Intelligent belt pulley

A technology of intelligent belts and pulleys, applied in belts/chains/gears, components with teeth, portable lifting devices, etc., can solve the problem that the reducer is difficult to meet the long-stroke, low-stroke pumping unit, etc., and achieve mechanical strength. protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

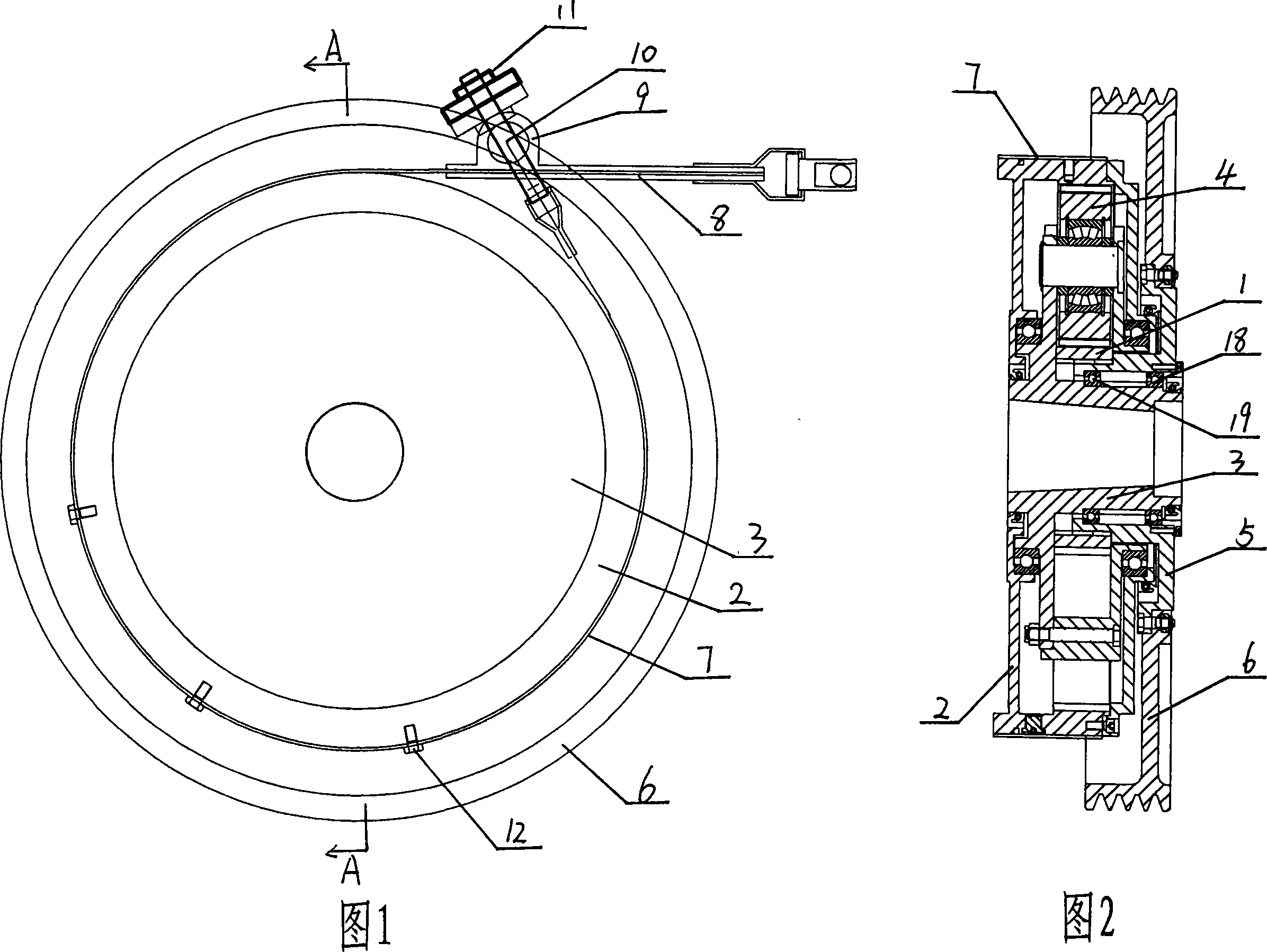

[0020] As shown in Figure 1 and Figure 2, the smart pulley includes a planetary gear mechanism consisting of a sun gear 1, an inner ring gear 2, a planetary carrier 3, and a planetary gear 4, and a pulley consisting of a pulley core 5 and a pulley 6. The pulley core 5. The bearings 18 and 19 are axially fixed to the planet carrier 3, the sun gear 1 is floatingly connected to the pulley core 5, and the inner ring gear 2 is wound with a friction belt 7, and one end of the friction belt 7 is provided with a connecting plate fixed on the reducer body 8, the other end is fixed with a screw 10 passing through the connecting plate 8 and fixed by a nut 11. The friction belt 7 is fixed with the ring gear 2 by bolts 12 . The coupling plate 8 is provided / opened with a collar 9 through which the screw rod 10 passes. At this time, the smart pulley only has the function of deceleration. Generally, its own deceleration ratio is set at 3-5. It is used on the decelerator, which is equivalent ...

Embodiment 2

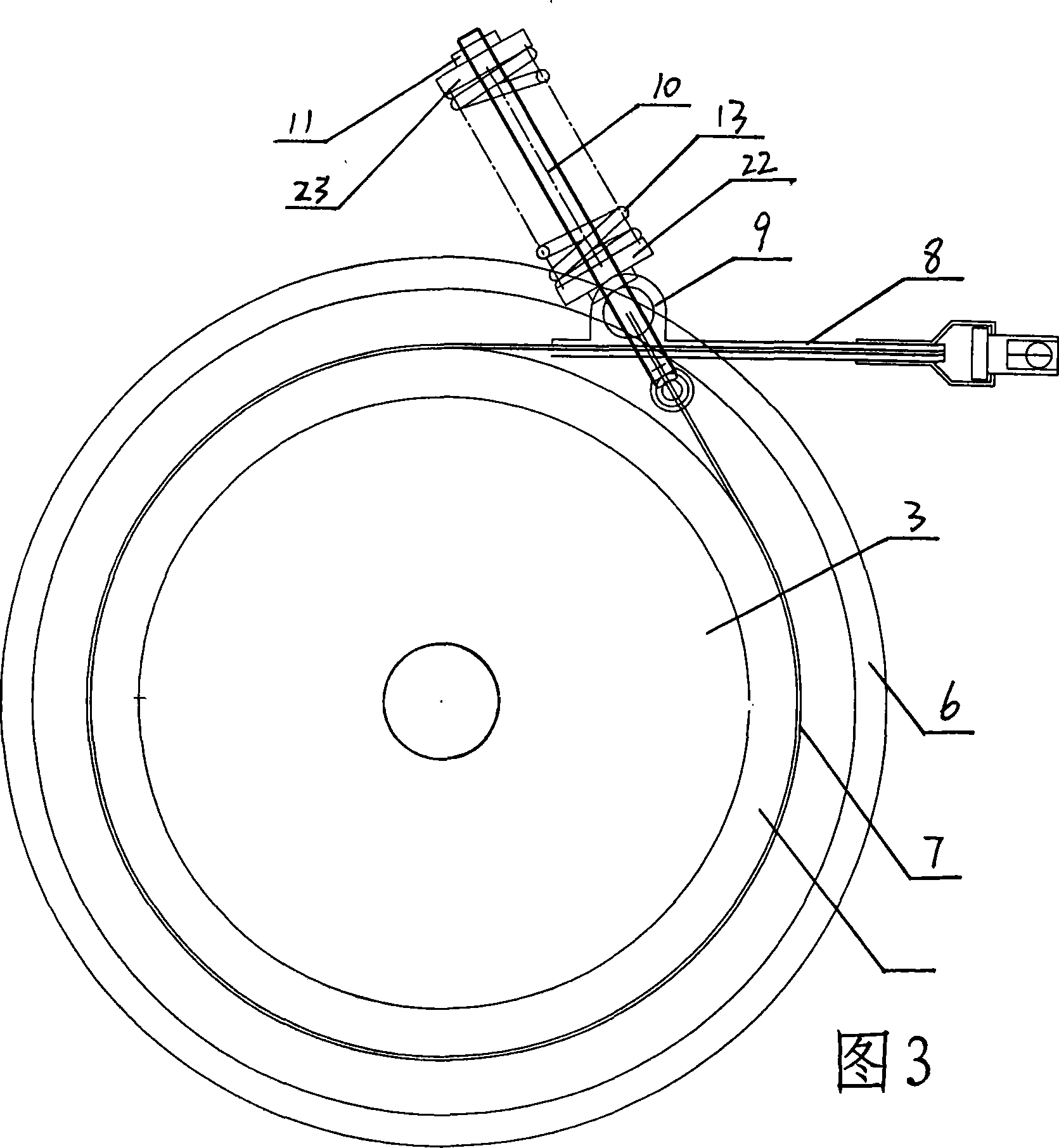

[0022] As shown in Figure 3, the smart pulley includes a planetary gear mechanism composed of a sun gear 1, an inner ring gear 2, a planetary carrier 3, and a planetary gear 4, and a pulley composed of a pulley core 5 and a pulley 6. The pulley core 5 passes through the bearing 18, 19 are axially fixed with the planet carrier 3, the sun gear 1 is floatingly connected with the pulley core 5, and the inner ring gear 2 is wound with a friction belt 7, one end of the friction belt 7 is provided with a connecting plate 8 fixed on the reducer body, and the other One end is fixed with a screw rod 10 passing through the connecting plate 8 and fixed by a nut 11 . A compression spring 13 is sleeved between the nut 11 on the screw 10 at the end of the friction belt 7 and the connecting plate 8, and the two ends of the compression spring 13 are provided with washers 22 and 23, and the compression of the compression spring between the two washers can be adjusted through the corresponding op...

Embodiment 3

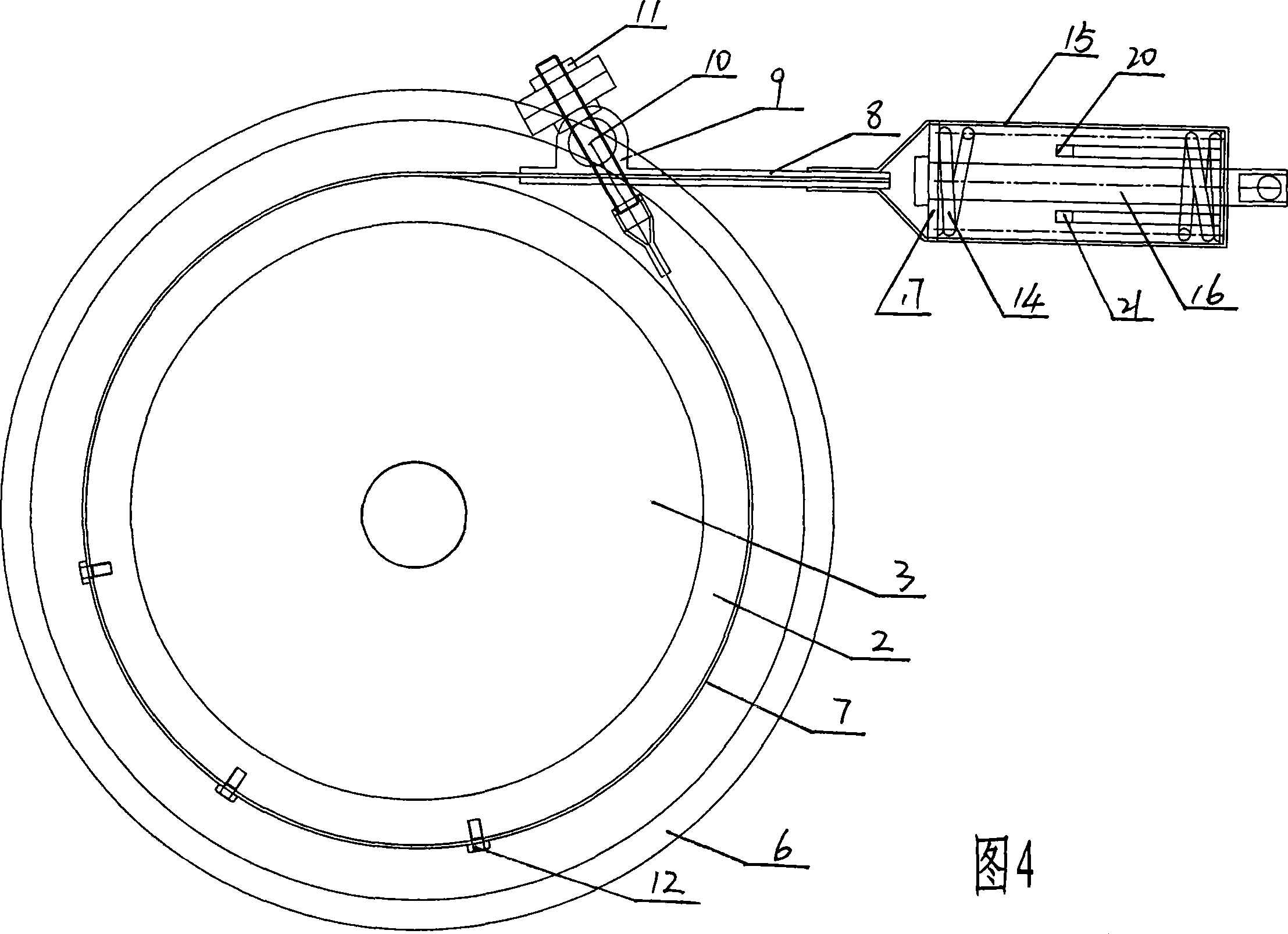

[0024]As shown in Figure 4, the smart pulley includes a planetary gear mechanism composed of a sun gear 1, an inner ring gear 2, a planetary carrier 3, and a planetary gear 4, and a pulley composed of a pulley core 5 and a pulley 6. The pulley core 5 passes through the bearing 18, 19 are axially fixed with the planet carrier 3, the sun gear 1 is floatingly connected with the pulley core 5, and the inner ring gear 2 is wound with a friction belt 7, one end of the friction belt 7 is provided with a connecting plate 8 fixed on the reducer body, and the other One end is fixed with a screw rod 10 passing through the connecting plate 8 and fixed by a nut 11 . The friction belt 7 is fixed to the ring gear 2 through bolts 12; an overload power-off protector is arranged on the connecting plate 8, and the overload power-off protector includes a housing 15 fixed to the connecting plate 8 at one end, and the housing 15 is provided with The contacts 20 and 21 that make the motor power supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com