Production process of fast biodegradable porous polyester fiber

A technology of biodegradation and polyester fiber, applied in the direction of fiber chemical characteristics, single-component polyester rayon, chemical post-treatment of synthetic polymer rayon, etc., can solve the problem of slow microbial degradation and longer biodegradation time , dense fiber structure and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

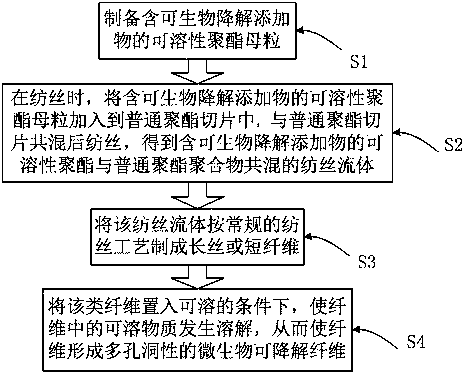

Method used

Image

Examples

Embodiment 1

[0056] (1) Preparation of soluble polyester masterbatch with biodegradable additives.

[0057] Mix biodegradable additives with soluble polyester, wherein the proportion of biodegradable additives is 20%, soluble polyester is water-soluble polyester, blend and granulate, and granulate to obtain water-soluble polyester containing biodegradable additives. permanent polyester masterbatch.

[0058] (2) Pre-crystallize ordinary polyester chips and then dry them.

[0059] (3) The soluble polyester masterbatch containing biodegradable additives is added to the dried ordinary polyester chips at a ratio of 2%, and sent to the spinning screw for blending and spinning to obtain polyester polymers. spinning fluid.

[0060] (4) The spinning fluid is made into filament DTY according to the conventional spinning process, 75D / 48F.

[0061] (5) The fiber strength is 3.8cn / dtex, and the elongation at break is 31%.

[0062] (6) Treat the fiber in 100-degree hot water for 60 minutes to dissol...

Embodiment 2

[0065] (1) Preparation of soluble polyester masterbatch with biodegradable additives.

[0066] Mix the biodegradable additive with the alkali-soluble polyester, wherein the proportion of the biodegradable additive is 15%, and the soluble polyester is alkali-soluble polyester, blend and granulate, and granulate to obtain the biodegradable additive. Water-soluble polyester masterbatch.

[0067] (2) Pre-crystallize ordinary polyester chips and then dry them.

[0068] (3) The soluble polyester masterbatch containing biodegradable additives is added to the dried ordinary polyester chips at a ratio of 5%, and sent to the spinning screw for blending and spinning to obtain polyester polymers. spinning fluid.

[0069] (4) The spinning fluid is made into filament FDY according to the conventional spinning process, 50D / 36F.

[0070] (5) The fiber strength is 3.5cn / dtex, and the elongation at break is 33%.

[0071] (6) Treat the fiber in a 100% sodium hydroxide solution with a concent...

Embodiment 3

[0074] (1) Preparation of soluble polyester masterbatch with biodegradable additives.

[0075] Mix the biodegradable additive with the alkali-soluble polyester, wherein the proportion of the biodegradable additive is 10%, and the soluble polyester is alkali-soluble polyester, blend and granulate, and granulate to obtain the biodegradable additive. Water-soluble polyester masterbatch.

[0076] (2) Pre-crystallize ordinary polyester chips and then dry them.

[0077] (3) The soluble polyester masterbatch containing biodegradable additives is added to the dried ordinary polyester chips at a ratio of 5%, and sent to the spinning screw for blending and spinning to obtain polyester polymers. spinning fluid.

[0078] (4) According to the conventional spinning process of the spinning fluid, the spinneret hole is designed to be hollow, and the short fiber with a hollow cross section is produced.

[0079] (5) The fiber specification is 1.5D*38mm, the strength is 3.5cn / dtex, and the el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com