Equipment capable of implementing automatic single-line conveyance of quasi-spherical fruits and uniformly turning them

A quasi-spherical, fruity technology, applied in the field of material supply mechanism, can solve the problems of affecting the classification accuracy, low detection accuracy, high missed detection rate of fruit surface, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

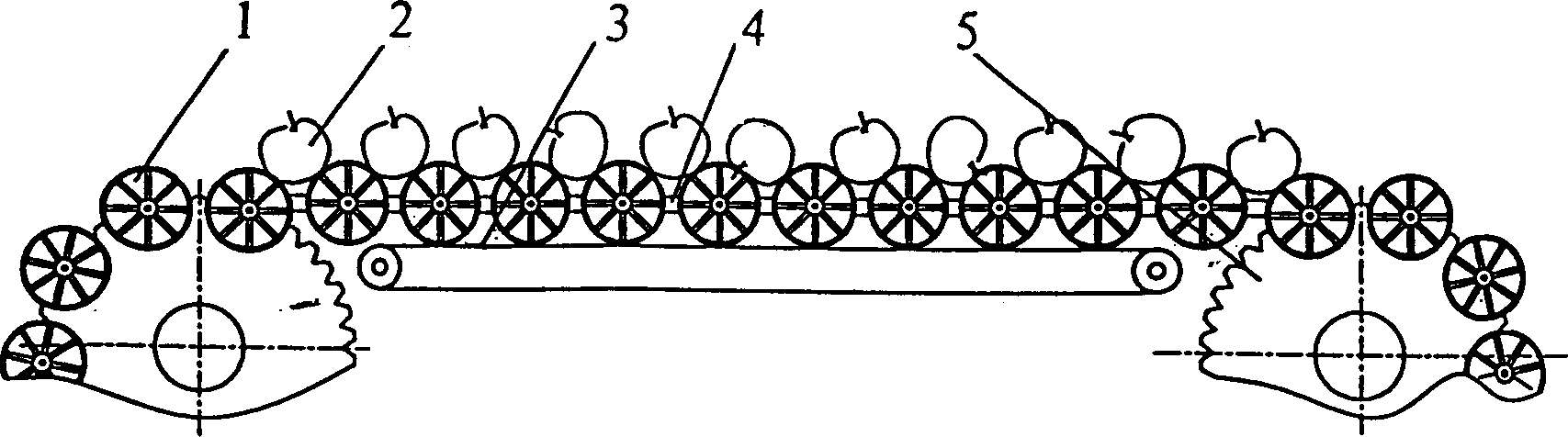

[0015] like figure 1 As shown, when the motor (not shown) drives the large sprocket 5, the chain 4 will move forward with the large sprocket, thereby driving the double-cone rollers 1 to convey horizontally forward through the horizontal small shaft.

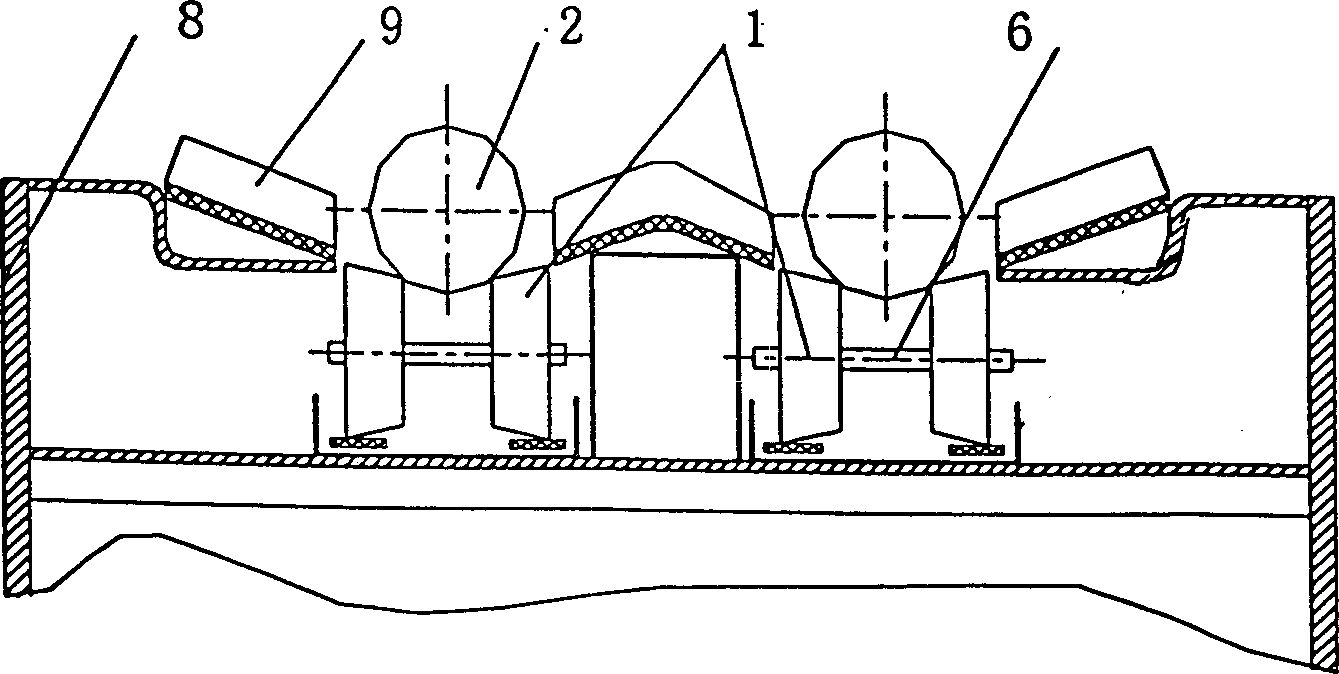

[0016] like figure 2 As shown, the double-cone roller 1 is evenly fixed on the chain 4 through the horizontal small shaft 6, and the double-cone roller 1 and the horizontal small shaft 6 are assembled with a gap, which can rotate freely around the horizontal small shaft 6, and can also follow the horizontal axis 6. Small axis 6 movement. Alternately installed between a pair of double-cone rollers 1 is a pallet 7, the pallet 7 is clamped on the horizontal small shaft 6, and can move together with the horizontal small shaft 6 to prevent the quasi-spherical fruit 2 from falling off. of blocking.

[0017] exist image 3 As shown, the racks 8 on both sides of each row of double-cone rollers 1 are provided with sloped plates 9 wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com