Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

107 results about "Cartridge heater" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A cartridge heater is a tube-shaped, heavy-duty, industrial Joule heating element used in the process heating industry, usually custom manufactured to a specific watt density, based on its intended application. Compact designs are capable of reaching a watt density of up to 50W/cm² while some specialty high temperature designs can reach 100w/cm².

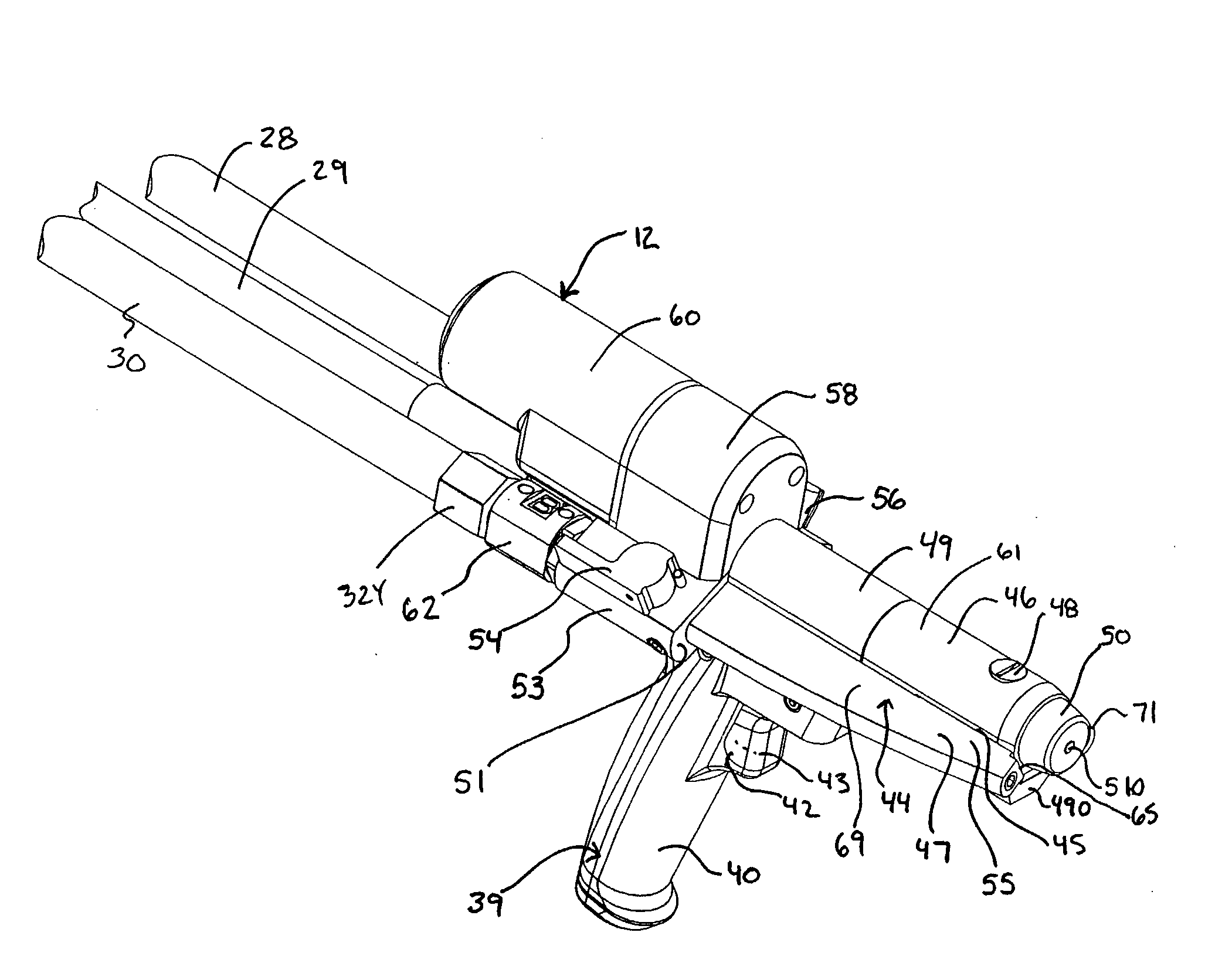

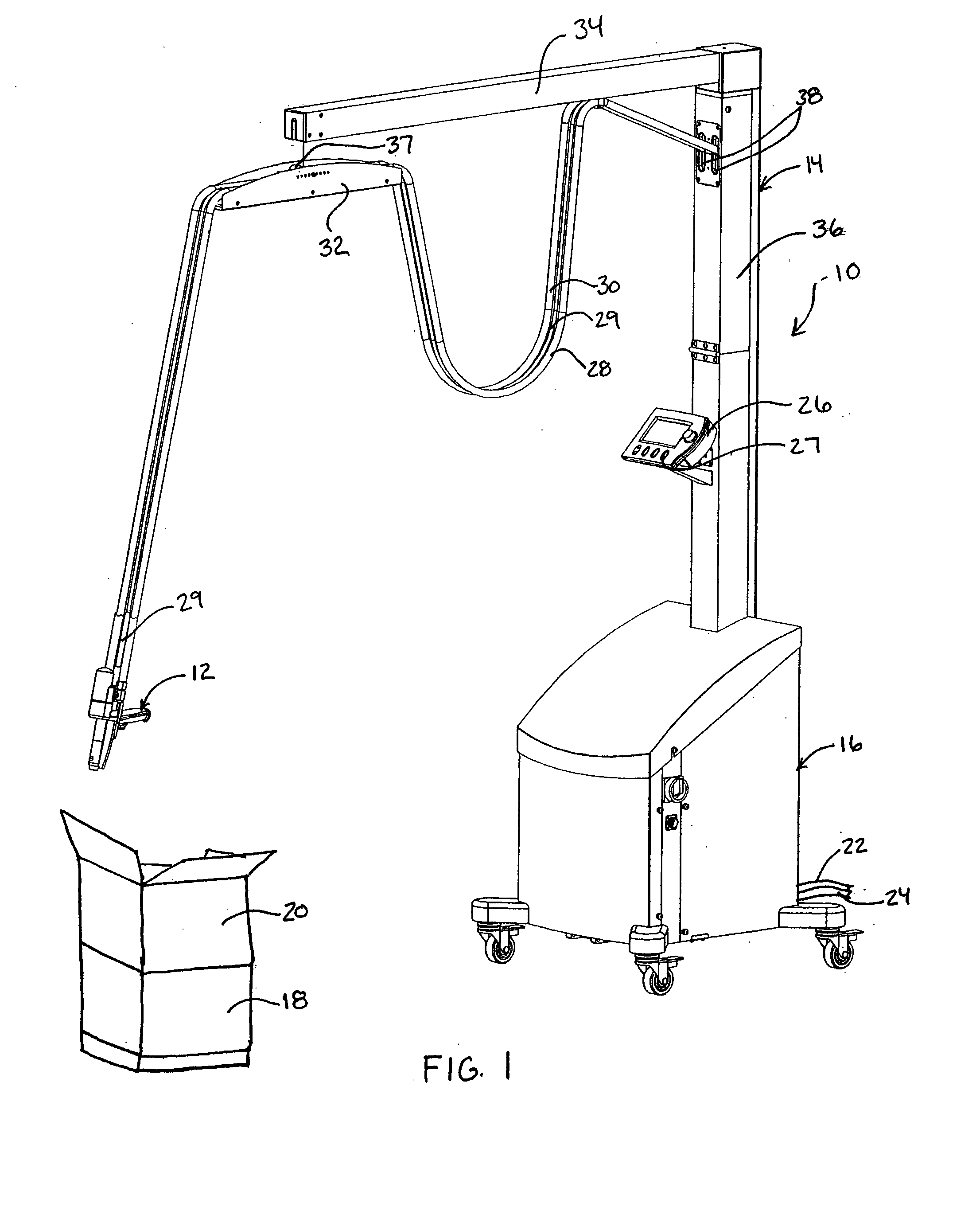

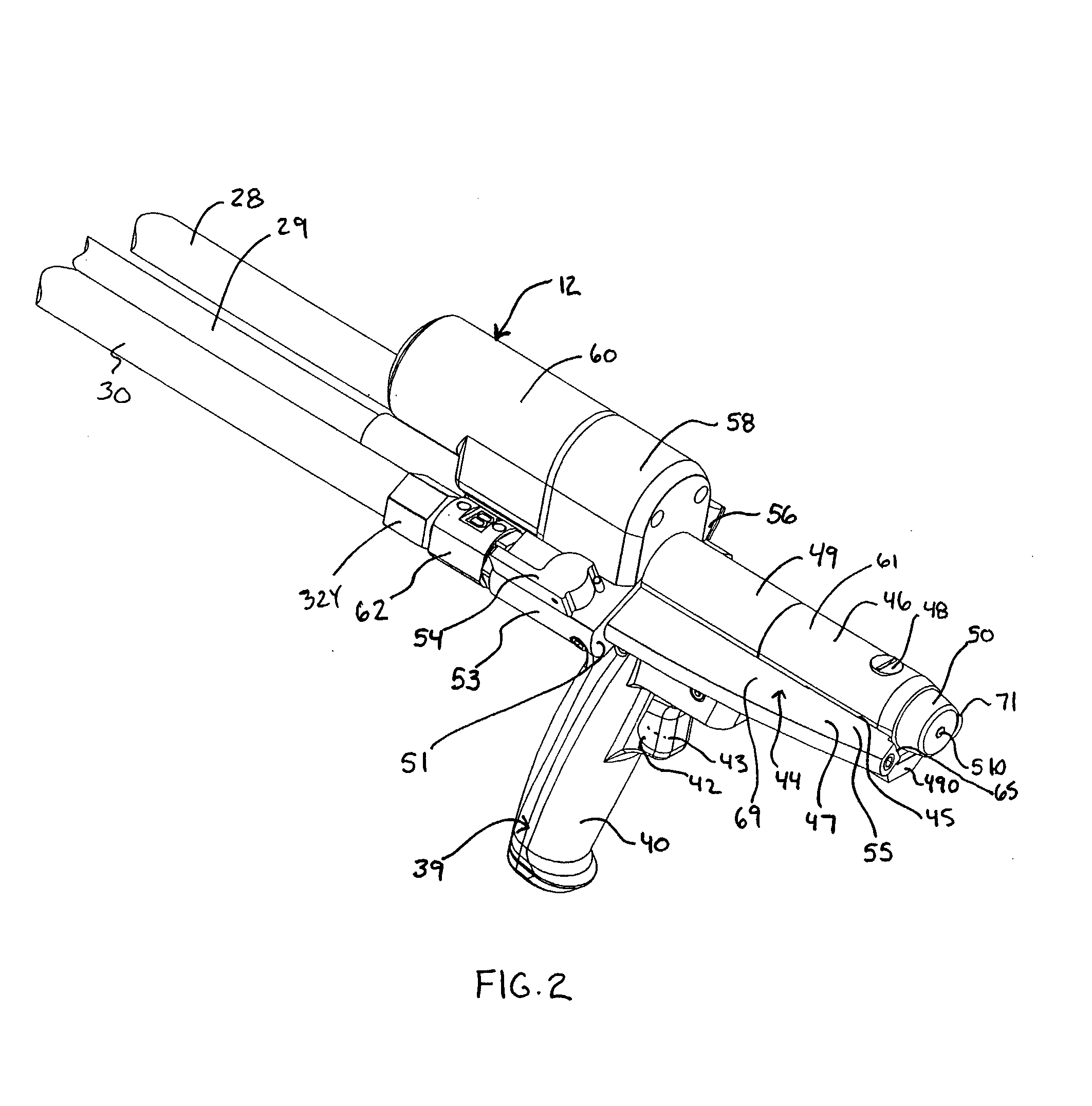

Hand Held Dispenser

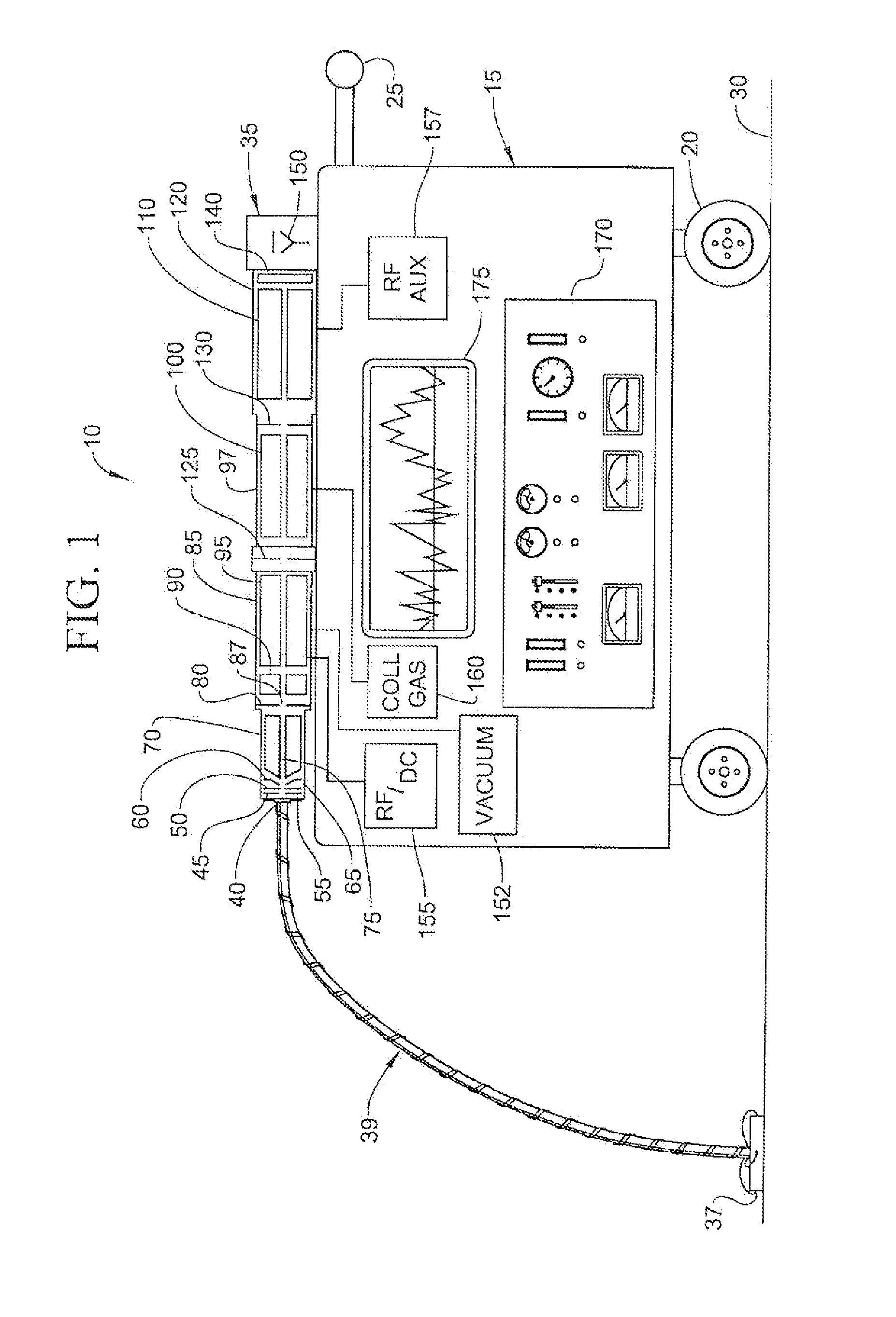

ActiveUS20080135579A1Minimize downtimeEasy to disassembleLiquid flow controllersLarge containersTemperature controlHand held

A hand held dispenser system with associated dispensed material supply assembly as in separate source chemical foam precursor feeding into, for example, streamlined chemical passageways preferably each comprised of, in series, a castellated swivel hose filter, a valve assembly housing, a wing extensions of a manifold, which manifold supports a high efficiency drive system and is supported by a handle that provides for a compact assembly and receives a rugged trigger assembly. The manifold design provides for elongated filter and, temperature controlled cartridge heater insertion. There is further provided in a preferred embodiment a readily releasable electric source feed line plug connection at the butt end of the dispenser. The dispenser is well suited for the dispensing of methane foam as in a product packaging setting.

Owner:PREGIS INTELLIPACK CORP

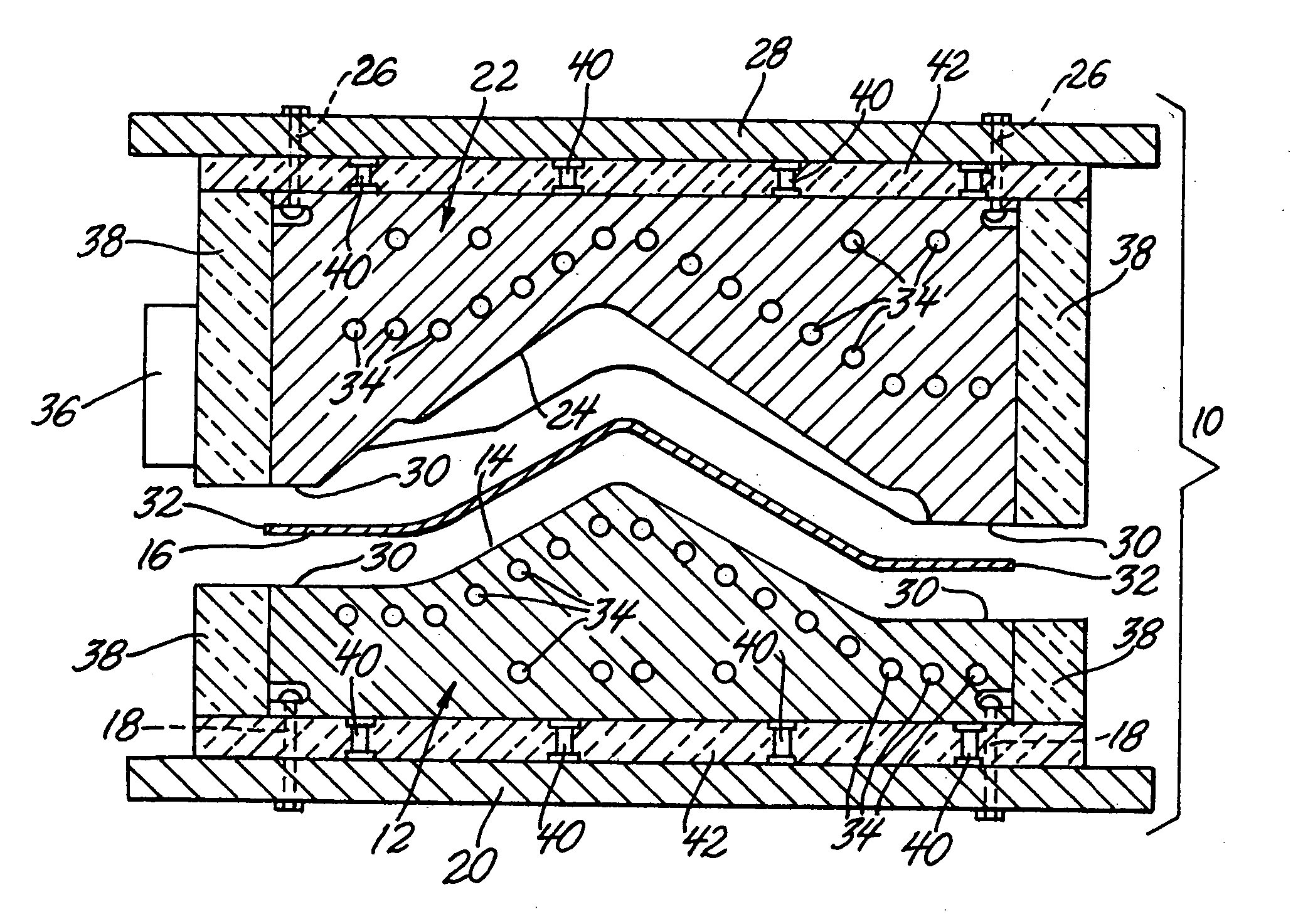

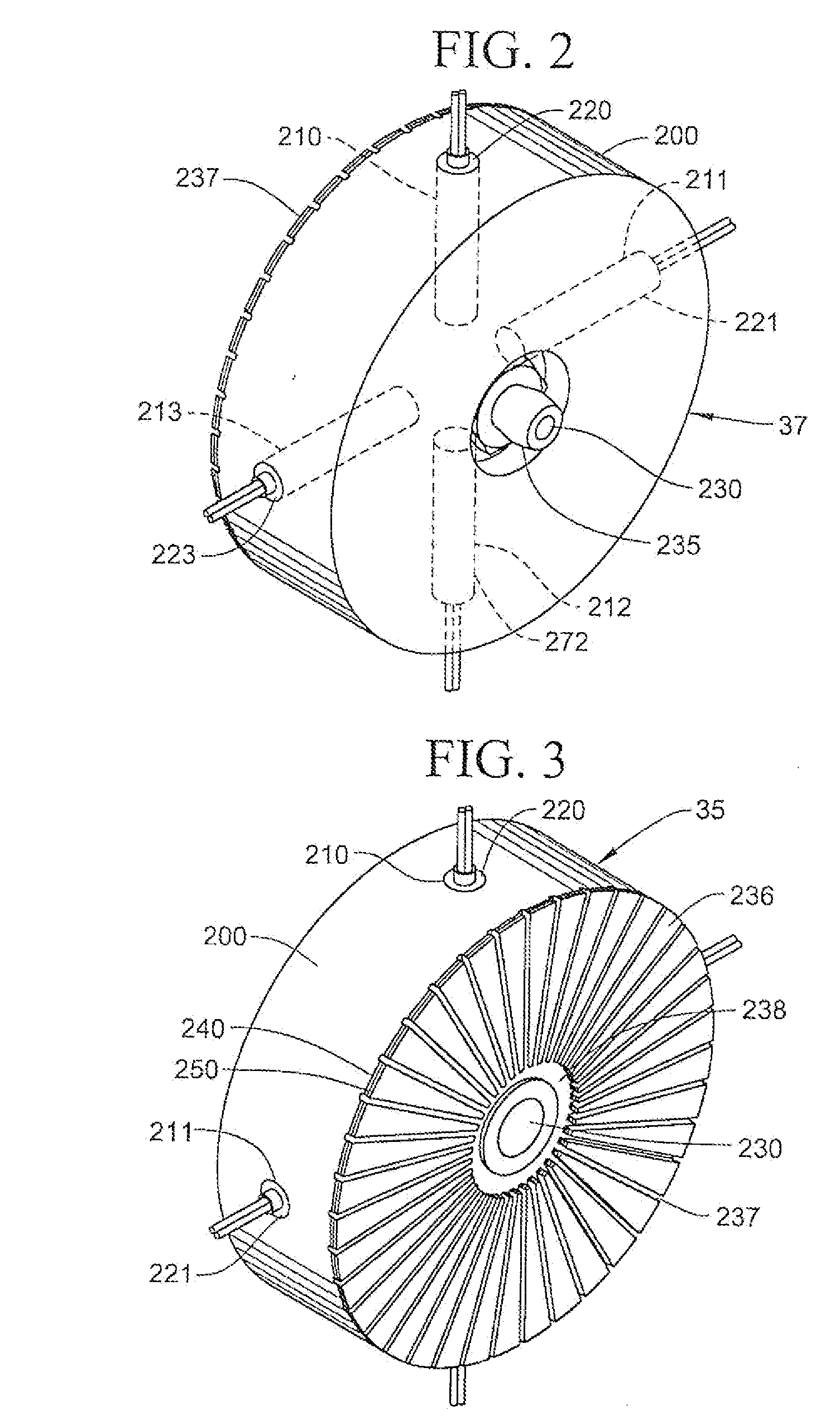

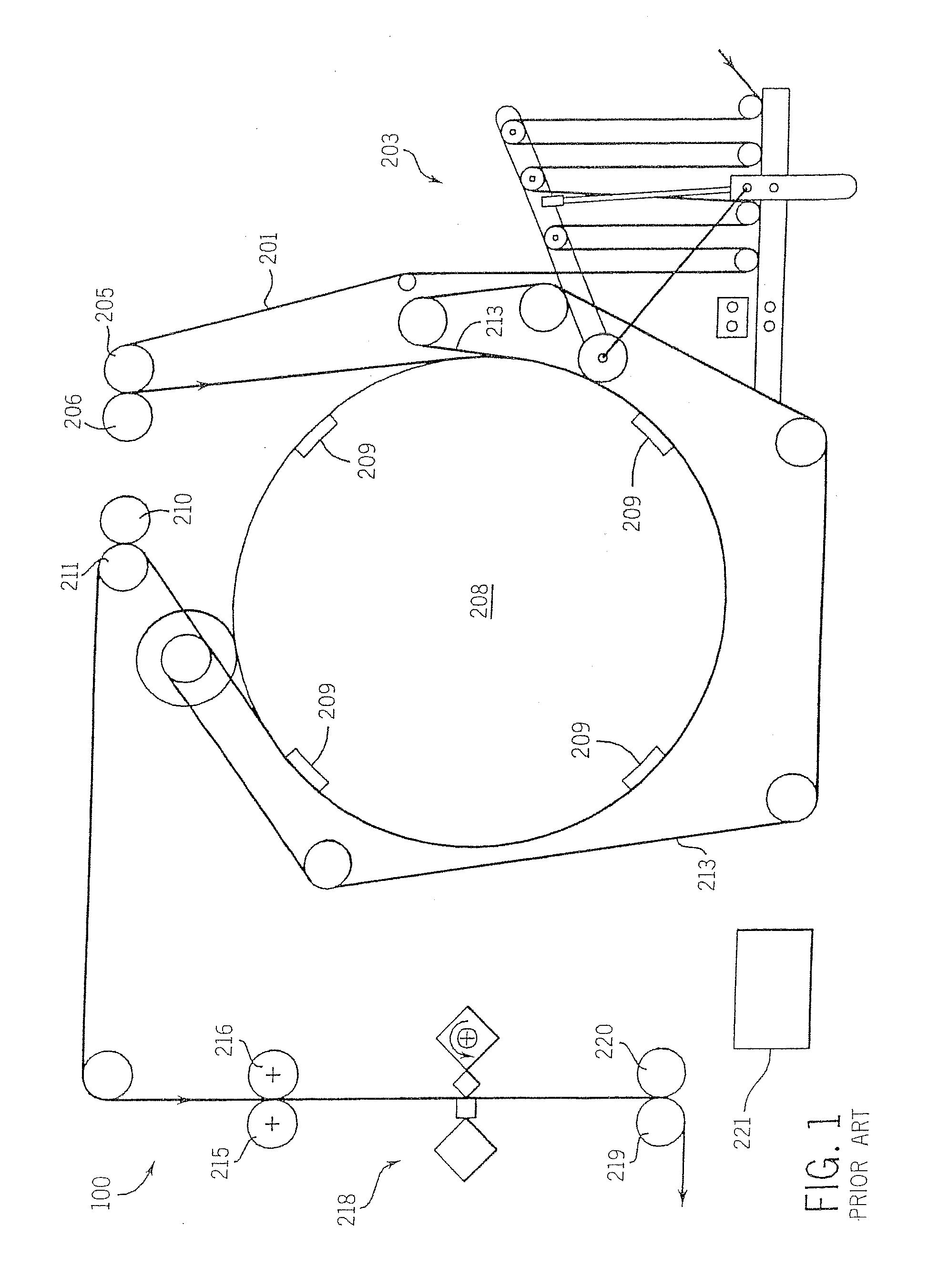

Method and apparatus for making bags

ActiveUS20070167304A1Envelopes/bags making machineryMechanical working/deformationMicrowaveEngineering

A machine and method for making bags is described and includes a web traveling from an input section to a rotary drum, to an output section. The rotary drum includes at least one seal bar, having a first sealing zone, and an adjacent weakening zone. The weakening zone may be a heated perforator, includes a heating wire, or be disposed to create an auxiliary sealed area. The heating wire can have, connected thereto, a source of power that is at an adjustable voltage or magnitude, and / or pulsed, and / or a feedback loop. The heating wire may be an NiCr wire and make intermittent contact with the web and be disposed in an insert. The weakening zone may create a line of weakness that is uniform or varies in intensity, is a separating zone, or includes a heat film, a toothed blade, a row of pins, a source of air, or a source of vacuum. The sealing zones may include temperature zones, cartridge heaters, cooling air, or heated air, or a source of ultrasonic, microwave or radiative energy.

Owner:CMD CORP

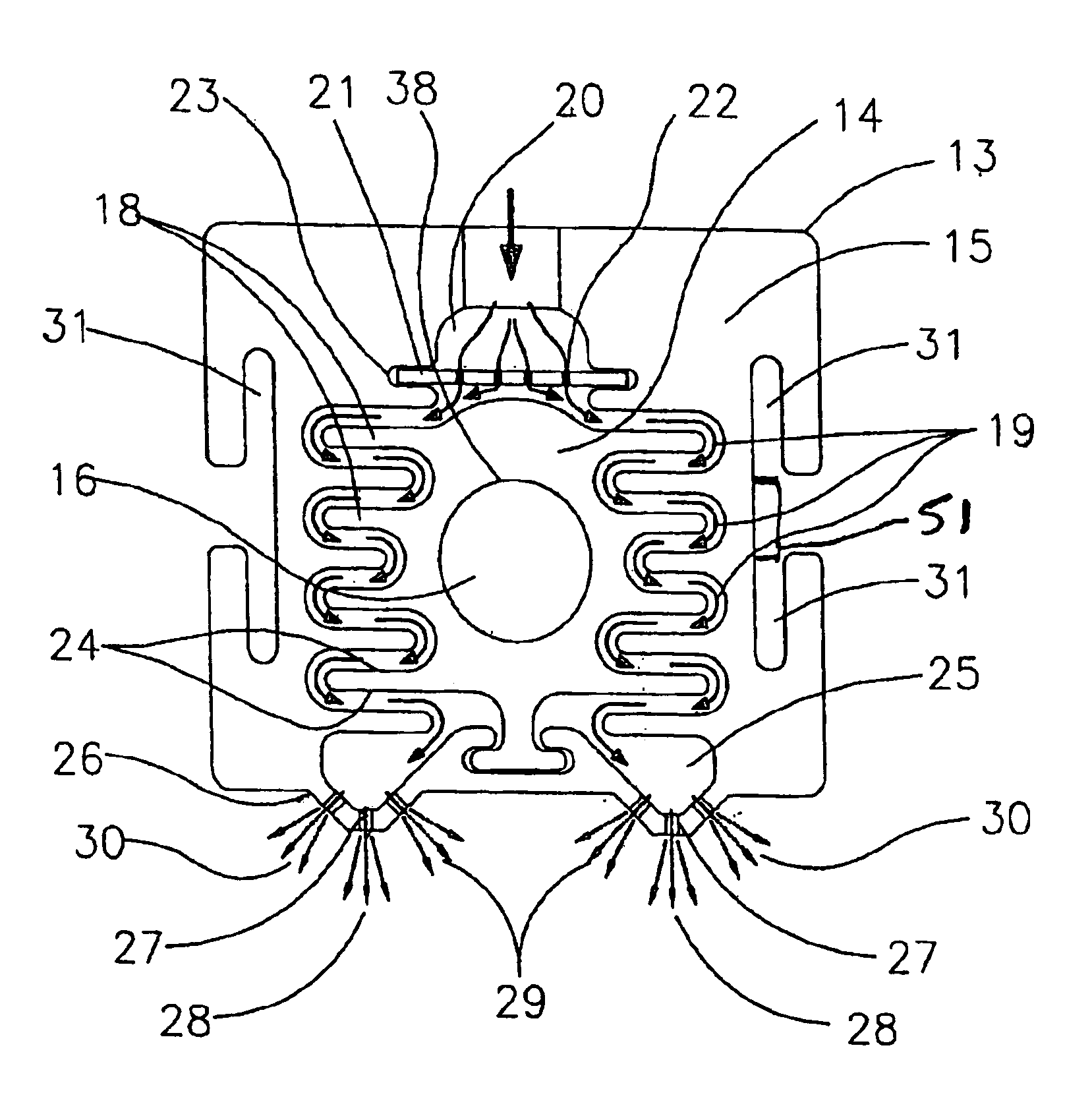

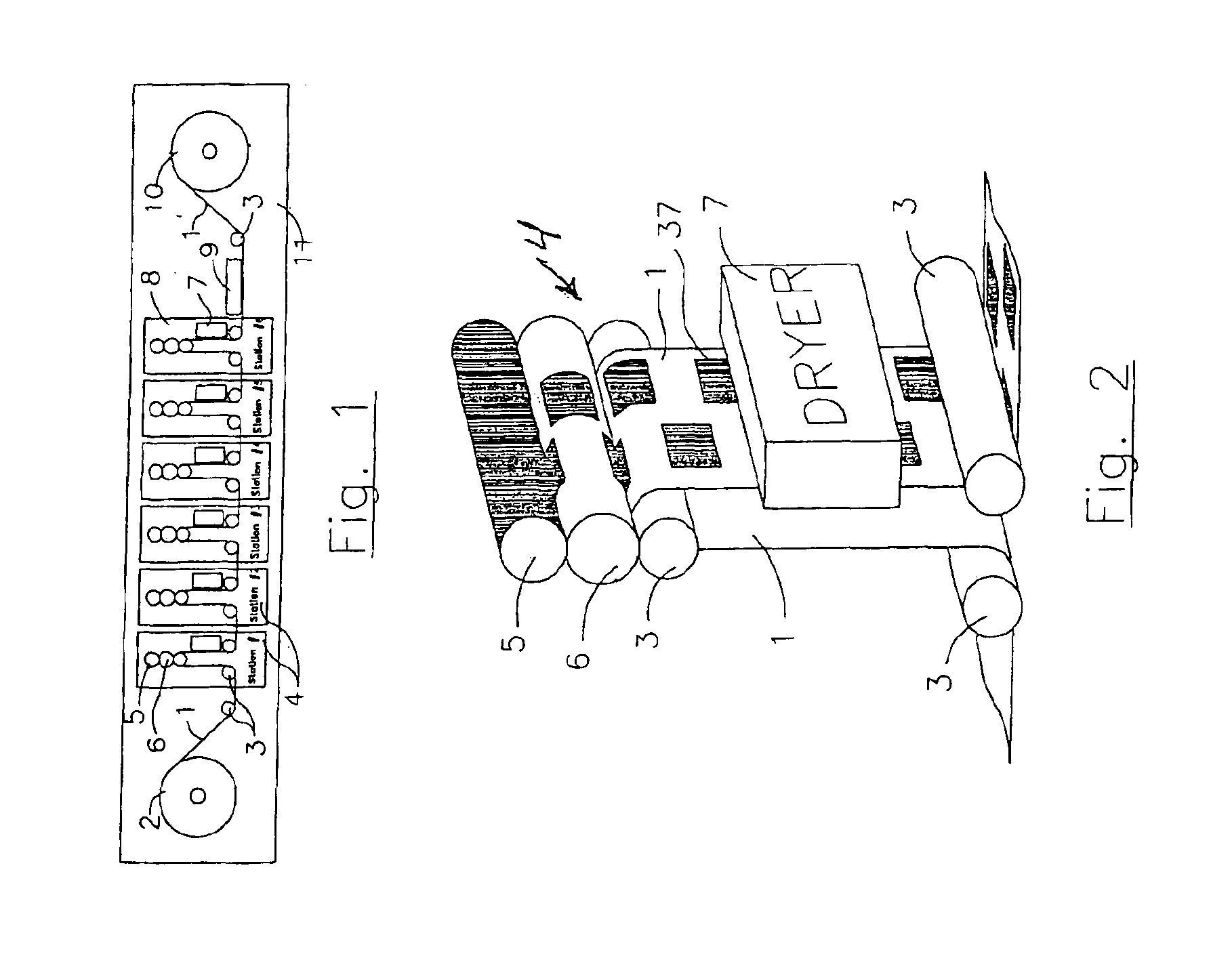

Compact integrated forced air drying system

InactiveUS6931205B2Simplify complexityReduced space requirementsDrying gas arrangementsAir heatersDistribution systemEngineering

A fully integrated drying or heating system utilizes forced air and electrical heaters. A solid cartridge heater is enclosed within a compact air plenum with a circuitous air path arranged within the plenum in heat transfer communication with the heater. The plenums are shaped and configured to be used in banks of plural plenums, with the operating controls and all the components of the air distribution system and air heating system fully integrated into a modular package.

Owner:FLEXAIR

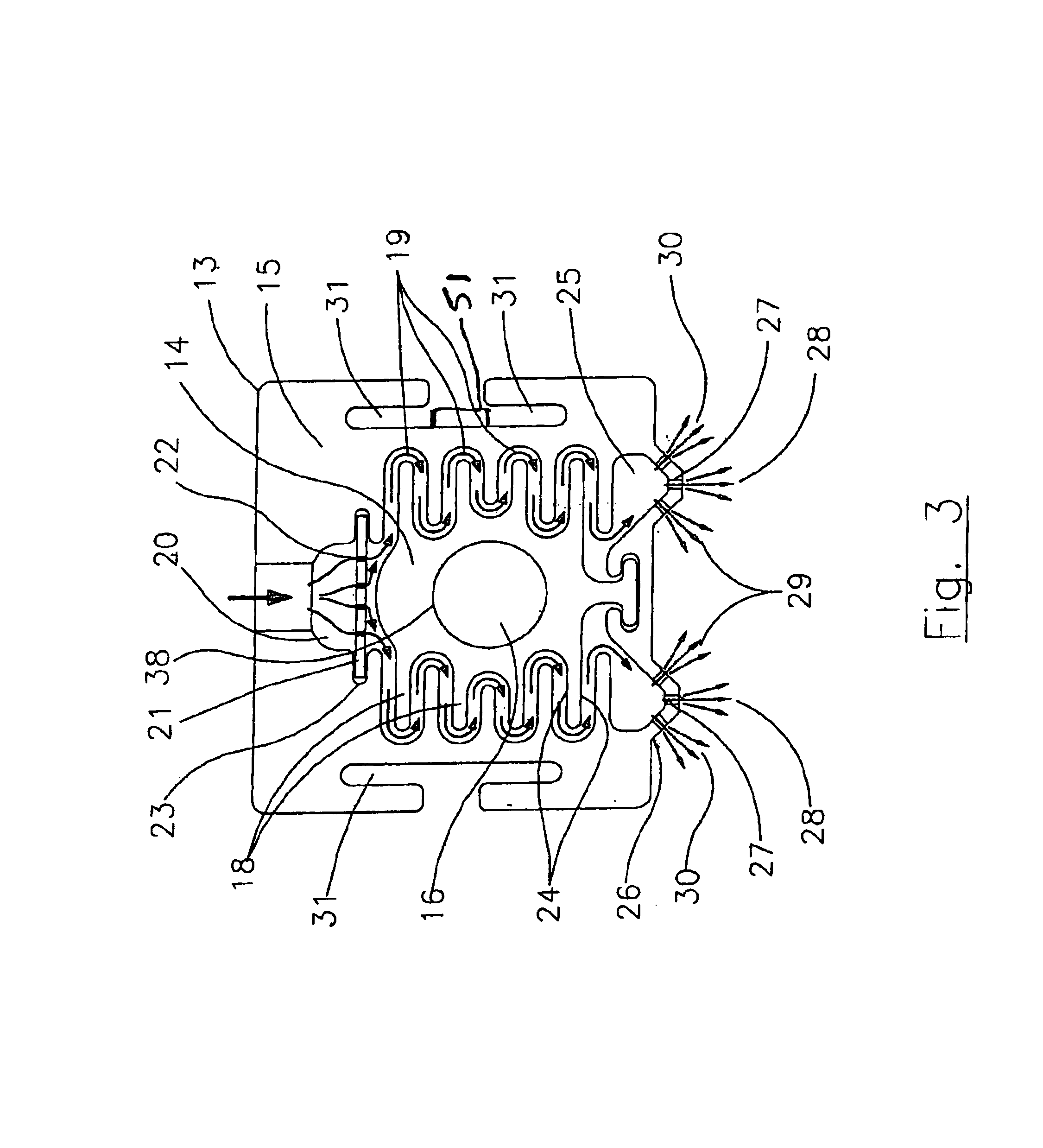

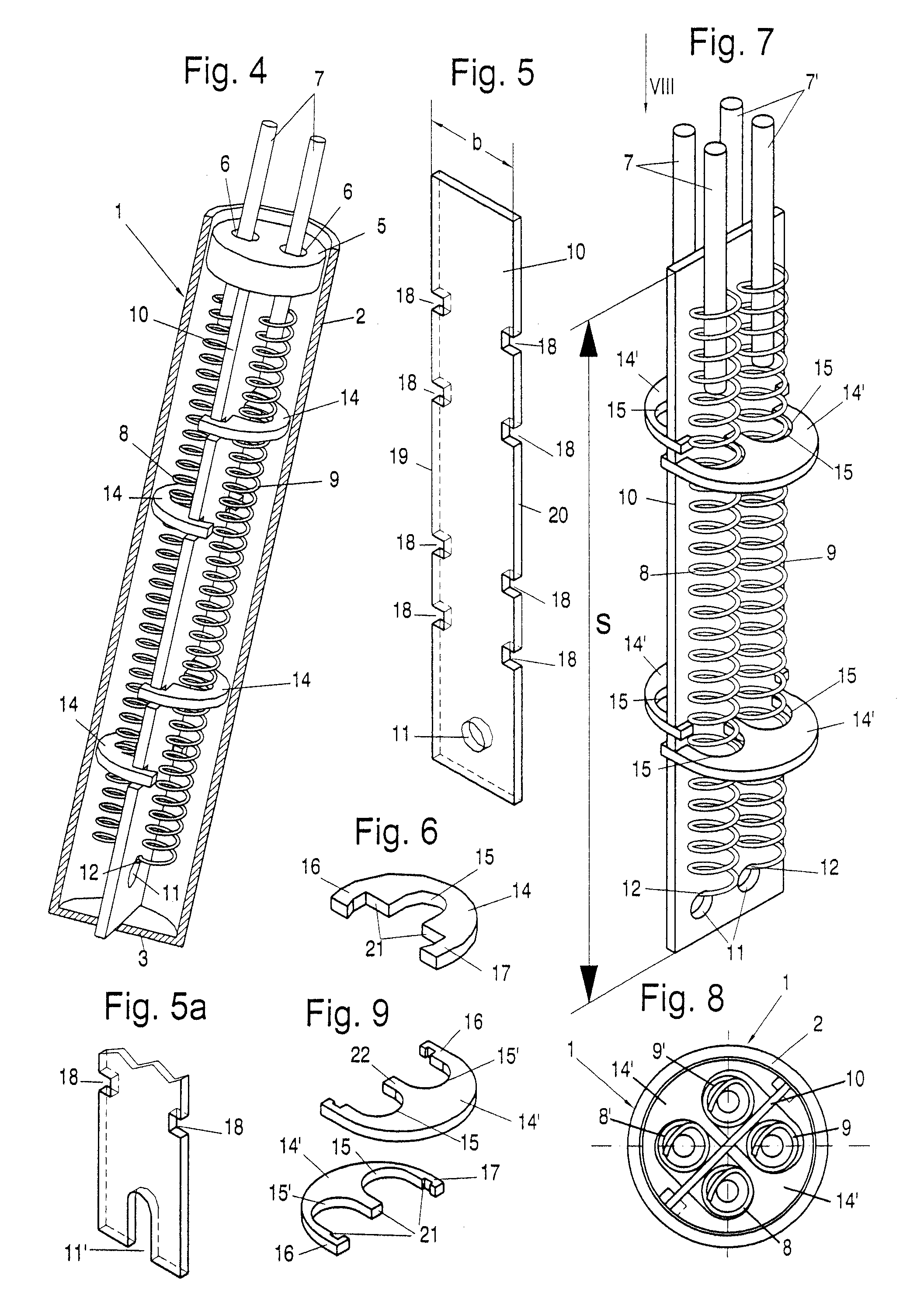

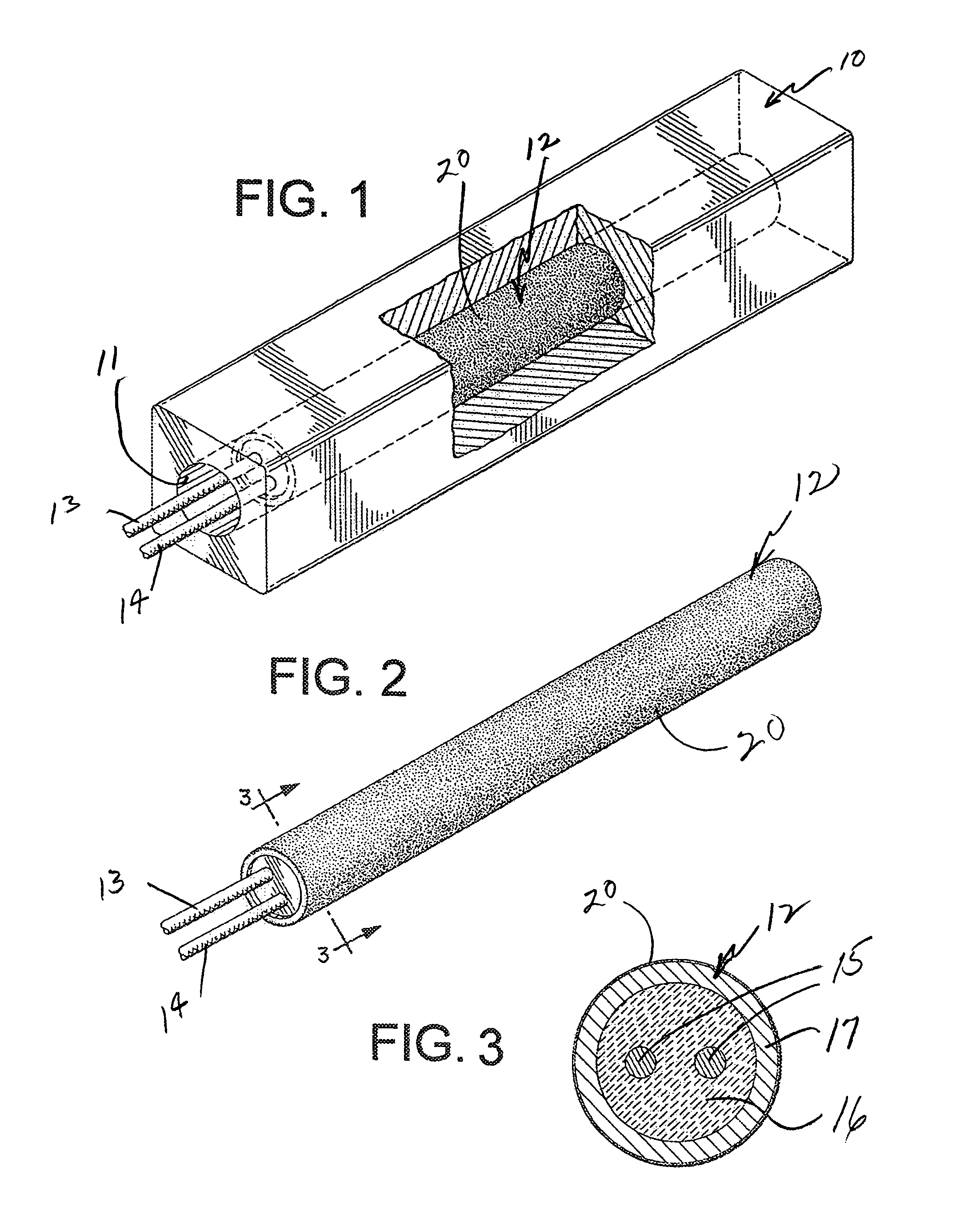

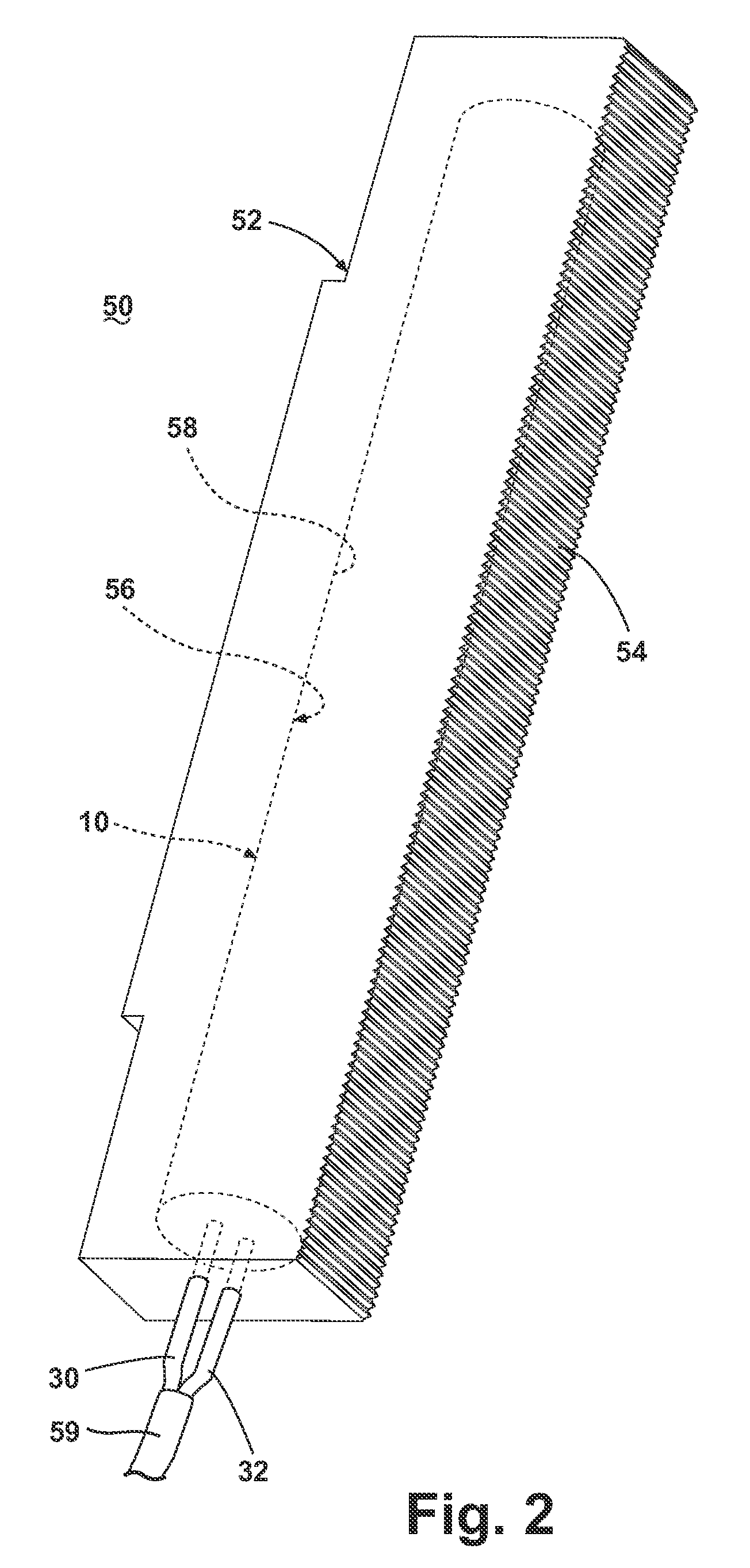

Compressed cartridge heater

ActiveUS7592572B2Minimal effortCarry-out quicklyArc welding apparatusPower cables with screens/conductive layersEngineeringCartridge heater

A cartridge heater, especially a compressed cartridge heater (1) has at least one heating coil (8, 9), which is arranged exposed in a metallic tubular body (2) and is embedded in a granulated insulating material. The ends of heating coil portions (8, 9) are provided with terminals (7) projecting from the tubular body (2). To make it possible to manufacture such a cartridge heater with minimal effort in terms of labor and material, a flat insulating plate (10) coordinated in its width with the internal diameter of the tubular body (2) is provided as the carrier. The heating coils (8, 9) extend along the two flat sides of the insulating plate (10) and the two heating coils (8, 9) are connected to one another by a coil section (12, 12′), which is led around a deflecting edge (27) of the insulating plate (10).

Owner:TUERK HILLINGER

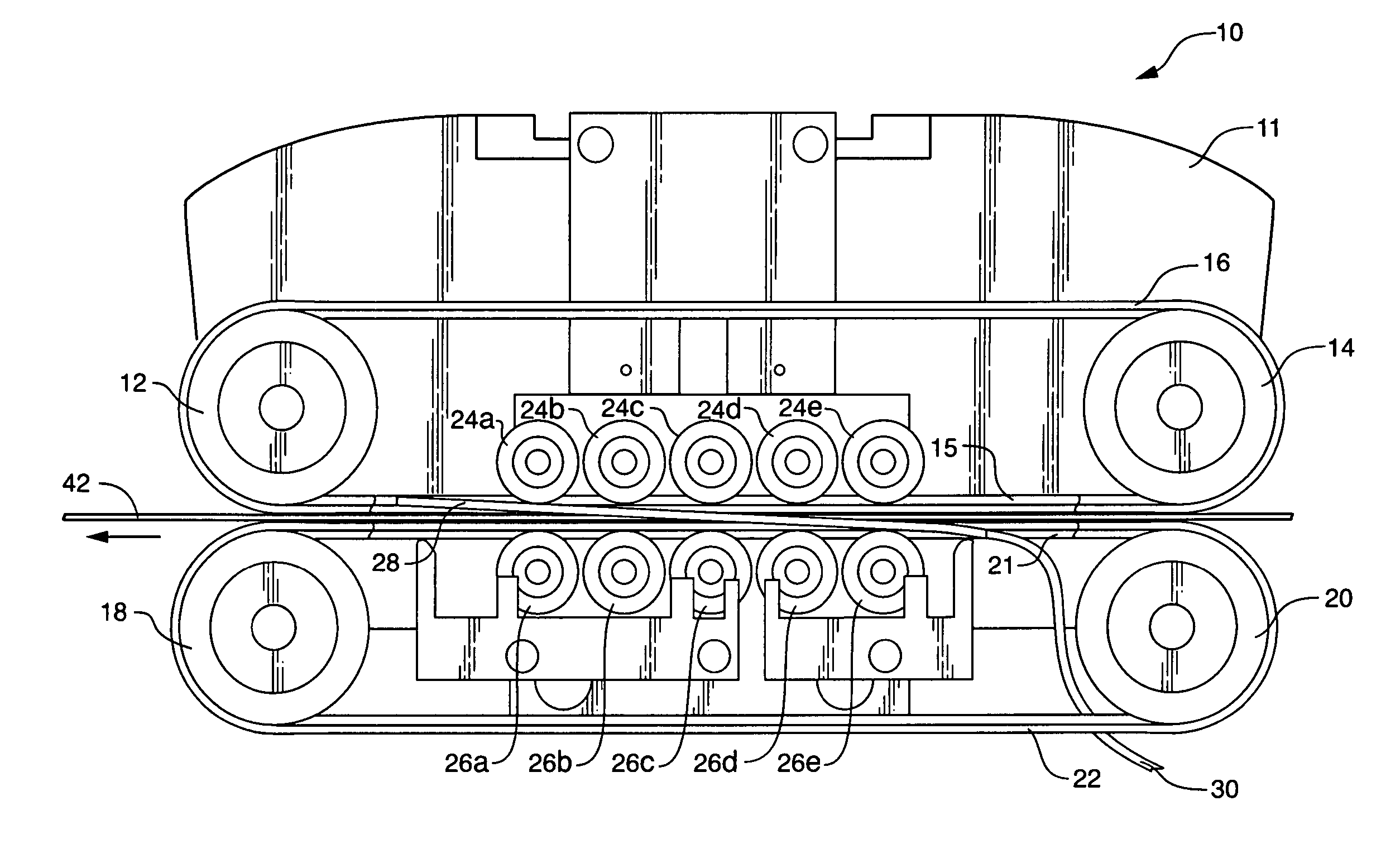

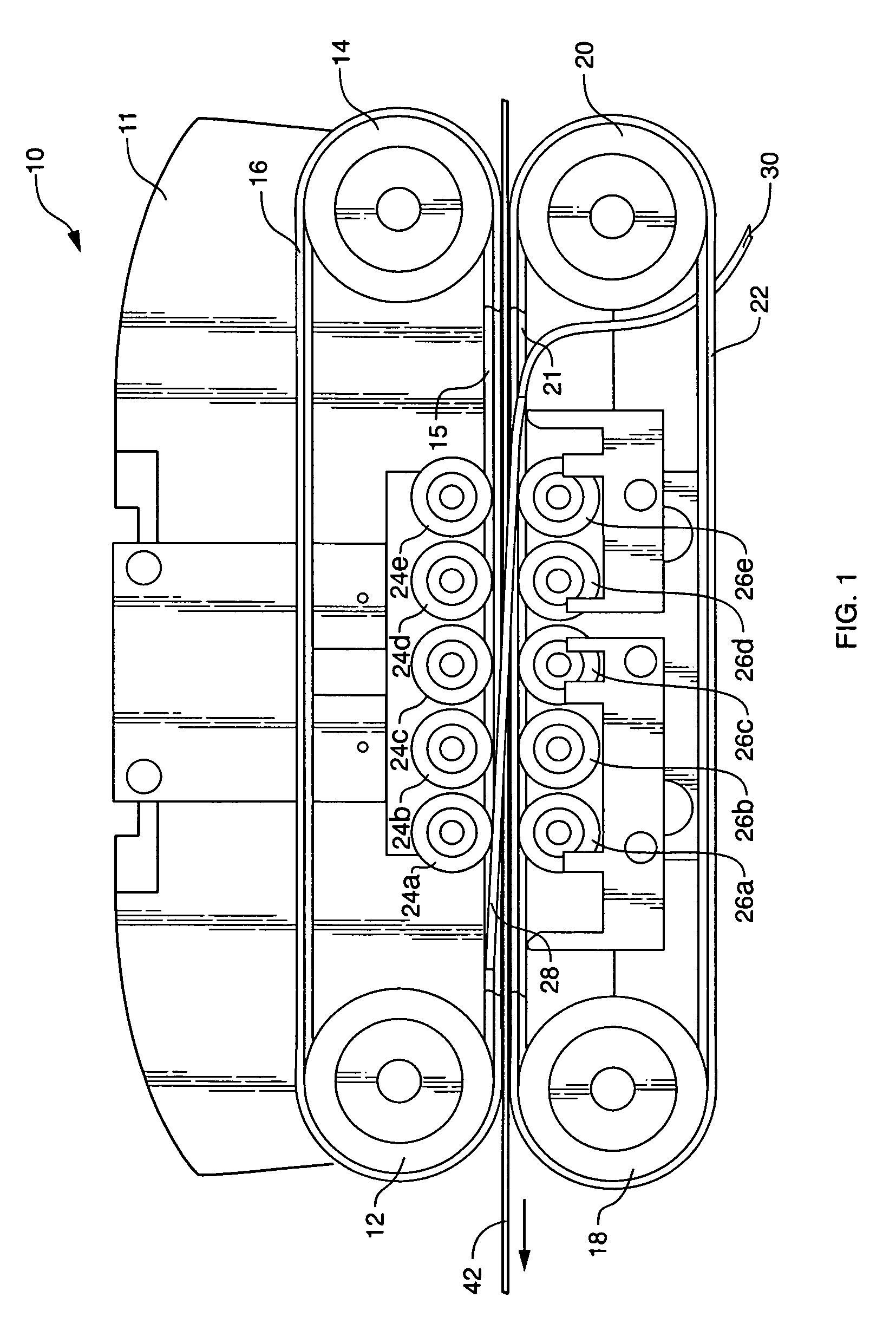

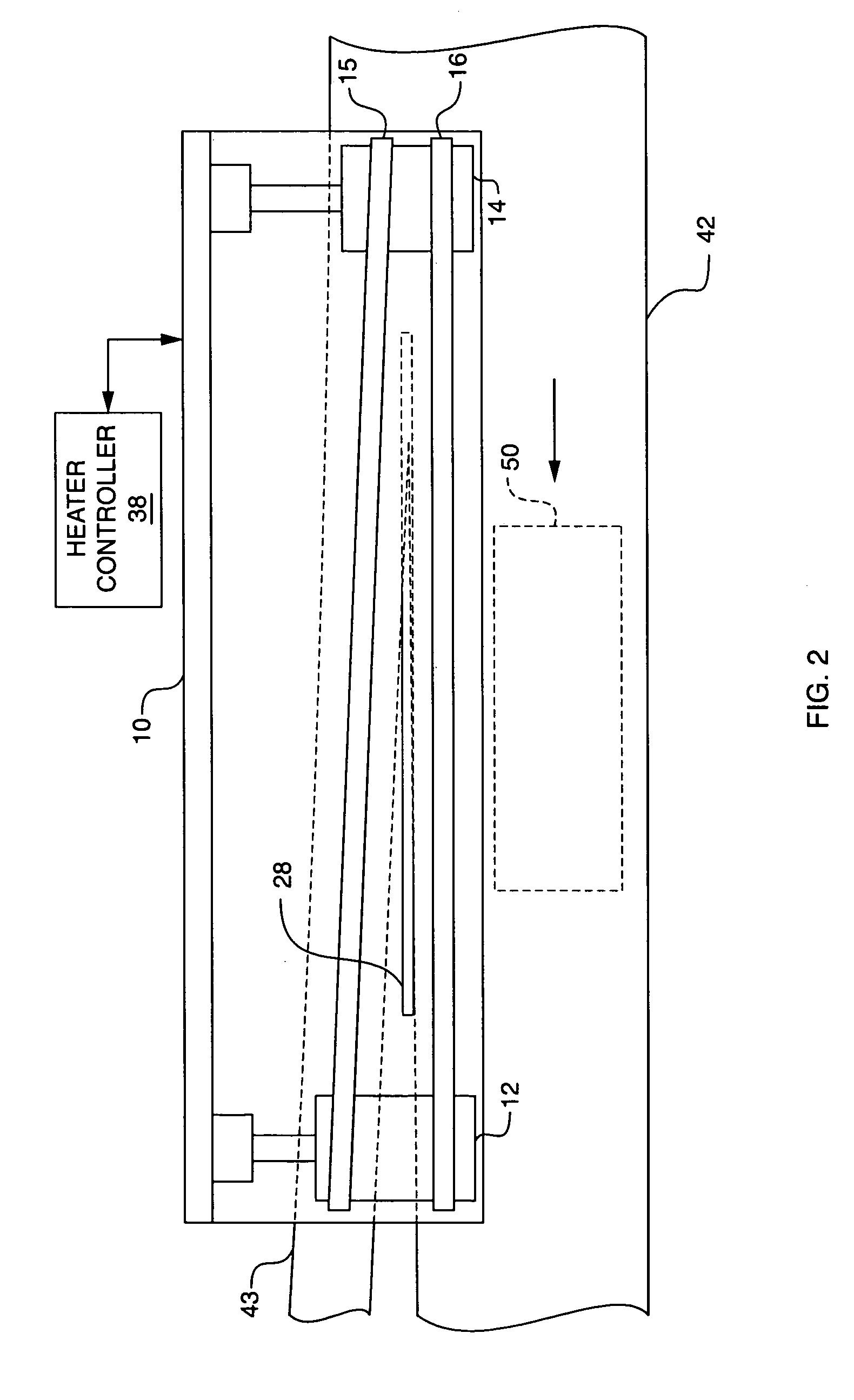

Film side sealing apparatus with closed-loop temperature control of a heater

InactiveUS20060107622A1Consistent sealingAesthetically pleasingConveyorsWrapper twisting/gatheringTemperature controlClosed loop

A side sealing apparatus for a shrink packaging machine comprising closed loop temperature control of a heater for maintaining an optimum temperature for cutting and sealing two layers of thermoplastic film. The heater comprises a cable or cartridge heater with an internal thermocouple, and it is connected to an automatic temperature controller. The heater is mounted on the side sealer apparatus between two sets of top and bottom V-belts mounted around drive rolls and idler rolls. The V-belts provide nip pressure against the film in order to drive the film. In one embodiment, nip pressure is generated by nip rollers on the scrap side of the film, and by low friction belt support guides on the package side of the film. In another embodiment, the belt support guides are replaced with a series of upper and lower nip rollers, and adjustable toggle clamps provide adjustable pressure on the series of upper and lower nip rollers.

Owner:SHRINK PACKAGING SYST

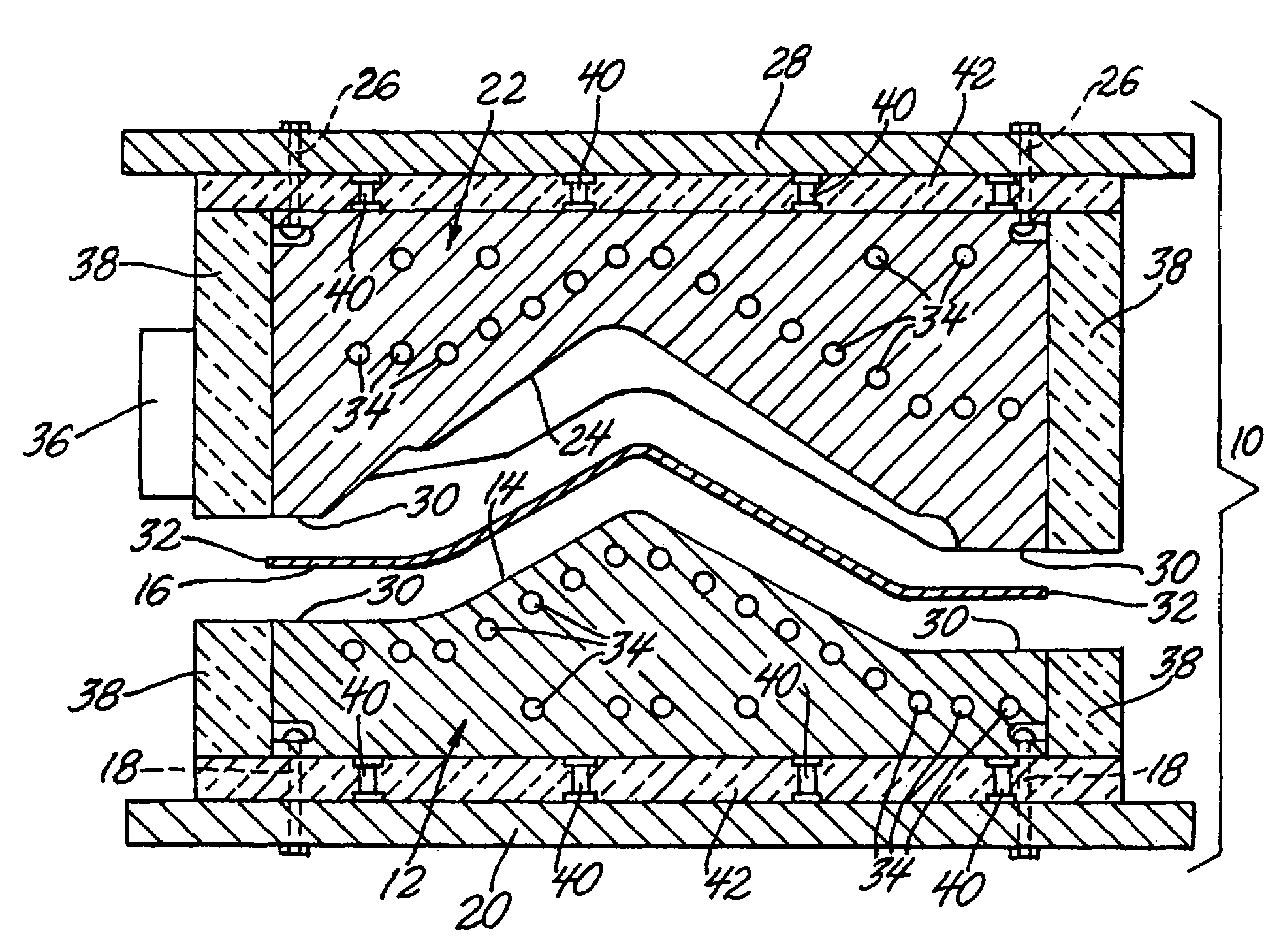

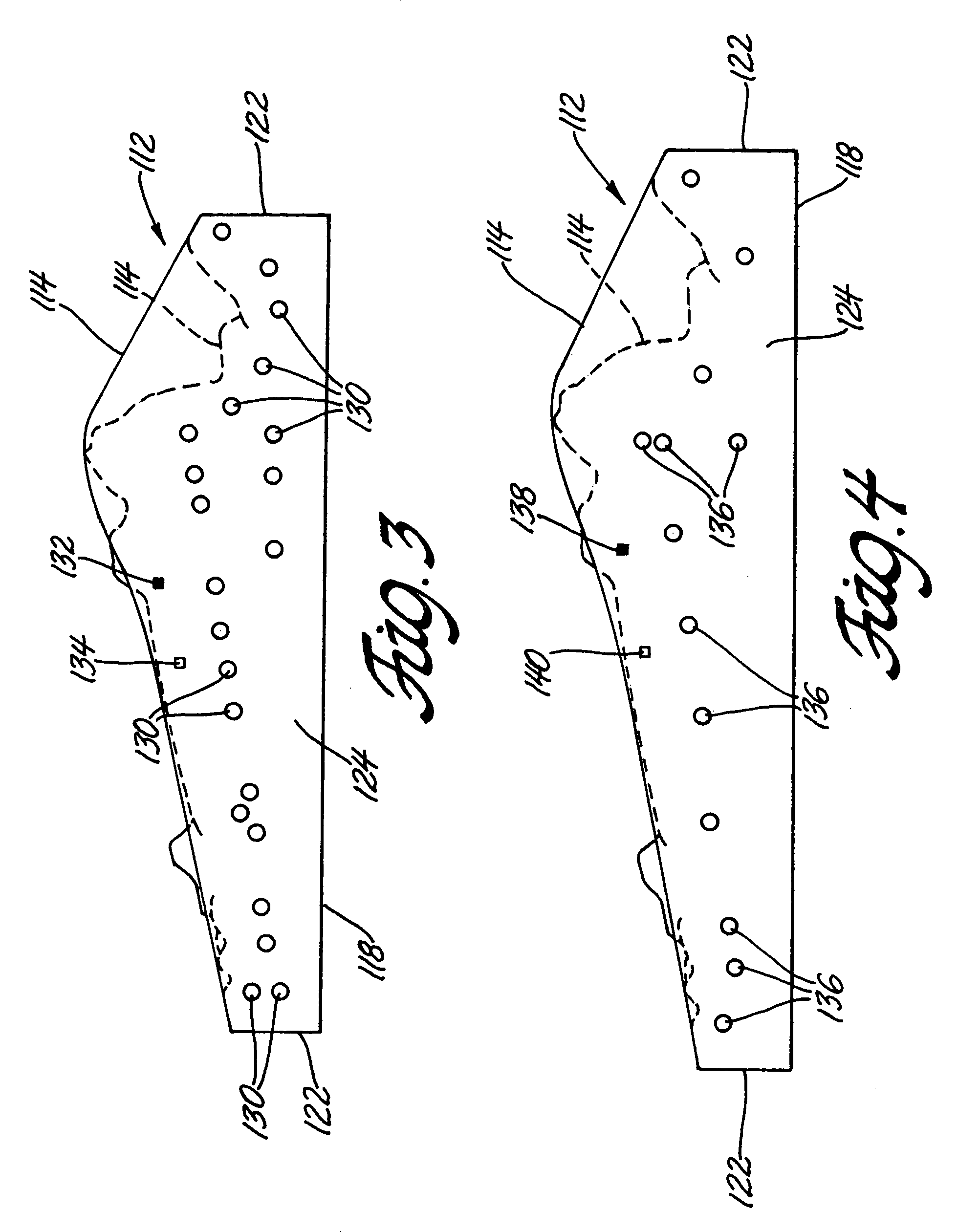

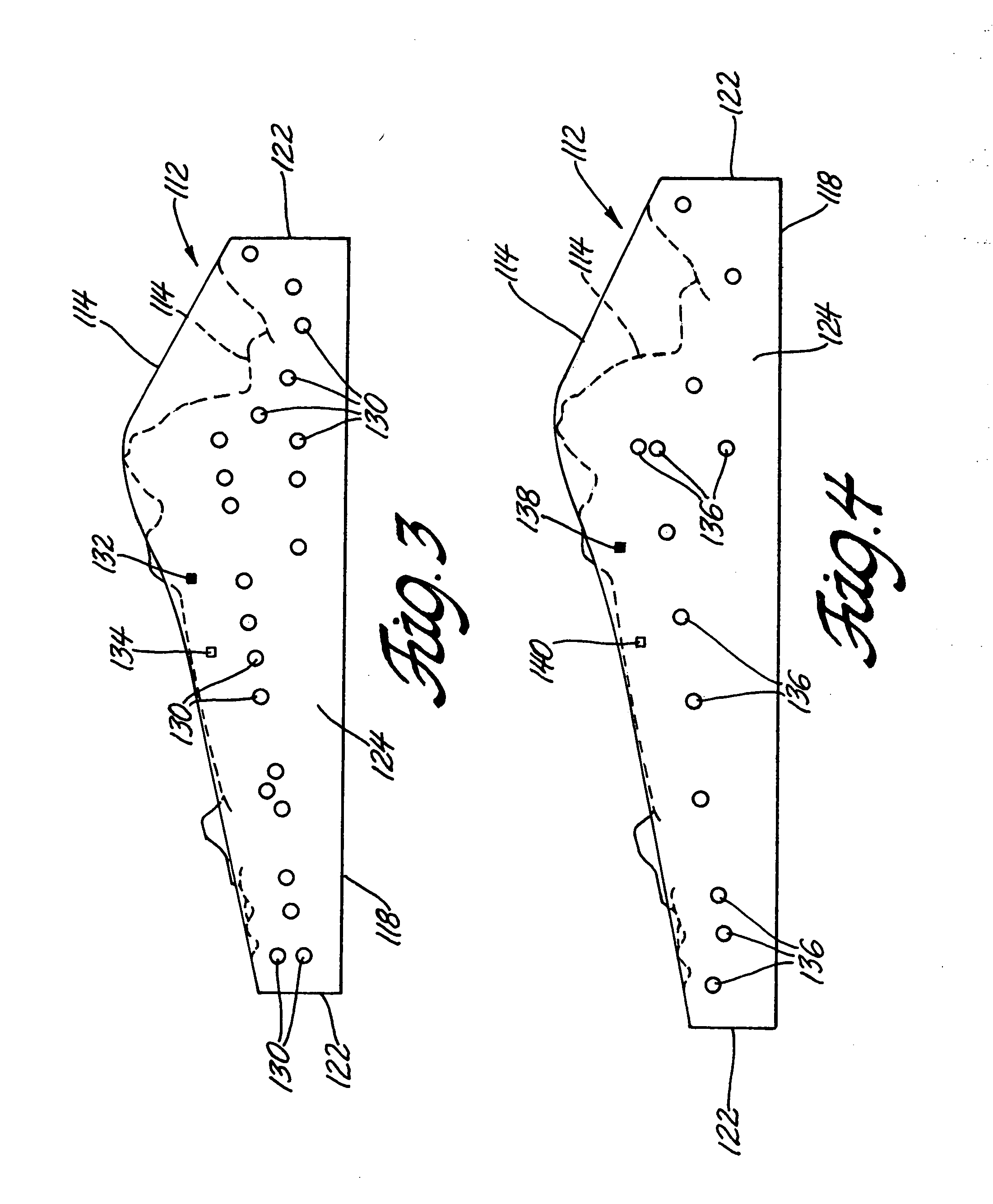

Heated die for hot forming

ActiveUS7159437B2Easy to operateImprove productivityShaping toolsCutting toolsElectrical resistance and conductanceEngineering

Owner:GM GLOBAL TECH OPERATIONS LLC

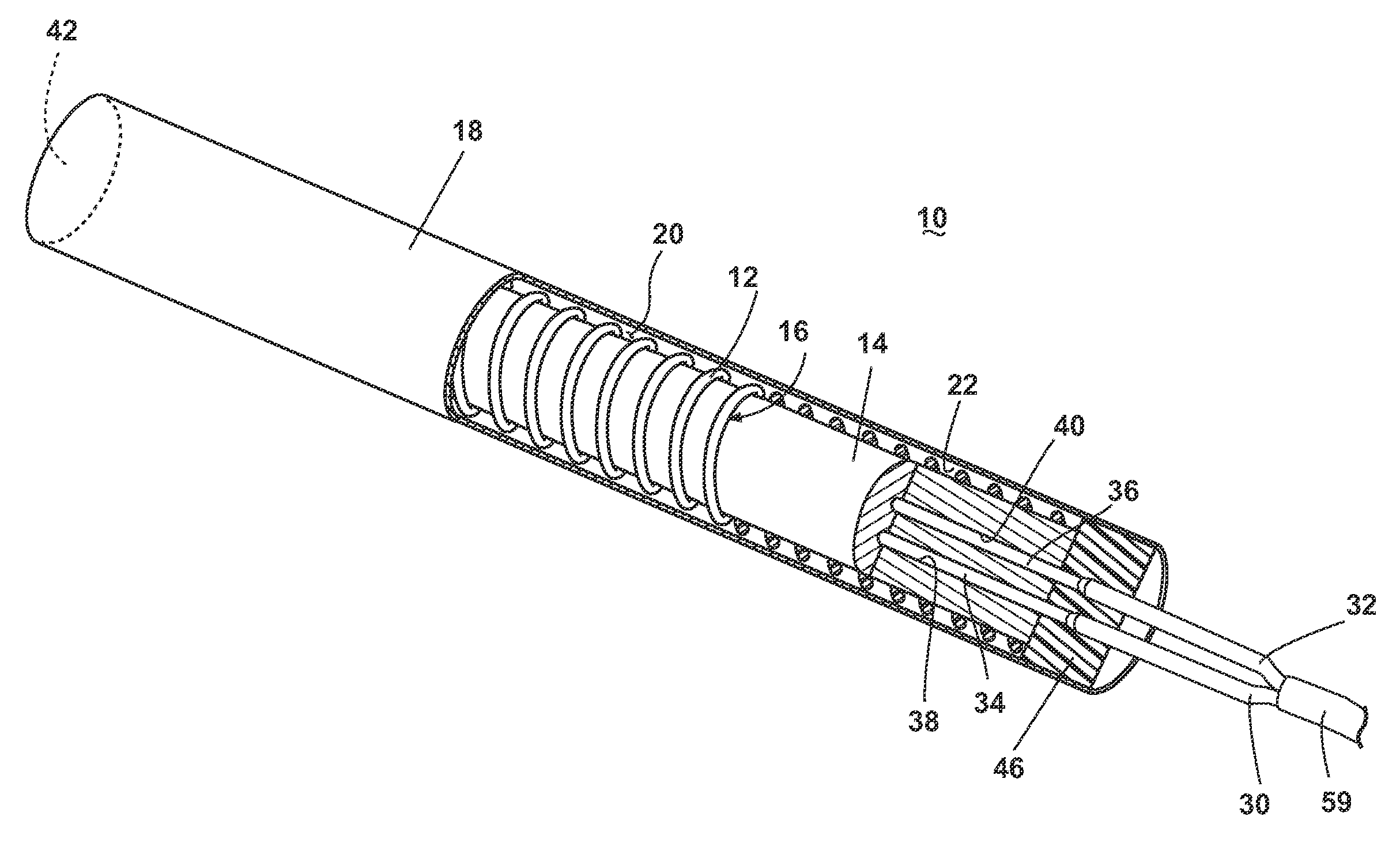

Heat exchanger for high purity fluid handling systems

InactiveUS7106957B2Easy maintenanceOvercome problemsHeat storage plantsLiquid transferring devicesPlate heat exchangerEngineering

A novel heat exchanger includes a thermal reservoir and a tube, the tube having straight sections and corrugated bends, and being in thermal contact with the thermal reservoir. The thermal reservoir has a first plate and a second plate fixed to the first plate. The first plate has a channel formed therein with straight sections to receive the straight sections of the tube, and curved sections for receiving the corrugated sections of the tube. The second plate has a channel formed therein as well that is complementary to the channel of the first plate. The heat exchanger is heated by one or more cartridge heaters. In a particular embodiment, two thermal reservoirs are fixed to one another and the cartridge heaters are disposed in channels formed therebetween. Optionally the thermal reservoirs can be heated or cooled by thermoelectric chips, and can include one or more heat sinks.

Owner:APPLIED INTEGRATED SYST

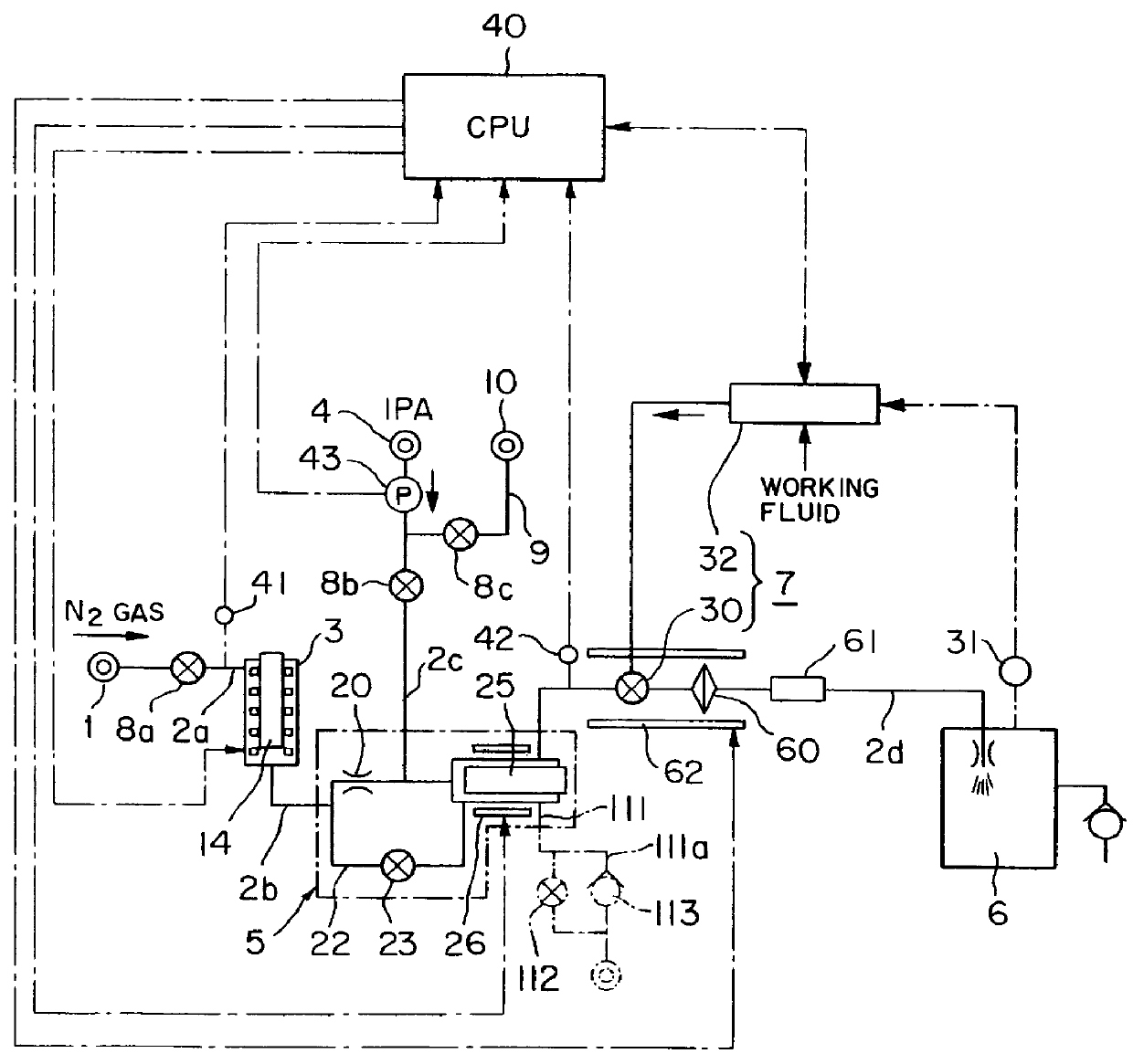

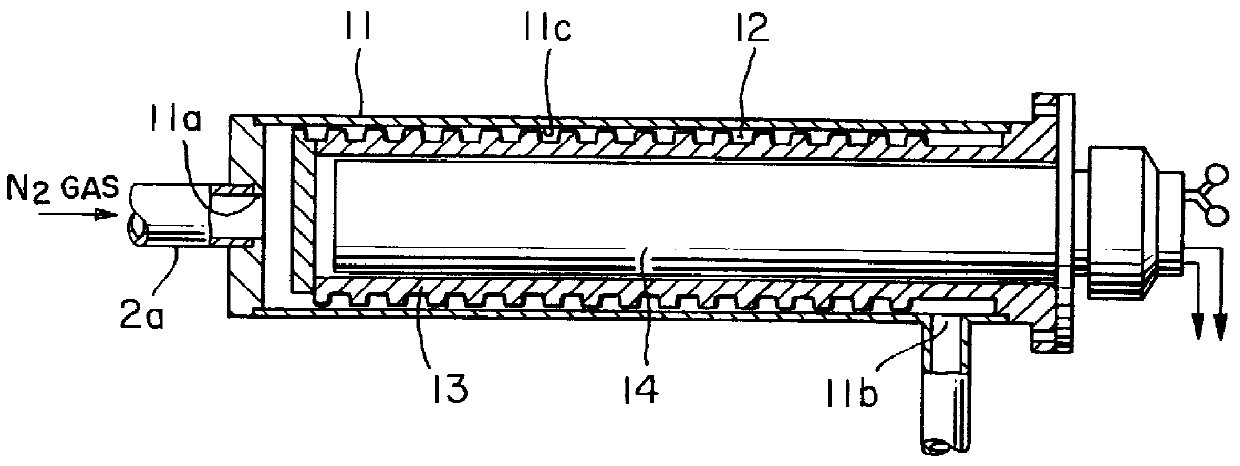

Method and system for controlling gas system

InactiveUS6167323AAvoid difficult choicesEasy to controlMechanical power/torque controlLevel controlControl signalProduct gas

Flow sensors 41 and 42 for detecting a flow load including the presence of a flow of gas are provided in supply lines 2a through 2d for supplying a given gas into a treatment chamber 6. A CPU 40 is provided for previously storing control parameters corresponding to the presence of a flow of gas. The presence of a flow of gas or a flow of IPA is detected by the flow sensors 41, 42 or an IPA supply pump 43, and detected signals are transmitted to the CPU 40. On the basis of a control signal outputted from the CPU 40, a cartridge heater 14, inner and outer tube heaters 25 and 26 and an insulation heater 52 are controlled. Thus, a control parameter adopted in accordance with the presence of a flow of gas to be used is determined, so that the control parameter previously stored in a data table 100 is selected in accordance with a control mode to control the temperature or pressure of the gas.

Owner:TOKYO ELECTRON LTD

Cartridge heater for a gas chromatography transfer device

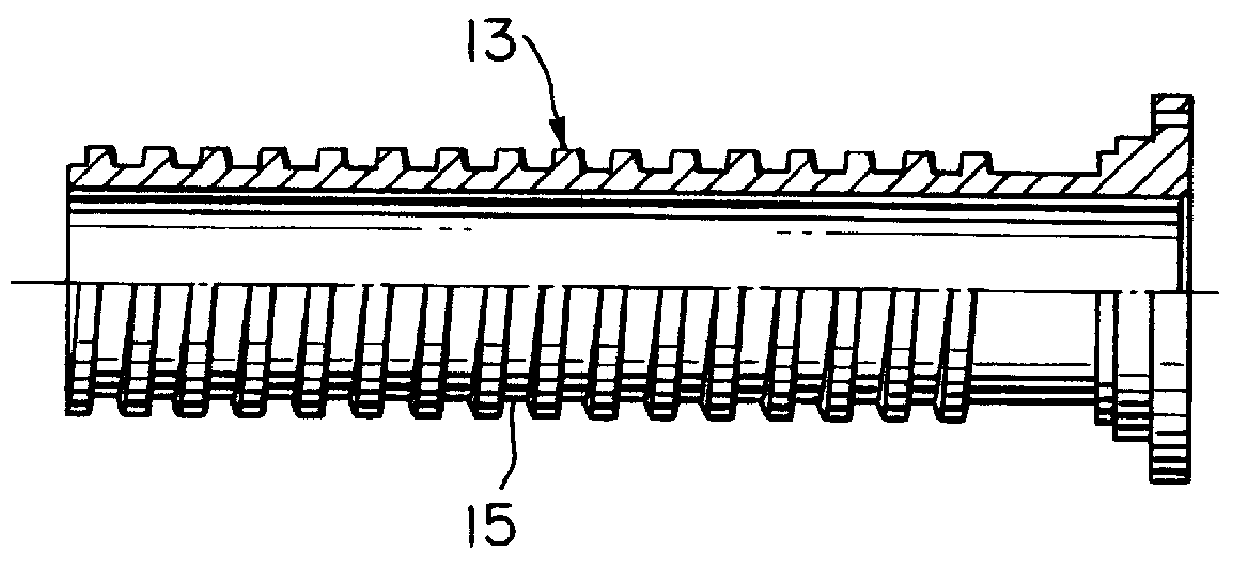

The invention relates to a cartridge heater for a gas chromatography transfer device for substances which are to be analyzed, having a metal tube for accommodating a tube section to be heated and a heating coil arranged outside the metal tube, the metal tube bearing, on the outside, a groove which corresponds to the shape of the heating coil and in which a heating conductor is embedded in an electrically insulated manner with respect to the metal tube.

Owner:GERSTEL

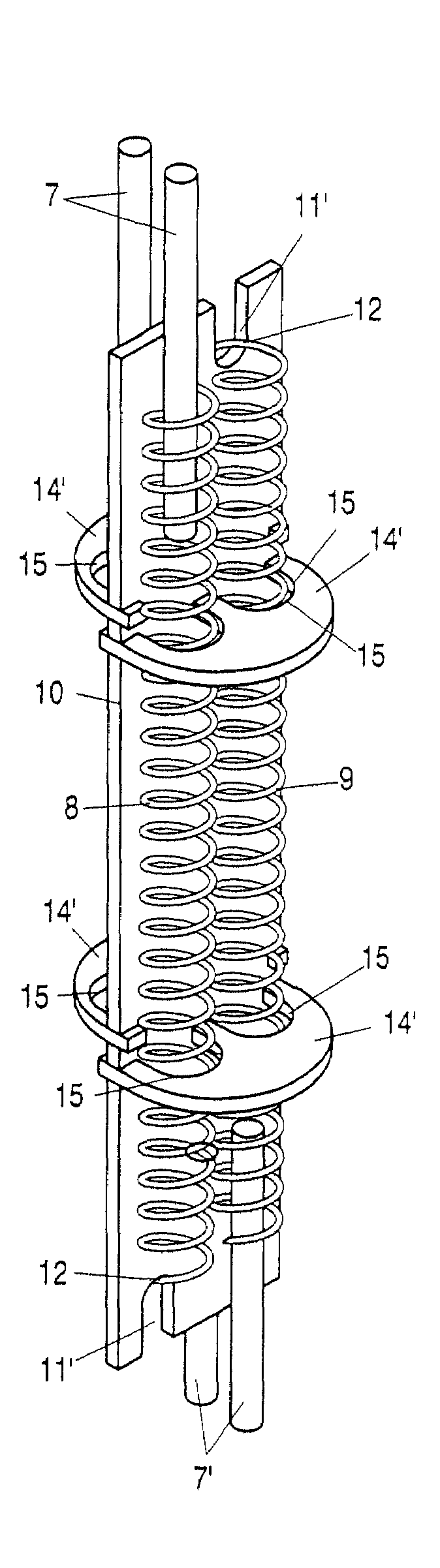

Cartridge type heater

ActiveUS8426779B2Reduce manufacturing costMinimal laborHeater elementsHeating element shapesOne-hotEngineering

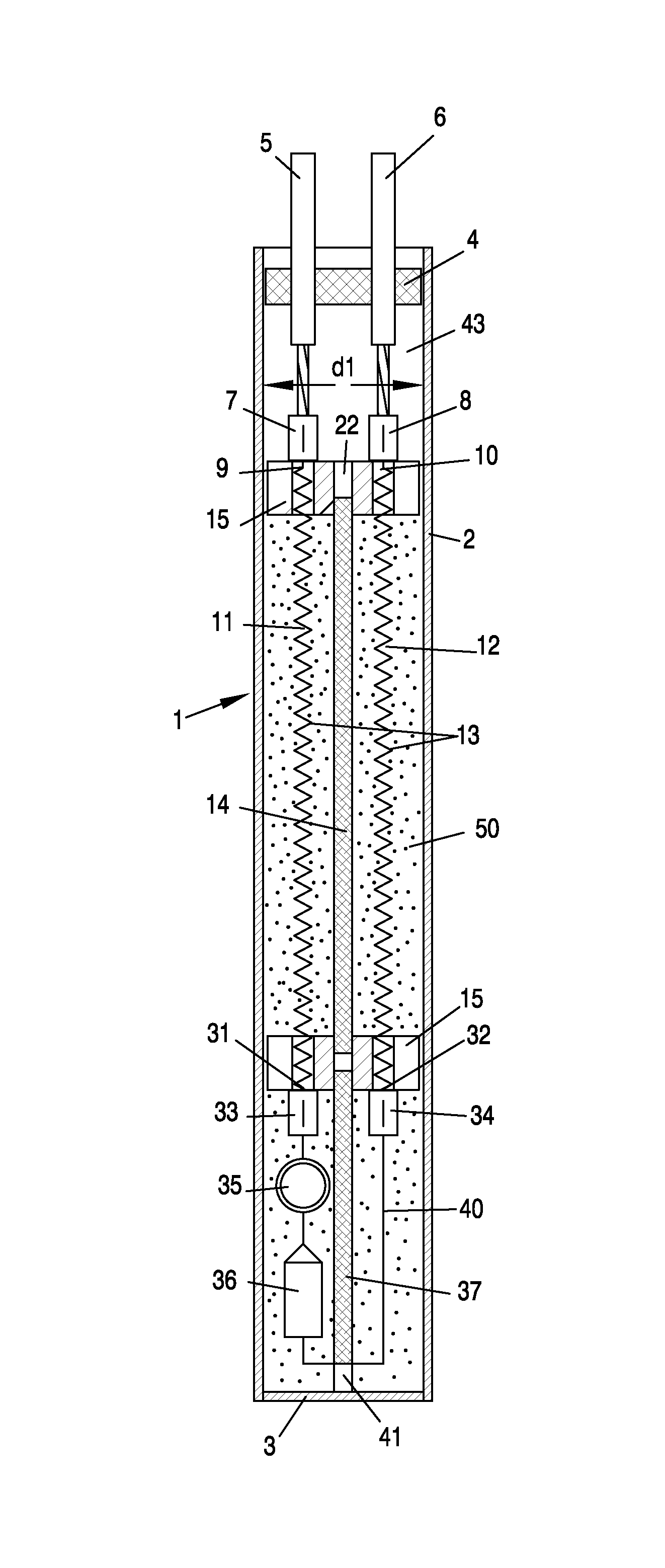

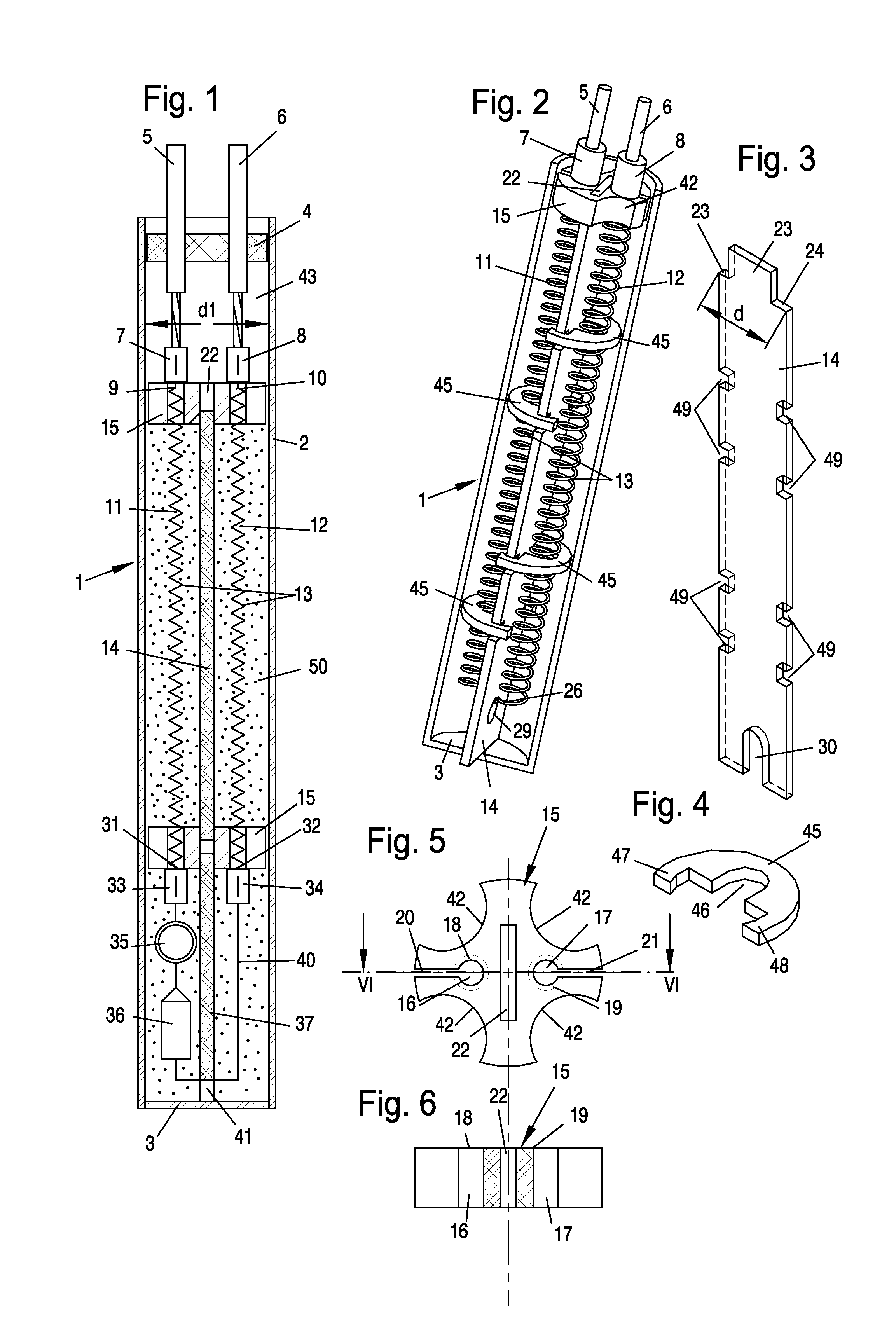

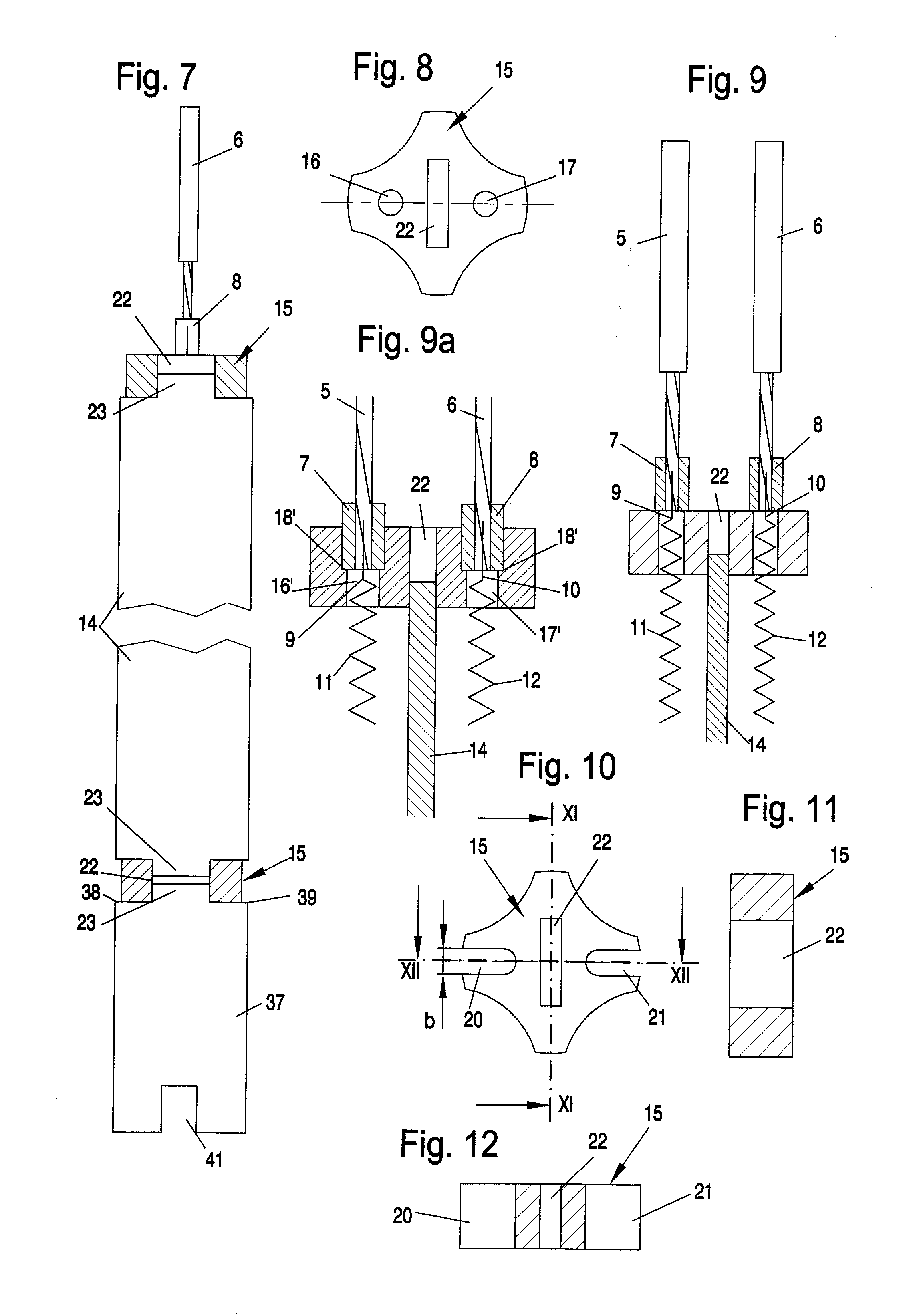

A cartridge type heater is provided with at least one hot wire coil (13), which has two coreless coil strands (11, 12), which extend in an insulating material (50) along the two sides of a carrier wall (14). The heater includes an insulating material that is coordinated with the internal diameter of a metal jacket (2). The hot wire ends (9, 10) are provided with terminals projecting from the same end of the metal jacket (2). The hot wire coils (11, 12) are electrically connected to one another in the area of an end edge of the carrier wall (14). This edge is located in the closed end area of the metal jacket (2) and the coils are guided by spacers (45) distributed at the longitudinal edges of the carrier wall (14). At least the terminal-side end of the dimensionally stable carrier wall (14) is provided with an attached coil holder (15, 15 / 1), to which the hot wire ends (9, 10) are fastened under tensile stress. This keeps the windings of the hot wire coil (13) spaced apart from each other. At least one filling opening (42) is provided for the granulated insulating material (50).

Owner:TUERK & HILLINGER

Method and apparatus for making skirtless seals

A machine and method for making bags is described and includes a web traveling from an input section to a rotary drum, to an output section. The rotary drum includes at least one seal bar, having a single sealing zone, and a weakening zone disposed within the single sealing zone. The single sealing zone may be a heated perforator, includes a heating wire. The heating wire may be an NiCr wire stitched into the heater, and be disposed on a cap or on the seal bar. The weakening zone may create a line of weakness that is uniform or varies in intensity. The sealing zone may include temperature zones, cartridge heaters, cooling air, or heated air, or a source of ultrasonic, microwave or radiative energy.

Owner:CMD CORP

Cartridge type heater

ActiveUS20100147826A1Reduce manufacturing costMinimal laborHeater elementsHeating element shapesOne-hotEngineering

A cartridge type heater is provided with at least one hot wire coil (13), which has two coreless coil strands (11, 12), which extend in an insulating material (50) along the two sides of a carrier wall (14). The heater includes an insulating material that is coordinated with the internal diameter of a metal jacket (2). The hot wire ends (9, 10) are provided with terminals projecting from the same end of the metal jacket (2). The hot wire coils (11, 12) are electrically connected to one another in the area of an end edge of the carrier wall (14). This edge is located in the closed end area of the metal jacket (2) and the coils are guided by spacers (45) distributed at the longitudinal edges of the carrier wall (14). At least the terminal-side end of the dimensionally stable carrier wall (14) is provided with an attached coil holder (15, 15 / 1), to which the hot wire ends (9, 10) are fastened under tensile stress. This keeps the windings of the hot wire coil (13) spaced apart from each other. At least one filling opening (42) is provided for the granulated insulating material (50).

Owner:TUERK & HILLINGER

Electric cartridge type heater and method for manufacturing same

ActiveUS20150001206A1Simple and cost-effectiveEnvelope/housing resistor manufactureHeater elementsElectricityInterior space

An electric cartridge type heater (100, 200, 300, 400, 500, 600, 700, 800, 900, 1000) has at least one the tubular metallic jacket (101, 201, 301, 401, 501, 601, 701, 801, 901, 1001), at least one electric heat conductor (102, 202, 302, 402, 502, 602, 702, 802, 902, 1002) arranged in the interior space of the tubular metallic jacket with two ends for electrically contacting the electric heat conductor, wherein the at least one electric heat conductor is electrically isolated from the tubular metallic jacket by an electrically insulating material (103, 203, 303, 403, 503, 603, 703, 903) arranged in the interior space of the tubular metallic jacket (101, 201, 301, 401, 501, 601, 701, 801, 901, 1001). The electric heat conductor is self-supporting. A method is also provided for manufacturing such an electric cartridge type heater.

Owner:TUERK & HILLINGER

PTC heating device with cathode oxygen depletion function for fuel cell vehicle

InactiveUS20090272727A1Avoid bubblingLow calorific valueFuel cell heat exchangeHeating element shapesCoolant flowEngineering

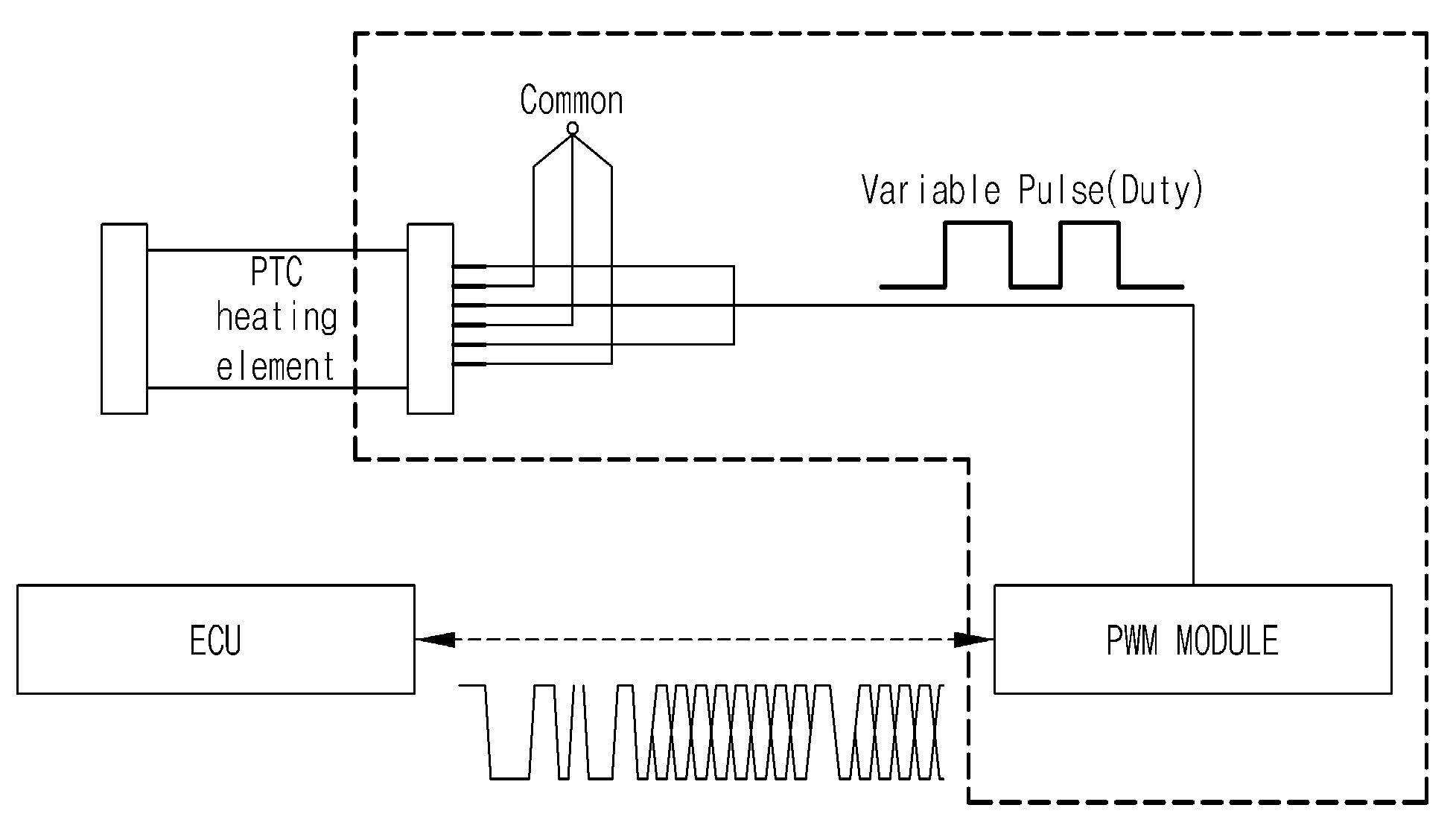

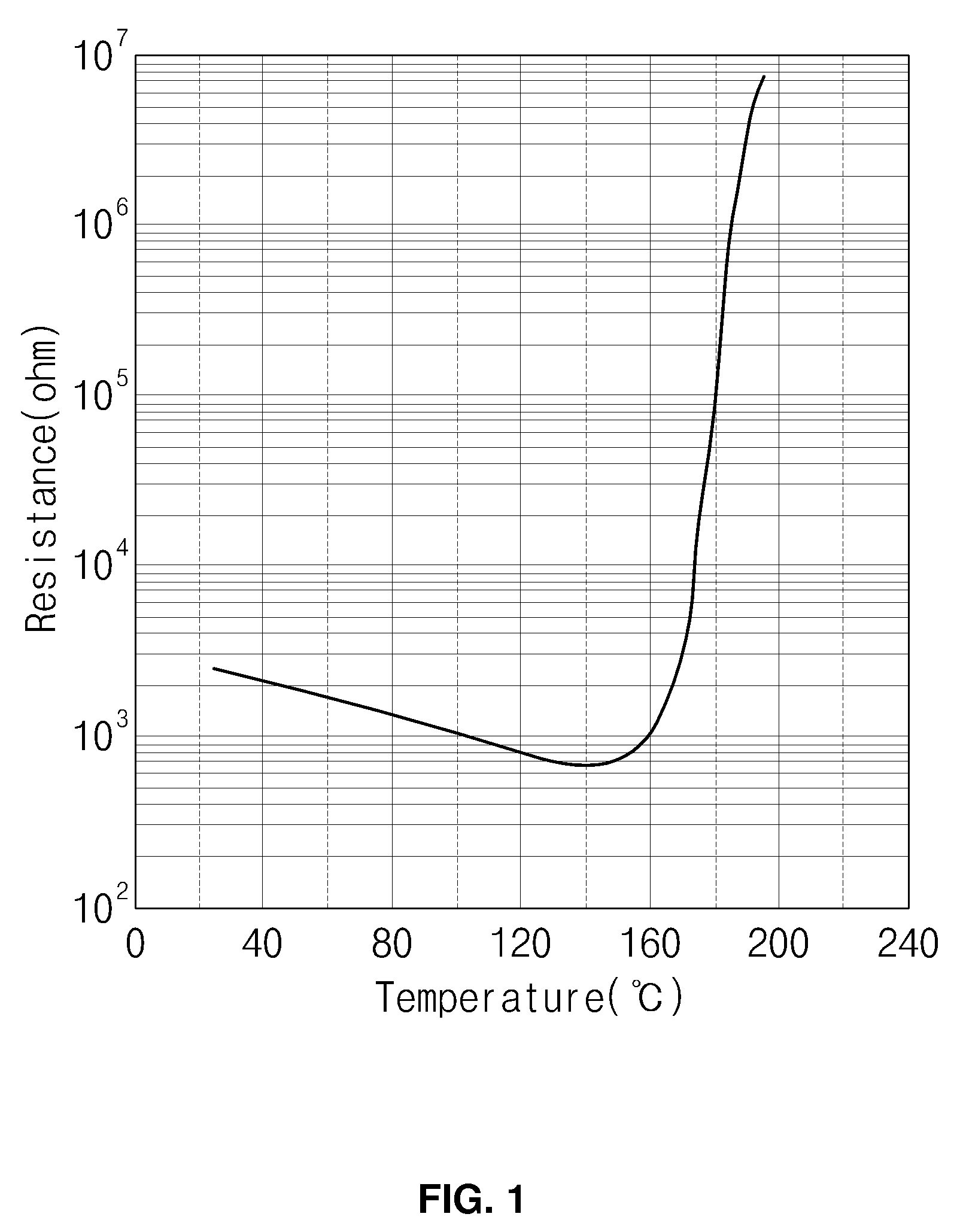

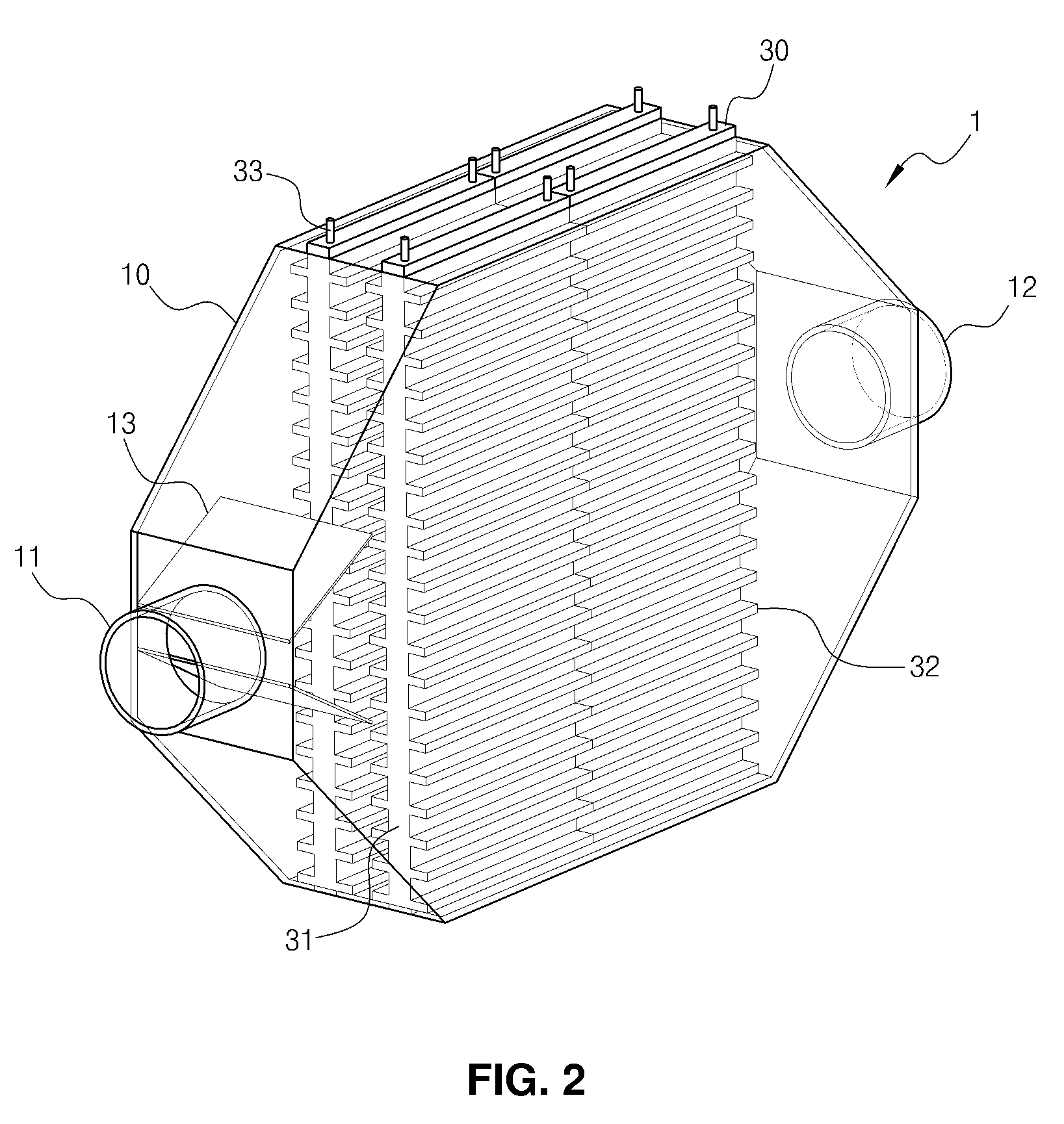

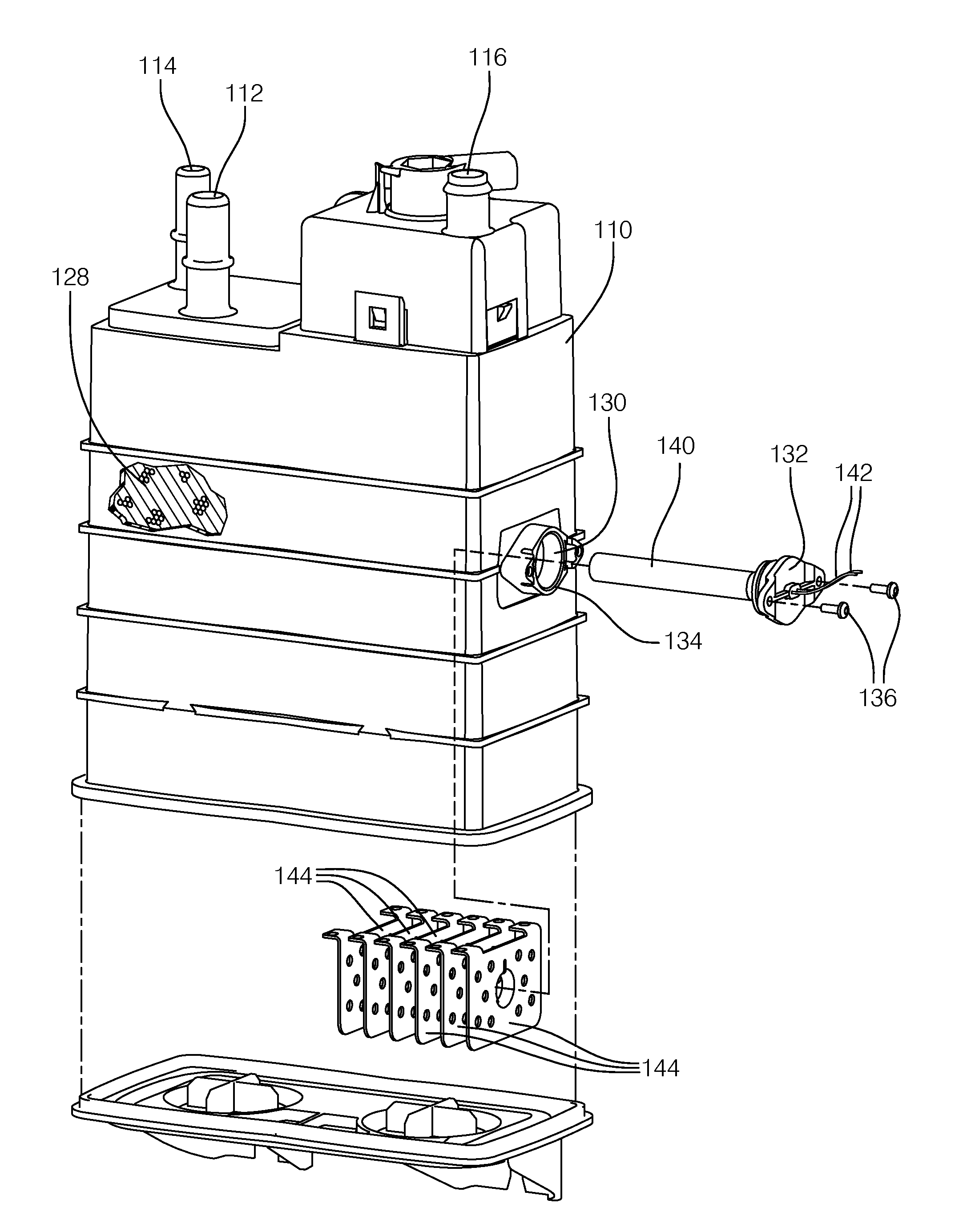

The present invention provides a positive temperature coefficient (PTC) heating device with a cathode oxygen depletion (COD) function for a fuel cell vehicle, which can improve durability of a fuel cell stack by reacting residual oxygen with hydrogen to be consumed as heat and improve cold startability by rapidly heating a coolant even at a temperature below the freezing point, the PTC heating device including a housing having an inlet and an outlet, formed on both ends there of, and a PTC heater fixed in the inside of the housing and including an electrode to which electric power is applied from the outside, a PTC heating element disposed on the electrode, and an insulating tape for insulating the PTC heater from a coolant flowing in the housing. Accordingly, it is possible to improve electrical safety and heat transfer performance and effectively prevent bubbles from forming, compared with a conventional cartridge heater.Moreover, the present invention provides the PTC heating device which includes at least one radiating plate including a plurality of radiating fins having concave and convex. Furthermore, the PTC heating element included in the PTC heater is inserted between two electrodes and the insulating tape is arranged on the surfaces of both sides of the electrodes. As a result, it is possible to improve heat transfer efficiency.In addition, the present invention provides the PTC heating device, in which a PWM control system is provided on the outside of the housing to control a heating current, thus facilitating the control of the surface temperature.

Owner:HYUNDAI MOTOR CO LTD

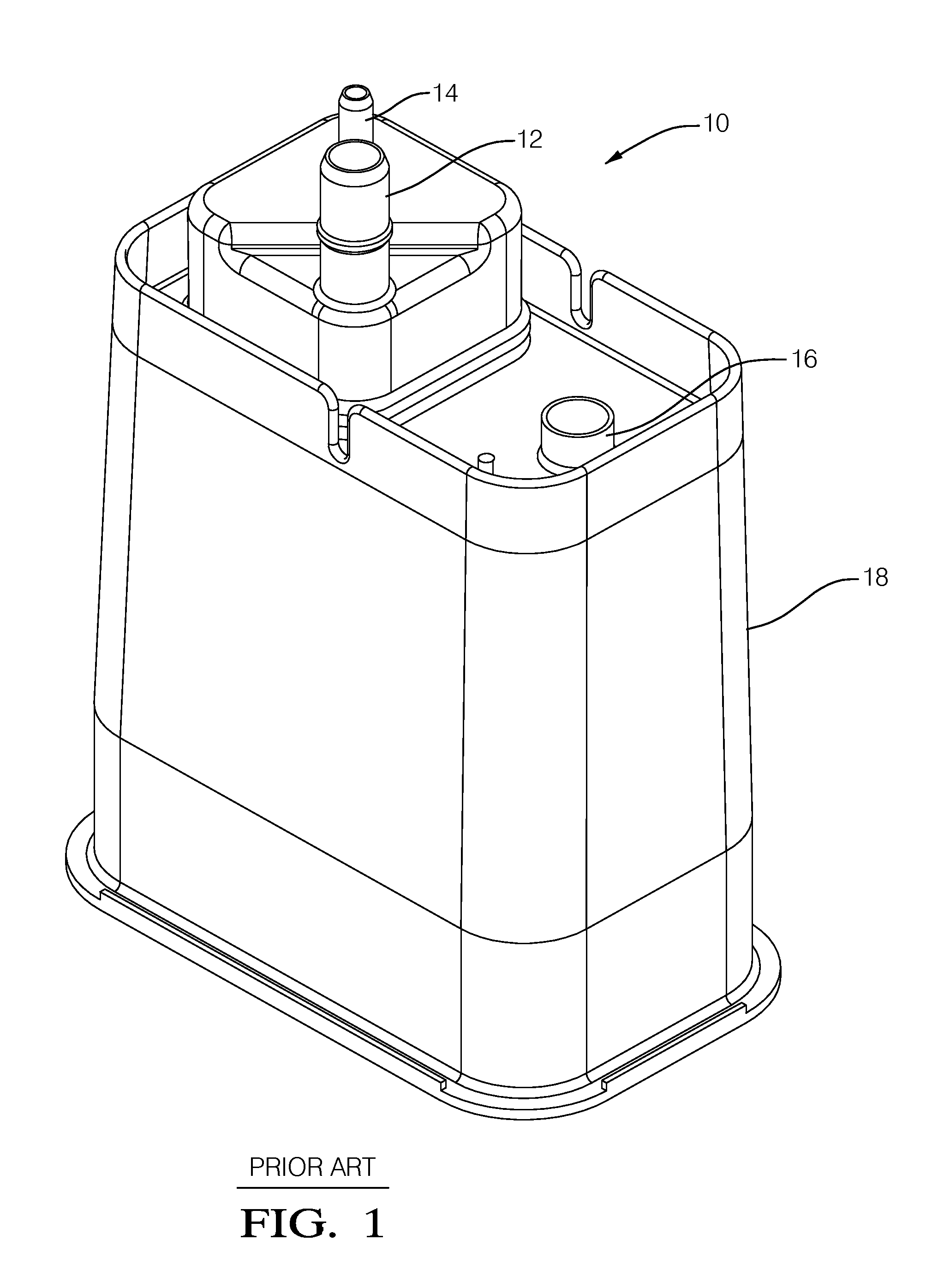

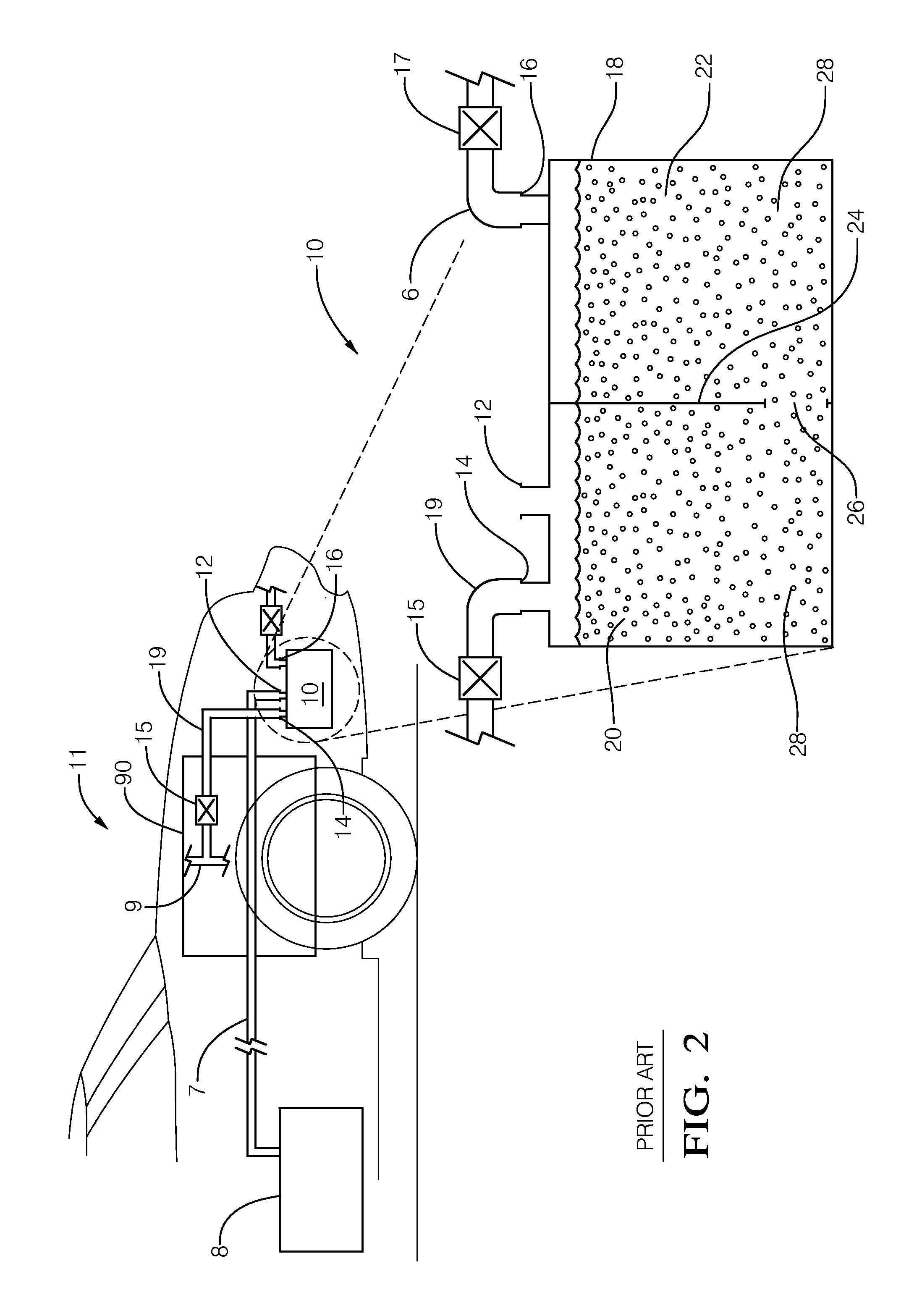

Carbon heating element for evaporative emission canister

ActiveUS20140158094A1Reduce the amount of fuelNon-fuel substance addition to fuelFuel injection apparatusControl systemSorbent

An evaporative emissions control system for reducing the amount of fuel vapor emitted from a vehicle includes a canister containing a sorbent material and a cartridge heater disposed at least partially within the canister in direct contact with the sorbent material. Electrical terminals for applying power to a heating element within the heater are disposed external to the canister. At least one heat sink may be included within the canister in direct contact with the heater. A method of manufacturing an evaporative emission control system that includes a cartridge heater disposed in a canister is also presented.

Owner:DELPHI TECH IP LTD

Cartridge heater with a release coating

InactiveUS7012226B1Easy curingOvercome problemsHeater elementsImmersion heating arrangementsEngineeringGraphite

A cartridge heater for mounting in the bore hole of a device to heat the device, having an improved release coating to facilitate the removal of the cartridge heater from the bore hole subsequent to operation at elevated temperatures, wherein the release coating is a fast-drying, graphite-based solid film lubricant that bonds to the heater.

Owner:DUREX IND INT +1

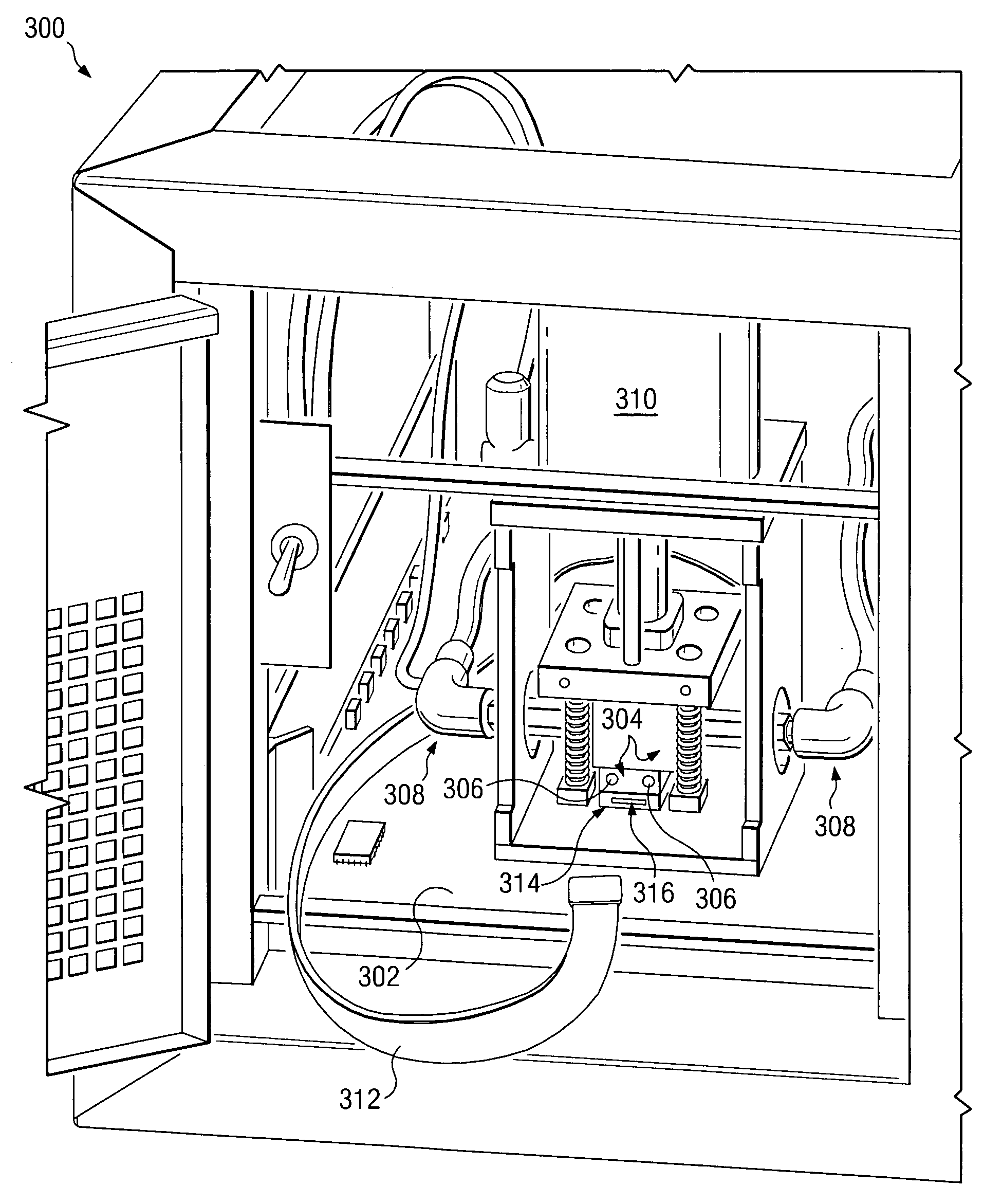

Hand held dispenser

ActiveUS8544689B2Minimized in sizeReduce the overall diameterLiquid flow controllersLarge containersTemperature controlHand held

A hand held dispenser system with associated dispensed material supply assembly as in separate source chemical foam precursor feeding into, for example, streamlined chemical passageways preferably each comprised of, in series, a castellated swivel hose filter, a valve assembly housing, a wing extensions of a manifold, which manifold supports a high efficiency drive system and is supported by a handle that provides for a compact assembly and receives a rugged trigger assembly. The manifold design provides for elongated filter and, temperature controlled cartridge heater insertion. There is further provided in a preferred embodiment a readily releasable electric source feed line plug connection at the butt end of the dispenser. The dispenser is well suited for the dispensing of methane foam as in a product packaging setting.

Owner:PREGIS INTELLIPACK CORP

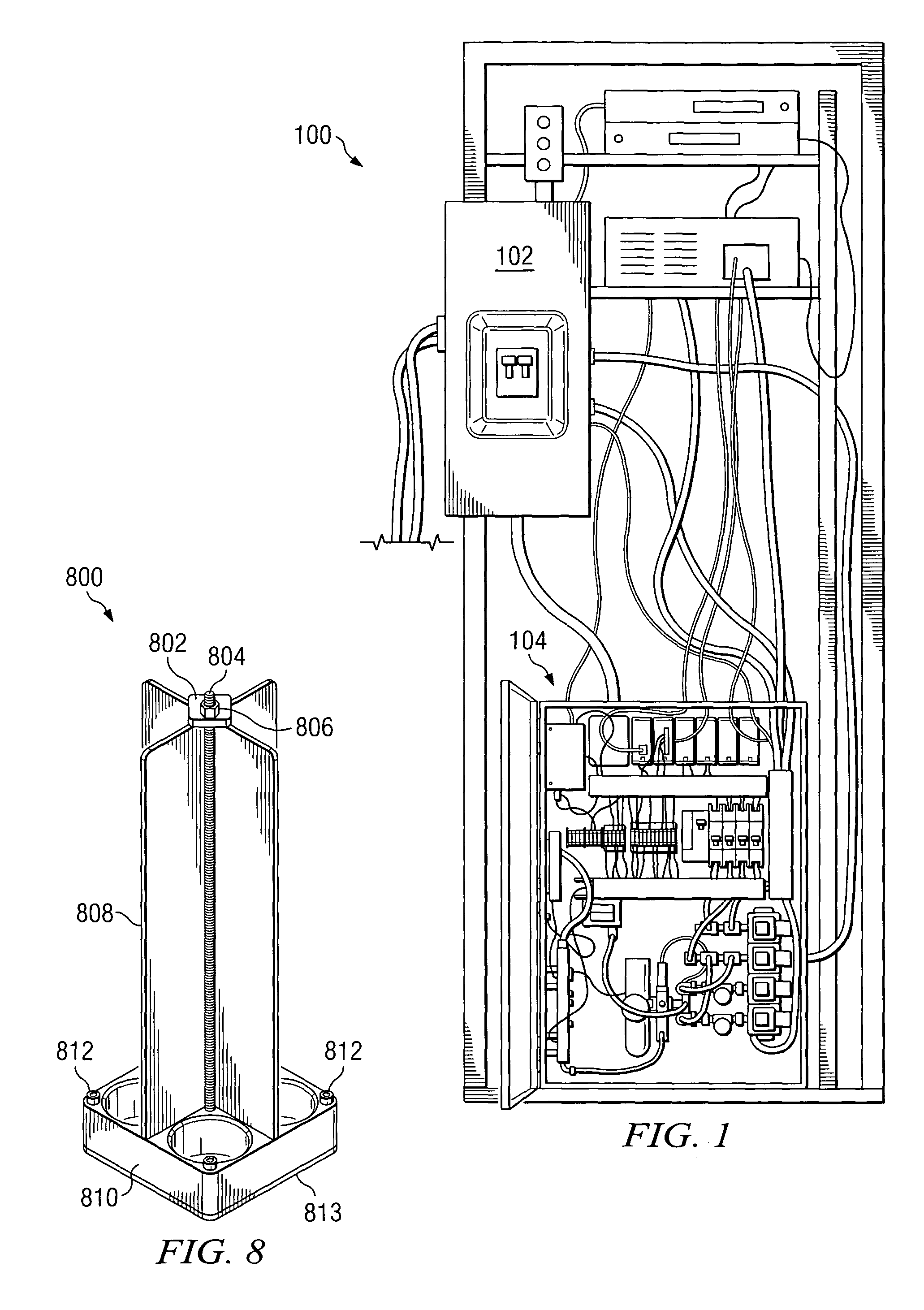

Temperature and condensation control system for functional tester

InactiveUS20050030052A1Electronic circuit testingFault location by increasing destruction at faultLoop controlEngineering

An innovative chip testing system and method includes controlling temperature and condensation during testing. Coarse temperature is controlled by providing a desired fluid flow rate and fluid temperature to a cold plate. Fine temperature control is provided by a feedback loop which controls the power dissipation of cartridge heaters installed within the cold plate. Condensation control is provided by insulating various components of the system, manipulation of dry compressed air in enclosures to reduce surface dew point temperatures, usage of cartridge heaters in a card backside stiffener plate, and by providing a heatsink assembly which prevents condensation on the insulation.

Owner:IBM CORP

Temperature and condensation control system for functional tester

InactiveUS7135877B2Electronic circuit testingFault location by increasing destruction at faultTemperature controlLoop control

An innovative chip testing system and method includes controlling temperature and condensation during testing. Coarse temperature is controlled by providing a desired fluid flow rate and fluid temperature to a cold plate. Fine temperature control is provided by a feedback loop which controls the power dissipation of cartridge heaters installed within the cold plate. Condensation control is provided by insulating various components of the system, manipulation of dry compressed air in enclosures to reduce surface dew point temperatures, usage of cartridge heaters in a card backside stiffener plate, and by providing a heatsink assembly which prevents condensation on the insulation.

Owner:IBM CORP

Heated die for hot forming

ActiveUS20060075799A1Simply controlledSimply poweredShaping toolsCutting toolsElectrical resistance and conductanceCartridge heater

A hot forming tool is heated with multiple electrical resistance cartridge heaters. The heaters are located in the body of the tool so as to maintain the entire forming surface within a predetermined temperature range. Numerical thermal and optimization analyses direct the placement of the heaters so that when each heating element is simultaneously powered on for an identical fraction of the time, an acceptable temperature distribution will be produced within the tool at the tool operating temperature.

Owner:GM GLOBAL TECH OPERATIONS LLC

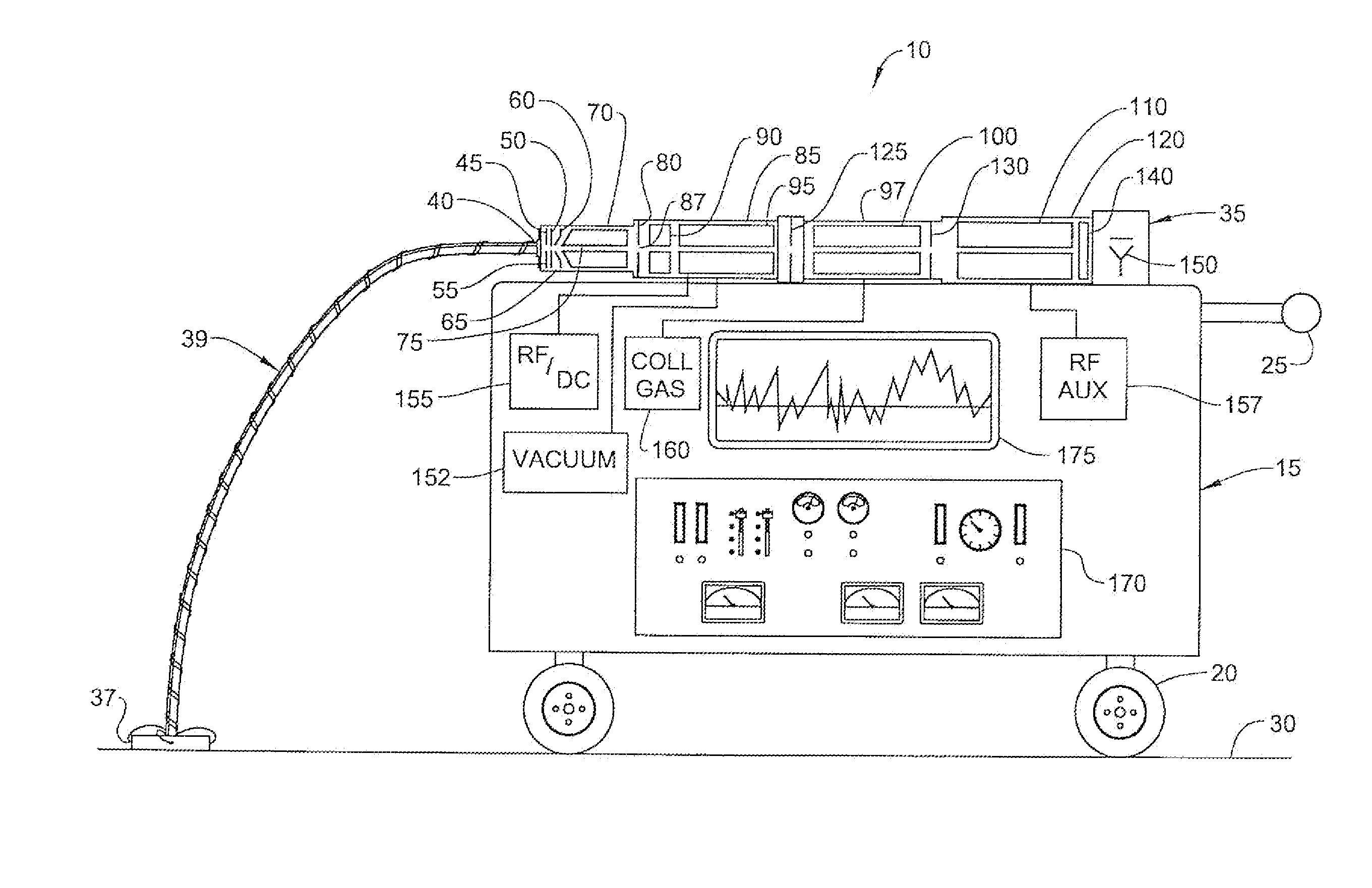

Surface Sampling Probe for Field Portable Surface Sampling Mass Spectrometer

InactiveUS20100096544A1Accurately determineEasy to transportSamples introduction/extractionIsotope separationMass analyzerCopper

A portable detection device includes a surface sampling probe connected to a mass spectrometer, preferably mounted on a portable cart, and a transfer line for transporting samples from the probe to the mass spectrometer. The surface sampling probe is formed from a circular block or disk of metal such as copper and is provided with various holes in which cartridge heaters are located. The disk is preferably electroplated with nickel and then gold to allow for efficient heat transfer to the surface to be sampled. With this arrangement, in addition to other advantages, the presence of very low volatile or non-volatile materials may be determined.

Owner:BATTELLE MEMORIAL INST

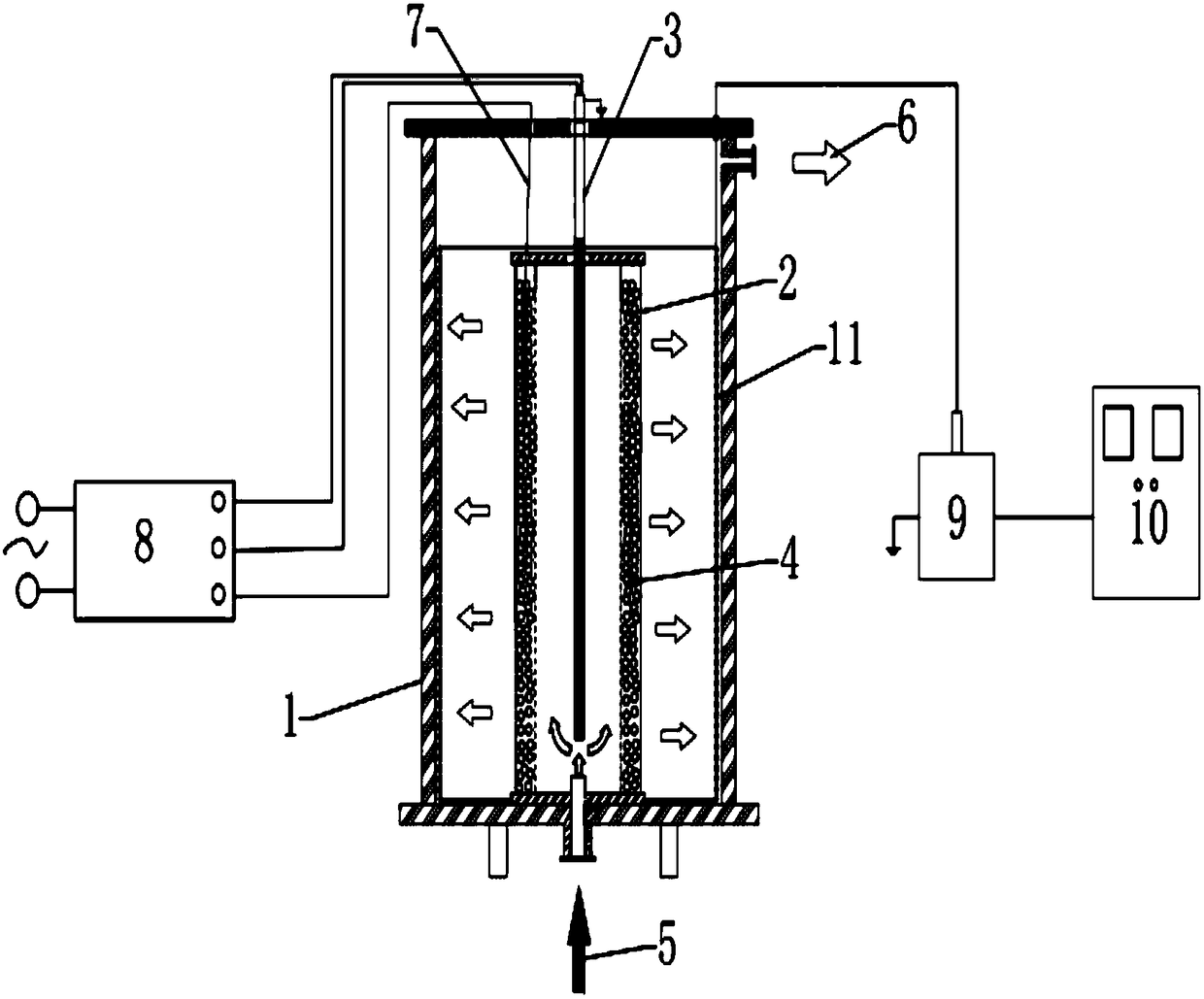

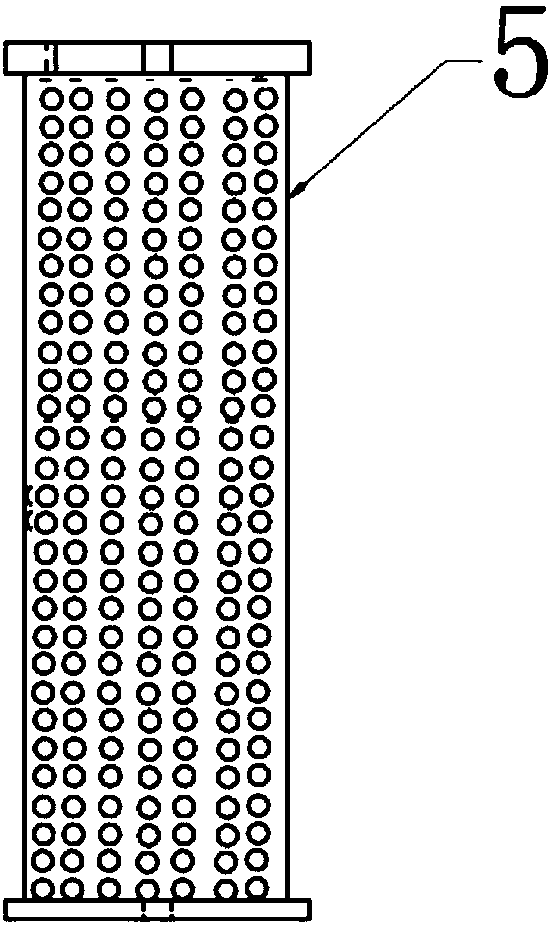

Device and method used for plasma cooperative electric cartridge heater screen catalytic treatment of VOCs

ActiveCN108452646APromote degradationImprove degradation selectivityGas treatmentDispersed particle separationHigh energyEngineering

The invention provides a device used for plasma cooperative electric cartridge heater screen catalytic treatment of VOCs. The device comprises a reaction chamber provided with an exhaust gas inlet andan exhaust gas outlet, and a catalytic module, a heating module, and a plasma generation module which are arranged in the reaction chamber; the catalytic module comprises a catalytic chamber, and a catalyst; at least a part of side walls of the catalytic chamber are prepared from double layer filter screens, and the catalytic chamber is provided with an opening connected with the exhaust gas inlet; the catalyst is stored in the double layer filter screens; the heating module comprises a heating element arranged in the catalytic chamber, a temperature control unit, and an electricity supply unit; the plasma generation module comprises a discharge electrode arranged around the periphery of the catalytic chamber, and a high-voltage pulse power supply; the discharge electrode is loaded with the high-voltage pulse power supply to generate high energy electrons and ion plasma in the reaction chamber. The invention also provides a method used for plasma cooperative electric cartridge heaterscreen catalytic treatment of VOCs. The device and the method are capable of achieving high removing efficiency; no secondary pollution is caused; and treatment cost is low.

Owner:JIANGSU JIAYU SPECIAL EQUIP CO LTD

Internally heated nozzle adapter

A nozzle adapter for an injection molding machine includes a body and one or more retainers mountable to an outer surface of the body. When the body and a retainer are assembled together they cooperate to define a cavity adapted to contain a cartridge heater between the body and the retainer. Access to allow replacement of the cartridge heater can be gained by removing the retainer from the body without removing the entire nozzle adapter from the injection molding machine.

Owner:APTIV TECH LTD

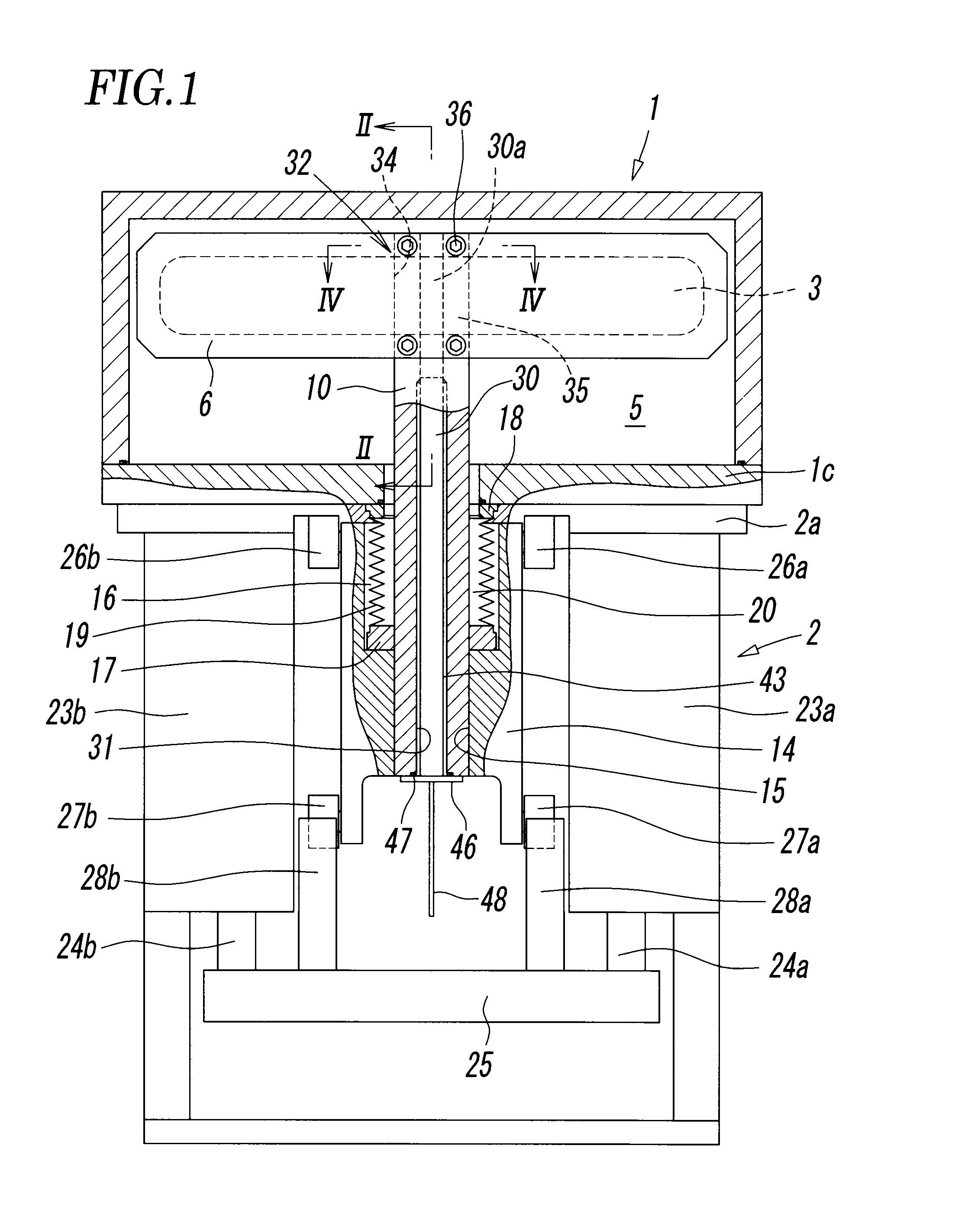

Vacuum valve

ActiveUS20110290340A1Improve heat transfer efficiencyEfficient heatingValve members for heating/coolingPipe heating/coolingEngineeringCartridge heater

A cartridge heater is accommodated in a heater bore in a shaft connected to a valve element, and a heating portion provided at an end portion of the cartridge heater is located at a joint portion of the shaft and the valve element. At the joint portion, a heat receiving groove and a pressurizing portion communicating with the heater bore are provided at a position between a surface of the valve element and that of the shaft located so as to oppose and to contact each other. The heat receiving groove includes an arcuate groove portion of the same radius as that of the heating portion of the cartridge heater, and the heating portion is pressed by the pressurizing portion to enter into plane-to-plane contact with an inner circumferential surface of the arcuate groove portion of the heat receiving groove, upon fastening the valve element and the shaft to each other with a bolt, with the heating portion located between the heat receiving groove and the pressurizing portion.

Owner:SMC CORP

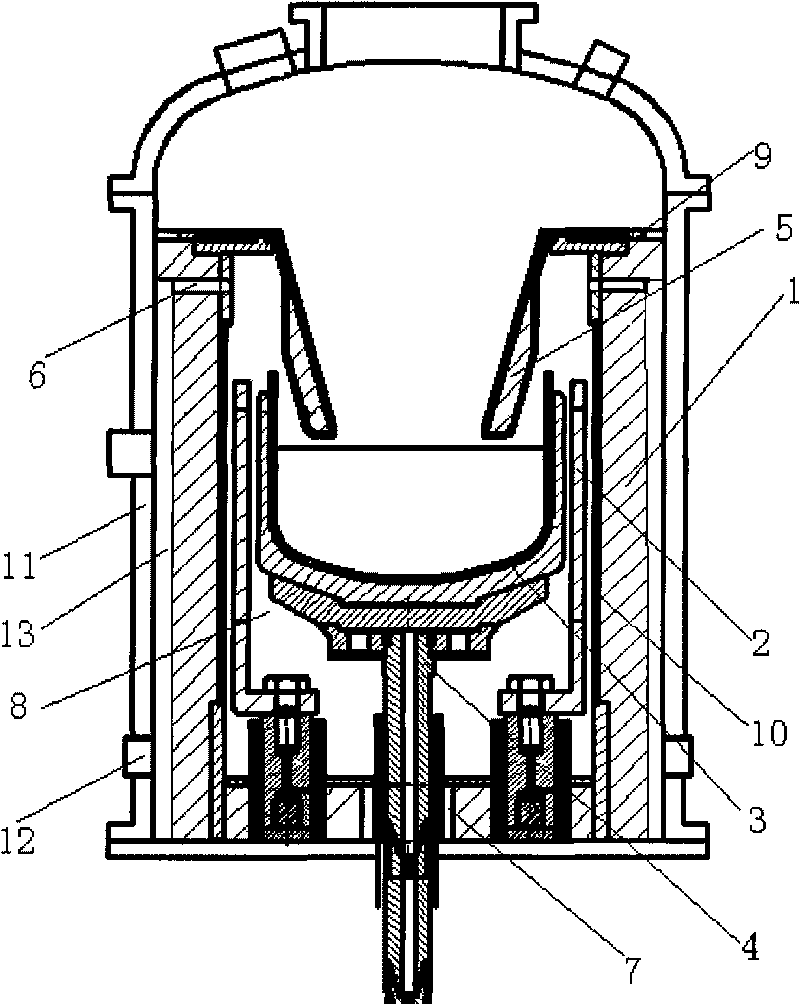

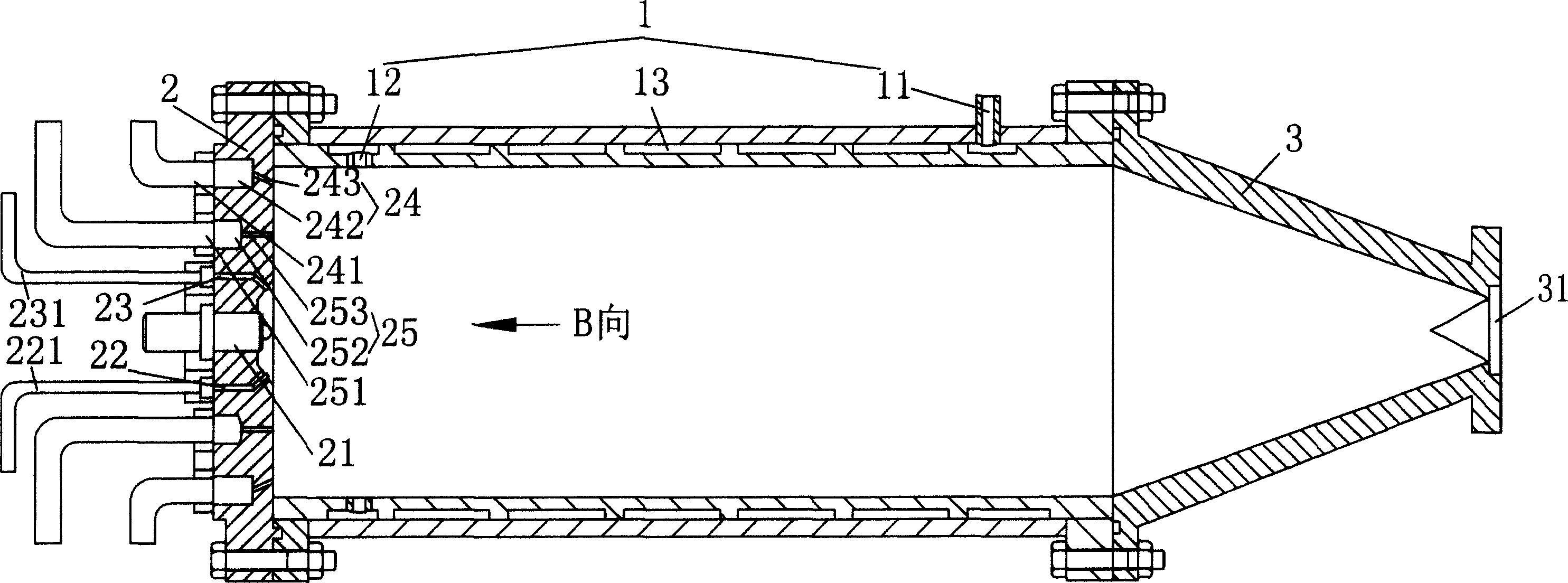

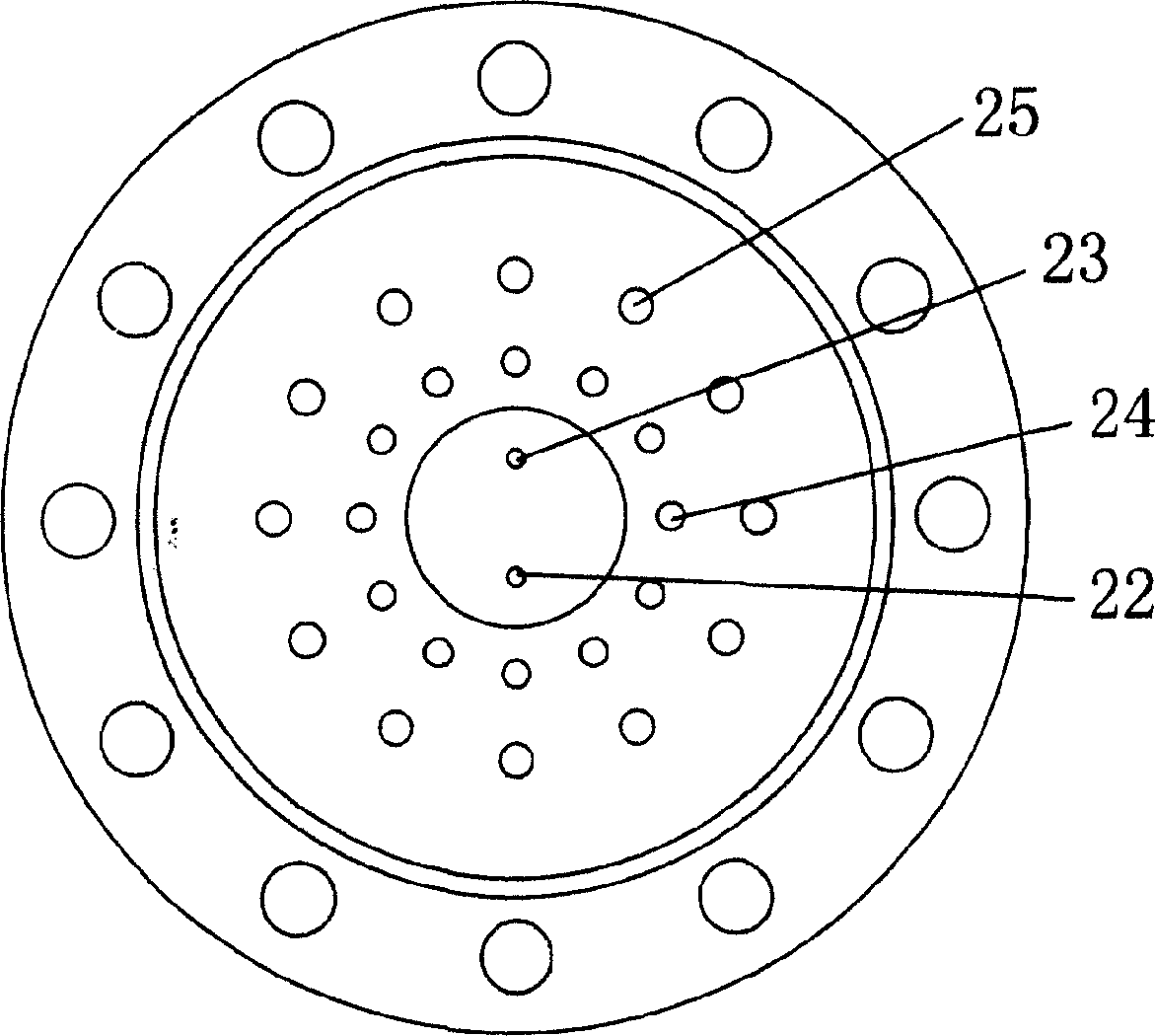

Silicon crystal growing device with two-way airflow

InactiveCN101713095AReduce corrosionReduce contact areaBy pulling from meltUnder a protective fluidCartridge heaterCorrosion

The invention discloses a silicon crystal growing device with two-way airflow, which comprises a furnace body; an inner cavity of the furnace body is provided with a cartridge heater inside; two electrodes at the bottom of the heater are respectively embedded into the bottom of the furnace body; the inside of the inner cavity of the heater is provided with a graphite crucible which is supported and fixed by a connecting rod passing through the bottom of the furnace body; an upper opening of the furnace body is provided with a guide cylinder capable of extending into an inner cavity of the graphite crucible; the side wall on the top of the furnace body is provided with a vent, and the bottom of the furnace body is provided with an argon inlet; the vent is communicated with the argon inlet through a gap between the inner wall of the heater and the outer wall of the graphite crucible; a gas cylinder is sleeved outside the furnace body; the side wall at the bottom of the gas cylinder is provided with an outlet; and the outlet is communicated with the vent through a gap between the gas cylinder and the furnace body. The silicon crystal growing device adopts the two-way airflow, the corrosion of harmful gases in the thermal field to graphite pieces can be reduced, and the contact area and contact time of oxygen and graphite are decreased, so that carbon oxides and the harmful gases on the surface of silicon liquid are quickly taken way from a thermal system under the driving of the flow direction of lower gases, and the carbon content in the crystal is effectively controlled.

Owner:芜湖升阳光电科技有限公司

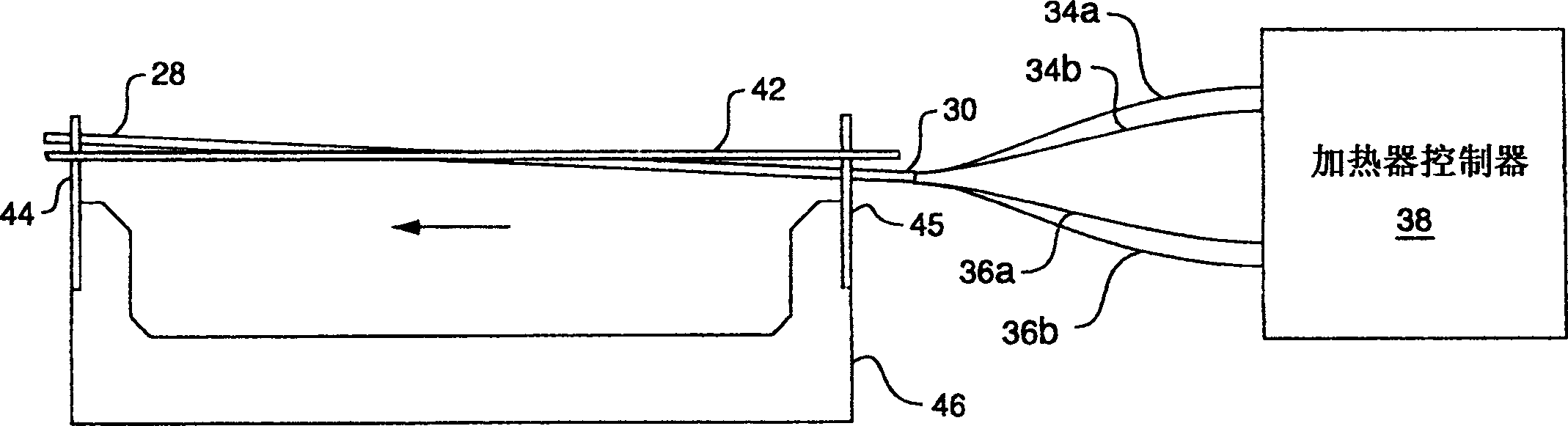

Film side sealing apparatus with closed-loop temperature control of a heater

An edge sealer for shrink wrap machines including a closed loop temperature controller for heaters to maintain the optimum temperature for cutting and sealing two layers of thermoplastic film. The heater consists of a cable or cartridge heater with an internal thermocouple connected to an automatic temperature controller. The heater is mounted to the edge seal between the top and bottom two sets of V-belts mounted around the drive and idler rolls. The V-belt exerts clamping pressure on the film so as to drive the film. In one embodiment, said clamping pressure is generated by means of a nip roll on the film slit side and by means of a low friction belt support guide plate on the film packaging side. In another embodiment, the belt support guide plate is replaced by a series of upper and lower nip rolls, and adjustable hinged clamps provide adjustable pressure on said series of upper and lower nip rolls.

Owner:SHRINK PACKAGING SYST

Air heater

The invention discloses an air heater, which comprises a direct sleeve, an air inlet disc and a cone, the two ends of the direct sleeve connect to the air inlet disc and cone individually, the spark plug, lighting hydrogen inlet, lighting air inlet, main flow hydrogen inlet and pure oxygen inlet are fixed on the air inlet disc, the jet is fixed on the cone. In that structure, the heat from burning hydrogen can warm the testing air in the cartridge heater, the included angle of the main flow hydrogen and pure oxygen is 30 deg. which can mix the hydrogen and oxygen even and burn completely. The lighting hydrogen inlet and lighting air inlet are set on the concentric ring of the sparking plug' outside, the intersection of the two flows has a distance from the air inlet disc, which makes the sparking plug lighting easier and the air inlet disc not burning-out because of the high temperature.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

Rotary Bag Machine With Skirtless Seal

InactiveUS20080093018A1Envelopes/bags making machineryBag making operationsMicrowaveCartridge heater

A machine and method for making bags is described and includes a web traveling from an input section to a rotary drum, to an output section. The rotary drum includes at least one seal bar, having a single sealing zone, and an weakening zone disposed within the single sealing zone. The single sealing zone may be a heated perforator, includes a heating wire. The heating wire may be an NiCr wire and make intermittent contact with the web and be disposed in an insert. The weakening zone may create a line of weakness that is uniform or varies in intensity. The sealing zone may include temperature zones, cartridge heaters, cooling air, or heated air, or a source of ultrasonic, microwave or radiative energy.

Owner:CMD CORP

Cartridge heater with an alloy case

InactiveUS20120085749A1Thin spaceHeater elementsWrapper twisting/gatheringCartridge heaterMaterials science

A cartridge heater may include an elongated core assembly inside an elongated metal sheath having first and second ends and wherein the elongated metal sheath is made from at least one of aluminum alloy and copper alloy. The elongated core assembly includes a resistance heating element mounted to an elongated insulating core with electric leads extending outside the elongated metal sheath. The core assembly substantially fills the elongated metal sheath with a very thin space between an inside surface of the elongated metal sheath and an outside surface of the core assembly

Owner:NEXTHERMAL CORP

System for heat-producing sludge gas by combination of solar and electric heating tubes

InactiveCN101130749AGuaranteed outputReduce lossesBioreactor/fermenter combinationsGas production bioreactorsCartridge heaterElectric heating

The invention discloses a system and a device which produce methane by heating with electrical cartridge heater and solar energy. The invention solves the present problem that the structure which produces methane with a plurality of energy is complicate, the operation fees are expensive and the large scale application is difficult. The water outlet of solar collector and the first end of the second magnetic valve are connected with the water outlet of incubator, the water outlet of the solar energy collector is connected with the first end of the first magnetic valve, the second ends of the first magnetic valve and the second magnetic valve are connected with the water outlet of the circulating water pump, the water inlet of the circulating water pump and the water outlet of the incubator are connected with methane tank, the electrical cartridge heater is arranged in the incubator, two temperature sensors are arranged on the pipe of the solar collector and incubator, the control input end of the circulating water pump and two magnetic valves are connected with the control output end of the temperature controller, and the signal output ends of two sensors are connected with the signal output end of the temperature controller.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com