Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

63 results about "Feeding procedures" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Feeding procedures in the omaha system, any method of giving food or fluid, including breast, formula, intravenous, or tube. supplemental feeding a planned additional food or nutrient that is added to the usual diet, often as a powder, formula, or tablet.

Process for producing coarse-particle anion-exchanger gels

InactiveUS6924317B2Improve stabilityHigh purityCation exchanger materialsIon-exchanger regenerationChemistryFeeding procedures

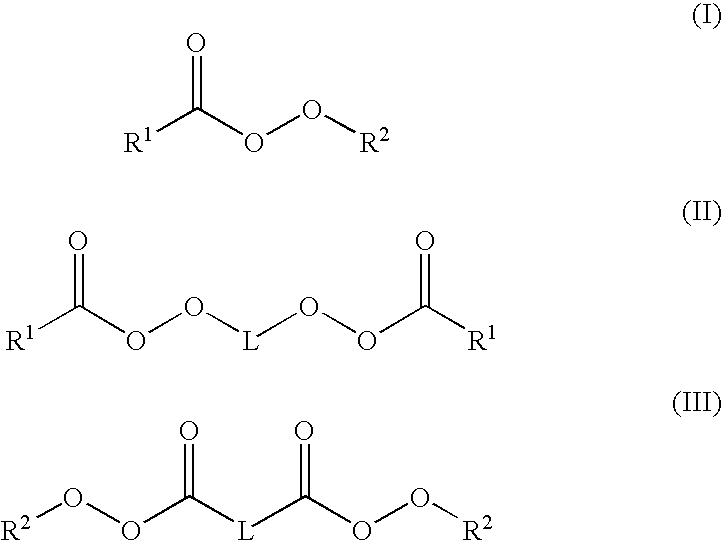

The present invention relates to a process for producing monodisperse anion-exchanger gels with high stability, purity and coarse particle size greater than 800 μm starting from a monodisperse bead polymer with a swelling index of from 2.5 to 7.5 and more than one subsequent feed procedure without any separation between the polymerization steps and then modifying to give the anion exchanger.

Owner:LANXESS DEUTDCHLAND GMBH

Tobacco leaf automatically boxing storage method

ActiveCN1875793AReduce volumeEliminate the limitation of uneven suction timeTobacco preparationComputer scienceManufacturing line

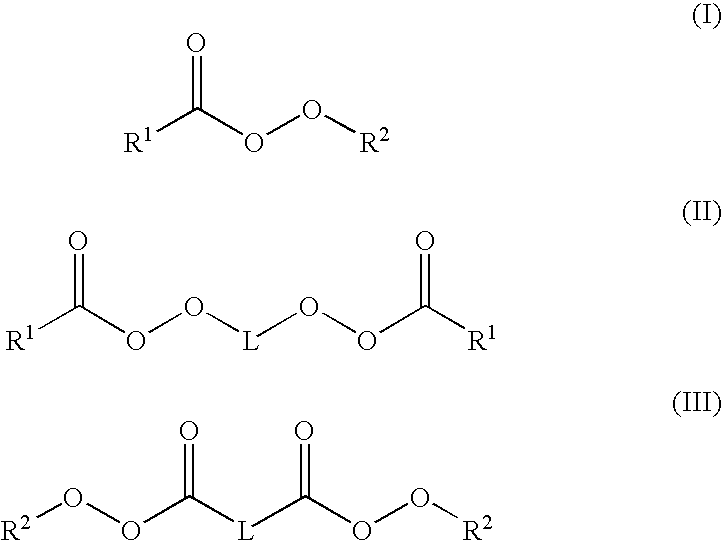

The invention discloses a storing method of tobacco automate-box, which comprises the following steps: loading quantitative tobacco leaf; adding cover; weighing; recording information; placing in the warehouse; storing and tracing information; taking out after enough reserving time; removing cover to record information; sending the box to subsequent turning-over feeding procedure. The invention guarantees the technological quality of subsequent throwing, which realizes optimum management for entire procedures and equipments.

Owner:KUNMING KSEC LOGISTIC INFORMATION IND

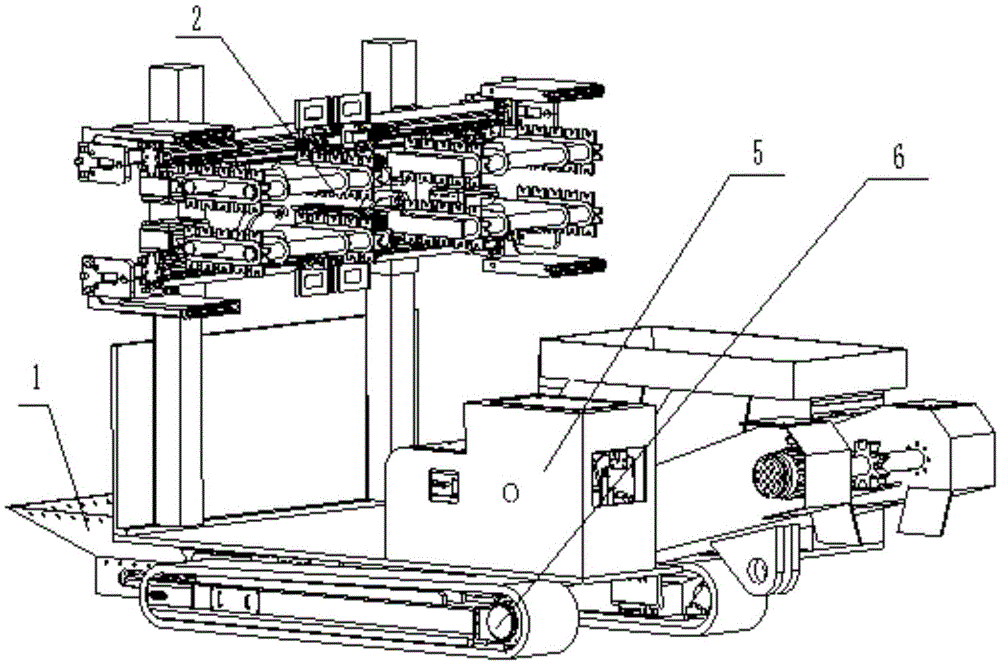

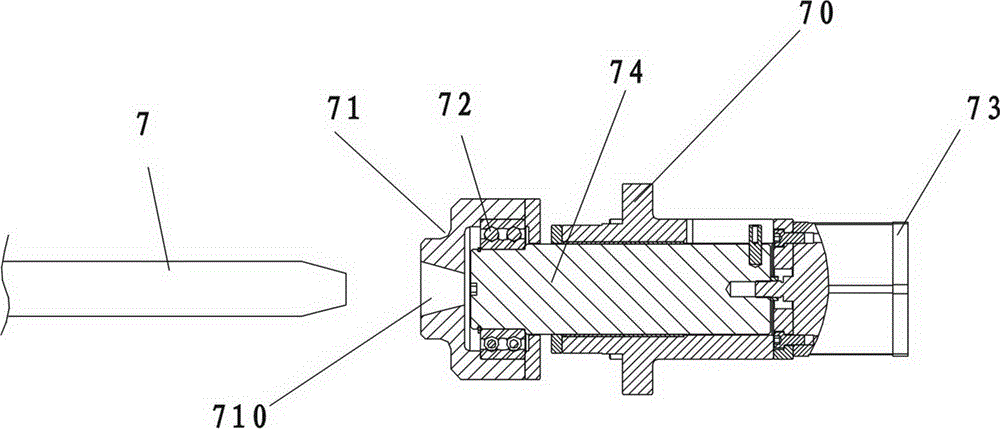

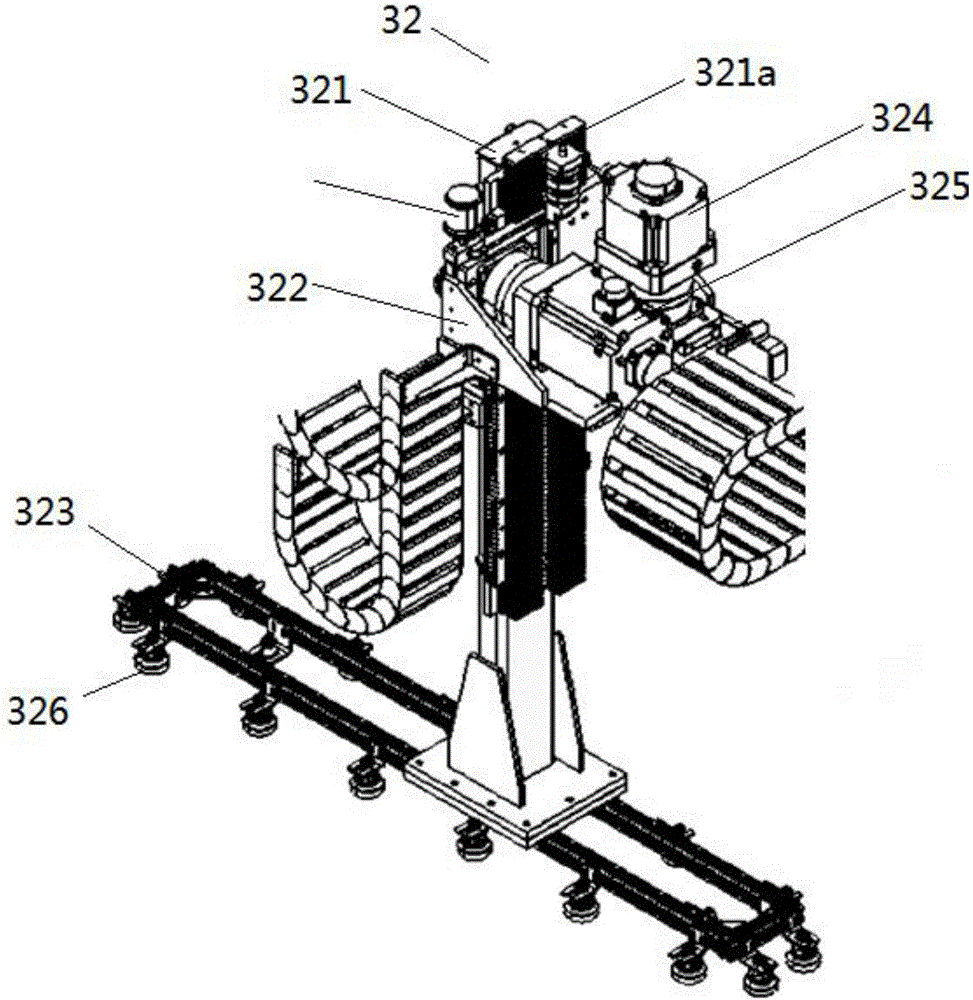

Side bolt drilling machine and side bolt drilling carriage with same

ActiveCN105626108ALarge storage capacityMeet construction needsDerricks/mastsAnchoring boltsEngineeringRock bolt

The invention discloses a side bolt drilling machine which comprises a fixing mechanism, a supporting mechanism, a sliding rack, a drilling box mechanism and a cartridge conveying box. The fixing mechanism comprises a base, a vertical plate and a connecting seat. Protrusions for fixing guide blocks are arranged on the vertical plate. The supporting mechanism and the sliding rack are in sliding connection with the opposite side faces of the vertical plate respectively through the guide blocks, and one end of the supporting mechanism and one end of the sliding rack are connected with the base through a telescopic oil cylinder. The drilling box mechanism comprises a bottom rack and two independent drilling box sliding seats. The bottom rack is fixedly connected with the base, the drilling box sliding seats can horizontally move along the bottom rack, and when the drilling box sliding seats move to the sliding rack, the drilling box sliding seats can be connected with the other guide rail face of the sliding rack and slide along the sliding rack. The cartridge conveying box is used for completing the automatic cartridge feeding procedure of the drilling machine. The invention further discloses a side bolt drilling carriage with the drilling machine. By means of automatic cartridge feeding and automatic anchor bolt mounting, mechanization and automation of anchor bolt supporting work are achieved, the construction needs of a plurality of rows of side bolts can be met, and the side bolt drilling carriage works in cooperation with heading equipment to synchronously complete side bolt supporting and transferring functions.

Owner:LANG FANG JING LONG GRAND IND MACHINERY CO LTD

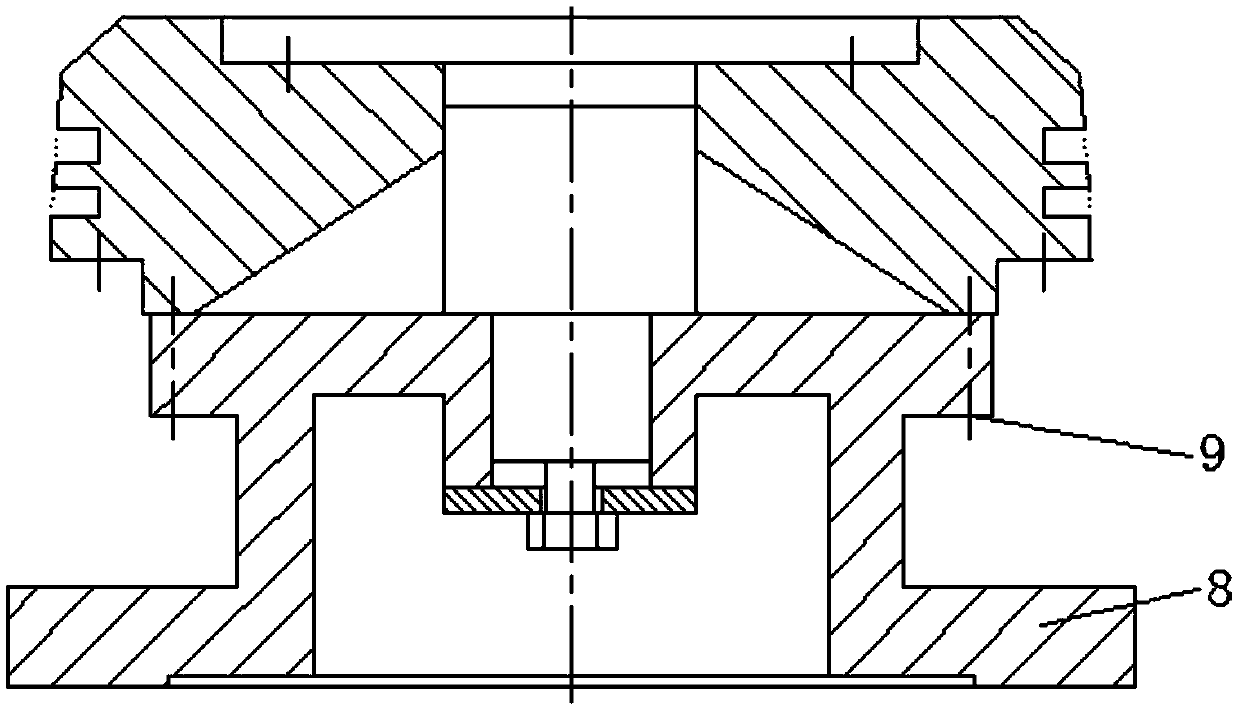

Automatic bobbin feeding device

The invention provides an automatic bobbin feeding device which comprises a cabinet and is characterized by further comprising a frame, an actuator and a conveyor belt. The frame is fixed onto the cabinet, the actuator and the conveyor belt are respectively arranged on two opposite sides of the frame, the actuator comprises a transmission bar and a cam, the cam can be driven by a motor, a rotary shaft of the cam penetrates the transmission bar to be fixed onto the cabinet, two pushing assisting blocks which are of cylindrical structures are arranged on the transmission bar, include a first pushing assisting block and a second pushing assisting block and are arranged on two sides of the cam in a central symmetry manner around the axis of the rotary shaft, the outer contour line of the cam is constantly tangential to the pushing assisting blocks when the cam rotates, the cam is provided with convex portions and concave portions, the convex portions and the concave portions are alternately arranged and are respectively alternately tangential to the first pushing assisting block and the second pushing assisting block, and a pushing head is arranged at an end of the transmission bar, is aligned to bobbins on the bottommost layer of the frame, and can be driven to push the bobbins on the bottommost layer of the frame onto the conveyor belt when the cam rotates and then the convex portions of the cam are tangential to the first pushing assisting block. The automatic bobbin feeding device has the advantages that workers do not need to carry weights in feeding procedures, and accordingly the automatic bobbin feeding device is low in labor intensity and high in feeding speed.

Owner:SUZHOU OUBBOO FASHION CO LTD

Feeding and managing method for pregnant swine

The invention discloses a feeding and managing method for a pregnant swine. The feeding and managing method comprises backfat thickness determining and feeding procedures, wherein the backfat thickness determining procedure comprises the steps that the backfat of each pregnant swine is determined at fixed time and fixed position each day by using a backfat instrument to obtain body conditions and nutritive indexes, so that the body conditions and the nutrition of the pregnant swine are digitalized; the feeding amount of each pregnant swine is determined and is recorded into an indication board according to Rating Scale for Swine Body Conditions; the physical conditions of the swine are ensured by artificial feeding. The body conditions and nutrition data of the pregnant swine are accurately determined by combining the backfat instrument as an advanced instrument, so that the body conditions and the nutrition of the pregnant swine are digitalized; each pregnancy time period of each pregnant swine is accurately controlled for feeding by combining the Rating Scale for Swine Body Conditions, the body conditions of each pregnant swine and piglets bred by the pregnant swine can be ensured, the later-stage growth of the piglets and the rehabilitation of the pregnant swine breeding the piglets are facilitated, further quick fat growth of the swine is ensured, the non-pregnant period is shortened and the annual yielding litter size is improved.

Owner:SONGTAO DEKANG AGRI & ANIMAL HUSBANDRY CO LTD

Liquor preparation method

The invention discloses a liquor preparation method which comprises feeding procedure, stewing procedure, cohobation procedure, retorting procedure, automatic cooling procedure, automatically adding little yeast procedure, culturing saccharification procedure, blending procedure, automatic adding large yeast procedure, fermentation procedure and distillation procedure. Compared with the traditional method, immersing materials is not necessary in the liquor preparation method. The production process of each batch is shortened by 24 hours. Compared with the traditional art, the consumption of the drinking water is lessened by 30%. The invention has the advantage of easy manufacturing. The quality of xiaoqu liquor is improved. The prepared liquor is rich and soft in taste. The liquor preparation method is an innovation on the traditional xiaoqu liquor method.

Owner:YUNNAN YIZHOU LIQUOR IND CO LTD

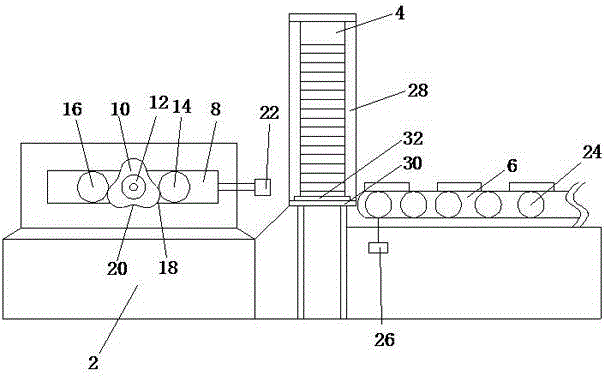

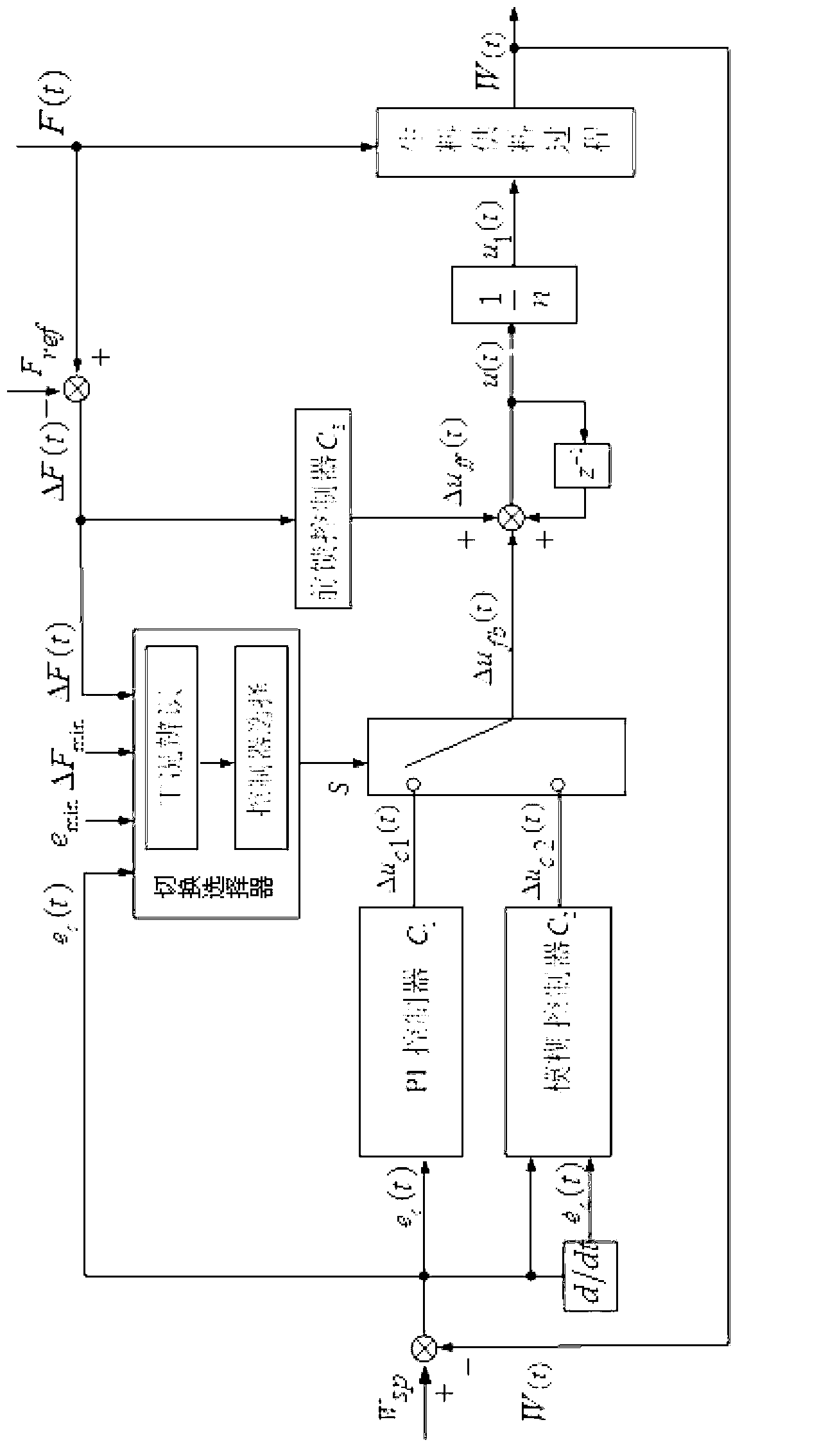

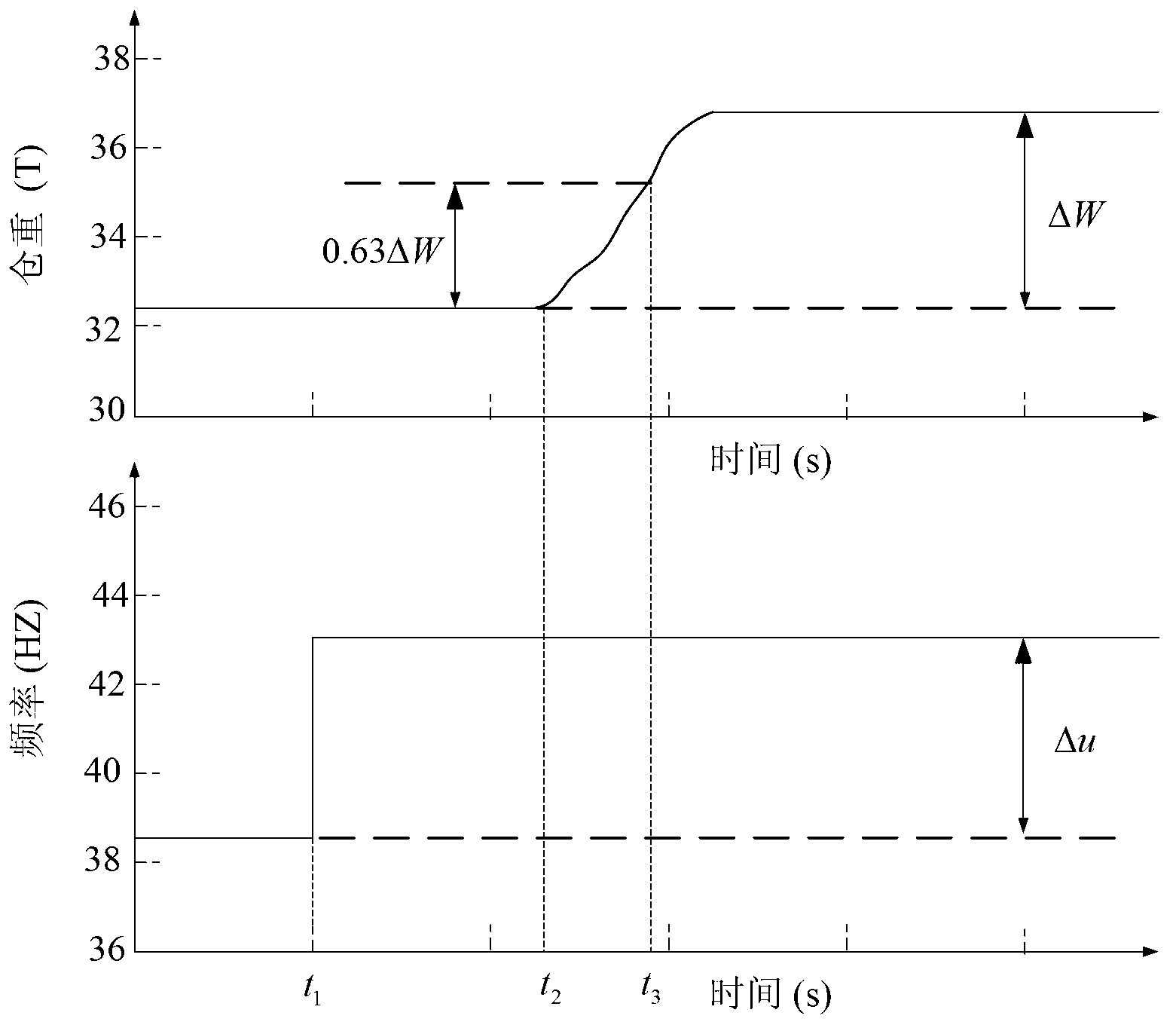

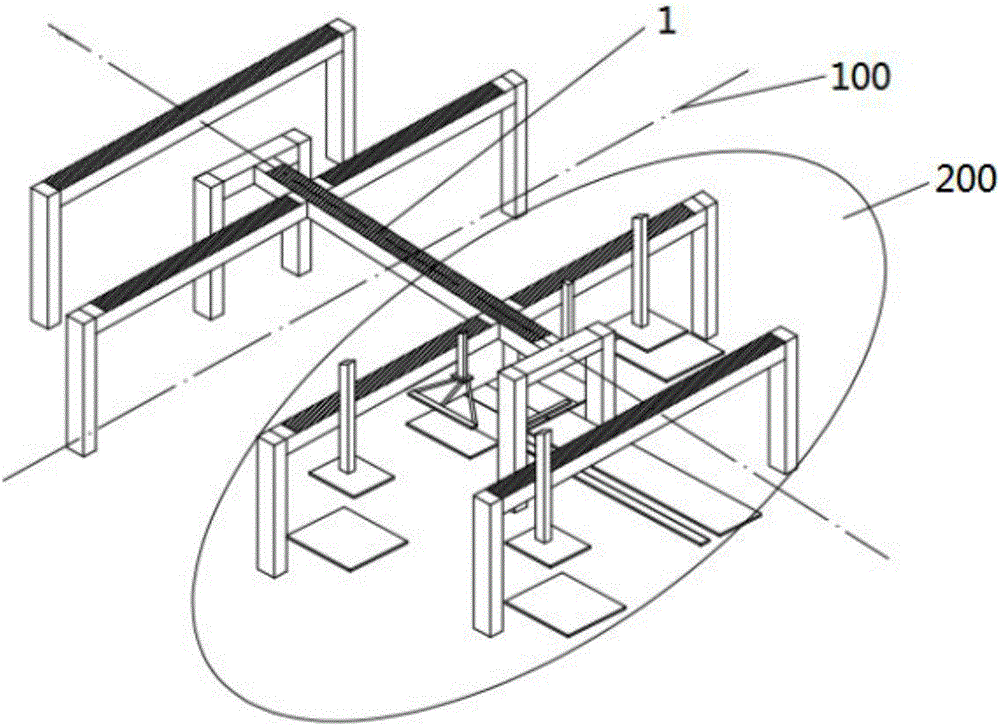

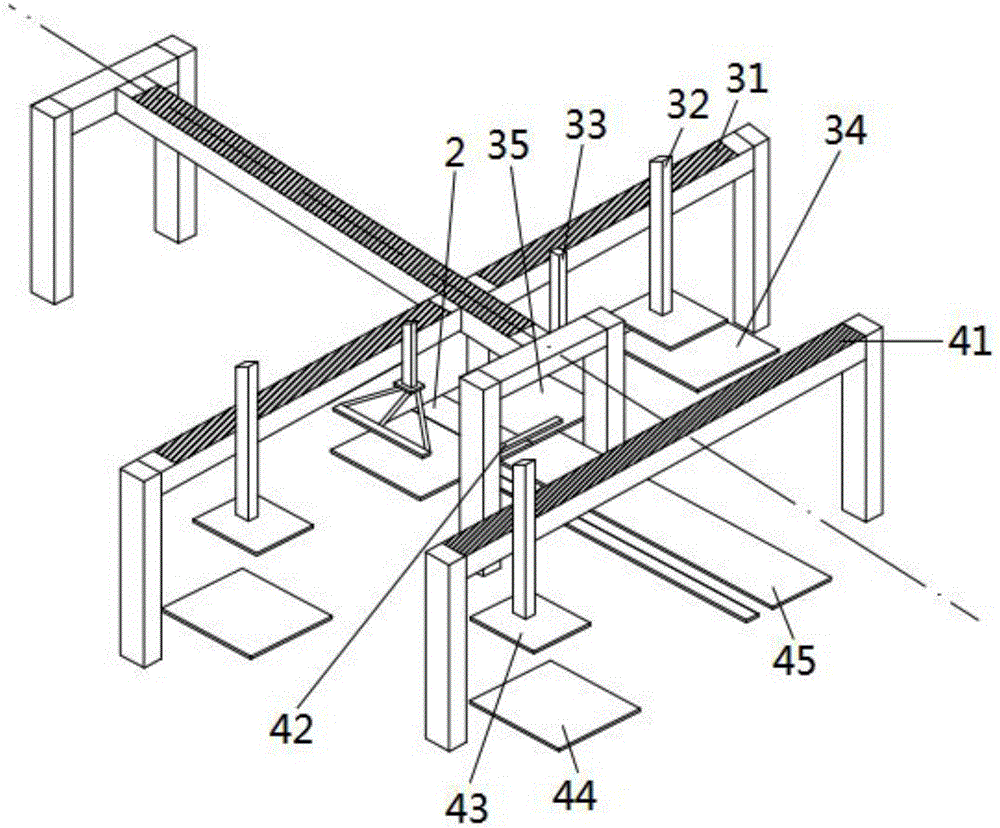

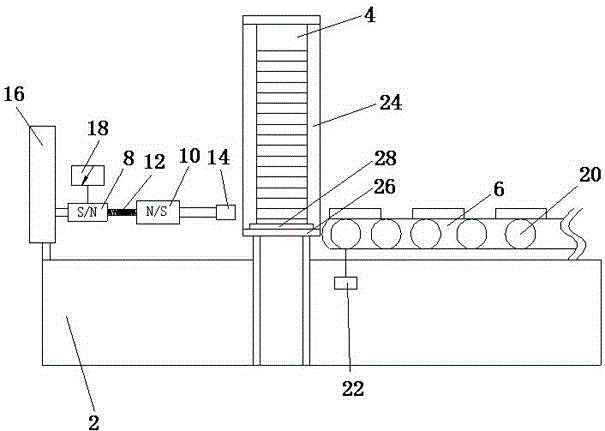

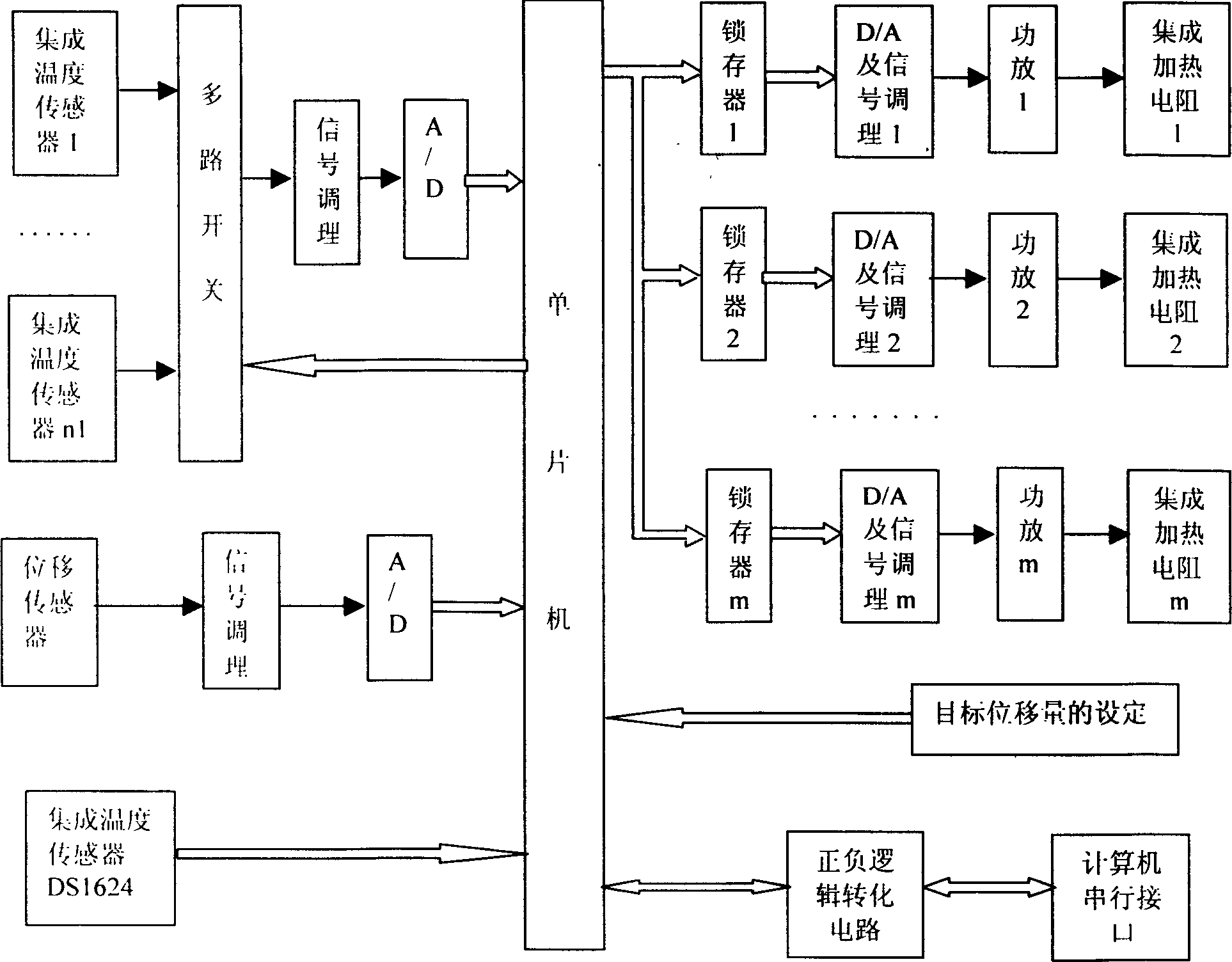

Intelligent switching control method based on bin weights and implemented in raw material feeding procedures and control system for intelligent switching control method

InactiveCN103235510AReduce work intensityHigh degree of automationAdaptive controlHandoff controlControl system

The invention provides an intelligent switching control method based on bin weights and implemented in raw material feeding procedures and a control system for the intelligent switching control method. The intelligent switching control method based on the bin weights and implemented in the raw material feeding procedures is implemented on the basis of the control system. The control system comprises a PI (proportion and integration) controller, a fuzzy controller, a feed-forward controller and a switching selector, the three controllers output frequency regulation signals, and the switching selector is switched selectively between the PI controller running in a PI control mode and the fuzzy controller running in a fuzzy control mode according to switching rules by the switching selector. The intelligent switching control method and the control system have the advantages that full-coverage automatic intelligent control for link of two regions which are respectively within a specified technical range and outside the specified technical range is implemented by the aid of a control model of the PI controller, a control model of the fuzzy controller and the switching rules for selective switching between the PI controller and the fuzzy controller, so that normal and smooth running states of the raw material feeding procedures are constantly guaranteed.

Owner:SHENYANG POLYTECHNIC UNIV +1

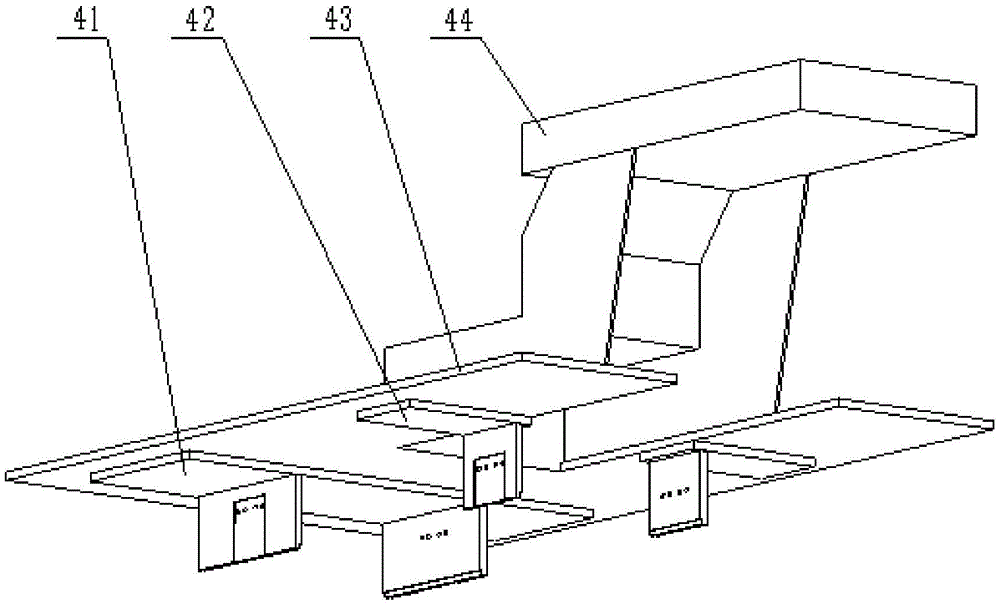

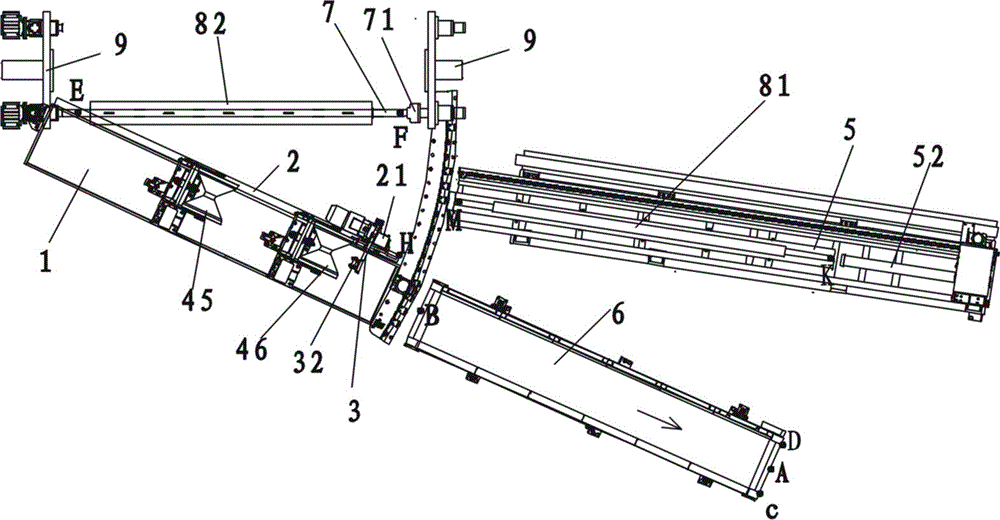

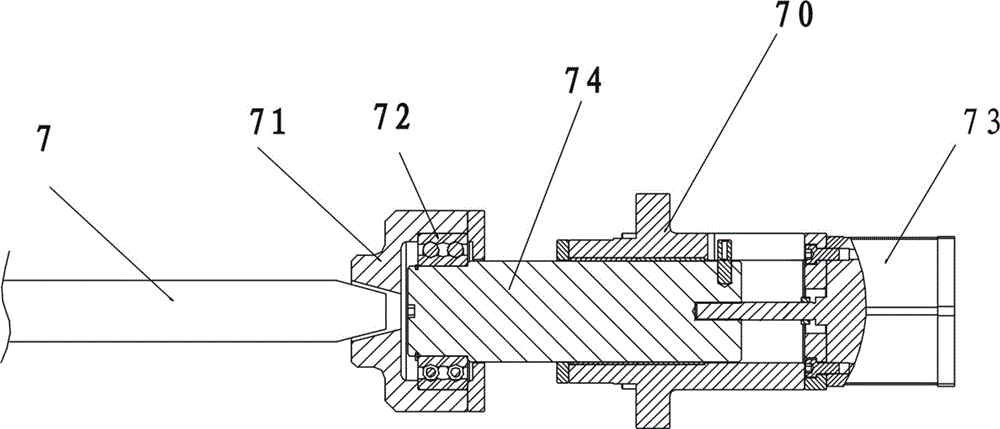

Automatic roll discharging and core feeding device and automatic roll discharging and core feeding method

The invention discloses an automatic roll discharging and core feeding device. A first rolling shaft support is provided with a shaft sleeve with an inner cavity with a taper angle, and the shaft sleeve is movably installed on a rack in the axial direction. A second rolling shaft support is provided with a vertical rotating shaft in a matched mode and is installed on the rack in a horizontal swinging mode through the vertical rotating shaft. A swinging support is horizontally installed below a rolling shaft in a swinging mode. The swinging support is provided with a horizontal guide rail, a sliding support and a sliding support driving mechanism. The horizontal guide rail is fixedly installed on the swinging support and swings along with the swinging support, and the sliding support driving mechanism can drive the sliding support to horizontally move along the horizontal guide rail. A swing arm is installed on the sliding support in a vertical swinging mode. A trundle is installed at the tail end of the swing arm, and the swinging support is provided with a left riding wheel and a right riding wheel. According to the automatic roll discharging and core feeding device, roll discharging and core feeding procedures can be automatically finished, the labor intensity of workers is relieved, and the time taken for the roll discharging and core feeding procedures is saved. The invention further provides an automatic roll discharging and core feeding method.

Owner:GUANGDONG JINMING MACHINERY

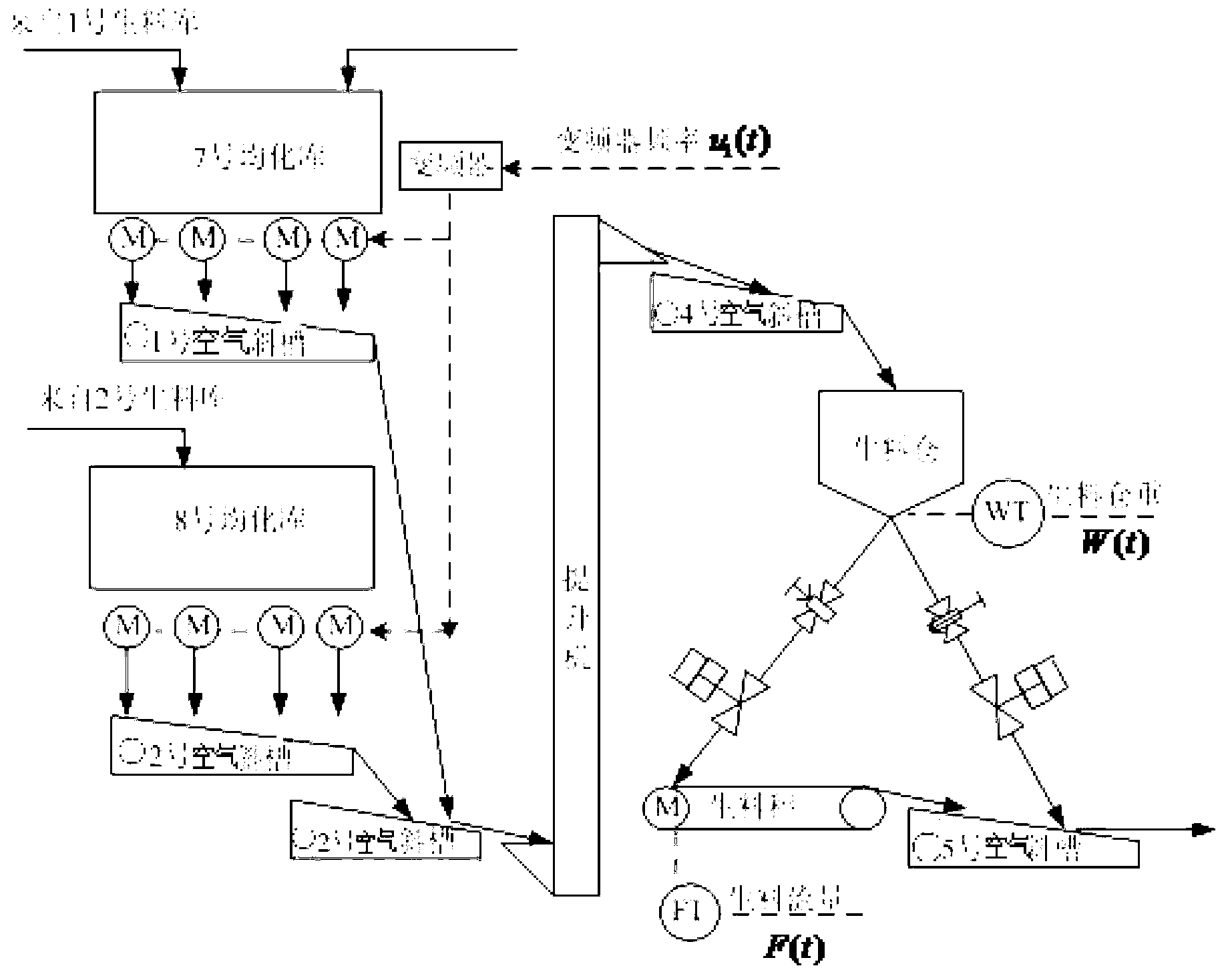

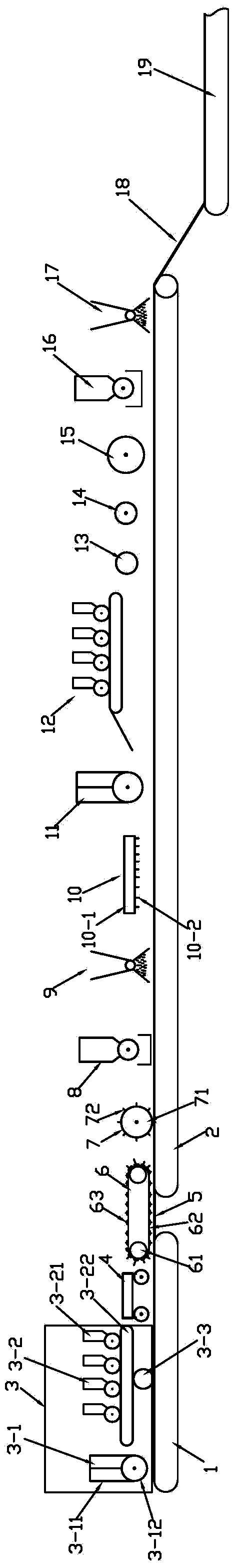

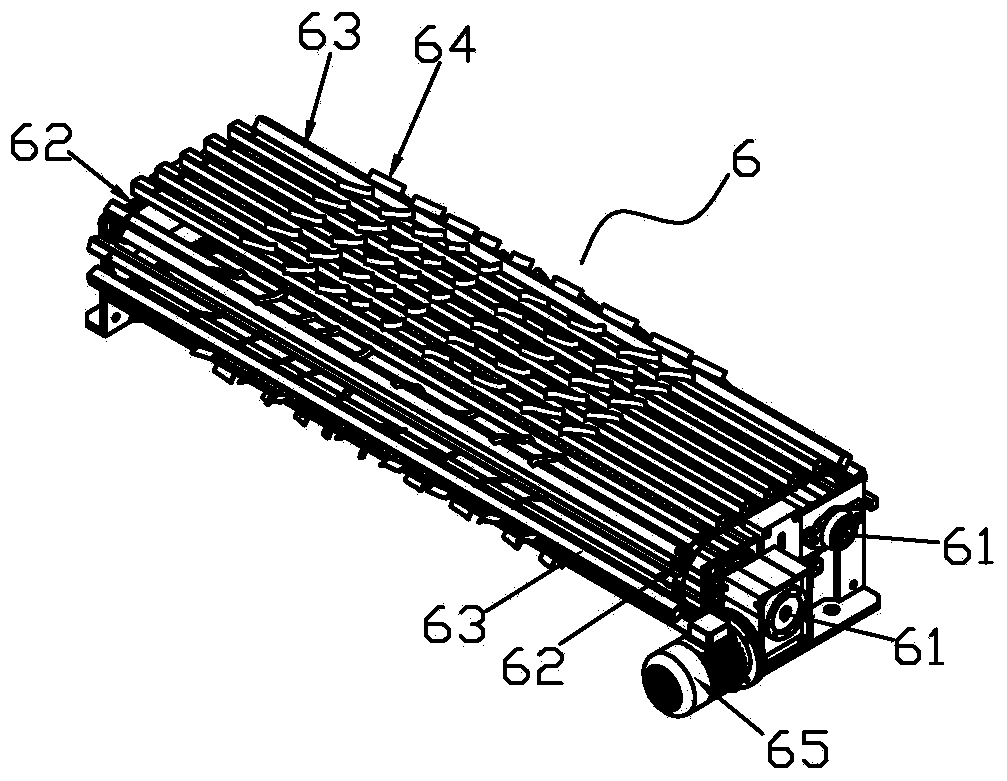

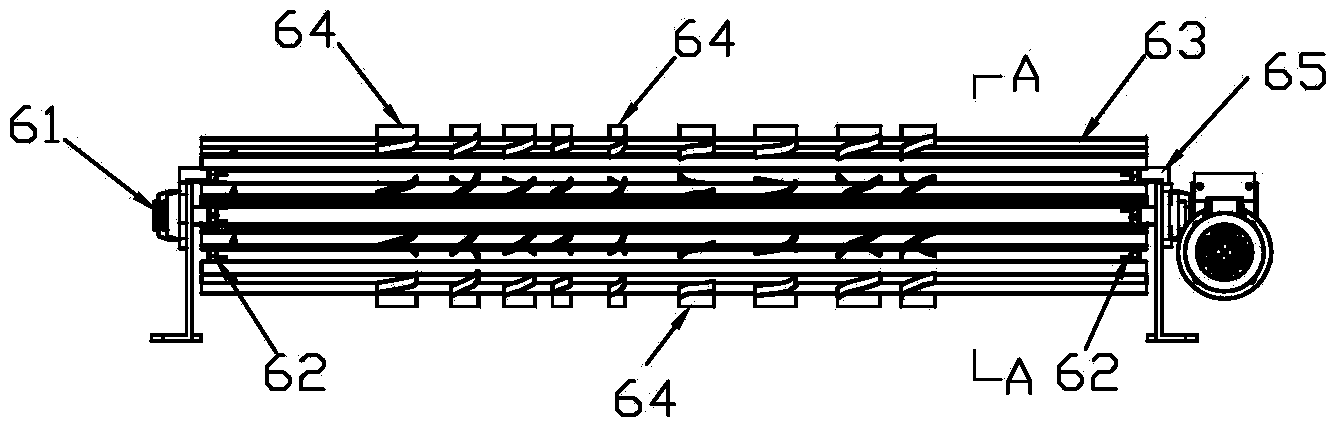

Distributing method for glazed ceramic tiles and equipment for implementing distributing method

The invention discloses a distributing method for glazed ceramic tiles and equipment for implementing the distributing method, belongs to the technical field of ceramic manufacture, and relates to distributing methods and equipment for manufacturing ceramic tiles. The distributing method includes steps of 1, feeding and distributing ceramic powder on a feeding belt, compressing and flattening the ceramic powder to obtain blocks, and feeding the blocks via the feeding belt to a transition flat plate between the feeding belt and another feeding belt; 2, scraping the ceramic powder blocks to obtain powder materials in various shapes, and then feeding the powder materials to the other feeding belt; 3, sequentially pricking the ceramic powder blocks to obtain cracks in various shapes with various sizes, distributing line materials on the ceramic powder materials with the cracks and spraying glaze slip on the ceramic powder materials with the cracks; 4, pricking the ceramic powder blocks again to obtain small cracks, and locally distributing ceramic powder layers with different thicknesses; 5, distributing a thick ceramic powder layer on each ceramic powder material, and flattening and compressing the ceramic powder materials; 6, cutting and shaping the ceramic powder materials, distributing line materials on the ceramic powder materials, and spraying glaze slip on the ceramic powder materials; 7, conveying the ceramic powder materials to a pressing machine, and shaping the ceramic powder materials. The invention further discloses the equipment for implementing the distributing method. The distributing method and the equipment have the advantages that excellent setting and retaining effects can be realized in feeding procedures, and shapes are high in pattern diversity, stability and consistency.

Owner:佛山市禅城区南庄科美达机械设备有限公司

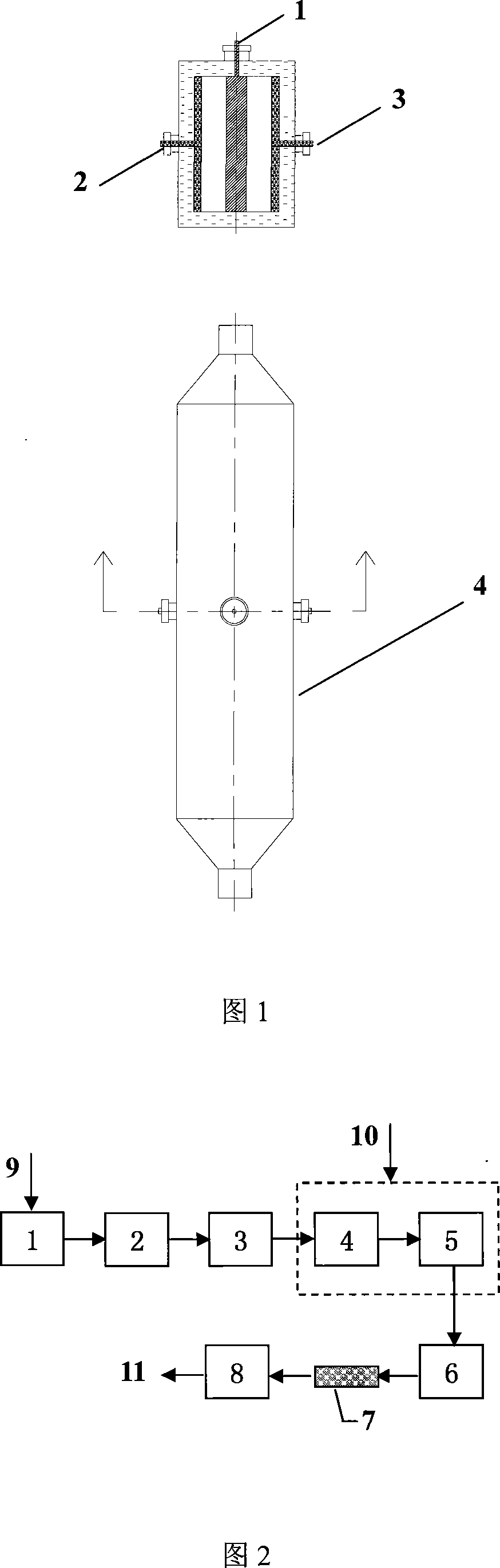

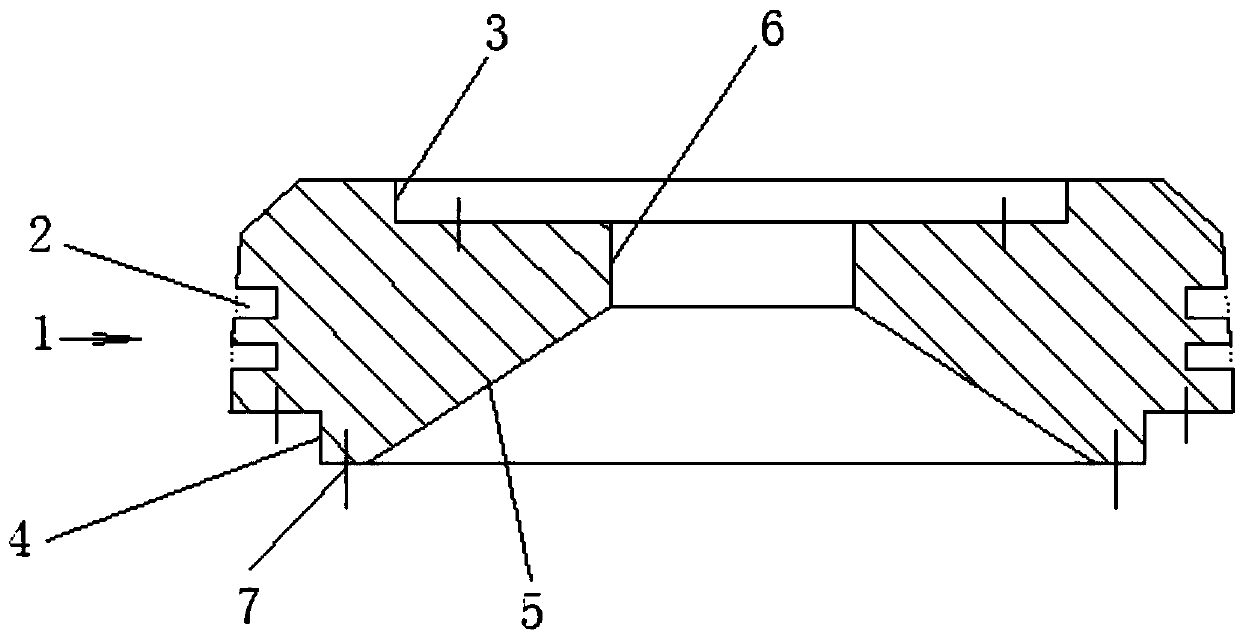

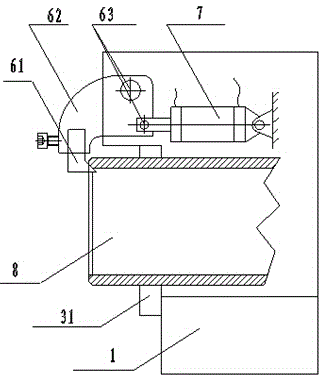

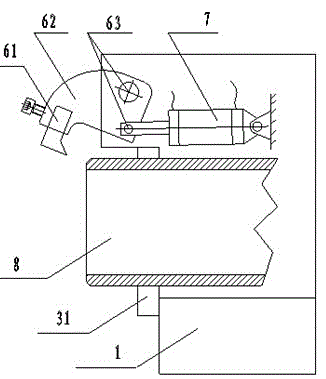

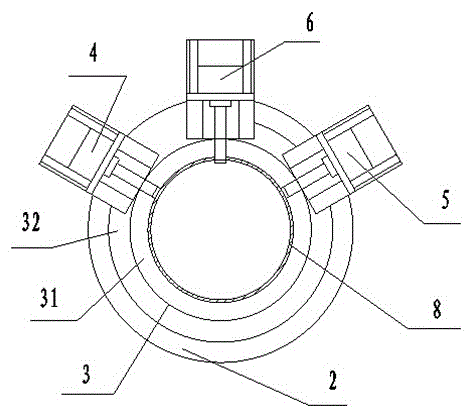

Fecal sewage decolorizing method and device

InactiveCN101195501ACompact structureReduce energy consumptionWater/sewage treatmentCyclic processFeces

The invention provides a decolorizing method for fecal sewage and equipment. The equipment is composed of an automatic salt-feed device, negative and positive electrodes and direct current supply. The equipment is installed on an outlet conduit of purified fecal sewage, the direct current supply is connected with a power control device of up-feed pumps via lead wires, and the synchronous operation of decolorizing and water-feeding procedures is realized. The invention realizes the cyclic process of electrolyzation-oxidation decolorizing-reduction by employing the principle of electrolysis of common salt liquor, and the clearance rate of the colourity of the fecal sewage reaches above 99%. The decolorizing equipment is compact in structure, low in energy consumption and excellent in performance, and can be compatible with a sewage treatment and a reclaimed water reusing system. The decolorizing equipment not only can be applied to the circulating water treatment of biological environmental protection toilets, but also can be applied to district reclaimed water reusing system and water reusing system of sewage treatment plants, further can be applied to decolorizing of circulating water of large air conditioners and sterilization and algae killing for reducing the energy consumption of the air conditioners, and the decolorizing equipment has a wide application prospect in the fields of sewage treatment and reclaimed water reusing.

Owner:深圳龙澄高科技环保股份有限公司

Vacuum adsorption front edge paper feed unit in carton making linkage machine

InactiveCN101579942AGuaranteed normal operationPaper feeding speedContainer making machineryCardboardReciprocating motion

The invention discloses a vacuum absorption front edge paper feed unit in a carton making linkage machine and aims at overcoming the disadvantage of easy occurrence of unsmooth paper feed in a back-push paper feed of the prior art. The vacuum absorption front edge paper feed unit comprises a machine table of the paper feed unit, a manipulation and control box, a main motor, a paper feed roller group and an air suction device. The vacuum absorption front edge paper feed unit is characterized in that the vacuum absorption front edge paper feed unit further comprises a drive mechanism for driving paper feed rollers, a paper feed belt reciprocating motion mechanism and a cam rotation motion mechanism; wherein an air suction box in the air suction device is arranged in a box body below the machine table of the paper feed unit; a long strip-shaped window is arranged in an upper cover plate of the air suction box; the window can lead the upper part of a paper feed belt to be positioned below the upper cover plate of the air suction box usually; when a cam rotates and props up the belt, the belt can be slightly protruded above the top surface of the upper cover plate so as to complete the vacuum absorption front edge paper board feed procedure.

Owner:黄锋

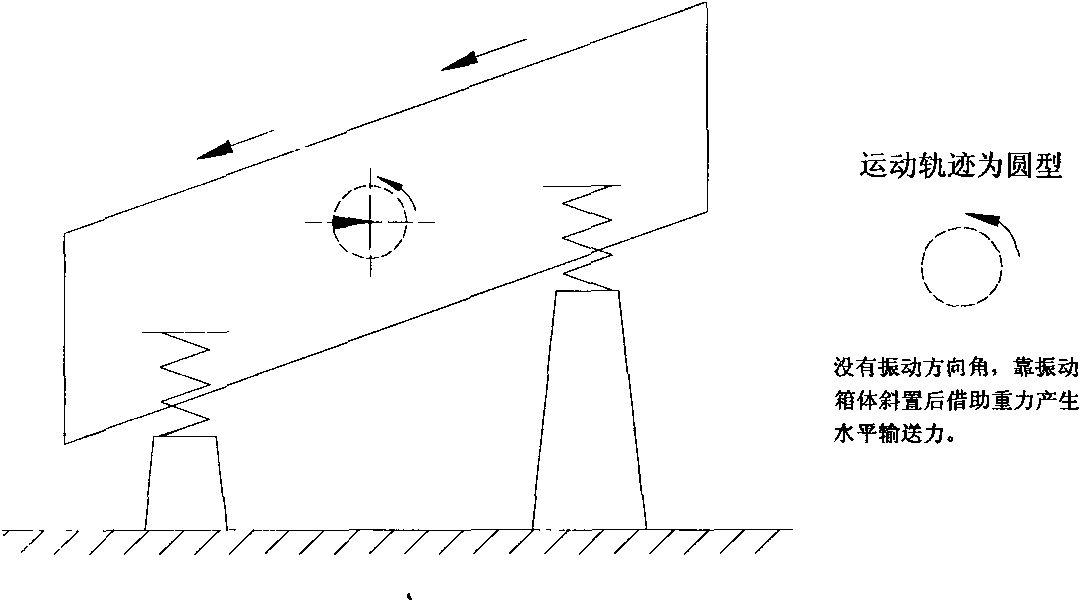

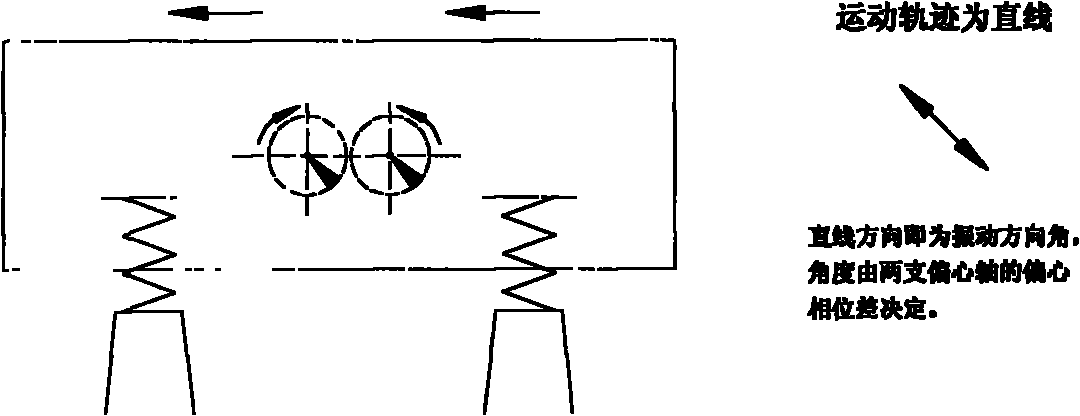

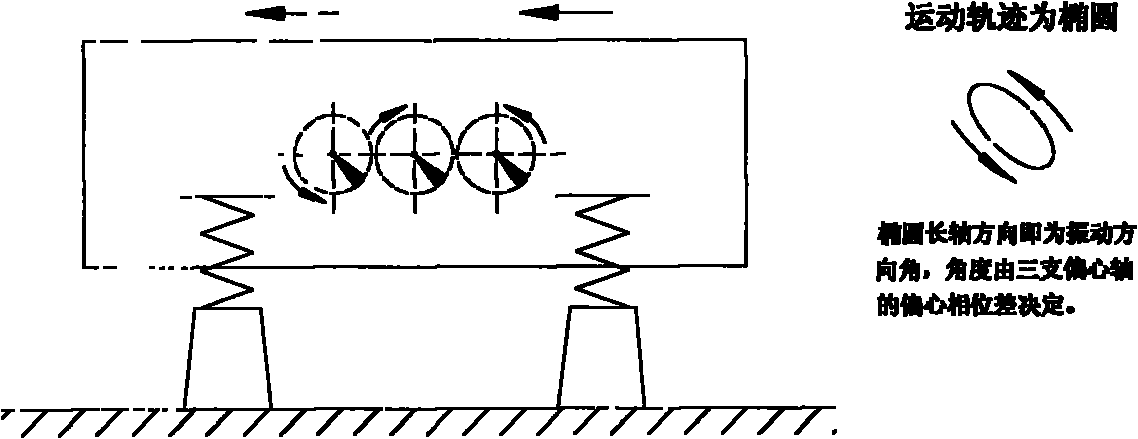

Single-shaft horizontally-arranged variable-track vibration exciter

InactiveCN102247944AEnhanced vibration balanceMechanical vibrations separationLinear motionElectricity

The invention discloses a single-shaft horizontally-arranged variable-track vibration exciter which comprises a vibrating case body, a spring and a base. The vibration exciter is characterized in that two telescopic rods are arranged on each side of the vibrating case body; the two telescopic rods are hinged with an upper connecting rod and a lower connecting rod to form a parallelogram mechanism; the two ends of the upper connecting rods, which are positioned on the two sides, are hinged with the upper pivot points of four telescopic rods and respectively fixed on a bearing seat and the vibrating case body which are positioned at the two ends of an eccentric shaft; and the two ends of the lower connecting rods are hinged with the pivot points of the lower ends of the four telescopic rodsand fixed in four arc-shaped adjuster slot holes which are formed on the base respectively. The invention has the most significant effect that different motion tracks, such as circular motion track, linear motion track and elliptic motion track, can be achieved in the same device by adjusting the slippage interval of the telescopic rods so as to meet the needs for different working conditions in the screening and feeding procedures. The vibration exciter disclosed by the invention has good excitation work-doing effects, high efficiency, low electricity consumption and low manufacturing cost, good vibration equilibrium, is convenient for maintenance, can be arranged horizontally during use and is convenient for adjustment. Besides, the traditional product can be transformed technically according to the technical scheme provided by the invention for improving the product performance.

Owner:ZHEJIANG SHENGDA MACHINERY

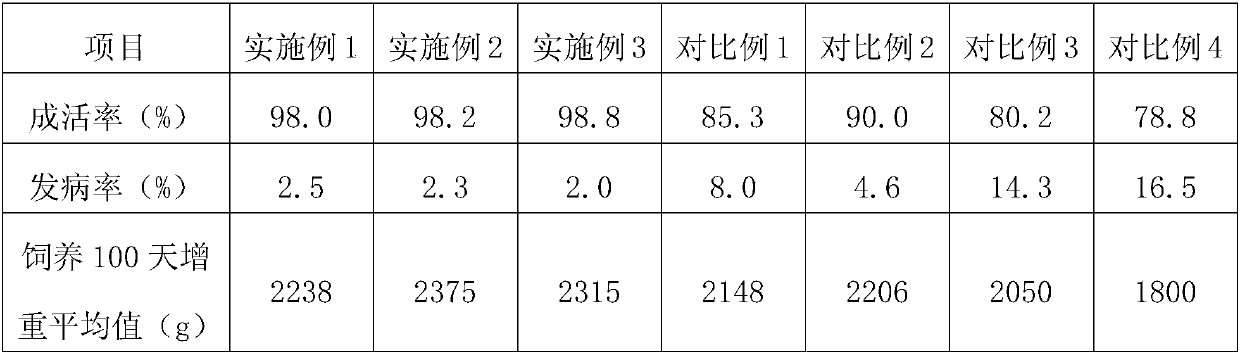

Breeding method for reducing morbidity of rabbits

InactiveCN107593609AReduce in quantityReduce reproductionFood processingAnimal feeding stuffDiseaseMortality rate

The invention discloses a breeding method for reducing the morbidity of rabbits, and belongs to the field of animal husbandry technologies. The breeding method includes building breeding places; releasing the rabbits; feeding the rabbits with special feed; controlling diseases and pests; managing rabbit houses. The special feed for feeding the rabbits in special feed feeding procedures comprises epidemic prevention agents, and the epidemic prevention agents are made of 2-4 parts of radix codonopsis, 2-4 parts of radix astragali, 2-4 parts of herba taraxaci, 1-2 parts of radix pulsatillae, 1-2parts of radix sophorae flavescentis, 0.5-1 part of cortex fraxini, 0.5-1 part of rhizoma coptidis and 1-2 parts of herba artemisiae scopariae; disease and pest preventive agents are added into drinking water for the rabbits in disease and pest control procedures and are made of 2-4 parts of rhizoma atractylodis macrocephalae, 2-4 parts of medicated leaven, 1-3 parts of herba taraxaci, 1-3 parts of flos lonicerae, 2-4 parts of herba portulacae, 2-4 parts of tangerine leaves, 1-2 parts of garlic, 1-2 parts of rhizoma zingiberis recens and 50-60 parts of sterile water. The breeding method has the advantage that problems of high incidence and death rate of rabbits bred by the aid of the traditional breeding methods can be solved by the aid of the breeding method.

Owner:巴马富泰种养农民专业合作社

Preparation method of high-nicotine reconstituted tobaccos

InactiveCN109090683AEfficient separationImprove the level of comprehensive utilizationTobacco preparationHigh concentrationAqueous solution

The invention provides a preparation method of high-nicotine reconstituted tobaccos. The preparation method of the high-nicotine reconstituted tobaccos and application thereof comprises the steps thatstage extraction by adopting ethanol aqueous solution of different concentrations, separation and concentration are conducted on remaining production concentrate to prepare stage concentrate pastes,stage extracts are returned to coating liquid in a coating feeding procedure of the reconstituted tobaccos, reconstituted tobacco bases are coated with the coating liquid before drying process, cutting and packaging are conducted to prepare the reconstituted tobaccos used for cigarettes. The method has the advantages of simple operation and lower cost, waste resources can be efficiently used to obtain products with higher added value, the products are returned to production and used, the reconstituted tobaccos prepared by means of the method has the advantages of high concentration and fragrance and has higher nicotine content, and nicotine content in the products can be adjusted according to demands of cigarette tobacco formula.

Owner:ZHONGYAN SHIWEICE (YUNNAN) RECONSTITUTED TOBACCO CO LTD

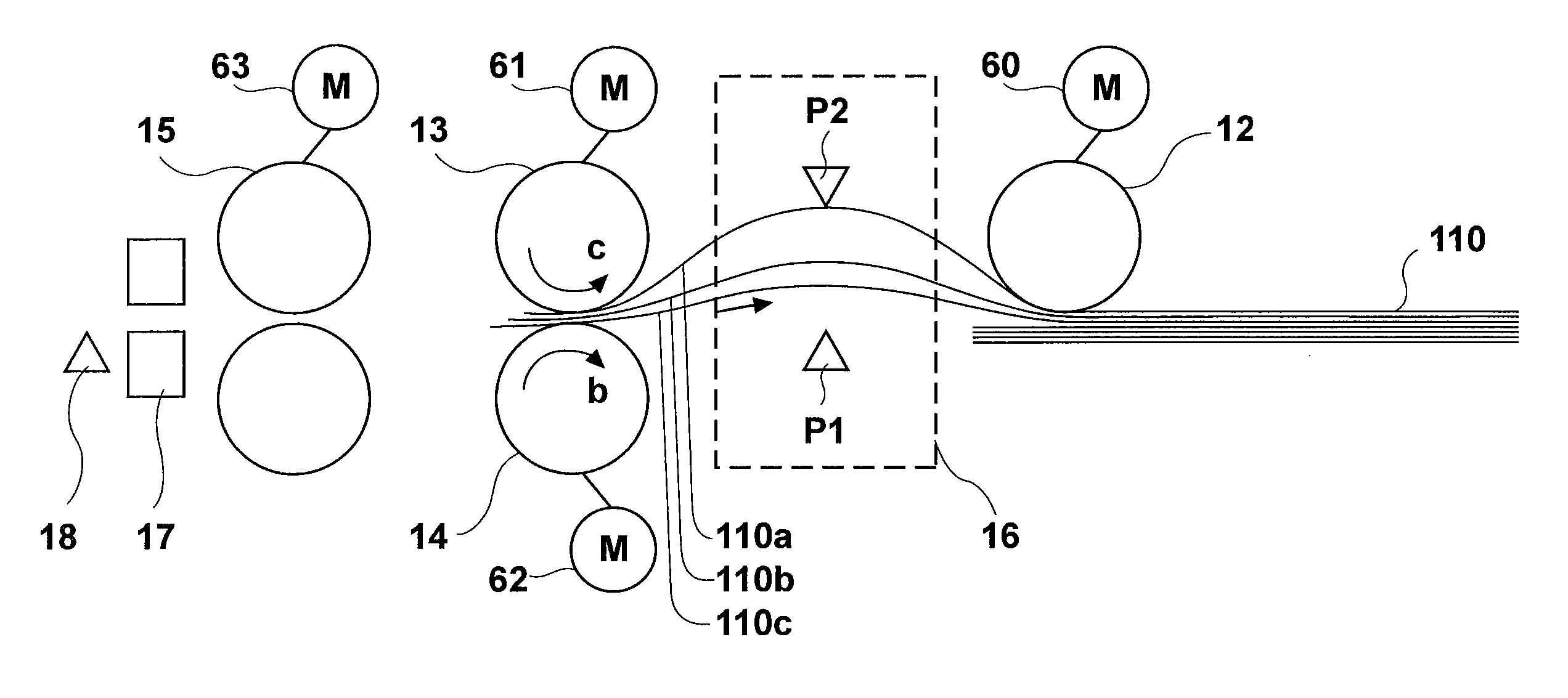

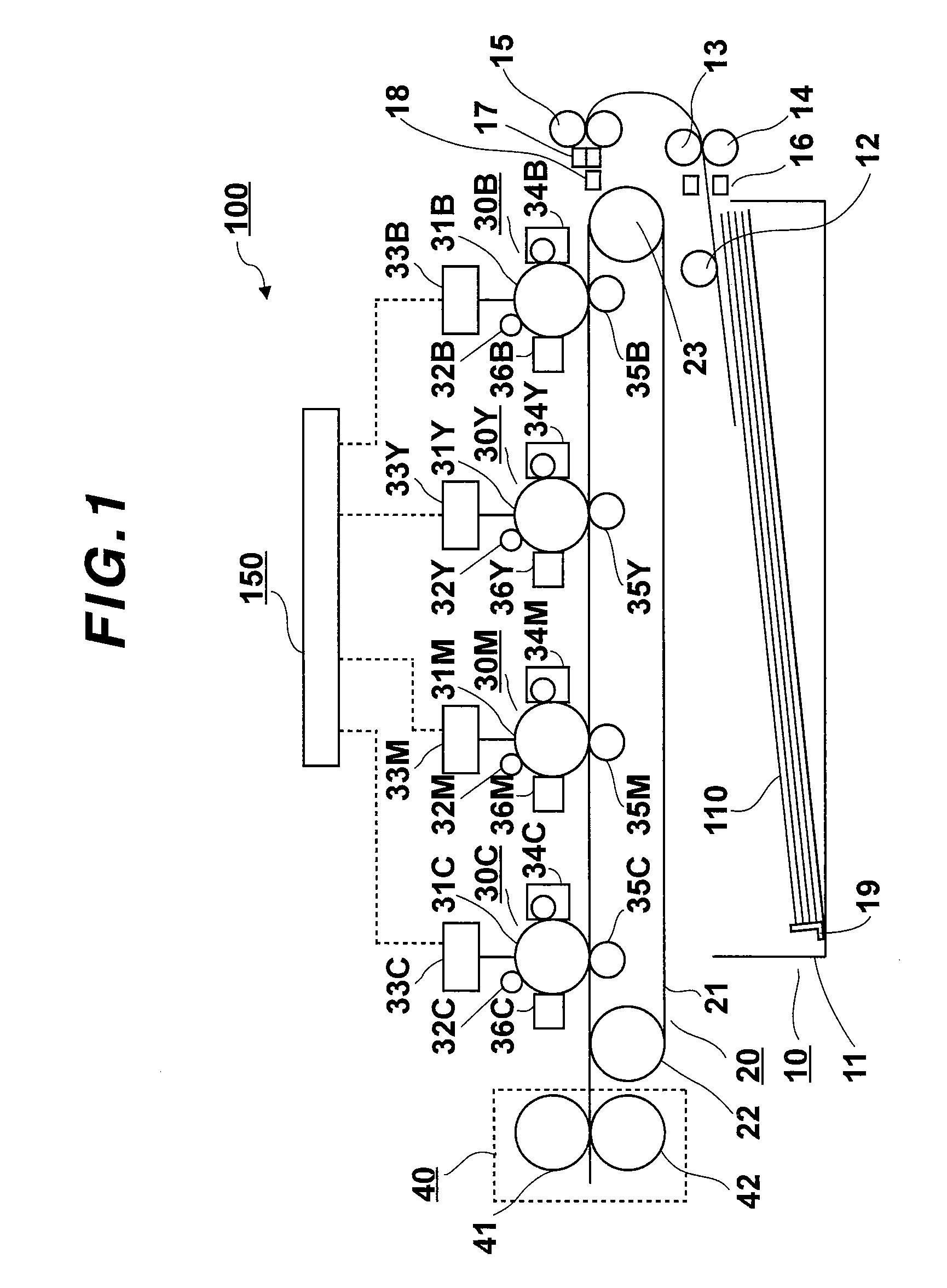

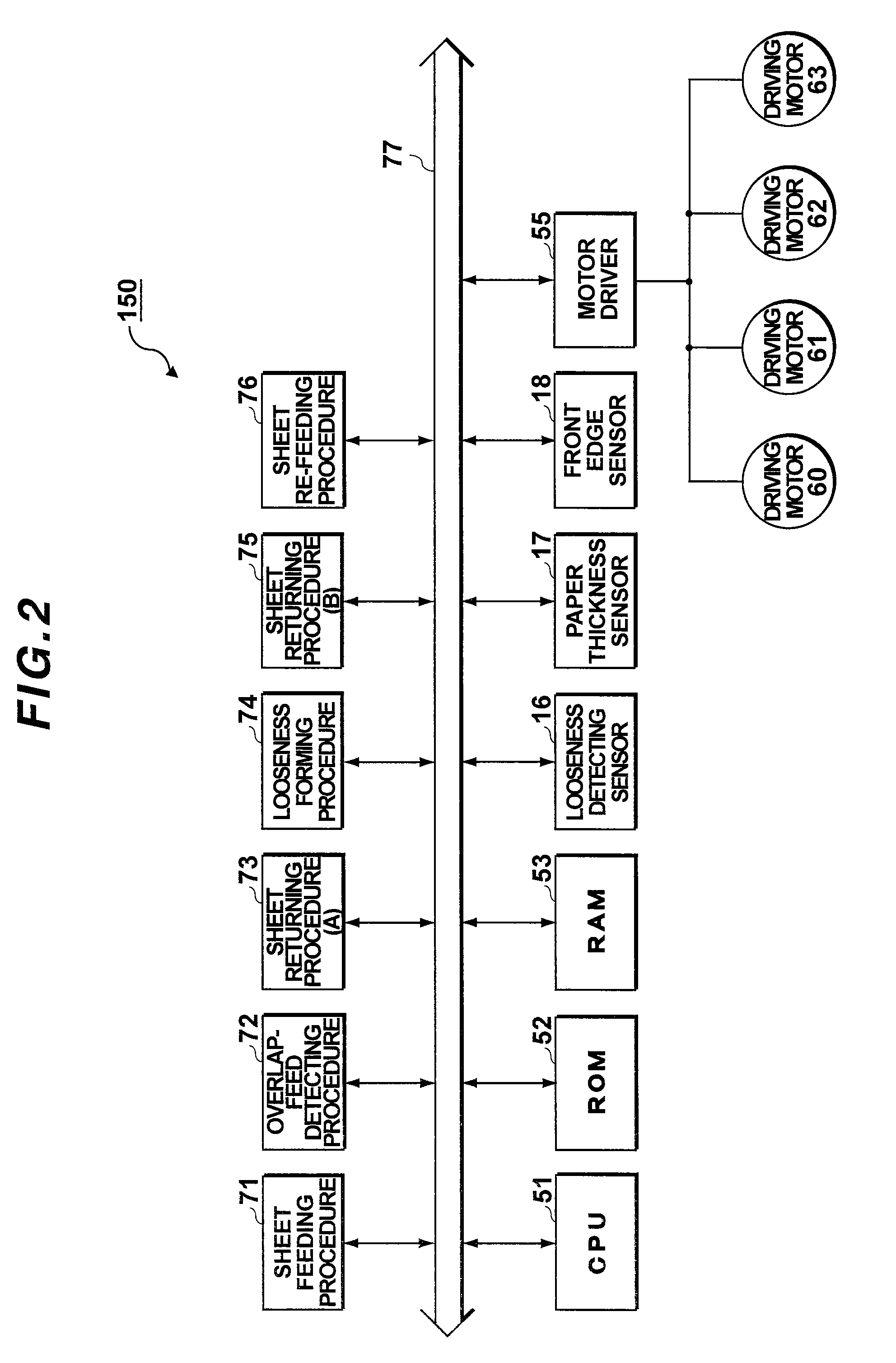

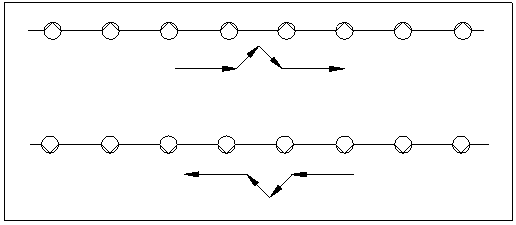

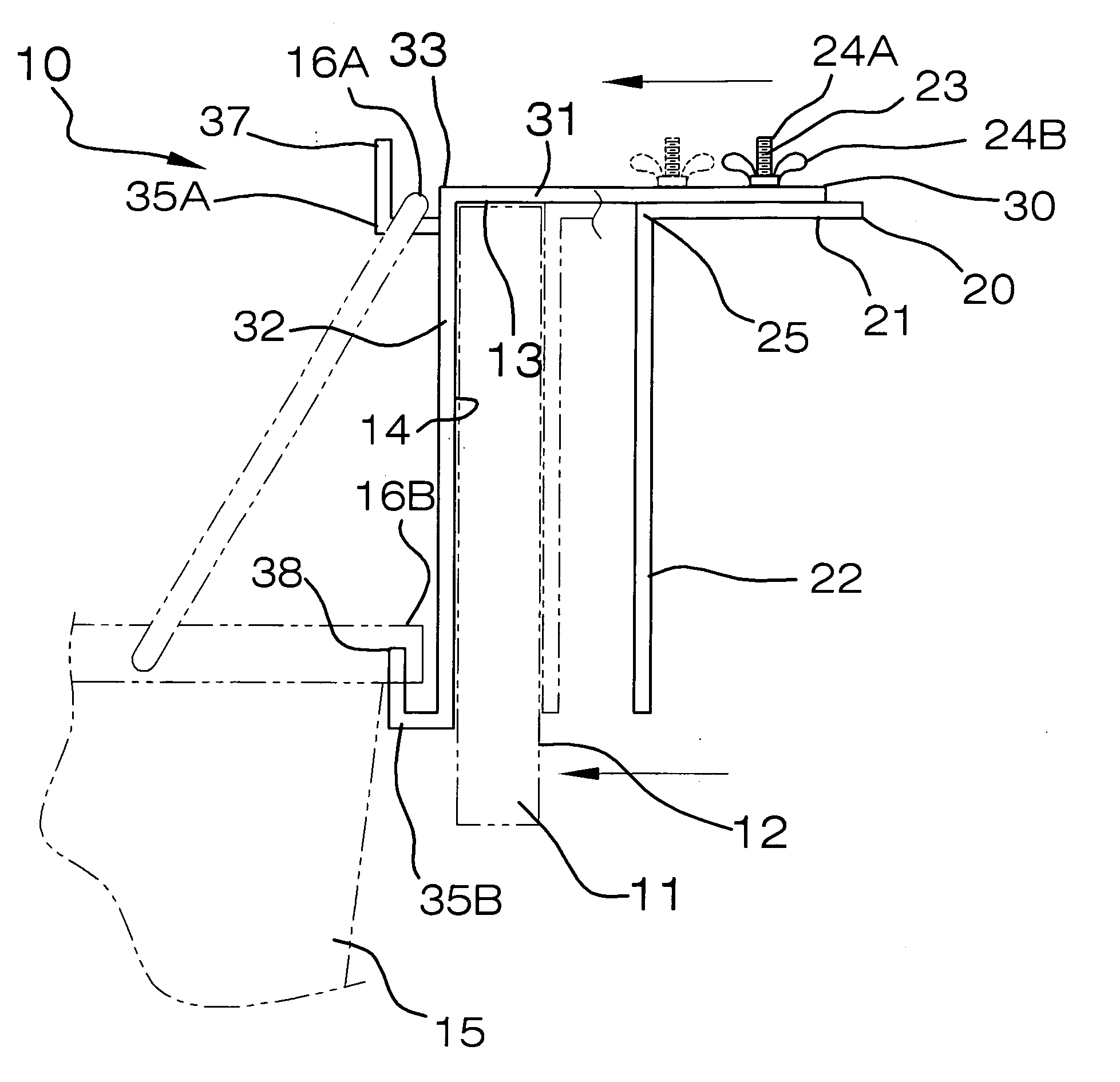

Medium conveying apparatus, medium feed control method, and image forming apparatus using the control method

A sheet feeding procedure supplies recording media from a medium enclosing portion to a medium conveying path. An overlap-feed detecting procedure monitors a thickness of recording media supplied to the medium conveying path, thereby detecting the overlap-feed media. Sheet returning procedures (A) and (B) return the overlap-feed media into the medium enclosing portion when the overlap-feed media are detected. A looseness forming procedure applies rotational forces of different rotation speeds to upper and lower surfaces of the overlap-feed media during the medium returning procedure, thereby forming a looseness in the overlap-feed media. A medium re-feeding procedure supplies again the returned recording media to the medium conveying path from the medium enclosing portion. In the medium feed control, the overlap-feed can be further certainly recovered.

Owner:OKI DATA CORP

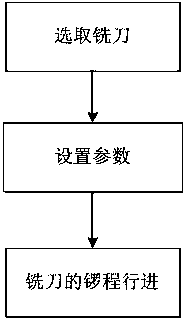

High TG panel PCB non-metallization half-hole CNC machining method

InactiveCN108237253AAvoid it happening againReduce the link of manual deburringMilling equipment detailsPolygonal lineMilling cutter

The invention relates to a high TG panel PCB non-metallization half-hole CNC machining method. The high TG panel PCB non-metallization half-hole CNC machining method comprises the following steps thatfirstly, a milling cutter is selected, and the milling cutter with the cutter diameter being 1.5 mm is selected; secondly, parameters are set, the rotation speed of the milling cutter is 34 krpm, thecutter advancing speed is 2.6 m / min, the cutter lowering speed is 0.6 m / min, the cutter retreating speed is 3m / min, and the PCB stack number is set to be 4pnl / stack; and thirdly, milling cutter routing path advancing is conducted, the parameters in the second step are set in forming equipment, and the feed procedure is conducted on multiple half holes in a PCB in a folded line feed manner according to the machining parameters. When CNC machining is conducted on the PCB through the method, particularly for the non-metallization half holes, burr generation can be prevented, the manual deburringlink is reduced, the machining efficiency is greatly improved, cost is reduced, and the quality risk is reduced; and the traditional milling cutter routing path advancing manner is changed, and a good promoting function is achieved for industry development.

Owner:惠州联创宏科技有限公司

Method for machining thin-walled components

InactiveCN106312152AGuaranteed quality and accuracyGuaranteed machining accuracyMilling equipment detailsEngineeringUltimate tensile strength

The invention discloses methods for machining thin-walled components, relates to the field of machining, and particularly relates to a method for machining thin-walled components. The method includes steps that thin-walled portions and other portions are roughly machined together, machining allowance of 1 mm needs to be reserved at wide locations of the thin-walled portions to prevent the thin-walled portions from deforming due to high speeds and engagement of cutting edges during rough machining, rough machining modes should be surrounding cutter feeding modes, and cutters are spirally extended to the side walls of the thin-walled components from the peripheries to the middles of the thin-walled components in each cutter feeding procedure; the cutters are selectively end milling cutters with tungsten steel cutters, so that deformation of the thin-walled portions due to impact force generated when the cutters approach the thin-walled portions can be effectively reduced, and requirements on sufficient strength of the cutters can be met; top curved surfaces are subjected to semi-finish machining, 6mm spherical cutters are selected for carrying out semi-finish machining on the top curved surfaces, excessive defective materials are removed, and accordingly uniform finish machining allowance can be reserved. The method has the advantages that the method is easy and convenient to implement, the machining quality and the machining precision of workpieces can be guaranteed, the production efficiency can be improved, and the production cost can be reduced.

Owner:SHAANXI QIYUAN TECH DEV

Artificial insemination method of breeder cocks

InactiveCN105816258ARaw materials are easy to getEasy to useAnimal reproductionAccessory food factorsDeferent ductSemen

The invention provides an artificial insemination method of breeder cocks. The method comprises the following steps: 1) artificially feeding breeder cocks before semen collection, namely selecting 55-week-old artificial insemination breeder cocks, adding feed additives to the conventional feed according to a ratio of 1.5-2.0wt%, feeding the breeder cocks until the breeder cocks are at the age of 68 weeks or the production cycle is ended according to a feeding procedure of continuously feeding for 7 days and later stopping for 7 days; 2) collecting semens; 3) diluting the semens, namely using semen diluents of which the volume is 2-4 times of that of the semen and slowly adding to semen collecting test tubes along the tube walls of the semen collecting test tubes, and then gently turning the semen collecting test tubes and repeating for 3-4 times; 4) carrying out artificial insemination, namely turning the anus of hens by anus turning members, transferring the diluted semens to deferent ducts by inseminators, and then gently inserting the deferent ducts into fallopian tubes of the hens by the inseminators and conveying the semens in the deferent ducts to conveying pipes, so as to realize the artificial insemination. The artificial insemination method disclosed by the invention is high in semen viability and insemination rate.

Owner:YONGSHENG YUSHUI NONGTE DEV CO LTD

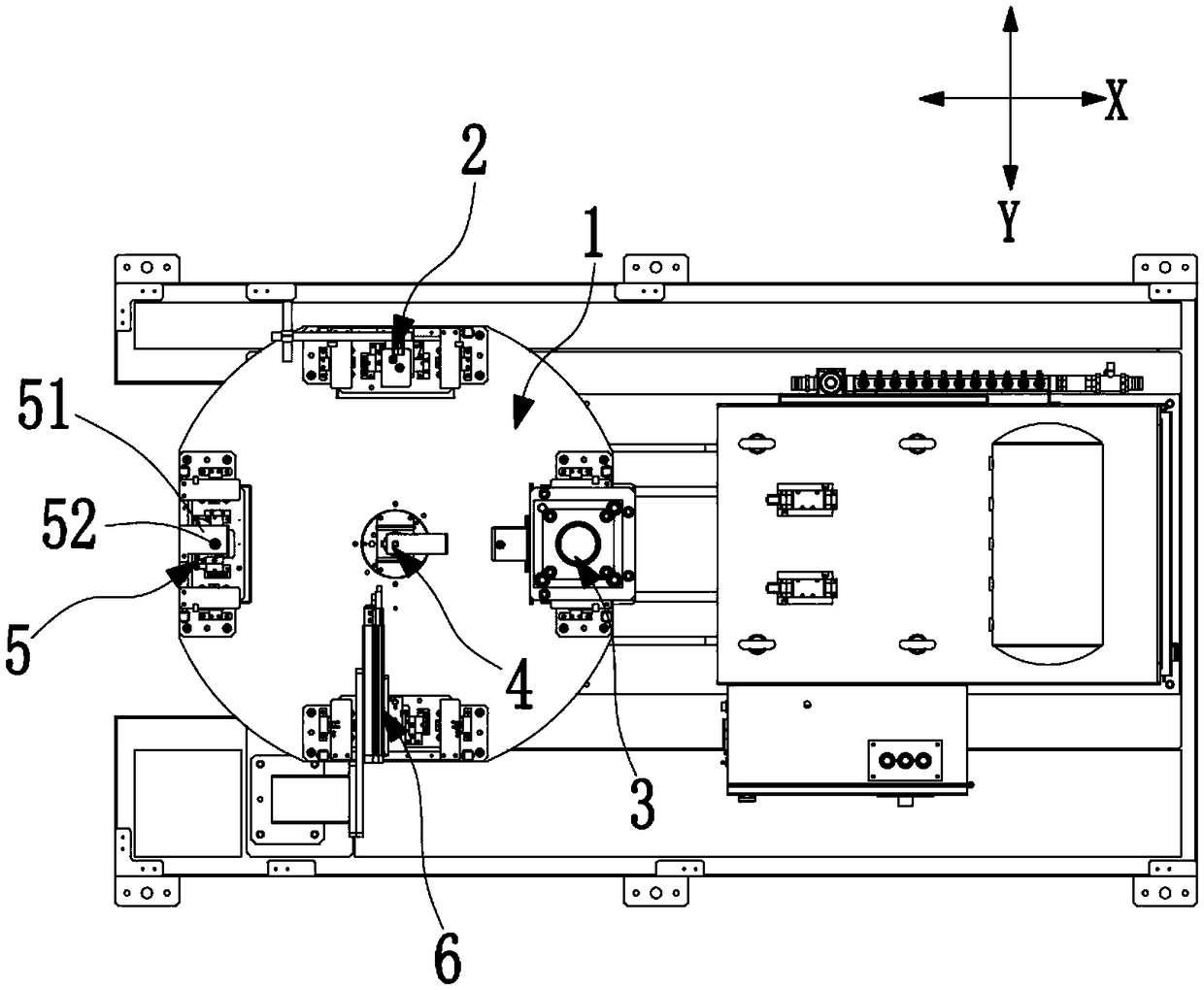

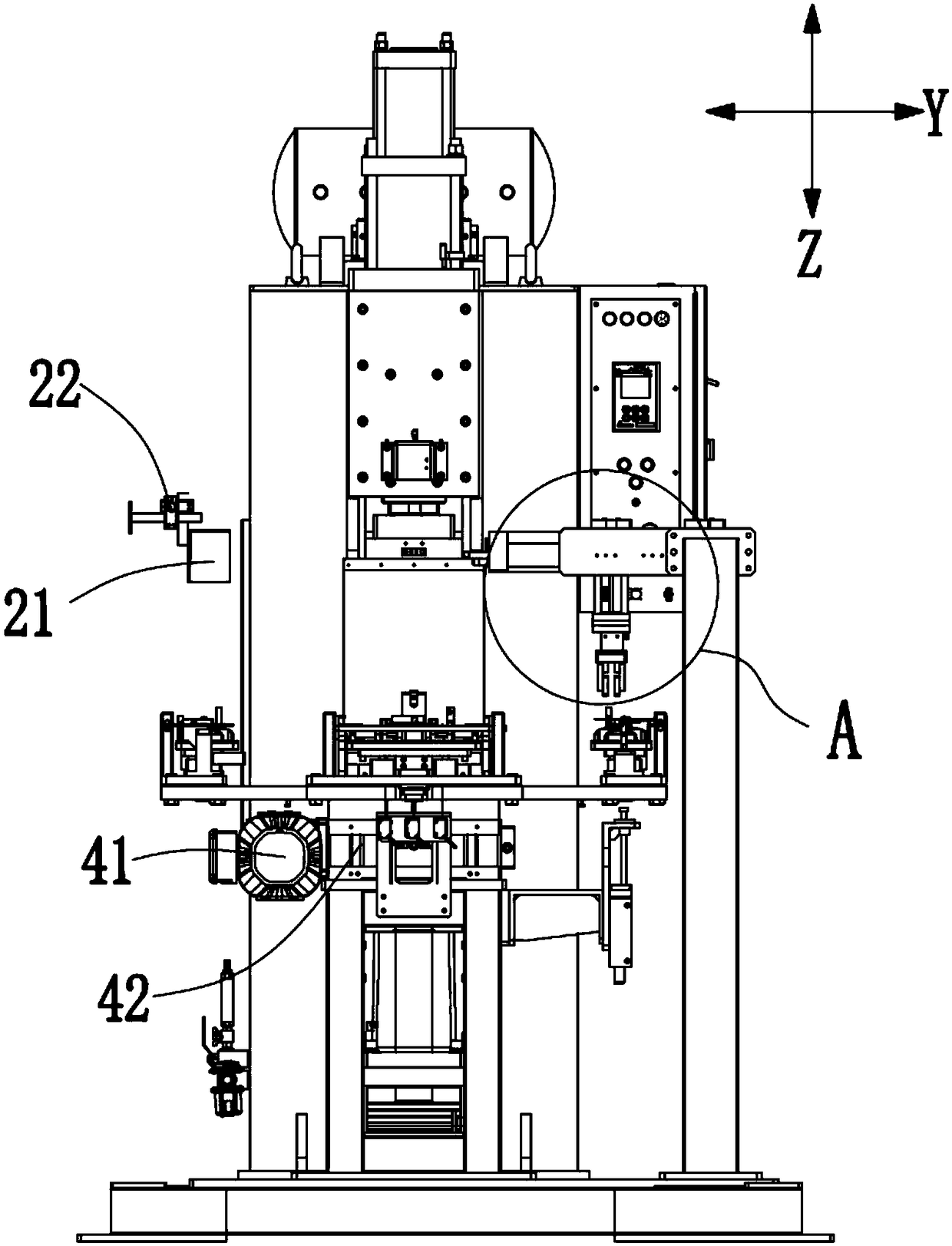

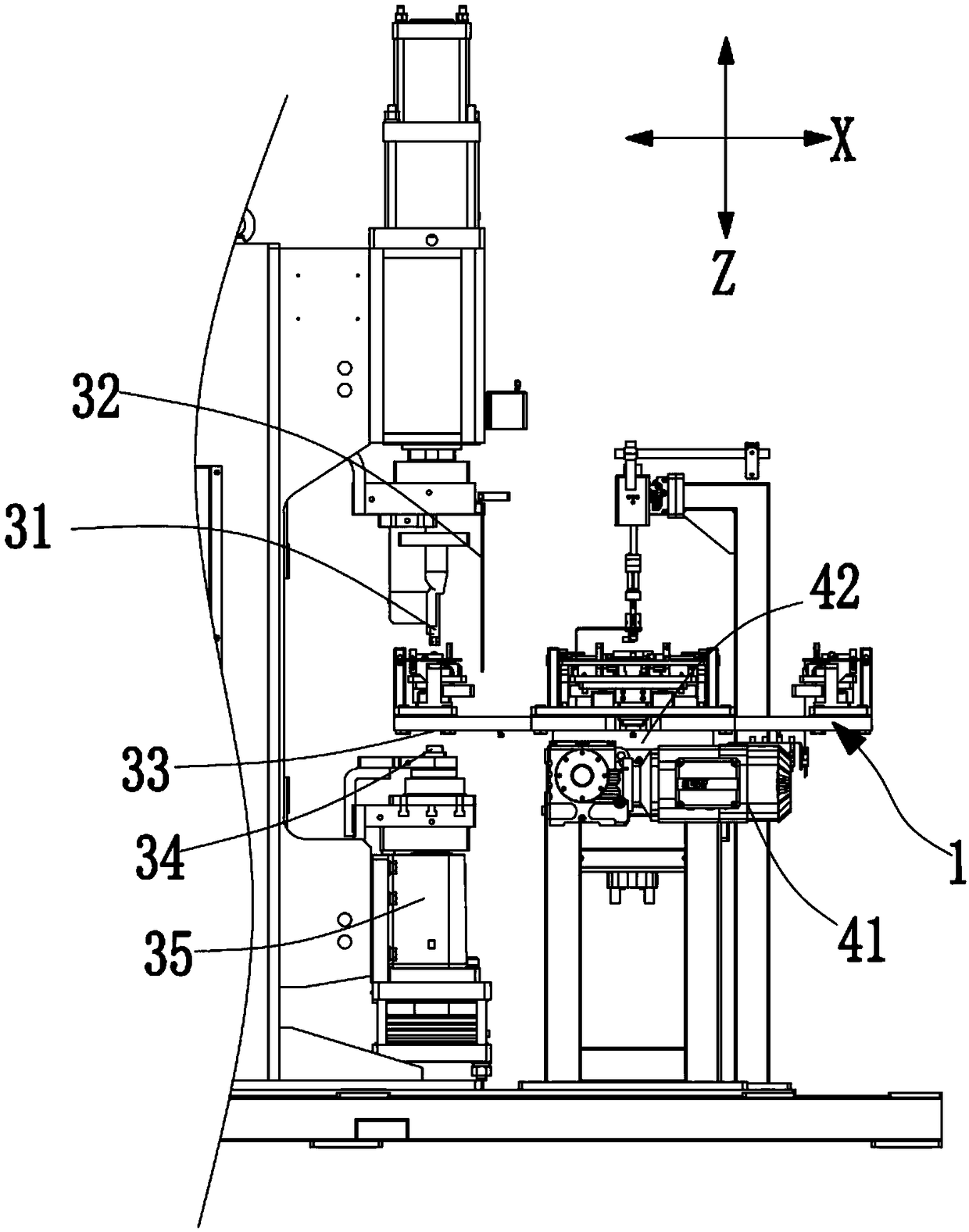

Efficient welding equipment

PendingCN109500539AShorten the time spent on weldingIncrease profitWelding/cutting auxillary devicesAuxillary welding devicesEngineeringUtilization rate

The invention discloses efficient welding equipment The efficient welding equipment comprises a rotary disc, a nut error-proofing detection device and a convex welding machine, wherein the rotary discis connected with a rotary disc driving device which drives the rotary disc to achieve autorotation around the axis of the rotary disc, at least four material loading tables which equally divide therotary disc are arranged on the top surface of the rotary disc, and each material loading table comprises turning plates capable of overturning towards the outer side of the rotary disc and a positioning pin used for positioning the nut and penetrating through the turning plates. When the nut error-proofing detection device corresponds to the position of one turning plate, the convex welding machine corresponds to the position of another adjacent turning plate. According to the welding equipment, the design is ingenious, the structure is simple, and a plurality of material loading tables are arranged on the rotary disc capable of achieving autorotation, so that a workpiece on one material loading table can be welded when feeding, discharging and detecting operations are carried out on other material loading tables, the time for welding one single workpiece can be effectively shortened, the utilization rate of time is increased, and the processing efficiency is improved. Meanwhile, workers are only responsible for feeding procedures, other procedures are automatically carried out, the labor intensity is low, and the automation degree is improved.

Owner:奇昊汽车系统(苏州)有限公司

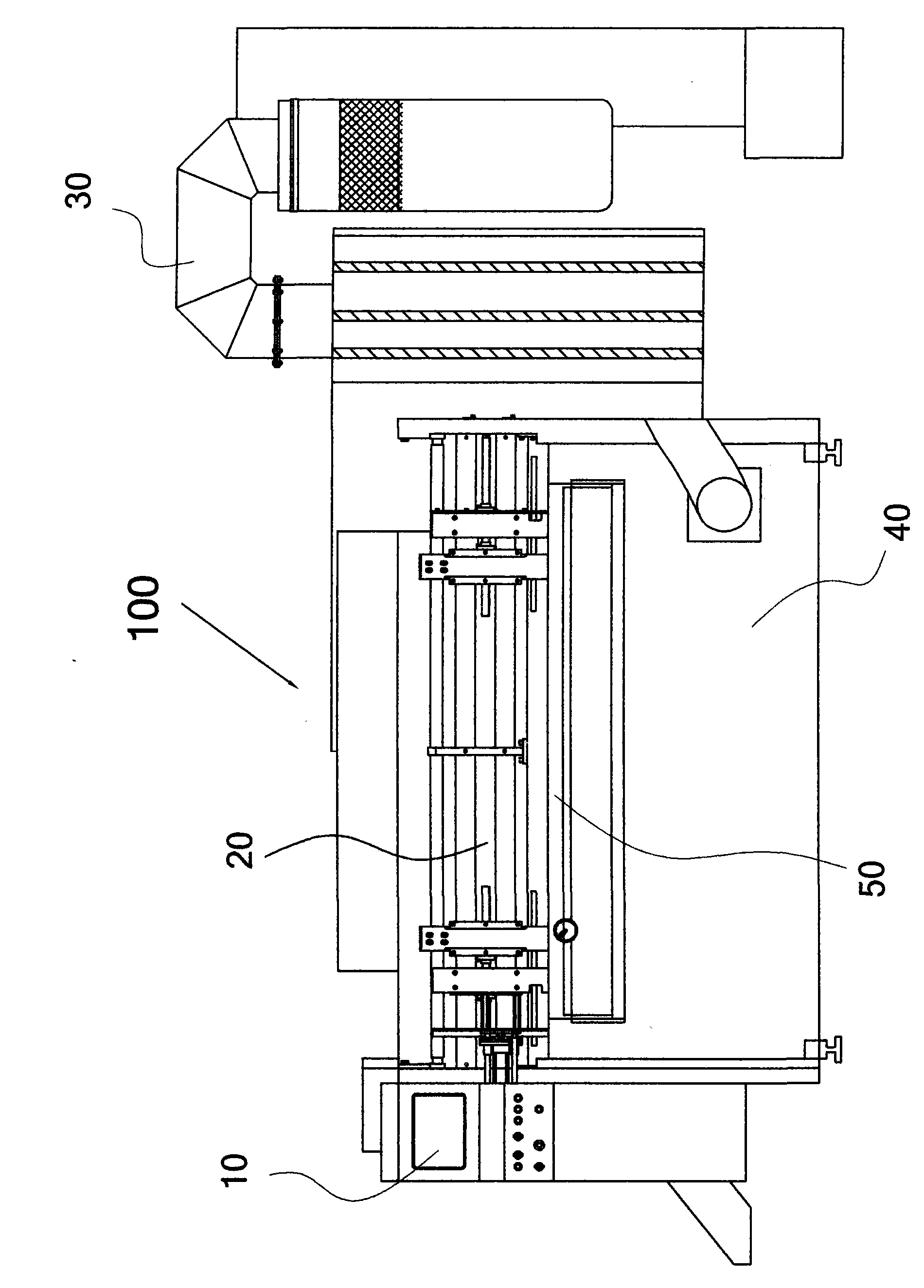

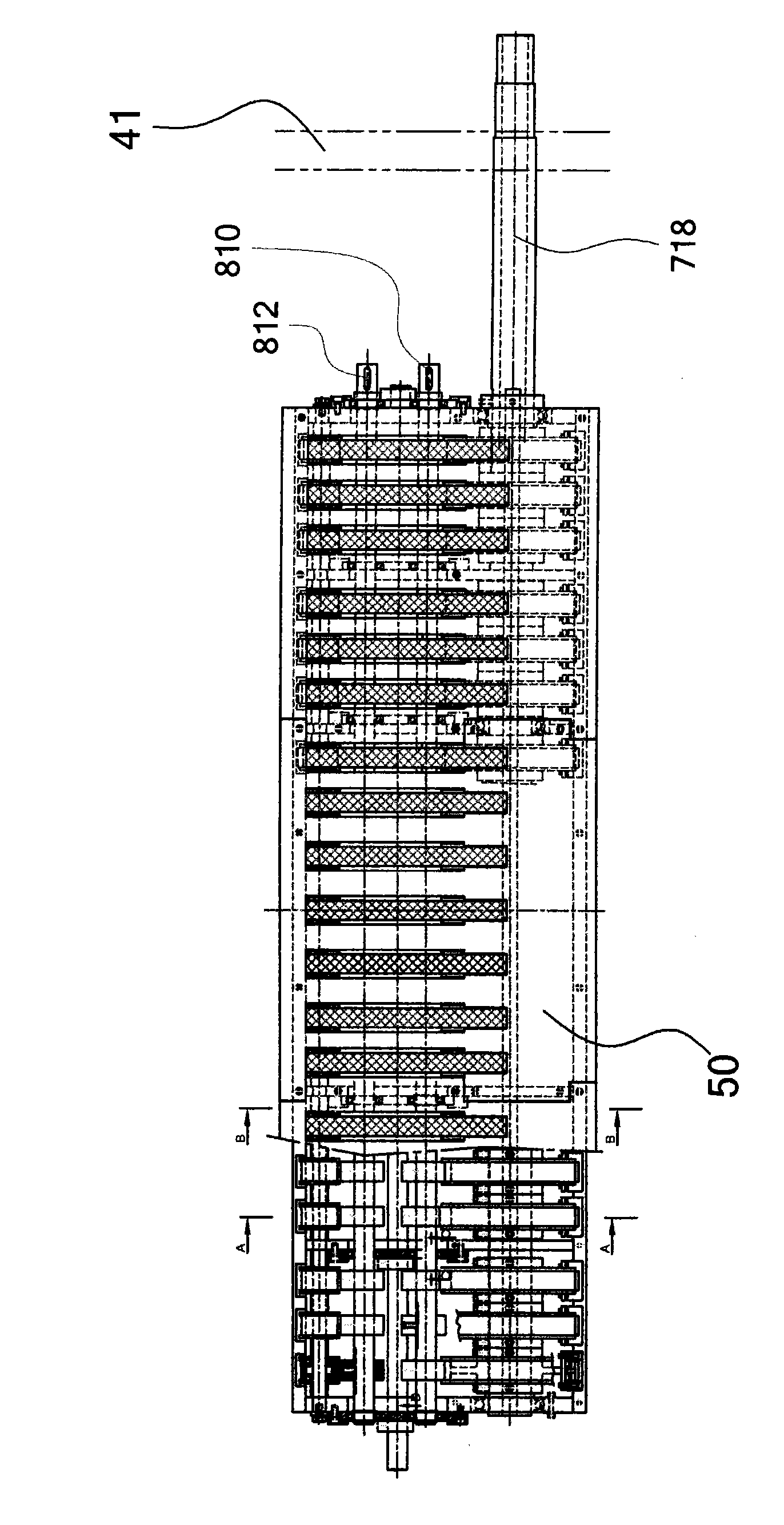

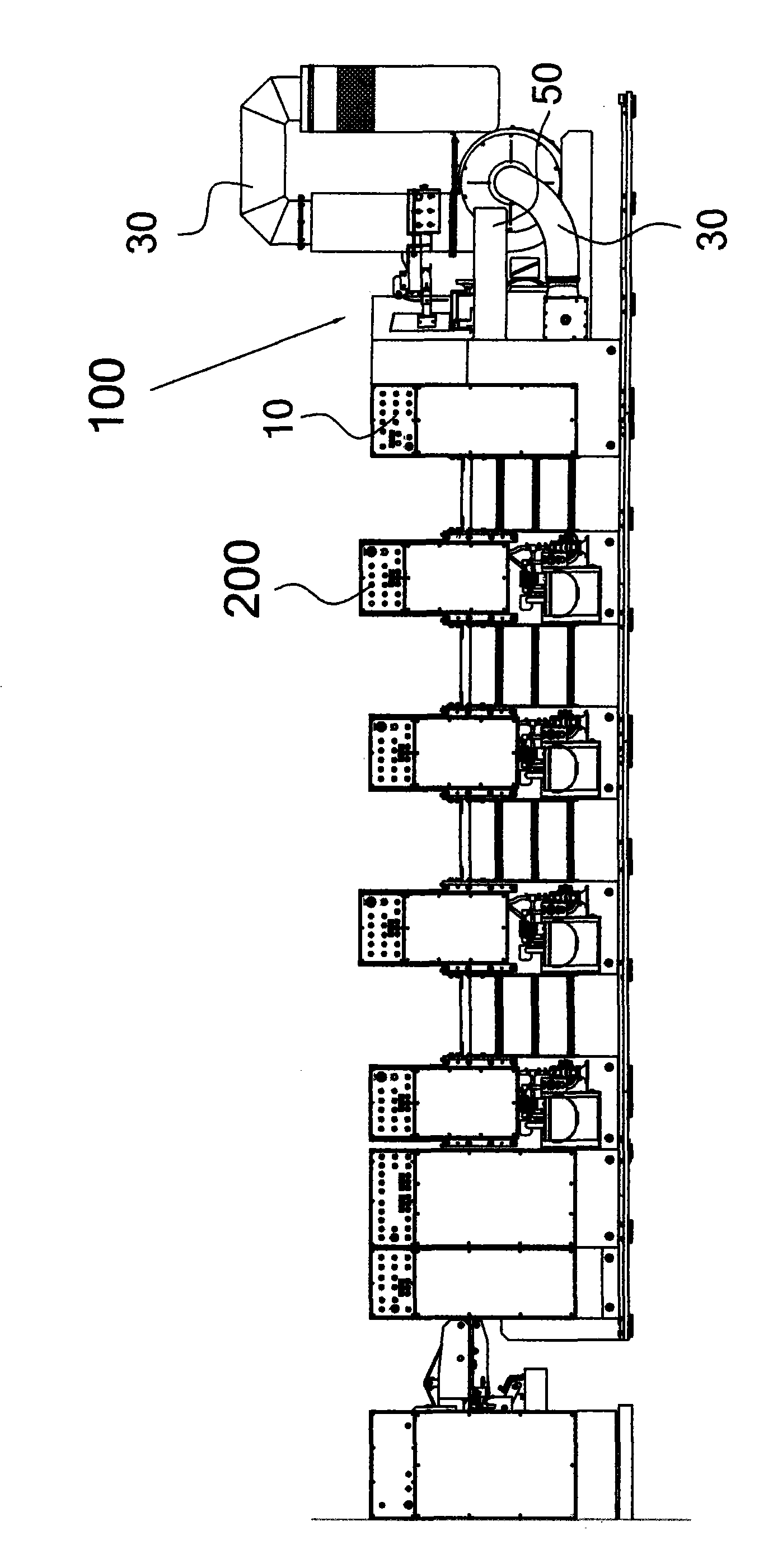

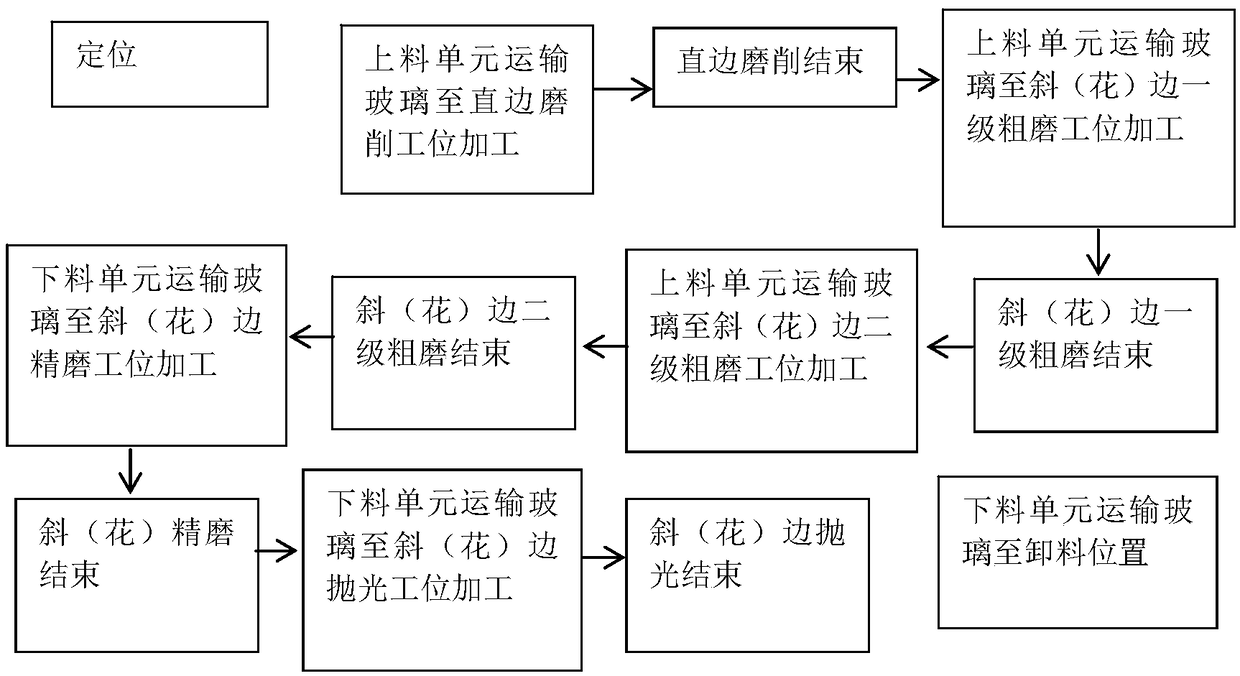

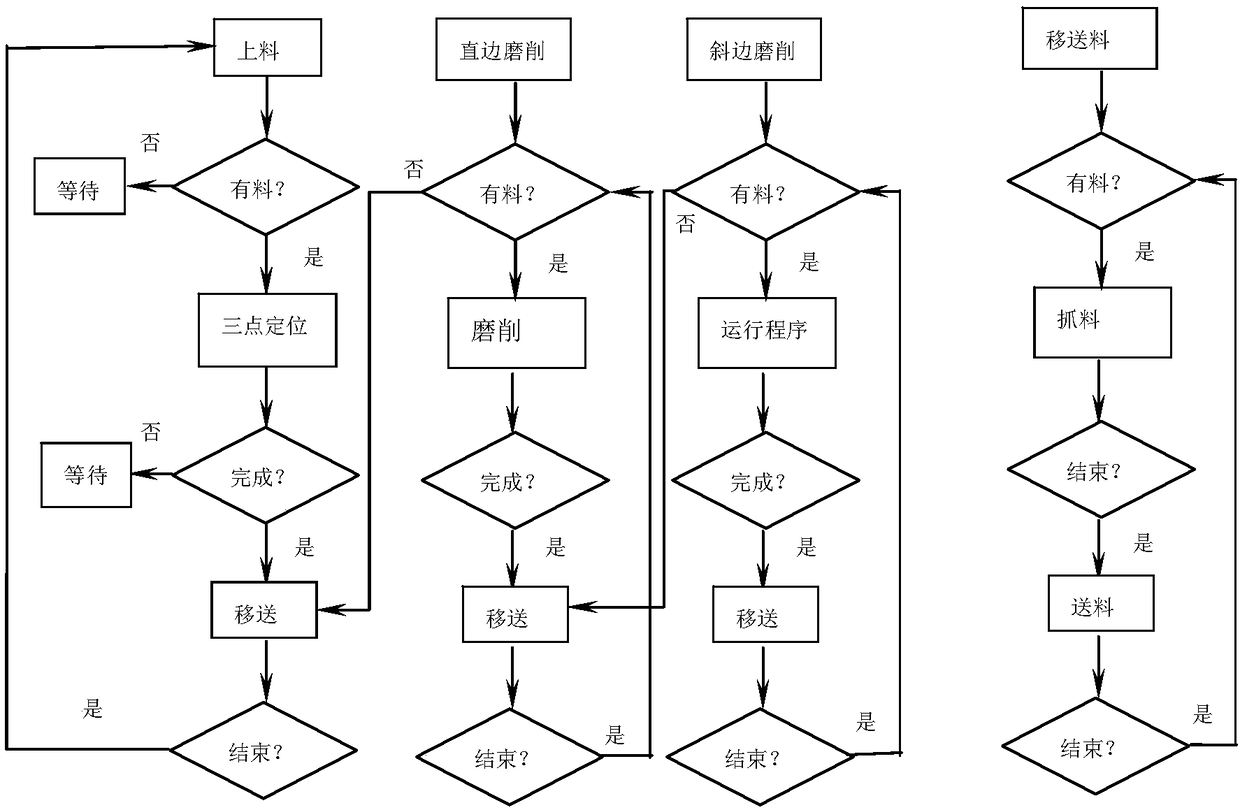

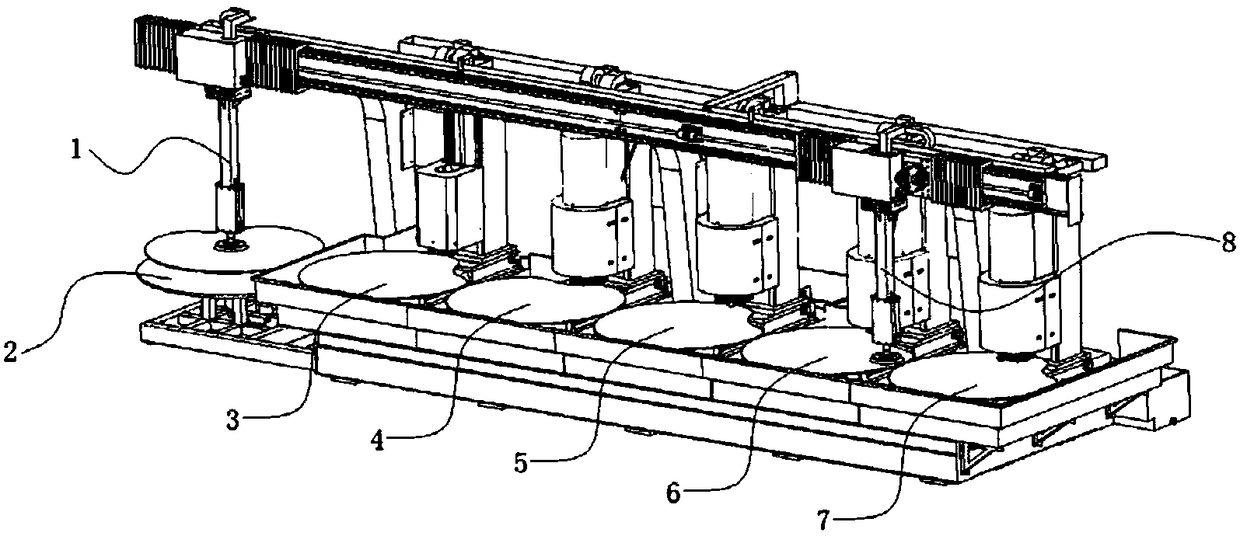

Glass edge continuous grinding method

InactiveCN108067971AReduce labor intensityShorten production timeEdge grinding machinesGrinding feedersMetallurgyMachining time

The invention provides a glass edge continuous grinding method, relates to the technical field of glass grinding and relates to a glass edge continuous grinding method. The glass edge continuous grinding method is designed for solving the problems that when the same glass needs straight edge and hypotenuse (or lace) grinding, automatic transfer of the glass in different procedures cannot be achieved, after machining devices are switched, multiple times of locating and tool setting are needed, consequently labor intensity is high, machining time is long, and production efficiency is low. The glass edge continuous grinding method comprises a feeding procedure, multiple grinding procedures and a discharging procedure. The feeding procedure comprises a locating procedure. All the grinding procedures are arranged sequentially and are performed at least once. A feeding unit is used for transferring to-be-machined glass to the prior one or multiple grinding procedures. A discharging unit is used for transferring to-be-machined glass to the later one or multiple grinding procedures. The machined glass is discharged through the discharging unit. Through the glass edge continuous grinding method, automatic transfer of the glass at different stations can be achieved.

Owner:ZHEJIANG SCI-TECH UNIV +1

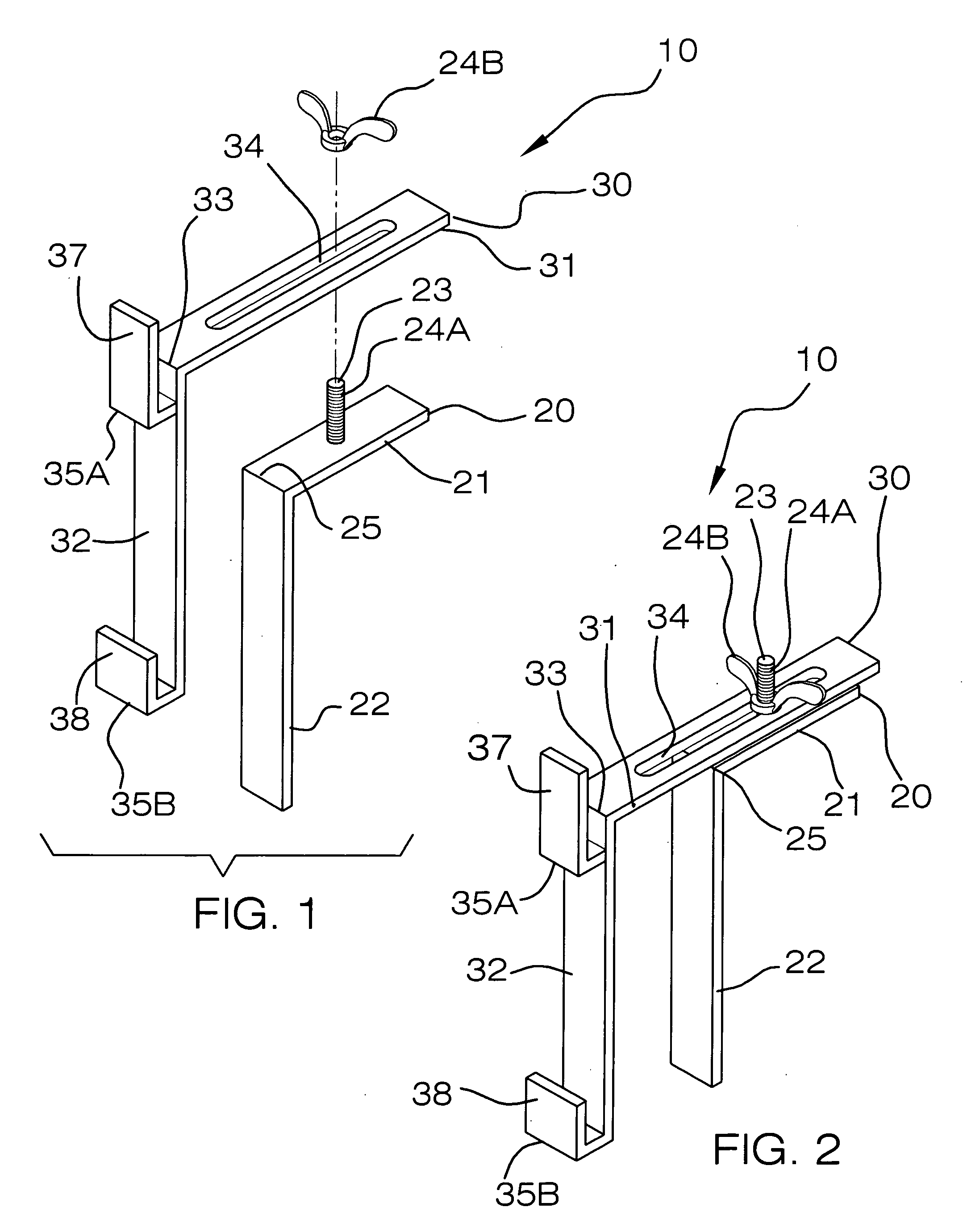

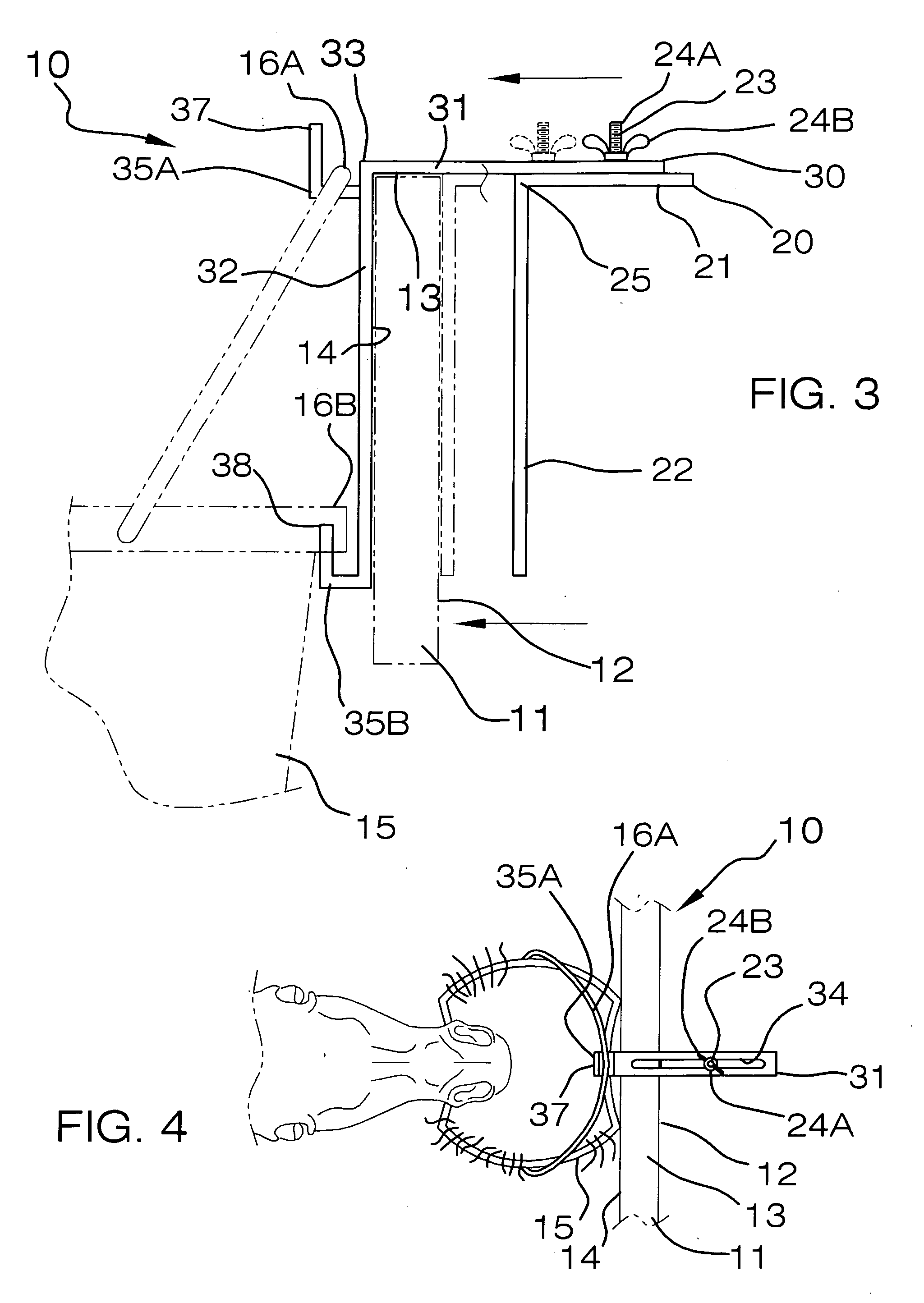

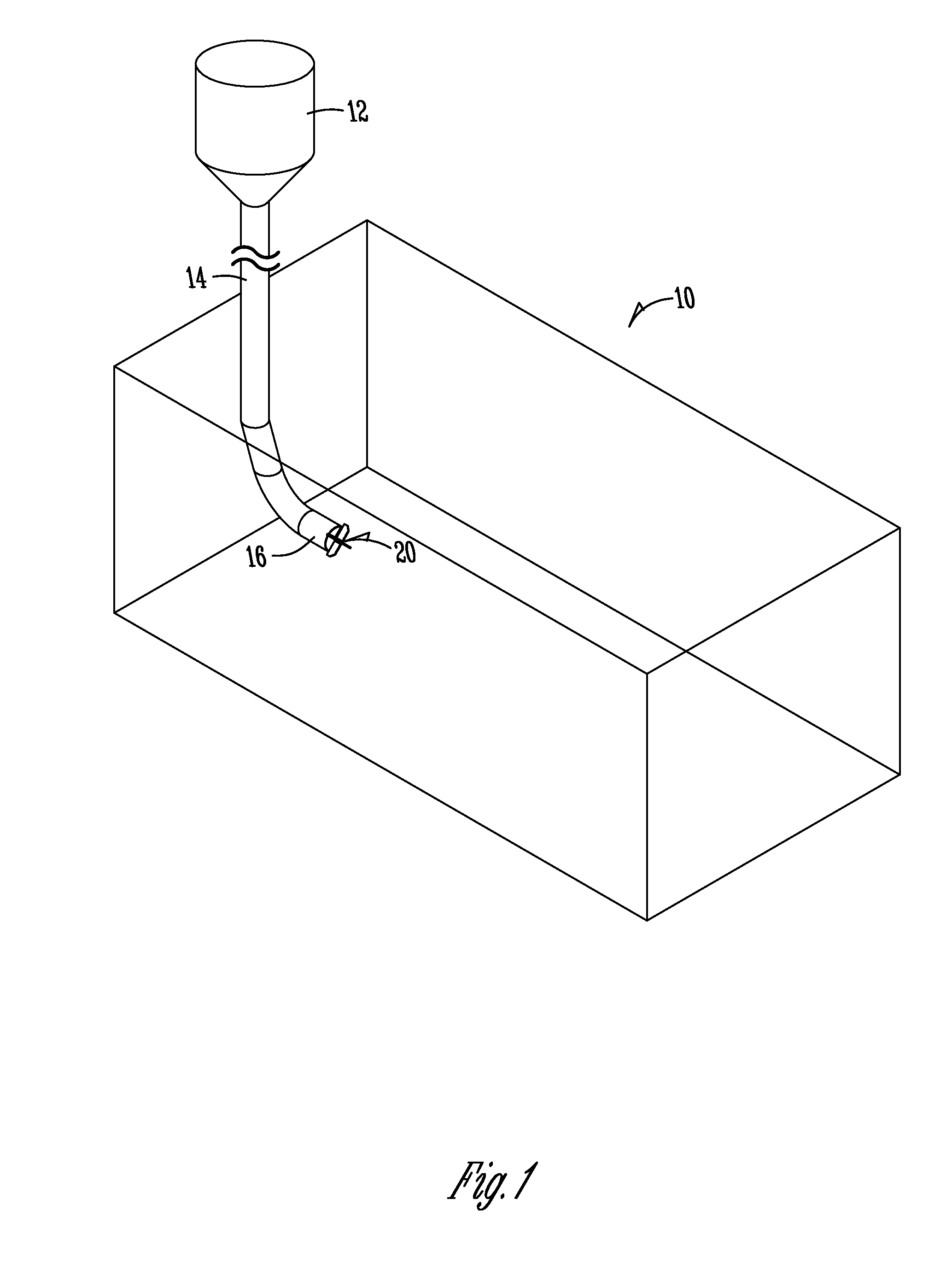

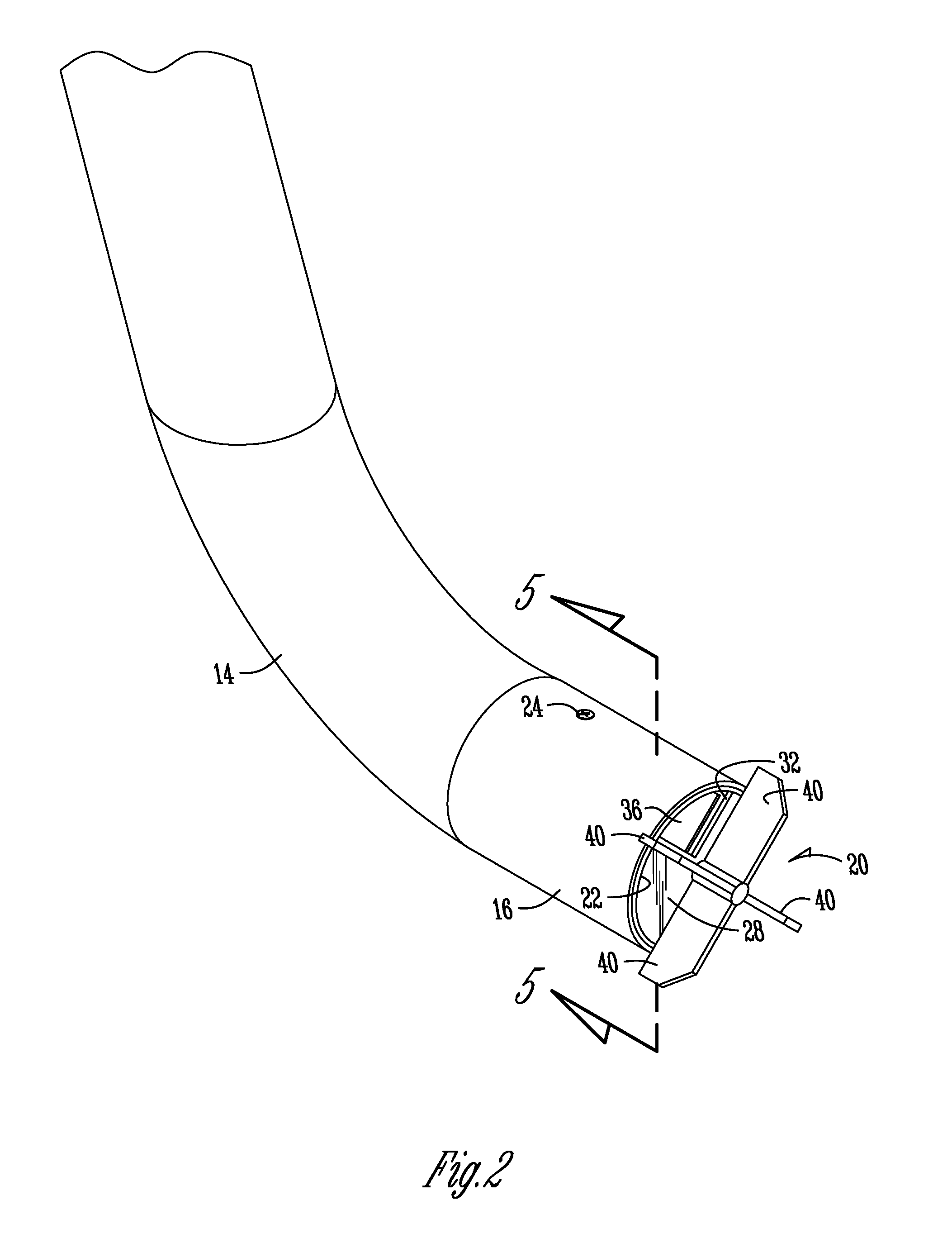

Adjustable mounting bracket for feed buckets and the like

InactiveUS20070209597A1Effective positioningConveniently attachedAnimal feeding devicesAnimal housingEngineeringHorizontal and vertical

A non-corrosive mounting bracket includes first and second members that have L-shapes and include horizontal and vertical portions defining a 90 degree elbow. The first member vertical portion is abutted against a post's rear surface and has a fastener assembly attached thereto. The fastener assembly includes a bolt and wing nut. The second member's vertical portion is abutted against the post's front surface, and the horizontal portion extends rearward along the post and travels parallel to the first member horizontal portion. The second member horizontal portion has a slot so that the fastener assembly is slidably positionable along the slot. L-shaped fingers are formed with the second member and protrude forwardly away from the post for receiving select portions of the feed bucket so that the bucket is maintained at a static position during feeding procedures.

Owner:BROCK TED A +1

Production technology of stretching film

The invention relates to a stretching film, in particular to a production technology of stretching film provided with a printing procedure. The invention comprises a feeding procedure in which raw material solid LDPE granules are delivered to the sequential procedures through a feeding orifice, the sequential procedures comprise: 1) high temperature melting procedure; 2) die orifice extruding procedure; 3) pulling and cooling procedure; 4) printing procedure; and 5)rolling and packaging procedure. The invention has the beneficial effects that: (1) the stretching film produced by a stretching film machine can be used for printing company trademarks and other contents according to the requirements of customers and can be demounted conveniently; (2) when the stretching film is produced, the pattern printing procedure can be finished in one step at the same time, exerting no impact on the productivity; and (3) various patterns can be printed according to the requirements of customers and can be used in advertisements.

Owner:孙和永

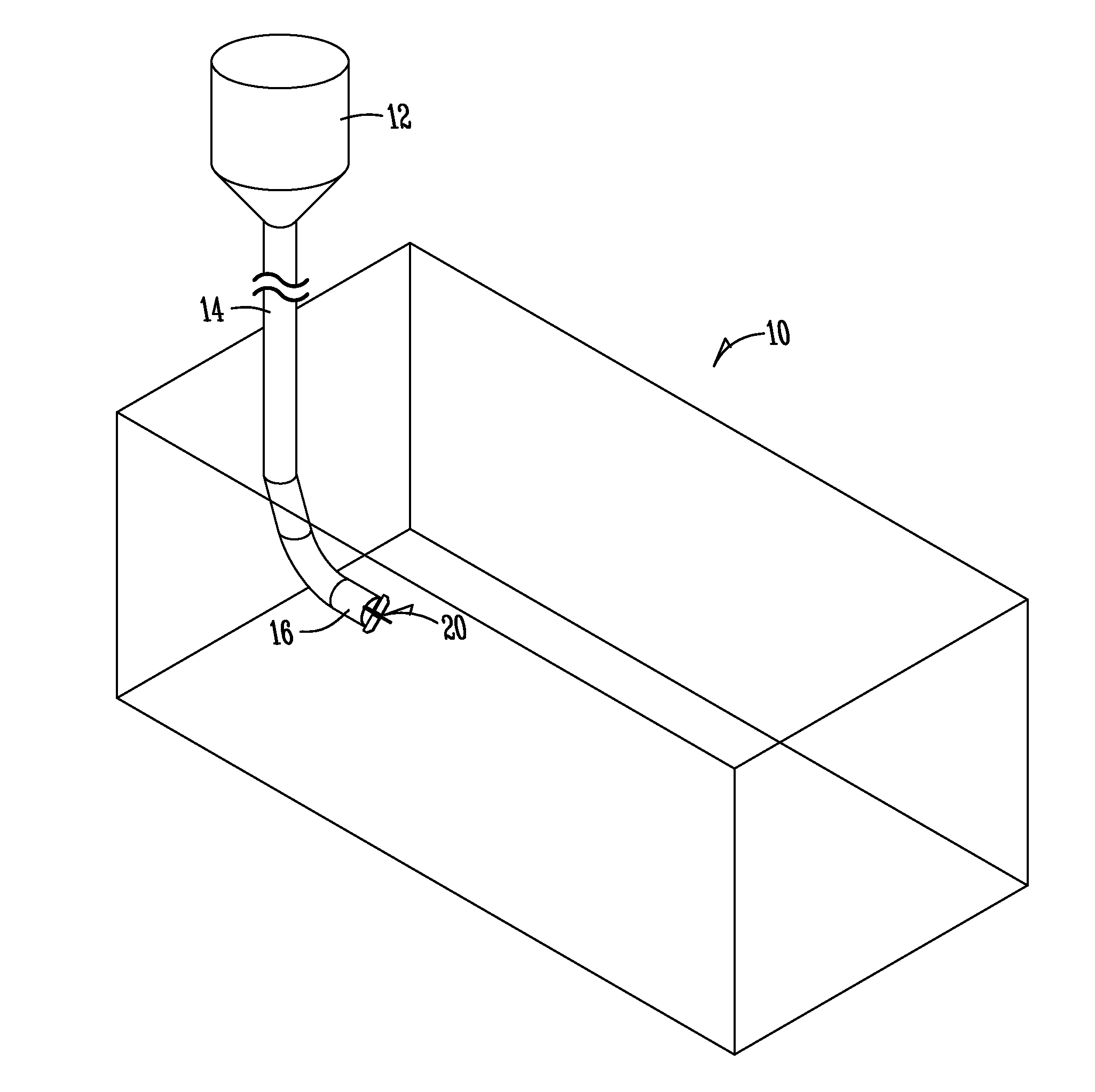

Sow gestation tube feeder

A plug insert matingly fits into the open lower end of a feed tube in a gilt or sow stall. The plug includes an inlet for receiving feed from the tube and an outlet for discharging feed onto the floor of the stall. The inlet and outlet are offset from one another. An axle extends through the plug, with spokes on the lower outer end of the axle, an anti-bridge bar on the upper end of the axle, and one or more fins on the central portion of the axle. Discharge of the seed is controlled by the gilt or sow as she rotates the spokes on the forward end of the plug, thereby rotating the fins or spiral flighting to carry feed from the inlet to the outlet. This self-feeding system eliminates or minimizes feed waste while providing an appropriate feeding program for the gilt or sow.

Owner:KLOCKE DAVE

Bidirectional laser welding system and bidirectional working method

ActiveCN106670646AAchieve double production capacityEnsure safetyLaser beam welding apparatusReference lineWork status

The invention provides a bidirectional laser welding system. The bidirectional laser welding system comprises a first steel structure, a laser head, a first working machine table, a second working machine table and a control device; the first steel structure is provided with a laser head walking shaft parallel to ground; the laser head is arranged to move along the laser head walking shaft; a reference line is arranged at the middle point of the laser head walking shaft, is perpendicular to the laser head walking shaft and is parallel to the ground; a plane passing through the reference line and perpendicular to the ground is defined as a second reference plane; the first working machine table and the second working machine table are the same in structure; and the first working machine table and the second working machine table are symmetrically arranged relative to the second reference plane. The bidirectional laser welding system provides two working machine tables, when one working machine table completes the welding procedure, the other working machine table completes the part discharging and feeding procedures, and therefore the laser head can be in a full-load working state, and the double capacity can be achieved.

Owner:南京埃斯顿精密装备有限公司

Processing technology of large flange with conical surface sealing structure

ActiveCN109513947AAchieve ultra-high precision machiningReduce manufacturing costSurface finishNumerical control

The invention relates to the technical field of machining, and discloses a processing technology of a large flange with a conical surface sealing structure. The processing technology comprises a flange outer conical surface rough lathe, a flange outer conical surface semi-finish lathe and a flange outer conical surface finish lathe, wherein the flange outer conical surface semi-finish lathe and the flange outer conical surface finish lathe are mounted on one numerical control vertical lathe; operation of the flange outer conical surface semi-finish lathe is completed at least through two-timefeed cutting; technological parameters of the last-time feed cutting of the flange outer conical surface semi-finish lathe are the same as technological parameters of feed cutting of the flange outerconical surface finish lathe; after the flange outer conical surface semi-finish lathe completes operation, the flange is placed on a high-precision three-coordinate detector to be detected, and processing errors of the flange outer conical surface semi-finish lathe are recorded; and during flange outer conical surface finish turning, the errors are compensated in the feed procedure of turning processing. According to the processing technology, ultrahigh-precision processing of flange outer conical surfaces is achieved, production cost is reduced, and the delivery date is shortened.

Owner:江阴普洋重工有限公司

Bobbin feeding device

The invention provides a bobbin feeding device which comprises a cabinet. The bobbin feeding device is characterized in that a frame which is used for stacking and accommodating bobbins from top to bottom is fixed onto the cabinet, the bobbin feeding device further comprises an actuator and a conveyor belt, the actuator and the conveyor belt are respectively arranged on two opposite sides of the frame, the actuator comprises a first magnet and a second magnet which have identical magnetism, one end of the second magnet is connected with the first magnet by a return spring, a pushing head is arranged at the other end of the second magnet and is aligned with the bobbins on the bottommost layer of the frame, the first magnet is mounted on a base of the cabinet, an electromagnetic valve is further electrically connected with the first magnet, and the second magnet is repelled by the first magnet after the electromagnetic valve is conducted, so that the pushing head can push the bobbins on the bottommost layer of the frame onto the conveyor belt. The bobbin feeding device has the advantages that workers do not need to carry weights in integral feeding procedures, accordingly, the labor intensity can be greatly relieved, and the feeding speeds can be increased owing to a pipelined feeding mode.

Owner:SUZHOU OUBBOO FASHION CO LTD

Automatic chamfering, cutting-off and deburring device for steel pipe

InactiveCN104985440AImprove machining accuracyReduce manufacturing costOther manufacturing equipments/toolsAutomatic controlEngineering

The invention relates to an automatic chamfering, cutting-off and deburring device for a steel pipe. The device comprises a machine tool, a bracket, a positioning mechanism, an outer corner chamfering mechanism, a cutting-off mechanism, an inner corner chamfering mechanism and a hydraulic cylinder, wherein the bracket is arranged on the machine tool; the positioning mechanism comprises a clamp and an auxiliary clamp; the outer corner chamfering mechanism, the cutting-off mechanism and the inner corner chamfering mechanism are arranged on the bracket; the inner corner chamfering mechanism comprises a cutter, a cutter rest and hinged shafts; the cutter is arranged on the cutter rest; the cutter rest is connected with an axial spindle and a radial spindle of the hydraulic cylinder through the hinged shafts respectively. The automatic chamfering, cutting-off and deburring device further comprises an automatic control system, and the automatic control system is electrically connected with the outer corner chamfering mechanism, the cutting-off mechanism and the inner corner chamfering mechanism. By the adoption of the automatic chamfering, cutting-off and deburring device, only one time of feeding procedure is conducted, and positioning, clamping, outer corner chamfering, cutting-off and inner corner chamfering of other procedures are sequentially and automatically conducted on the machine tool, so that the steel pipe concentric machining precision is improved, and the automatic chamfering, cutting-off and deburring device has the characteristics of being simple in structure, high in degree of automation, high in deburring effect, convenient to use and suitable for batch production and machining.

Owner:GUIZHUO SHUNAN ELECTROMECHANICAL EQUIP CO LTD

Nano sized intellectual driving unit with large feeding force for super precisively machining

InactiveCN1472038AImplement self-testAchieve adaptiveMachines/enginesLarge fixed membersStress concentrationFeeding force

A nano-class intelligent driver with high feeding powder for ultraprecision machining is composed of multiple deformable bodies and multiple insulating bodies, all of which are alternatively arranged. Its advantages are symmetrical structure for self-test, adaptive and self-leaning functions, no stress concentration in feeding procedure, high precision and wide feeding range.

Owner:ZHEJIANG UNIV

A method of feeding and managing pregnant sows

Owner:SONGTAO DEKANG AGRI & ANIMAL HUSBANDRY CO LTD

An automatic feeding pet cage

InactiveCN106106205AImprove sanitationSimplify the feeding routineAnimal feeding devicesAnimal housingEngineeringControl valves

The invention discloses an automatic feeding pet cage, which comprises a pet cage body, a feeding port, a feed box, a material storage box, a feeding pipe and a timing control valve. In the feeding port, the storage box is arranged on the top of the storage cage body, the two ends of the feeding pipe are respectively connected to the feed box and the storage box, and the timing control valve is arranged at the interface between the storage box and the feeding pipe. Through the above method, the present invention provides an automatic feeding pet cage, which uses a timing control valve and a storage box instead of manual feeding, simplifies the feeding procedure, saves manpower expenditure, and improves the sanitary environment of the pet cage.

Owner:SUZHOU NEW DISTRICT FENGQIAO PURIFICATION EQUIP FACTORY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com