Board material of charing heat-pringting pattern and the method and device for producing the same

A pattern and carbonization technology, applied in the field of boards, can solve the problems affecting the aesthetics, practicality and service life of the floor, the veneer or wood grain paper is easy to fall off, and the use time is long, and achieves the effect of simple structure, consistent style and color, and environmental protection of products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

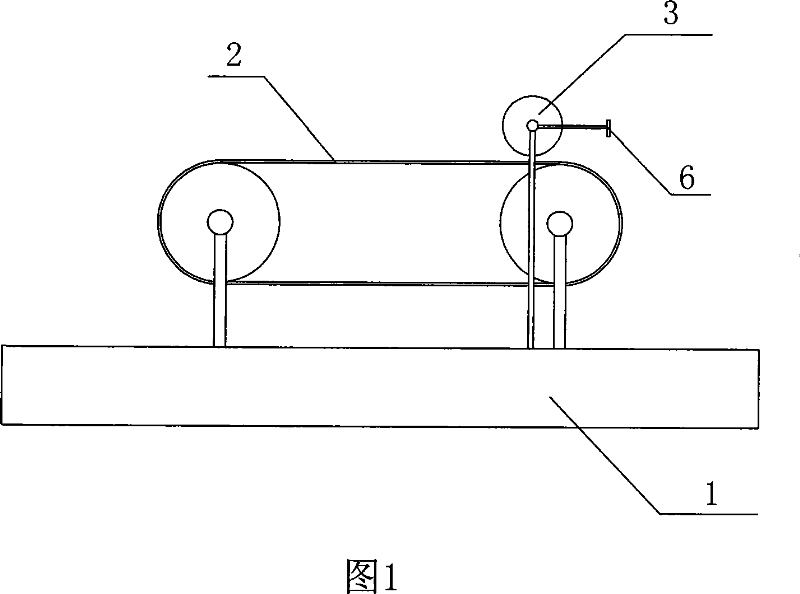

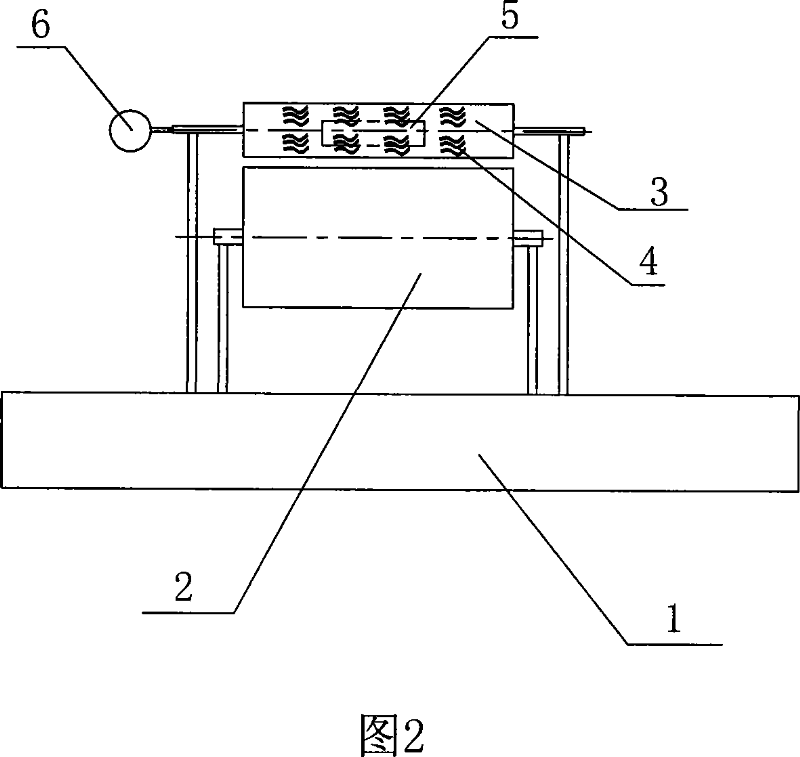

[0022] 1) Select the carbonization hot stamping equipment shown in Fig. 1 and Fig. 2 for use;

[0023] 2) Place the plank that needs to be carbonized and hot stamped in the gap between the heating roller 3 and the upper surface of the conveyor 2 in the equipment shown in Figure 1 and Figure 2, and adjust the heating roller 3 and The spacing between the upper surfaces of the conveying device 2 is such that the wood grain-like protruding pattern 4 on the surface of the heating roller 3 is in contact with the upper surface of the plank, and the temperature on the surface of the heating roller 3 is controlled to be 250 degrees;

[0024] 3) The conveying device 2 drives the plank, and when the plank moves, the friction drives the heating roller 3 to rotate and roll, and the rotation and rolling speed of the heating roller 3 is controlled to 2.5m / min, so that the protruding pattern 4 of the wood pattern on the surface of the heating roller 3 is hot stamped on the surface of the heati...

Embodiment 2

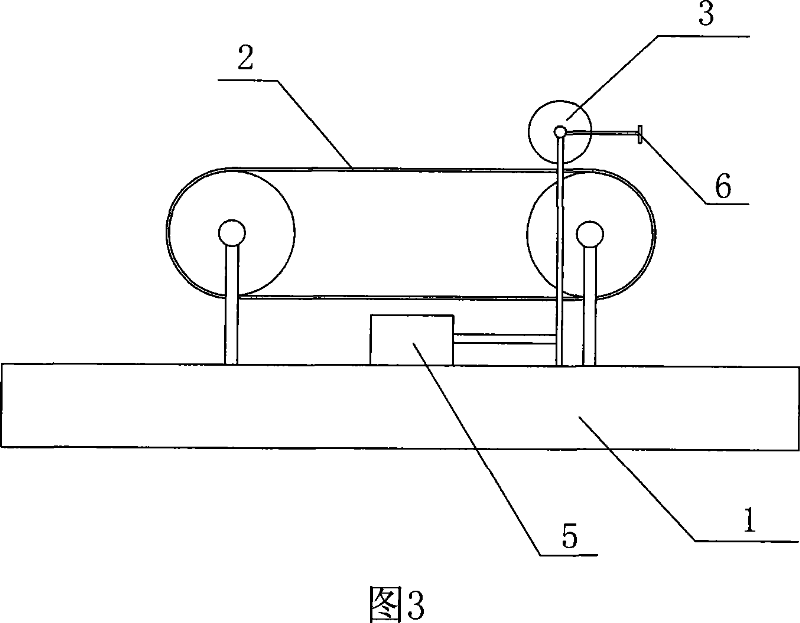

[0026] 1) Select the carbonization hot stamping equipment shown in Fig. 3 and Fig. 4 for use;

[0027] 2) Place the bamboo board that needs to be carbonized and hot stamped in the gap between the heating roller 3 and the upper surface of the conveyor 2 in the equipment shown in Figure 3 and Figure 4, and adjust the heating roller according to the thickness of the bamboo board 3 and the distance between the upper surface of the conveying device 2, so that the surface of the heating roller 3 with the concave pattern 7 on the surface is in contact with the upper surface of the bamboo board; the temperature on the surface of the heating roller 3 is controlled to be 200 degrees;

[0028] 3) The transmission device 2 drives the bamboo board, and when the bamboo board moves, the friction drives the heating roller 3 to rotate and roll, and the rotation and rolling speed of the heating roller 3 is controlled to 2.0m / min, so that the surface of the heating roller 3 with the concave patte...

Embodiment 3

[0030] 1) Select the carbonization hot stamping equipment shown in Fig. 1 and Fig. 2 for use;

[0031] 2) Place the decorative plate that needs to be carbonized and hot stamped in the gap between the heating roller 3 and the upper surface of the conveyor 2 in the equipment shown in Figure 1 and Figure 2, and adjust the heating roller according to the thickness of the decorative plate 3 and the gap between the upper surface of the conveying device 2, so that the wood grain-like protruding pattern 4 on the surface of the heating roller 3 is in contact with the upper surface of the decorative plate. The temperature control of heating roller 2 surface is 280 degree.

[0032] 3) The transmission device 2 drives the decorative plate, and when the decorative plate moves, the friction drives the heating roller 3 to rotate and roll, and the rotation and rolling speed of the heating roller 3 is controlled to 1.5m / min, so that the wood grain pattern on the surface of the heating roller 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com