Polishing machine for pot body

A technology of polishing machine and pot body, which is applied to surface polishing machine tools, grinding/polishing equipment, metal processing equipment, etc. The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

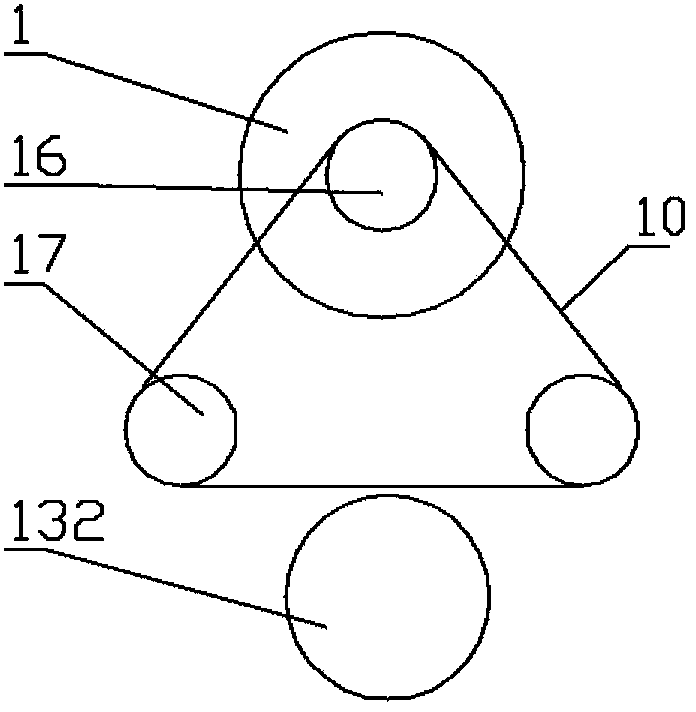

[0015] Example: see figure 1 , 2 As shown, the pot body polishing machine includes a rotary motor 1 and a polishing motor 2, a linear slide rail 4 is fixed on the frame 3, a slide plate 5 is inserted on the linear slide rail 4, and a cylinder 6 is fixed on the frame 3. The piston rod of 6 is fixed together with slide plate 5;

[0016] The guide column 7 is fixed on the slide plate 5, the lifting table 8 is inserted on the guide column 7, the lifting cylinder 9 is fixed on the frame 3, the piston rod of the lifting cylinder 9 is fixed on the lifting table 8; the rotating motor 1 is fixed on the lifting table 8, the rotating motor 1 drives the friction belt 10 to rotate;

[0017] Sliding plate 5 is fixed with workpiece frame 11, and pulley 12 is installed on the workpiece frame 11, and kettle body frame 13 is made up of axle 131, friction disc 132, bearing 133 and kettle body positioning mold 134, is fixed with friction disc 132 on the axle 131, bearing The inner ring of 133 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com