Sole abrasion resistance testing device capable of simulating various environments

A technology of wear resistance and testing device, which is applied to the measurement device of feet or shoe lasts, footwear, clothing, etc., can solve the problems of high price, large size of equipment, poor stability, etc., to avoid experimental errors, compact structure, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

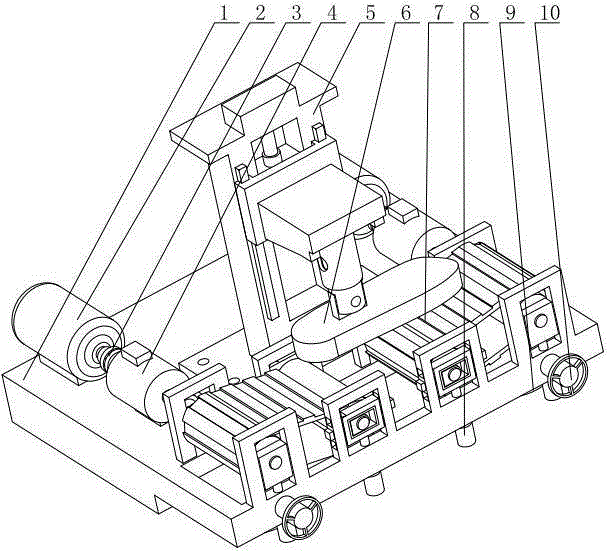

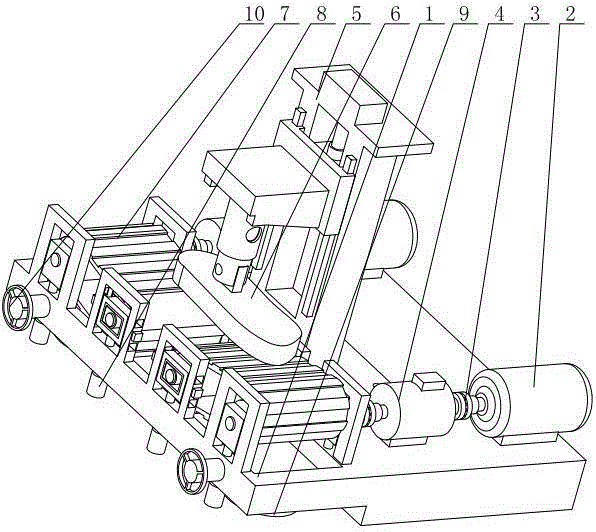

[0035] Such as figure 1 with figure 2 As shown, the test device for the wear resistance of shoe soles under various environments that can be simulated in this embodiment includes a test bench base 1, the front end of the test bench base 1 is provided with a friction test device 7, and two groups of friction test devices 7 are installed at intervals, and A drive motor 2, a coupling 3 and a torque sensor 4 are respectively installed at both ends of the base 1 of the test bench to control its motion; a hydraulic pressurizing device 5 is installed in the middle of the base 1 of the test bench, and the output end of the hydraulic pressurizing device 5 is connected to Foot model device 6, the foot model device 6 is located on top of the friction test device 7.

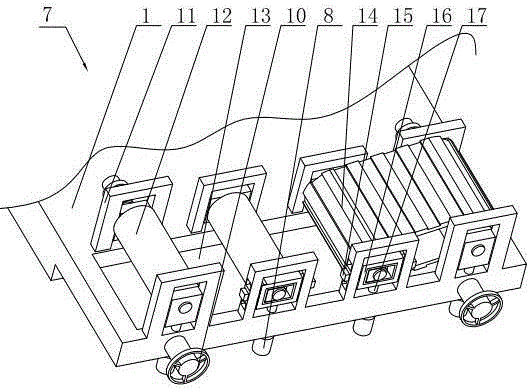

[0036] Such as image 3 As shown, the structure of the friction test device 7 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com