Environmental stress screening method of electronic device by using stepping stress

A technology for environmental stress screening and electronic equipment, applied in the direction of measuring electricity, measuring electrical variables, measuring devices, etc., can solve the problems of low screening efficiency and insufficient screening effect, so as to improve the screening effect, strengthen the popularization, and improve the effectiveness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described by examples below, but it should be noted that the purpose of announcing examples is to help further understand the present invention, but those skilled in the art can understand: without departing from the spirit and spirit of the present invention and the appended claims Various alternatives and modifications are possible within the scope. Therefore, the present invention should not be limited to the content disclosed in the examples, and the protection scope of the present invention is subject to the scope defined in the claims.

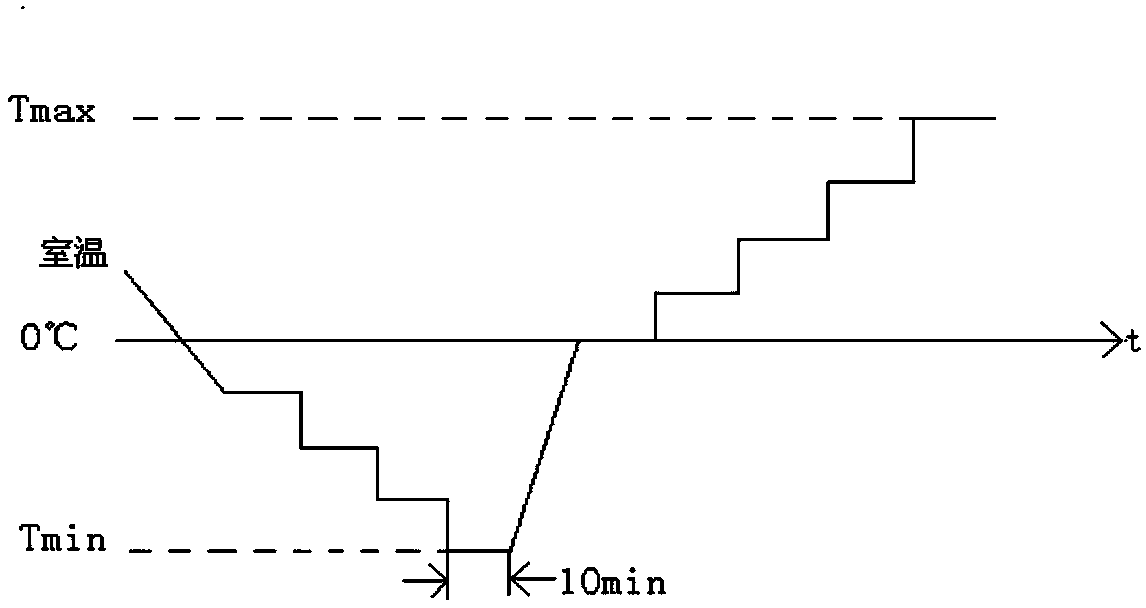

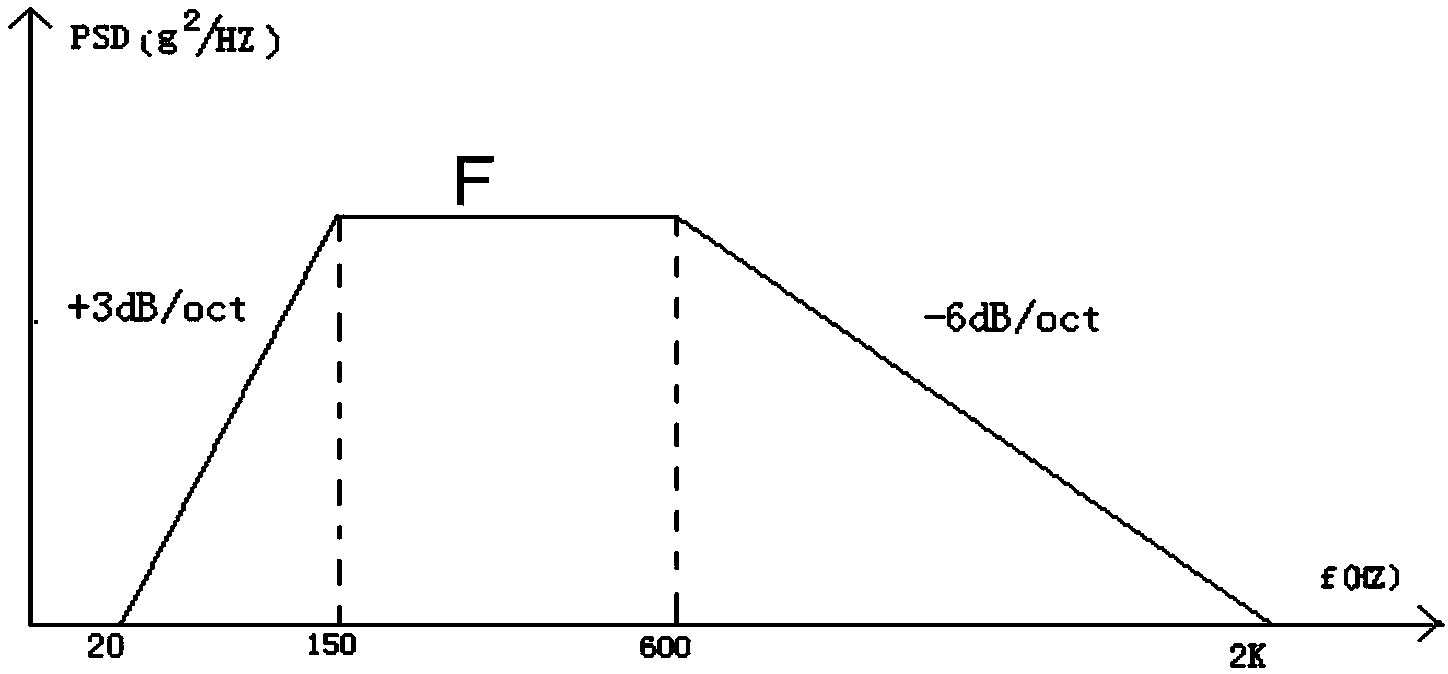

[0027] The specific environmental stress screening methods are as follows:

[0028] The first step is to build an environmental stress screening system

[0029] The environmental stress screening system includes a temperature box, a vibration table, and test equipment for screening objects. The screening object and test equipment are connected through test cables or channels on the temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com