Heat conduction mechanism of high and low temperature circulating device with wide temperature range

A high and low temperature cycle, wide temperature technology, used in lighting and heating equipment, coolers, refrigerators and other directions, can solve problems such as point contact, increased thermal resistance, heat transfer table rise, and cooling rate decline.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

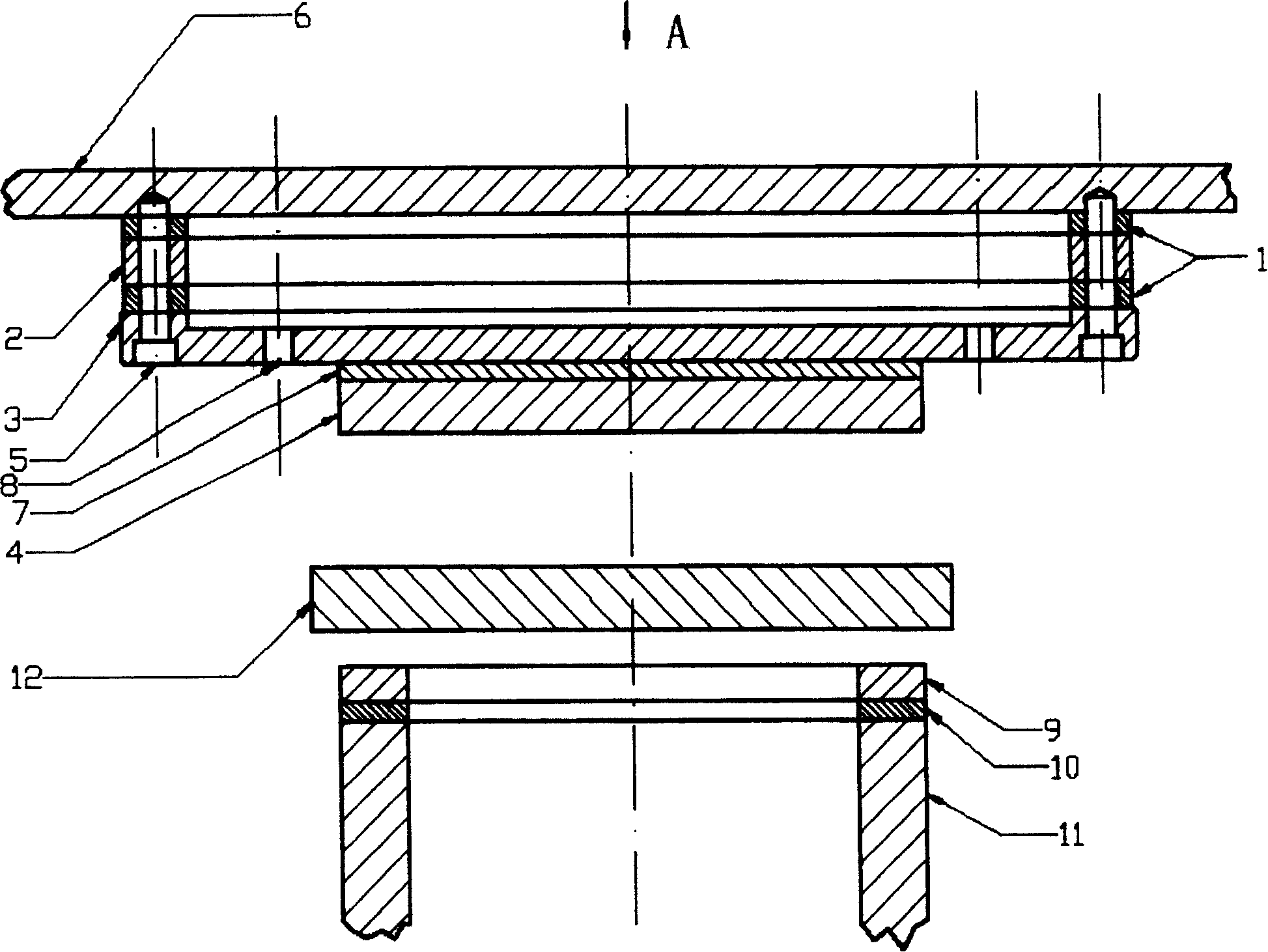

[0011] Below in conjunction with accompanying drawing, the specific embodiment of the present invention is described in detail:

[0012] The heat conduction mechanism of the present invention includes: a low temperature heat conduction mechanism and a high temperature heat conduction machine.

[0013] The low-temperature heat conduction mechanism is placed outside the bottom of the liquid nitrogen sub-cylinder, and consists of ring-shaped indium sheets 2 coated with heat-conducting silicone grease layers 1 on both sides, transition cold heads 3 and circular indium sheets 4 arranged in sequence from top to bottom. The ring-shaped indium sheet 2 and the transition cold head 3 are fixed on the bottom of the liquid nitrogen sub-cylinder 6 by screws 5, and the circular indium sheet 4 is pasted on the bottom surface of the transition cold head 3 through a heat-conducting silicone grease layer 7. The ring-shaped indium sheet 2 requires the upper and lower sides to be processed flat, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flatness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com