Intelligent switching control method based on bin weights and implemented in raw material feeding procedures and control system for intelligent switching control method

A control method and technology of intelligent switching, applied in general control systems, control/regulation systems, adaptive control, etc., can solve the problems of low degree of automation, insignificant control effect, inability to accurately and effectively complete control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

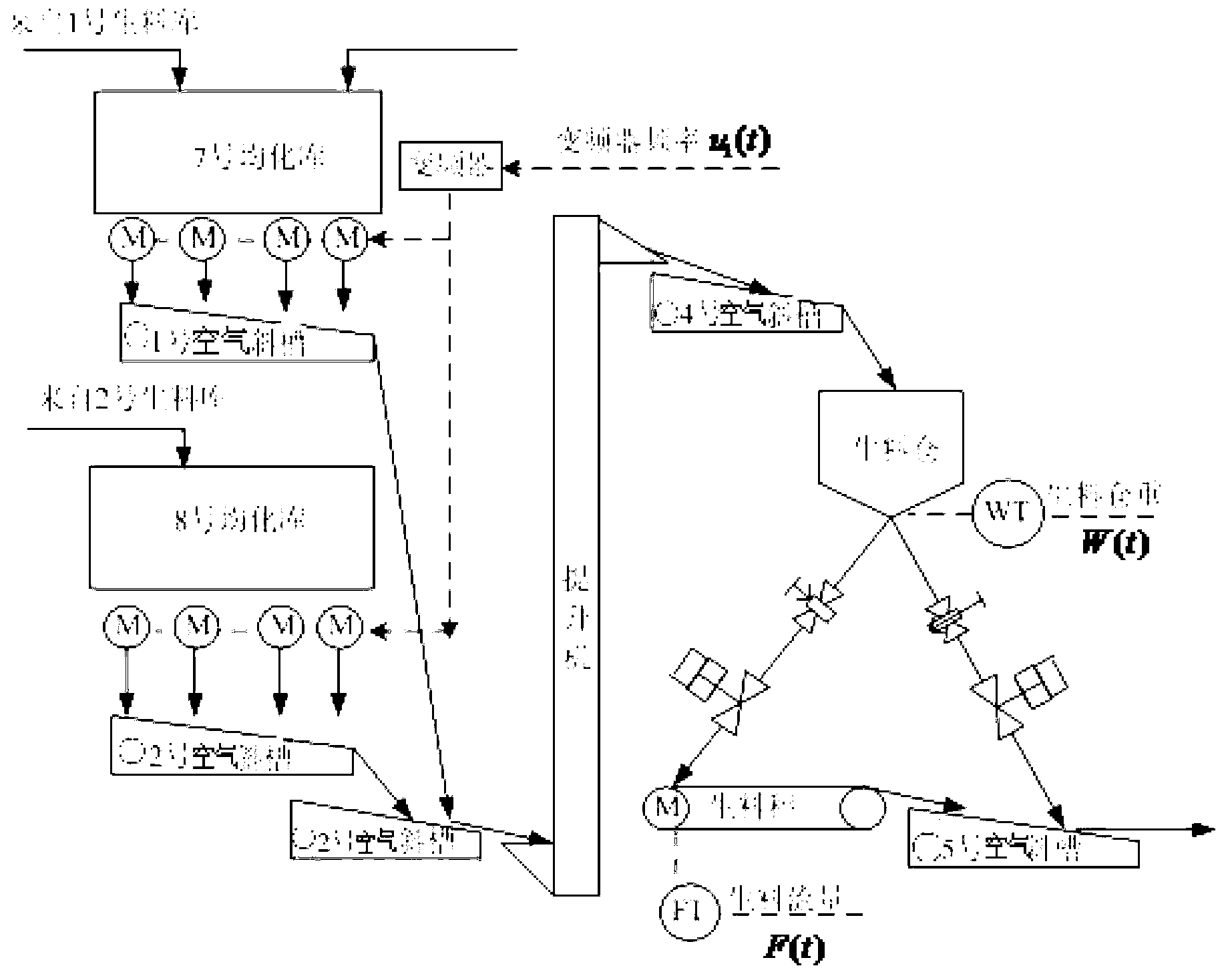

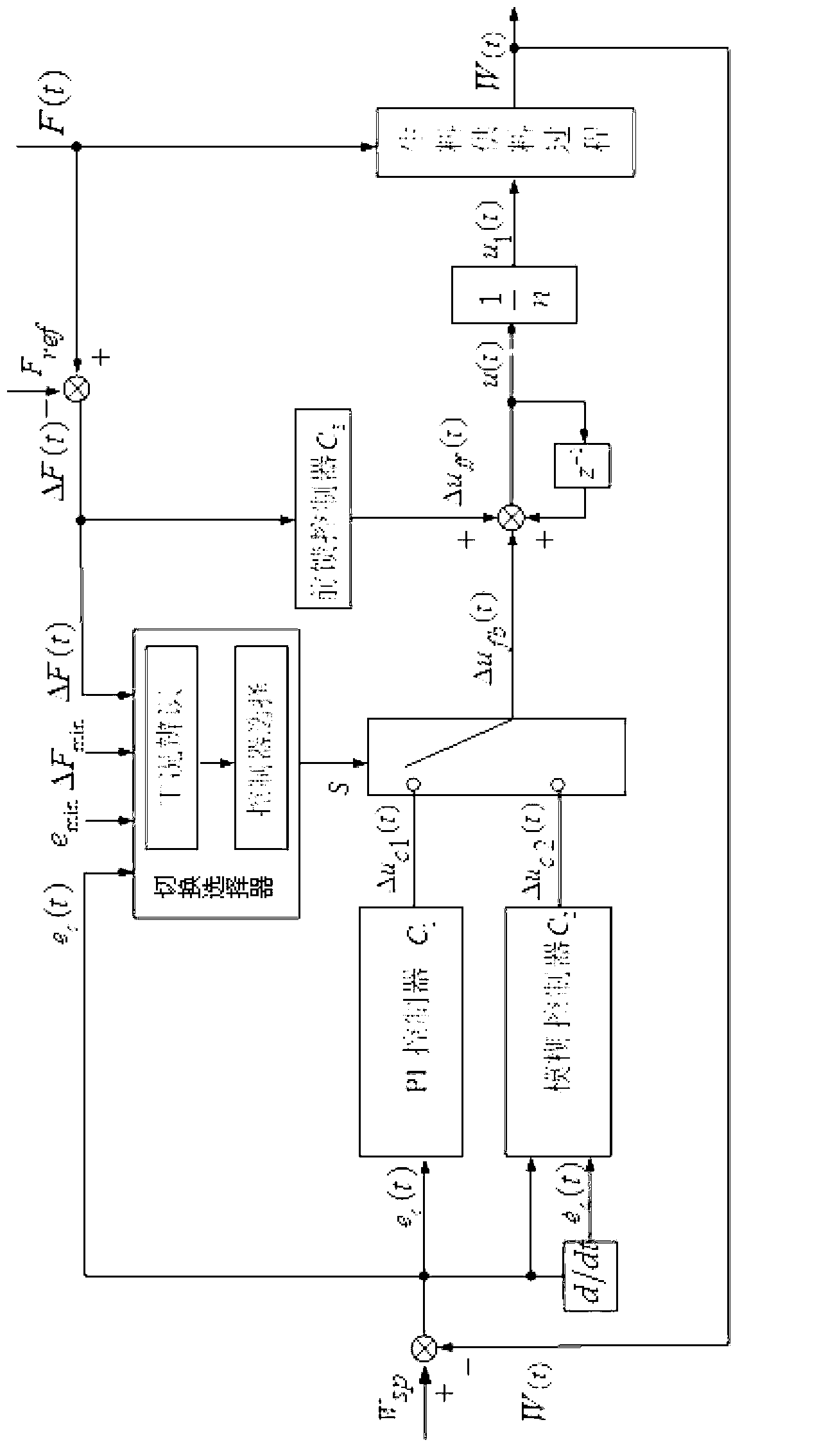

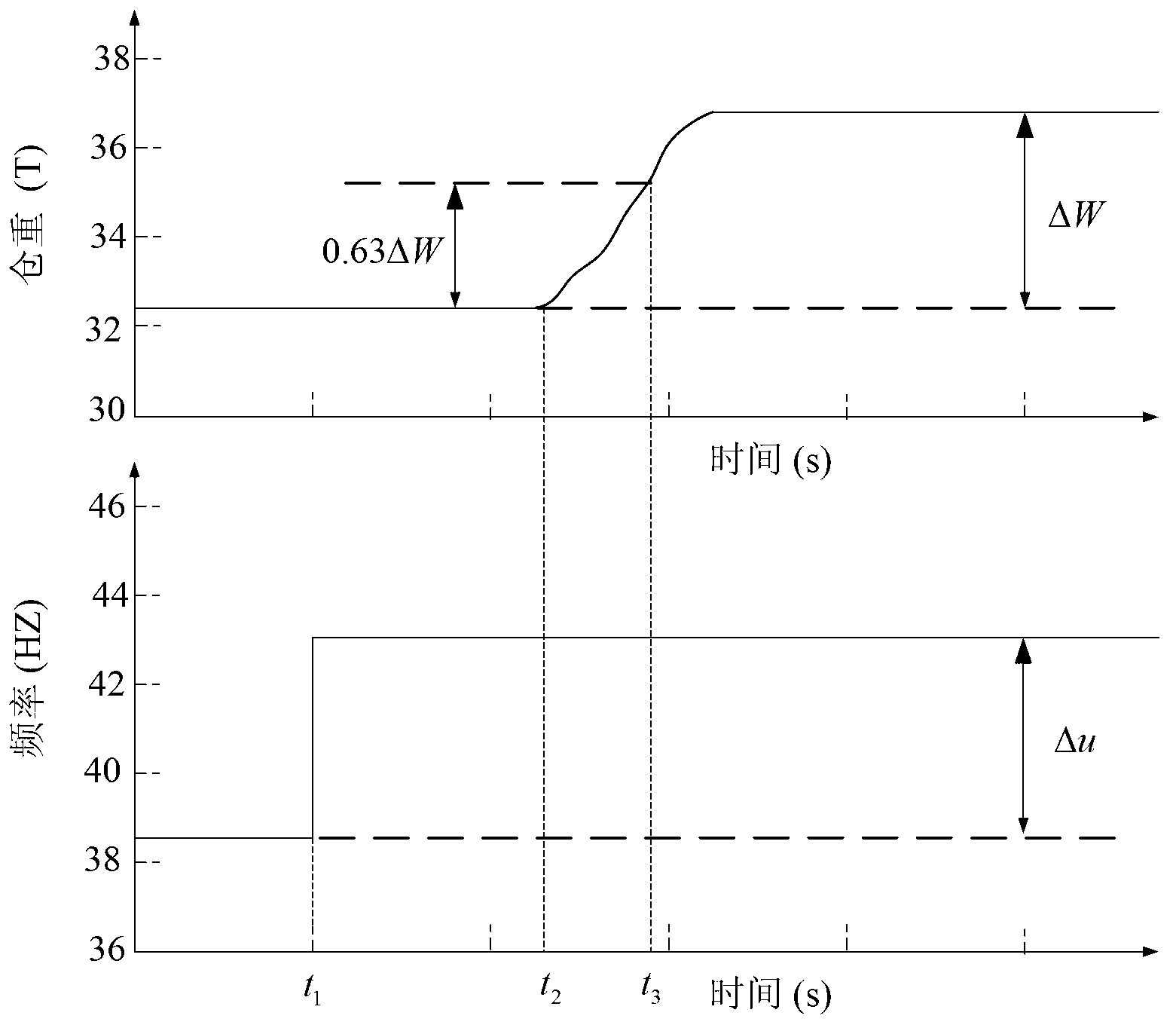

[0043] The intelligent switching control method of bin weight in the raw meal feeding process provided by the patent application of the present invention is based on the following smart bin weight switching control system in the raw meal feeding process. This control system includes real-time output frequency control values for homogenization The three major controllers that are regulated by the rotary feeder M of each feed port of the warehouse, the first controller of which is PI controller C1, which is the PI control when the weight deviation of the raw material bin is within the range specified by the process. The second controller is a fuzzy controller C2, which is a fuzzy controller when the weight deviation of the raw material silo exceeds the range specified by the process, and the third controller is a feedforward controller C3. The deviation value of the discharge flow of the silo is used to obtain the frequency adjustment value and feed into the feed-forward contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com