Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33 results about "Environmental stress screening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Environmental stress screening (ESS) refers to the process of exposing a newly manufactured or repaired product or component (typically electronic) to stresses such as thermal cycling and vibration in order to force latent defects to manifest themselves by permanent or catastrophic failure during the screening process. The surviving population, upon completion of screening, can be assumed to have a higher reliability than a similar unscreened population.

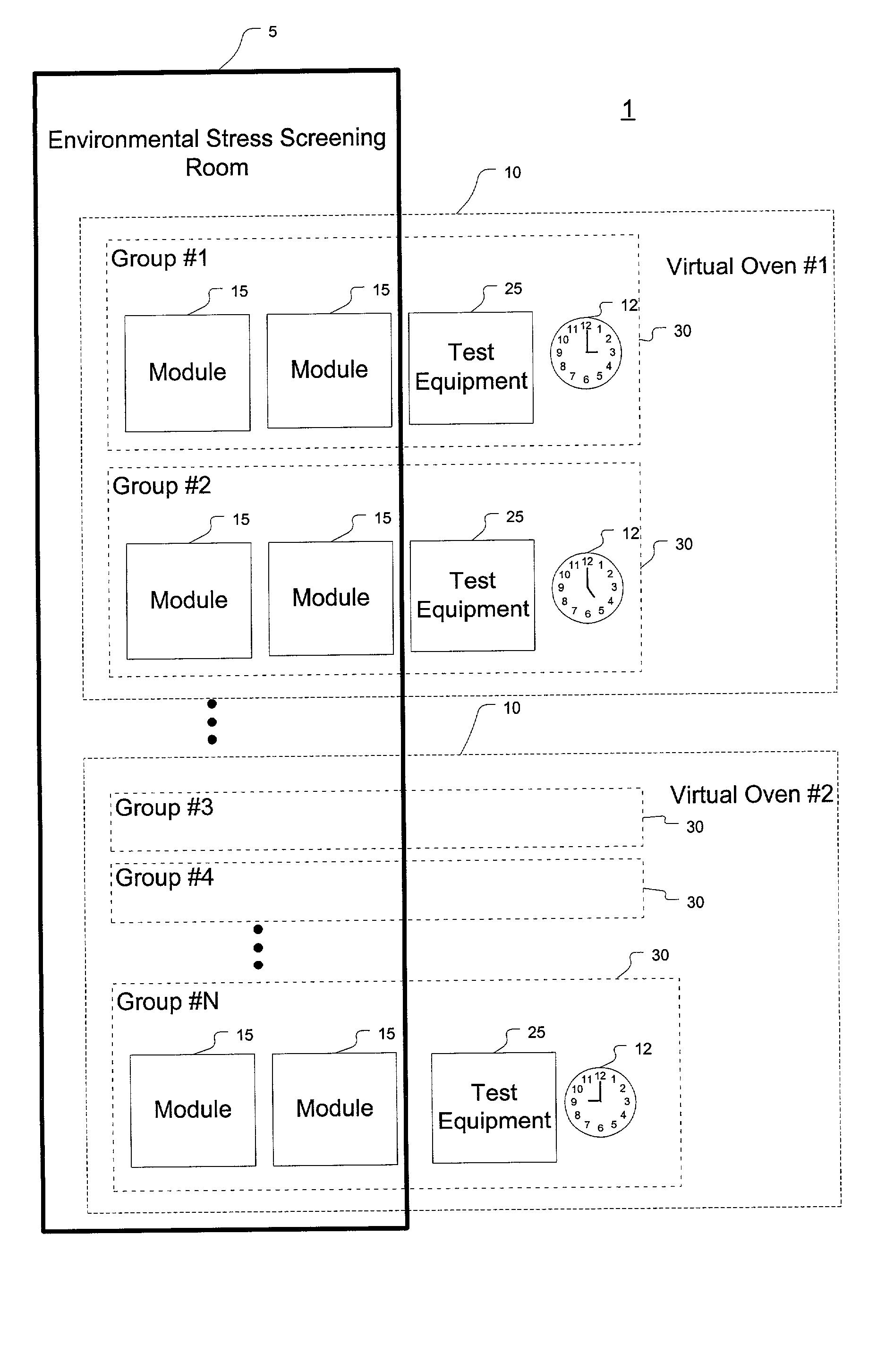

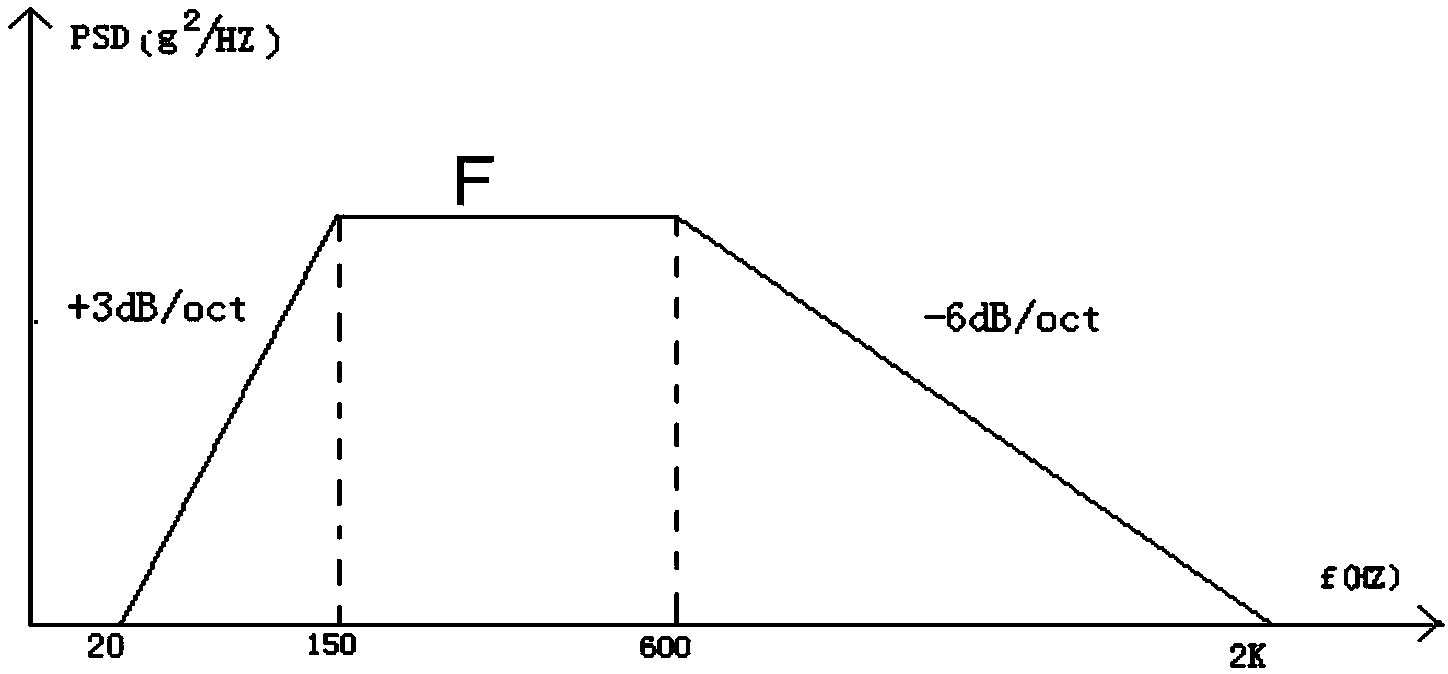

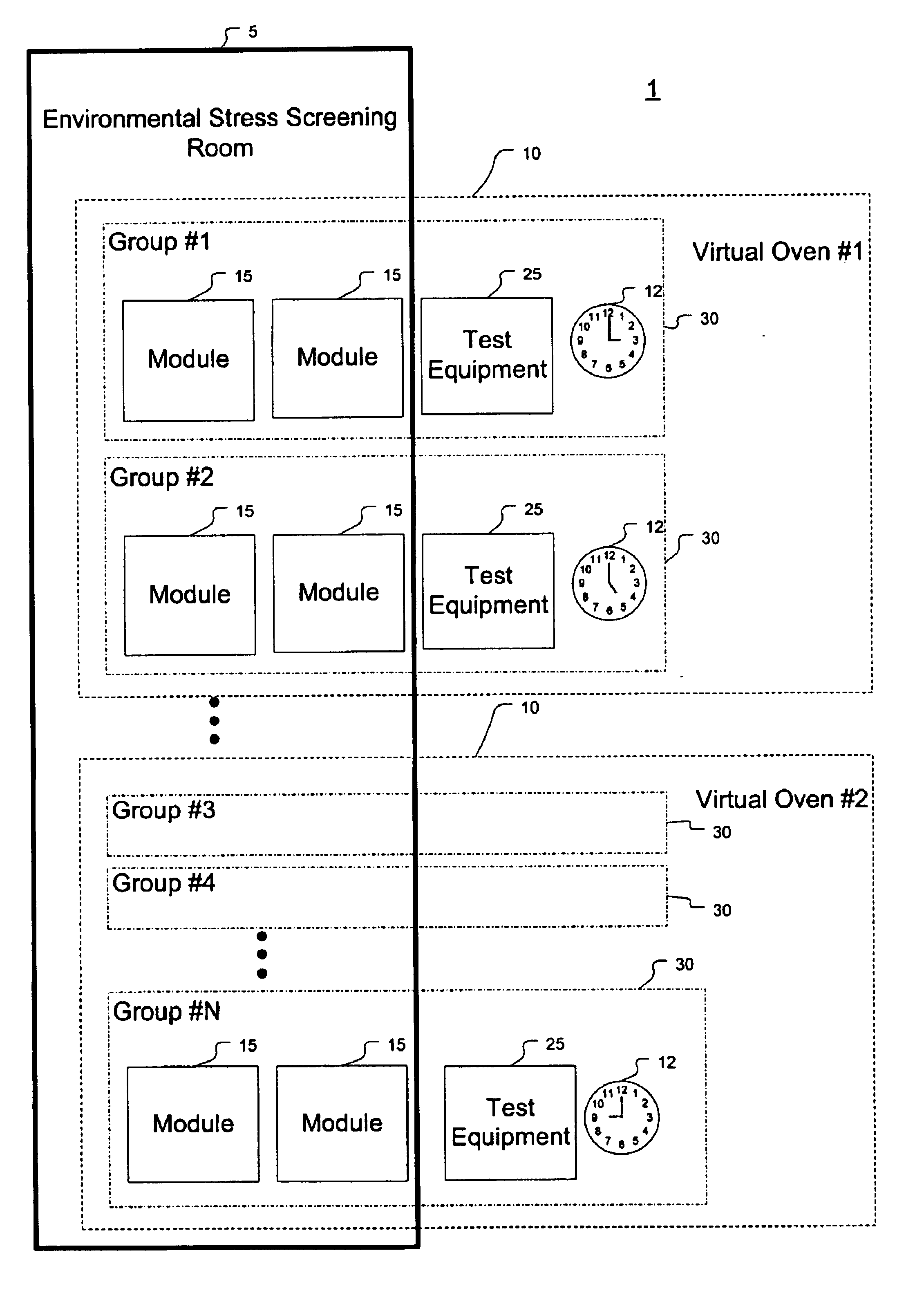

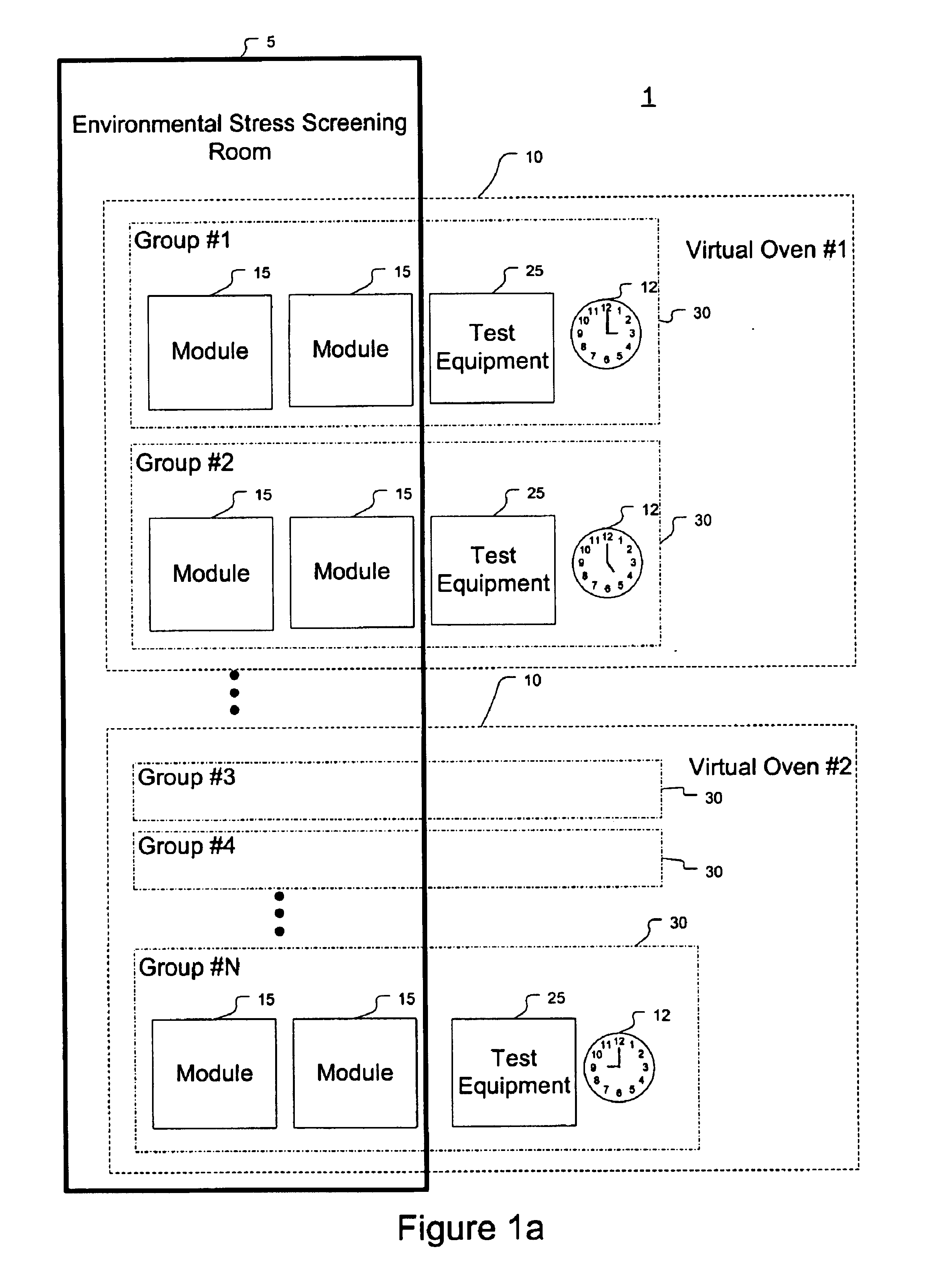

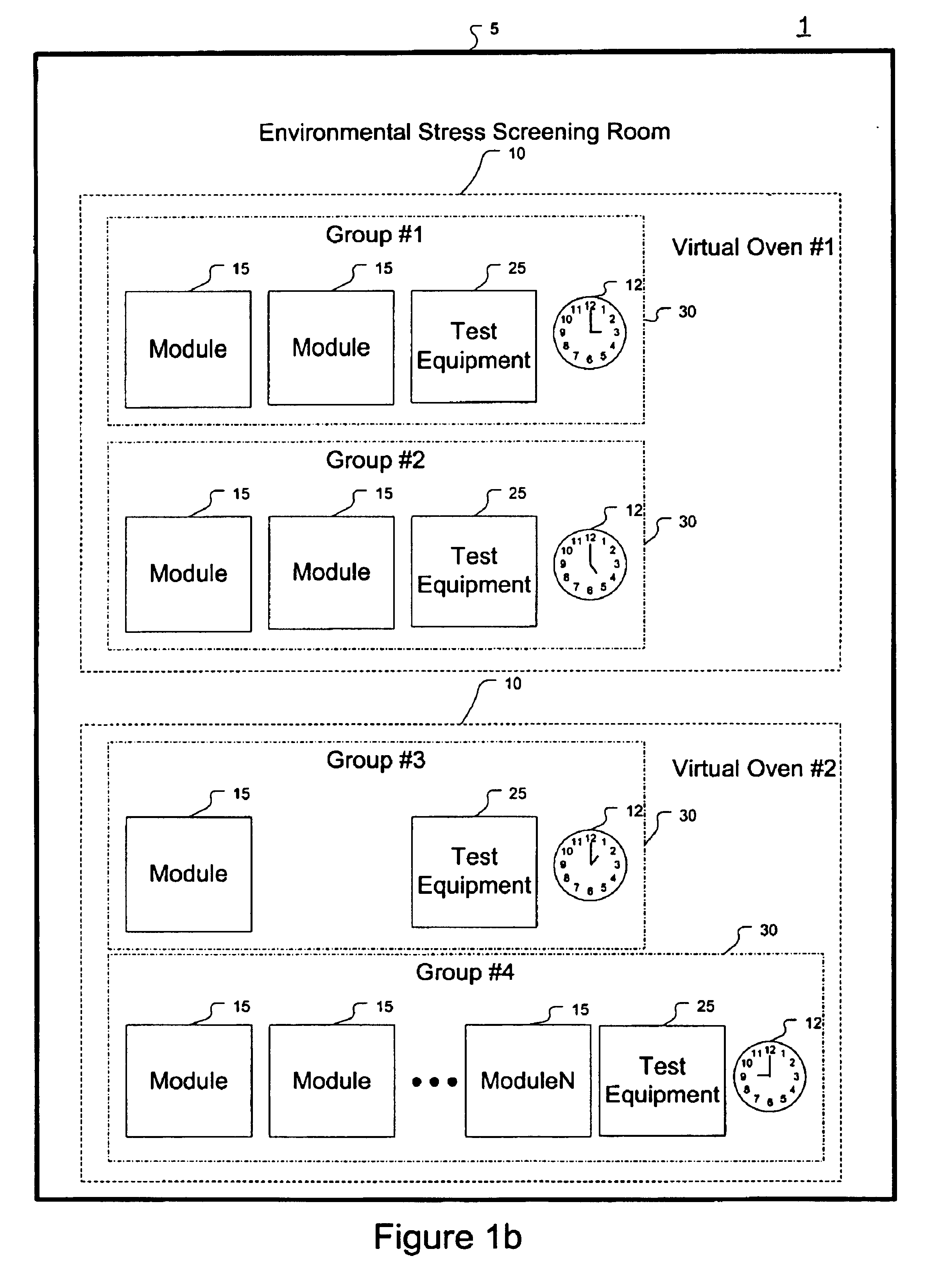

Automated monitoring system, virtual oven and method for stress testing logically grouped modules

InactiveUS20020105355A1Data processing applicationsResistance/reactance/impedenceComputer hardwareNetwork connection

A virtual oven efficiently conducts stress testing of large numbers of modules. The virtual oven includes a logical grouping of modules, a controller, test instruments and a database which are all connected via a network. The logical groupings of modules of several virtual ovens may be physically accommodated within a single environmental stress screening room. Switching between modules in a logical group permits a single test piece of test equipment to be time-shared among the modules in the logical group. The method of bum-in testing a logical group of modules rotates a test sequence, including passive and active test cycles, between the modules. A test signal is split and supplied to multiple modules. Passive testing may be performed by monitoring parameters of the module while the test signal is supplied to the module. Active testing may be a functional test of the module in which the test signal is supplied to, processed by, and output from the module. Such test signals output from the modules are switched to the test equipment on a time-share basis. In this way, the number or expensive test equipment set-ups may reduced. The controller for each virtual oven also generates displays so that a user can track the test progress of all modules within the virtual oven. The controller also builds a database of the active and passive tests for each module. A graphical user interface may be used to interact with the virtual oven, control the testing, and view the database.

Owner:CIENA

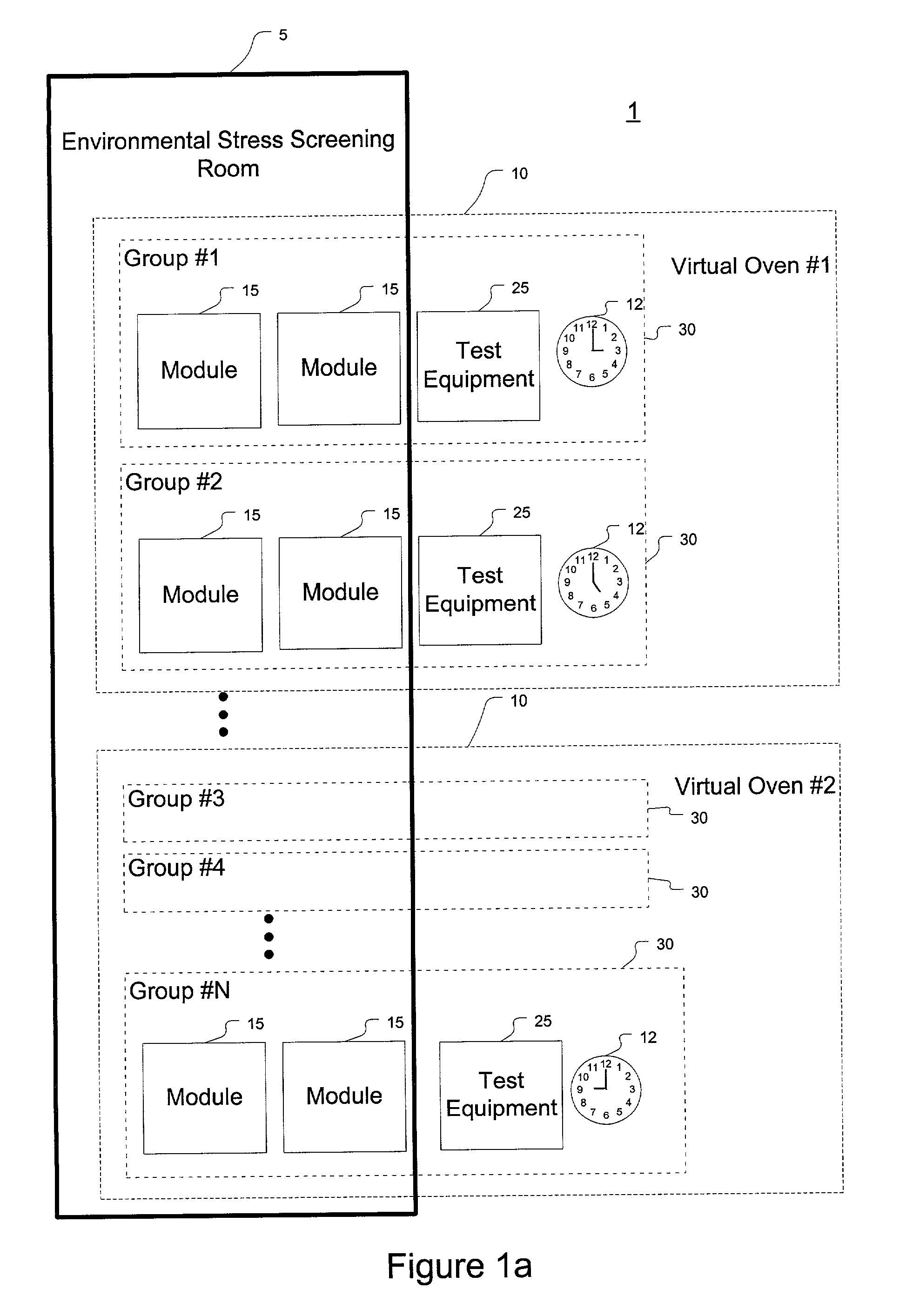

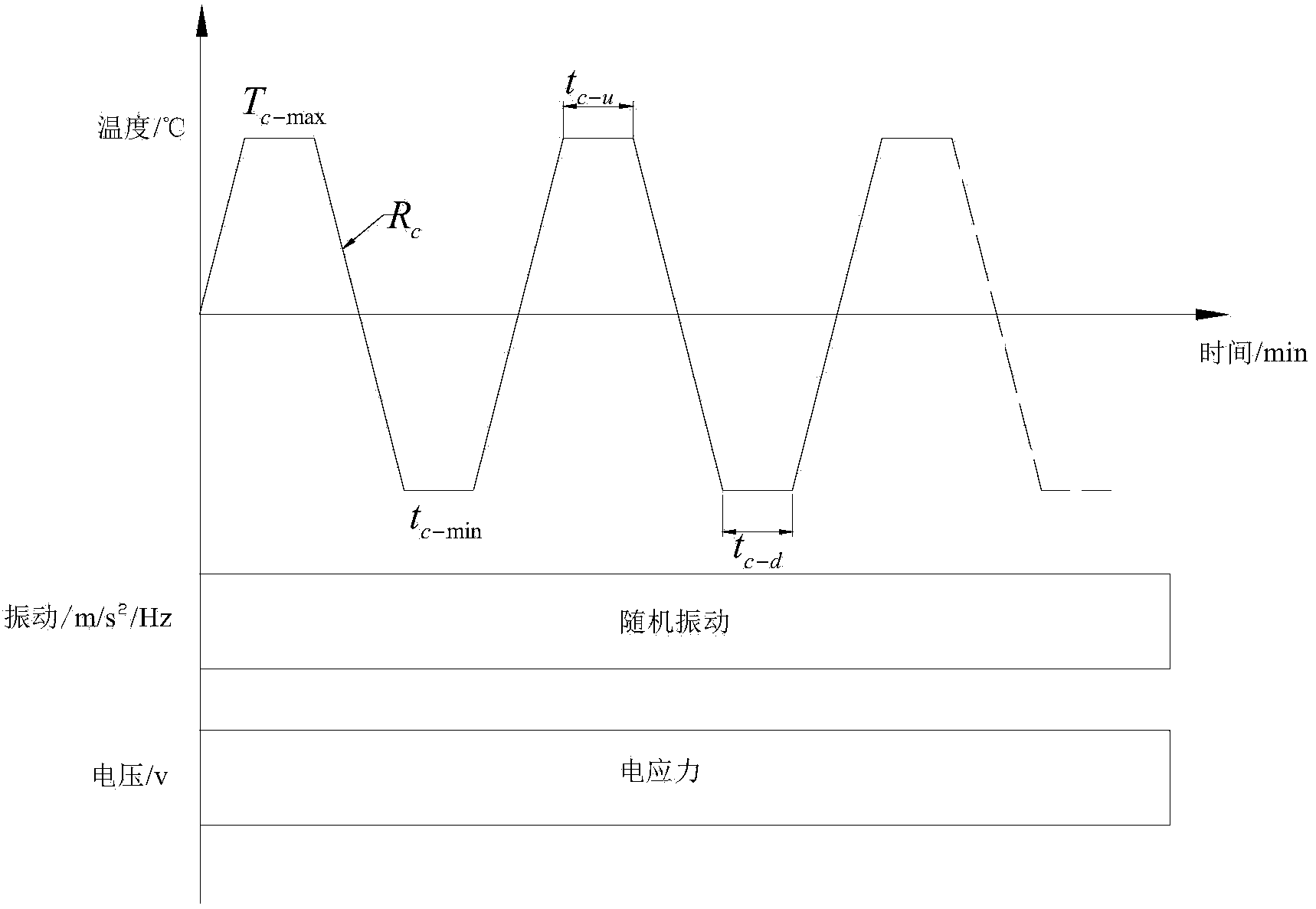

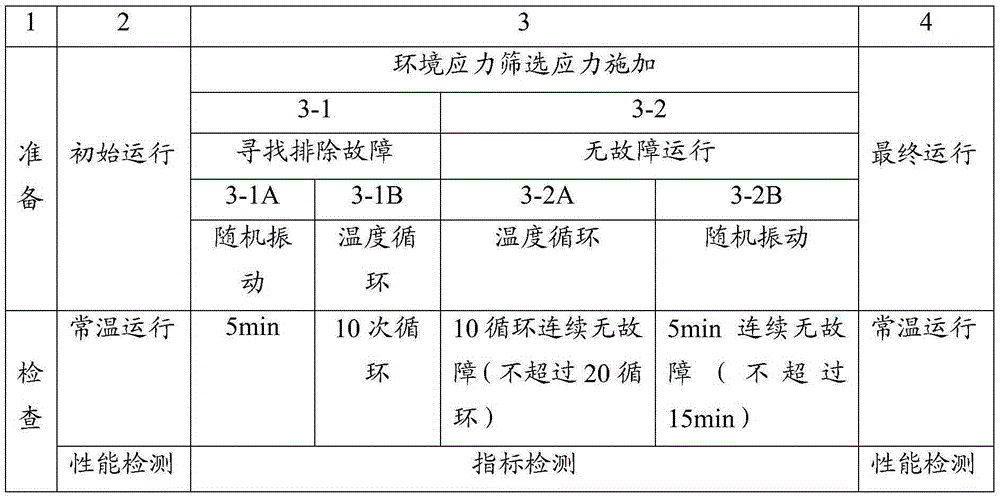

Environmental stress screening method of electronic device by using stepping stress

InactiveCN103852672AImprove effectivenessImprove filtering effectElectrical testingScreening effectScreening method

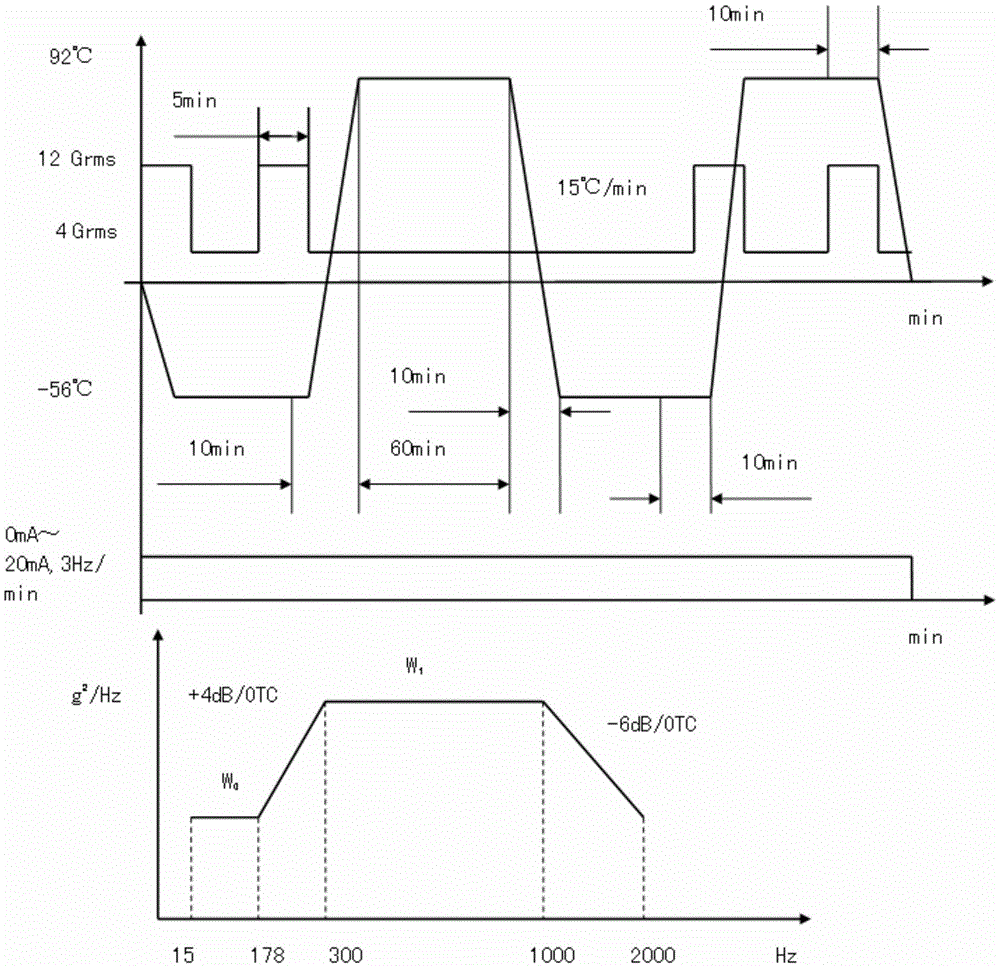

The invention discloses an environmental stress screening method of an electronic device by using stepping stress. A screening system comprises a temperature box, a vibrating table and a test device. According to the method, electronic devices which are invalid early are removed by using stepping stress, and a mode of only exerting constant temperature circulation or constant vibration stress in a previous screen method is changed; meanwhile, a combined stress screening method is firstly adopted. By exerting environment screening stress of stepping stress and combined stress to the electronic device, the screening validity and the screening effect of environmental stress are effectively increased. The environmental stress screening method is successfully implemented in a product of a certain type, the delivered electronic device passes the check of actual application, which proves the validity and the applicability of the control method; thus, the environmental stress screening method has strong generalization performance during the production process of electronic devices.

Owner:中国航天科工运载技术研究院北京分院

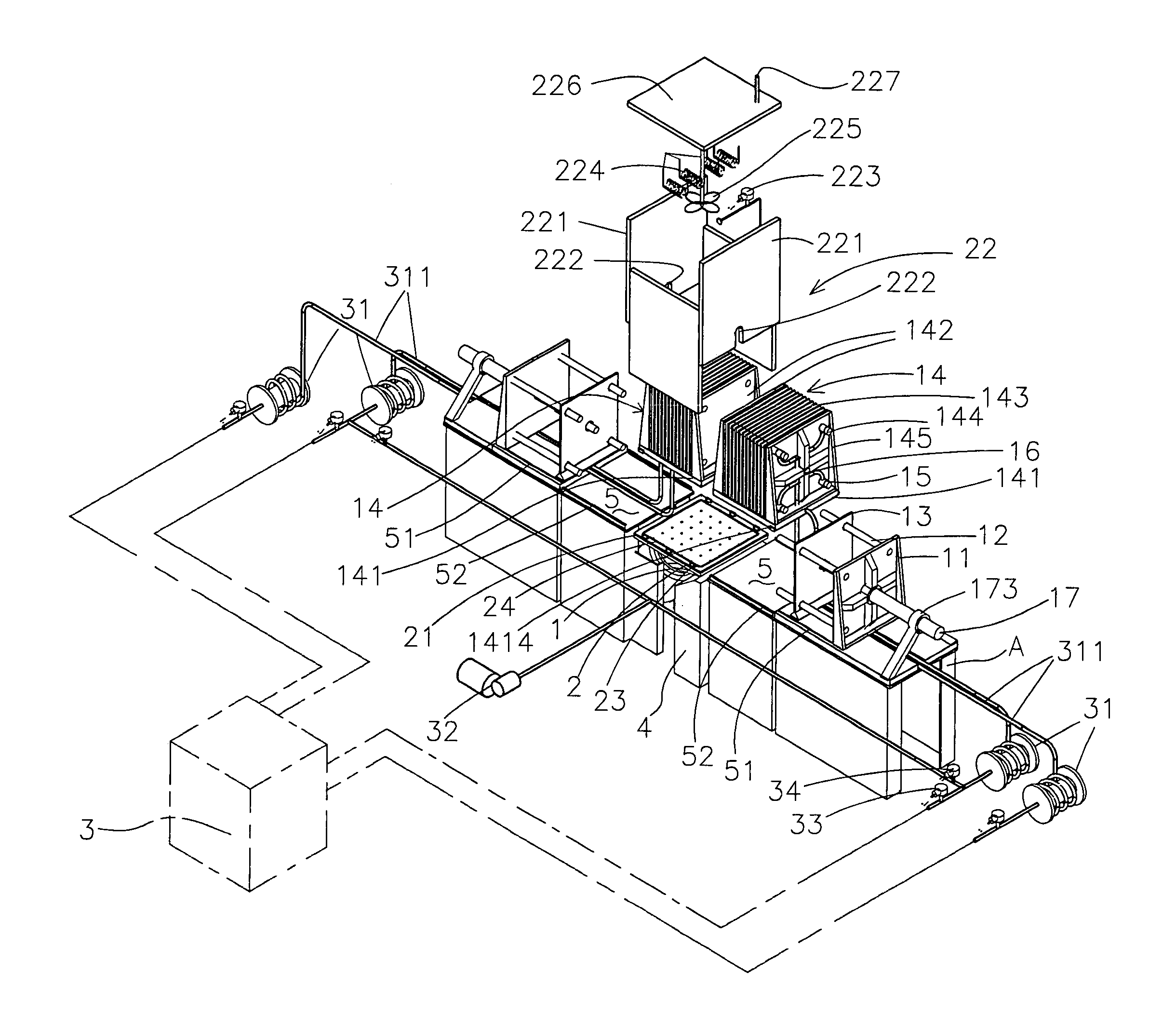

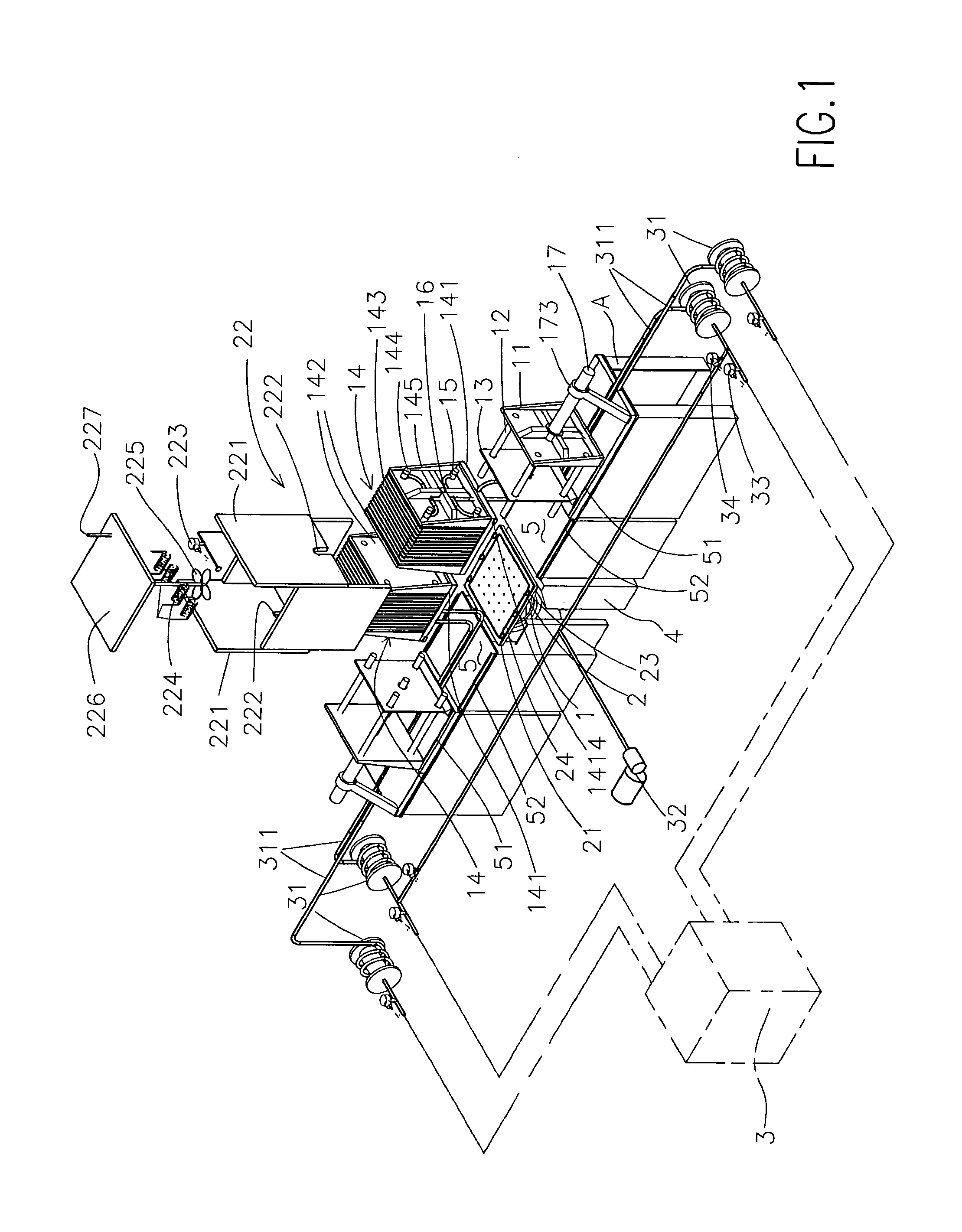

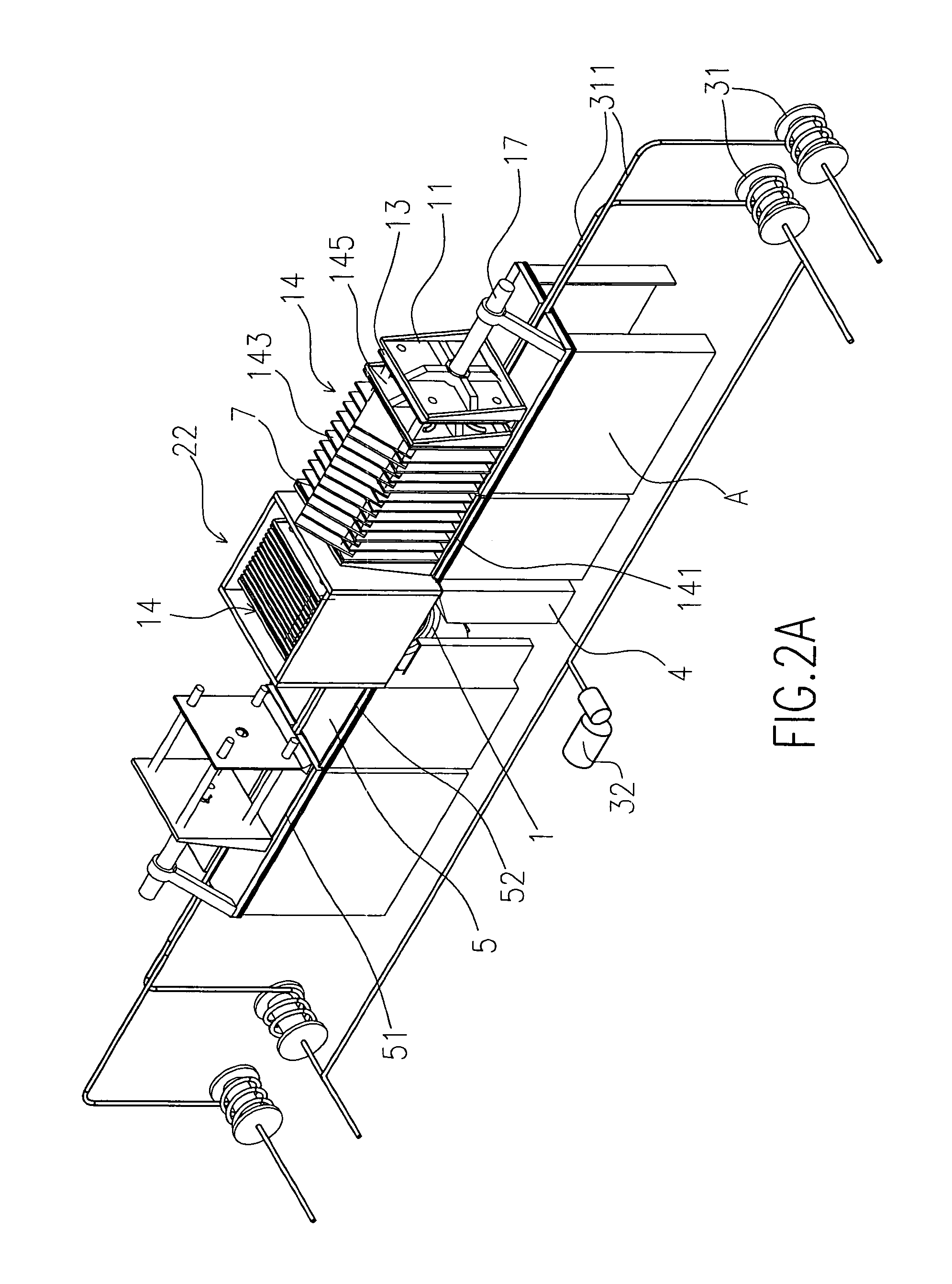

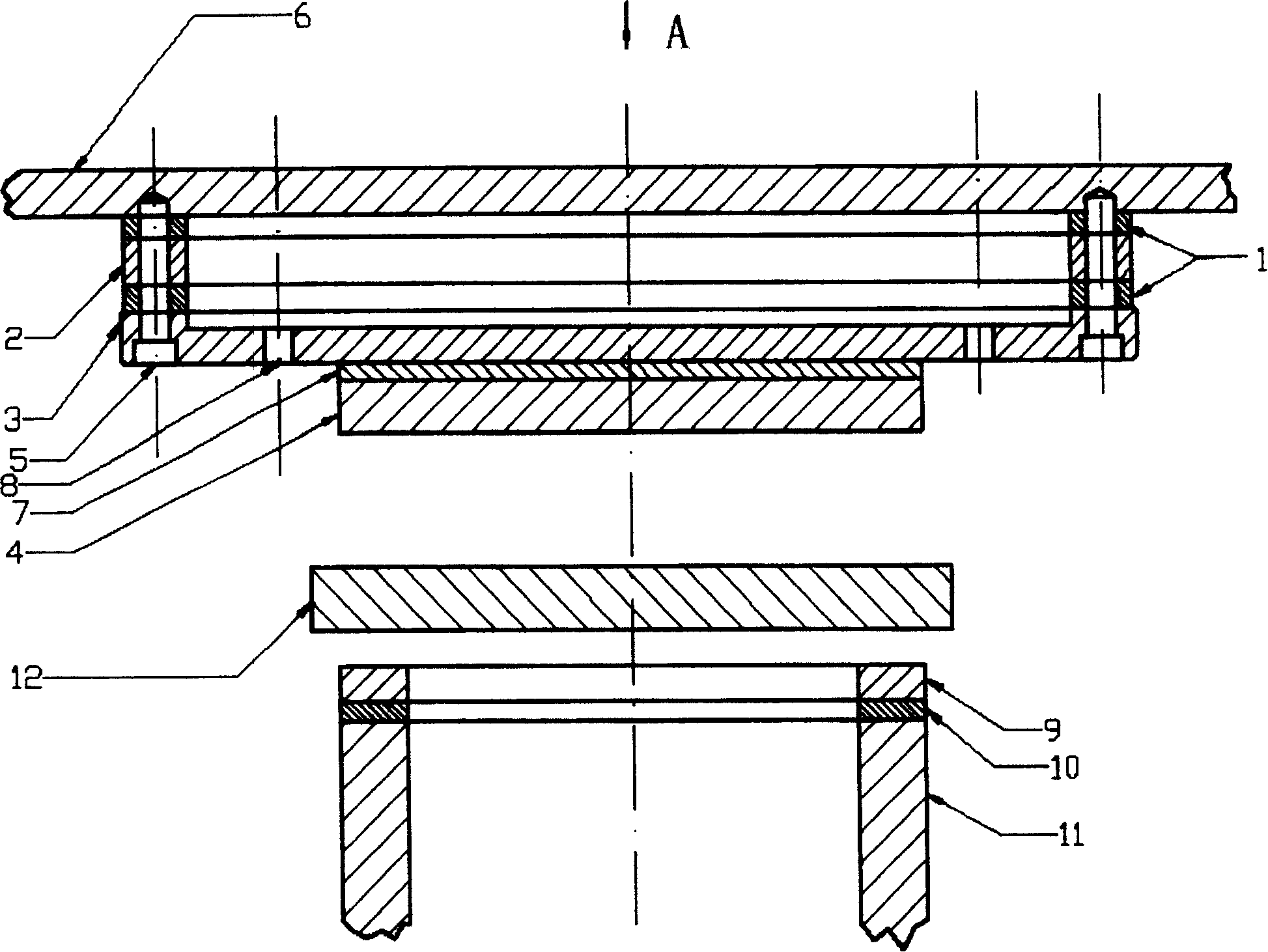

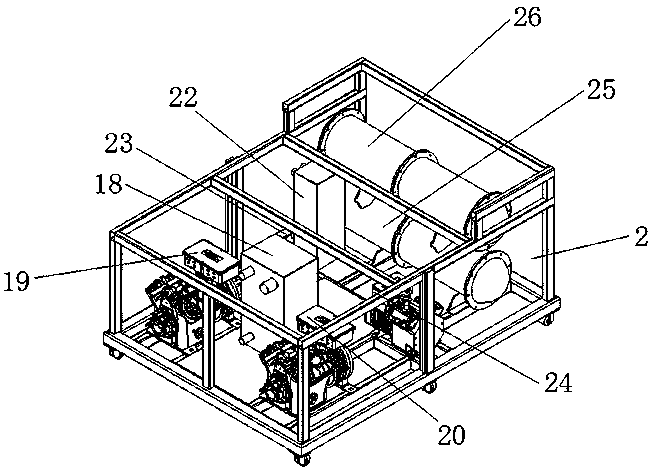

Production line environmental stress screening system

InactiveUS7015712B1Low costShorten the timeFault location by increasing destruction at faultOhmic-resistance heatingProduction lineEngineering

A production line environmental stress screening system consists of a shaker, a head expander, a fast ramping temperature chamber, two transporting trays, two PCB according fixture assemblies, a vacuum pump, a compressed air system, and a base table. The two PCB according fixture assemblies move back and forth and alternately enter the fast ramping temperature chamber to receive vibration and high and low temperature screening. This system will greatly reduce the screening time required, drastically increase the production efficiency and significantly reduce the screening cost.

Owner:LIU HONG SUN

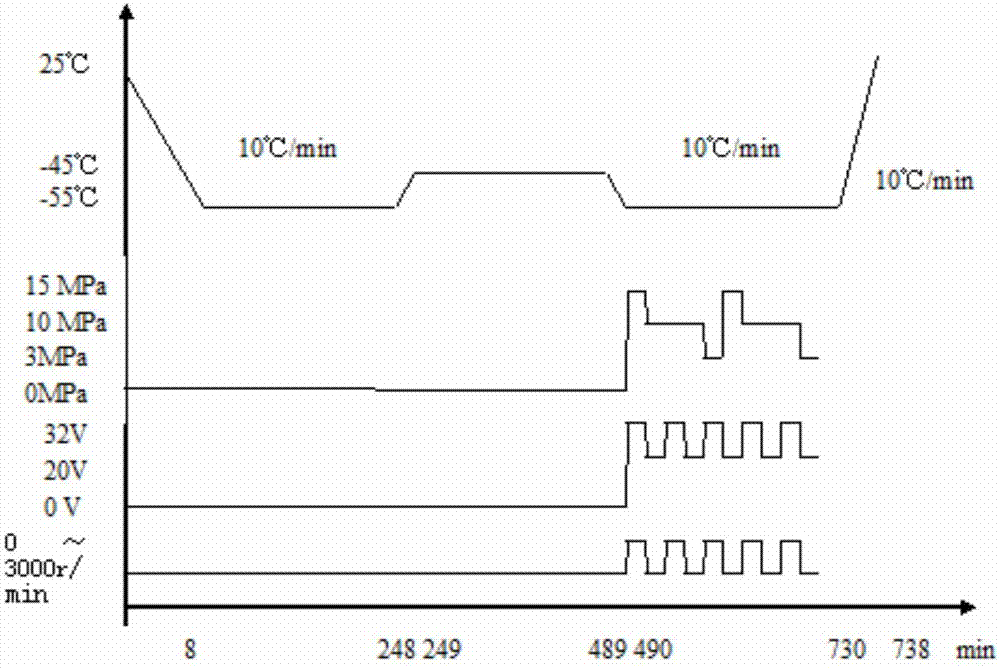

BGA (ball grid array) welding point acceleration service life prediction method

ActiveCN104344988AGet Predicted LifespanThe test method is simple and reliableStrength propertiesAcceleration factorMechanical equipment

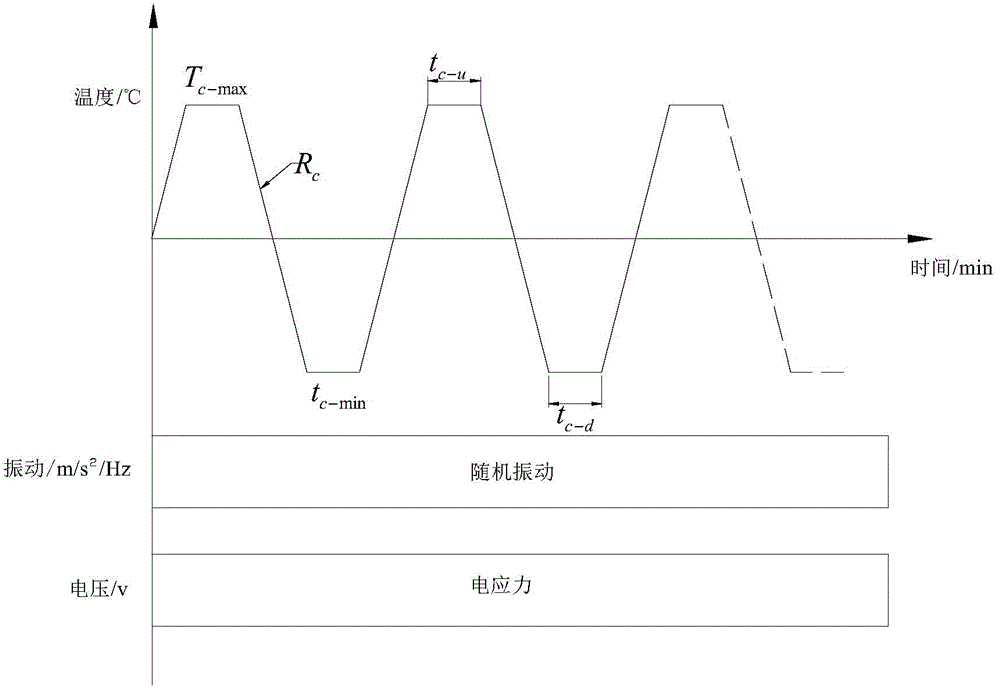

The invention relates to a BGA (ball grid array) welding point acceleration service life prediction method, which comprises the following steps that (a) n BGA welding point samples are randomly selected, wherein the n is greater than or equal to 5, and the BGA welding point samples are subjected to environment stress screening processing; (b) the samples processed in the step (a) are subjected to integral stress processing, and the integral stress processing comprises second temperature circulation processing, random vibration processing and electric stress processing on the samples processed in the step (a), and in addition, the sample failure time is recorded; (c) the samples processed in the step (b) are subjected to third temperature circulation processing; (d) a model shown in a formula (III) is used for calculating an acceleration factor, and finally, a formula (IV) is used for calculating the use average failure before time MTTR<use> for predicting the service life of the BGA welding point. The invention also provides application of the method to the preparation of electronic products and mechanical equipment.

Owner:ZHUZHOU CSR TIMES ELECTRIC CO LTD

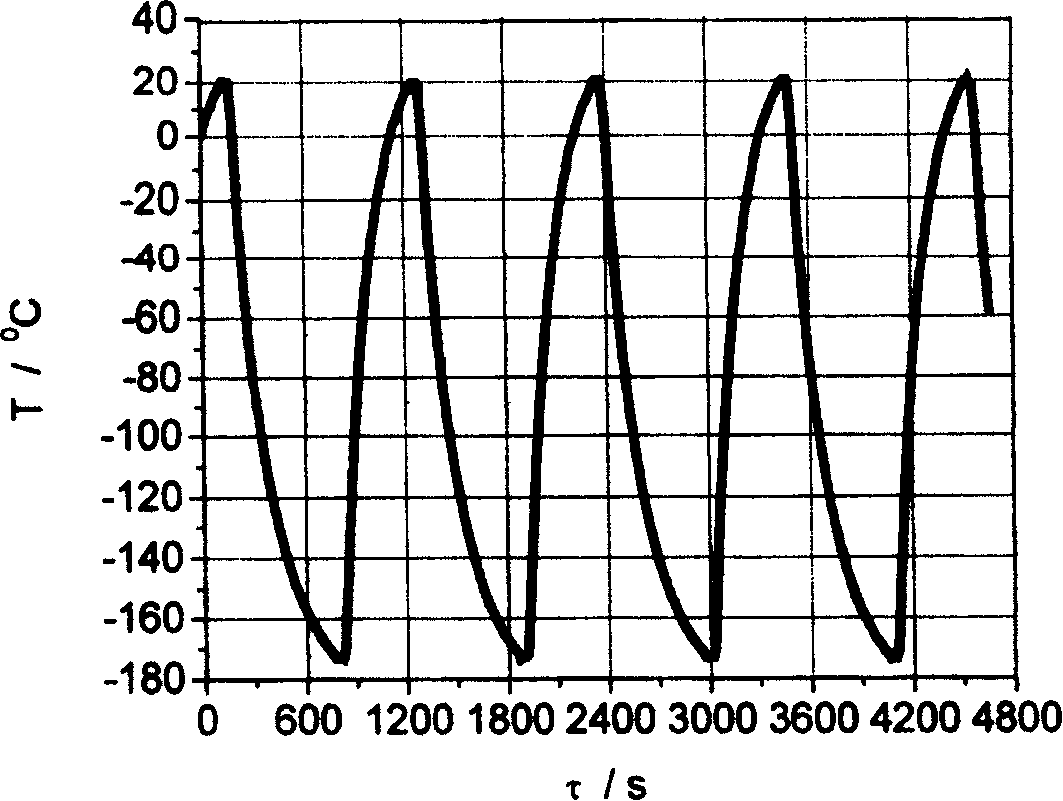

High and low temperature recycle unit with wide temperature range

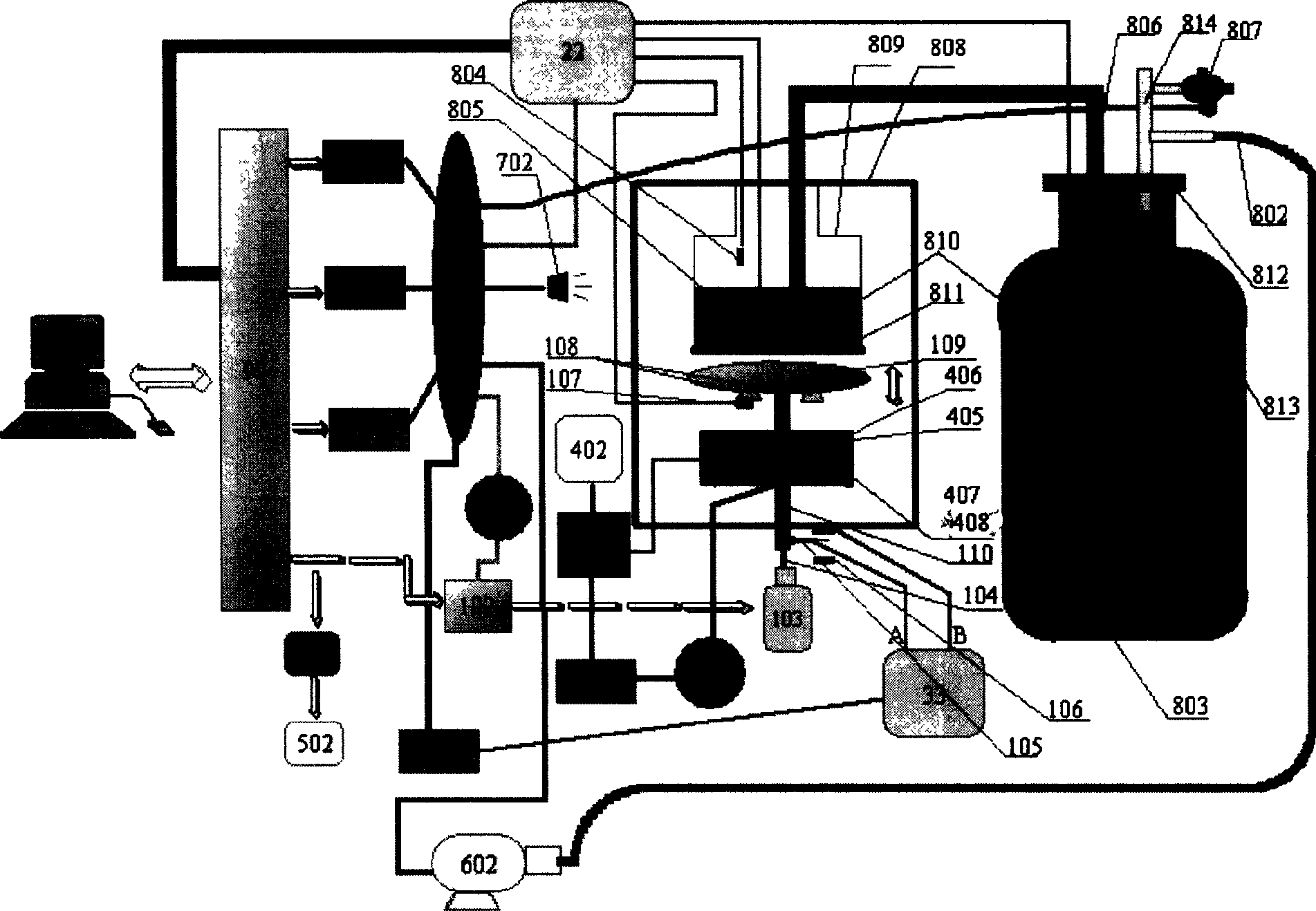

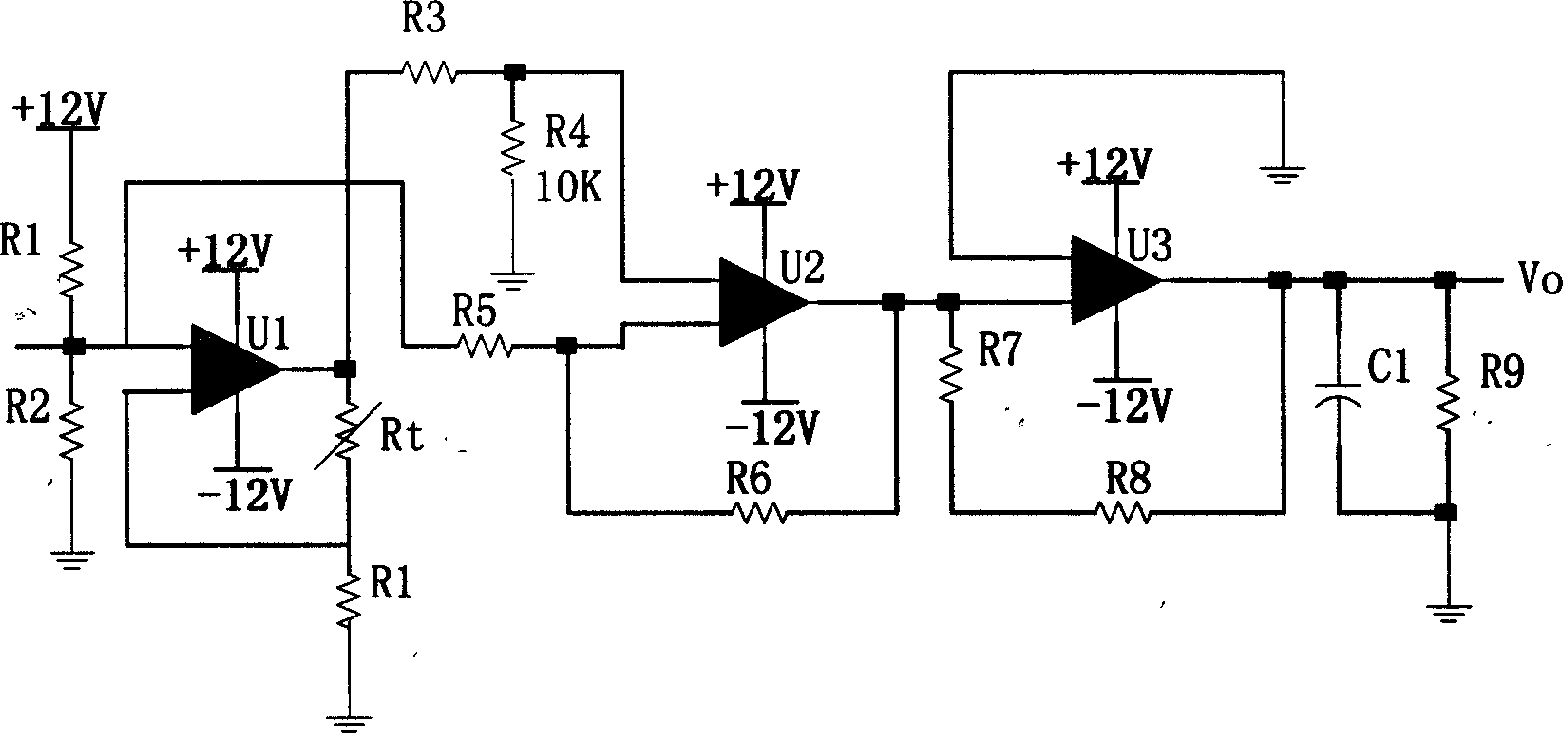

InactiveCN1603778AAvoid lostFully automatedThermometers using electric/magnetic elementsCompression machinesEngineeringS system

It is temperature recycle apparatus from high to low with large temperature range, which is main applied in man-made satellite infrared detector environment strain filtering. The apparatus comprises one main system, a slave system and a PC machine. The main system is responsible for temperature recycle and its control, while the slave system is for automatic compensation of liquid nitrogen of the cold environment of main system. The apparatus can record heat environment temperature and display the recycle times on the control panel.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

Automated monitoring system, virtual oven and method for stress testing logically grouped modules

InactiveUS6766267B2Data processing applicationsResistance/reactance/impedenceComputer hardwareNetwork connection

A virtual oven efficiently conducts stress testing of large numbers of modules. The virtual oven includes a logical grouping of modules, a controller, test instruments and a database which are all connected via a network. The logical groupings of modules of several virtual ovens may be physically accommodated within a single environmental stress screening room. Switching between modules in a logical group permits a single test piece of test equipment to be time-shared among the modules in the logical group. The method of bum-in testing a logical group of modules rotates a test sequence, including passive and active test cycles, between the modules. A test signal is split and supplied to multiple modules. Passive testing may be performed by monitoring parameters of the module while the test signal is supplied to the module. Active testing may be a functional test of the module in which the test signal is supplied to, processed by, and output from the module. Such test signals output from the modules are switched to the test equipment on a time-share basis. In this way, the number or expensive test equipment set-ups may reduced. The controller for each virtual oven also generates displays so that a user can track the test progress of all modules within the virtual oven. The controller also builds a database of the active and passive tests for each module. A graphical user interface may be used to interact with the virtual oven, control the testing, and view the database.

Owner:CIENA

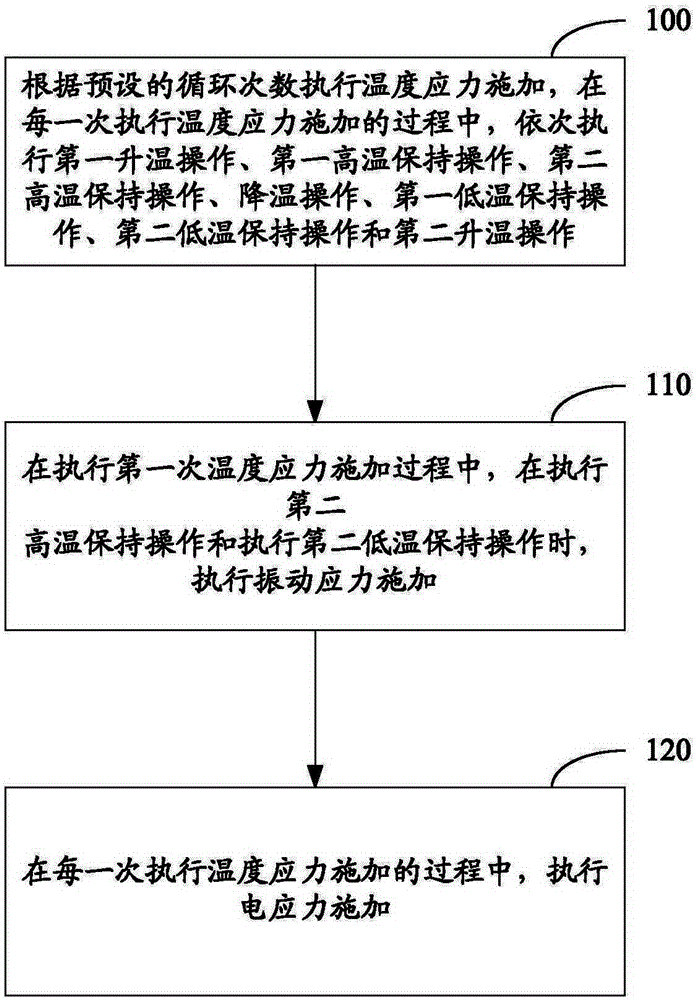

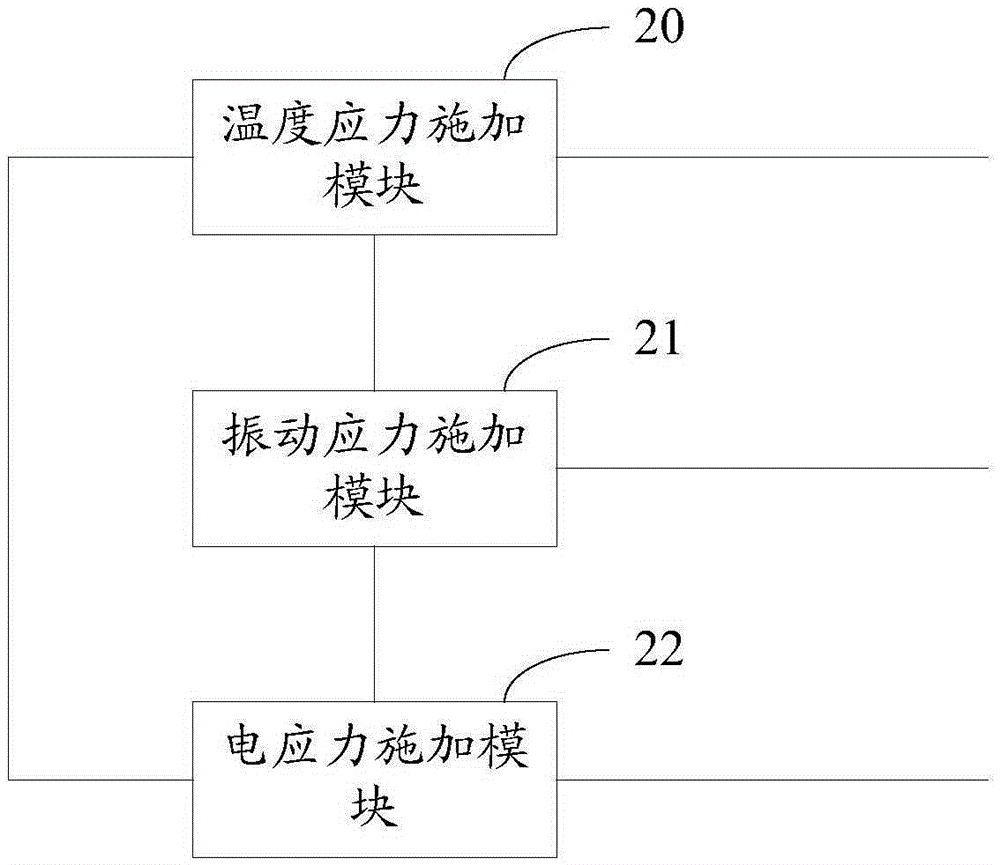

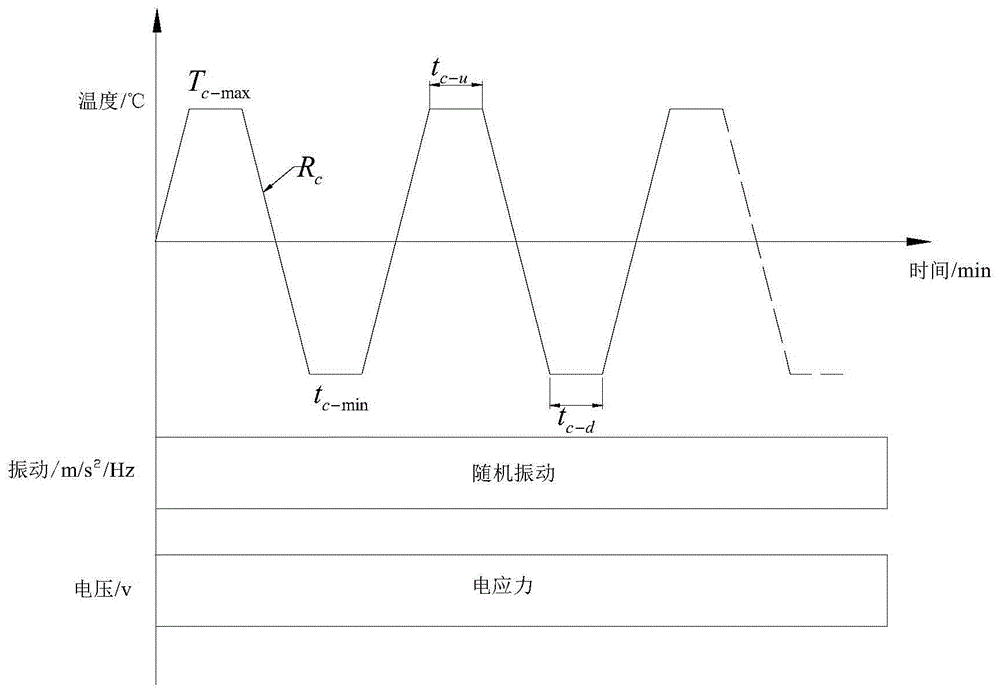

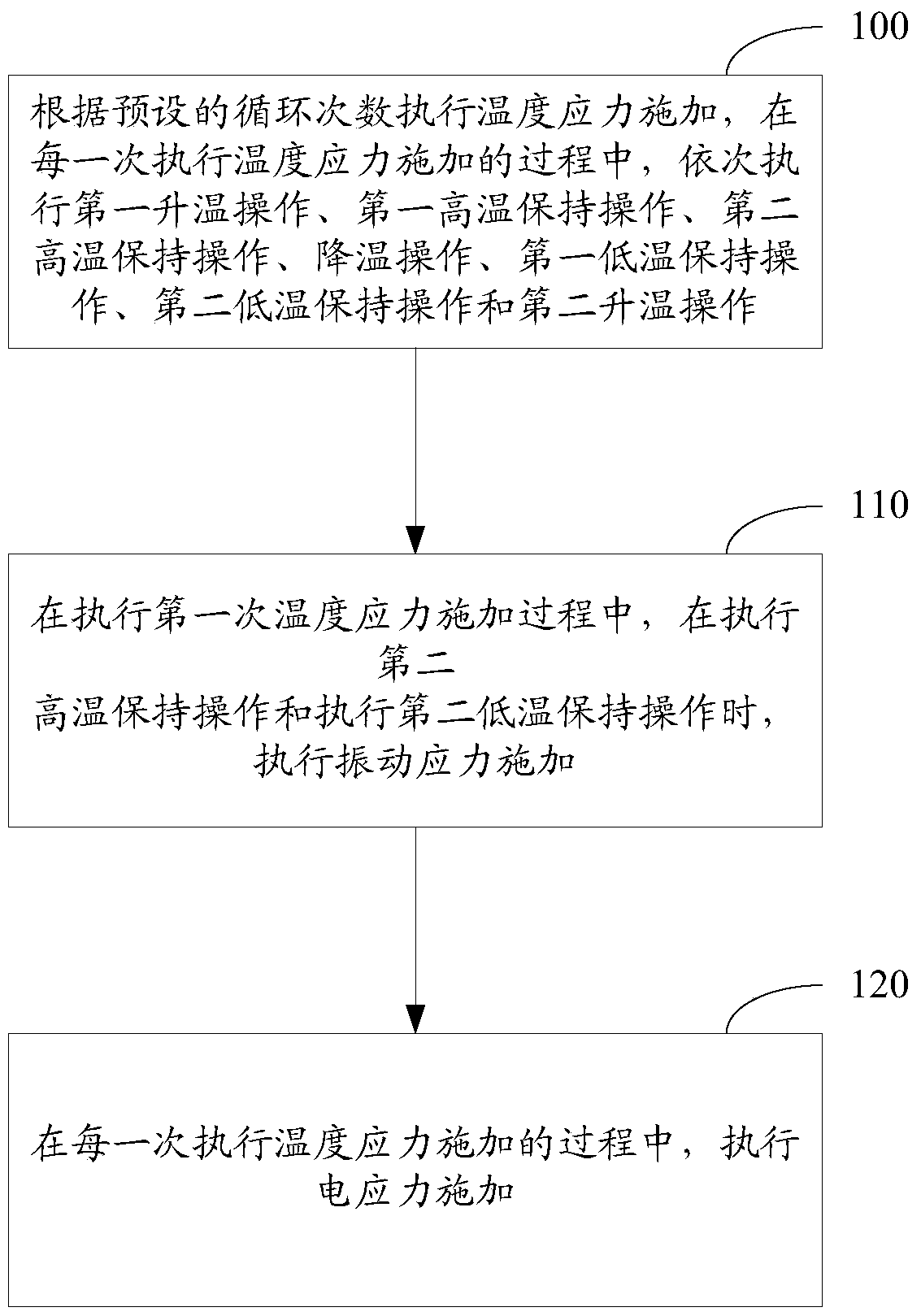

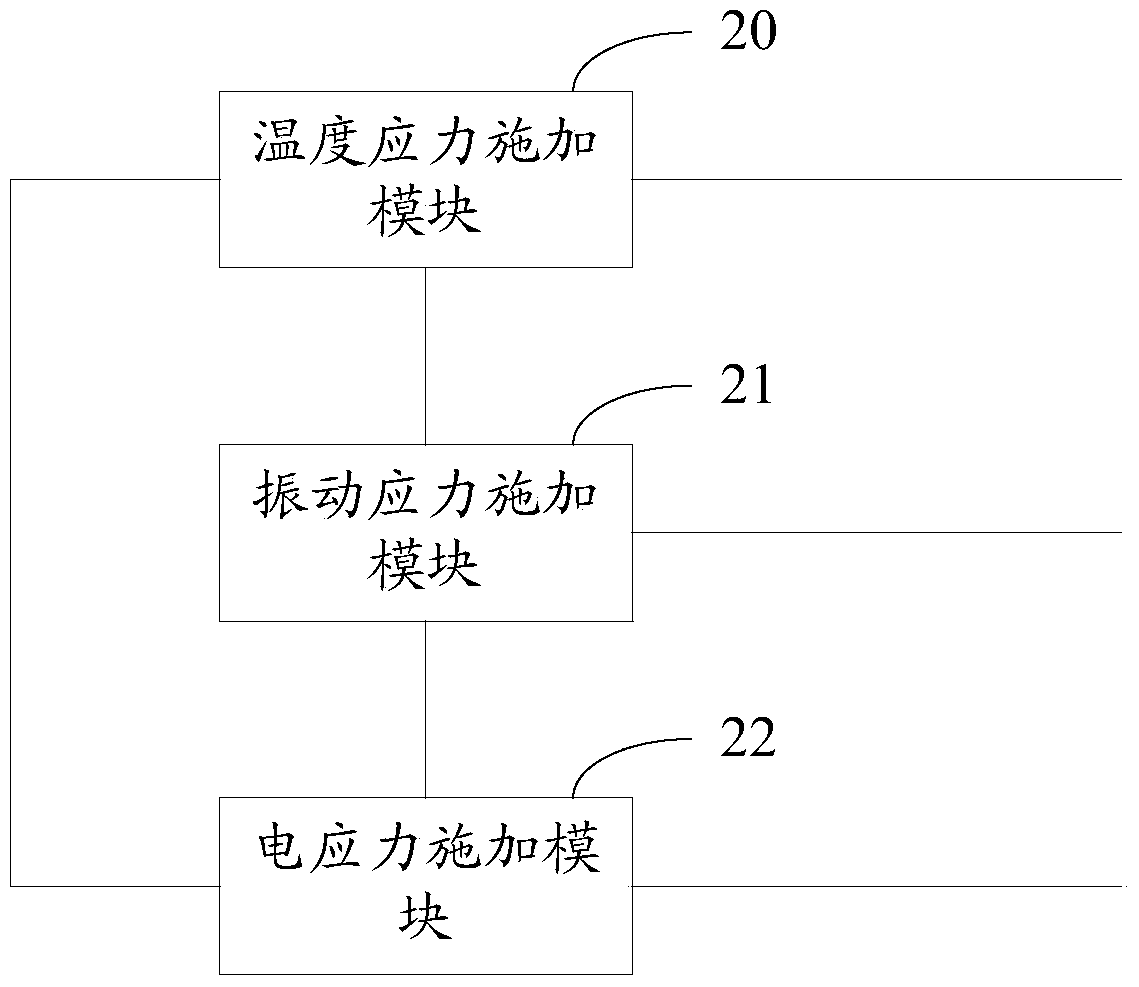

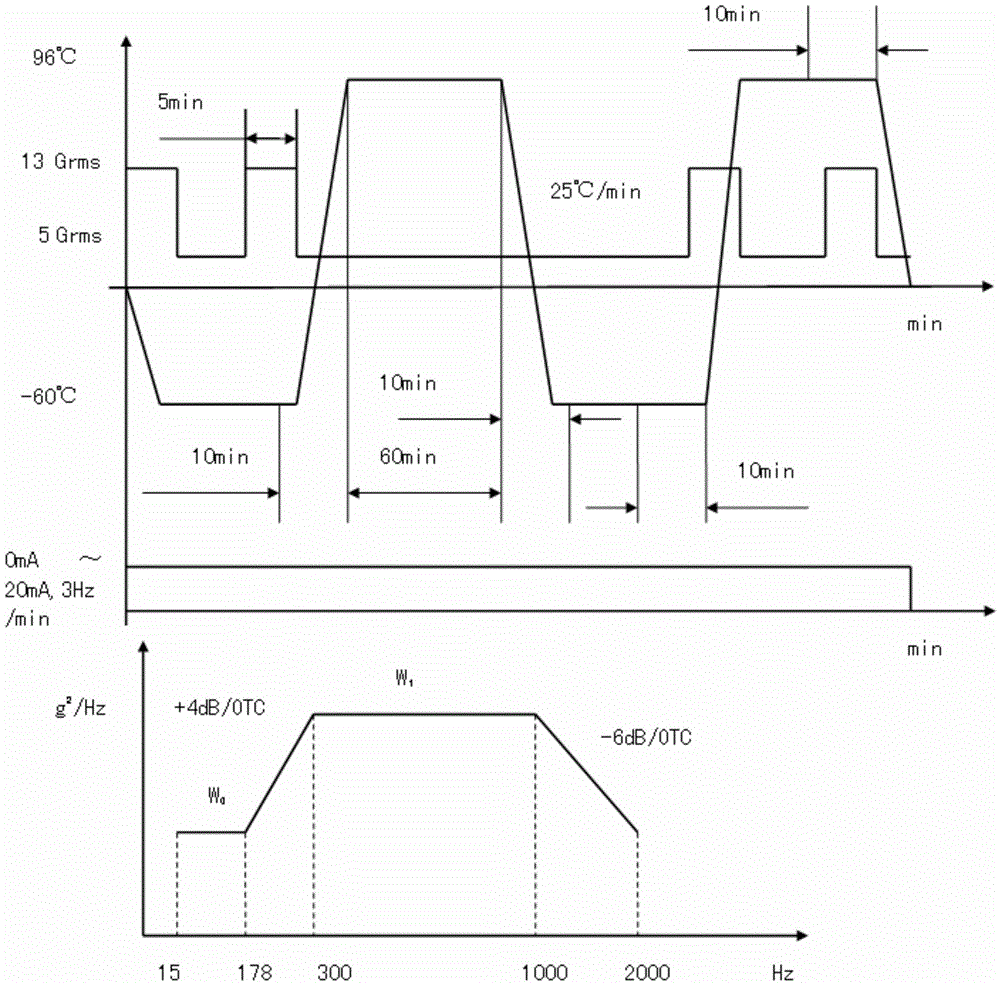

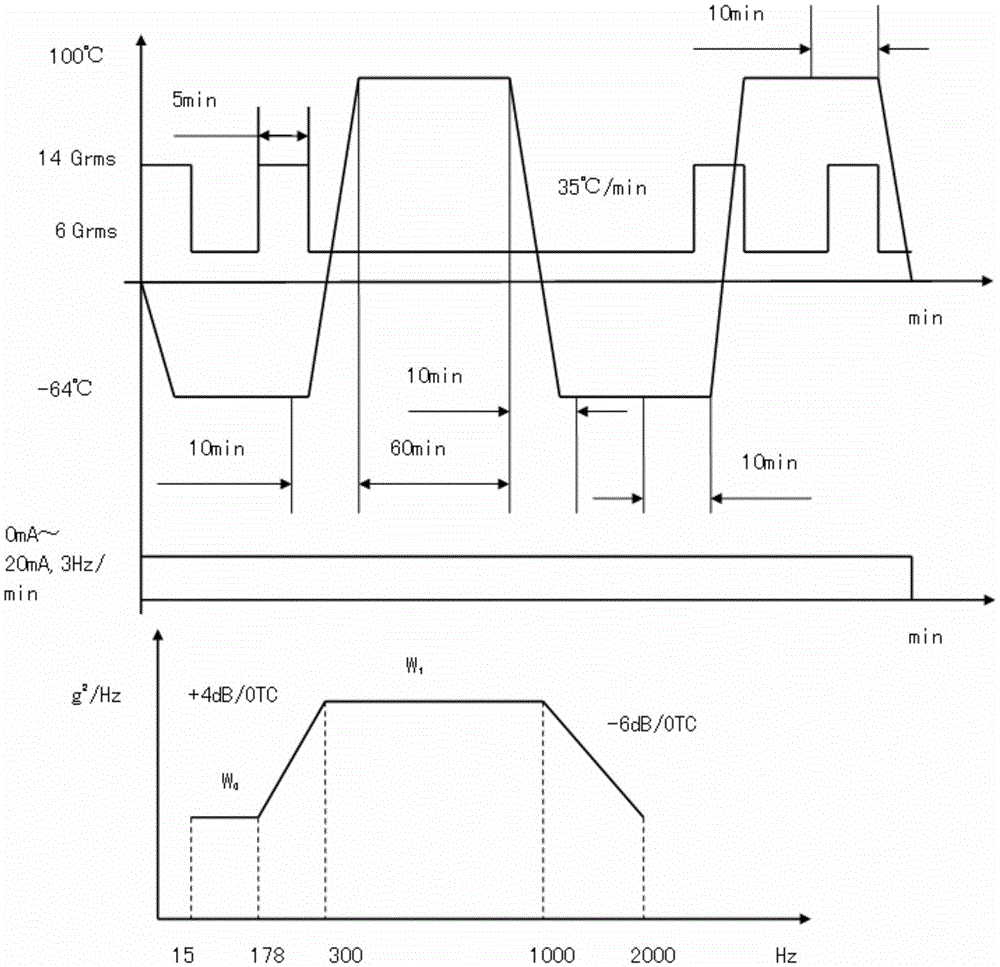

Environmental stress screening test method and device

The invention discloses an environmental stress screening test method and device, and aims at improving timeliness and effectiveness of environmental stress screening test. The method comprises that temperature stresses are applied according to a preset cycle index, and each time the temperature stress is applied, a first heating operation, a first high temperature maintaining operation, a second high temperature maintaining operation, a cooling operation, a first low temperature maintaining operation, a second low temperature maintaining operation and a second heating operation are executed successively; when the temperature stress is applied for the first time, a vibration stress is applied while the second high temperature maintaining operation and the second low temperature maintaining operation are executed; and each time the temperature stress is applied, an electric stress is applied. Thus, the environmental stress screening test can be completed in one test with once establishment of a test environment, three types of stresses are applied at the same time, defects in an integrated stress state can be screened, and the test timeliness and effectiveness are improved.

Owner:DATANG MOBILE COMM EQUIP CO LTD

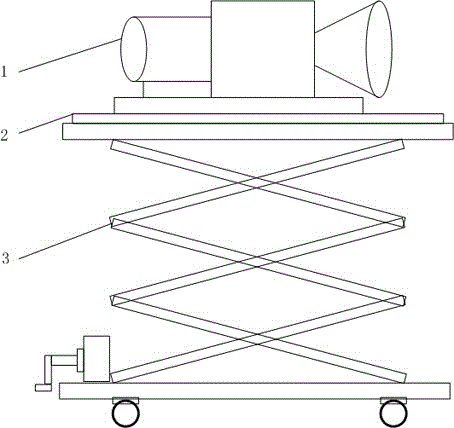

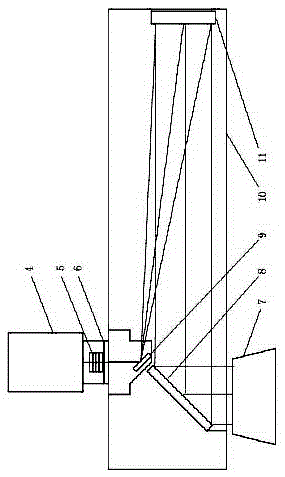

Mid-range infrared target simulator equipment

InactiveCN106839878AGuaranteed alignmentEasy position adjustment and lockingAiming meansUltrasound attenuationSimulation

The invention provides mid-range infrared target simulator equipment. A modular combined structure is adopted, and the mid-range infrared target simulator equipment is mainly composed of an infrared optical system, a one-dimensional rotating platform system, a lifting mechanism and the like, wherein the infrared optical system comprises a black body, an adjustable diaphragm, an adjustable attenuation slice, a collimator assembly, a light-shading hood and the like, horizontal rotating and locating of a platform within a certain range are achieved through the one-dimensional rotating platform system, and the accuracy is 0.1 degree, and the lifting mechanism mainly completes overall up-and-down rising and falling of the equipment and achieves whole-distance fine tuning and the self-locking function; and moving rolling wheels and a fixed mechanism are designed on the bottom face of the equipment, and moving and transporting and the testing stability requirement of the equipment are achieved. The mid-range infrared target simulator equipment has the advantages of being convenient and easy to use, attraction in equipment, easy to maintain, long in service life and the like, and infrared target simulation in certain-type mid-range infrared guidance missile vibration environment stress screening tests is successfully achieved.

Owner:SHANGHAI INST OF ELECTROMECHANICAL ENG

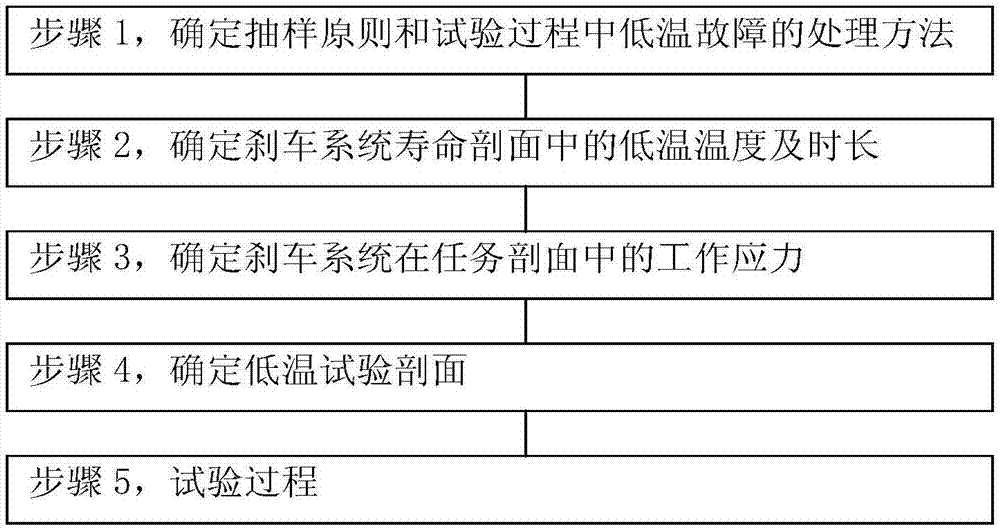

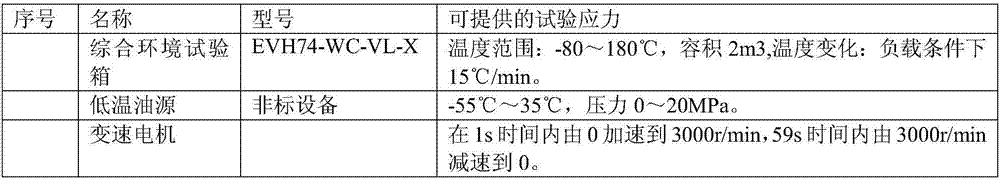

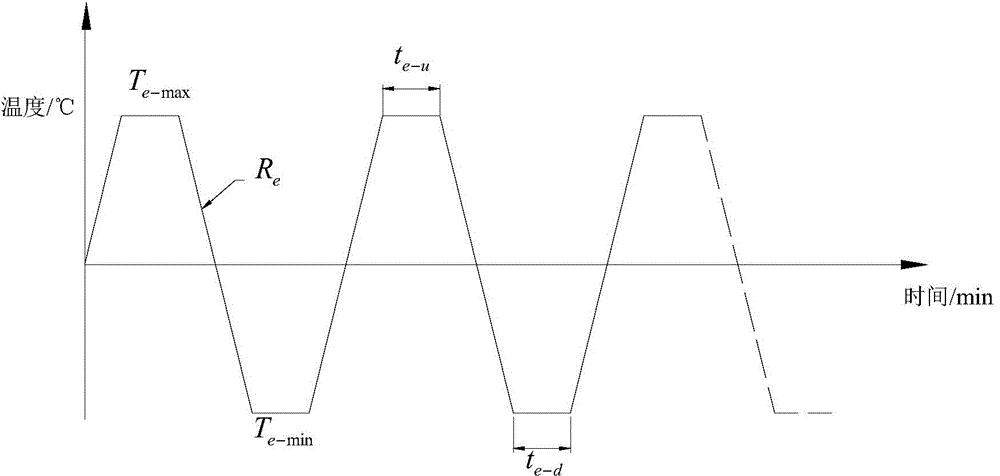

Aircraft brake system low temperature test method

InactiveCN107389322ASuitable for low temperature failure hazardsMake up for limitationsMachine part testingEngineeringAir temperature

The invention provides an aircraft brake system low temperature test method, and aims at exciting the low temperature fault hidden trouble of a brake system in the service life. The test time is determined according to the low temperature time in the life requirement, the test low temperature value is determined according to the low temperature value in the service life and all the products of the brake system are installed in a low temperature test box according to the system connection mode, and low temperature hydraulic oil is piped into the brake system under the condition that the temperature is low temperature. A low temperature test profile is determined according to the low temperature test time and the low temperature value. The low temperature test profile meets the low temperature condition in use. The aircraft brake system low temperature test method is suitable for exciting the low temperature fault hidden trouble of the brake system in the service life so that the limitation of environment stress screening can be compensated, the test period can be shortened and the test cost can be reduced.

Owner:XIAN AVIATION BRAKE TECH

Environmental stress screening method for BGA (ball grid array) welding spots

InactiveCN104360187APredicted Lifespan AcquisitionThe test method is simple and reliableElectrical testingElectric stressMechanical equipment

The invention relates to an environmental stress screening method for BGA (ball grid array) welding spots. The environmental stress screening method includes steps of a), randomly selecting n BGA welding spot samples and carrying out environmental stress screening processing on the BGA welding spot samples; b), carrying out comprehensive stress processing on the samples processed in the step a), to be more specific, carrying out second temperature cycle processing, random vibration processing and electric stress processing on the samples processed in the step a), recording failure time of the samples, and screening the BGA welding spots according to mean processing time to failure. The n is larger than or equal to 5. The invention further provides application of the method to manufacturing electronic products and mechanical equipment.

Owner:ZHUZHOU CSR TIMES ELECTRIC CO LTD

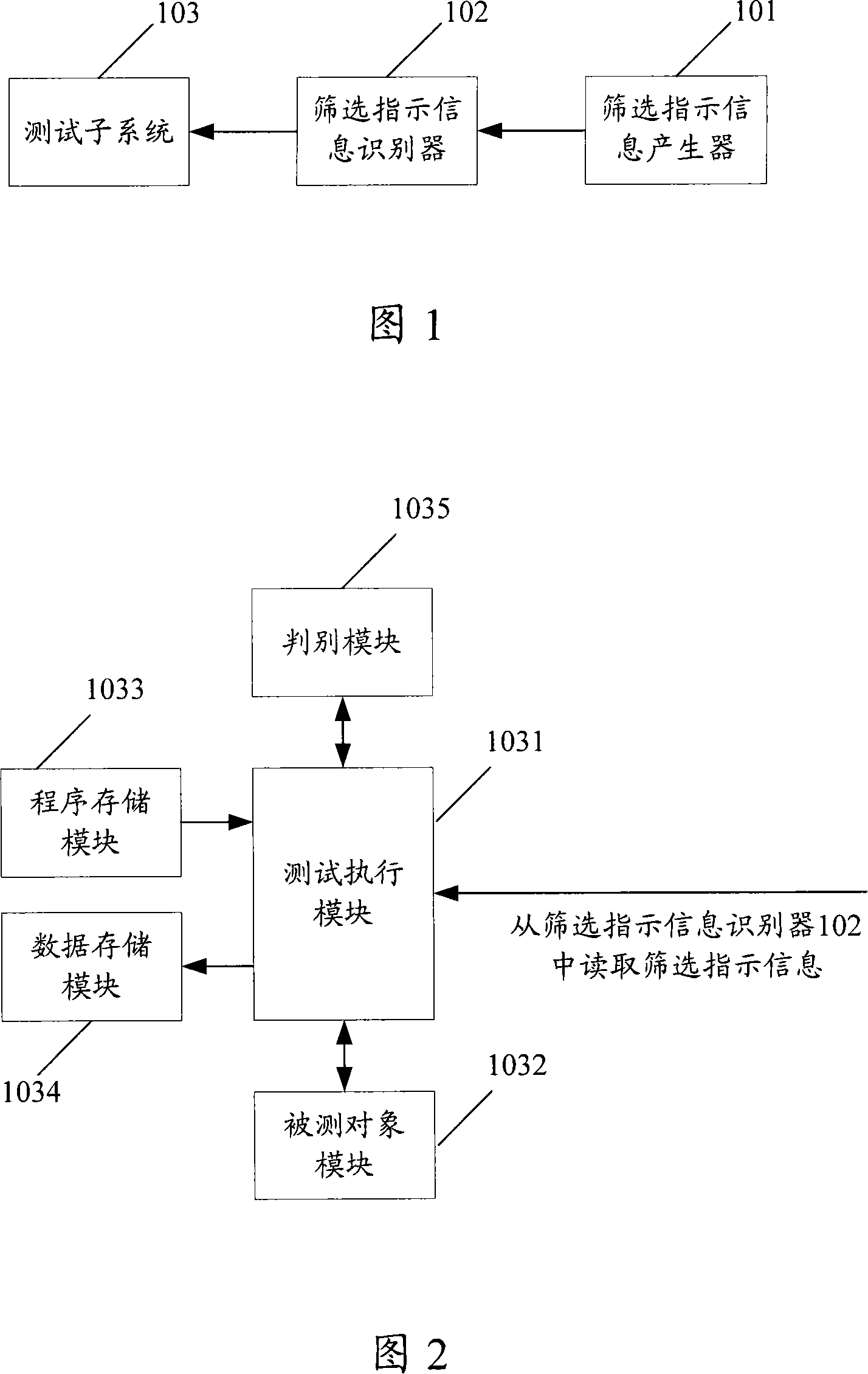

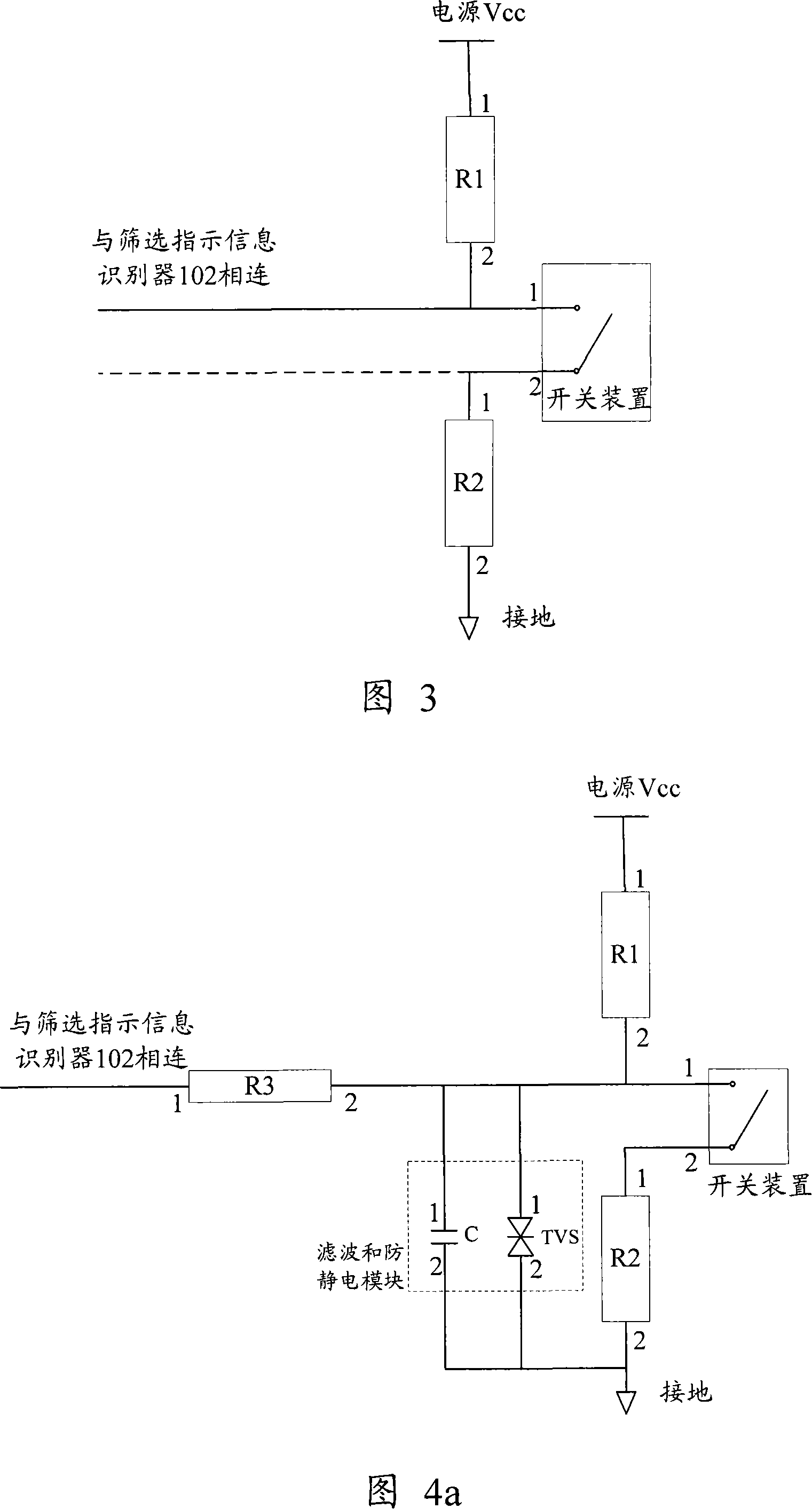

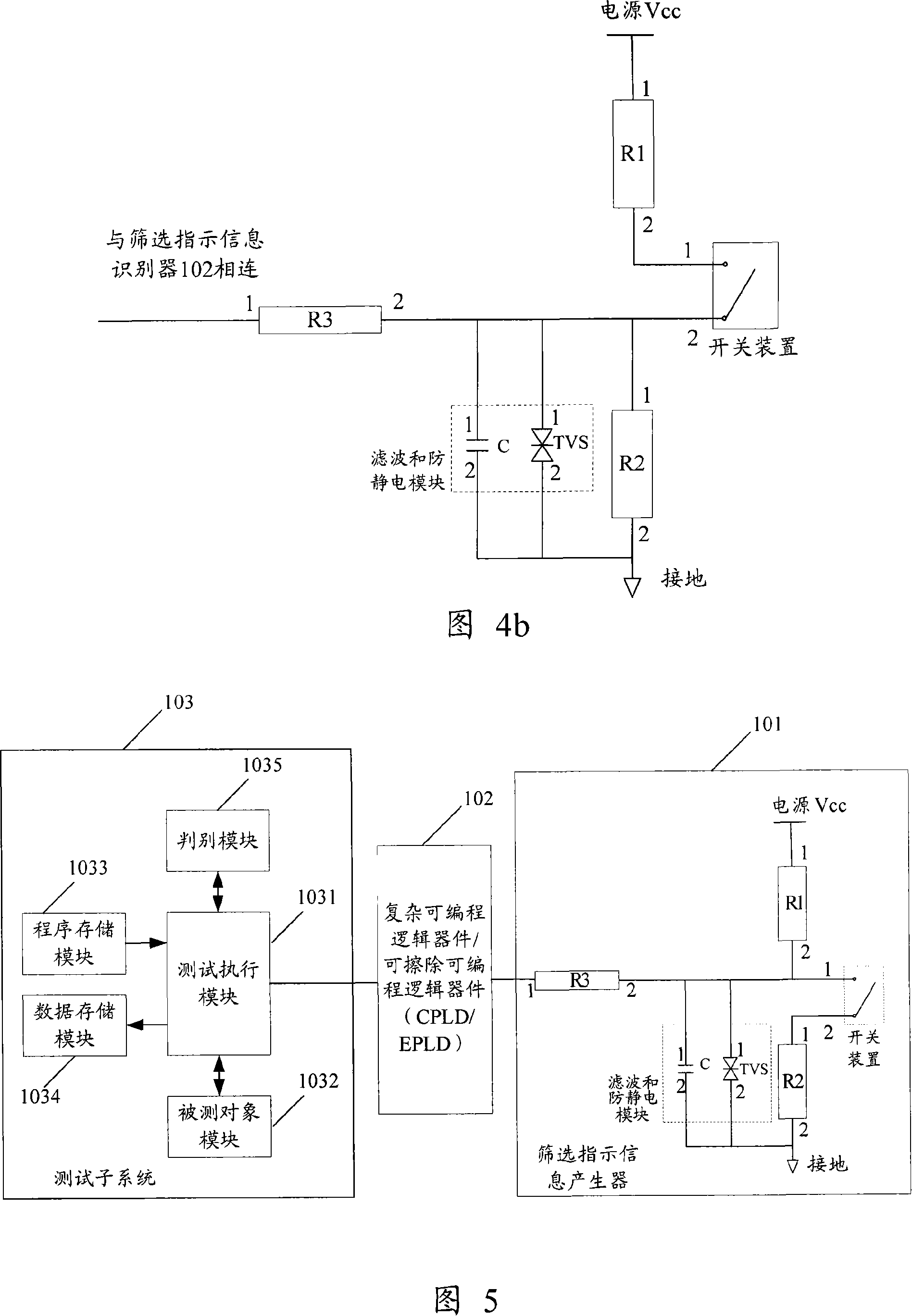

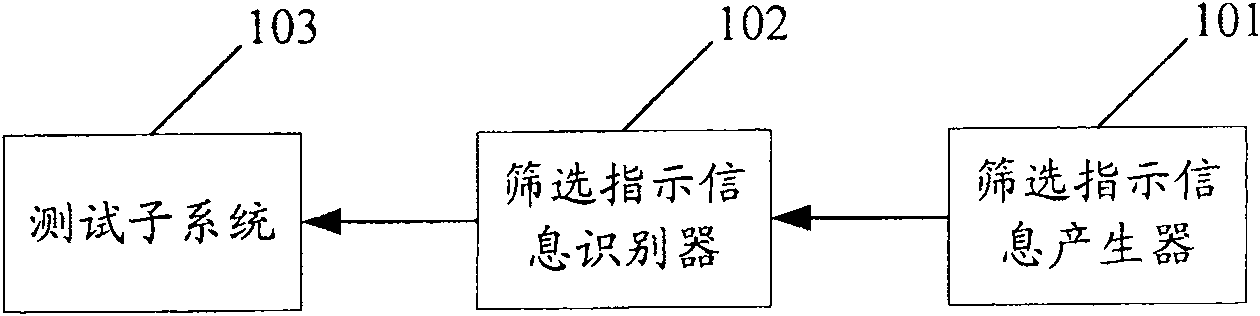

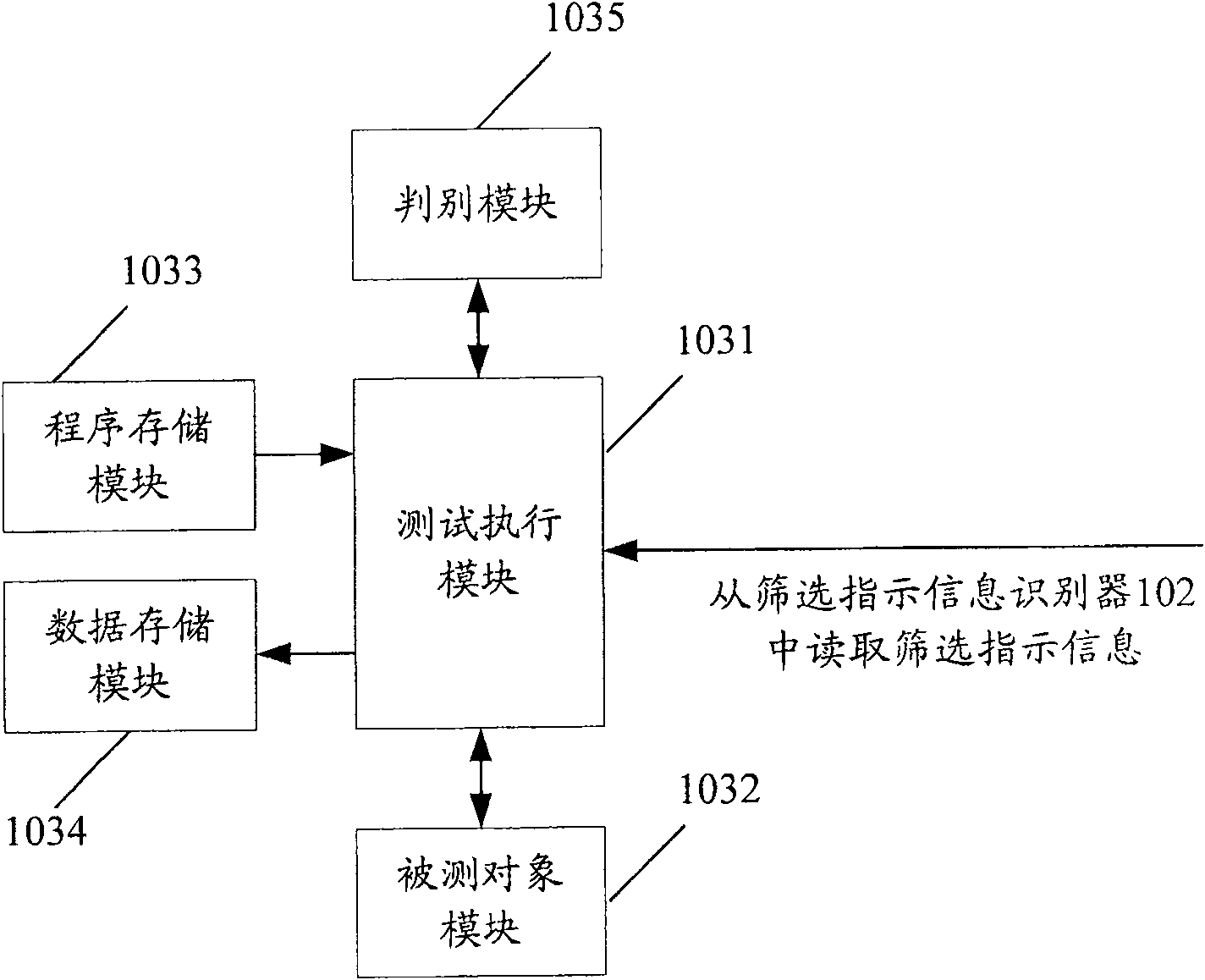

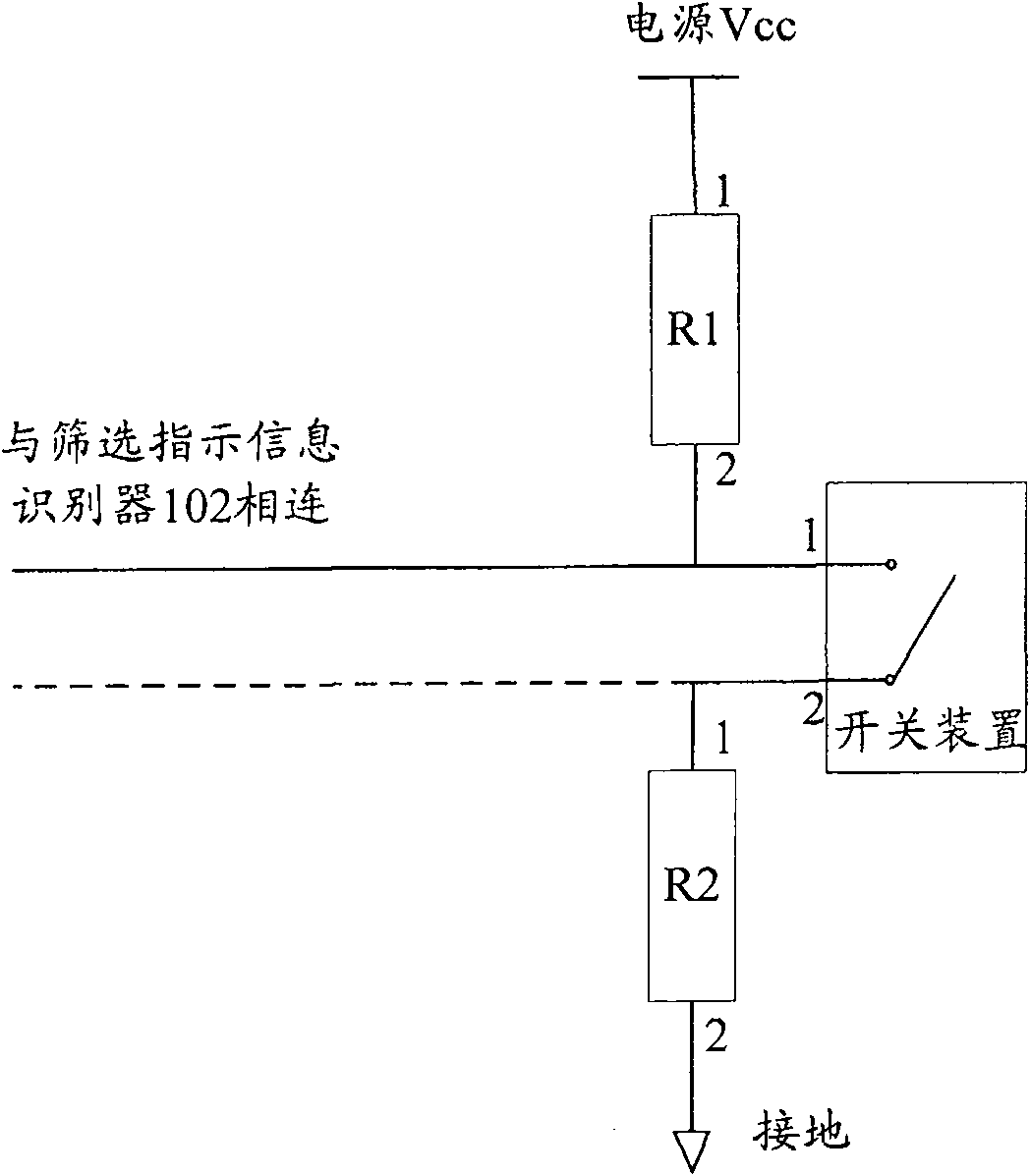

Electronic device and method for realizing dynamic environmental stress screening

This invention provides a realization of environmental stress screening dynamic electronic equipment and methods, in particular: When activated, electronic equipment, have read prior instructions and the preservation of the screening information, in accordance with instructions Screening Information Executive Environmental Stress Screening procedures, in order to achieve electronic equipment own environmental stress screening. Application of this invention program, as in the electronic equipment prior to the commencement of electricity can be generated automatically screen instructions and identification information, electronic equipment, electric start, the screening can be directly under the instructions of information automatically implementation of environmental stress screening procedures, without manual intervention, so as to achieve electronic equipment dynamic environmental stress screening purposes.

Owner:NEW H3C TECH CO LTD

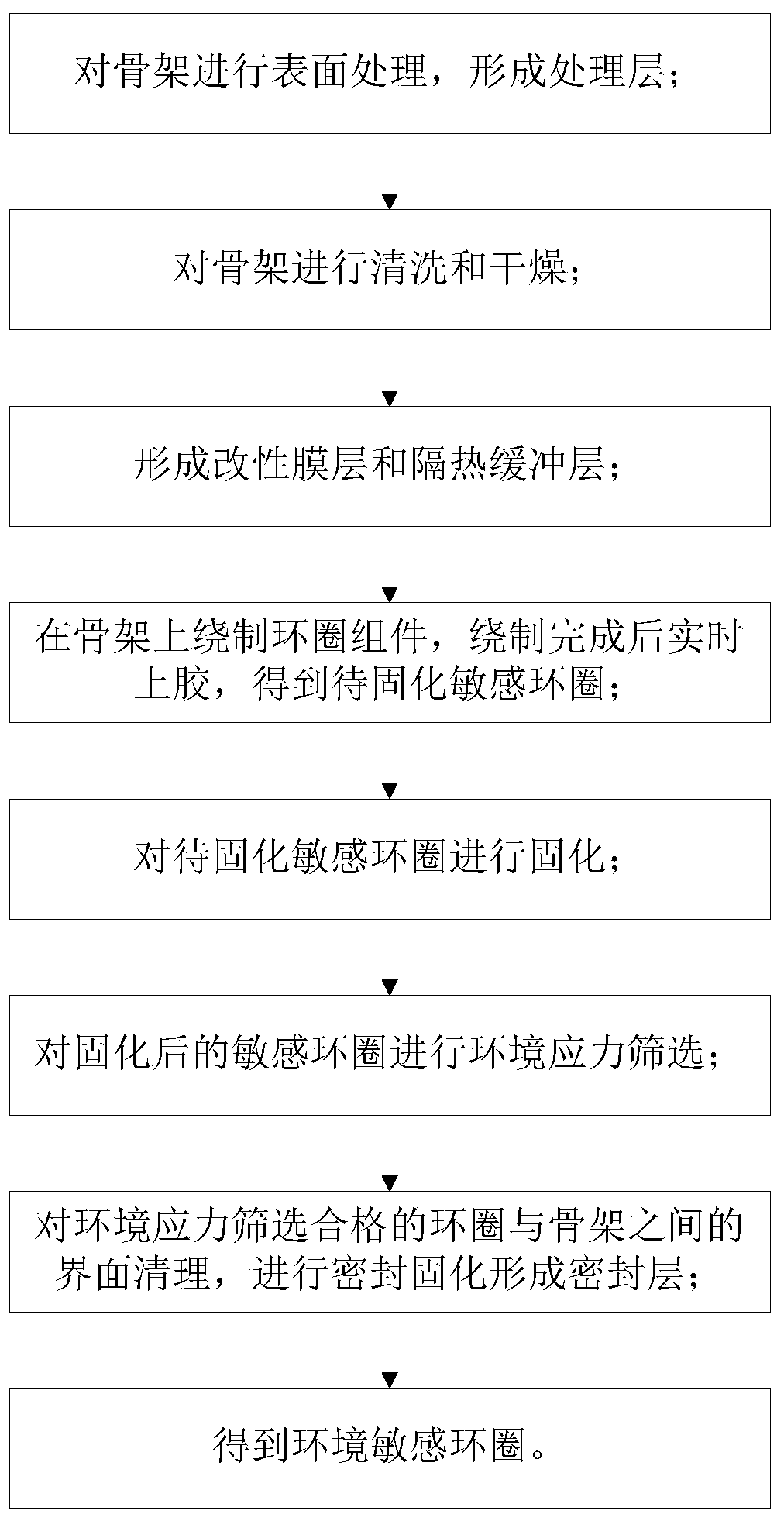

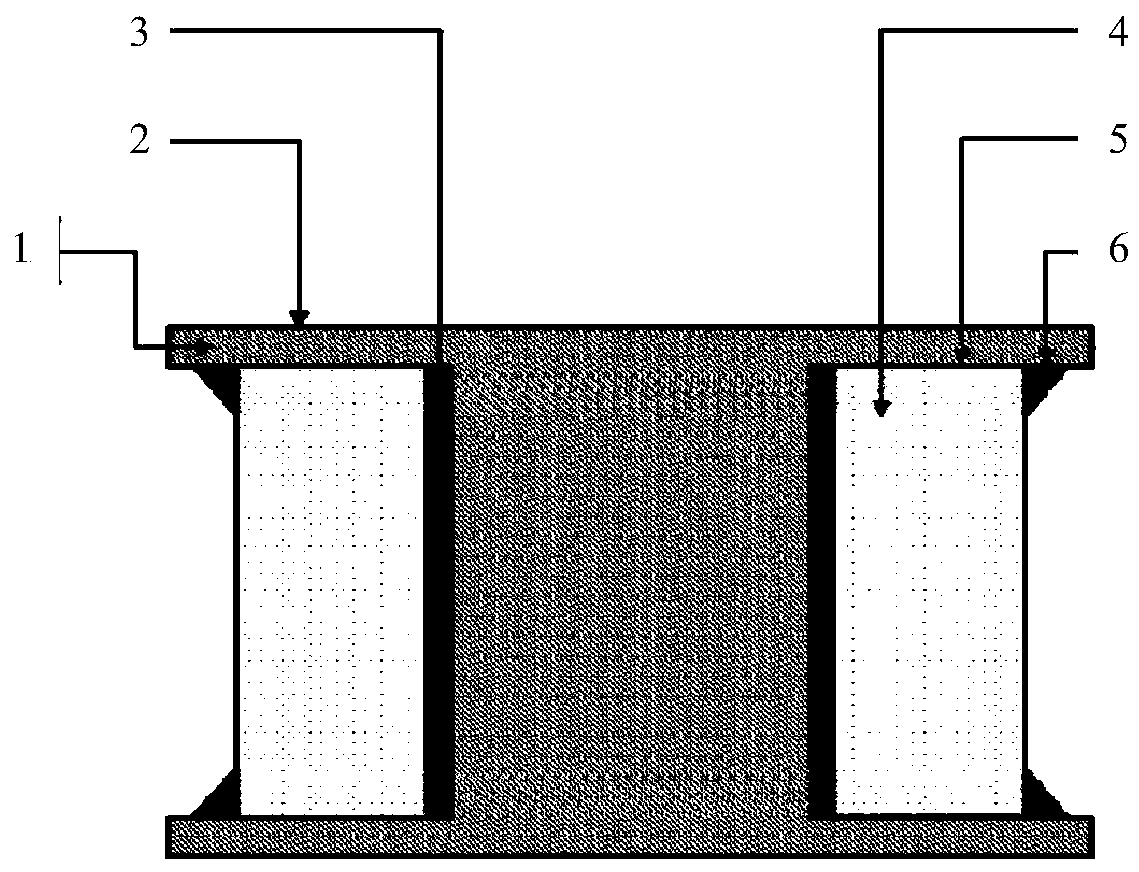

Preparation method for environmentally sensitive loops

ActiveCN109974685AImprove the level of engineering applicationHigh surface energySagnac effect gyrometersGyroscopeThermal insulation

The invention discloses a preparation method for environmentally sensitive loops, and belongs to the technical field of fiber optic gyroscopes and fiber optic sensing. Thus, the problems of large non-orthogonal angle changes and difficult application on large vibration level of sensitive loops in the prior art can be solved. The preparation method includes the following steps: performing surface treatment, cleaning and drying on a frame; forming a modified film and a thermal insulation buffer layer; winding a loop assembly on the frame, and performing real-time gluing and curing after winding;performing environmental stress screening on a cured sensitive loop; and cleaning the interface between the loop qualified through environmental stress screening and the frame, and adopting sealant to perform sealing and fixing. The preparation method can be used for preparing the environmentally sensitive loops.

Owner:中航捷锐(北京)光电技术有限公司 +2

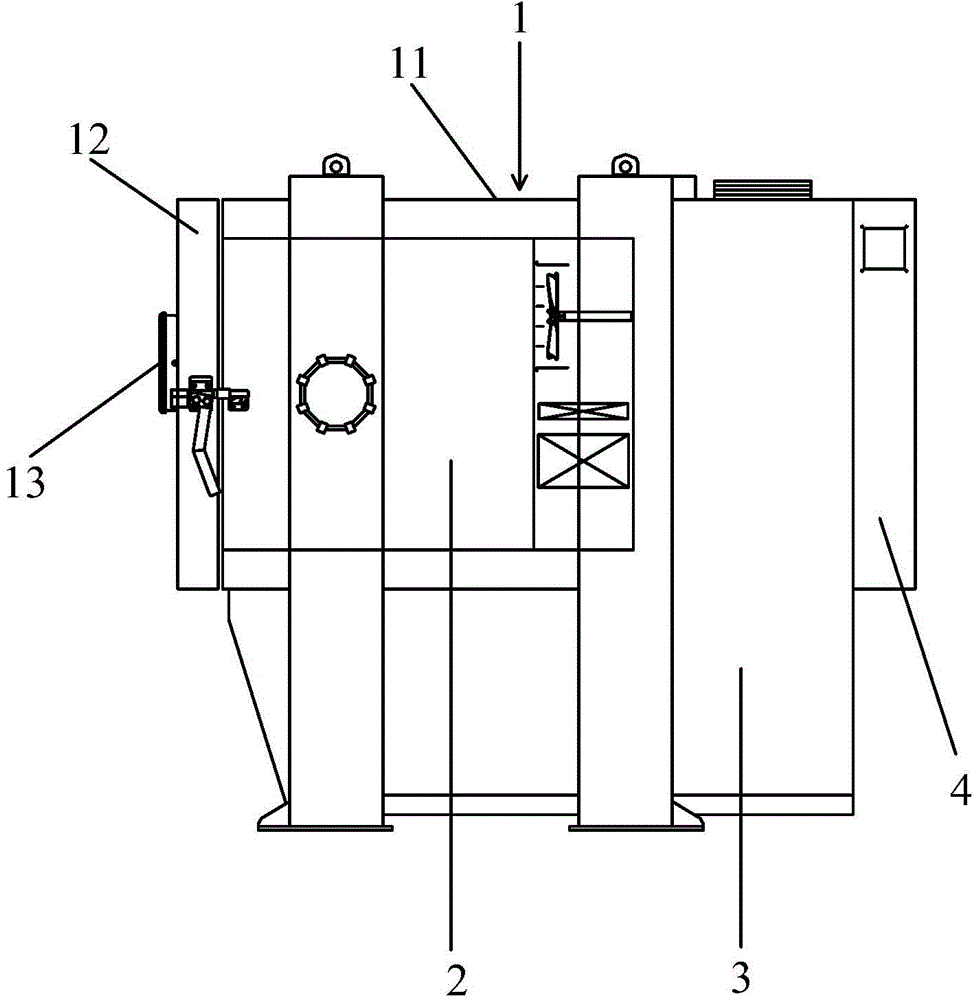

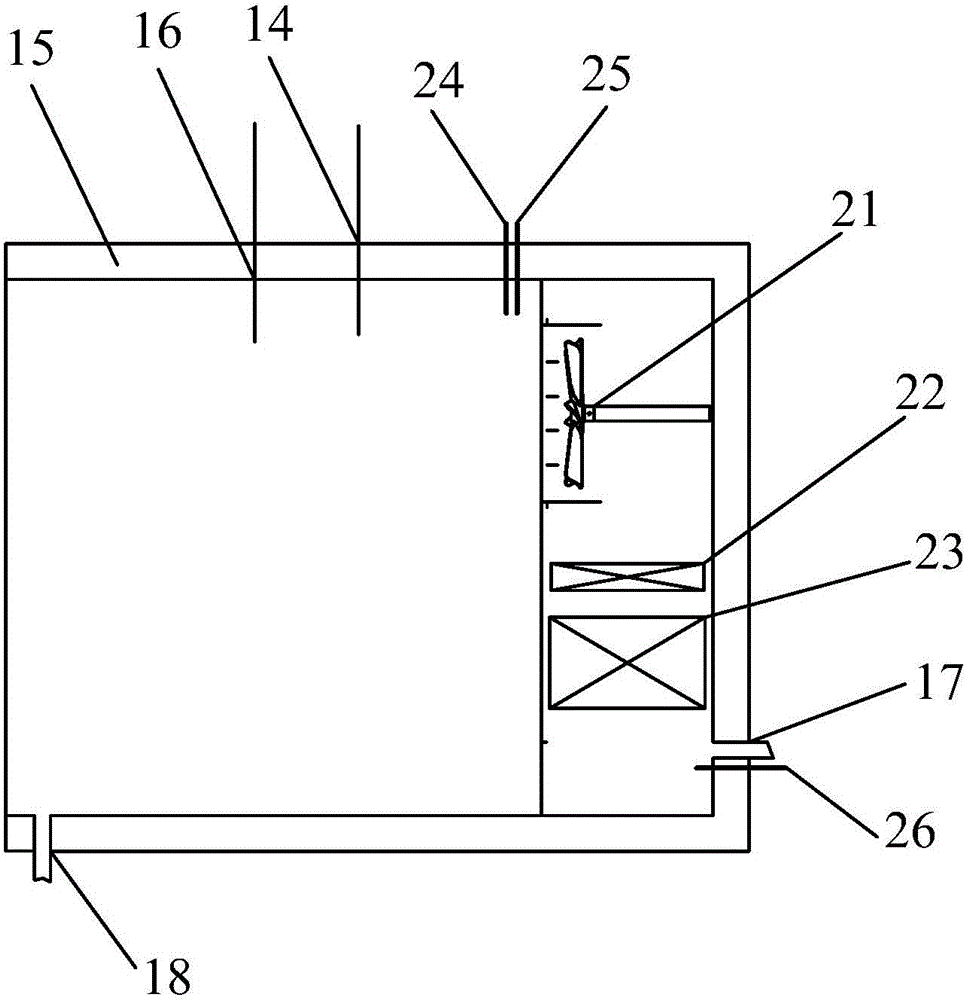

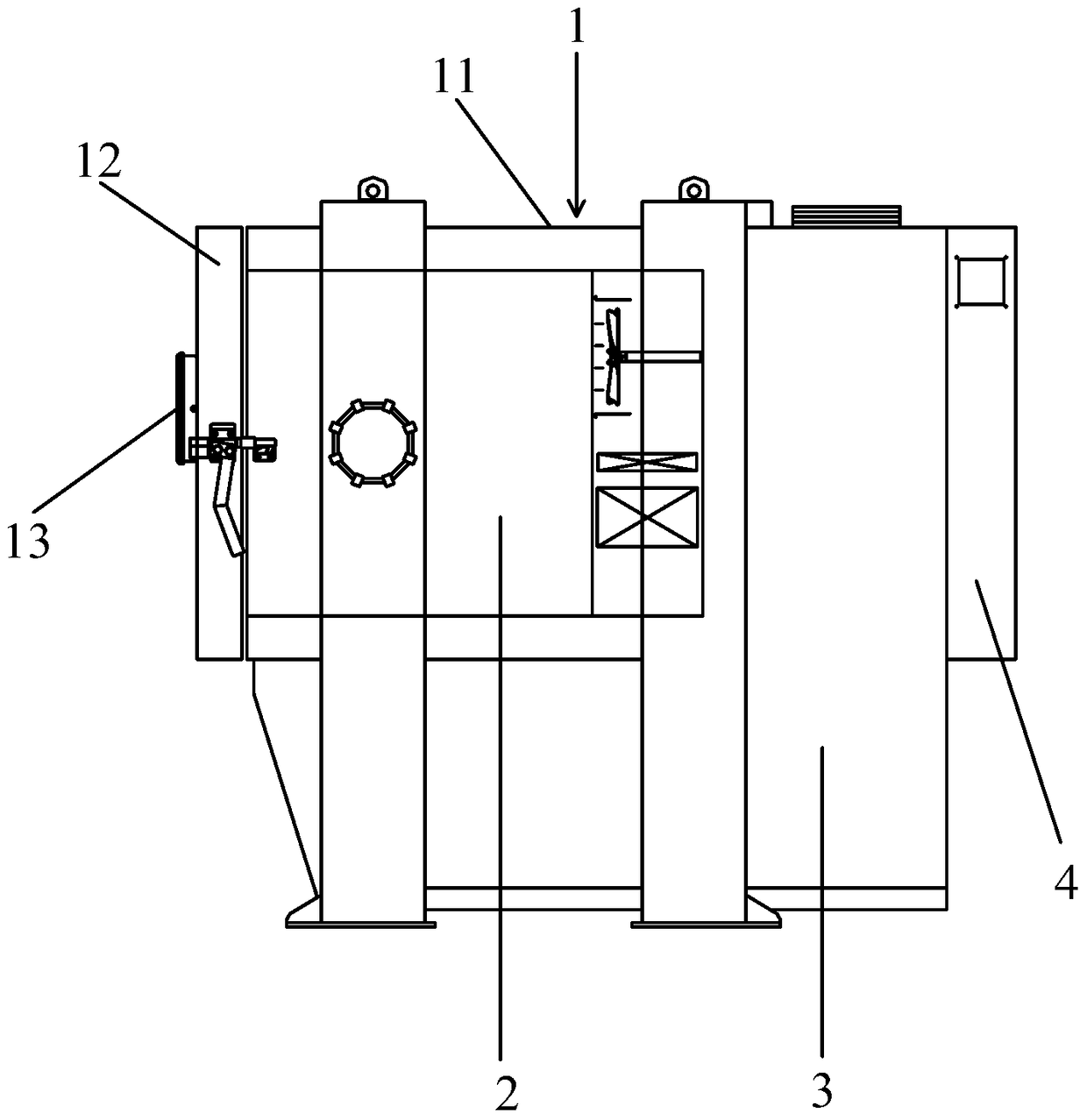

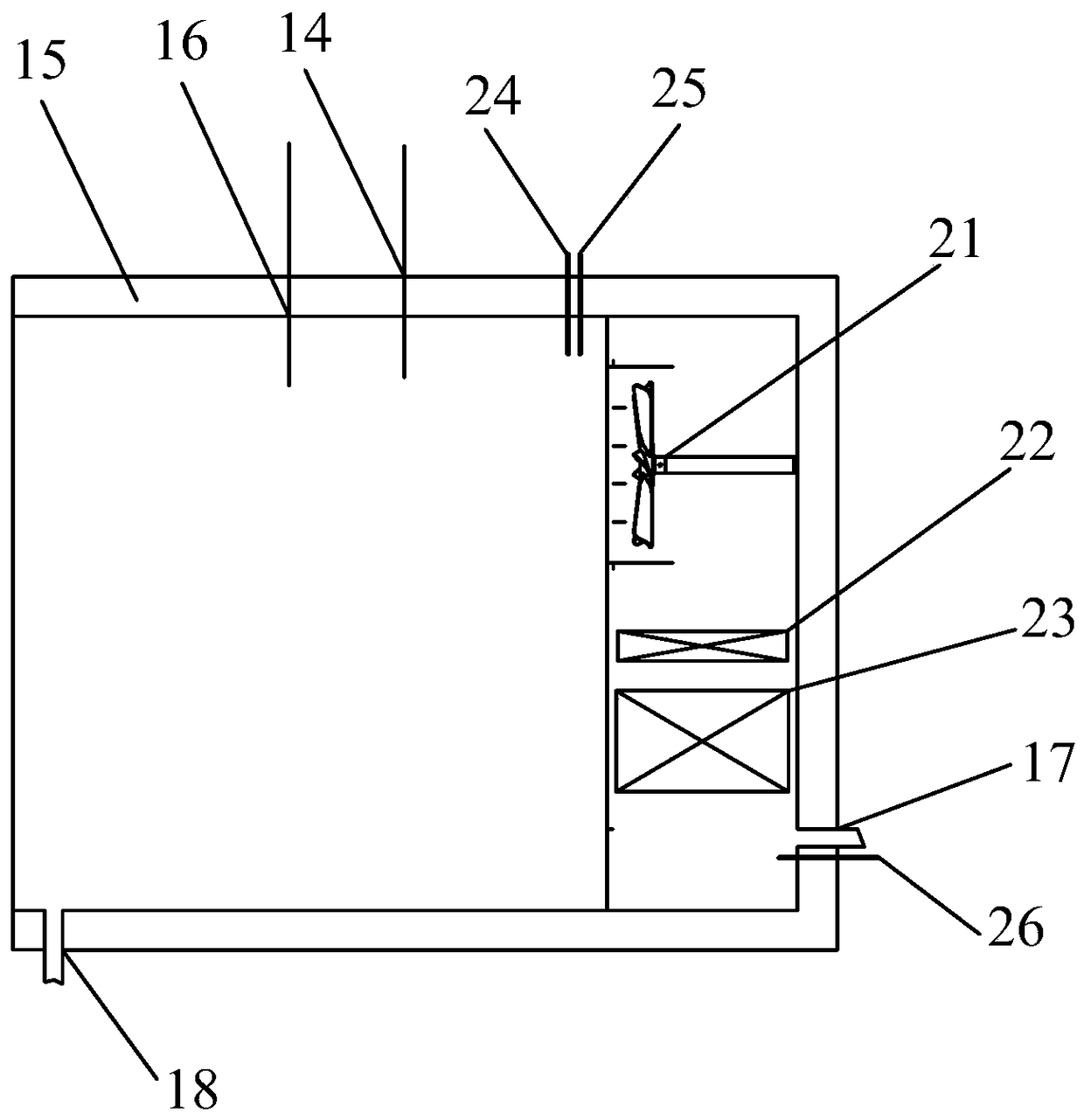

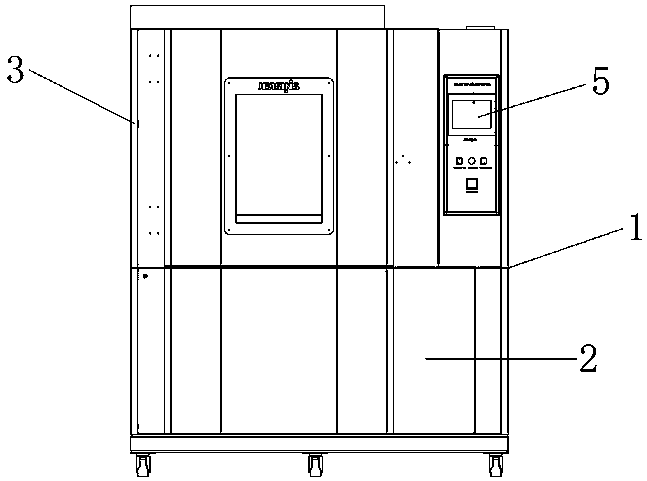

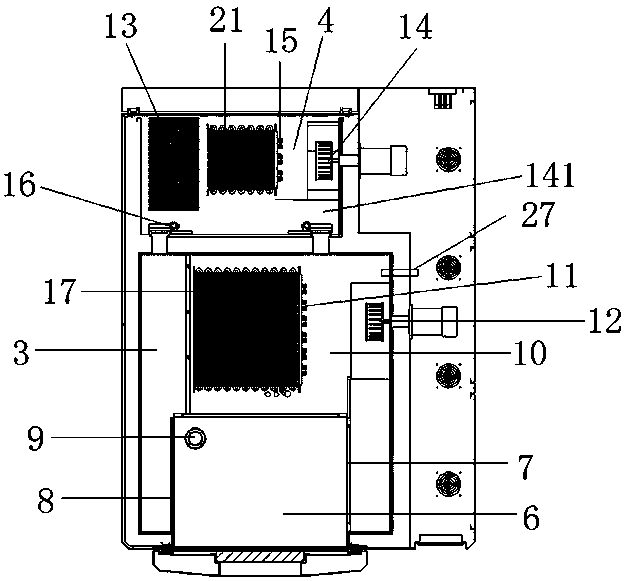

Rapid temperature change test box

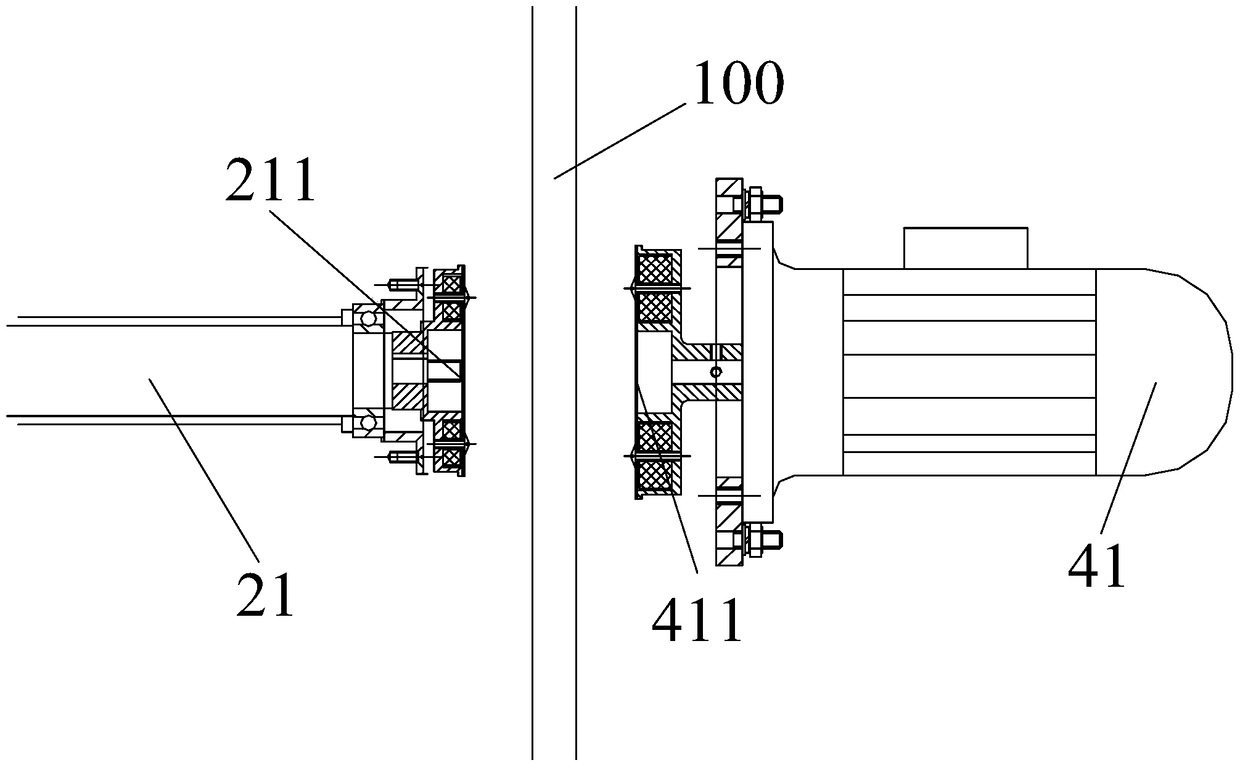

ActiveCN104932410AImprove sealingAffect accuracyProgramme control in sequence/logic controllersMotor driveDrive shaft

The invention discloses a rapid temperature change test box, and belongs to the field of environmental stress screening test equipment. The rapid temperature change test box comprises a box which comprises a box body and separating layers which separate the internal part of the box body into three intervals. The three intervals are a work room, a refrigerating room and a power distribution room in turn. The work room is internally provided with an axial flow blower. The power distribution room is internally provided with a motor driving the axial flow blower. Magnetic transmission is adopted between the motor and the axial flow blower. Magnetic transmission is adopted between the motor and the axial flow blower, and a through hole does not need to be arranged on the box between the motor and the axial flow blower for arrangement of a transmission shaft so that a box sealing performance problem caused by existence of the through hole can be avoided, and box sealing performance can be enhanced. With increasing of sealing performance, moist air exchange inside and outside the test box is reduced, and humidity in the box is relatively low in the test process so that influence on the test result caused by condensation on the product can be avoided and accuracy of the test result can be enhanced.

Owner:NO 722 RES INST OF CHINA SHIPBUILDING IND

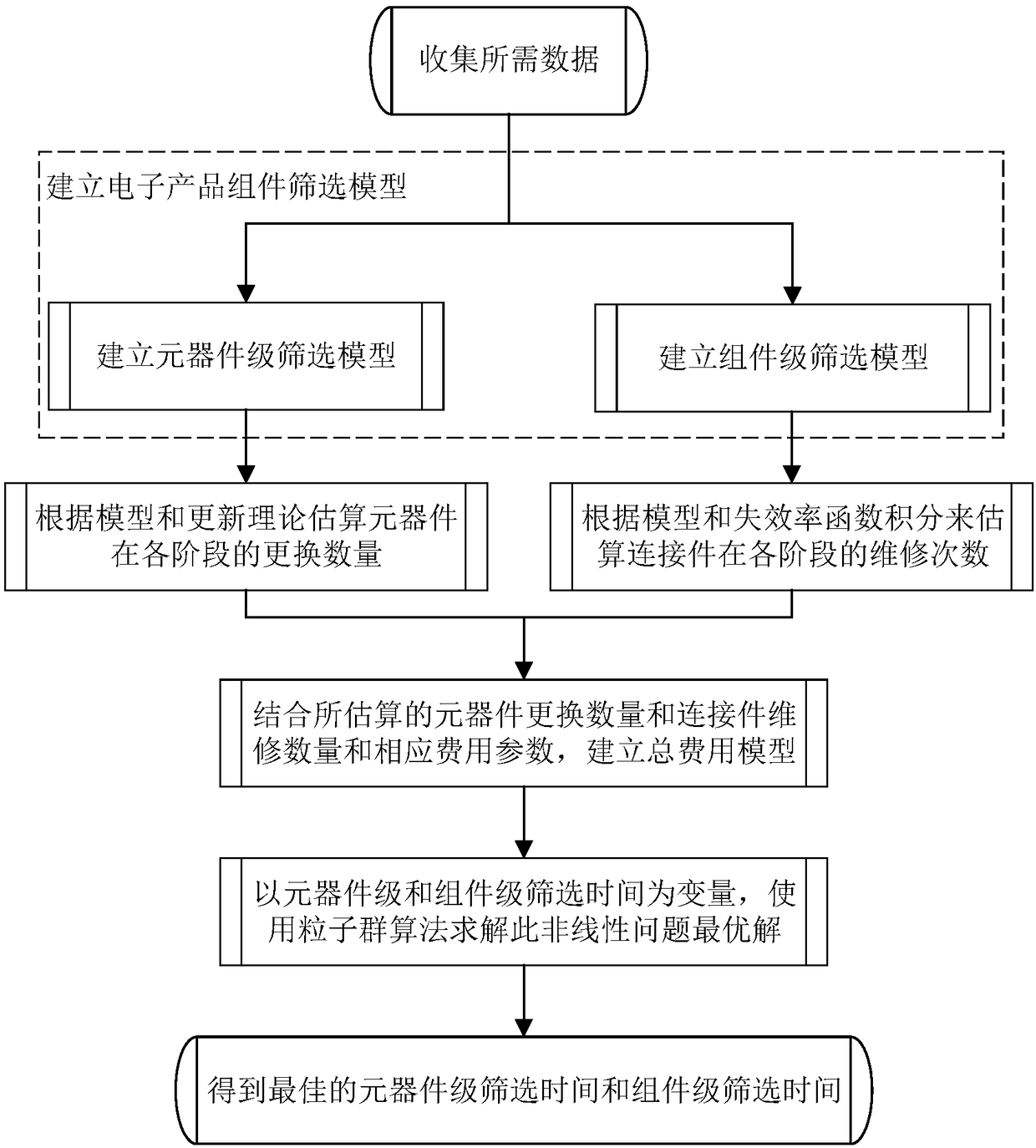

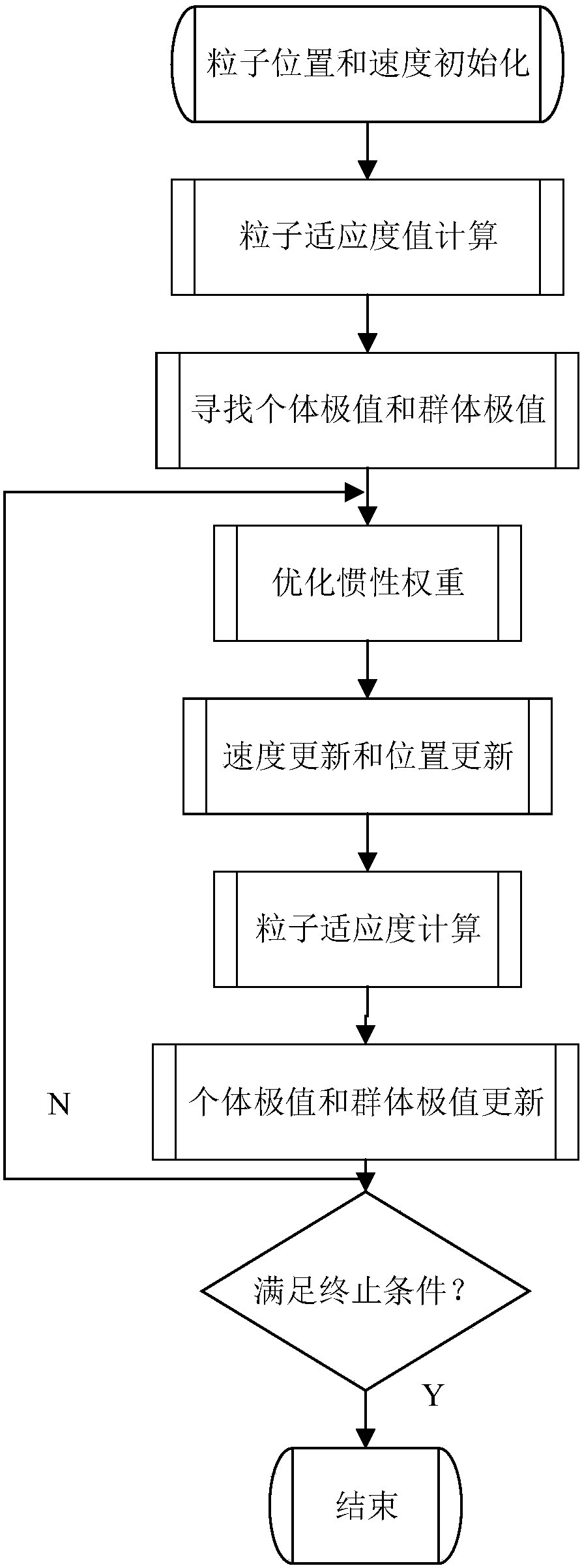

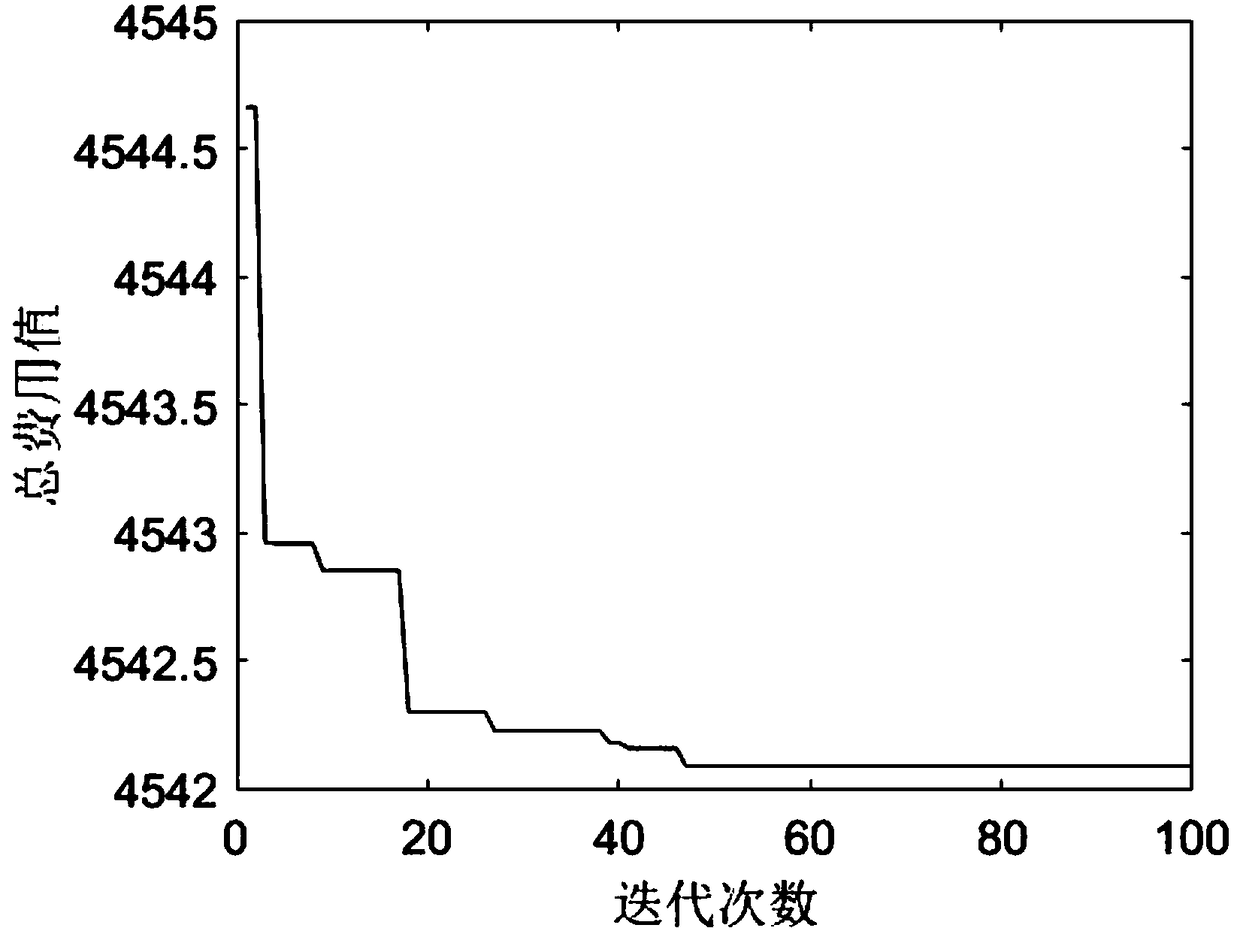

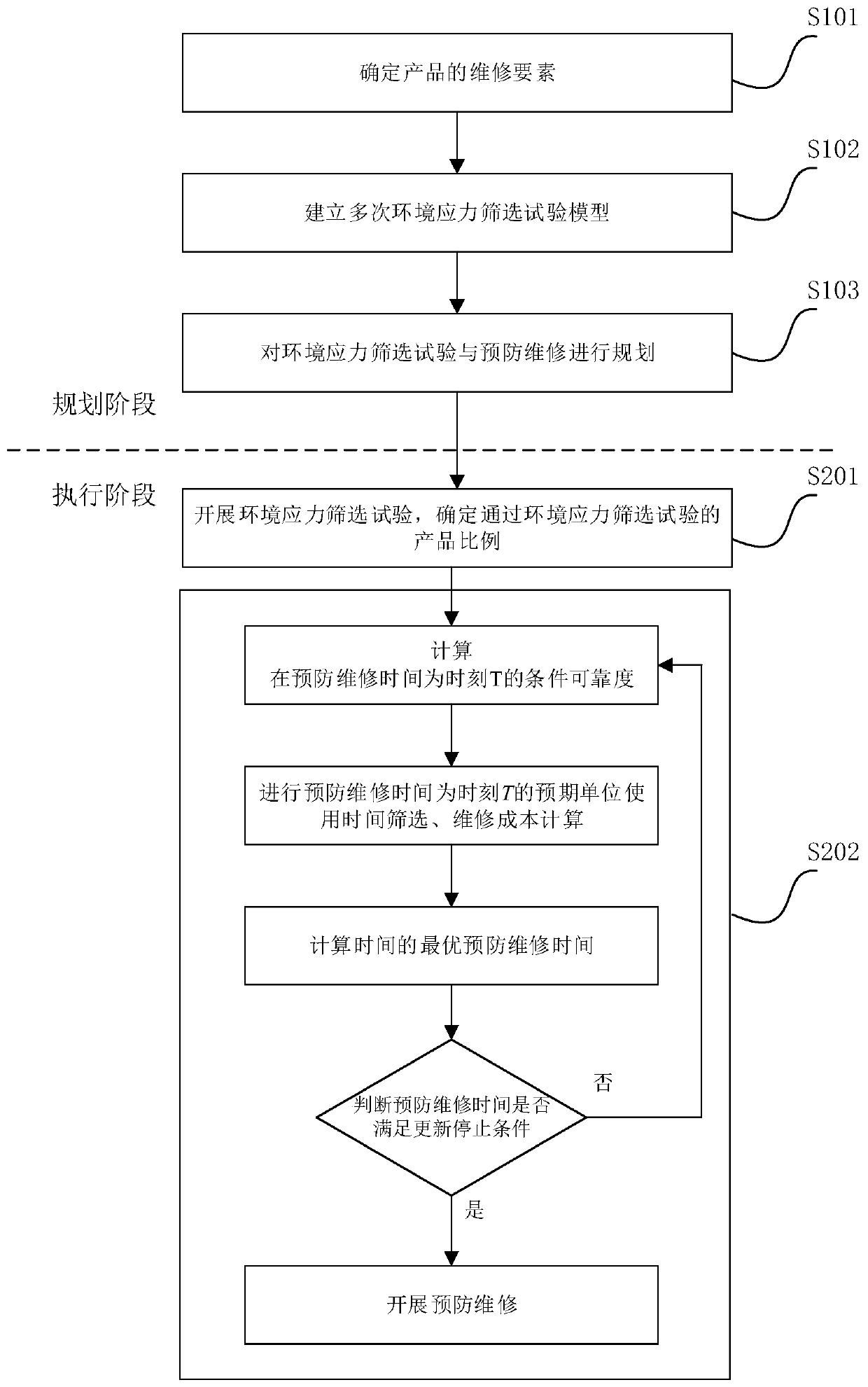

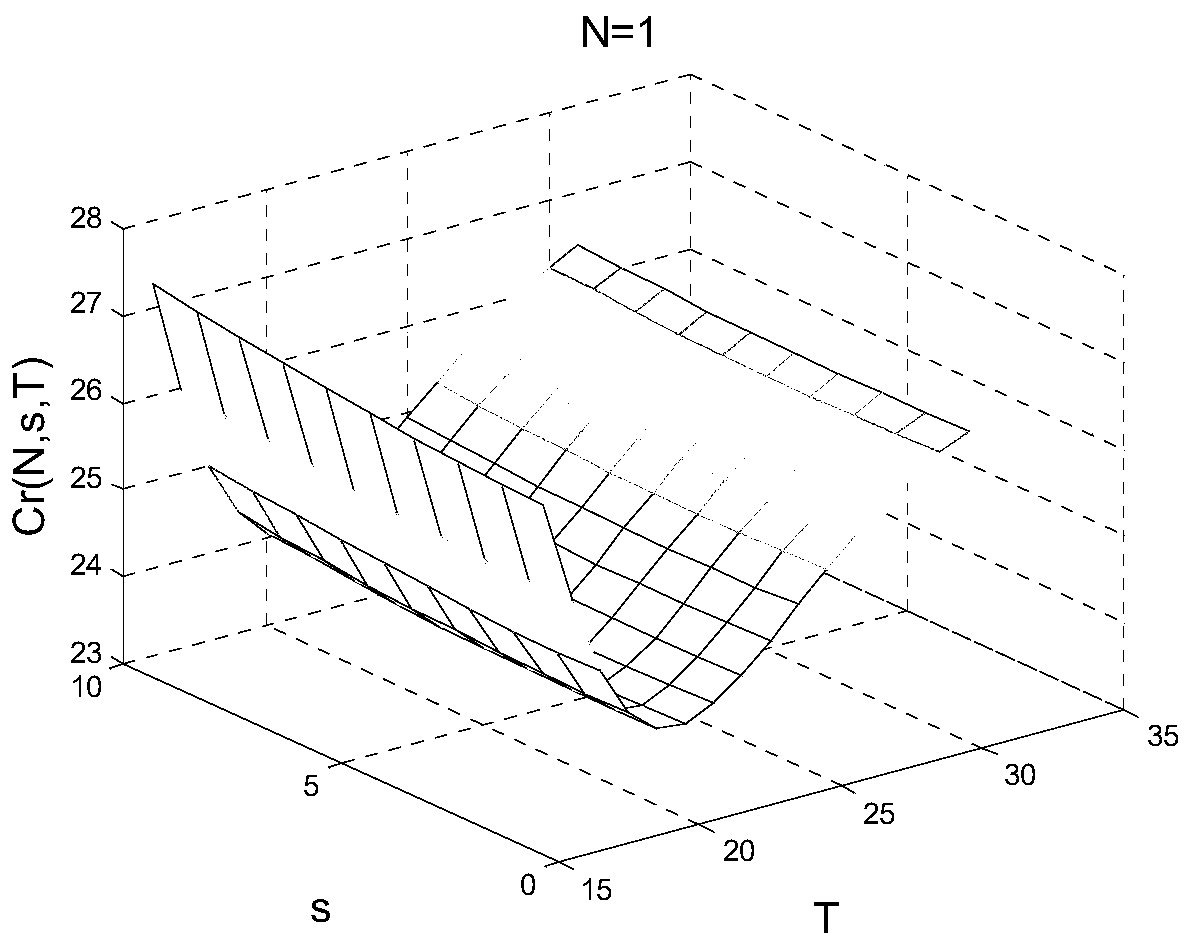

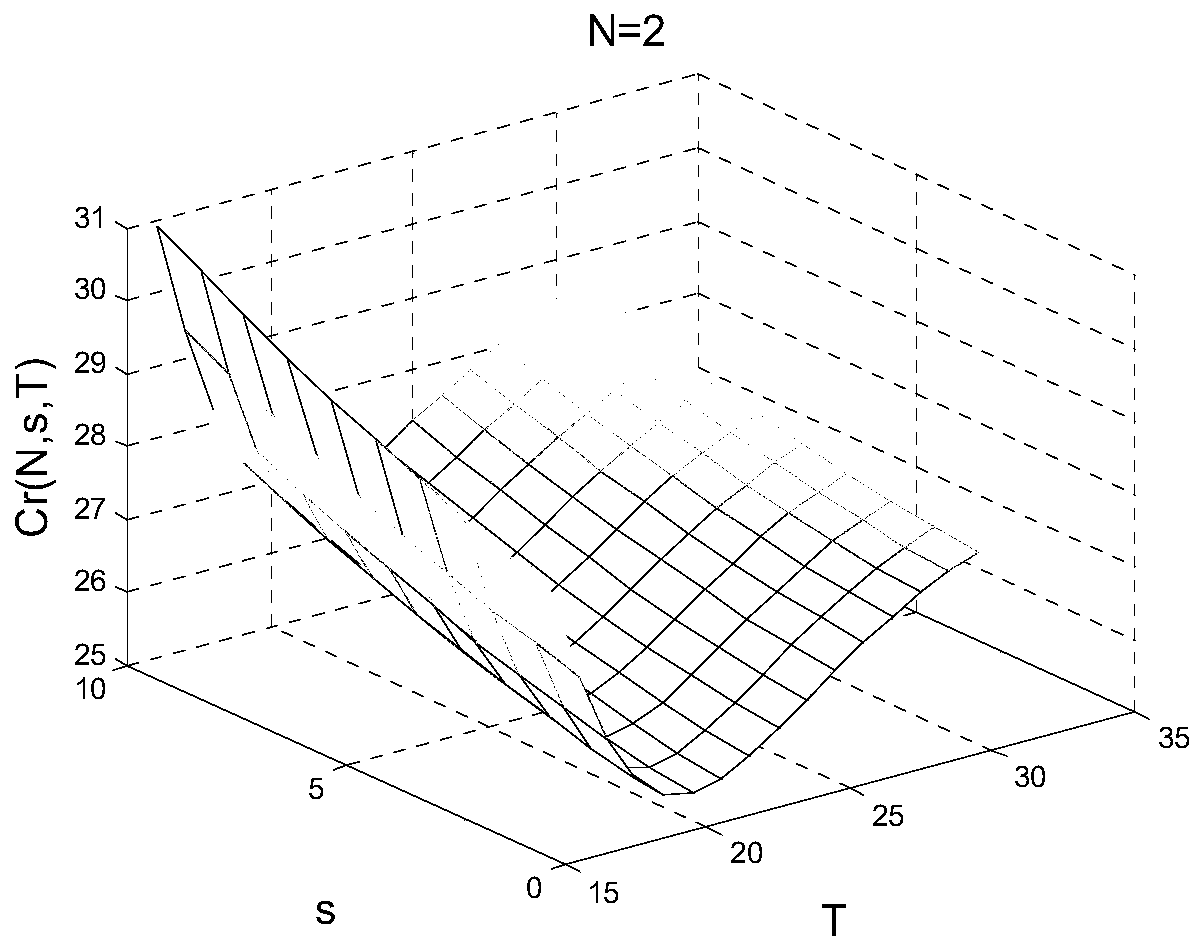

Environmental stress screening test and forecasting repair comprehensive optimizing method

ActiveCN108229761AOptimize preventive maintenance timeLow costForecastingDesign optimisation/simulationScreening effectRepair time

The invention discloses an environmental stress screening test and forecasting repair comprehensive optimizing method, which comprises a planning stage and an executing stage; the planning stage includes three steps which are environmental stress screening test modeling for many times, repair element confirming module and environment stress screening test, and preventive repair planning comprehensive optimization; the executing stage includes the implementation of environmental stress screening test and the predicting repair planning and execution. The method comprehensively considers the environment stress screening effect and the screening cost before the product is put into use, and the influence of the selection of the repair time on the repair cost after the product is put into use; before the product is put into use, the environmental stress condition and the test frequency are comprehensively optimized and selected on the basis of the environmental stress screening test model and the forecasting repair planning model; after putting the product into use, the preventive repair time of is optimized according to the state monitoring data of every product in use after the productis put into use; the method can effectively reduce the total cost of screening and repair.

Owner:36TH RES INST OF CETC

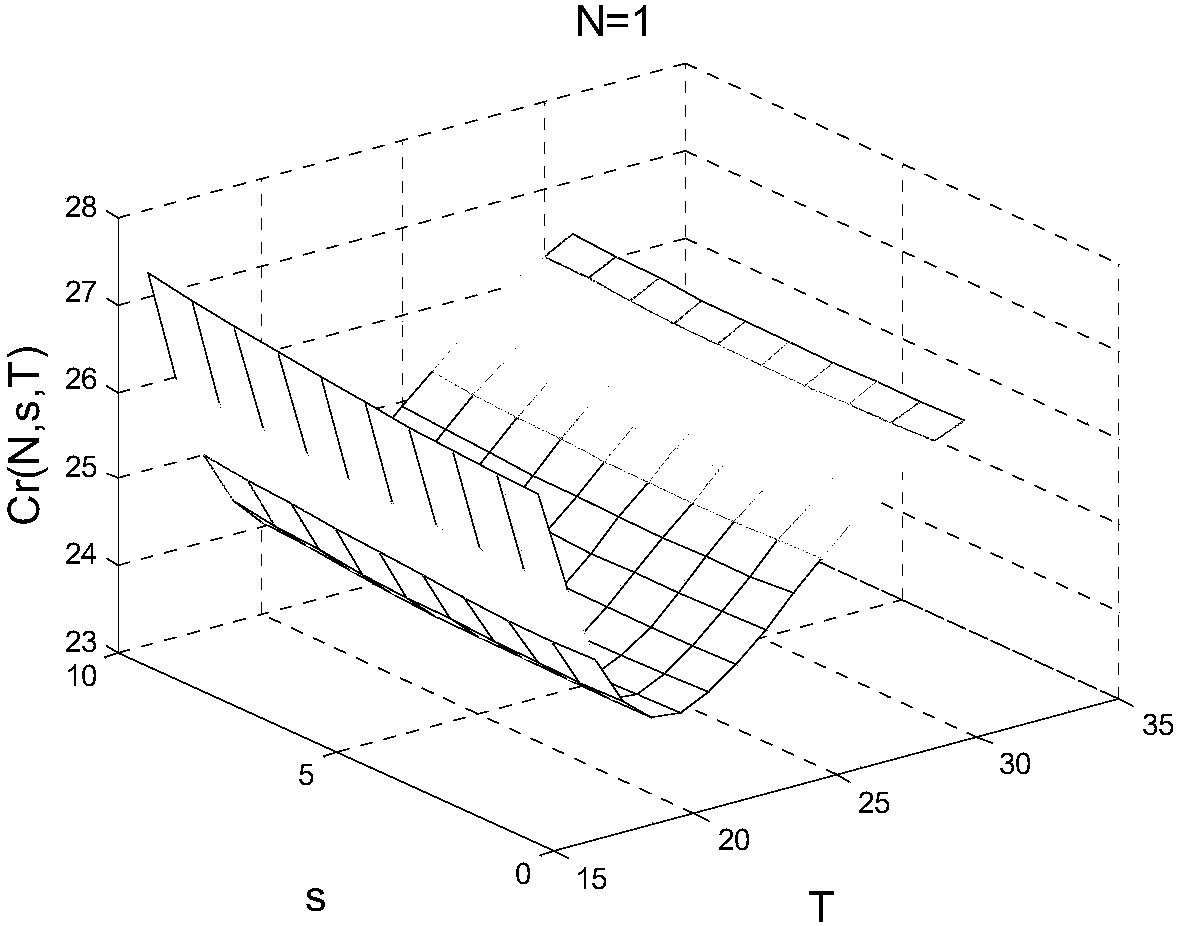

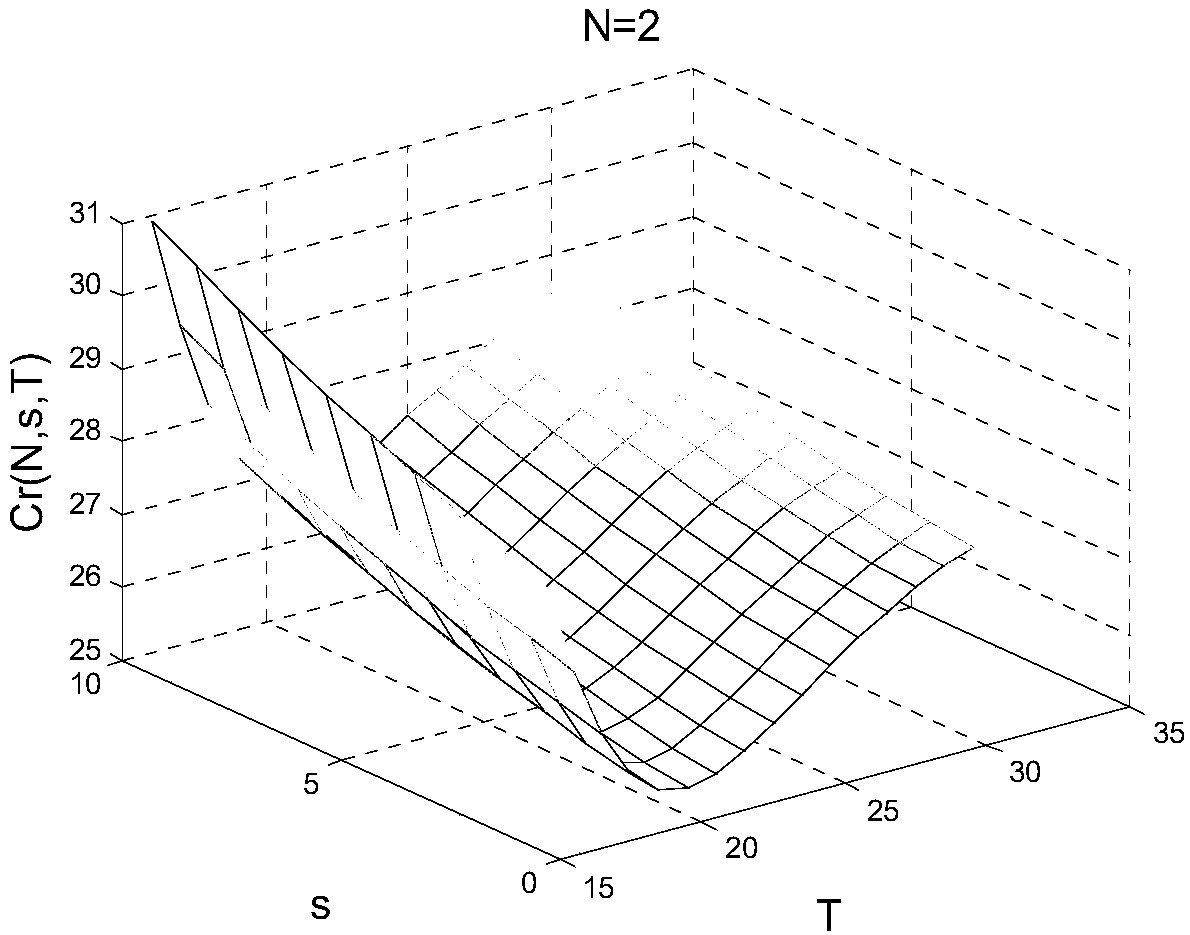

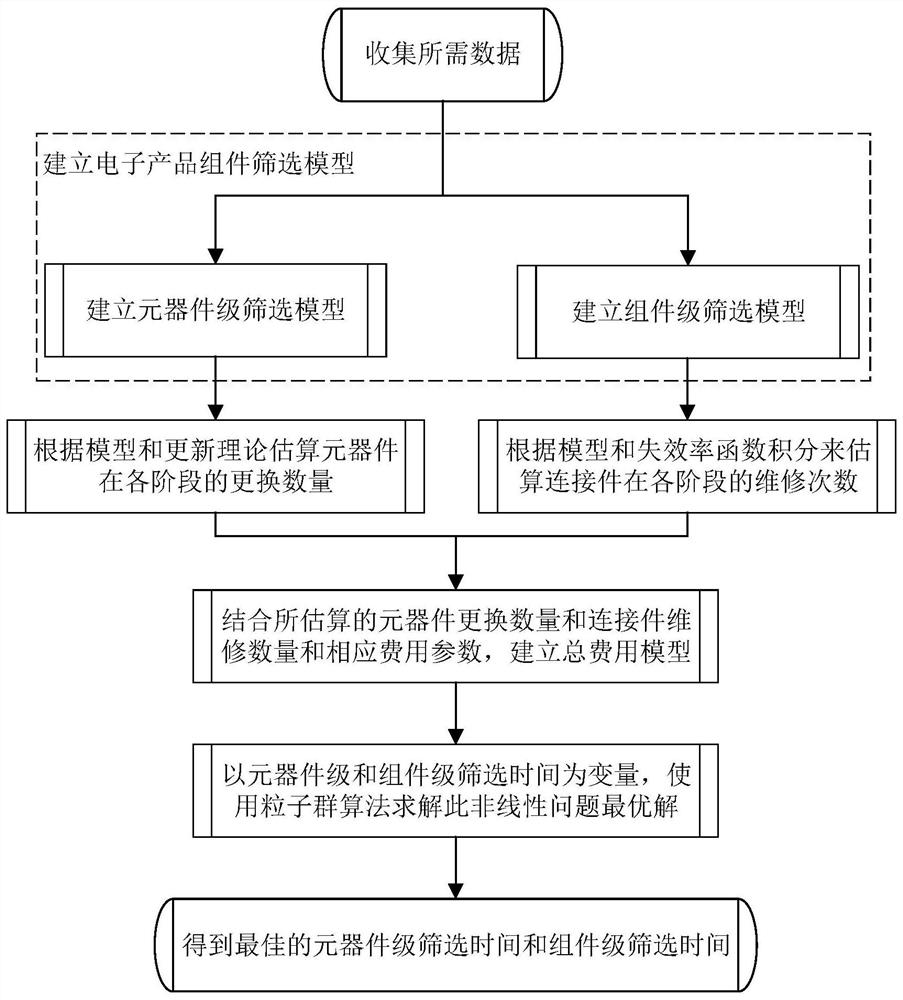

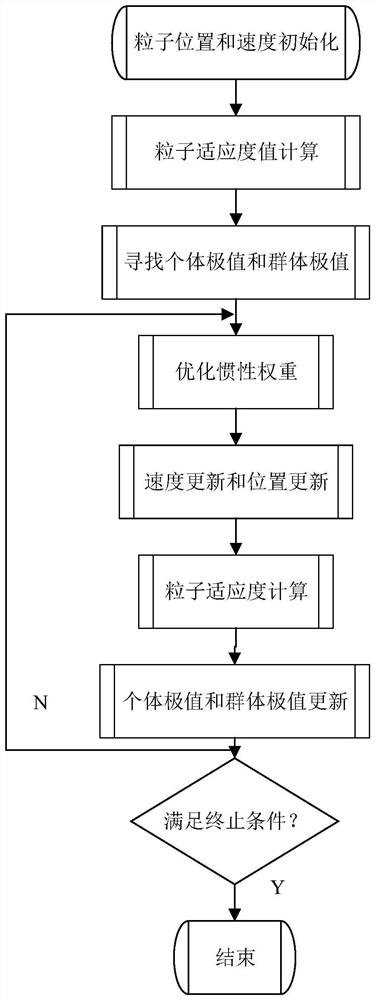

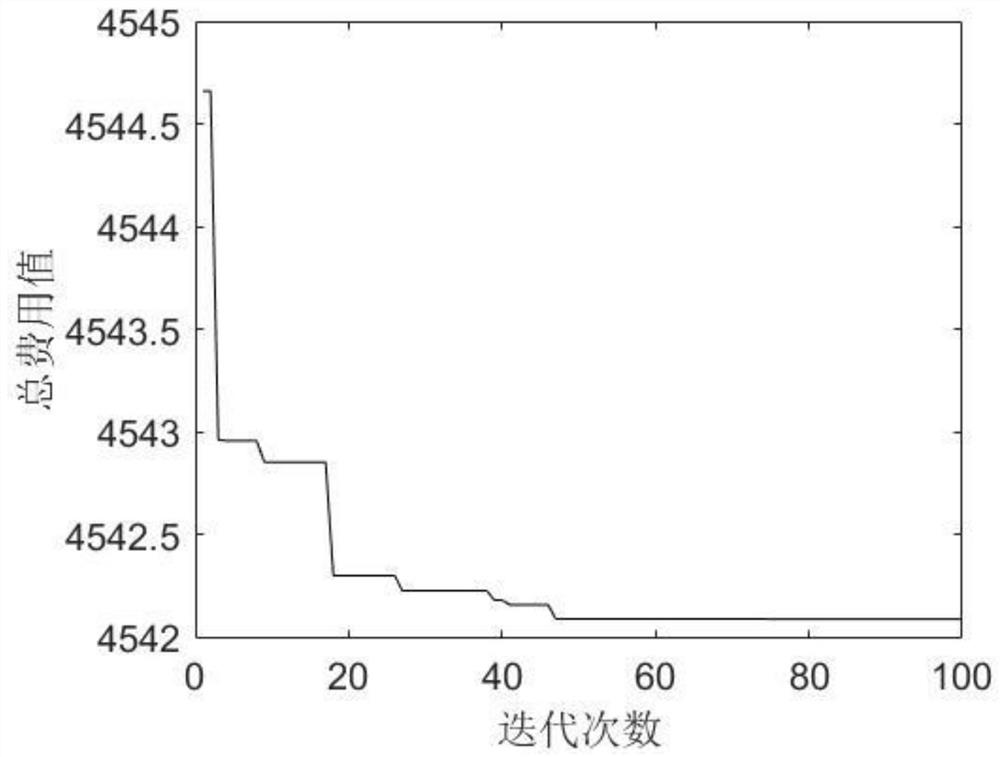

Environmental stress screening time optimizing method and equipment

The invention discloses an environmental stress screening time optimizing method and environmental stress screening time optimizing equipment for an electronic product, and belongs to the field of reliability tests of electronic products. Environmental stress screening is an important means for eliminating early failures of a product, and is achieved by applying an appropriate environmental stressto the product before leaving a factory and eliminating potential defects so as to guarantee using reliability of the product. Implementation of the environmental stress screening can reduce the maintenance cost after the product is put into use while the production cost is increased. During the environmental stress screening, component-level and assembly-level screening cost is fully considered,and especially calculation of time and expense cost is introduced, so that the screening time cost is fully considered during the environmental stress screening, and while the design reliability is improved, the screening time is shortened and the production cost is reduced so as to improve the economic efficiency and the production efficiency of an enterprise.

Owner:HUAZHONG UNIV OF SCI & TECH

A rapid temperature change test chamber

ActiveCN104932410BImprove sealingAffect accuracyProgramme control in sequence/logic controllersMagnetic tension forceMotor drive

The invention discloses a rapid temperature change test box, and belongs to the field of environmental stress screening test equipment. The rapid temperature change test box comprises a box which comprises a box body and separating layers which separate the internal part of the box body into three intervals. The three intervals are a work room, a refrigerating room and a power distribution room in turn. The work room is internally provided with an axial flow blower. The power distribution room is internally provided with a motor driving the axial flow blower. Magnetic transmission is adopted between the motor and the axial flow blower. Magnetic transmission is adopted between the motor and the axial flow blower, and a through hole does not need to be arranged on the box between the motor and the axial flow blower for arrangement of a transmission shaft so that a box sealing performance problem caused by existence of the through hole can be avoided, and box sealing performance can be enhanced. With increasing of sealing performance, moist air exchange inside and outside the test box is reduced, and humidity in the box is relatively low in the test process so that influence on the test result caused by condensation on the product can be avoided and accuracy of the test result can be enhanced.

Owner:NO 722 RES INST OF CHINA SHIPBUILDING IND

An accelerated life prediction method for bga solder joints

ActiveCN104344988BGet Predicted LifespanThe test method is simple and reliableStrength propertiesAcceleration factorElectric stress

The invention relates to a BGA (ball grid array) welding point acceleration service life prediction method, which comprises the following steps that (a) n BGA welding point samples are randomly selected, wherein the n is greater than or equal to 5, and the BGA welding point samples are subjected to environment stress screening processing; (b) the samples processed in the step (a) are subjected to integral stress processing, and the integral stress processing comprises second temperature circulation processing, random vibration processing and electric stress processing on the samples processed in the step (a), and in addition, the sample failure time is recorded; (c) the samples processed in the step (b) are subjected to third temperature circulation processing; (d) a model shown in a formula (III) is used for calculating an acceleration factor, and finally, a formula (IV) is used for calculating the use average failure before time MTTR<use> for predicting the service life of the BGA welding point. The invention also provides application of the method to the preparation of electronic products and mechanical equipment.

Owner:ZHUZHOU CSR TIMES ELECTRIC CO LTD

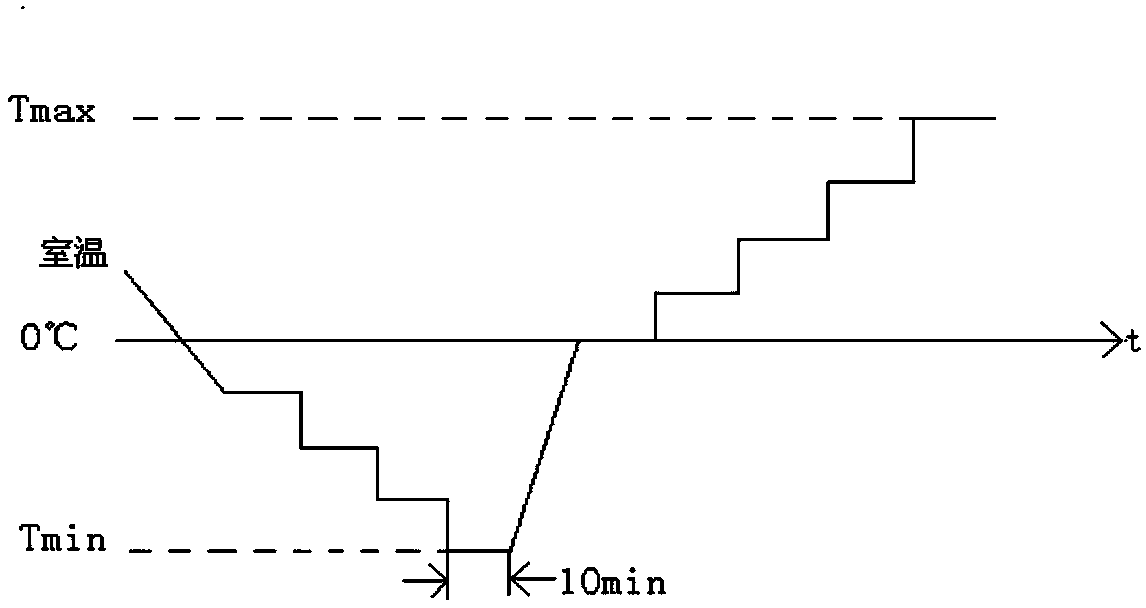

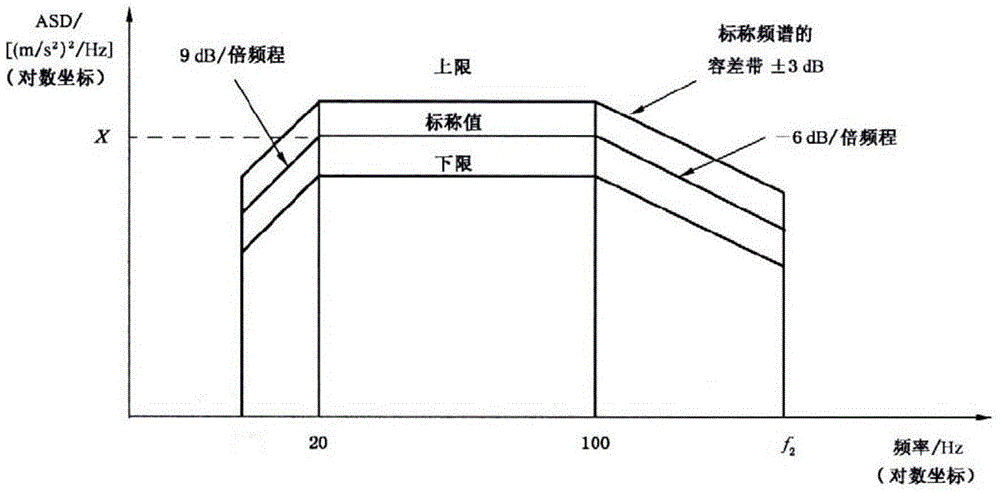

Photoelectric product environmental stress screening method

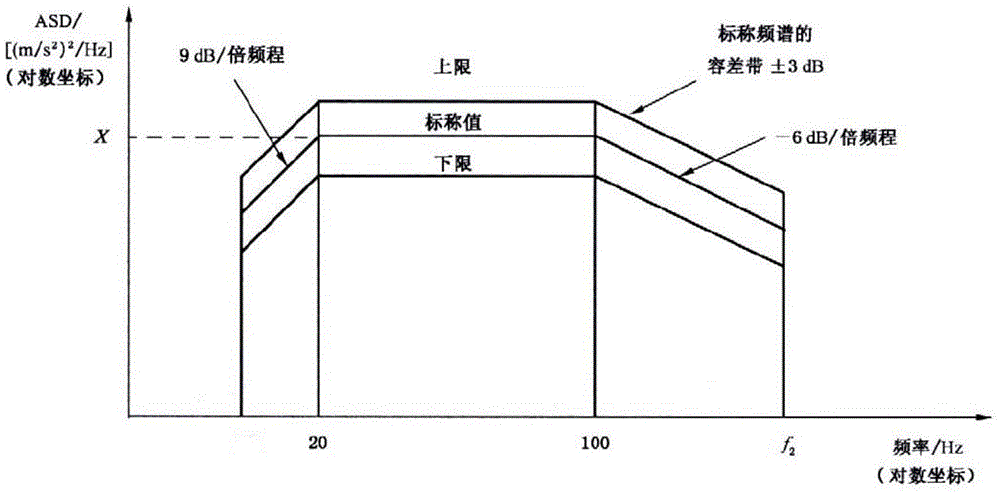

ActiveCN109492313ADesign optimisation/simulationSpecial data processing applicationsElement modelEngineering

The invention discloses a photoelectric product environmental stress screening method, and the method comprises the steps: carrying out the modal analysis and verification test of a photoelectric product, so as to ensure the correctness of a finite element model; the correctness of the random vibration analysis method is ensured by carrying out random vibration analysis and verification tests on the photoelectric product; Modal and random vibration analysis is carried out on main or key components in the photoelectric product, and the random vibration spectrum shape and magnitude stipulated byGJB1032 are cut according to the analysis result, so that the environmental stress screening method of the photoelectric product is completed. According to the method, the finite element model of thephotoelectric product can be accurately established in a short time, and the inherent frequency is confirmed. And through random vibration analysis, weak links of the product are clear, and the method is an environmental stress screening method with a very good popularization prospect.

Owner:BEIJING INST OF REMOTE SENSING EQUIP

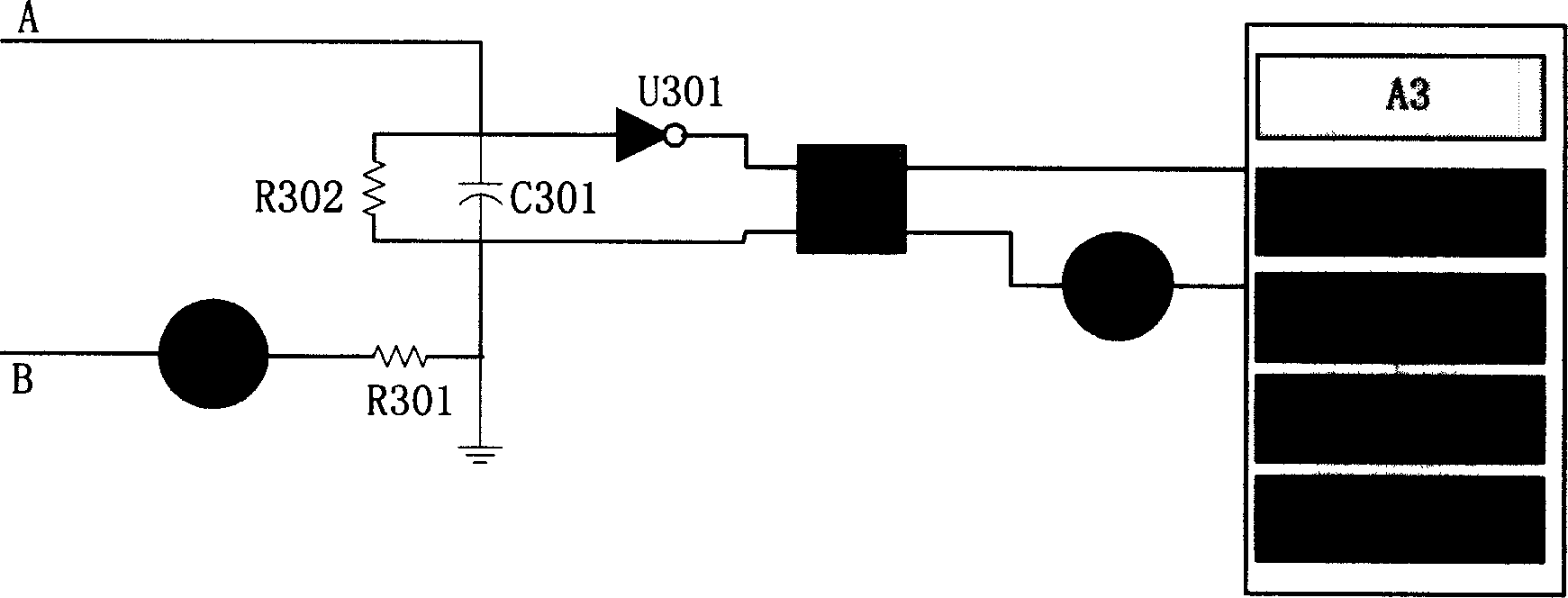

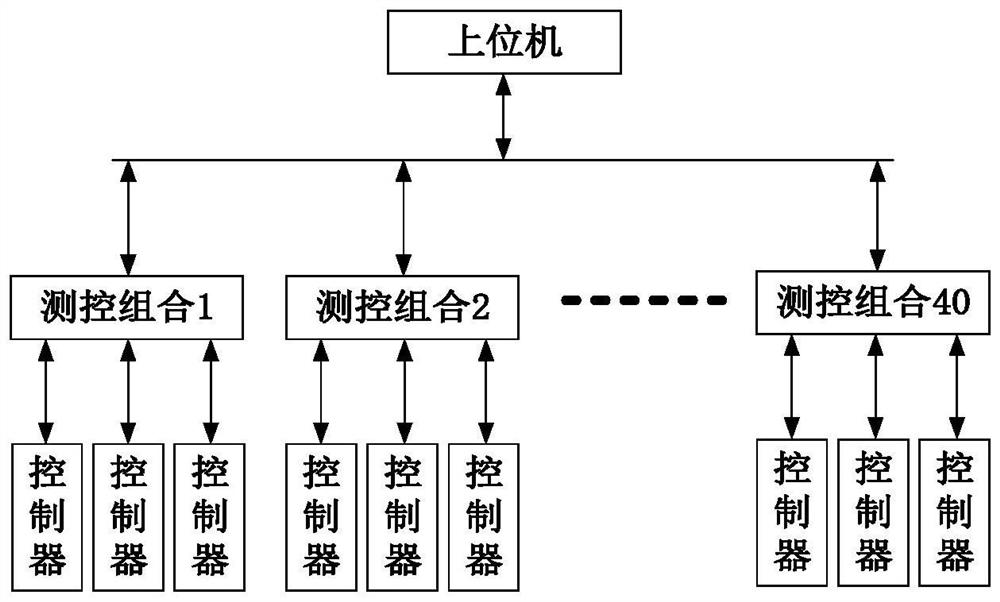

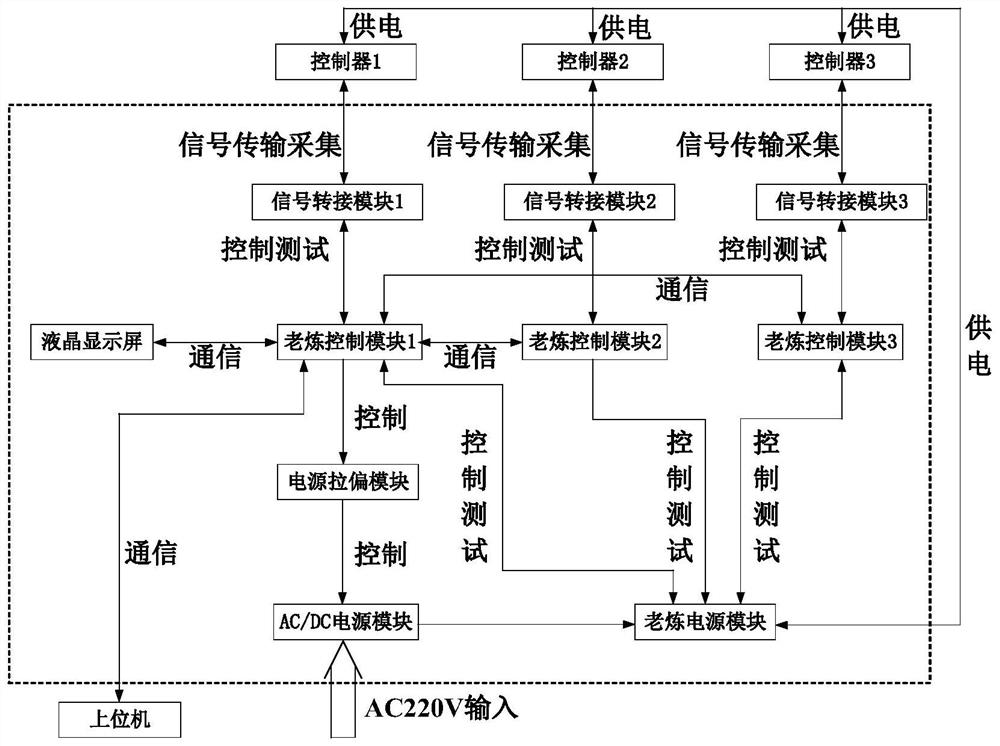

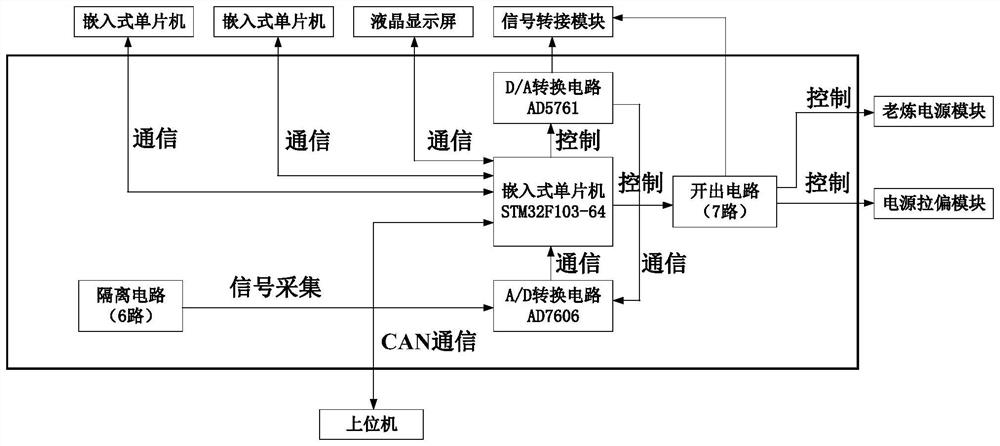

Automatic measurement and control system and method for controller environmental stress screening test

PendingCN114397872AImprove detection efficiencyImprove detection accuracyProgramme controlElectric testing/monitoringCommunication interfaceAutomatic control

The invention provides an automatic measurement and control system and related measurement and control method for a controller environmental stress screening test, and the system is based on a CAN communication protocol, and comprises an integrated embedded single-chip microcomputer, an aging control module of an A / D and D / A conversion circuit, a signal switching module, an aging power supply module, a signal switching module, a power supply bias module, a power supply module, and an upper computer. Automatic control and data storage of a plurality of controllers in a debugging stress screening test, a routine test and a product life extension aging test by one system are realized, the reliability, the stability and the detection precision of the system for an environmental stress screening test are greatly improved, and the accuracy and the traceability of data are ensured; by expanding the system optimization through a CAN communication interface, 120 controllers can be automatically monitored and controlled at the same time, and the detection efficiency of an environmental stress screening test is greatly improved.

Owner:BEIJING XINLI MACHINERY

A Comprehensive Optimization Method for Environmental Stress Screening Test and Predictive Maintenance

ActiveCN108229761BOptimize preventive maintenance timeLow costForecastingDesign optimisation/simulationRepair timePredictive maintenance

The invention discloses an environmental stress screening test and forecasting repair comprehensive optimizing method, which comprises a planning stage and an executing stage; the planning stage includes three steps which are environmental stress screening test modeling for many times, repair element confirming module and environment stress screening test, and preventive repair planning comprehensive optimization; the executing stage includes the implementation of environmental stress screening test and the predicting repair planning and execution. The method comprehensively considers the environment stress screening effect and the screening cost before the product is put into use, and the influence of the selection of the repair time on the repair cost after the product is put into use; before the product is put into use, the environmental stress condition and the test frequency are comprehensively optimized and selected on the basis of the environmental stress screening test model and the forecasting repair planning model; after putting the product into use, the preventive repair time of is optimized according to the state monitoring data of every product in use after the productis put into use; the method can effectively reduce the total cost of screening and repair.

Owner:36TH RES INST OF CETC

An environmental stress screening test method and device

The invention discloses an environmental stress screening test method and device, and aims at improving timeliness and effectiveness of environmental stress screening test. The method comprises that temperature stresses are applied according to a preset cycle index, and each time the temperature stress is applied, a first heating operation, a first high temperature maintaining operation, a second high temperature maintaining operation, a cooling operation, a first low temperature maintaining operation, a second low temperature maintaining operation and a second heating operation are executed successively; when the temperature stress is applied for the first time, a vibration stress is applied while the second high temperature maintaining operation and the second low temperature maintaining operation are executed; and each time the temperature stress is applied, an electric stress is applied. Thus, the environmental stress screening test can be completed in one test with once establishment of a test environment, three types of stresses are applied at the same time, defects in an integrated stress state can be screened, and the test timeliness and effectiveness are improved.

Owner:DATANG MOBILE COMM EQUIP CO LTD

An environmental stress screening time optimization method and equipment

ActiveCN108564224BImprove design reliabilityTime cost reductionForecastingDesign optimisation/simulationScreening durationIndustrial engineering

Owner:HUAZHONG UNIV OF SCI & TECH

Electronic device and method for realizing dynamic environmental stress screening

This invention provides a realization of environmental stress screening dynamic electronic equipment and methods, in particular: When activated, electronic equipment, have read prior instructions and the preservation of the screening information, in accordance with instructions Screening Information Executive Environmental Stress Screening procedures, in order to achieve electronic equipment own environmental stress screening. Application of this invention program, as in the electronic equipment prior to the commencement of electricity can be generated automatically screen instructions and identification information, electronic equipment, electric start, the screening can be directly under the instructions of information automatically implementation of environmental stress screening procedures, without manual intervention, so as to achieve electronic equipment dynamic environmental stress screening purposes.

Owner:NEW H3C TECH CO LTD

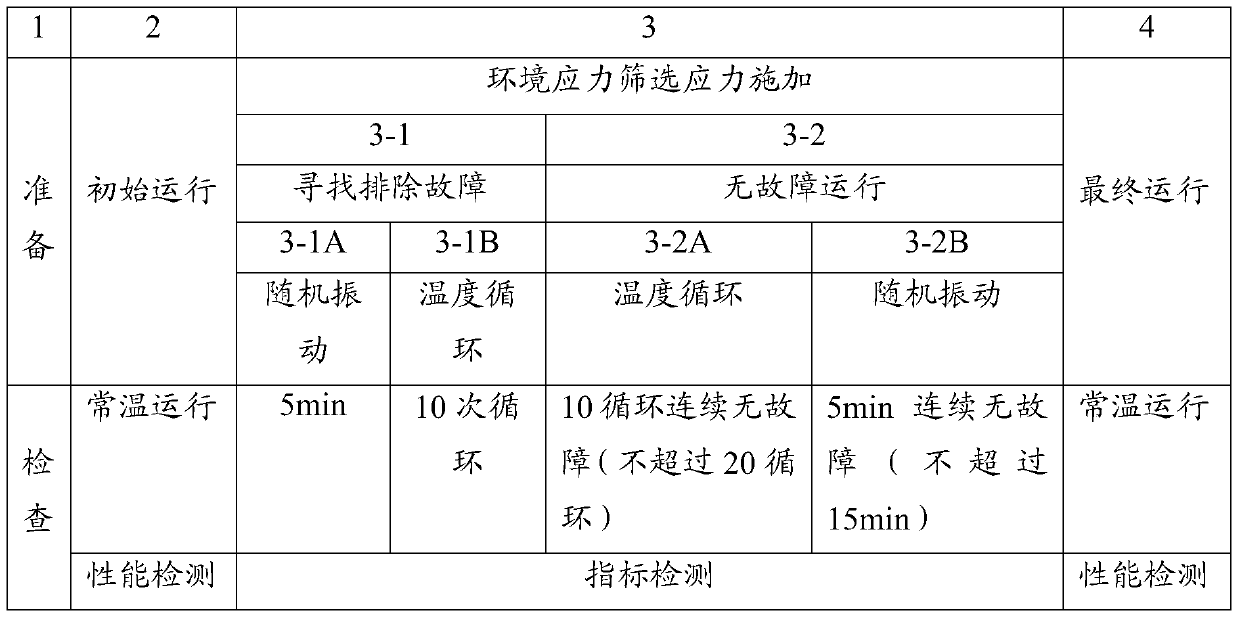

Environmental screening method of array antenna

InactiveCN108918984AEliminate workmanship defectsAvoid early failureVibration testingAntenna radiation diagramsScreening methodEngineering

The invention discloses an environmental screening method of an array antenna. The environmental screening method of the array antenna mainly comprises the following steps that under the standard atmospheric pressure condition, initial function detection is carried out on screened products according to items and requirements specified by product technical conditions, detection data is recorded, and environmental stress screening is not carried out on products which are unqualified in detection; meanwhile the screened products with qualified function detection are subjected to function detection through temperature circulation and vibration circulation ; and then the final function detection is carried out under the standard atmospheric condition. Circulation is carried out for 10 times ina temperature change box, and stress test is carried out for 5 min in the environment with the temperature being +85 DEG C to -55 DEG C and the temperature change rate being 5 DEG C / min and in vibration environment to eliminate defective parts, components and process defects in products and prevent early failure.

Owner:SICHUAN LAIYUAN TECH CO LTD

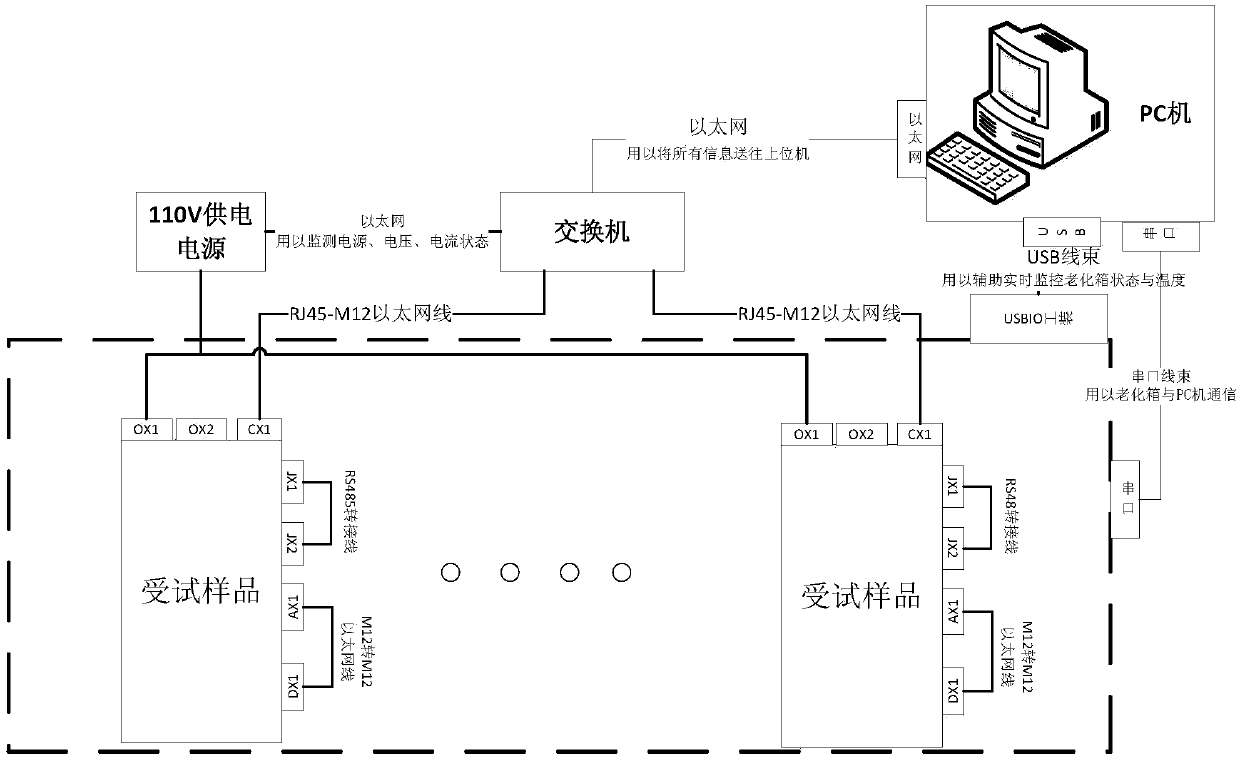

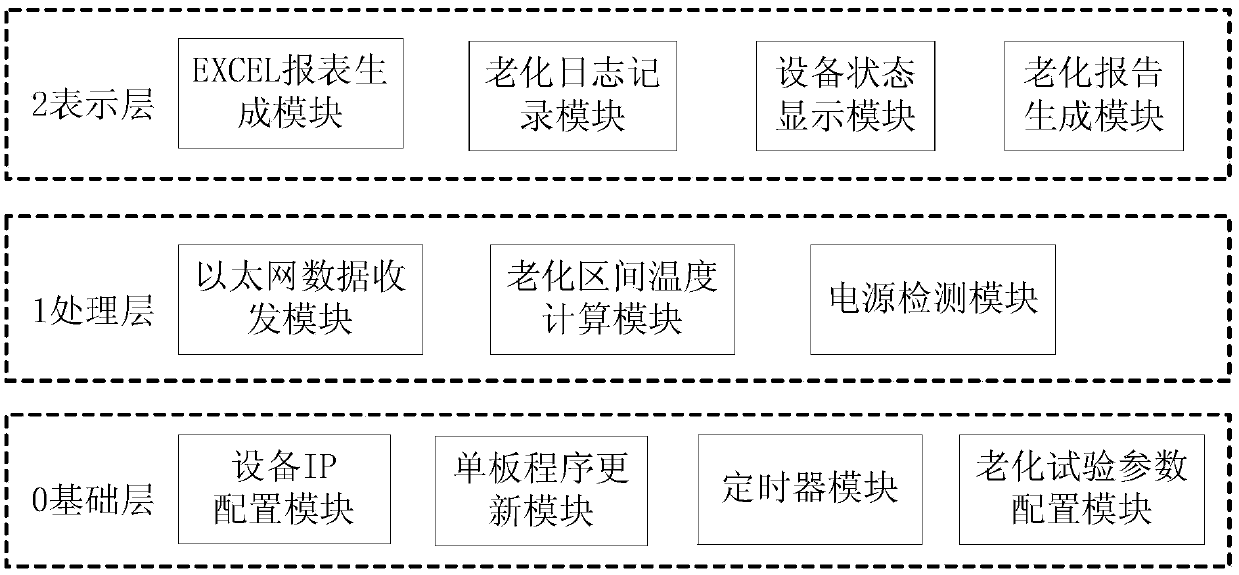

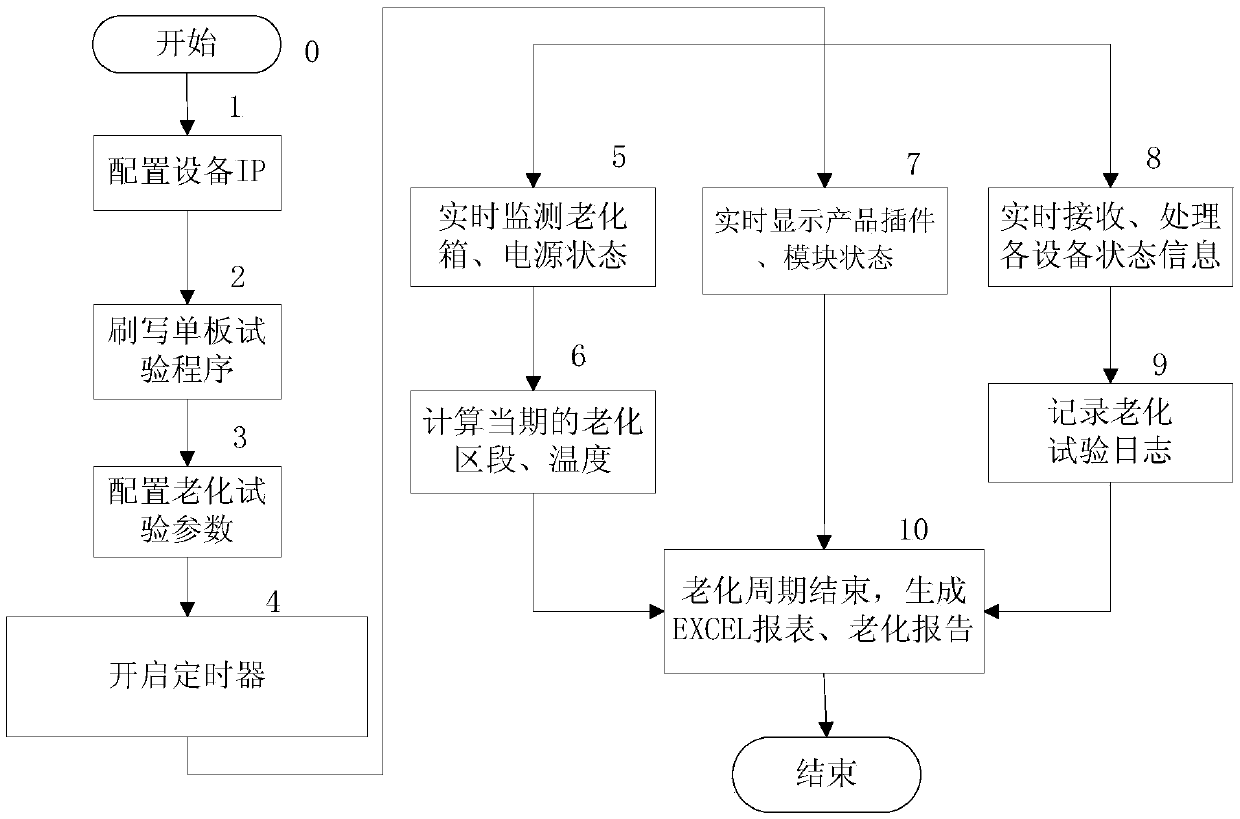

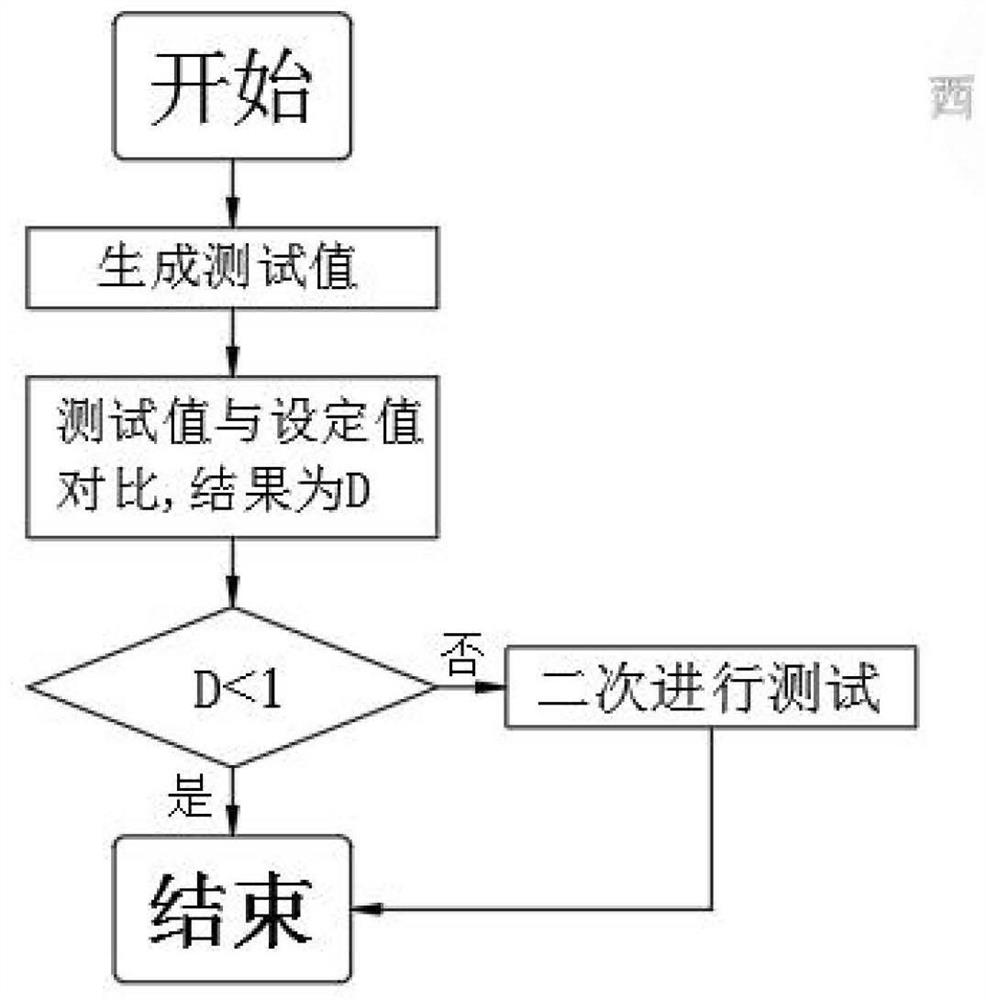

Wireless transmission device diagnosis system and method based on environmental stress screening test

InactiveCN110907342ASimple structureEasy to install and debug on siteWeather/light/corrosion resistanceEnvironmental resource managementWireless transmission

The invention discloses a wireless transmission device diagnosis system based on an environmental stress screening test, and the system comprises: a power supply unit which is used for supplying powerto a tested sample; a high-temperature and low-temperature cyclic aging box which is used for providing a test stress screening environment for the tested sample; a control unit which is connected with the power supply unit and used for monitoring the voltage or / and current state of the power supply unit in real time, is connected with the aging box and used for monitoring the real-time temperature state and aging period of the aging box, and is connected with the tested sample and used for monitoring the state of the tested sample. The invention also discloses a diagnosis method which comprises the following steps: S01, configuring the IP of each tested sample, and configuring aging parameters; s02, opening the high-low temperature cycle aging box, performing timing, and monitoring the state data of the high-low temperature cycle aging box, the power supply unit and the tested sample in real time; and S03, performing operation processing on the state data in the step S02 to obtain anaging report. The system and the method have the advantages of simplicity and convenience in operation, high universality and the like.

Owner:ZHUZHOU CSR TIMES ELECTRIC CO LTD

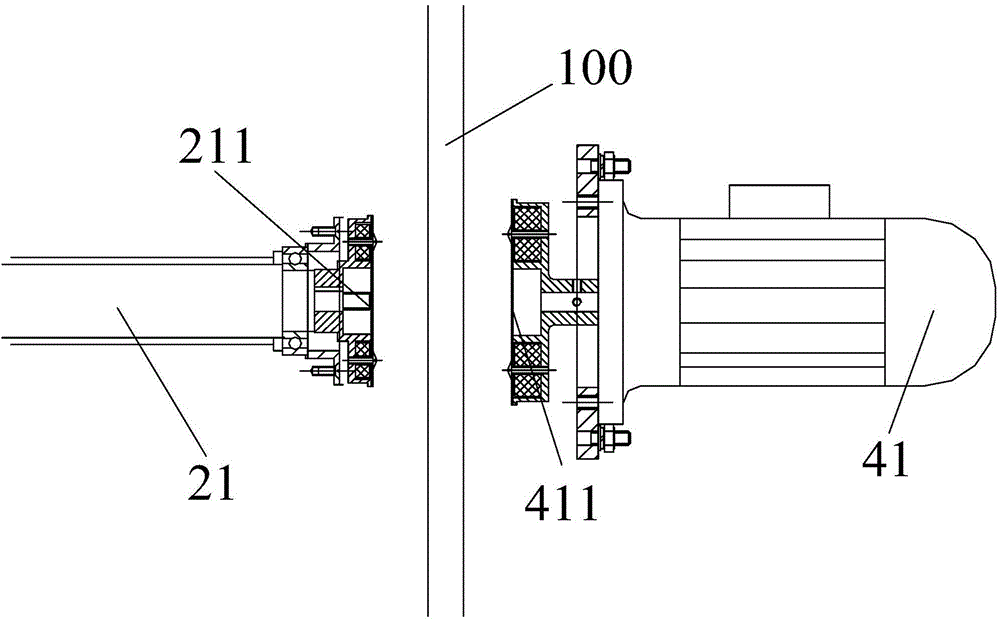

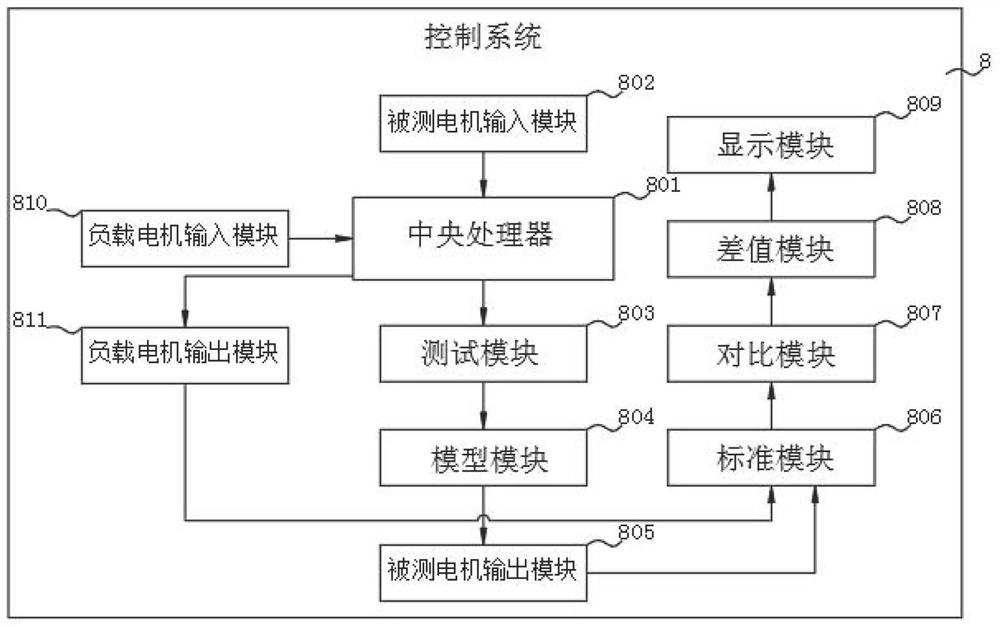

Aging test system for permanent magnet synchronous motor

PendingCN111624490ASimple structureSimplify maintenance workloadDynamo-electric machine testingElectric machineControl system

The invention discloses an aging test system for a permanent magnet synchronous motor. The test system comprises an industrial personal computer, a tested motor driver, a tested motor, a simple motortwin trawling test board, a load motor, a load box, a test cable and a control system, wherein the industrial personal computer is electrically connected with the tested motor driver through test cables, and the tested motor is electrically connected with the tested motor driver through two test cables; one cable provides output power, and the other cable provides a rotary transformer feedback signal, and the invention relates to the technical field of motor analysis and measurement. The aging test system for the permanent magnet synchronous motor is simple in structure, the maintenance workload is simplified, and the maintenance cost can be reduced; the test system is convenient to use and adapts different test situations, and the labor cost and the test cost are reduced; the motor load is convenient to control and adapts to the requirements of different motors; the device is used for testing the functional performance of the motor under various environmental conditions during environmental stress screening, and provides a test basis for the stability and reliability of products.

Owner:湖北泰和电气有限公司

A Screening Method for Environmental Stress of Cable Network

The invention discloses a cable network environmental stress screening method, which solves the problems of large differences in previous cable network screening methods and the rationality of screening parameters. The steps of the method are: firstly, determine the stress type for environmental stress screening; Theoretical and design schemes are tested, and the stress parameters are initially determined through data analysis; and then the rationality of the stress parameters is verified through verification tests. This method conducts special research on the performance structure characteristics and main failure modes of connectors, potting bodies and cable nets in the cable net, and determines that the stress that can effectively stimulate the cable net faults is temperature cycle and random vibration. The airtightness test is carried out on the cable network with airtightness requirements, which achieves the unification of the screening methods and ensures the reasonableness of the parameters.

Owner:CASIC DEFENSE TECH RES & TEST CENT

A method for high acceleration stress screening of anti-skid brake control box

The invention relates to an anti-sliding brake control box high-acceleration stress sieving method. Three comprehensive test devices are adopted, working currents are added into an anti-sliding brake control box in a test scheme, stoppage is stimulated under the common action of environment stress and the working currents and a more comprehensive improvement measure is obtained. The green effects of saving resources and time are achieved in developing the anti-sliding brake control box. By means of a high-acceleration stress sieving test profile of the anti-sliding control box, data formulating is achieved according to a high-acceleration service life test. A formulation principle is that stoppage of the anti-sliding brake control box is sieved without damaging the anti-sliding brake control box. Under the conditions, the high-acceleration stress sieving profile is composed of high temperature, low temperature, temperature vibration, vibration and the working currents. Effectiveness and safety of the test profile are verified and then the test profile can be applied to high-acceleration environment stress sieving in production to replace normal sieving in GJB1032 electronic product environment stress sieving.

Owner:XIAN AVIATION BRAKE TECH

Heat conduction mechanism of high and low temperature circulating device with wide temperature range

InactiveCN100401081CSemiconductor/solid-state device testing/measurementCompression machinesIndiumHeat conducting

The disclosed heat conduction mechanism in high-low temperature cycle unit with wide temperature range is used to reliability testing for semiconductor device and environmental stress screening for China patent 200410067891.9, which comprises: a low-temperature heat conduction mechanism in the outer bottom of liquid nitrogen sub-cylinder and contained a ring indium plate with heat-conducting silicon resin layer on both surfaces, a transient cooling head and a circular indium plate; and a high-temperature heat conduction mechanism on the heating station and formed by sticking heat-conducting silicon resin layers on the station. This invention improves the speed for testing and screening.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

Environmental stress screening tester

PendingCN108421565ASolve the problem that the heating and cooling speed is generally slowAdjustable load capacityHeating or cooling apparatusTemperature control using electric meansPositive pressureEngineering

The invention discloses an environmental stress screening tester. Temperature can be increased and decreased at a speed of 25 DEG C per minute, and temperature increasing and decreasing speed is adjustable, so that the problem that existing environmental stress screening testers are generally low in temperature increasing and decreasing speed. After the tester runs, dry air can be continuously delivered into a testing area, so that positive pressure and environment dryness of the testing area are maintained; when a cold accumulation area starts cold accumulation, a circulating airway of the testing area starts air circulation, so that in this way, quick temperature increase can be realized; after reaching set temperature, the testing area can enter a constant-temperature state; after constant temperature time is up, each compressor is controlled to work for quick cooling; when cooling speed cannot reach set cooling speed, cold of the cold accumulation area can enter the circulating airway of the testing area by only opening a valve of the cold accumulation area, so that cooling speed can be accelerated; when the cooling speed reaches the set cooling speed or when temperature reaches a set value, the valve of the cold accumulation area is off automatically.

Owner:DONGGUAN JIEXIN TESTER EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com