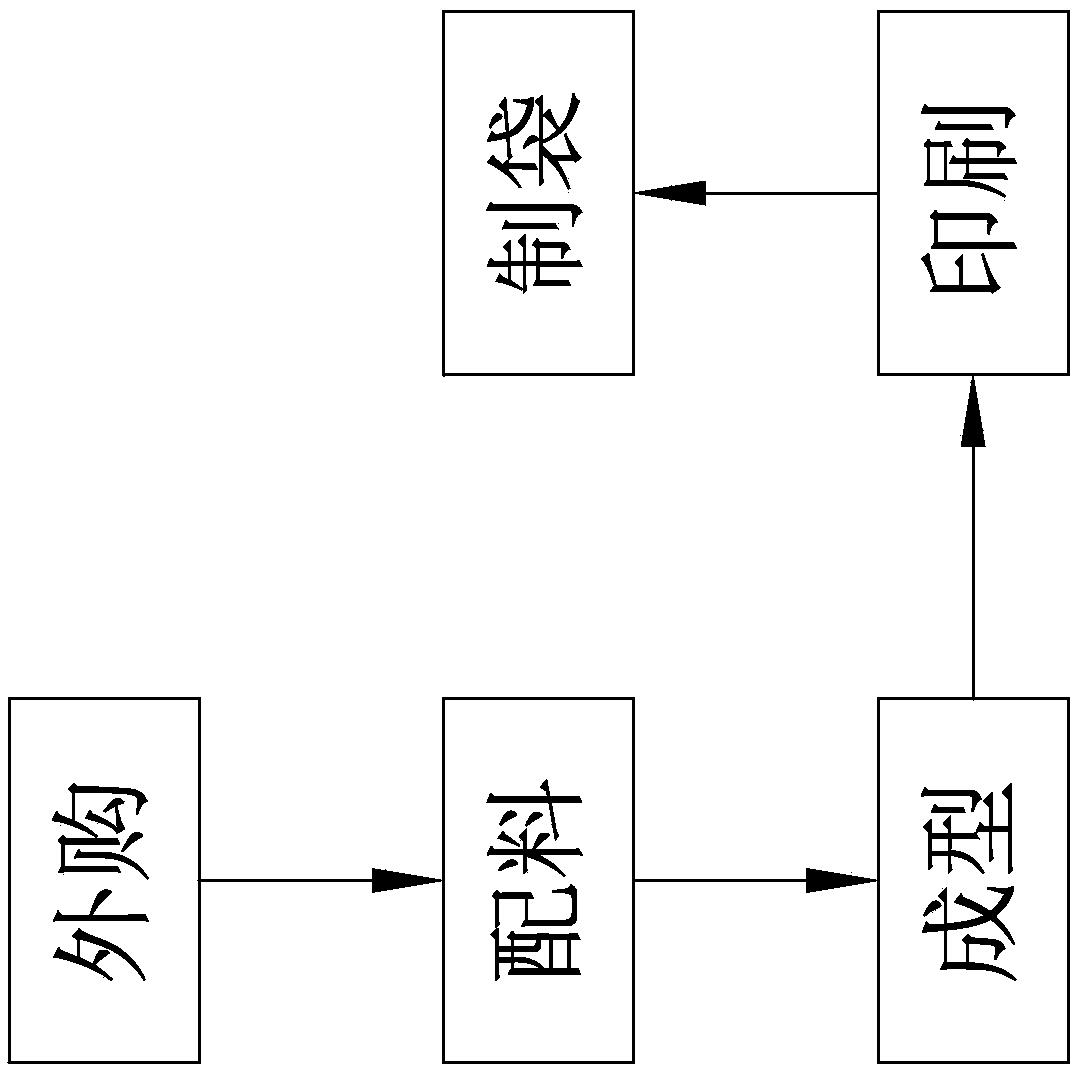

Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48 results about "Biodegradable additives" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Biodegradable additives are additives that enhance the biodegradation of polymers by allowing microorganisms to utilize the carbon within the polymer chain as a source of energy. Biodegradable additives attract microorganisms to the polymer through quorum sensing after biofilm creation on the plastic product. Additives are generally in masterbatch formation that use carrier resins such as polyethylene (PE), polypropylene (PP), polystyrene (PS) or polyethylene terephthalate (PET).

Stone Based Copolymer Substrate

InactiveUS20130101774A1Facilitates and promotes recyclingLayered productsBottlesPolymer scienceBiopolymer

A stone based copolymer substrate includes calcium carbonate (CaCO3) from approximately fifty to eighty-five percent (50-85%) by weight and varying in size generally from 1.0 to 3.0 microns, high-density polyethylene (HDPE) from approximately two to twenty-five percent (2-25%) by weight and a biopolymer from approximately two to twenty-five percent (2-25%) by weight. The substrate may include a biodegradation additive from approximately three fourths of a percent to two percent (0.75-2%) by weight. By selectively adjusting the ranges of the substrate's components, various products can be made to replace current tree-based and plastic-based products. The substrate can be configured to be tear proof, water proof, fade resistant and fire retardant while utilizing less energy and producing less waste during its manufacture. In an exemplary embodiment of the invention, the stone used in the substrate includes limestone.

Owner:ICAST PLASTICS

Degradable composite plastic sheet

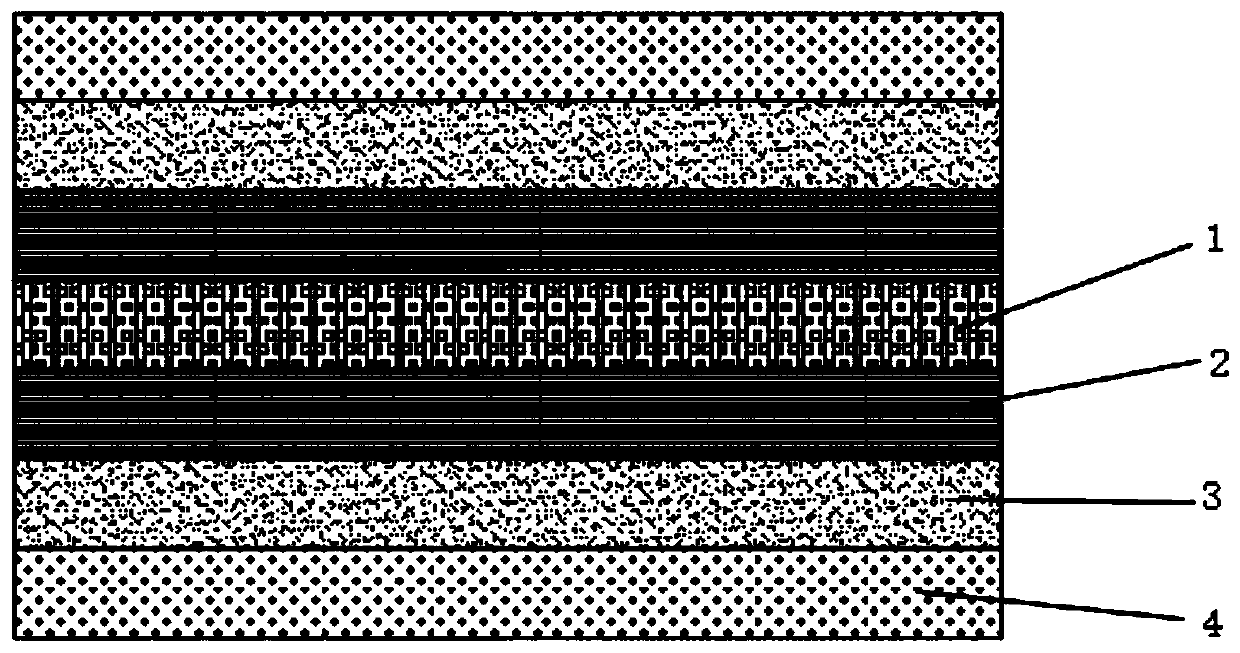

ActiveCN101722699ASoft textureImprove water resistanceSynthetic resin layered productsPolymer scienceSurface layer

The invention relates to a degradable composite plastic sheet. The composite plastic sheet is characterized by consisting of an upper polymer surface layer, a lower polymer surface layer and a polylactic acid core layer, wherein each polymer surface layer has the thickness of 0.01-0.02 mm and contains oxidized biodegradable additives; and the polylactic acid core layer is modified by a plasticizer. The integral bending modulus of the sheet is 0.02-1.0GPa. The composite plastic sheet has flexibility, and good waterproof property and anti-mildew property during normal use, and can be completely degraded in the outdoor composting environments after being discarded. The composite plastic sheet can replace the nondegradable soft polyvinyl chloride sheets, and can be used as daily products of tableclothes, dinner pads, table pads and the like.

Owner:DONGGUAN IUIU HOUSEHOLD PROD

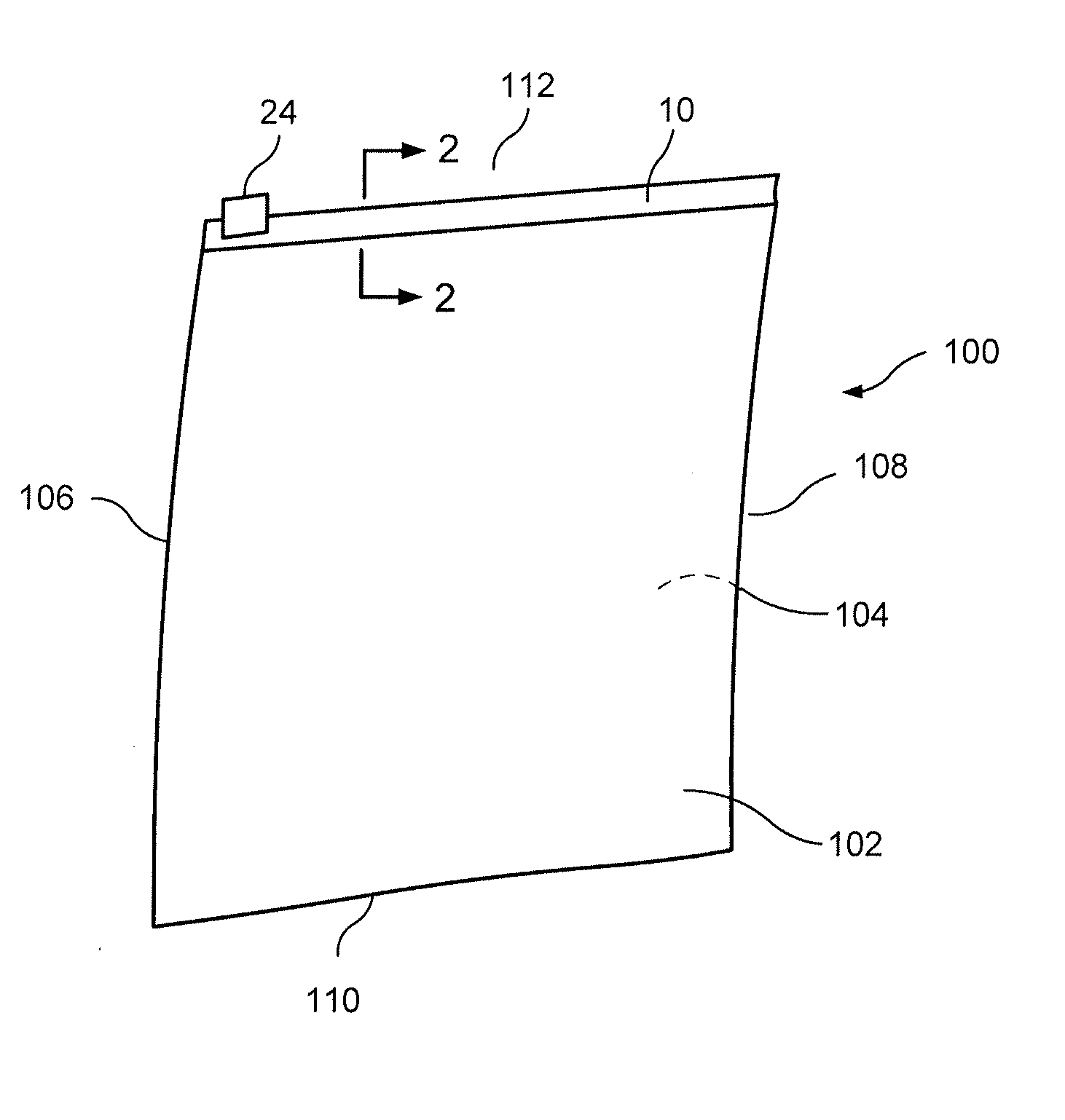

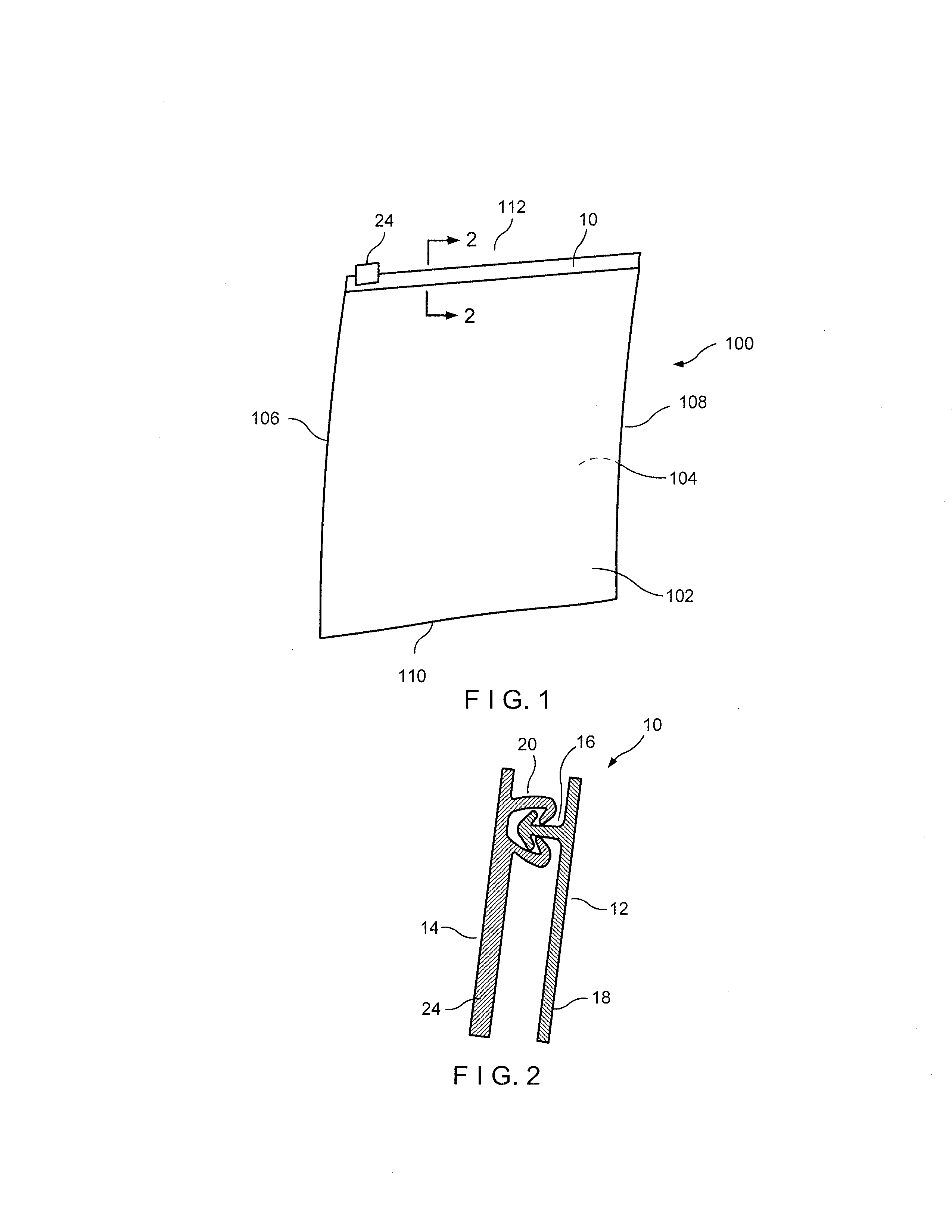

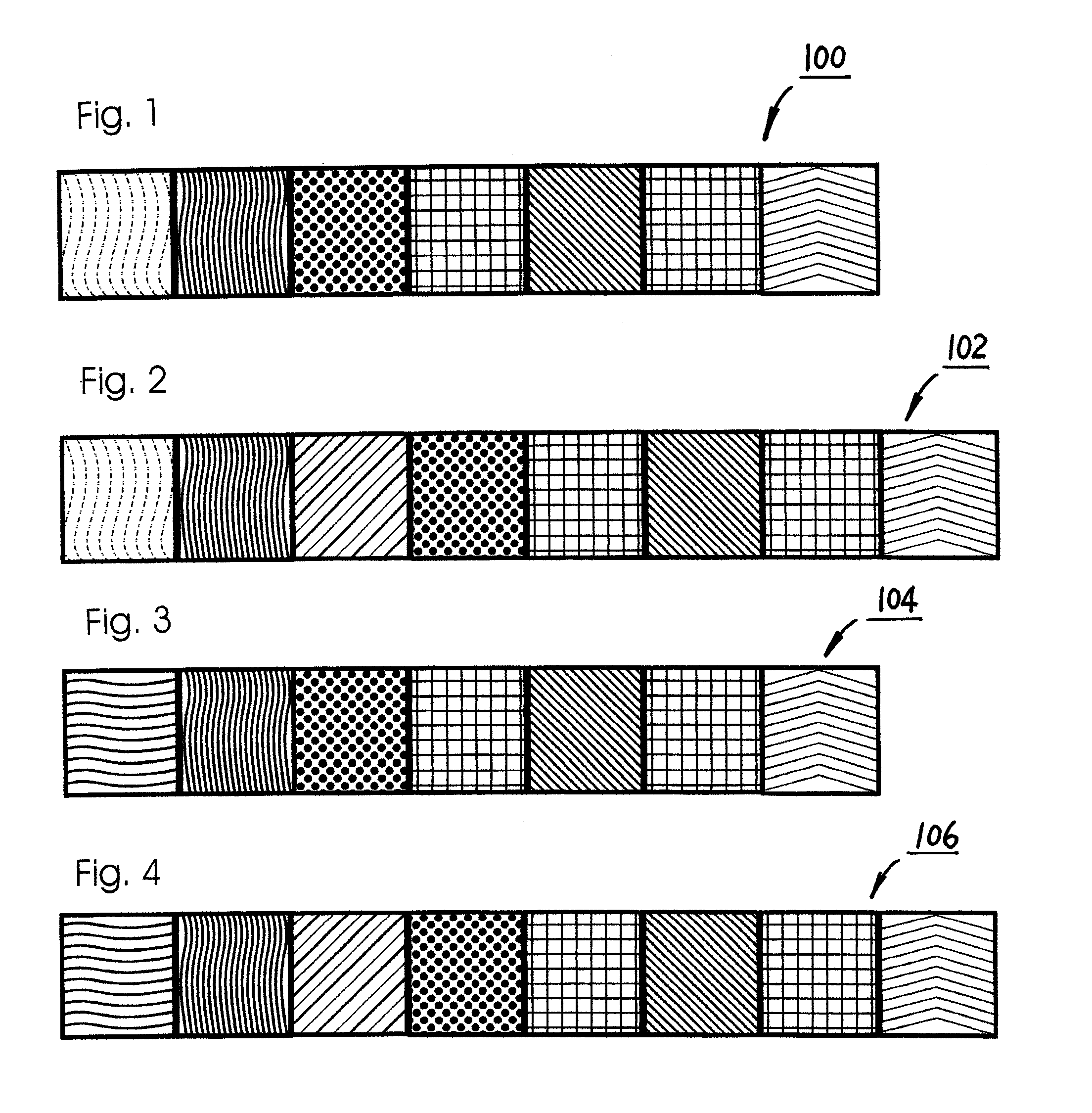

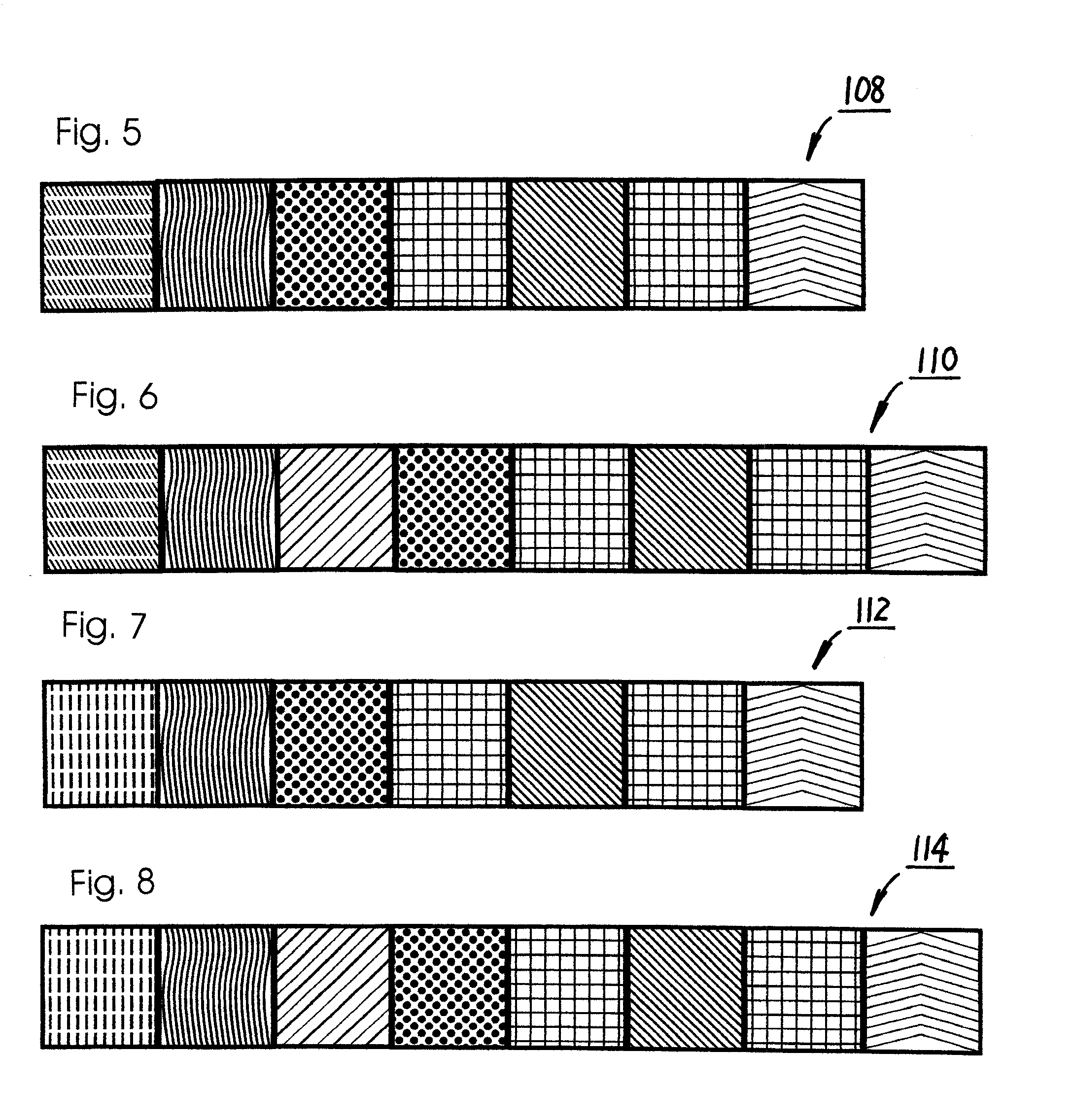

More sustainable biodegradable foamed zipper

InactiveUS20130174386A1Promote degradationIncrease ratingsSnap fastenersSlide fastenersMedicineBiodegradable additives

The present disclosure relates to zipper for a reclosable package, particularly a zipper which has been foamed with the use of bioresins or biodegradable additives to increase the degradability of the zipper. The combination of the process of foaming with the use of bioresins or biodegradable additives typically increases the rate of degradability of the zipper, particularly in biodegradable environments, such as landfills.

Owner:ILLINOIS TOOL WORKS INC

Stone based copolymer substrate

InactiveUS20120071574A1Facilitates and promotes recyclingDyeing processChemical recyclingPolymer scienceBiopolymer

A stone based copolymer substrate includes calcium carbonate (CaCO3) from approximately fifty to eighty-five percent (50-85%) by weight and varying in size generally from 1.0 to 3.0 microns, high-density polyethylene (HDPE) from approximately two to twenty-five percent (2-25%) by weight and a biopolymer from approximately two to twenty-five percent (2-25%) by weight. The substrate may include a biodegradation additive from approximately three fourths of a percent to two percent (0.75-2%) by weight. By selectively adjusting the ranges of the substrate's components, various products can be made to replace current tree-based and plastic-based products. The substrate can be configured to be tear proof, water proof, fade resistant and fire retardant while utilizing less energy and producing less waste during its manufacture. In an exemplary embodiment of the invention, the stone used in the substrate includes limestone.

Owner:ICAST PLASTICS

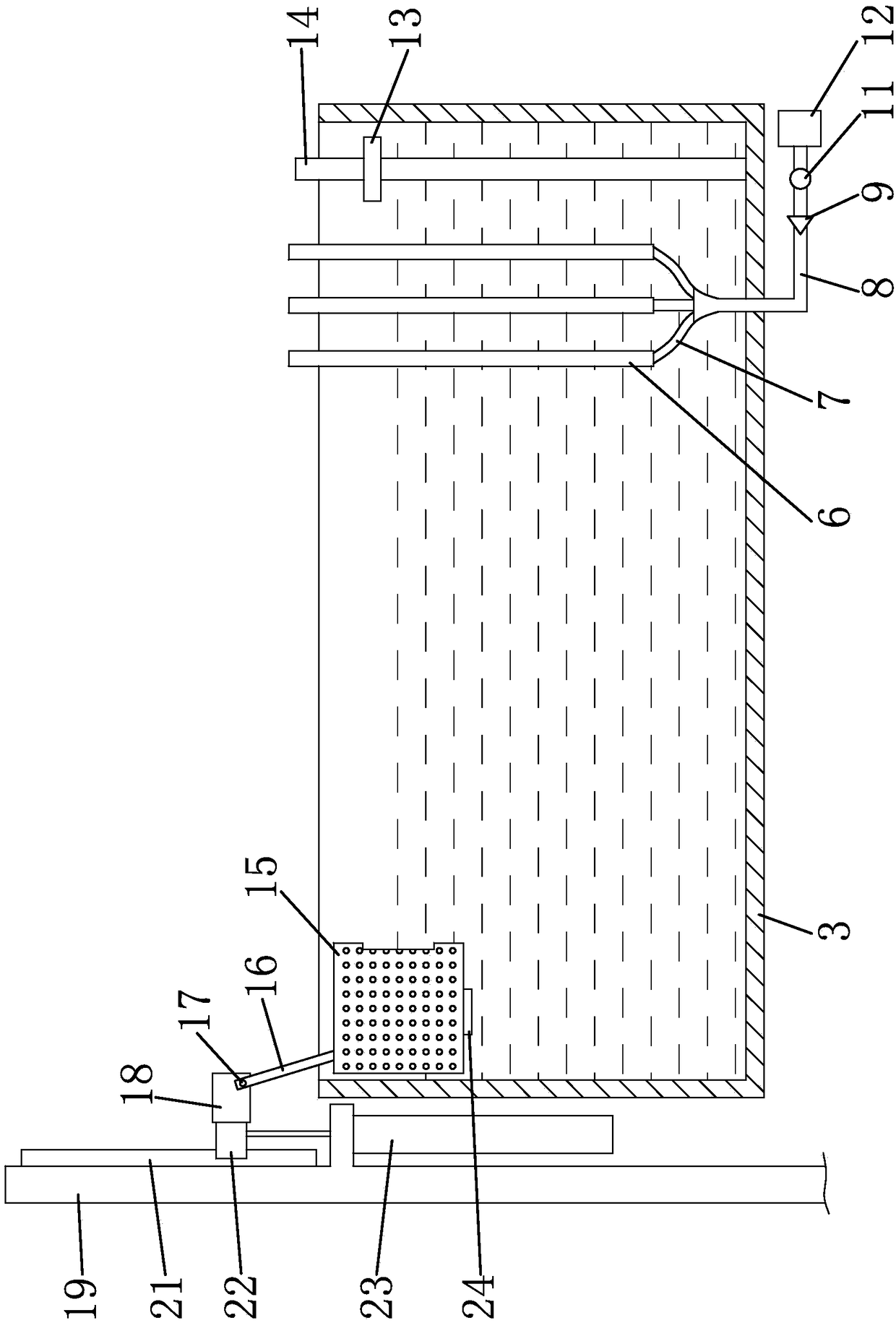

Degradable inflaming retarding air bubble film and preparation method thereof

InactiveCN103435885AAvoid pollutionImprove antistatic performanceLinear low-density polyethyleneLow-density polyethylene

The invention relates to a degradable inflaming retarding air bubble film and a preparation method thereof, and belongs to the technical field of macromolecular materials. The air bubble film comprises the following raw materials in parts by weight: 100-200 parts of low density polyethylene resin, 30-40 parts of linear low density polyethylene resin, 10-20 parts of ethylene- acetic acid vinyl resin, 5-10 parts of nitrogen flame retardant, 2-5 parts of silicane coupling agent, 1-4 parts of oxo-biodegradable plastic additive, 0.5-1 part of antioxygen, and 3-5 parts of fatty alcohol polyoxyethylene ether. The invention preserves the advantages of the prior art, and has good antistatic performance and inflaming retarding performance; the wasted product can be directly subjected to biological degradation in virtue of the added oxo-biodegradable plastic additive, so that the pollution to the environment is avoided.

Owner:WUJIANG YINGLIDA PLASTIC PACKAGING

High barrier film laminate

InactiveUS20120196141A1Promote decompositionSynthetic resin layered productsDomestic containersAdhesiveDecomposition

A film of laminate construction for producing on a packaging machine a flexible container for containing food includes the following layers. A layer of natural kraft paper for forming an outside layer of the container followed by a layer of adhesive. A layer of PE also known as polyethylene followed by a layer of tie adhesive for bonding two layers together. A layer of EVOH also known as ethylene vinyl alcohol and another layer of tie adhesive for bonding two layers together. A layer of PE sealant also known as polyethylene sealant for forming an inside layer of the container, wherein the layers preferably containing an organoleptic biodegradable additive to accelerate decomposition of the film laminate.

Owner:POCIUS ROBERT

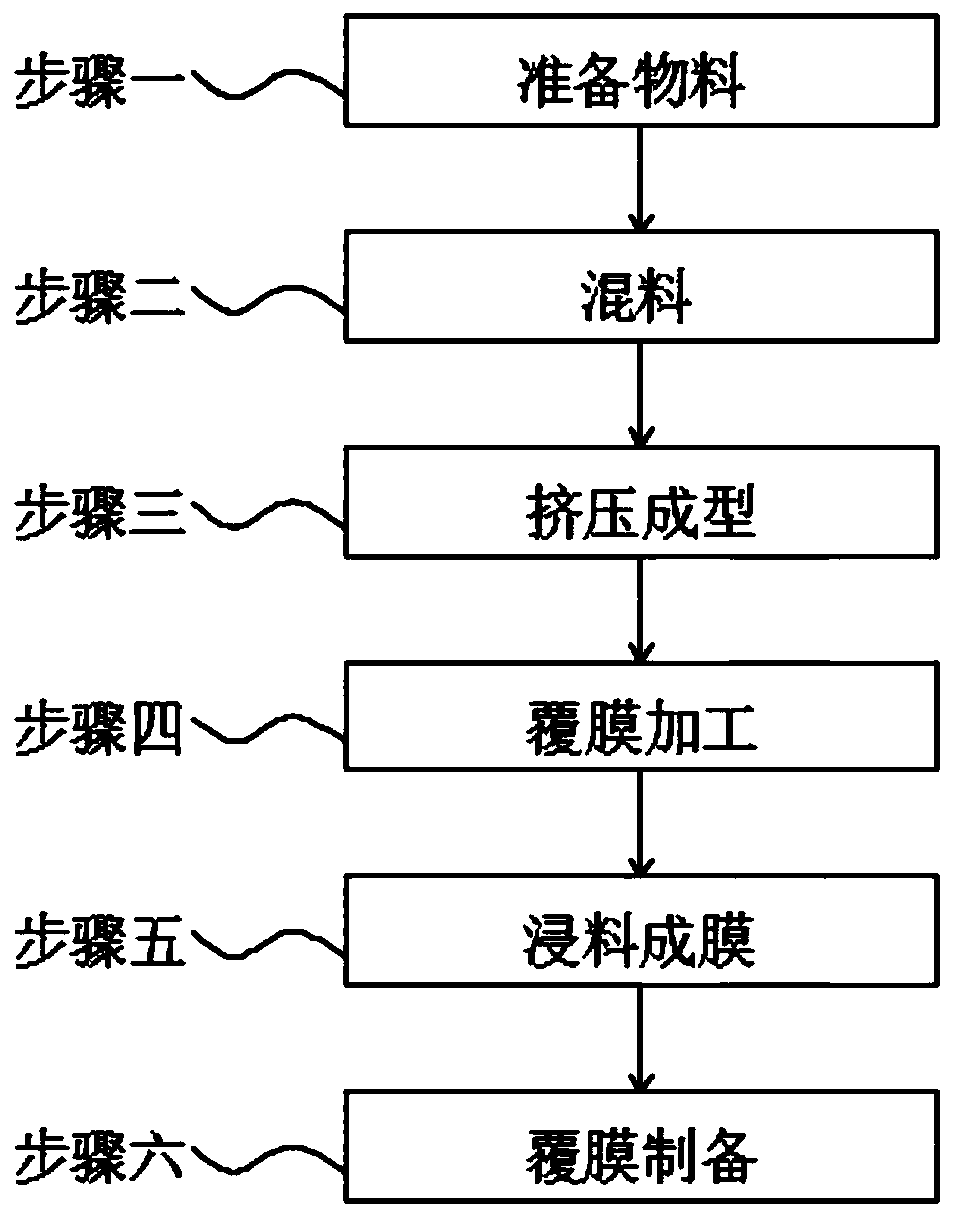

Degradable high strength composite bubble film and processing method thereof

InactiveCN110421943AHigh tensile strengthEnhance friction strengthFlexible coversWrappersPolymer scienceWear resistant

The invention discloses a degradable high strength composite bubble film and a processing method thereof. The degradable high strength composite bubble film comprises a bubble film layer, reinforced layers, wear-resistant layers and flame-retardant layers. The bottom side of the bubble film layer is provided with a reinforced layer, a wear-resistant layer is arranged at the bottom side of the reinforced layer, a flame-retardant layer is arranged at the bottom side of the wear-resistant layer, and the top side of the bubble film layer is symmetrically equipped with a reinforced layer, a wear-resistant layer and a flame-retardant layer in order. A biodegradation additive is added to the bubble film with polyethylene as the matrix to improve the degradation speed, and at the same time, the externally used reinforced layers and wear-resistant layers are both organic matters, do not cause pollution, and also can increase the tensile strength and friction strength of the bubble film, which is not easily damaged during use, the setting of the flame-retardant layers can improve the high temperature resistance of the bubble film and achieve a better use effect. The making process adopted bythe invention is simple, and the product has market competitiveness and can bring better benefits.

Owner:四会市金利达包装有限公司

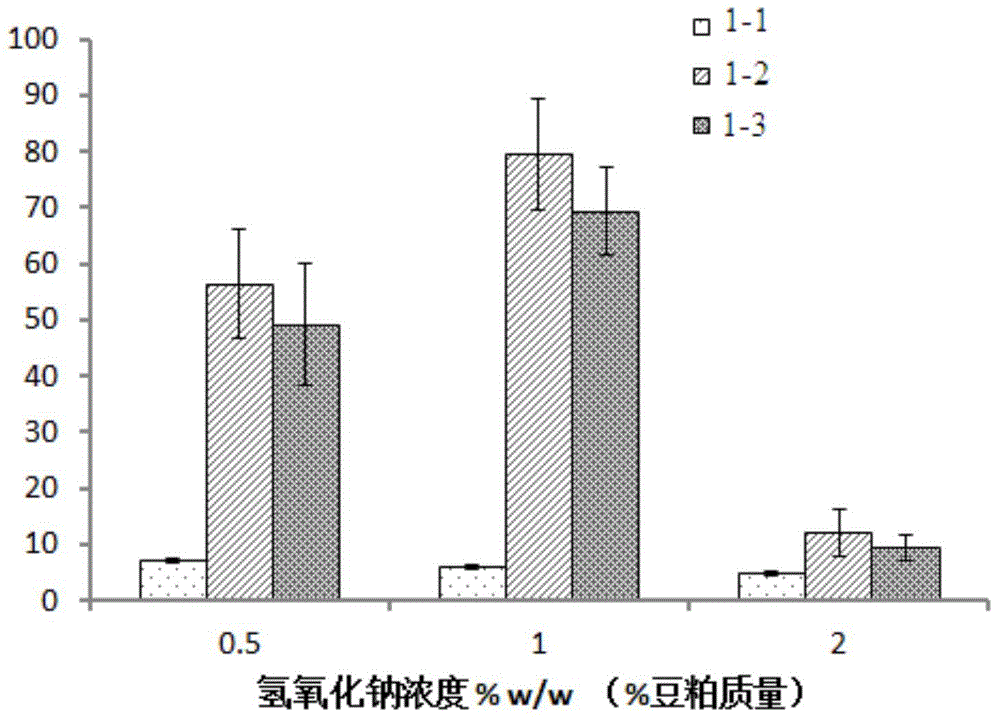

Biodegradable additive for improving property of PVA-substituted sizing agent

The invention relates to a biodegradable additive for improving the property of a PVA-substituted sizing agent. The biodegradable additive is prepared from the following steps: by adopting agricultural side products and wastes as materials, obtaining a biodegradable mixture by alkaline extraction, and preparing the additive based on the agricultural side products and the wastes; or adopting anhydride (acetic anhydride, butanedioic anhydride and the like), unsaturated polar monomers (crylic acid, acrylonitrile, styrene and derivative and the like) to modify the additive based on the agricultural side products and the wastes, and preparing the modified additive based on the agricultural side products and the wastes; or adopting biodegradable polyhydric alcohol or polyhydric alcohol amine as the materials and preparing a plasticizing additive based on the agricultural side products and the wastes together with the additive based on the agricultural side products and the wastes. The biodegradable additive has the advantages that the sizing property of the biodegradable textile sizing agent for cotton yarns, polyester, cotton-polyester blended yarns and other blended yarn threads can be improved, and simultaneously the degradability of the novel sizing agent is not weakened, so that the biodegradable additive is a green sizing-agent additive with low preparation cost and excellent biodegradability.

Owner:JIANGNAN UNIV

Biodegradation-enhanced synthetic fiber and methods of making the same

PendingCN110832124AMonocomponent polyesters artificial filamentArtifical filament manufacturePolymer sciencePolymer chemistry

The disclosure provides a synthetic biodegradation-enhanced fiber, methods of making such fiber, and articles including such fiber. The fiber includes a polymer material and 0.1 to 10 wt % one or morebiodegradation additives at least partially contained within the polymer material. The biodegradation additives enhance the biodegradation rate of the polymer material in a biodegradation environment. The biodegradation additives may comprise at least one of an aliphatic-aromatic ester, a polylactide, an organoleptic, a monosaccharide, an aldohexose or a combination thereof. The synthetic fiber may be micro-denier fiber have a denier of less than or equal to 1, or macro-denier fiber having a denier greater than 1. The synthetic fiber may be siliconized.

Owner:普莱玛有限公司

Allergy-free and fully-degradable nonwoven material for medical treatment and health care

InactiveCN105908370ACreate pollutionAchieve antibacterial effectCarbon fibresBiochemical fibre treatmentCarbon fibersAllergy

The invention provides an allergy-free and fully-degradable nonwoven material for medical treatment and health care, and relates to the technical field of nonwoven materials. A preparation method of the nonwoven material comprises the following steps: opening and scotching a wood pulp fibreboard into a monofilament state through an air lay; then agglutinating monofilaments on a net curtain through an air flow method; outputting the monofilaments together with carbon fibers, glass fibers, artificial fibers and biodegradable fibers from a fiber net through a carding machine; reinforcing to obtain a semi-finished product of the nonwoven fabric; soaking the semi-finished product in a starch solution; adding a biodegradable additive and few herbaceous plant plants; heating; foaming to form; sequentially soaking in antibacterial liquid and an antistatic treating agent; then drying. The allergy-free and fully-degradable nonwoven material for medical treatment and health care can be naturally biodegraded after use, so that no environment pollution is caused, and the antibacterial effect can be achieved.

Owner:HENAN YADU IND

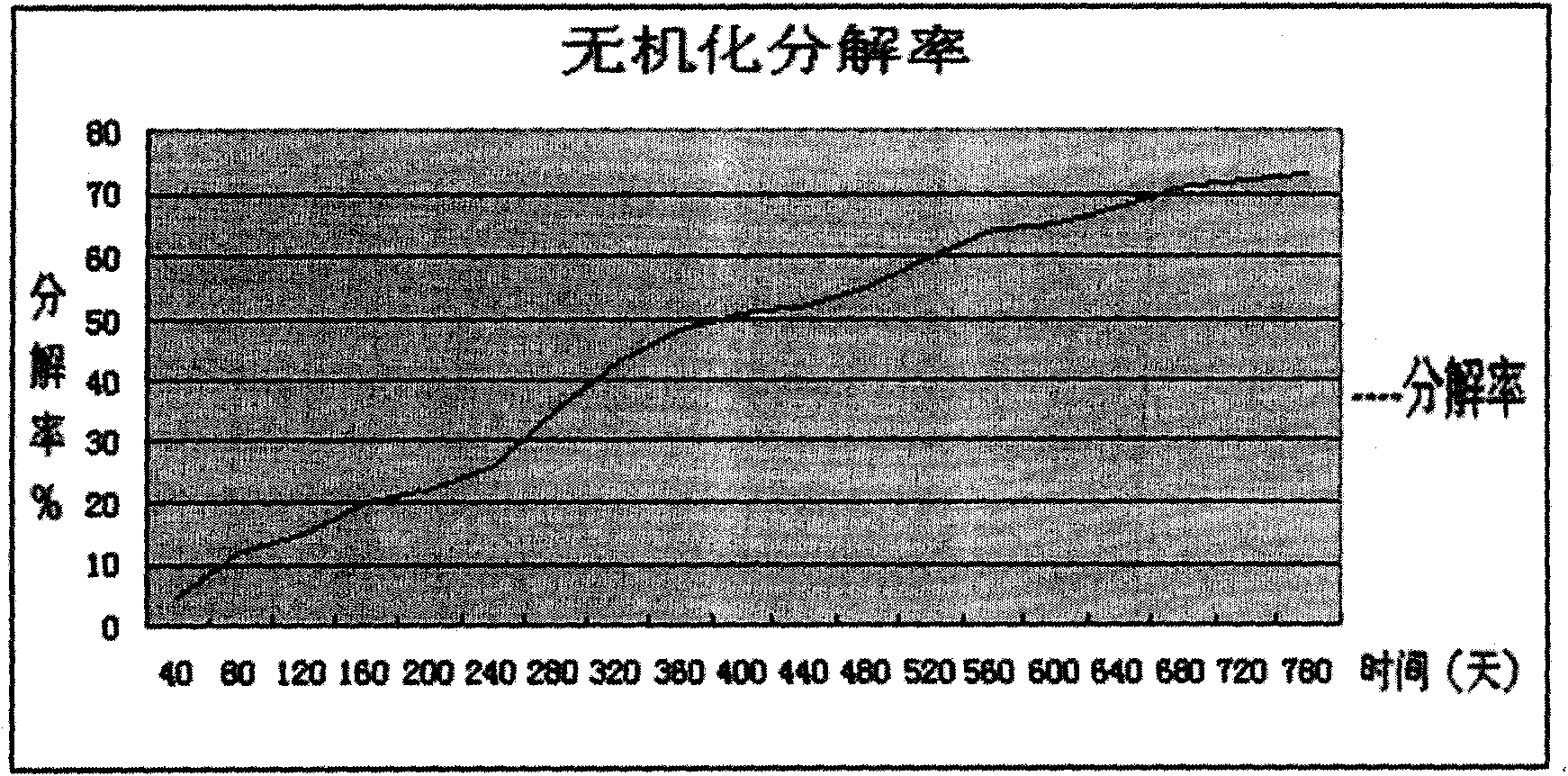

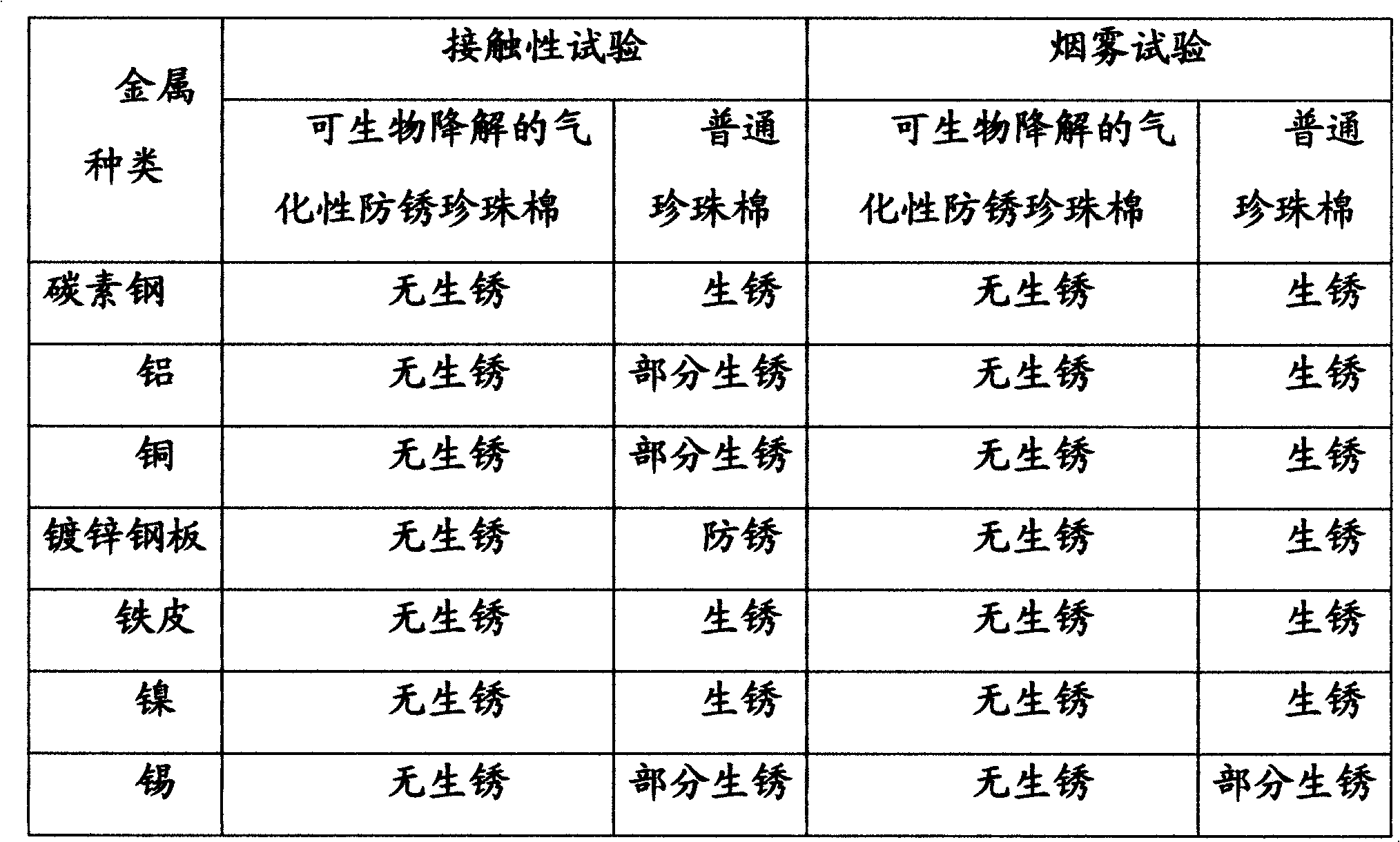

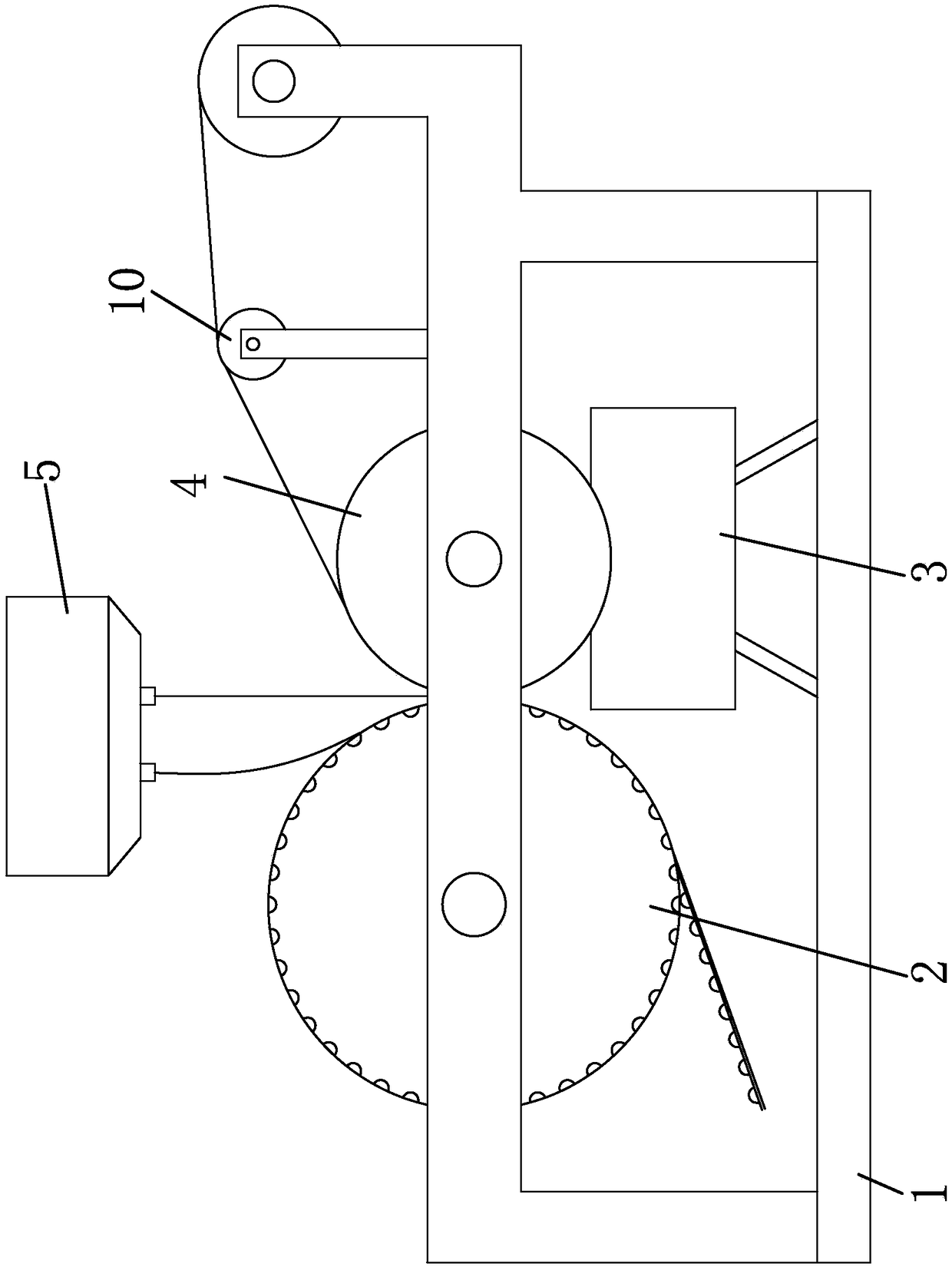

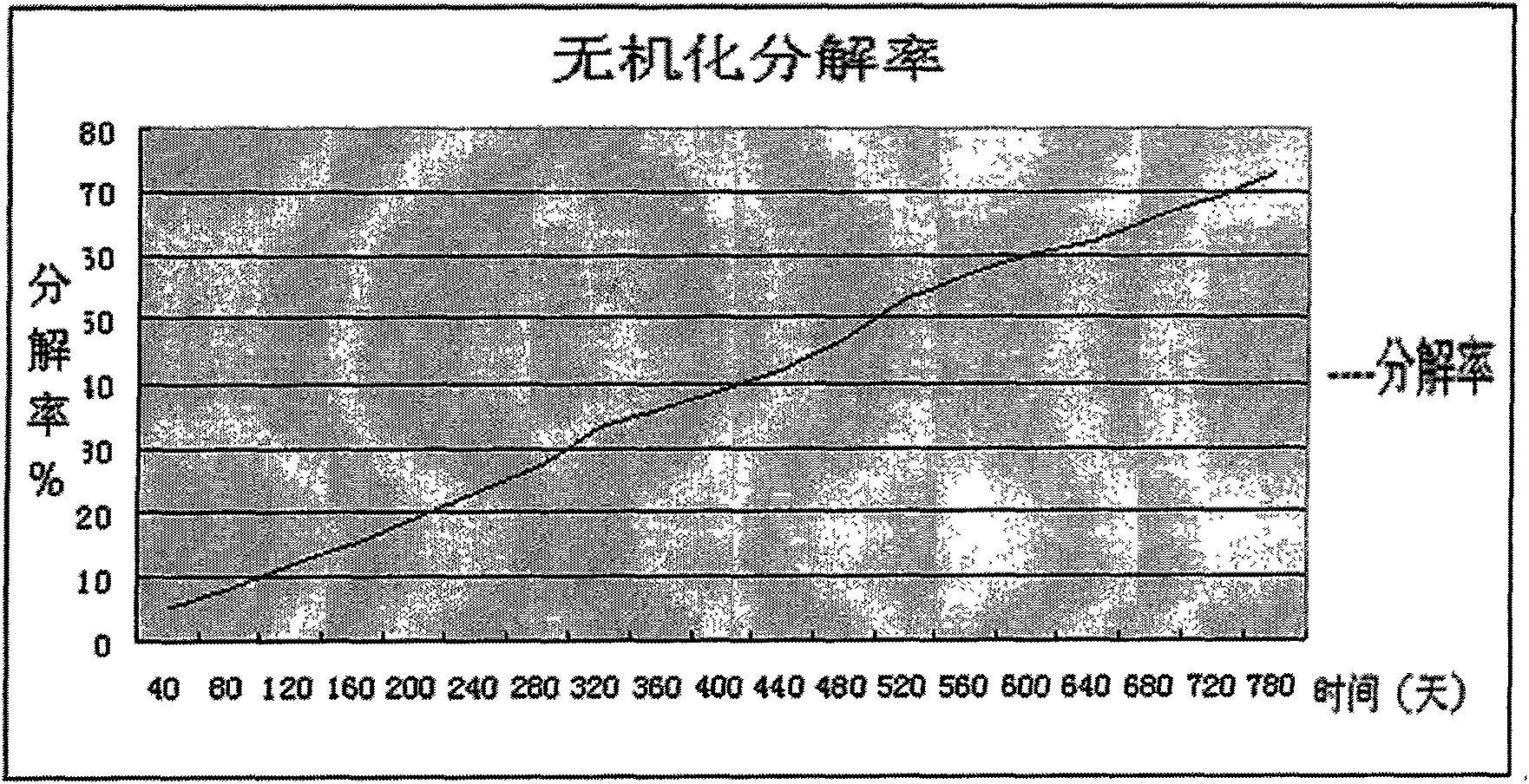

Biodegradable gasified antirust pearl cotton and manufacturing method thereof

InactiveCN101648627APromote degradationImprove physical performanceFlexible coversWrappersLow-density polyethyleneParaffin wax

The invention discloses a biodegradable gasified antirust pearl cotton and a manufacturing method thereof. The manufacturing method comprises the steps of preparing raw materials in parts by weight, mixing materials, preparing dispersants, mixing the materials for the second time, preparing additives, mixing the materials for the third time and blow forming. According to the method, the pearl cotton is obtained, and the pearl cotton comprises the following components in parts by weight: 5 to 15 parts of sodium benzoate, 2 to 6 parts of dextrine, 3 to 9 parts of benzotriazole, 3 to 9 parts of sodium molybdate, 3 to 8 parts of hydroxyethyl cellulose, 4 to 10 parts of zinc stearate, 4 to 10 parts of polyethylene wax, 2500 to 7500 parts of low-density polyethylene, 50 to 150 parts of oxygen-bearing biodegradable additives and 250 to 750 parts of metallocene paraffin polymer. The invention has advanced process, not only improves the biodegradability of the pearl cotton, but also strengthens the physical properties of the pearl cotton, and can maintain uniform antirust properties.

Owner:金福东

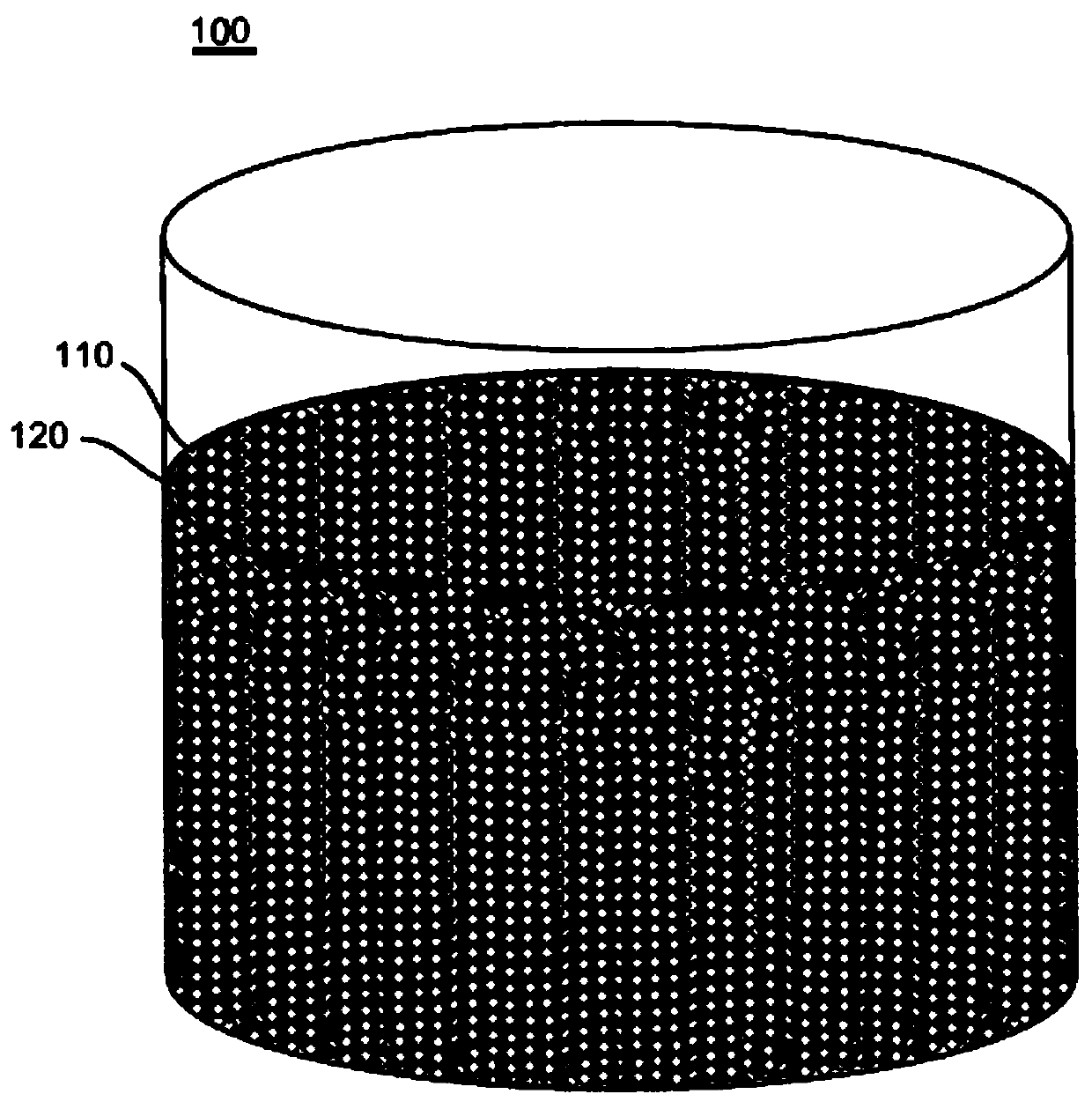

Earth plant compostable biodegradable substrate and method of producing the same

ActiveUS10882977B1Widely availableWidely cost-effectiveBio-packagingChemical recyclingPolymer sciencePolymer chemistry

An earth plant-based compostable biodegradable composition for the formation of a bioplastic and method of producing said resin, the composition comprising: about 17.5 to 45% ethanol-based green polyethylene by weight, about 20 to 25% calcium carbonate by weight, about 2 to 12% hemp hurd or soy protein by weight, about 32 to 45% thermoplastic starch by weight, and about 0.5 to 1% biodegradation additive by weight to enable biodegradation and composting of the bioplastic; wherein the composition is produced by first mill grinding the ethanol-based green polyethylene, calcium carbonate, hemp hurd or soy protein, thermoplastic starch and the biodegradation additive into fine powders, then mechanically mixing the fine powders one by one into a final mixture for about 5-25 minutes at a time, dry and without heat, and then heating the final mixture to about 220- to 360-degrees Fahrenheit.

Owner:SHOWALTER EDWARD

Biodegradable packaging material and preparation method thereof

The invention relates to the technical field of packaging materials, in particular to a biodegradable packaging material and a preparation method thereof. The biodegradable packaging material is prepared from starch, cellulose, chitin, protein, polyvinyl alcohol, a polymerizing agent, a plasticizer and a biodegradable additive; the material is prepared from the following components in parts by weight: 20-40 parts of starch, 15-25 parts of cellulose, 15-25 parts of chitin, 10-20 parts of protein, 2-6 parts of polyvinyl alcohol, 1-3 parts of a polymerizing agent, 2-4 parts of a plasticizer and 3-5 parts of a biodegradable additive. The material is good in hydrophobic capacity, oil resistance, water resistance and high temperature resistance, and has the excellent properties of proper strength, grease resistance, flexibility, transparency, odorlessness, odorlessness, easiness in degradation, and has the good film forming characteristic; The biodegradable packaging material is high in decomposition rate, can realize biodegradation, improves environmental protection, and has better biodegradation characteristics.

Owner:YUYAO SUN RAIN SPRAYER

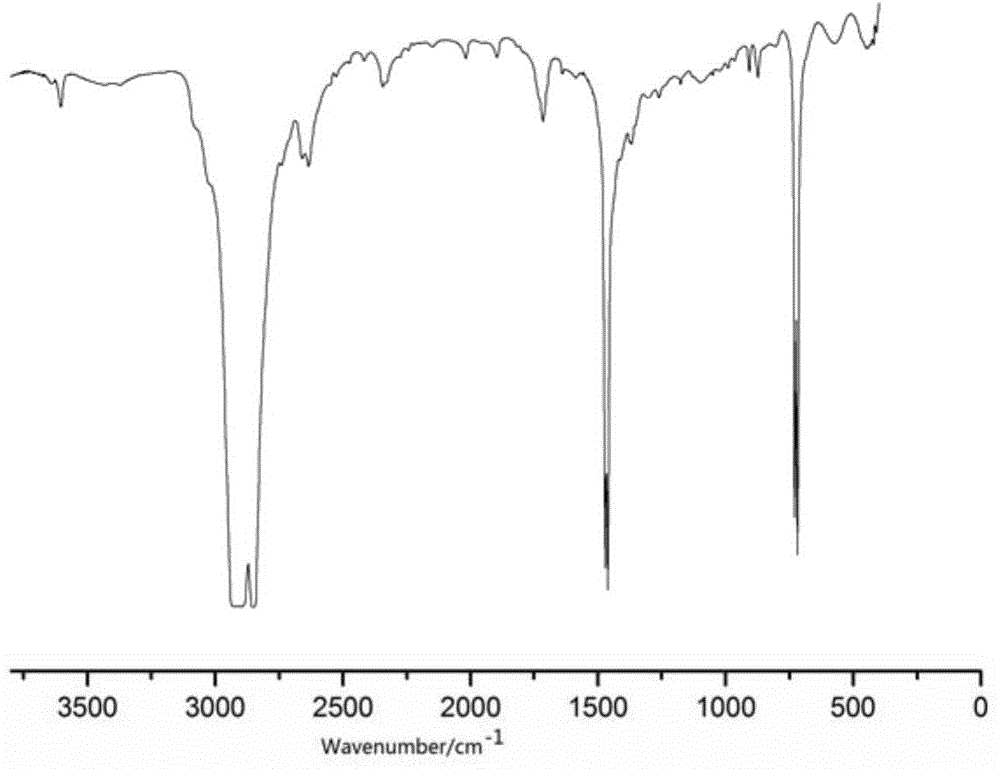

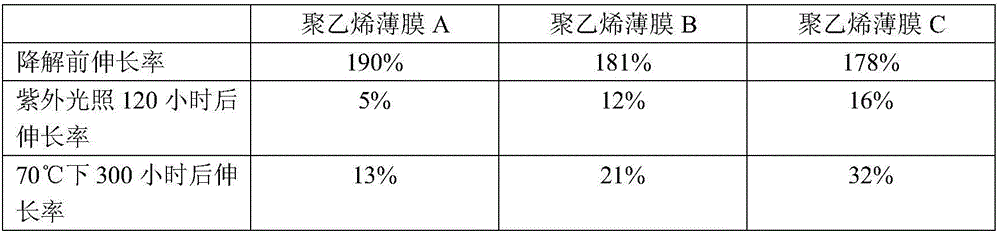

Polyolefin plastic light-biodegradable modified additive as well as preparation and application thereof

The invention provides a polyolefin plastic light-bio-degradable modified additive. The polyolefin plastic light-biodegradable modified additive is characterized by having the structural formula as shown in the description. The invention further discloses a preparation method and application of the polyolefin plastic light-bio-degradable modified additive. Because of the special design on the structure, the controllable light biodegradable polyolefin additive disclosed by the invention has high affinity with polyolefin substrates, so that the uniform dispersion of the controllable light biodegradable polyolefin additive in the polyolefin substrates is facilitated; the light-biodegradable modified additive is very high in light-bioactivity, and can also improve the light-bio-degradability of the polyolefin substrates and regulate and control the induction period of degradation. According to the controllable light-biodegradable additive disclosed by the invention, polyolefin plastics can be controlled to be degraded completely within 1.5 to 30 months by controlling the adding proportion of the controllable light-biodegradable additive in the polyolefin substrates, so that the controllable light-biodegradable additive has an extremely high application value.

Owner:SHANTOU UNIV +1

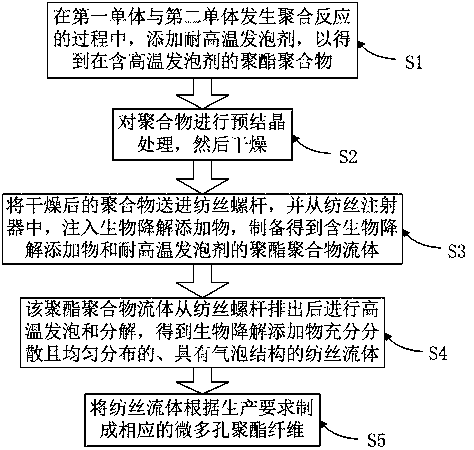

Production process of rapidly biodegradable micro-porous polyester fibers

InactiveCN111270339ALoose structureFully dispersedFilament forming substance formingArtificial thread manufacturing machinesPolyesterPolymer science

The invention discloses a production process of rapidly biodegradable micro-porous polyester fibers. A high-temperature foaming agent and a biodegradable additive are added, the biodegradable additivein the micro-porous polyester fibers is fully dispersed and uniformly distributed in high-temperature foaming and decomposition processes, and meanwhile, the micro-porous polyester fibers become a porous fiber material, so that the micro-porous polyester fibers become fibers with the fully dispersed and uniformly distributed biodegradable additive and the loose structure, the fibers are easy to biodegrade, the biodegradation speed is increased, and the degradation period is doubly shortened.

Owner:BOJU SHANGHAI ECOLOGICAL TECH CO LTD

Environment friendly gasified rust-proof weaved film and manufacturing method thereof

InactiveCN101643128APromote degradationImprove physical performanceFlexible coversWrappersLow-density polyethyleneSodium metasilicate

The invention discloses an environment friendly gasified rust-proof weaved film and a manufacturing method thereof, wherein the manufacturing method comprises the following steps: preparing raw materials according to proportion of parts by weight, mixing material, mixing material for the second time, manufacturing high enriched rust-proof master batch, unfolding plastic woven cloth, and melting down the high enriched rust-proof master batch and spraying on the plastic woven cloth. The rust-proof weaved film is obtained according to the method; and the proportion of parts by weight of each component is as follows: 3-9 parts of sodium benzoate, 0.1-0.3 parts of sodium metasilicate, 4-13 parts of sodium molybdate, 3-9 parts of benzotriazole, 1-5 parts of hydroxyethyl cellulose, 2500-7500 parts of low density polyethylene, 1500-4500 parts of polyethylene, and 500-1500 parts of oxygen-contained biodegradation additive. The invention has advanced technology, and can be applied to the fieldsof transportation, storing and packaging of ferrous and nonferrous metal products. The invention has very outstanding degradation effect and rust-proof effect, and is environment friendly.

Owner:金福东

Environment-friendly degradable bubble packaging bag and manufacturing process thereof

ActiveCN109291512APlay an isolation rolePlay a buffer roleBag making operationsPaper-makingAntistatic agentPlasticizer

The invention provides an environment-friendly degradable bubble packaging bag and a manufacturing process thereof. The technical problems that an existing packaging bag is too complex in structure, capable of meeting simple use requirements, poor in using effect and the like are solved. The environment-friendly degradable bubble packaging bag comprises an inner bag body, a middle bag body and anouter bag body, wherein the inner layer bag body is a shower film layer, the middle layer bag body is a bubble film layer, the outer bag body is a mask layer, and the outer layer bag body comprises, by weight, 80-90% of polyethylene, 1-5% of flame retardants, 2.5-6.5% of plasticizers and 5-10% of biodegradable additives; the middle layer bag body comprises, by weight, 82-92% of plasticizers, 3-9%of plasticizers and 5-10% of biodegradable additives; and the inner layer bag comprises, by weight, 75-85% of polyethylene, 3-9% of antistatic agents, 5-8% of plasticizers, 5-8% of biodegradable additives, and 5-10% of degradant additives. The environment-friendly degradable bubble packaging bag has the advantage of being good in using effect.

Owner:DONGGUAN SENGTOR PLASTIC PROD CO LTD

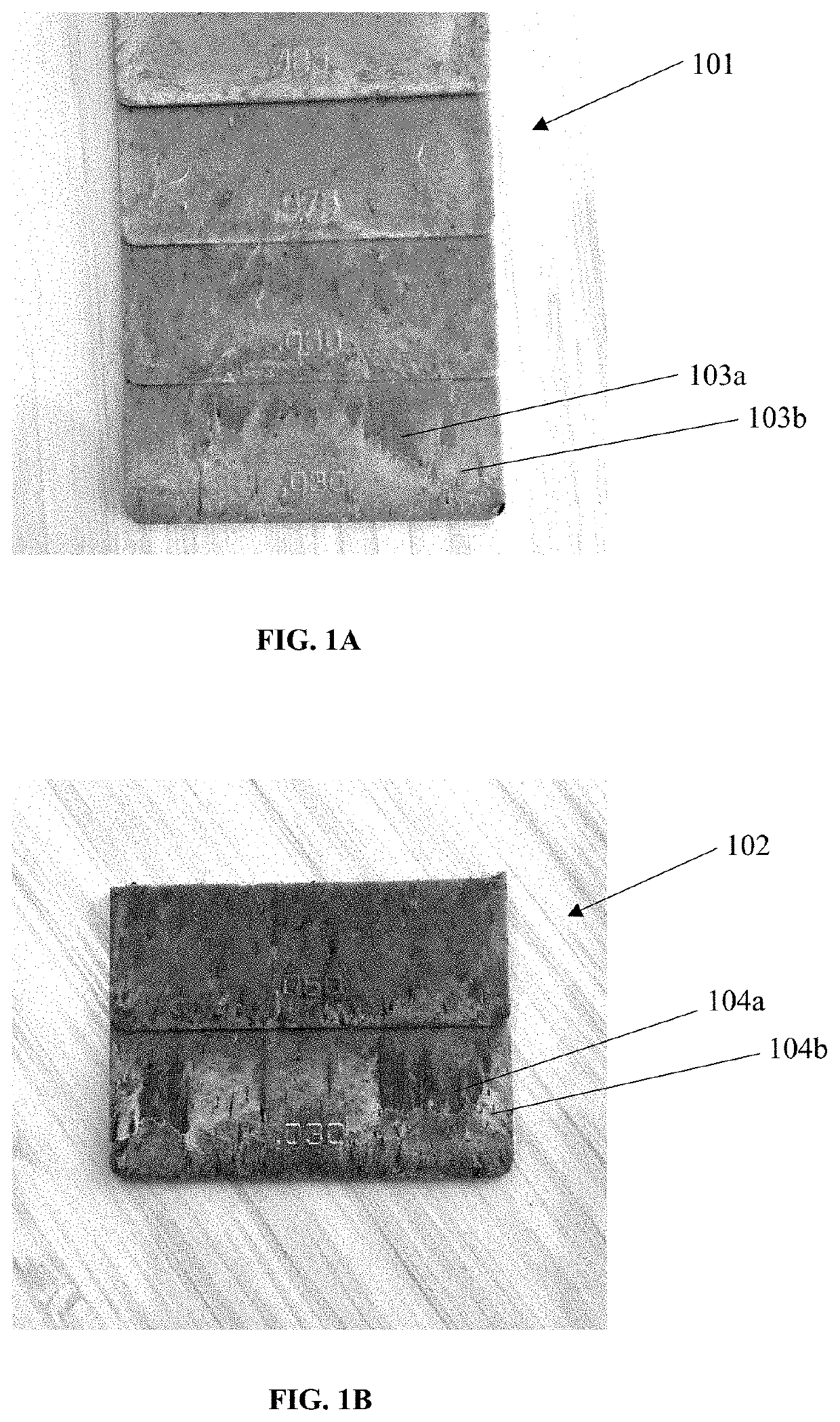

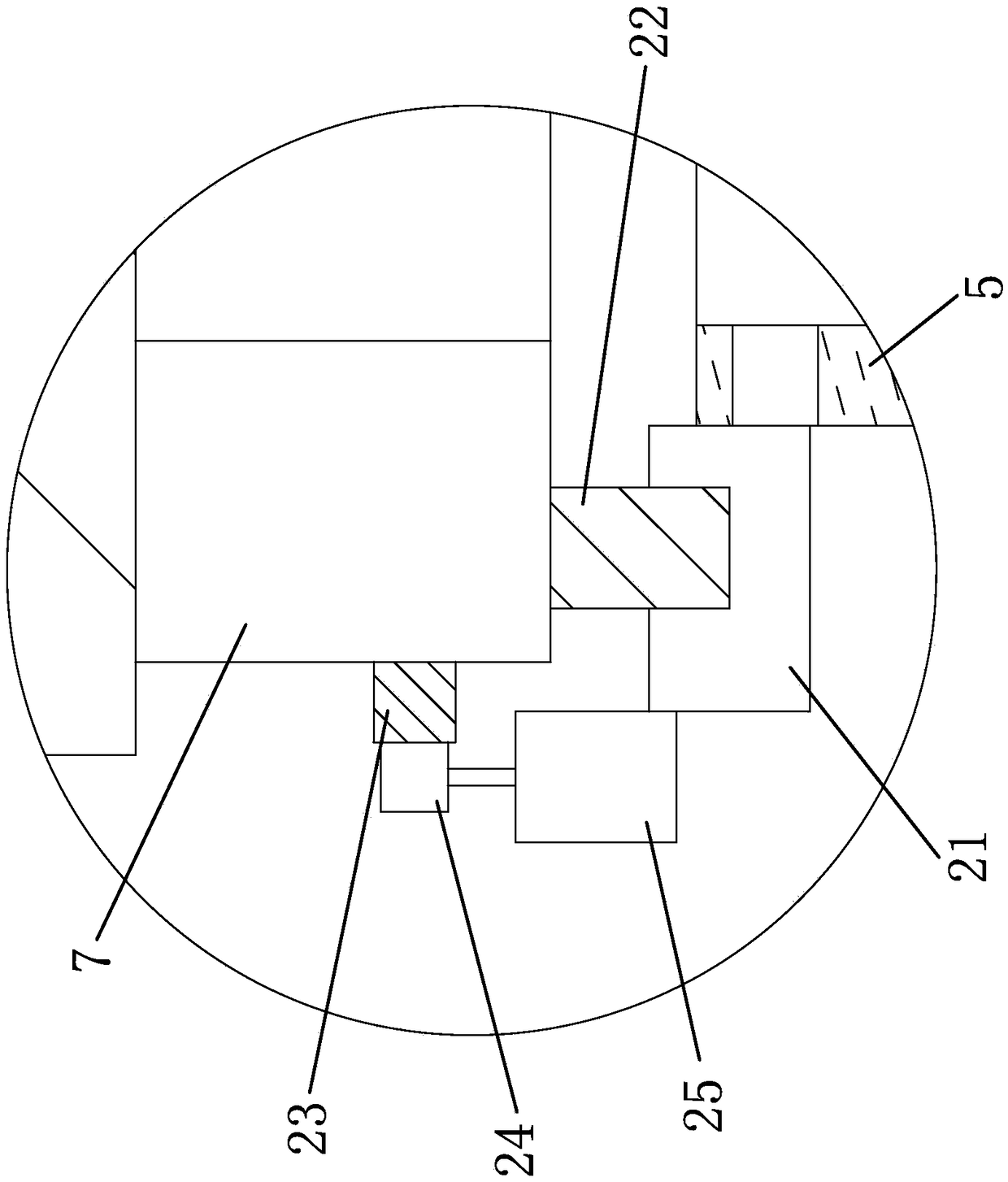

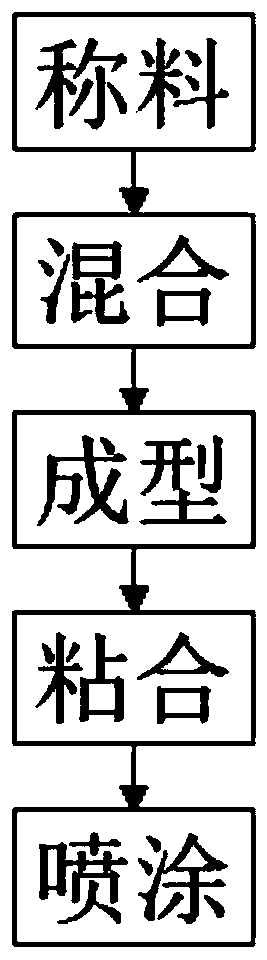

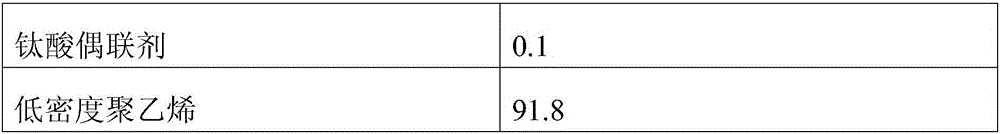

Biodegradable additive and plastic products with addition of additive

The invention relates to a biodegradable additive prepared from a copper powder, an iron powder, a silane coupling agent, a titanate coupling agent and low density polyethylene as raw materials, wherein the biodegradable additive comprises the following components: 8 to 12 mass% of the copper powder, 8 to 12 mass% of the iron powder, 0.5 to 1.5 mass% of the silane coupling agent, 0.5 to 1.0 mass% of the titanate coupling agent, and the balance low density polyethylene. The invention also relates to a preparation method of the biodegradable additive and plastic products with addition of the biodegradable additive, especially polyethylene plastic thin film products, wherein the plastic products have good biodegradability and do not produce white pollution.

Owner:SUZHOU TIANJIAN METAL NEW MATERIAL

Earth plant compostable biodegradable substrate and method of producing the same

ActiveUS11149131B2Widely availableWidely cost-effectiveBio-packagingChemical recyclingMaterials sciencePoly ethylene

An earth plant-based compostable biodegradable composition for the formation of a bioplastic and method of producing said resin, the composition comprising: about 17.5 to 45% ethanol-based green polyethylene by weight, about 20 to 25% calcium carbonate by weight, about 2 to 12% hemp hurd or soy protein by weight, about 32 to 45% starch by weight, and about 0.5 to 1% biodegradation additive by weight to enable biodegradation and composting of the bioplastic; wherein the composition is produced by first mill grinding the ethanol-based green polyethylene, calcium carbonate, hemp hurd or soy protein, starch and the biodegradation additive into fine powders, then mechanically mixing the fine powders one by one into a final mixture for about 5-25 minutes at a time, dry and without heat, and then heating the final mixture to about 220 to 430 degrees Fahrenheit.

Owner:SHOWALTER EDWARD

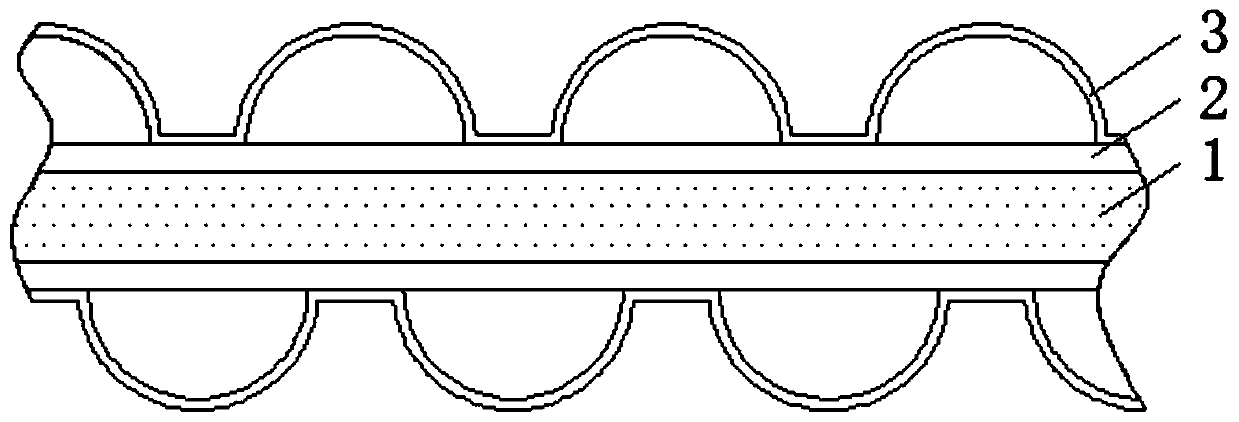

Degradable high-strength composite air bubble film and processing method thereof

InactiveCN109294027AEasy to observeEasy to assistSynthetic resin layered productsTectorial membranePlasticizer

The invention provides a degradable high-strength composite air bubble film and a processing method thereof, and solves technical problems that the existing composite air bubble film is too simple instructure, unable to be quickly degraded after being discarded, etc. The degradable high-strength composite air bubble film consists of outer layers and an inner layer. The outer layers are protectivefilms and the inner layer is an air bubble film. The air bubble film consists of the following raw materials in parts by weight: 42-54 parts of polyethylene, 1.3-1.8 parts of flame retardants, 0.6-1.1 parts of antimicrobial agents, 0.5-1.2 parts of plasticizers and 2.2-4.6 parts of biodegradable additives. The invention has an advantage of convenient degradation.

Owner:TONGXIANG KAIRUI PACKAGING MATERIAL

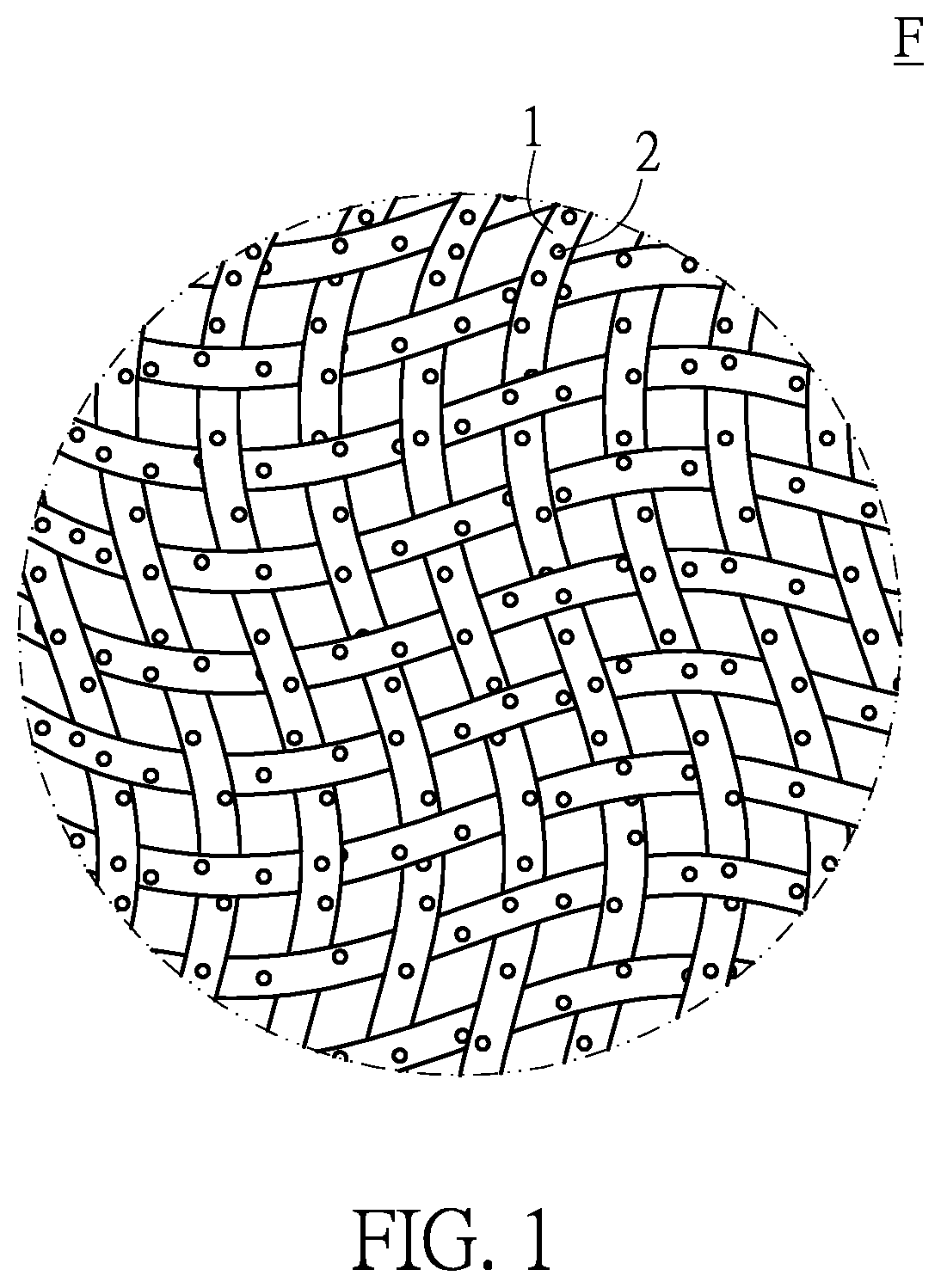

Degradable air bubble film and preparation process thereof

InactiveCN111421908AImprove anti-reflection effectImprove durabilityFlexible coversWrappersPolymer scienceFouling layer

The invention discloses a degradable air bubble film and a preparation process thereof. The invention relates to the technical field of packaging materials, in particular to the air bubble film, whichcomprises a base layer; the upper surface and the lower surface of the base layer are both fixedly connected with bubble film layers, the outer surfaces of the bubble film layers are provided with waterproof anti-fouling layers, and the base layer is a grid surface formed by weaving bamboo charcoal fibers, and the weight part is 60-70 parts. The invention discloses a degradable air bubble film and a preparation process thereof. The base layer and the two bubble film layers are bonded together; therefore, the film has excellent use strength; the outer surface of the air bubble film layer is coated with a waterproof anti-fouling layer; therefore, the characteristics of hydrophobicity and pollution resistance can be provided, and damage of water stains and dust to wrapped articles is reduced; and meanwhile, the biodegradable additive is added into the mixed components, so that the degradable air bubble film can be quickly degraded after being discarded, and the degradable air bubble filmis simple in manufacturing process and has market competitiveness, and better benefits can be brought.

Owner:武汉巨品佳包装材料有限公司

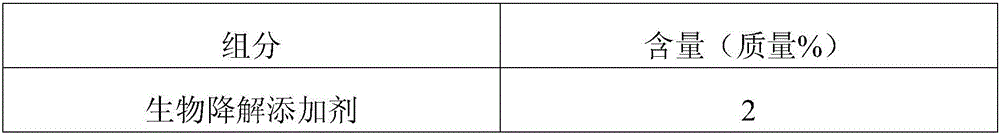

Production method of biodegradable medical plastics

InactiveCN102746689AWith degradable functionTo achieve the purpose of environmental protectionEngineeringBiodegradable additives

The invention discloses a production method of environment-friendly biodegradable medical plastics. The method includes the following steps of: putting ordinary plastic particles and a biodegradable additive into a blender according to a mass ratio of 100:1-100:2, stirring, blending them fully for 25-35 minutes, then putting the blended plastic particles into an oven for baking at a temperature of 100-400DEG C for 1-4h.The method disclosed in the invention has the advantage that it can produce medical plastics with a degradable function. After a landfill treatment of a medical plastic product in the soil for a period of time, the whole product can be completely degraded and be fully absorbed by the soil, thus reaching the purpose of environmental protection.

Owner:YANCHENG JINWO MEDICAL TECH

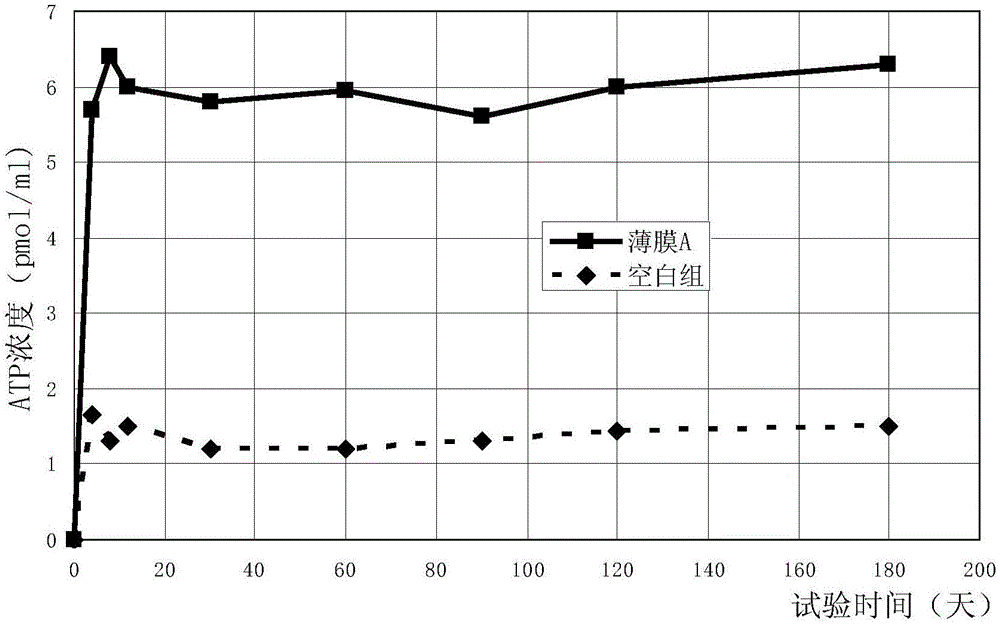

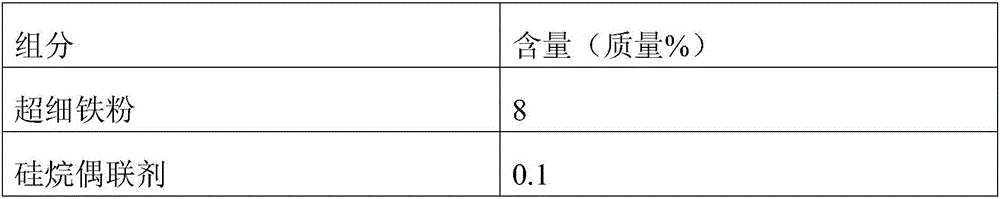

Biodegradable additive, and plastic product used for food packaging and prepared by using additive

The invention relates to a biodegradable additive. The biodegradable additive consists of the following components in percentage by mass: 5 to 10 percent of ultrafine iron powder, 0.01 to 0.20 percent of a silane coupling agent, 0.02 to 0.40 percent of a titanate coupling agent and the balance of low-density polyethylene. The invention further relates to a preparation method of the biodegradable additive, and a food packaging material containing 1 to 3 percent by mass of the biodegradable additive, such as a polyethylene film. The experimental results prove that the biodegradable plastic products provided by the invention accord with national regulation and can be applied to food packaging.

Owner:SUZHOU TIANJIAN METAL NEW MATERIAL

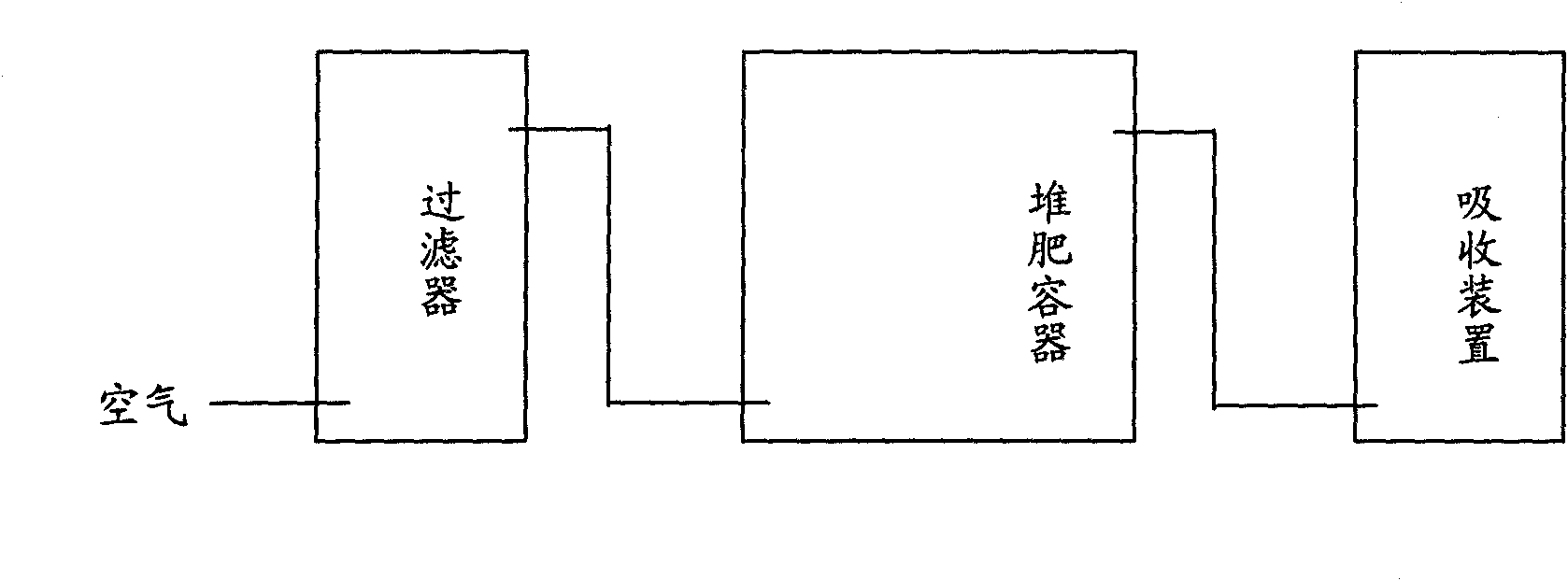

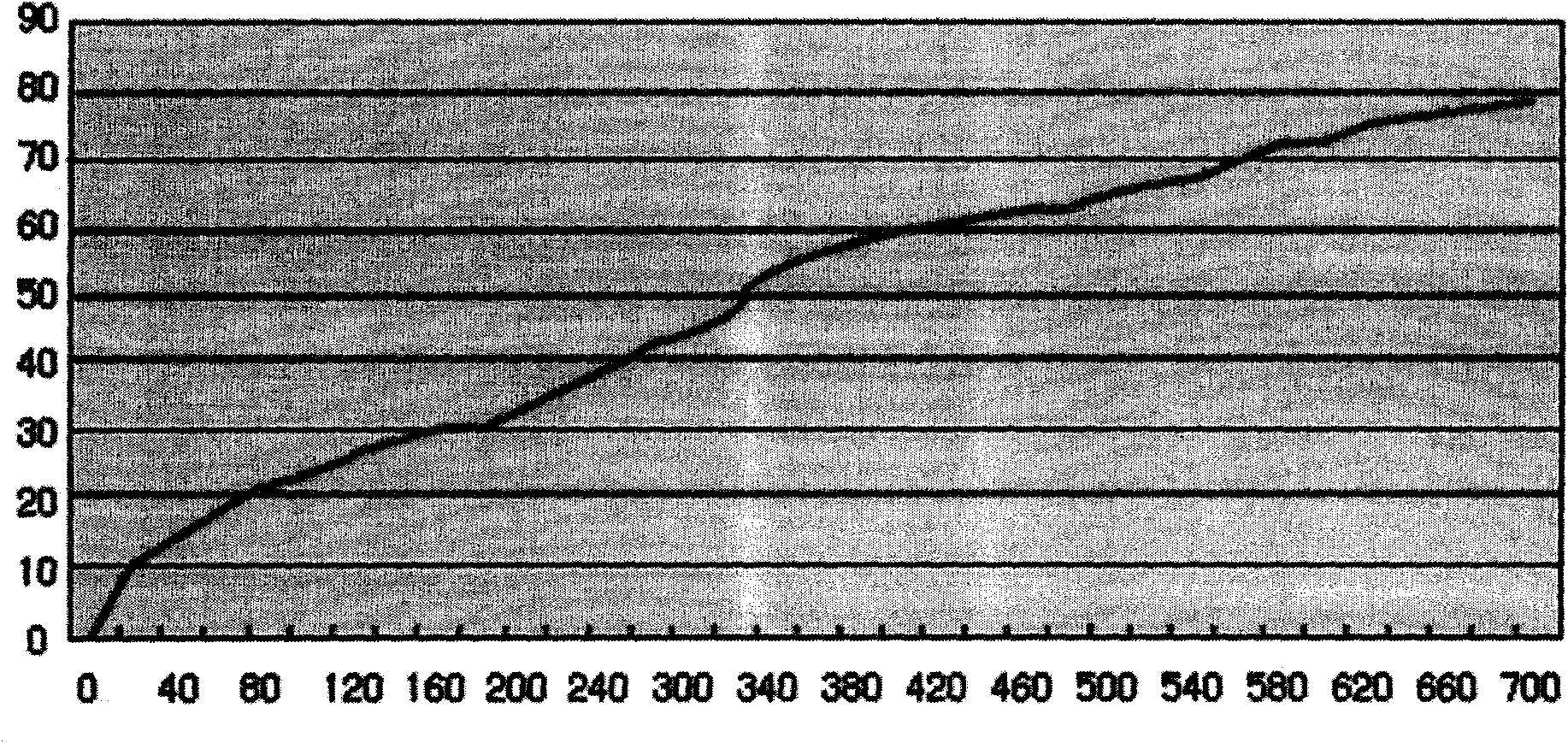

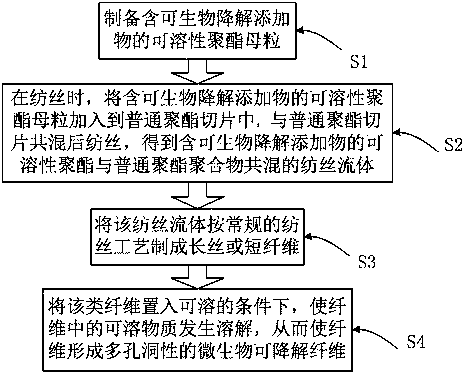

Production process of fast biodegradable porous polyester fiber

InactiveCN111235682APromote degradationMonocomponent polyesters artificial filamentSynthetic polymer filament chemical after-treatmentPolyesterPolymer science

The invention discloses a production process of fast biodegradable porous polyester fiber. By proportionally adding soluble slices containing biodegradable additives to polyester and blending with thepolyester, then soluble substances in the fiber are placed in a dissolved solution to dissolve the soluble substances, the fiber is enabled to form porous fiber or textiles, and cavities in the fiberstructure accelerate the degradation of a polyester material by biomass to prepare the fast biodegradable porous polyester fiber.

Owner:BOJU SHANGHAI ECOLOGICAL TECH CO LTD

Degradable bubble protective film and processing method thereof

InactiveCN109384987APromote degradationPromote environmental protectionLow-density polyethyleneTectorial membrane

The invention provides a degradable bubble protective film and a processing method thereof. The degradable bubble protective film of the invention solves the technical problems that conventional bubble protective films cannot be degraded, easily cause white pollution, has poor environmental protection performance and the like. The degradable bubble protective film of the invention is composed of the following components by weight: 60-80 parts of low-density polyethylene, 3-5 parts of an antioxidant, 1.5-2.5 parts of a plasticizer and 2.4-4.6 parts of a biodegradable additive. The degradable bubble protective film of the invention has the advantages of good environmental protection performance.

Owner:TONGXIANG KAIRUI PACKAGING MATERIAL

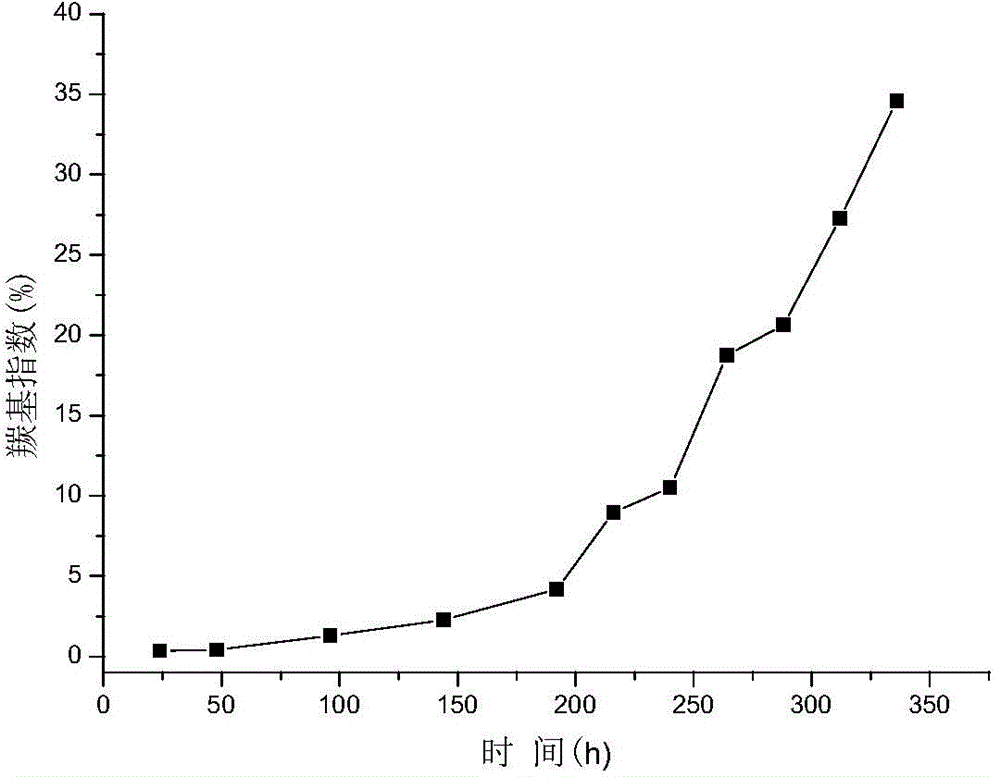

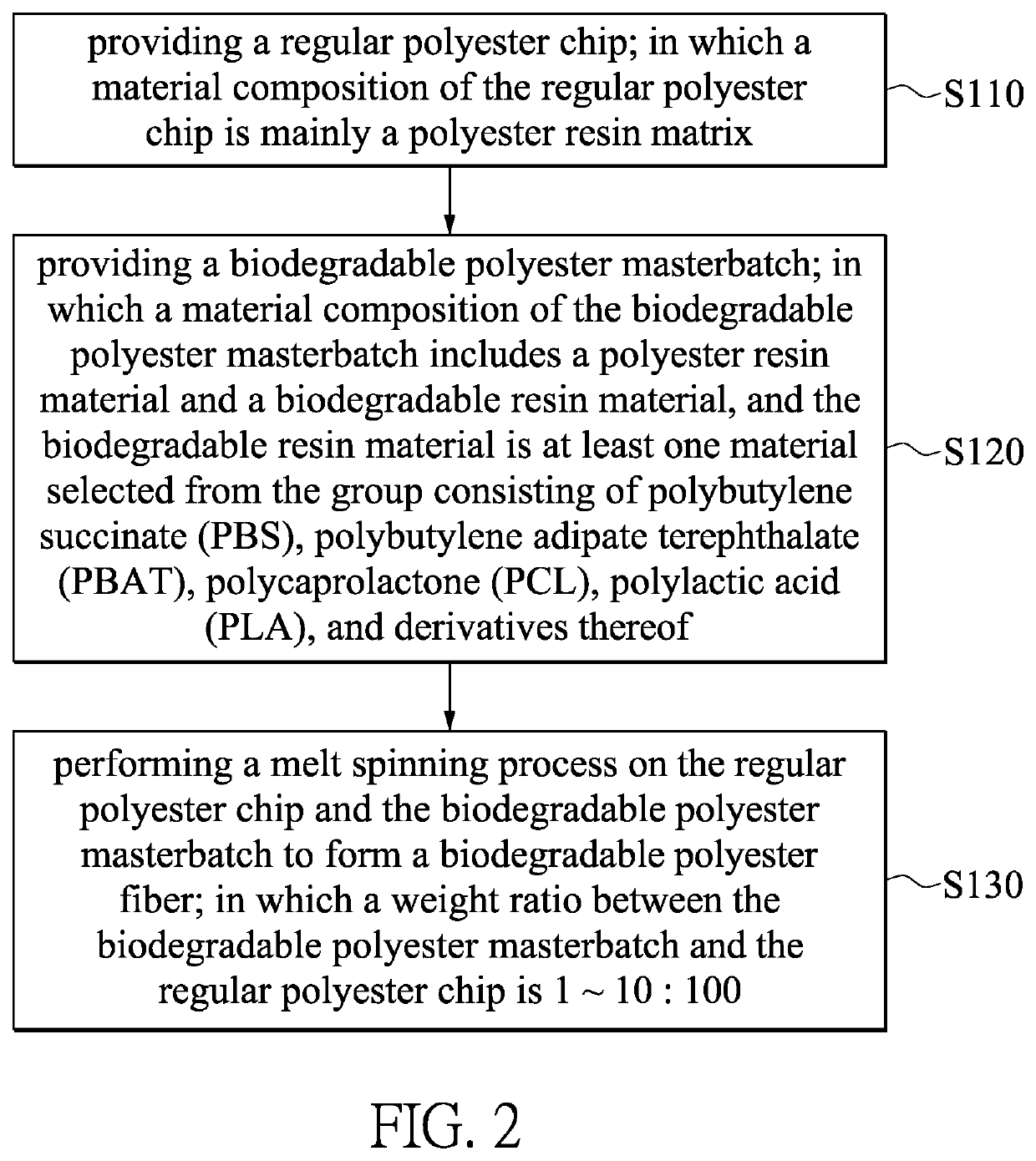

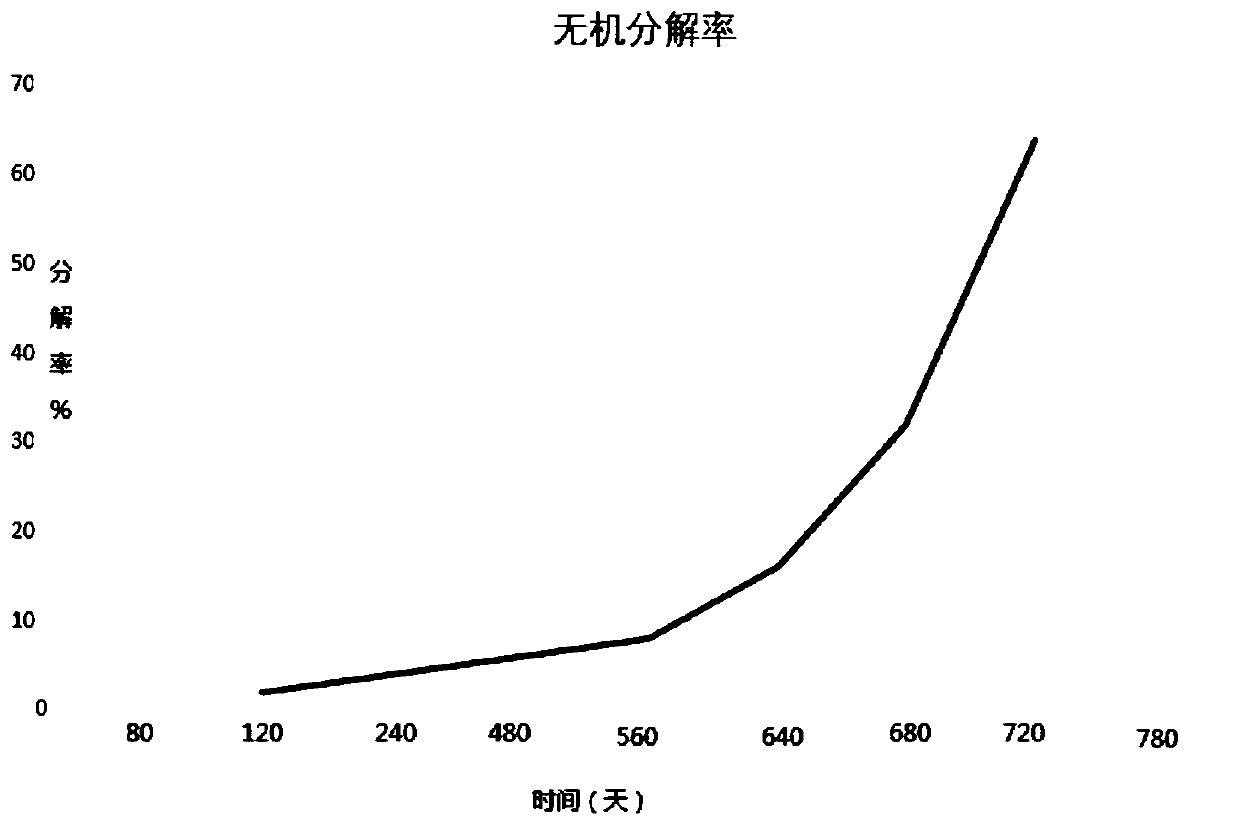

Biodegradable additive, biodegradable polyester fiber and method for producing the same, and biodegradable fabric

PendingUS20220267936A1High commercial application valueEnvironmental hazardMelt spinning methodsWoven fabricsFiberPolymer science

A biodegradable additive, a biodegradable polyester fiber and a method for producing the same, and a biodegradable fabric are provided. The biodegradable additive includes a polyester resin material and a biodegradable resin material. The biodegradable resin material is at least one material selected from the group consisting of polybutylene succinate (PBS), polybutylene adipate terephthalate (PBAT), polycaprolactone (PCL), polylactic acid (PLA), and derivatives thereof. In the biodegradable additive, a content range of the polyester resin material is between 40 wt % and 80 wt %, and a content range of the biodegradable resin material is between 20 wt % and 60 wt %.

Owner:NANYA PLASTICS CORP

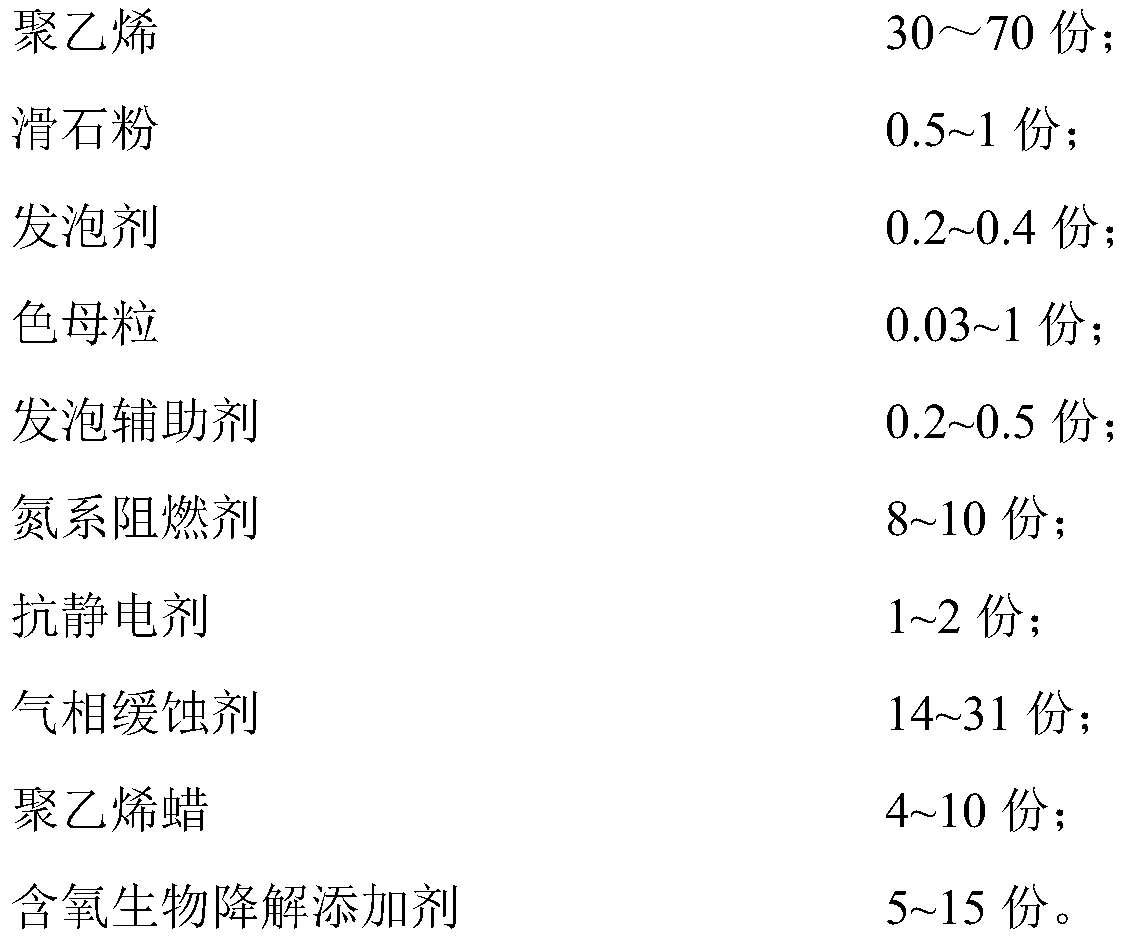

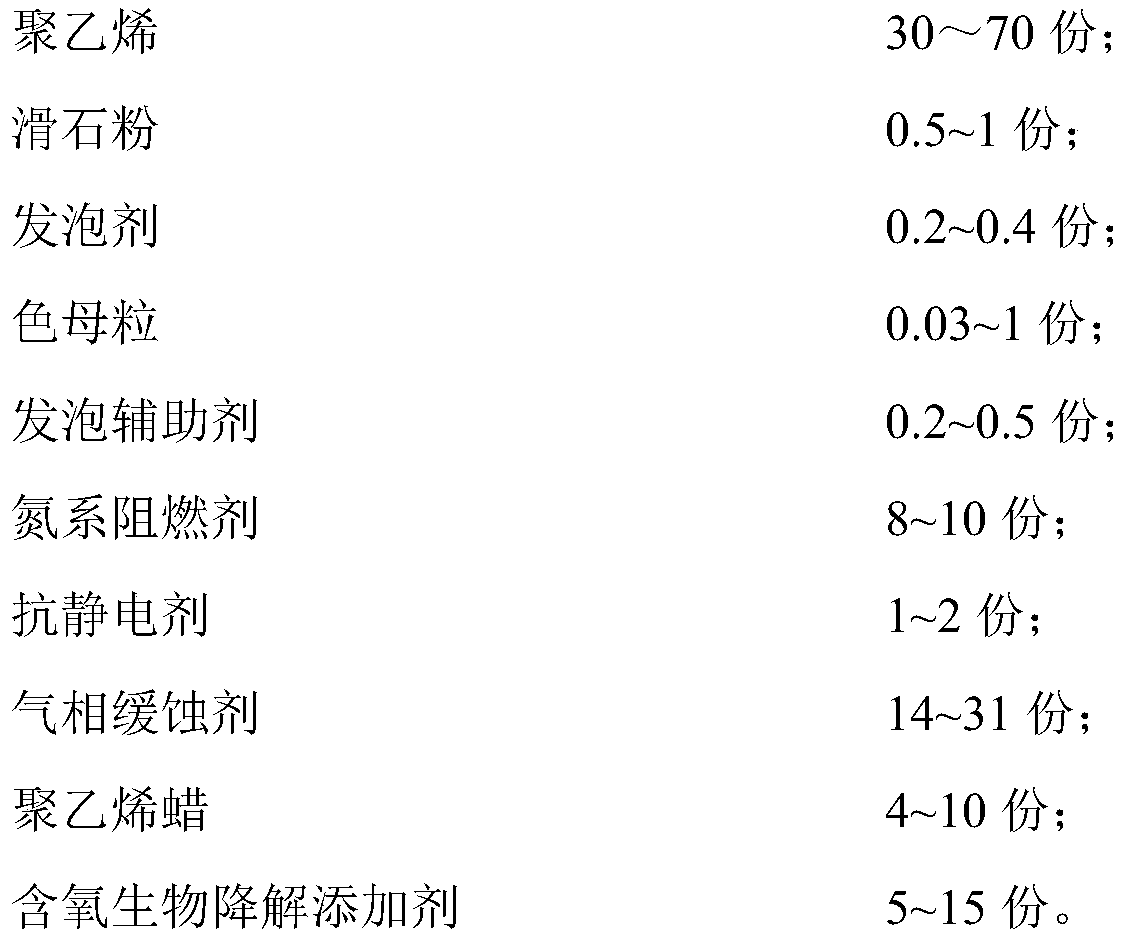

Pearl wool as well as preparation method and application thereof

InactiveCN111205537APromote degradationImprove flame retardant performanceFlexible coversWrappersPolymer scienceFoaming agent

The invention relates to the technical field of high polymer materials, in particular to a pearl wool as well as a preparation method and application thereof. The pearl wool is prepared from the following raw materials in parts by weight: 30-70 parts of polyethylene; 0.5 to 1 part of talcum powder; 0.2 to 0.4 part of a foaming agent; 0.03 to 1 part of a color master batch; 0.2 to 0.5 part of a foaming auxiliary agent; 8-10 parts of a nitrogen-based flame retardant; 1-2 parts of an antistatic agent; 14-31 parts of a gas phase corrosion inhibitor; 4-10 parts of polyethylene wax; and 5-15 parts of an oxygen-containing biodegradable additive. The pearl wool product disclosed by the invention not only has good biodegradability, but also strengthend flame retardance and antistatic property, cankeep uniform antirust property, and can be widely applied to the field of metal antirust packaging.

Owner:布兰诺工业包装材料(上海)有限公司

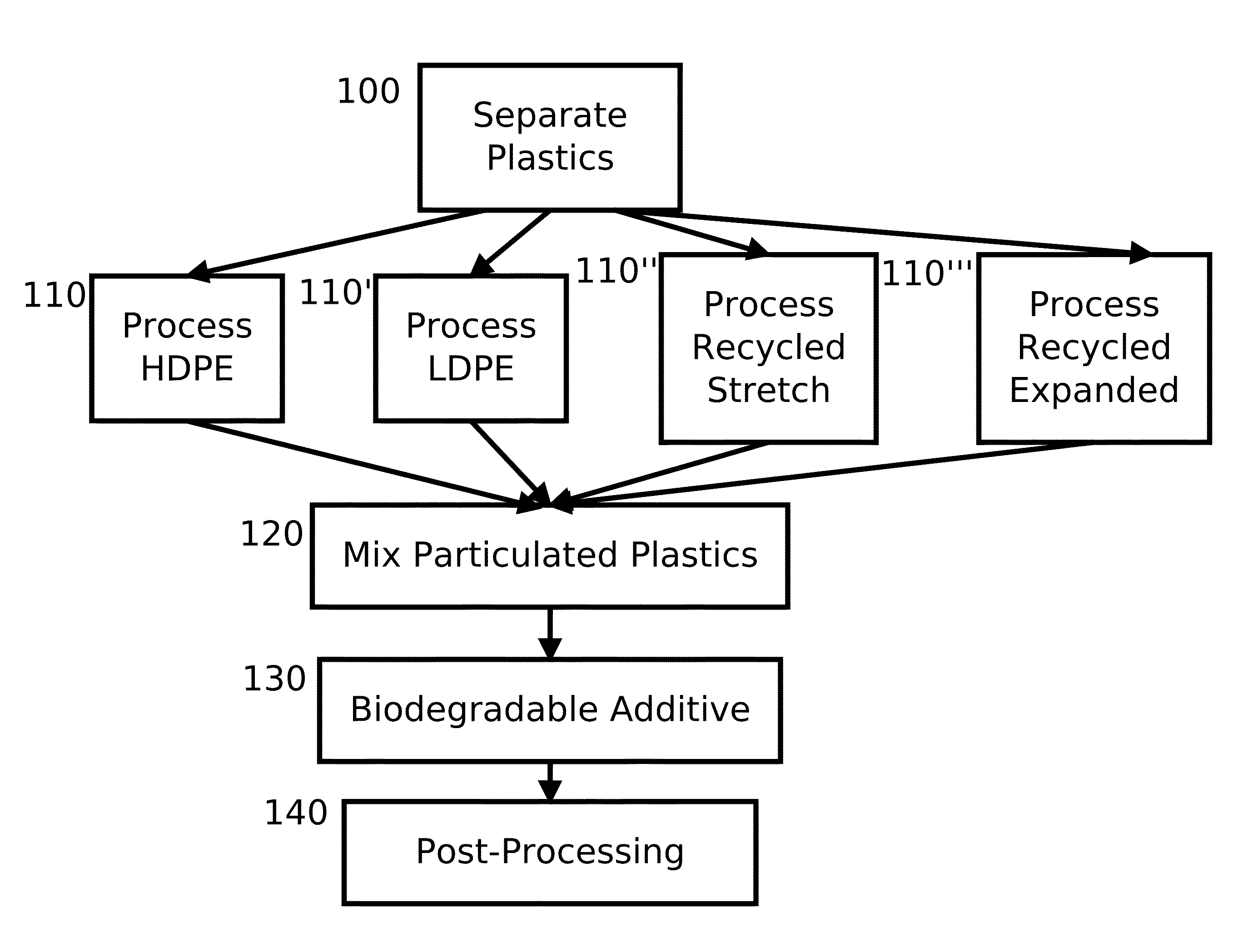

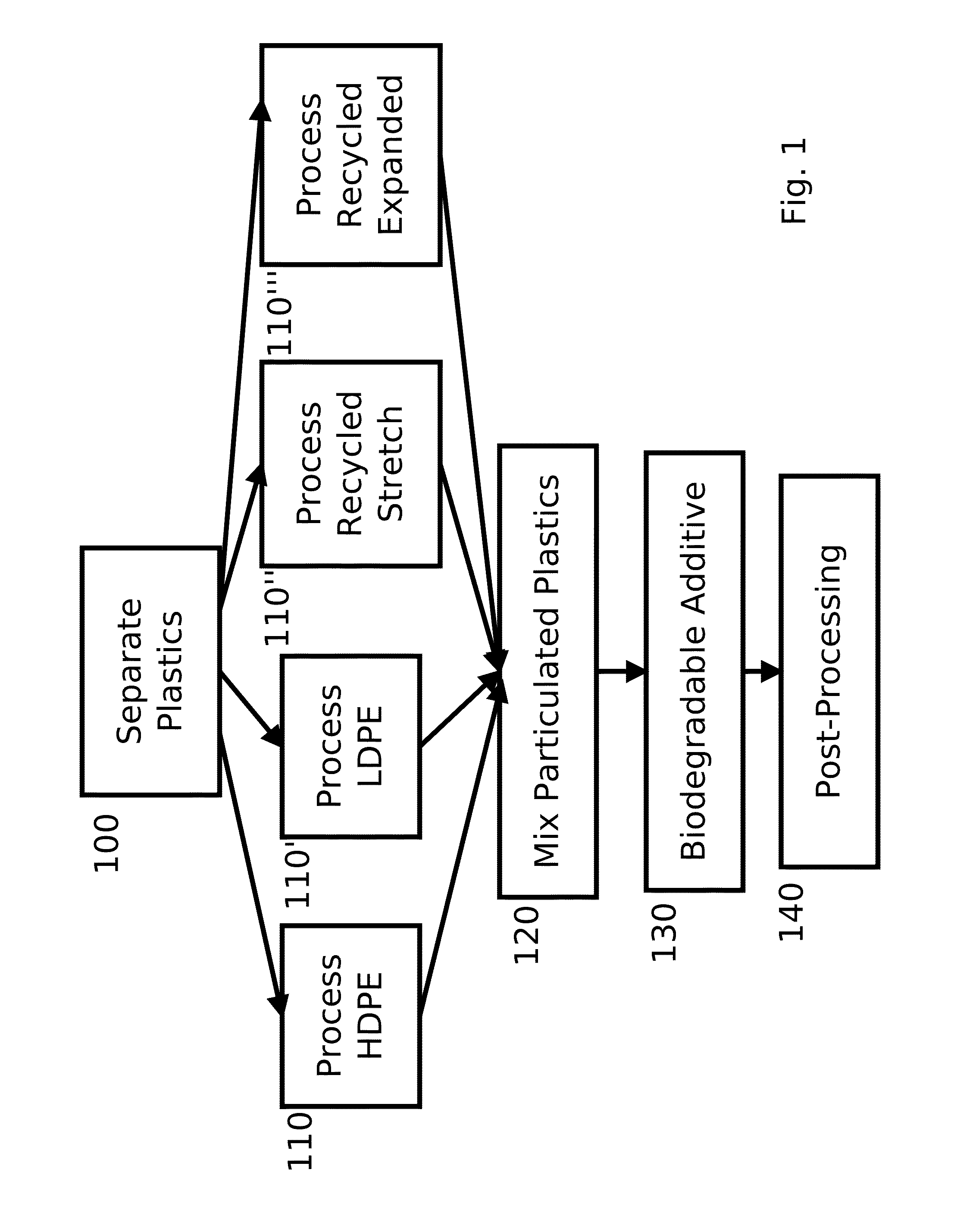

Biodegradable plastic and manufacture thereof from recyclable plastic

InactiveUS20160108217A1Maintain temperaturePlastic recyclingCeramic shaping apparatusLow-density polyethyleneParticulates

The present invention is directed to a process for manufacturing biodegradable plastic from high percentage recyclable plastic feedstock and the product thereof. The process comprises receiving recyclable plastic feedstock including high density polyethylene, low density polyethylene, expanded polyethylene, and stretched wrap, separating the plastic feedstock by plastics of like type, grinding the separated plastics into particulate while maintaining the temperature below said separated plastic's decomposition and melting point. The plastics are mixed in proportion, adding a biodegradable additive to the particulated plastic mixture with further mixing to produce the biodegradable plastic. Optionally, the resulting plastic is extruded for later use.

Owner:JEFFERSON DRUMMOND

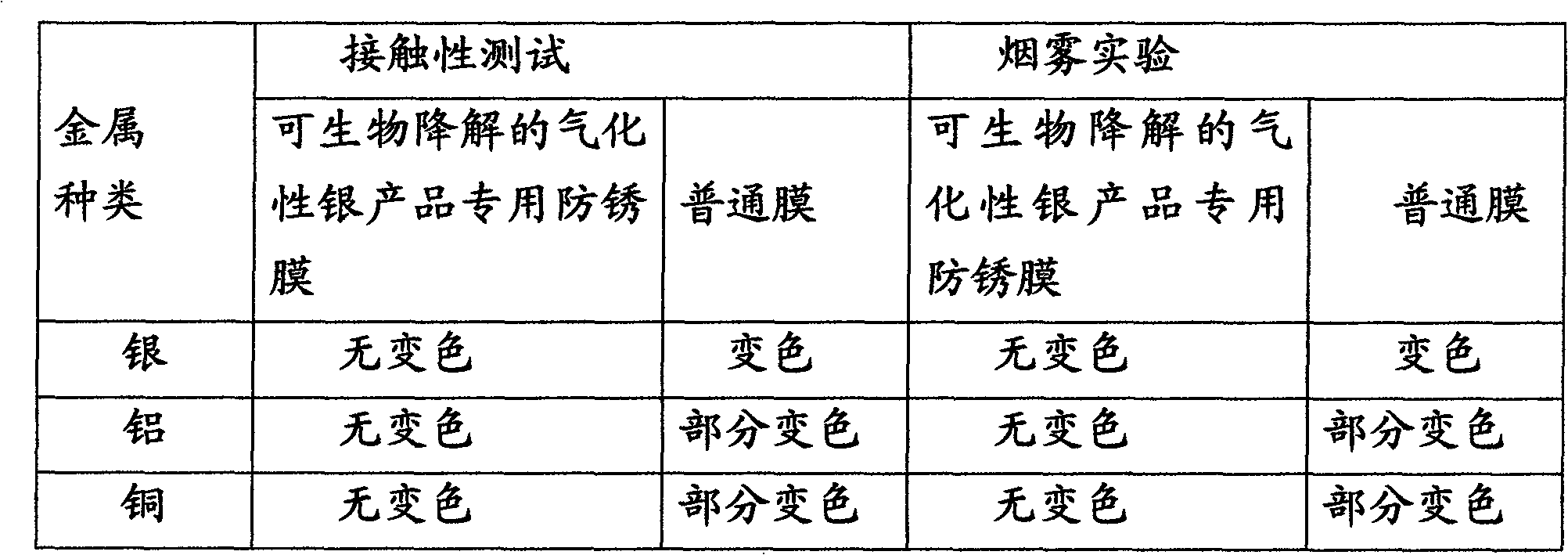

Gasified antirust film for silver products and manufacturing method thereof

InactiveCN101648628APromote degradationImprove physical performanceFlexible coversWrappersLow-density polyethyleneParaffin wax

The invention discloses a gasified antirust film for silver products and a manufacturing method thereof. The gasified antirust film comprises the following raw materials in parts by weight: 3 to 9 parts of sodium formate, 1 to 3 parts of dextrine, 4 to 8 parts of benzotriazole, 4 to 12 parts of methylbenzotriazole, 2 to 6 parts of sodium molybdate, 1 to 3 parts of zinc oxide and 2500 to 7500 partsof low-density polyethylene; a dispersant comprises the following components in parts by weight: 3 to 7 parts of hydroxyethyl cellulose, 5 to 9 parts of zinc stearate and 5 to 9 parts of polyethylene wax; and a additive comprises the following components in parts by : 80 to 120 parts of oxygen-bearing biodegradable additives and 350 to 650 parts of metallocene paraffin polymer. The manufacturingmethod comprises the steps of preparing raw materials, crashing the raw materials, adding secondary raw materials, adding the additive and blow forming. The manufacturing method is simple, quick andefficient. The invention has advanced process, not only improves the biodegradability of the product, but also strengthens the physical properties, maintains the uniform antirust properties as well asdiscoloration preventing performance and solves the environmental problem caused by the destruction of traditional packaging films.

Owner:金福东

Compositions and methods for use in plastics manufacturing

PendingUS20210324173A1Easy to combineSmall particle sizeLuminescent compositionsCottonseed oilPhotopigment

Compositions and methods for making biodegradable plastic products are provided. The compositions include a destabilizing agent that makes the finished plastic biodegradable. The compositions also can include an oil-based carrier, such as cottonseed oil, that allows the biodegrading agent to be metered into a continuous plastic manufacturing process. The compositions further can include an additive that allows the biodegrading additive to combine with the carrier; an optical brightener to improve the appearance of the finished plastic product, and to indicate the presence of the composition in the finished product; and a pigment, so that the composition can act as a liquid coloring agent.

Owner:IRISH CHARLES B +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com