Power Transmission Device of Jacquard Loom

A power transmission device, loom technology, applied in the direction of jacquard machine, weaving, textile and paper making

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

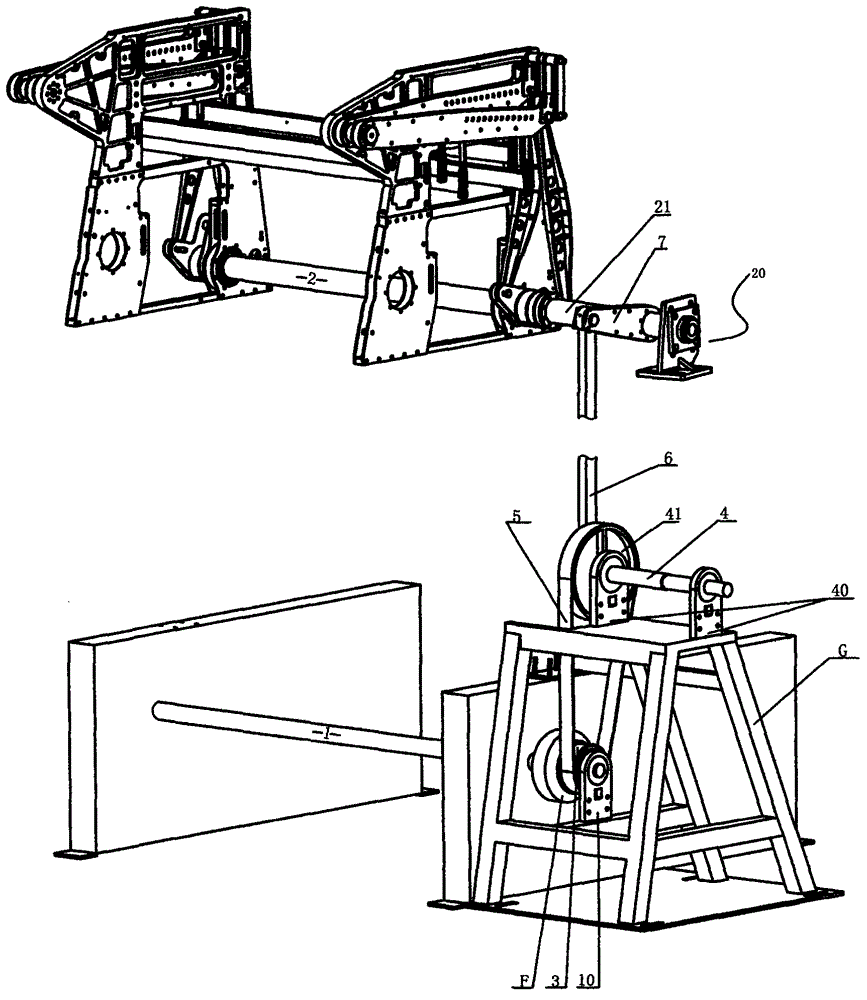

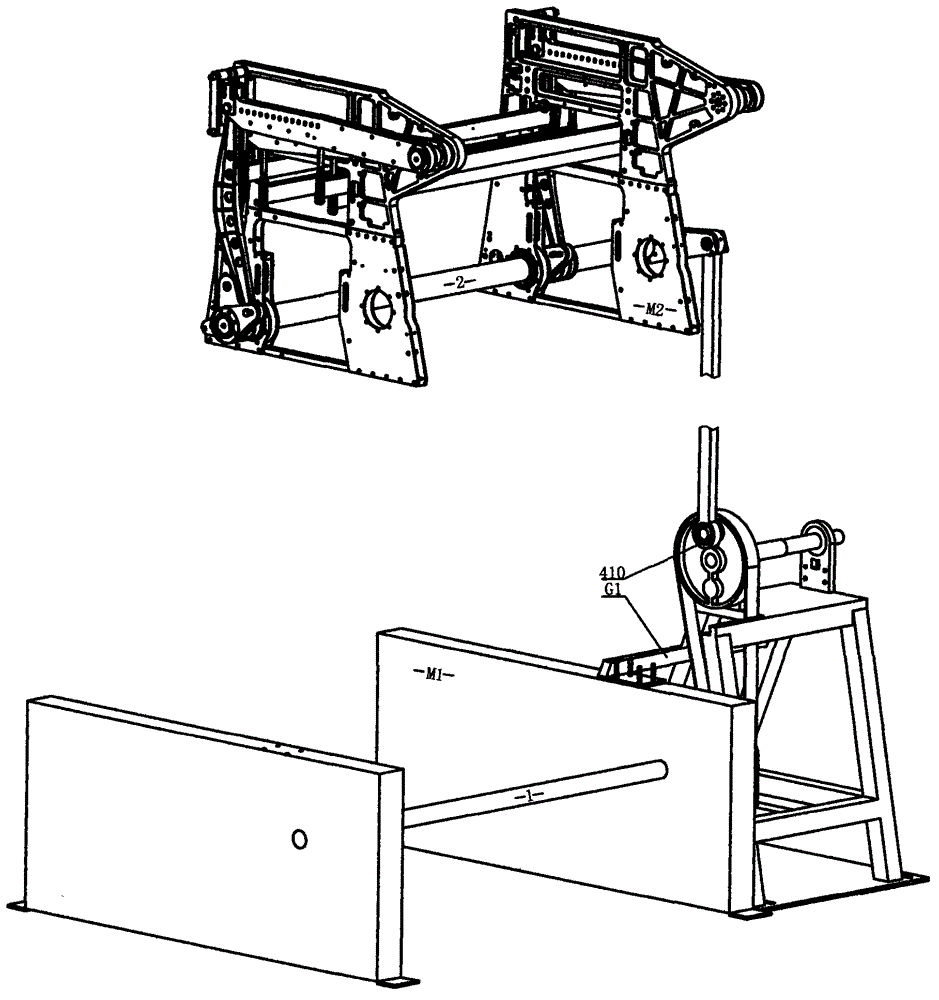

[0028] The loom wall panel is composed of the left wall panel and the right wall panel M1. In the figure, the right protruding end of the main transmission shaft 1 of the loom passes out of the right wallboard M1 for respectively installing the flywheel F and the main transmission wheel 3, in order to improve the rotation stability of the right protruding end of the main transmission shaft 1 of the loom , Supported by bearing housing 10 with bearings. The continuous rotation power of the main transmission shaft 1 of the loom is realized by driving the flywheel F through the main motor (not shown). Of course, the flywheel F can also be installed on the left end of the main transmission shaft 1 of the loom. The left end of axle 1 passes outside above-mentioned left wallboard.

[0029] In the prior art, the wall panels of the jacquard faucet also consist of a left wall panel and a right wall panel M2, and the left wall panel and the right wall panel M2 are installed on the botto...

Embodiment 2

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com