Method for preventing honeycomb from sliding

A honeycomb and slip technology, applied in the field of composite material manufacturing, can solve complex repair problems and other problems, and achieve reliable process assurance, production schedule assurance, and easy realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

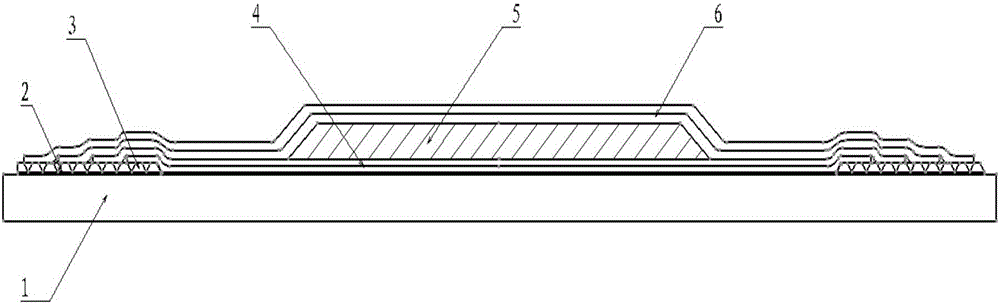

[0014] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments:

[0015] This method for forming sandwich-type composite parts takes the cover forming of a certain type of machine as an example, and its operation steps are as follows:

[0016] 1) Prepare the forming tooling 1, scrub the forming mold with butanone to ensure that the surface of the forming tooling 1 is smooth and free of grease, and paste the anti-slip tape 3 with glue 2 at a place 20-30 mm outside the product cutting line of the forming tooling, and it must be completely cured on the anti-slip tape After that, the parts can be layered. The width of the anti-slip belt 3 is determined according to the number of paving cloth layers required by the design. For each additional layer of skin, the anti-slip belt is increased by 10mm; the outer edge of the anti-slip belt and the edge of the forming tooling are set aside at l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com