Preparation method for environmentally sensitive loops

An environment-sensitive, ring-shaped technology, which is applied in gyroscope/steering sensing equipment, instruments, surveying and navigation, etc., can solve problems such as difficulty in applying large vibration levels and large changes in non-orthogonal angles, and achieve improved wettability and contact angle. Reduce and increase the effect of application level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

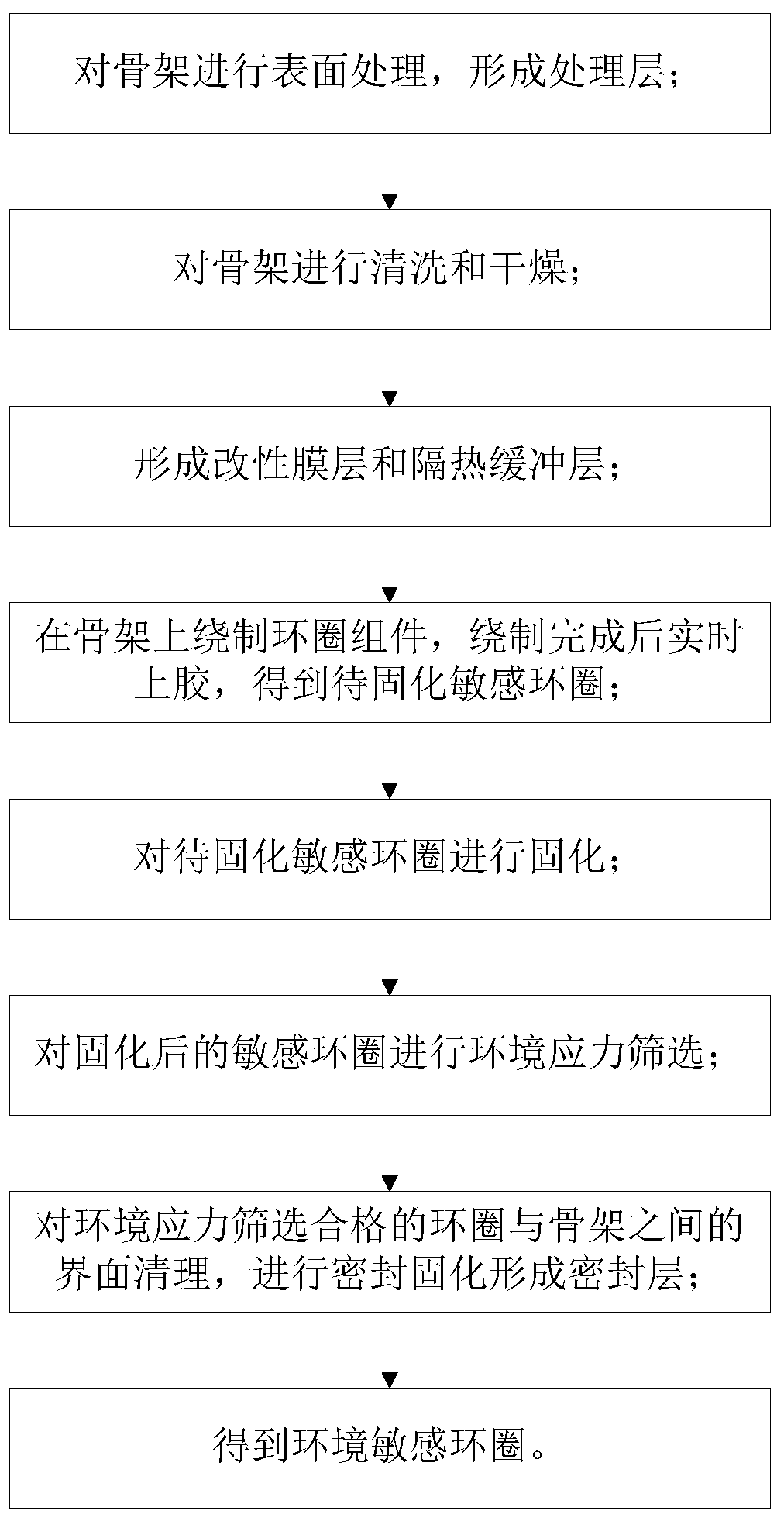

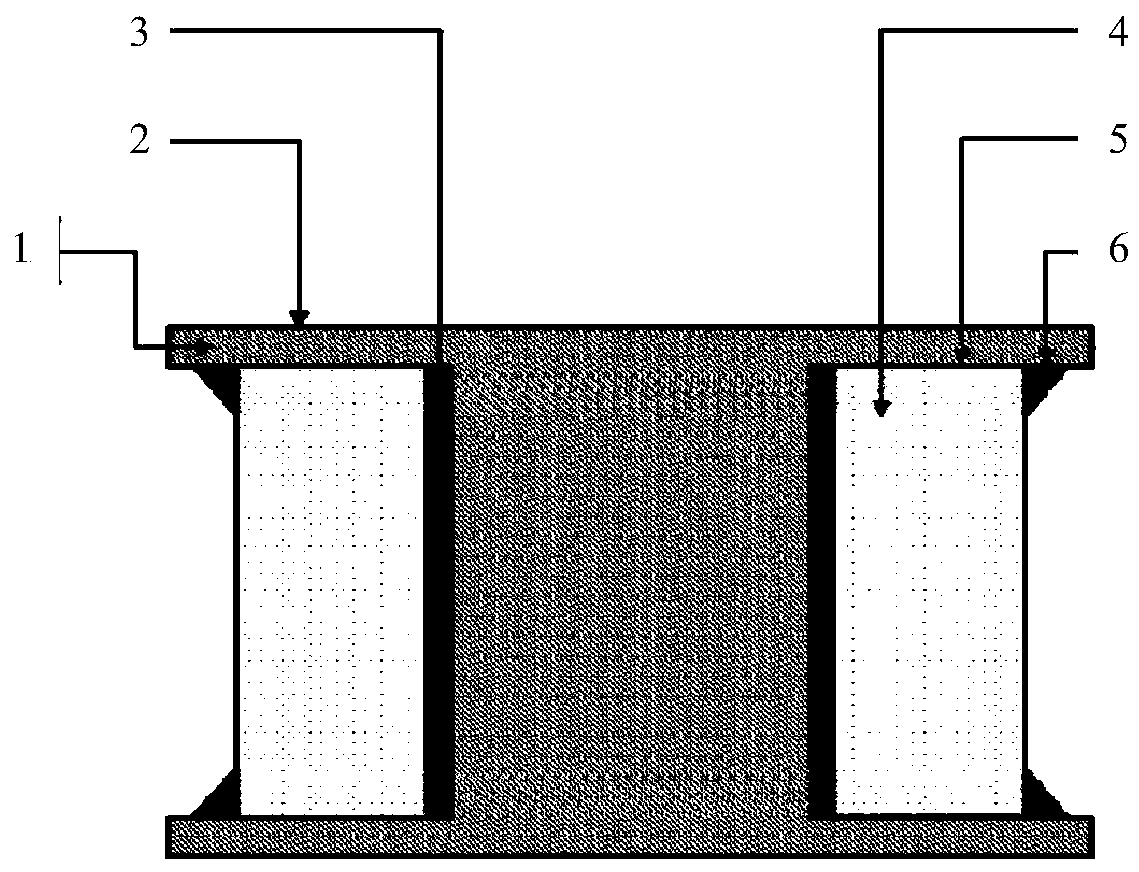

[0035] The invention provides a method for preparing an environmentally sensitive ring, see Figure 1 to Figure 4 , including the following steps:

[0036] Step 1: Carrying out surface treatment to skeleton 1 to form treatment layer 2;

[0037] Step 2: cleaning and drying the skeleton 1 obtained in step 1;

[0038] Step 3: forming a modified film layer 3 and a thermal insulation buffer layer 4 on the surface of the treatment layer 2;

[0039] Step 4: Wind the ring component 5 on the skeleton 1 obtained in step 3, and apply glue in real time under the condition of 50-60°C after the winding is completed, to obtain the sensitive ring to be cured;

[0040] Step 5: curing the sensitive ring to be cured;

[0041] Step 6: Carry out environmental stress screening on the cured sensitive ring. Environmental stress screening can effectively release stress before interface sealing, and avoid damage to the sealing layer 6 by stress creep;

[0042] Step 7: Clean the interface between th...

Embodiment 1

[0057] For the convex-shaped hard aluminum alloy (2A12T4) skeleton, the chromic acid anodic oxidation treatment layer is used as the treatment layer, the KH792 silane coupling agent of Nanjing Nende Company is used as the modified film layer, and two layers homologous to the sensitive optical fiber are used Single-mode non-polarized optical fiber is used as the heat-insulating buffer layer 4, and a panda-type polarization-maintaining optical fiber with a cladding diameter of 80 microns / coating diameter of 165 microns is used as the optical fiber for the sensitive ring, and a self-made acrylic resin UV ring adhesive is used. It is wound in a symmetrical way, and Chenguang GD414 is used as the sealing layer.

[0058] Compared with the original sulfuric acid anodized layer, without modified film layer, the same sensitive optical fiber is used as the thermal insulation buffer layer 4, and the panda-type polarization-maintaining optical fiber with a cladding diameter of 80 microns / c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com