Plastic bottle pipe heater locating friction-conveying chain

A technology for conveying chains and plastic bottles, which is applied in the field of plastic machinery, and can solve problems such as difficulty in stretching and blowing machine processes, uneven speed of bottle tubes, and affecting the heating effect of bottle tubes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

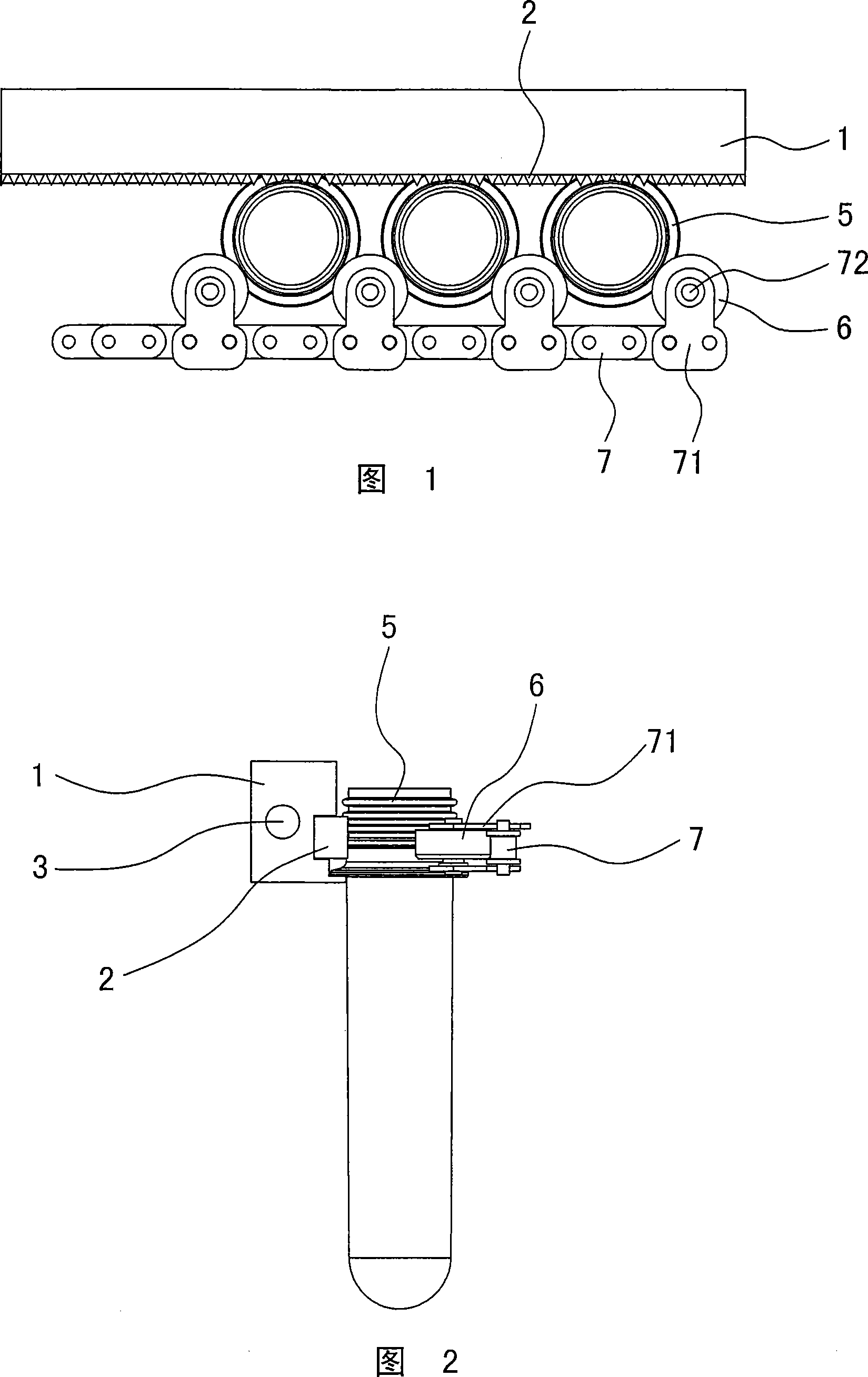

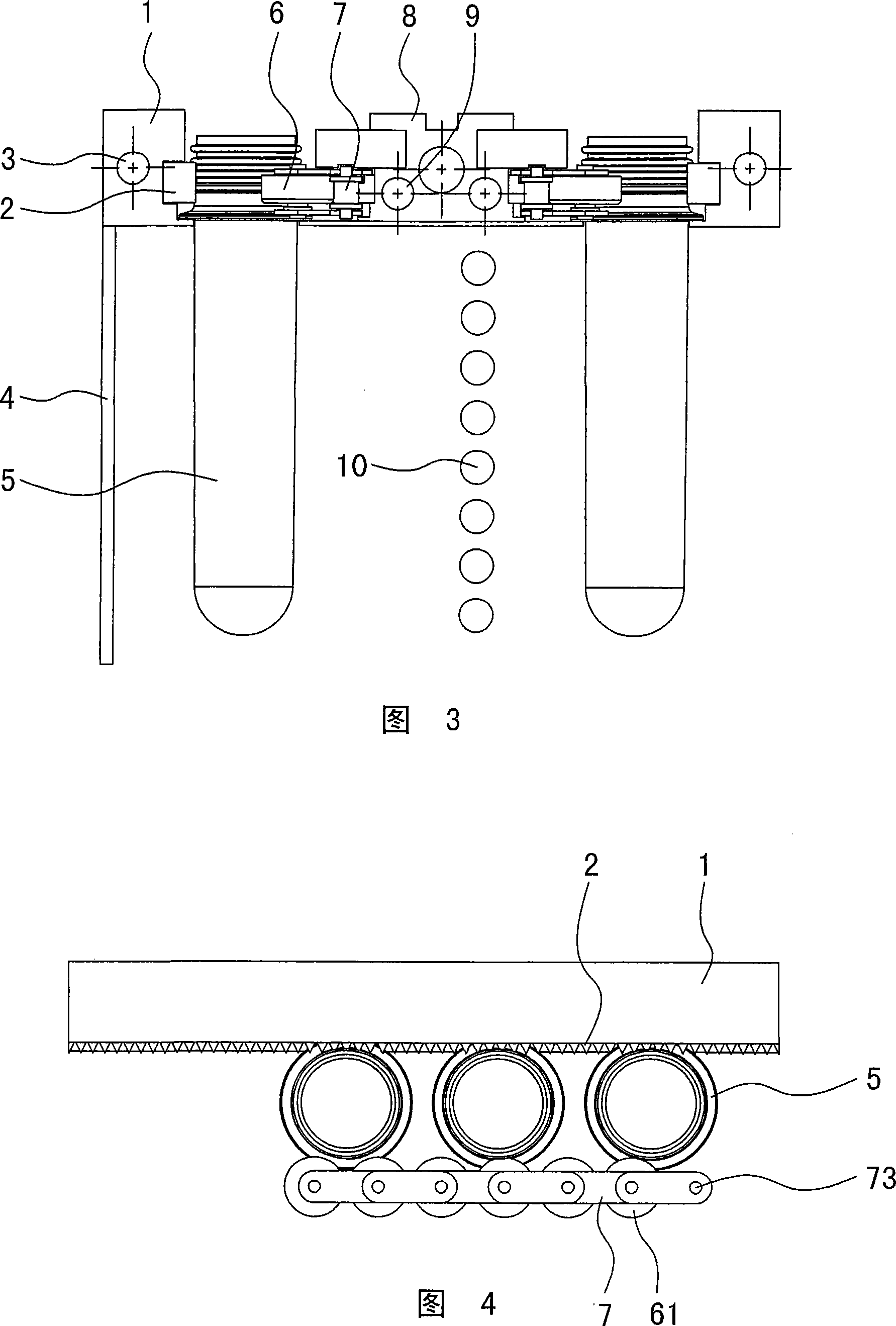

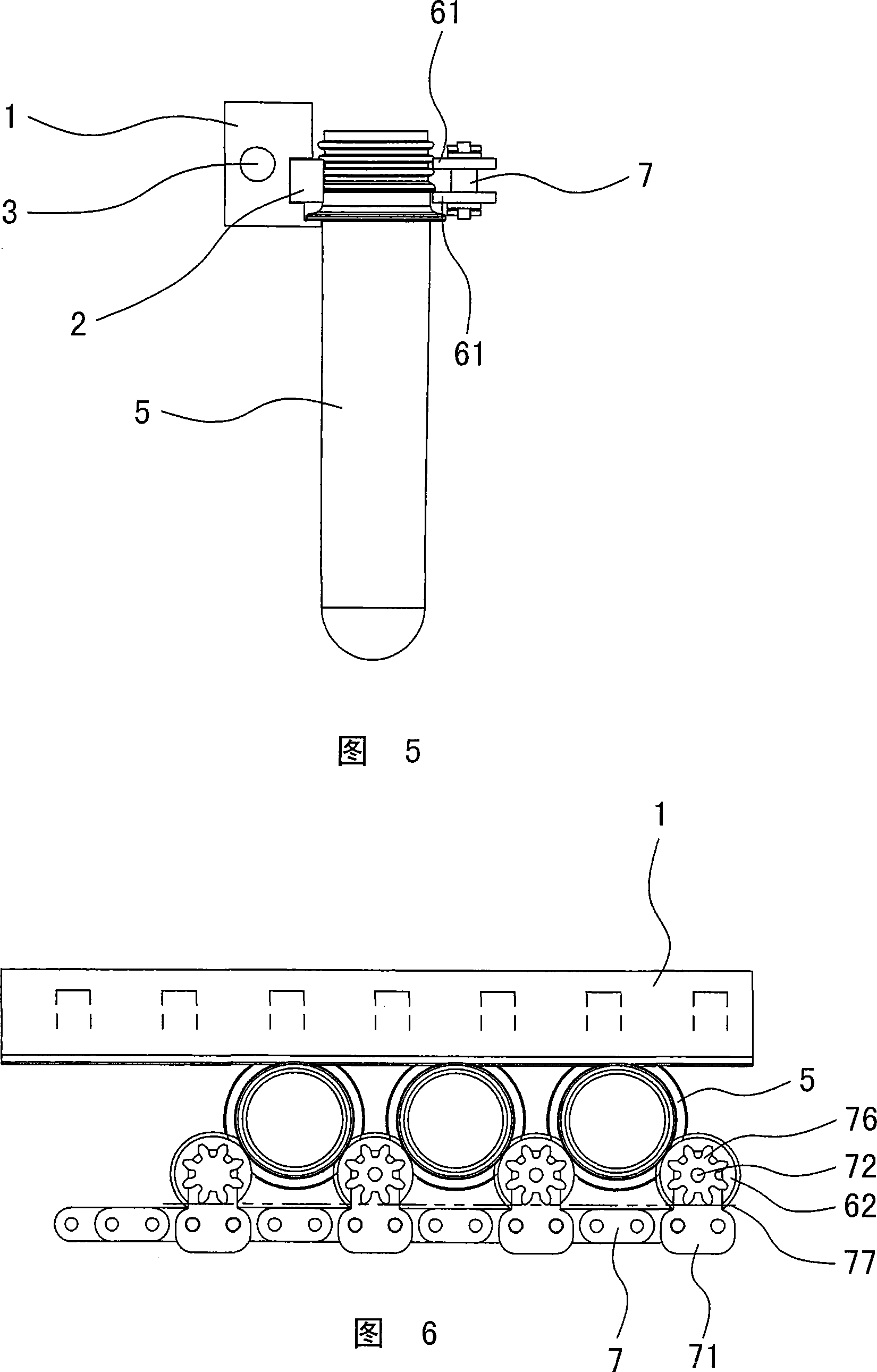

[0014] The invention relates to a plastic bottle tube heater positioning friction conveying chain. A friction bracket 1 and a chain bracket 8 are arranged on the heater. A friction belt 2 is installed in the friction bracket 1. The friction belt includes a toothed belt made of various materials or There is no toothed belt, and the transmission chain 7 is installed in the chain bracket 8. The chain is driven by a special transmission mechanism to run continuously, and the plastic bottle tube 5 is transported between the friction belt 2 and the chain 7. Its main technical feature is that the chain 7 is installed Rotate location friction wheel 6,61,62, the concrete structure of rotation location friction wheel, pattern have many kinds, and rotation location friction wheel 6,61,62 stretches between the plastic bottle tube 5 in operation and with plastic bottle tube 5 ends contact with each other. This scheme has installed the rotatable positioning friction wheel in the chain (can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com