Degradable high-strength composite air bubble film and processing method thereof

A processing method and technology of air bubble film, applied in the direction of chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problems that the composite air bubble film structure is too simple and cannot be degraded quickly, and achieve simple and convenient processing Observation, the effect of good use strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

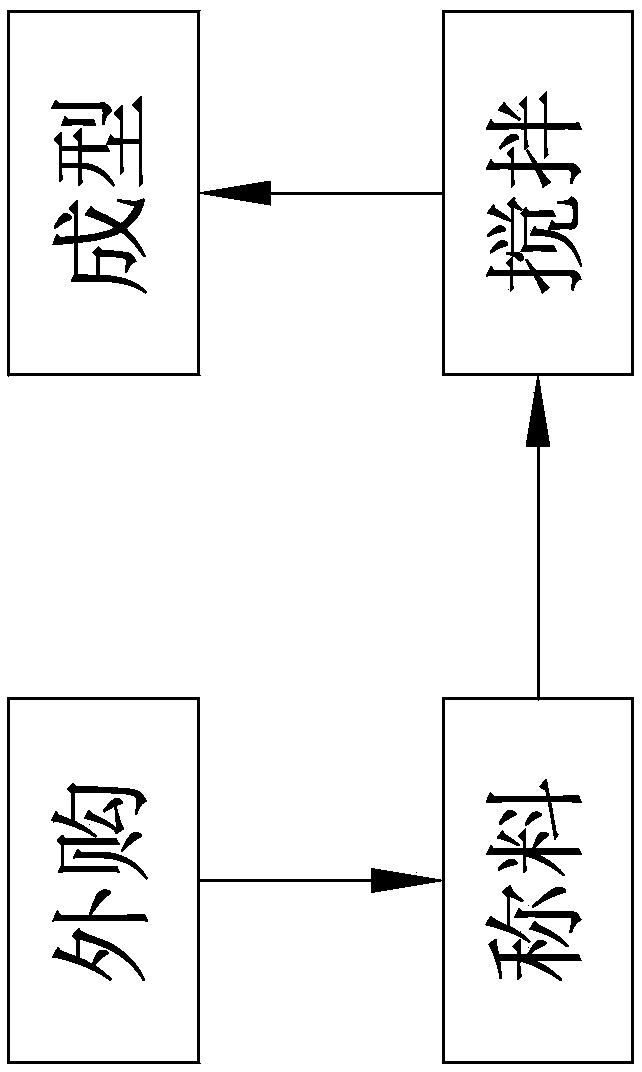

[0074] The processing method of the degradable high-strength composite bubble film comprises the following steps:

[0075] a. Outsourcing: purchase the existing protective film on the market, and conduct an appearance inspection on it; the thickness of the protective film is 0.3mm;

[0076] B. Weighing: by weight, weigh 45 parts of polyethylene, 1.5 parts of flame retardant, 0.8 part of antibacterial agent, 0.7 part of plasticizer and 3.7 parts of biodegradable additive;

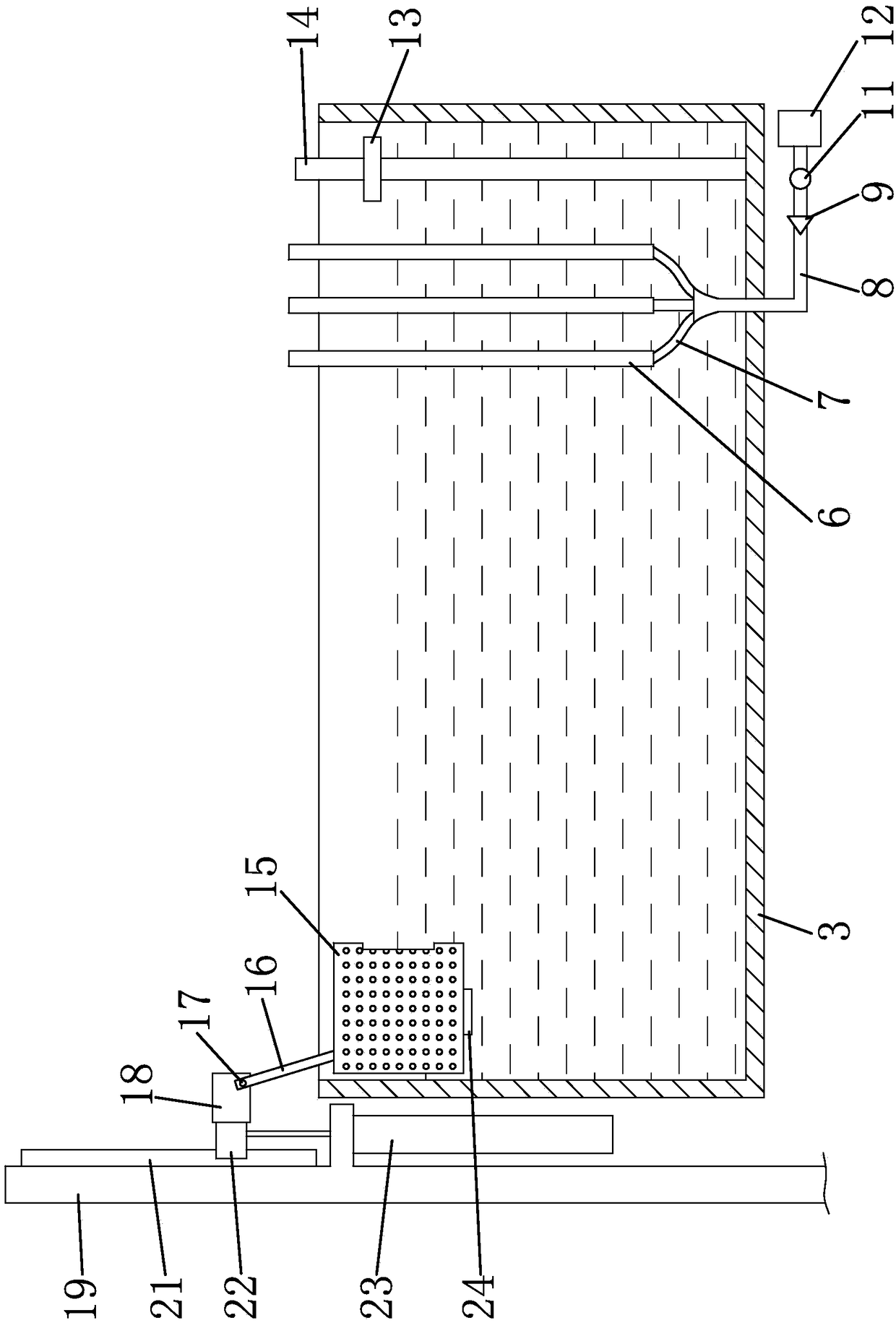

[0077] c. Stirring: Add polyethylene, flame retardant, antibacterial agent and plasticizer to the mixing equipment, and after stirring for 25 minutes, add biodegradable additives to the mixing equipment, and stir for 15 minutes to prepare the mixture; step c The stirring speed in is 180rmp;

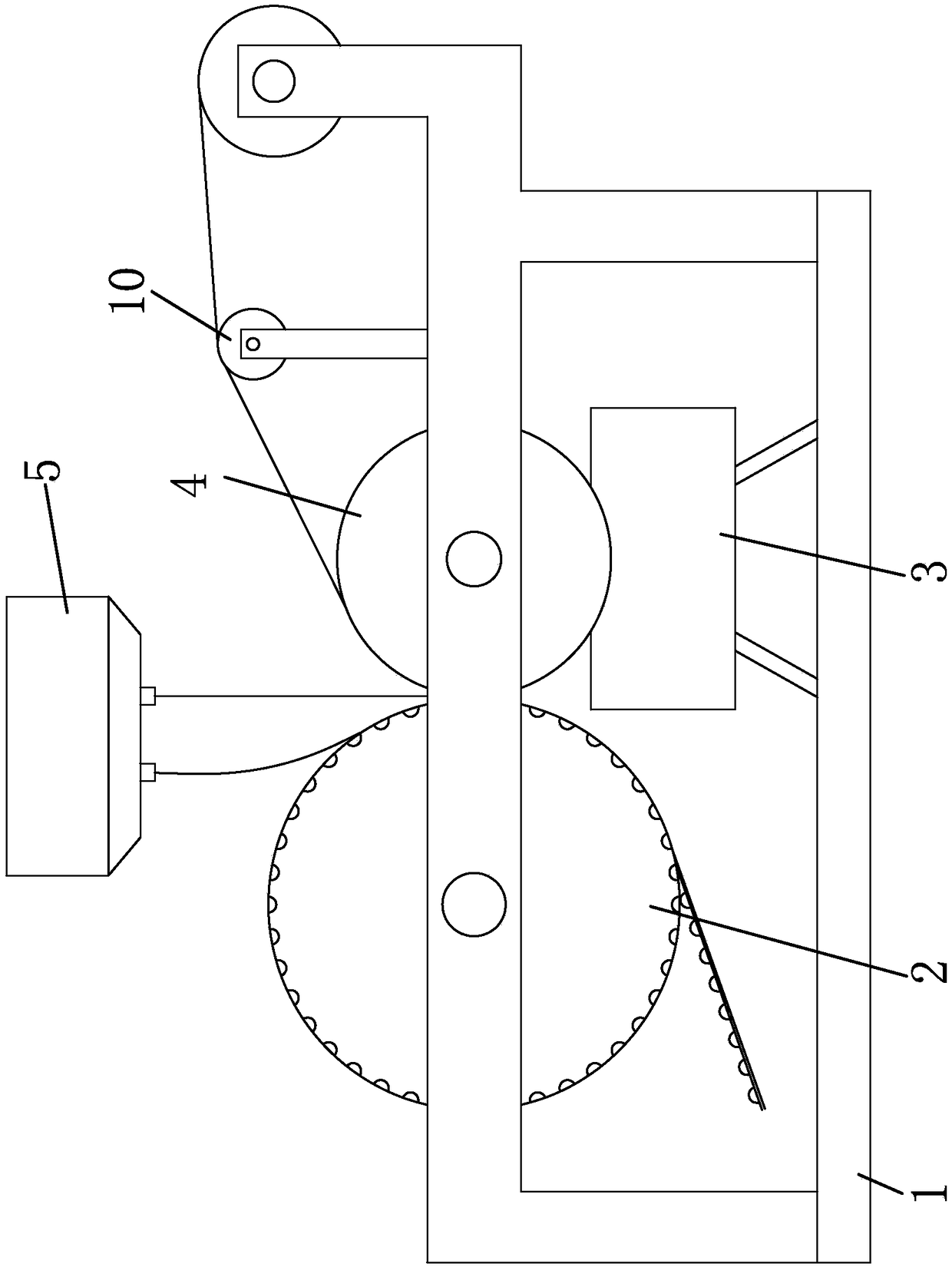

[0078] d. Forming: Put the mixture into the air bubble film machine and extrude it first, then form it to form the air bubble film. When the air bubble film is formed, it is pressed together with the protective film to...

Embodiment 2

[0080] The processing method of the degradable high-strength composite bubble film comprises the following steps:

[0081] a. Outsourcing: purchase the existing protective film on the market, and conduct an appearance inspection on it; the thickness of the protective film is 0.3mm;

[0082] B. Weighing: by weight, weigh 43 parts of polyethylene, 1.4 parts of flame retardant, 0.7 part of antibacterial agent, 0.6 part of plasticizer and 2.4 parts of biodegradable additive;

[0083] c. Stirring: Add polyethylene, flame retardant, antibacterial agent and plasticizer to the mixing equipment, after stirring for 22 minutes, then add biodegradable additives to the mixing equipment, and stir for 13 minutes to prepare the mixture; step c The stirring speed in is 180rmp;

[0084] d. Forming: Put the mixture into the air bubble film machine and extrude it first, then form it to form the air bubble film. When the air bubble film is formed, it is pressed together with the protective film t...

Embodiment 3

[0086] The processing method of the degradable high-strength composite bubble film comprises the following steps:

[0087] a. Outsourcing: purchase the existing protective film on the market, and conduct an appearance inspection on it; the thickness of the protective film is 0.3mm;

[0088] B. Weighing: by weight, weigh 52 parts of polyethylene, 1.7 parts of flame retardant, 1.1 parts of antibacterial agent, 1.2 parts of plasticizer and 4.5 parts of biodegradable additive;

[0089]c. Stirring: Add polyethylene, flame retardant, antibacterial agent and plasticizer to the mixing equipment, and after stirring for 28 minutes, add the biodegradable additive to the mixing equipment, and stir for 17 minutes to prepare the mixture; step c The stirring speed in is 180rmp;

[0090] d. Forming: Put the mixture into the air bubble film machine and extrude it first, then form it to form the air bubble film. When the air bubble film is formed, it is pressed together with the protective fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com