Rapid temperature change test box

A temperature change, test box technology, applied in electrical program control, program control in sequence/logic controllers, etc., can solve problems such as product condensation, affecting test results, high humidity, etc., to improve accuracy and strengthen the box. Body sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

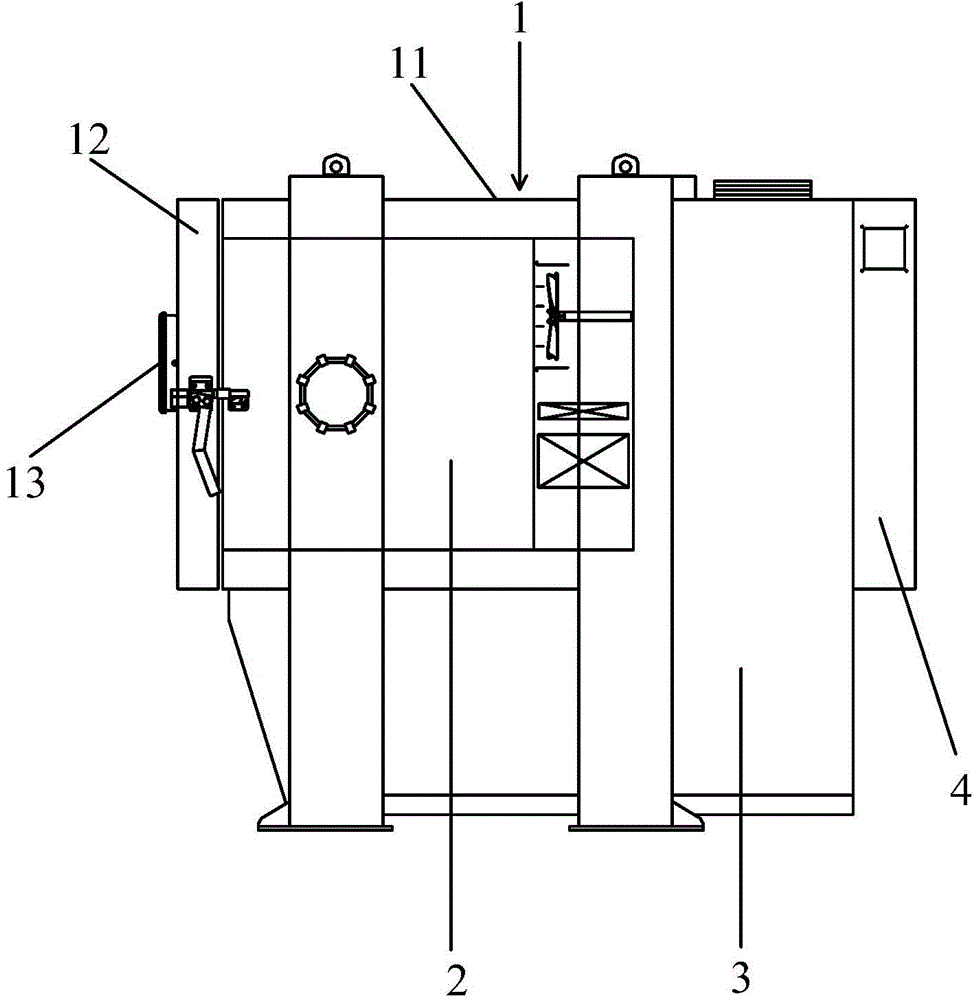

[0032] Embodiments of the present invention provide a rapid temperature change test chamber, see figure 1 , the rapid temperature change test box includes a box body 1, and the box body 1 includes a box body 11 and a partition layer (not shown) that separates the box body 11 into three sections, and the three sections are successively working chambers. 2. Refrigeration room 3 and power distribution room 4.

[0033] Wherein, on the box body 11 forming the working chamber 2 , a box door 12 is provided on the side opposite to the isolation layer forming the working chamber 2 .

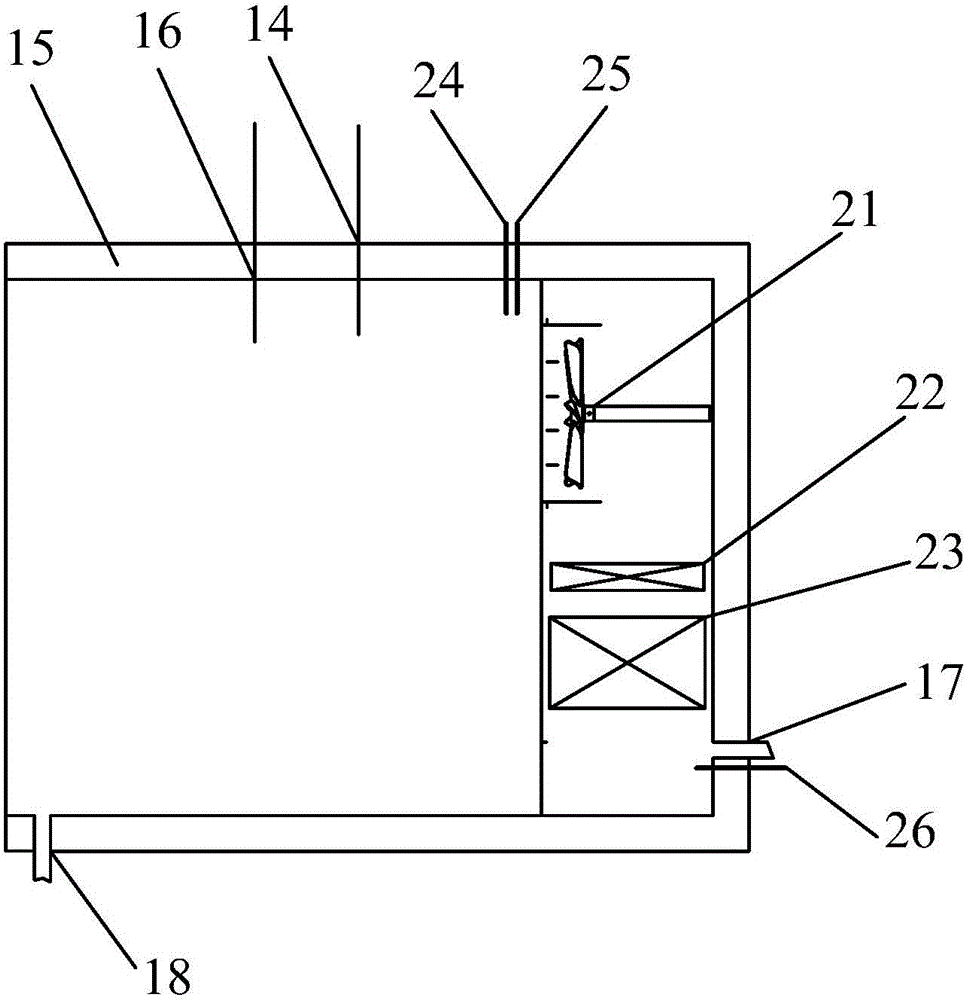

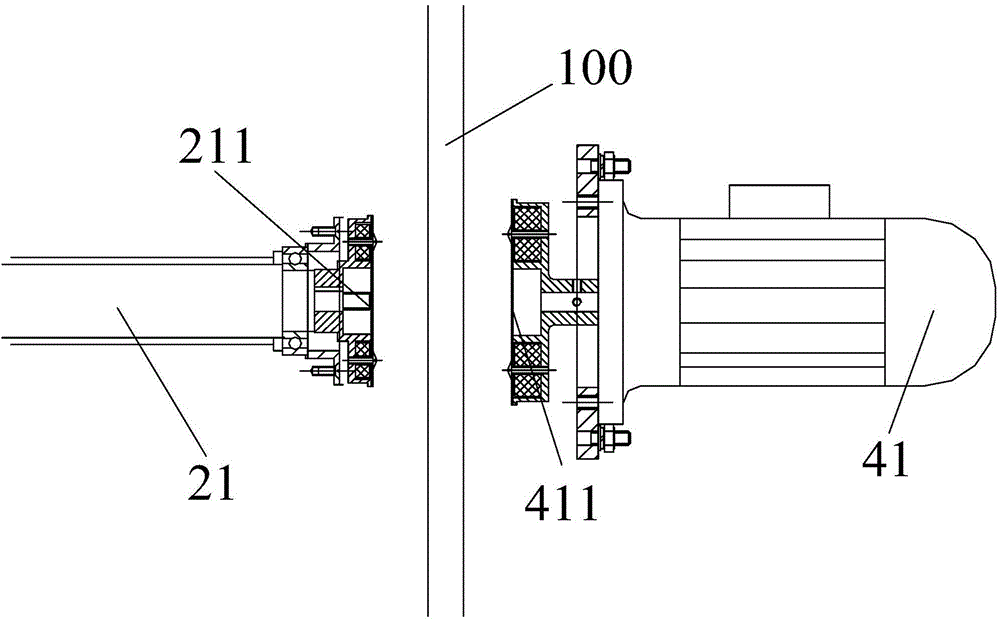

[0034] see figure 2 , the studio 2 is provided with an axial flow fan 21, a heater 22, a cooling evaporator 23, and a humidifying water basin (not shown in the figure), and the heater 22, the cooling evaporator 23, and the humidifying water basin are all provided with a working The pipeline connecting indoor and outdoor. Preferably, the axial flow fan 21, the heater 22, and the refrigeration evaporato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com