Aircraft brake system low temperature test method

A brake system and low-temperature test technology, which is applied in the low-temperature test field of civil aircraft brake systems, can solve the problems of inability to verify low-temperature adaptability and low-temperature life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

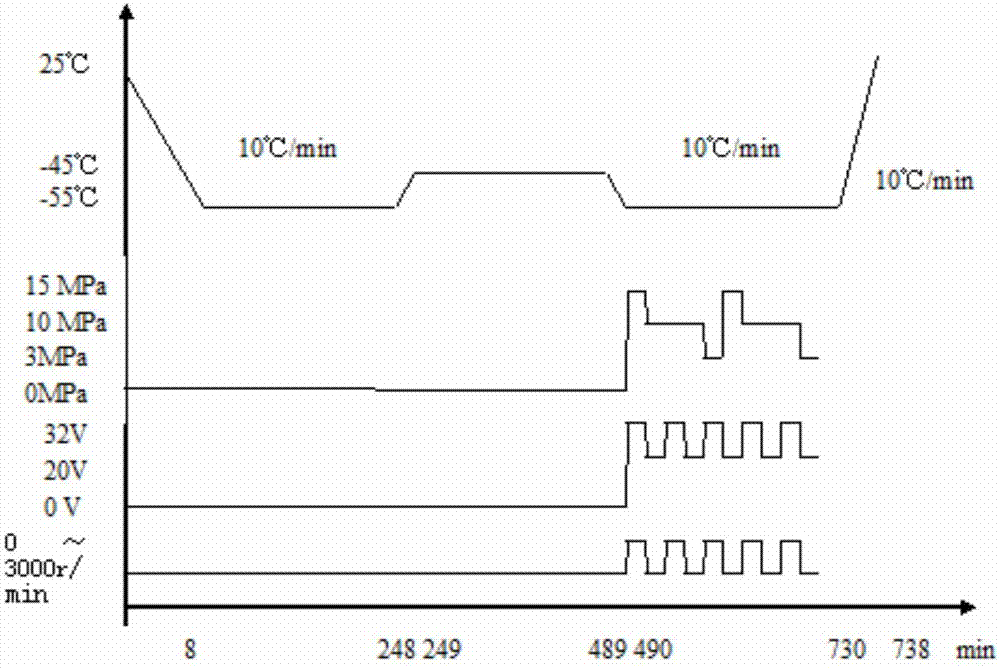

[0078] In this embodiment, a low-temperature test is carried out on a brake system of a civil aircraft. The service life of the brake system is 5000 landings / 10 years, whichever comes first. The low-temperature storage and low-temperature working test profiles shall be formulated according to the life requirements.

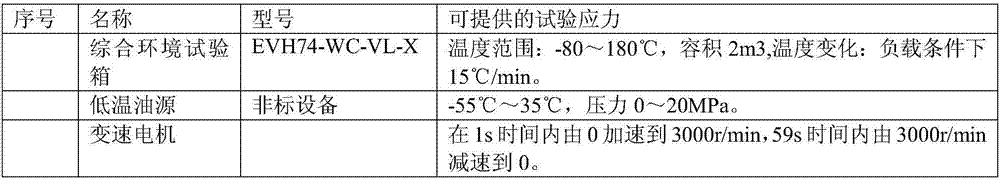

[0079] This embodiment uses the test equipment shown in Table 1.

[0080] Table 1 Summary of Low Temperature Test Equipment for Civil Aircraft Braking System

[0081]

[0082] The matching products of the civil aircraft braking system described in this embodiment are shown in Table 2.

[0083] Table 2 Supporting Products of Civil Aircraft Braking System

[0084]

[0085]

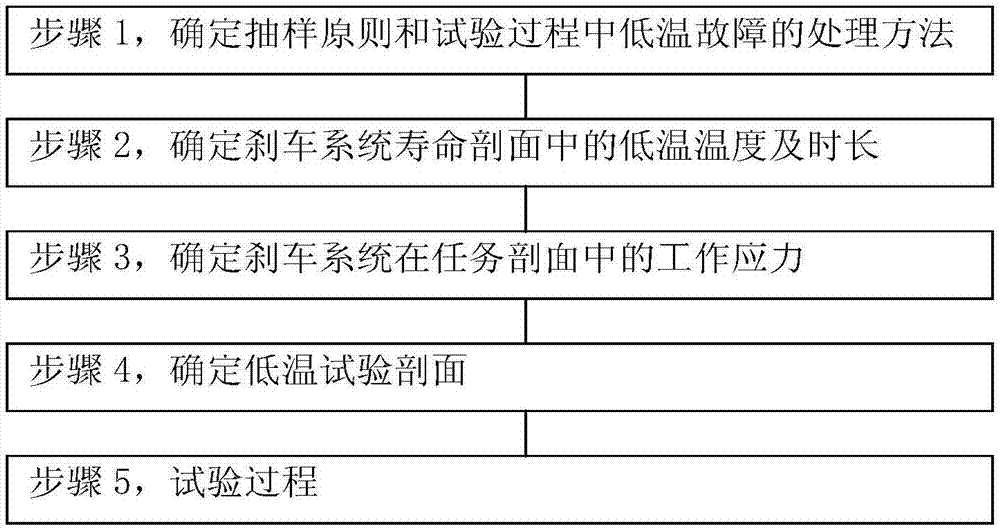

[0086] The concrete process of this embodiment is:

[0087] Step 1. Determine the sampling principle and the treatment method for low temperature faults during the test.

[0088] One set of brake system is randomly selected to represent the model for low temperature test. If no fail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com