A method for high acceleration stress screening of anti-skid brake control box

A high-acceleration stress and anti-skid braking technology, which is applied in the testing of machines/structural components, measuring devices, vibration testing, etc., can solve the problem of poor excitation of faults, and achieve the effect of saving resources and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

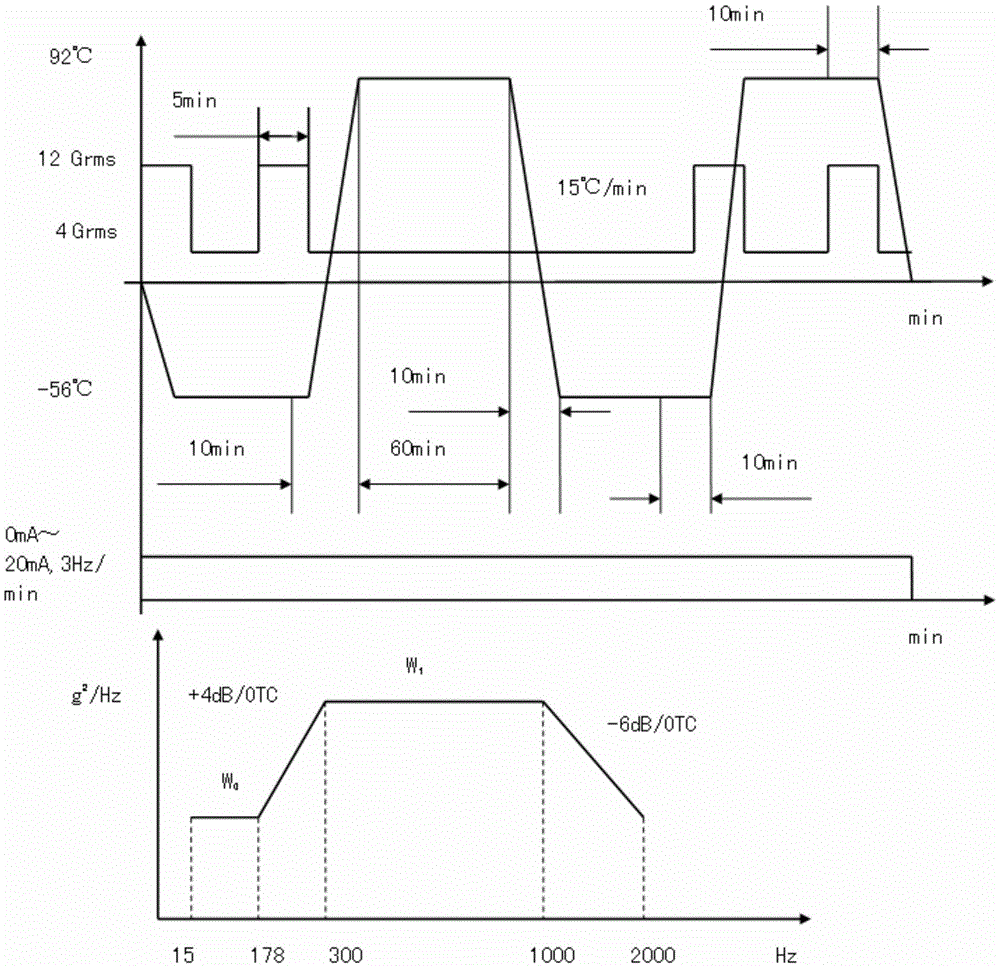

Embodiment 1

[0098] In this embodiment, a high-acceleration stress screening test is carried out on the anti-skid brake control box of the first domestic regional aircraft braking system. Highly accelerated stress screening test profile, complete the verification of the effectiveness and safety of the highly accelerated stress screening test profile, and the verified high accelerated stress screening test profile can be implemented in production.

[0099] The specific steps of the test are:

[0100] Step 1. Determine the high temperature damage limit of the antiskid brake control box

[0101] The high-temperature damage limit of the anti-skid brake control box is determined by prior art. The high-temperature damage limit is used to determine the high-temperature temperature of the high-accelerated stress screening test section, and the temperature range of the high-temperature damage limit is 115° C. to 125° C. In this embodiment, 115° C. is used as the high-temperature damage limit.

[...

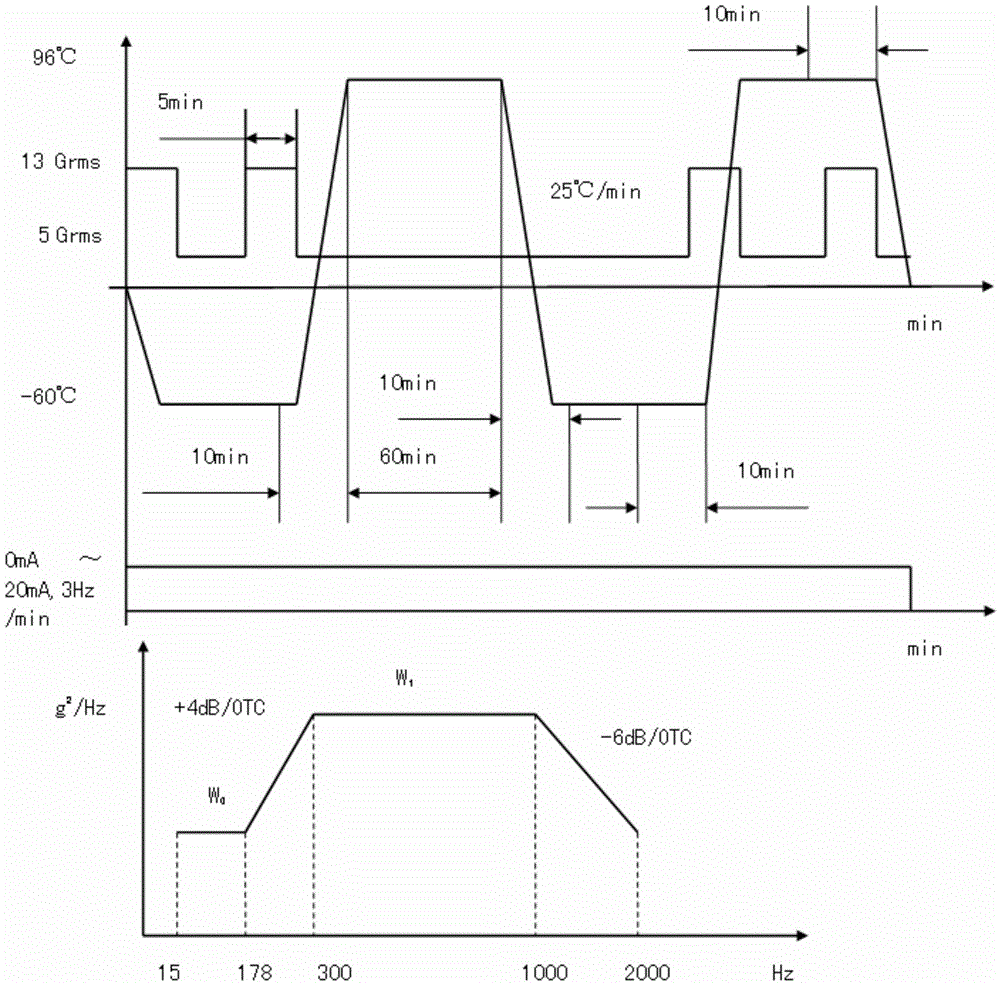

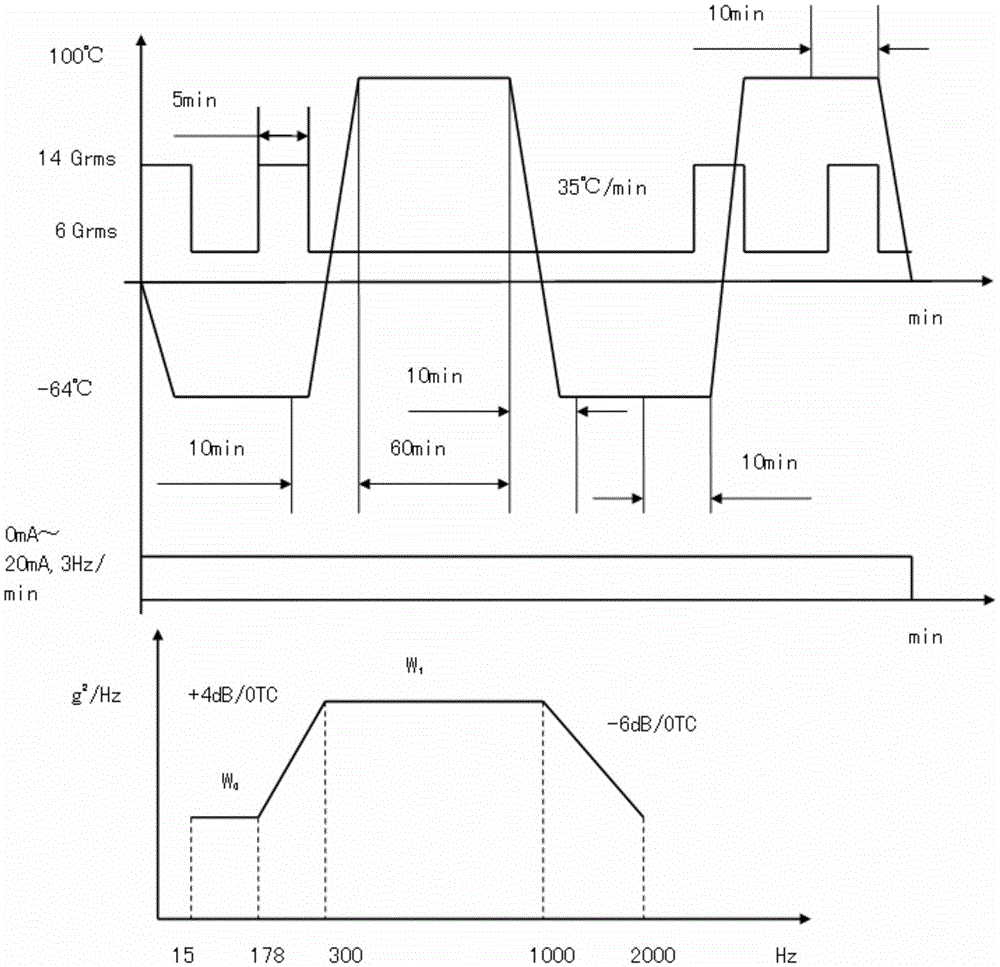

Embodiment 2

[0150] The processes of embodiment 2 and embodiment 3 all include testing the high-temperature damage limit of the anti-skid brake control box, adopting liquid nitrogen auxiliary temperature control to test the low-temperature damage limit of the anti-skid brake control box, and adopting sine frequency sweep and broadband to randomly test the damage limit of the anti-skid brake control box Hidden dangers of vibration failure, triggering the failure of the anti-skid brake control box under the condition of rapid temperature change, applying comprehensive environmental stress and working stress to stimulate the failure of the anti-skid brake control box, test and verification of the improved anti-skid brake control box, based on the high accelerated life test Data formulate the steps of the high-accelerated stress screening test profile, the validity verification of the high-acceleration stress screening test profile, and the safety verification of the high-acceleration stress scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com