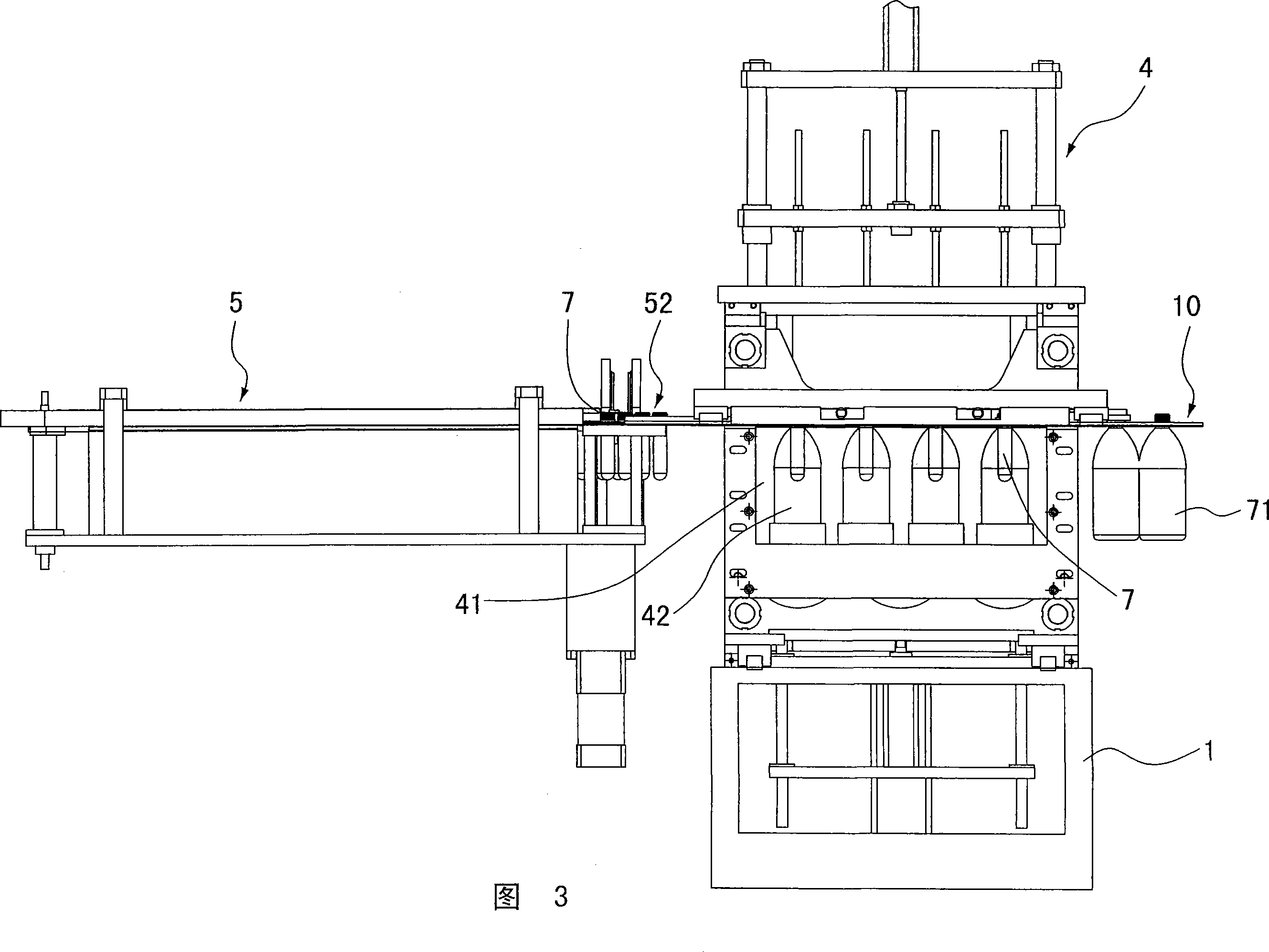

Curve friction transportation automatic plastic container forming machines

InactiveCN101077616ASimple structureImprove friction performanceHollow articlesMolding machineEngineering

The curved friction pipe conveying automatic plastic container forming machine has a drawing and blowing machine seat, a template with mold, a mold clamping mechanism, a drawing and blowing mechanism, a heating mechanism with support, a plastic bottle pipe conveying mechanism with heating channel, a pipe supporting device and a conveying friction belt or chain on two sides of the heating channel, a driving mechanism to drive the conveying friction belt or chain, and an electric heater below the heating channel. It features the at least two S-shaped heating channels with one material inlet and one material outlet, the bottle pipe arranging mechanism in the material outlet, and the material feeding mechanism to convey the arranged bottle pipe into the mold of the drawing and blowing machine.

Owner:ZHEJIANG HONGZHEN MASCH MOULD GRP CO LTD

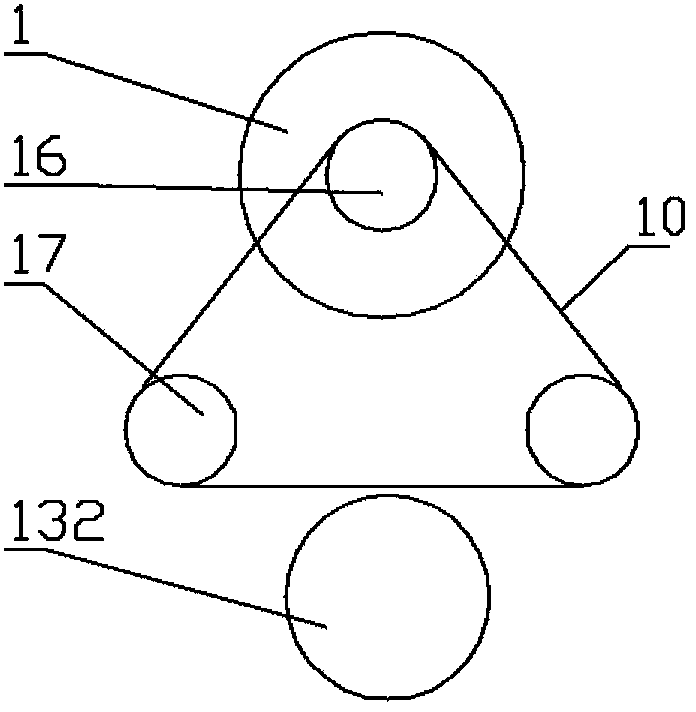

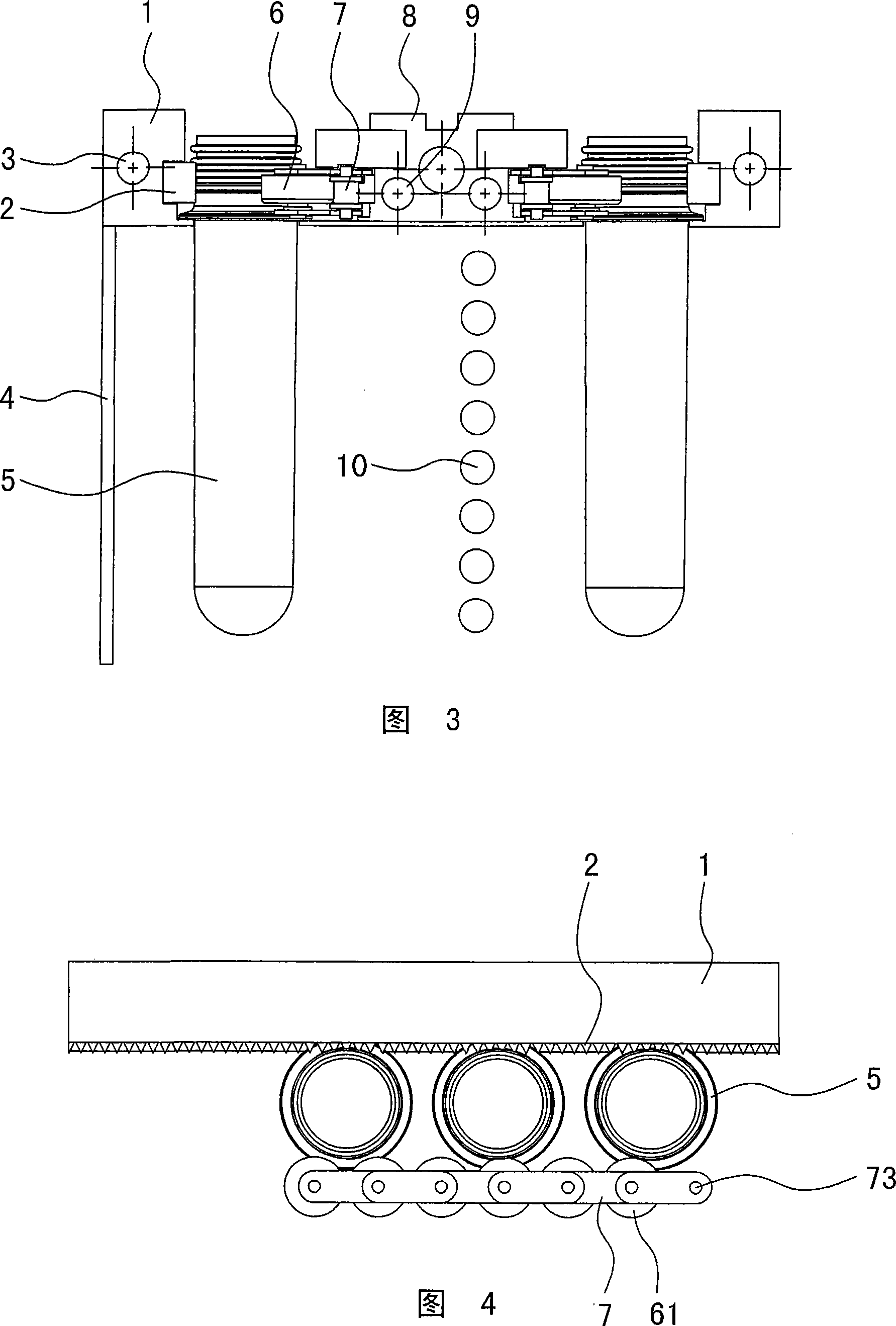

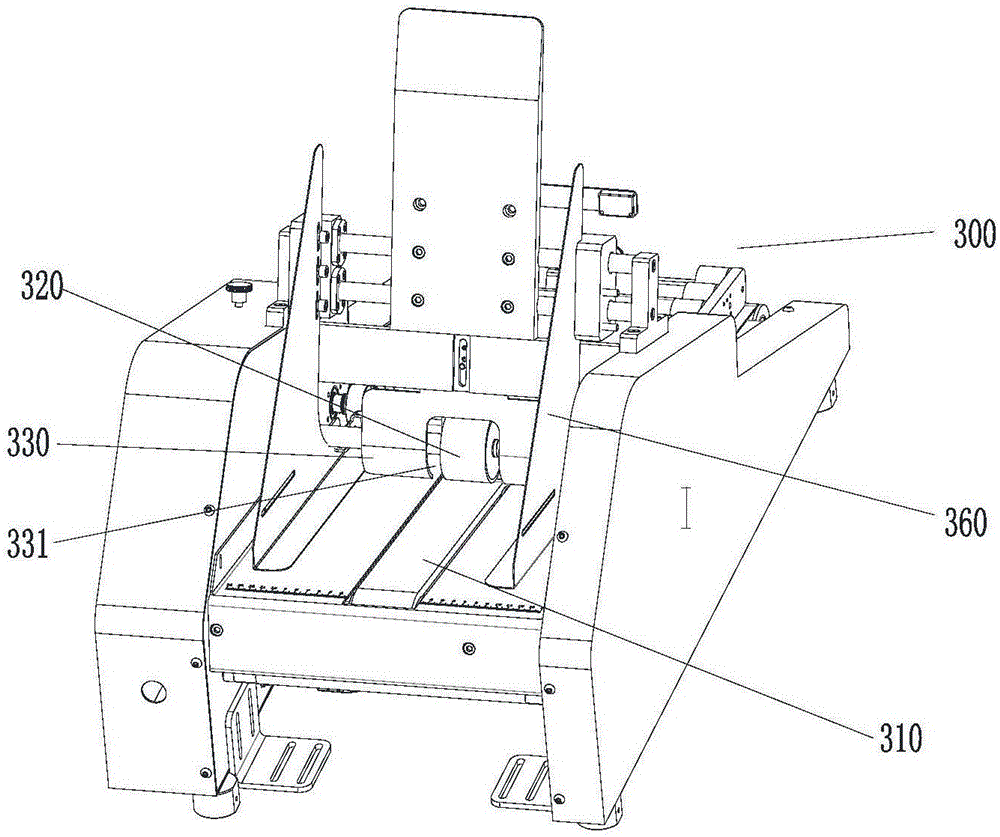

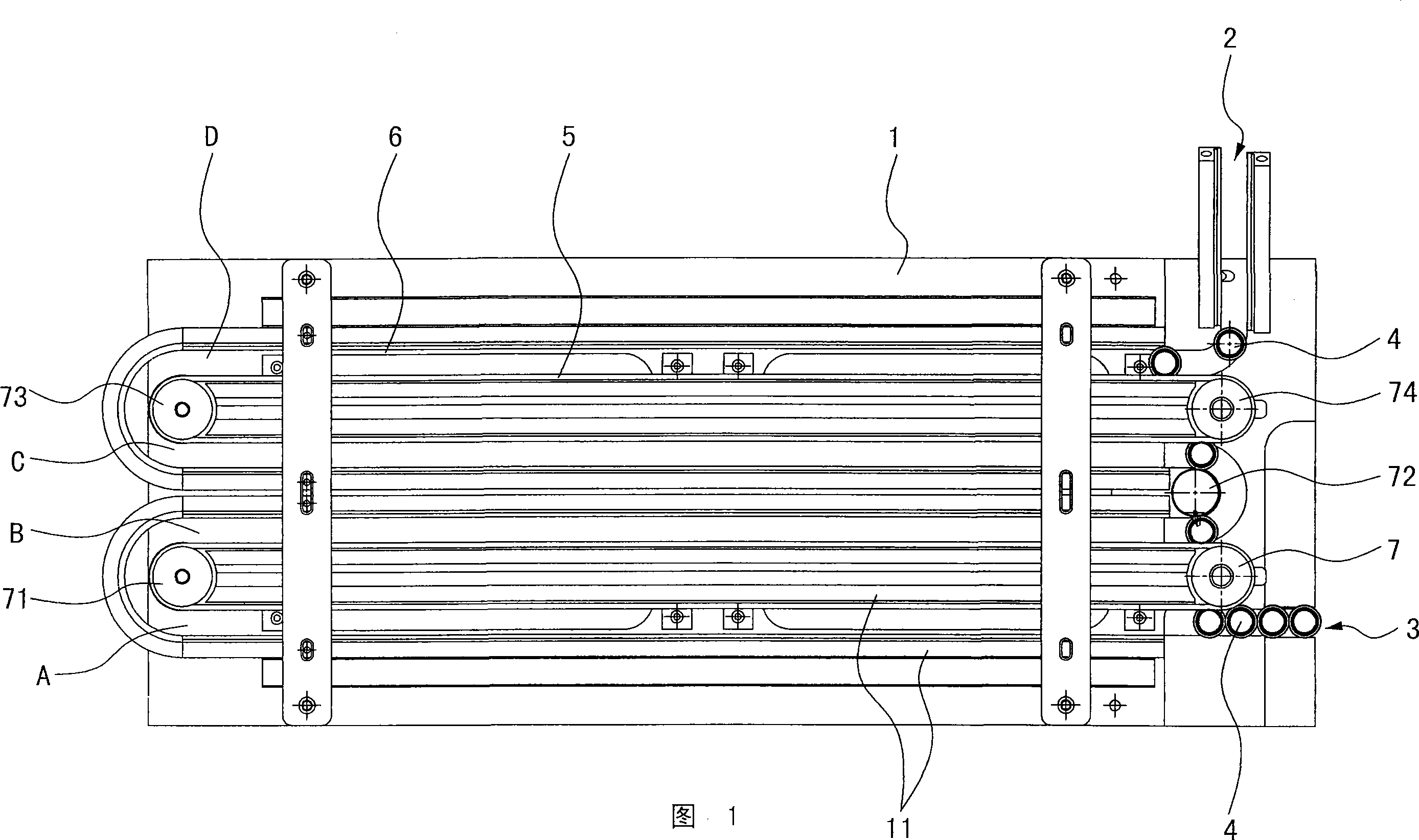

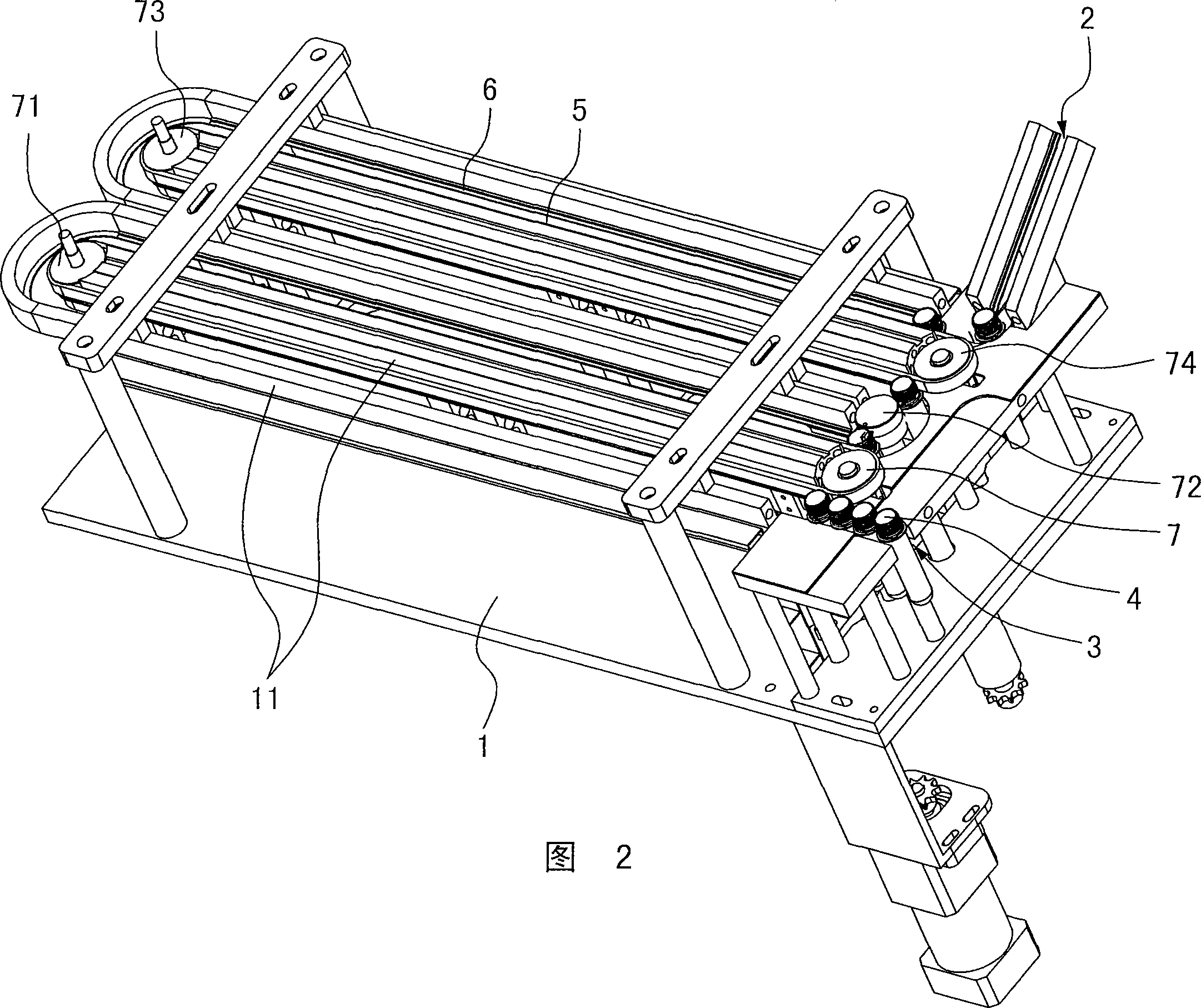

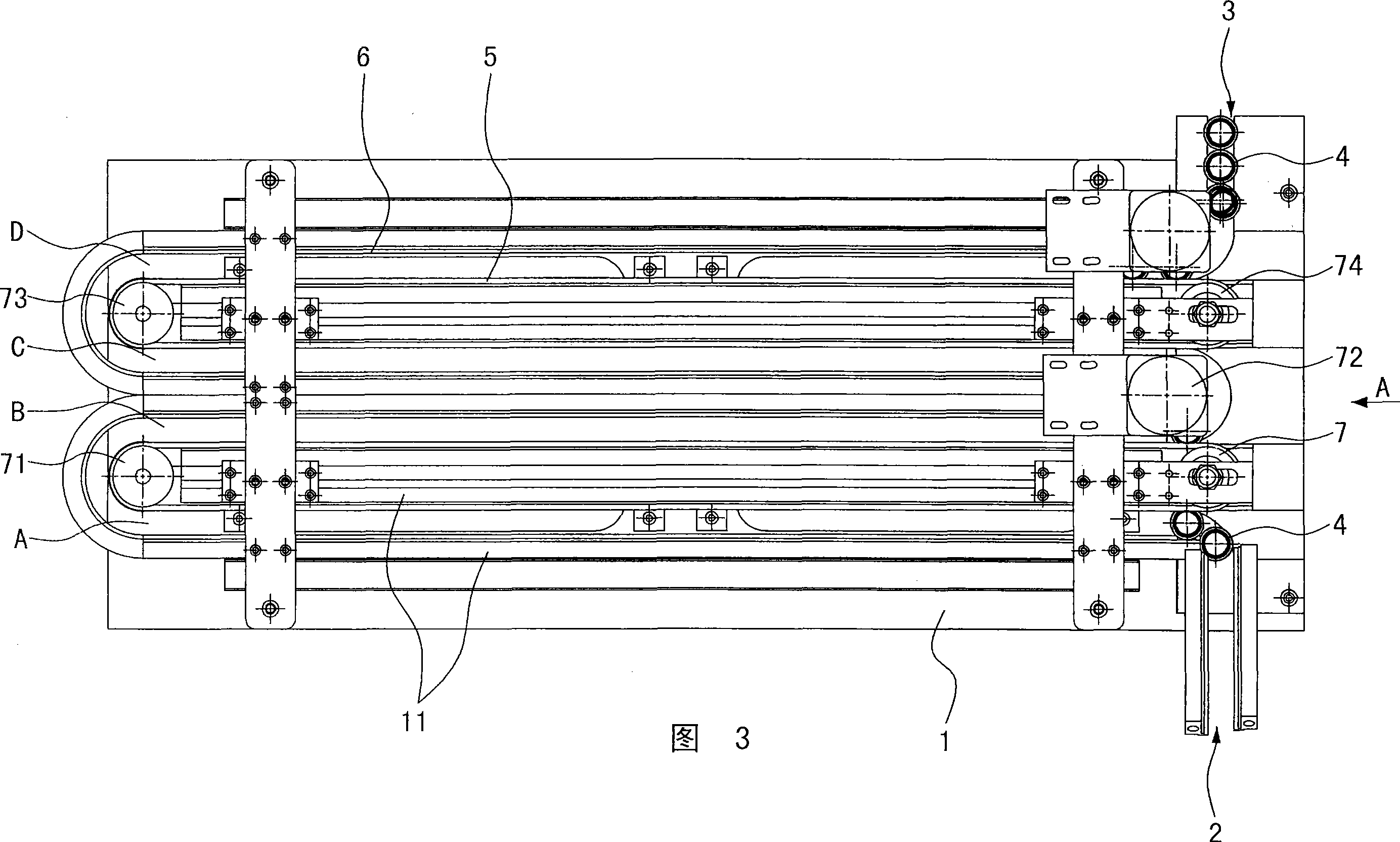

Conveying mechanism used for cylinder side face defect visual inspection

InactiveCN107352214AGuaranteed contactEasy to installMaterial analysis by optical meansRoller-waysFace detectionVisual inspection

The invention belongs to the field of mechanical conveying / appearance defect detection, particularly relates to a conveying mechanism used for cylinder side face defect visual inspection. The mechanism mainly comprises a rack, a friction belt, a transmission roller, a power shaft, a belt and a camera. Power is output through the belt, the belt drives the power shaft, and therefore rotation of the friction belt relative to the transmission roller is achieved, full circumference rolling of a cylinder is achieved, the side face of the cylinder is completely exposed under a detecting device, the requirement of cylinder side face detection is met, and the cylinder side face defect detecting efficiency and detecting quality are improved.

Owner:HARBIN UNIV OF SCI & TECH

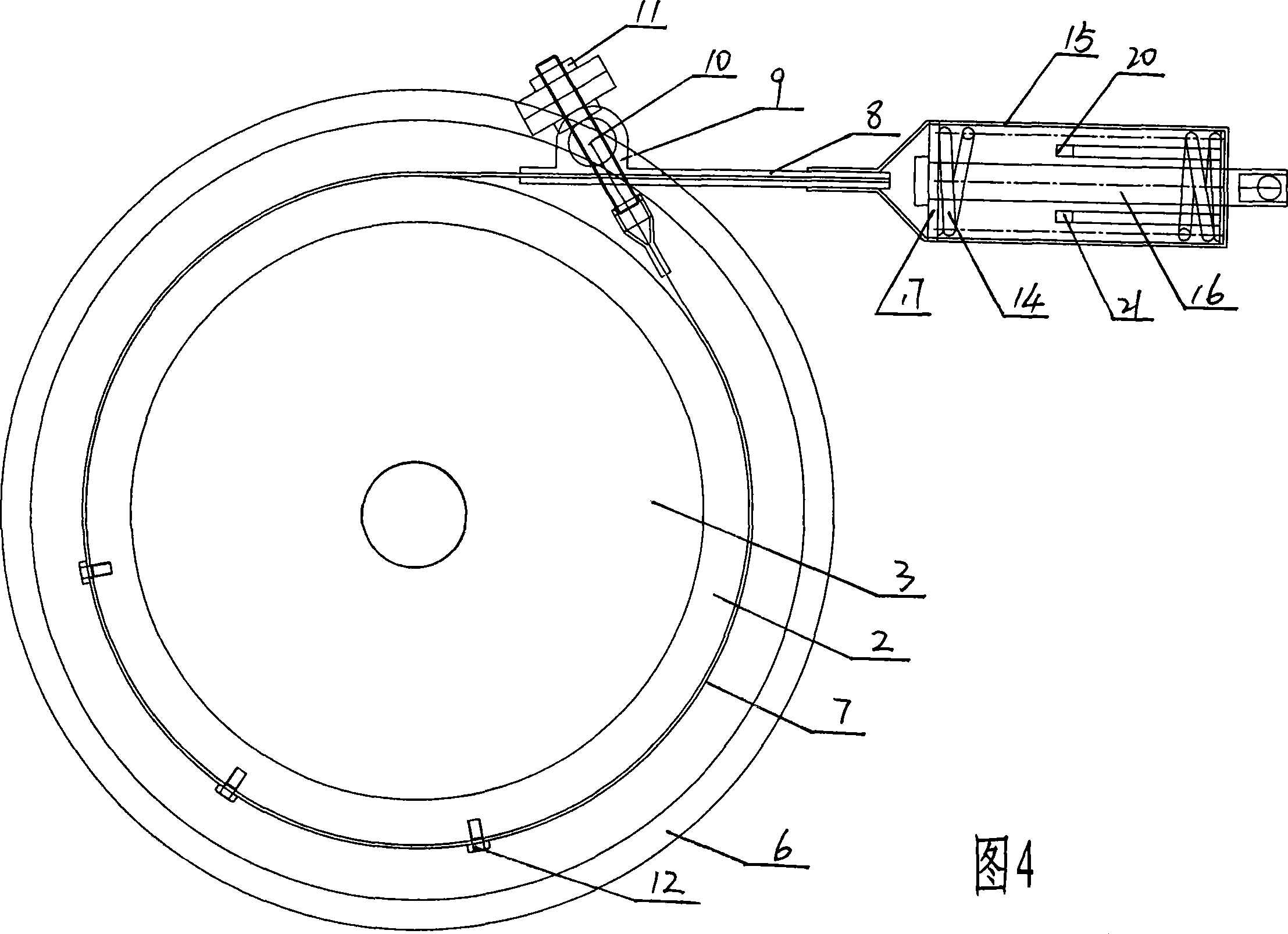

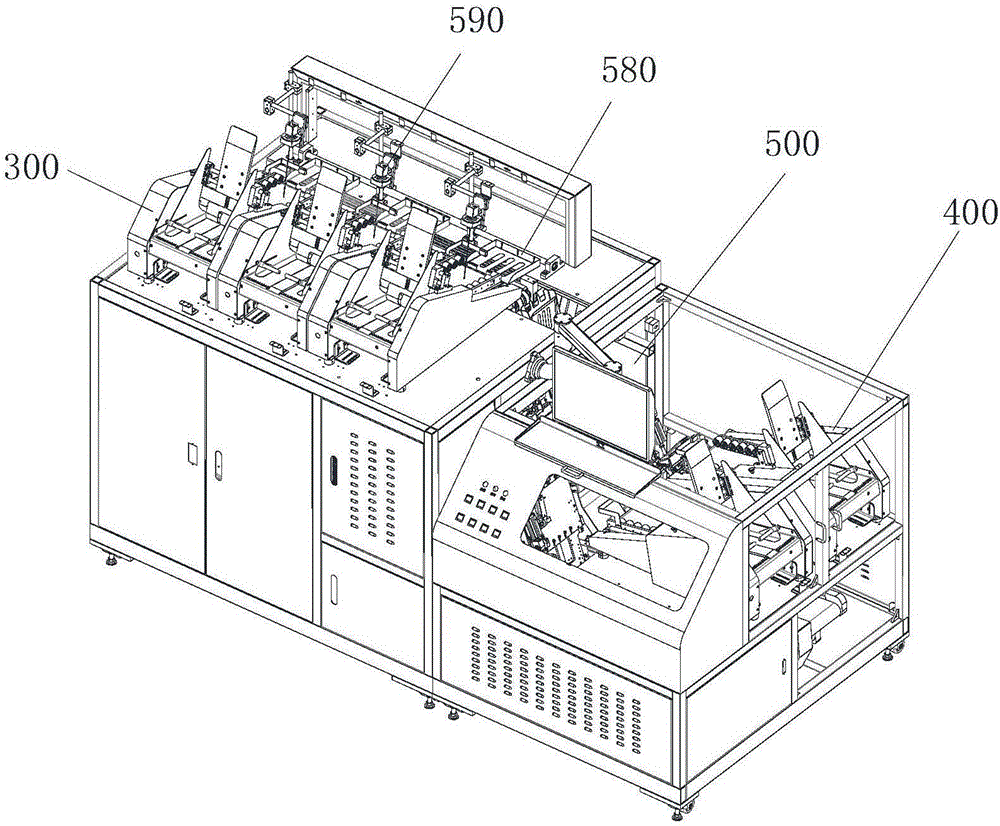

Bagging machine

ActiveCN106829034ALow efficiencyPaper article packagingIndividual articlesProcess engineeringFriction tape

The invention provides a bagging machine. The bagging machine comprises a paper conveyance mechanism, a bag conveyance mechanism and an bag opening and paper loading mechanism; the paper conveyance mechanism is provided with a first friction band used for conveying to-be-bagged paper; the bag conveyance mechanism is provided with a second friction band used for conveying a charging bag to be filled with the paper; and the bag opening and paper loading mechanism is arranged between the paper conveyance mechanism and the bag conveyance mechanism to load the paper conveyed from the first friction band into the charging bag conveyed from the second friction band. The bagging machine solves the problem that the efficiency of bagging methods in the prior art is relatively low.

Owner:ZHUHAI GREE INTELLIGENT EQUIP TECH RES INST CO LTD +1

Motorized window shades for RVs

ActiveUS20190085630A1Increase aesthetic appealPromote sportsWindowsSunshadesWindow openingFriction tape

A motorized shade assembly is provided having a discontinuous web extending between two rollers, one of which is motorized and the other is tensioned or biased toward rotation away from the other roller. The roller motor can be mounted inside of one of the rollers, and the tensioning device, such as a torsion spring, can be mounted inside of the other roller. The web includes a shade portion and a strap portion, with a rigid draw bar at the junction of those portions. Rotation of the rollers causes the strap portion to wrap over one of the rollers as the shade portion unwraps from the other roller. The shade assembly can be positioned between an inclined or curved vehicle window and an interior shroud for the window, such as found with a cab-over window of a Class B motorhome. The draw bar and fasteners connecting the strap to the draw bar facilitate movement of the shade when in contact with the shroud. Friction reducing tape or surface treatment on the periphery of the window opening in the shroud can also facilitate movement of the shade when in contact with the shroud. Motor actuation can be hardwired to a desired location within the vehicle, or wirelessly controlled by the user, as with an RF device.

Owner:JAYCO INC

Multiple bend circuit friction conveying plastic bottle tube heater

InactiveCN101081544AGuaranteed to move forwardGuarantee bottle tube advance and effectively generate advanceHollow articlesEngineeringFriction tape

The curved friction conveying plastic bottle pipe heater includes one heater support, and one S-shaped plastic bottle pipe conveying and heating mechanism with a pipe supporting unit of plate or strip, a friction belt driven with a transmission mechanism and an electric heating unit. The friction belt is flat one or toothed one; and the conveying and heating mechanism has also a feeding mechanism and one discharge mechanism. The present invention has simple structure, easy installation, short heating path, high heat efficiency, low production cost and other advantages.

Owner:ZHEJIANG HONGZHEN MASCH MOULD GRP CO LTD

Automatic polishing equipment

InactiveCN108500791ASimple structureReasonable designBelt grinding machinesGrinding work supportsDrive wheelEngineering

The invention discloses automatic polishing equipment comprising a transmission device, a telescopic rod, a rotating device, an electric permanent magnet, a machined piece, a friction belt, a drivingwheel, a driven wheel and magnetic blocks. The right side of the transmission device is provided with the telescopic rod, the rotating device is arranged at the bottom end of the right side of the telescopic rod, a rotating rod is arranged at the bottom end of the rotating device, the electric permanent magnet is arranged at the bottom end of the rotating rod, the machined piece is adsorbed onto the electric permanent magnet, and the bottom end of the machined piece makes contact with the friction belt; the front end of the friction belt is arranged on the driving wheel in a sleeving mode, therear end of the friction belt is arranged on the driven wheel in a sleeving mode, and the magnetic blocks are arranged at the upper ends of the driving wheel and the driven wheel correspondingly. Theautomatic polishing equipment is high in automatic degree, the different machining modes can be selected according to the different machined pieces, and the working efficiency is improved.

Owner:SUZHOU JU SHENG ELECTROMECHANICAL EQUIP ENG CO LTD

Energy recharging device for vehicle

The invention aims to provide an energy recharging device (1) for a vehicle. The energy recharging device (1) comprises at least one power supply device (8) located outside the vehicle (2) and at least one electric power collector (9) fixed on the vehicle (2). The electric power collector (9) has a central part with at least one friction tape, which is intended for supplying power to the vehicle (2) during movement of the vehicle (2). The central part is partially extended along the horizontal direction. At least one horn is formed by a metal material to serve as a member and has an upper surface. At least a part of the upper surface of the horn forms a contact zone, which directly contacts with a corresponding contact surface of the power supply device (8) when the vehicle (2) is stopped at a stop station (7), so as to ensure energy transfer between the electric power collector (9) and the power supply device via the contact zone.

Owner:ALSTOM TRANSPORT SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com