Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33 results about "Automatic quartz" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Automatic quartz is a collective term describing watch movements that combine a self-winding rotor mechanism (as used in automatic mechanical watches) to generate electricity with a piezoelectric quartz crystal as its timing element. Such movements aim to provide the advantages of quartz without the inconvenience and environmental impact of batteries. Several manufacturers employ this technique.

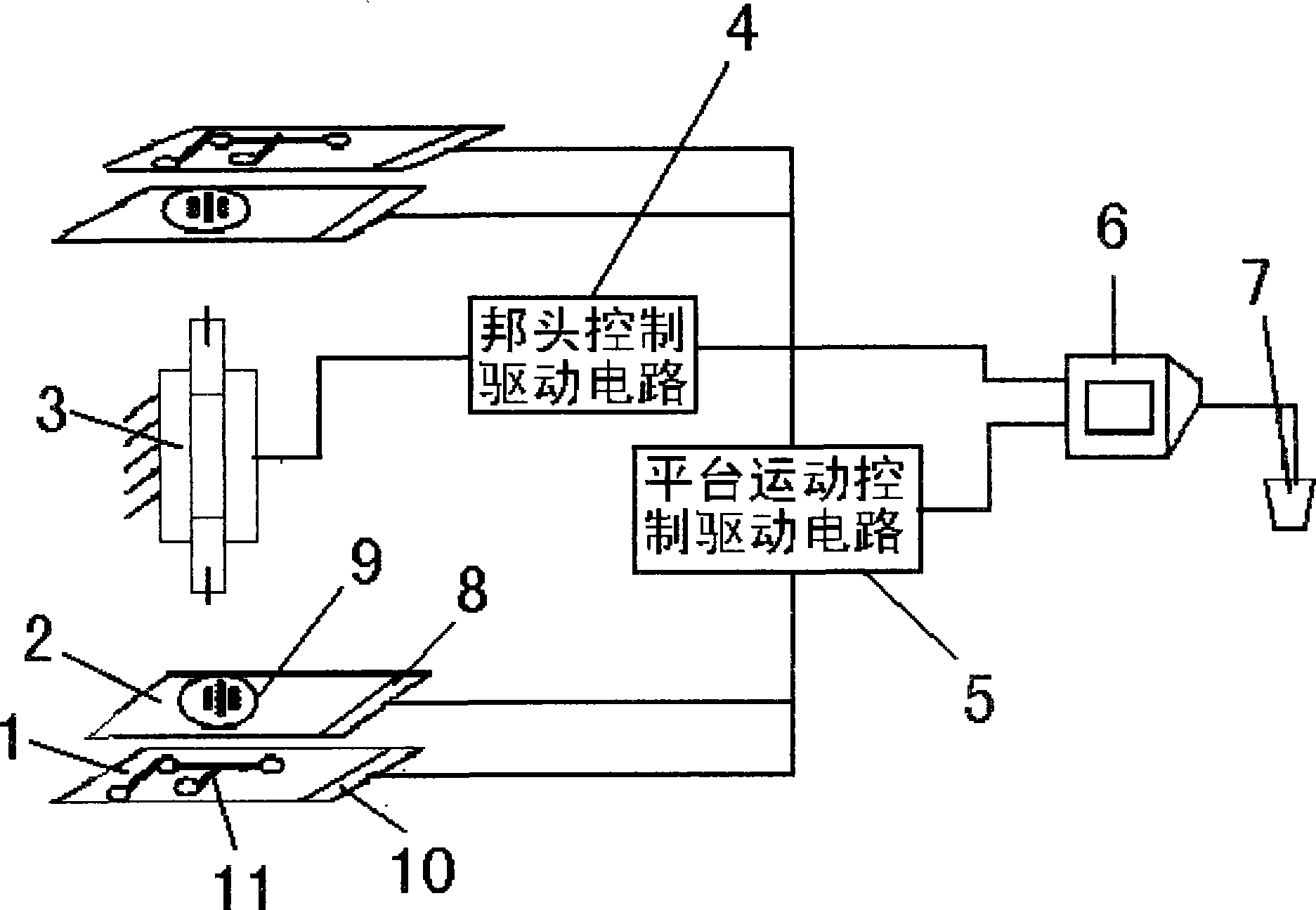

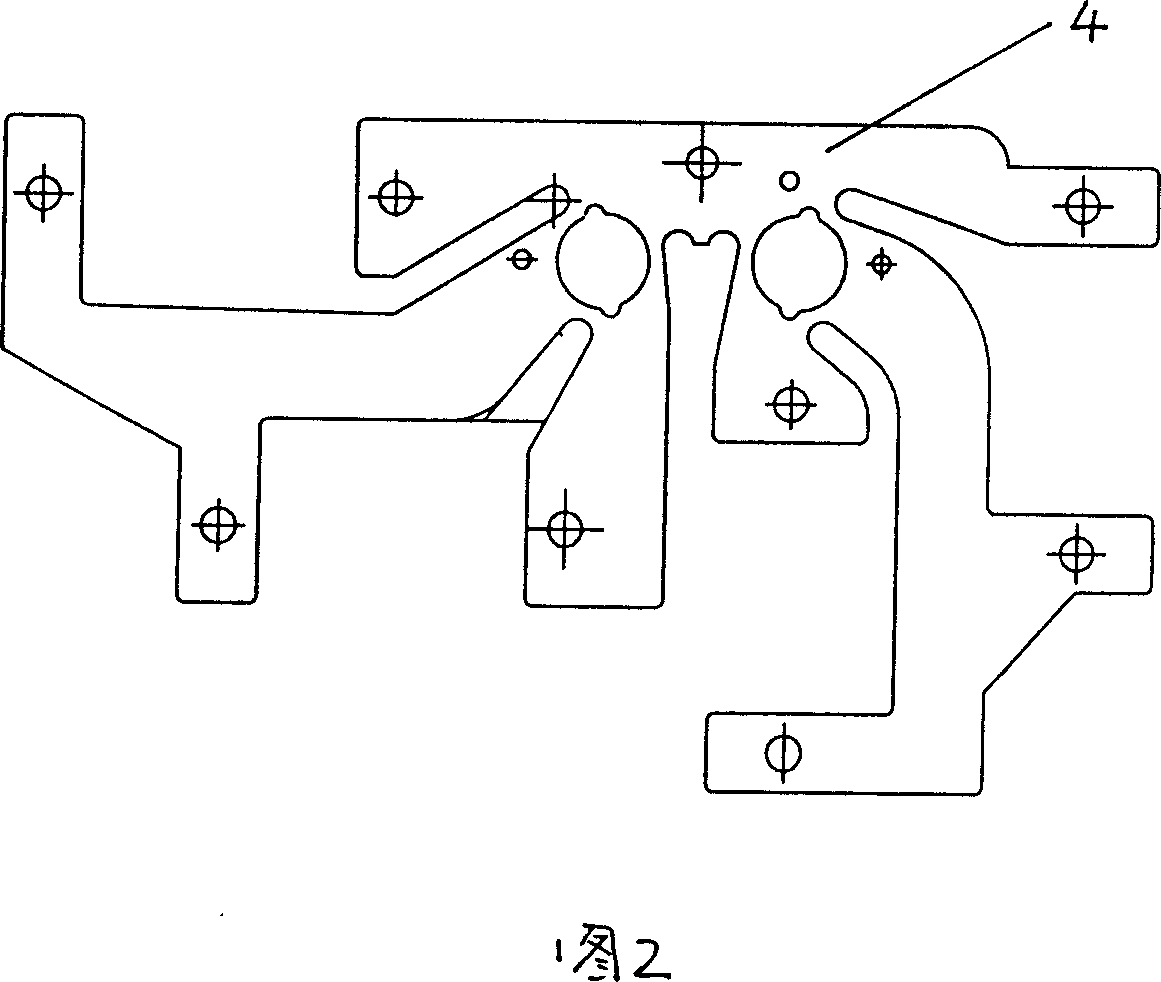

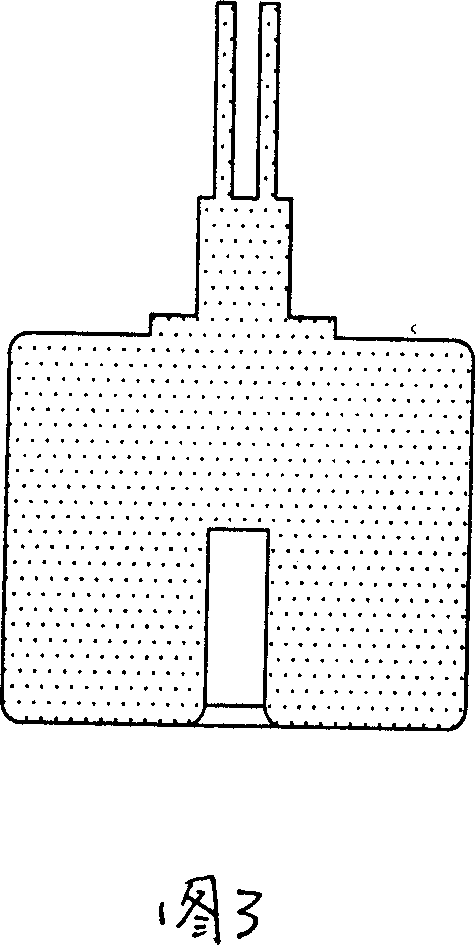

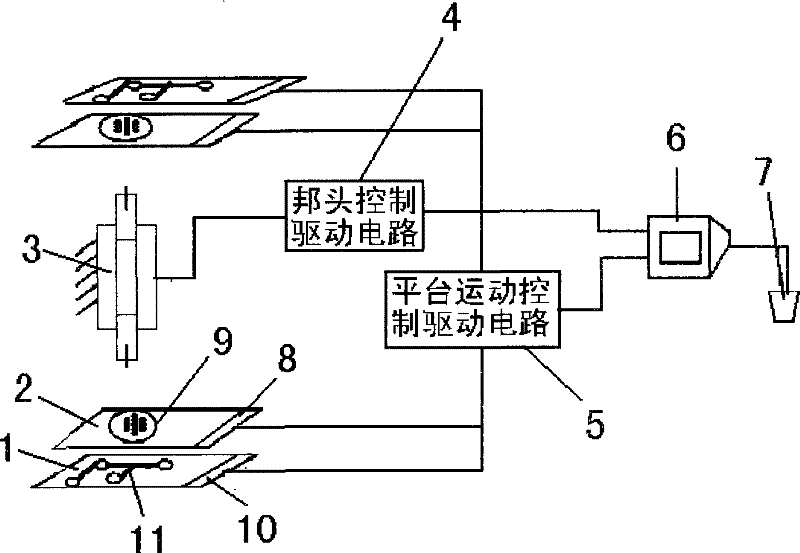

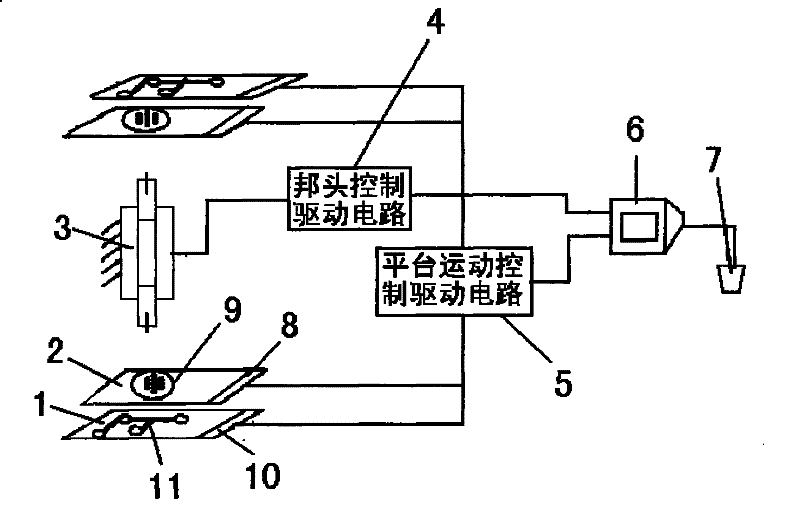

Die bonding method for automatic quartz alignment by image recognition

InactiveCN101488552AImprove Die Bonding EfficiencyLow costSemiconductor/solid-state device manufacturingProgramme total factory controlAutomatic quartzPosition control

A high-speed die bond method for crystal by automatic image recognition is characterized in that the die bond method comprises the following steps: (1) a wafer platform and a circuit board platform realize driving in X and Y direction, the two platforms all select a Bonder Head position moving up and down as an origin of coordinate, all the origins automatically reset to zero when starting up; (2) image data are input into a computer which is responsible for analyzing, computing and processing the input images, the computer can process a plurality of groups of image data at the same time and match and compute the deviation of coordinates of corresponding points in each group based on the requirements; (3) movement to the place right under the Bonder Head or right above the Bonder Head is carried out according to the regulated time sequence, the wafer is pressed and mounted on the circuit board, thus completing die bond. The method has the advantages that the automatic position control of computer is adopted, the Bonder Head does not need reciprocation, the die bond efficiency is high, a plurality of groups of die bond images can be processed simultaneously, the cost is saved and the requirement of improving the die bond speed and accuracy is met.

Owner:NANCHANG HANGKONG UNIVERSITY

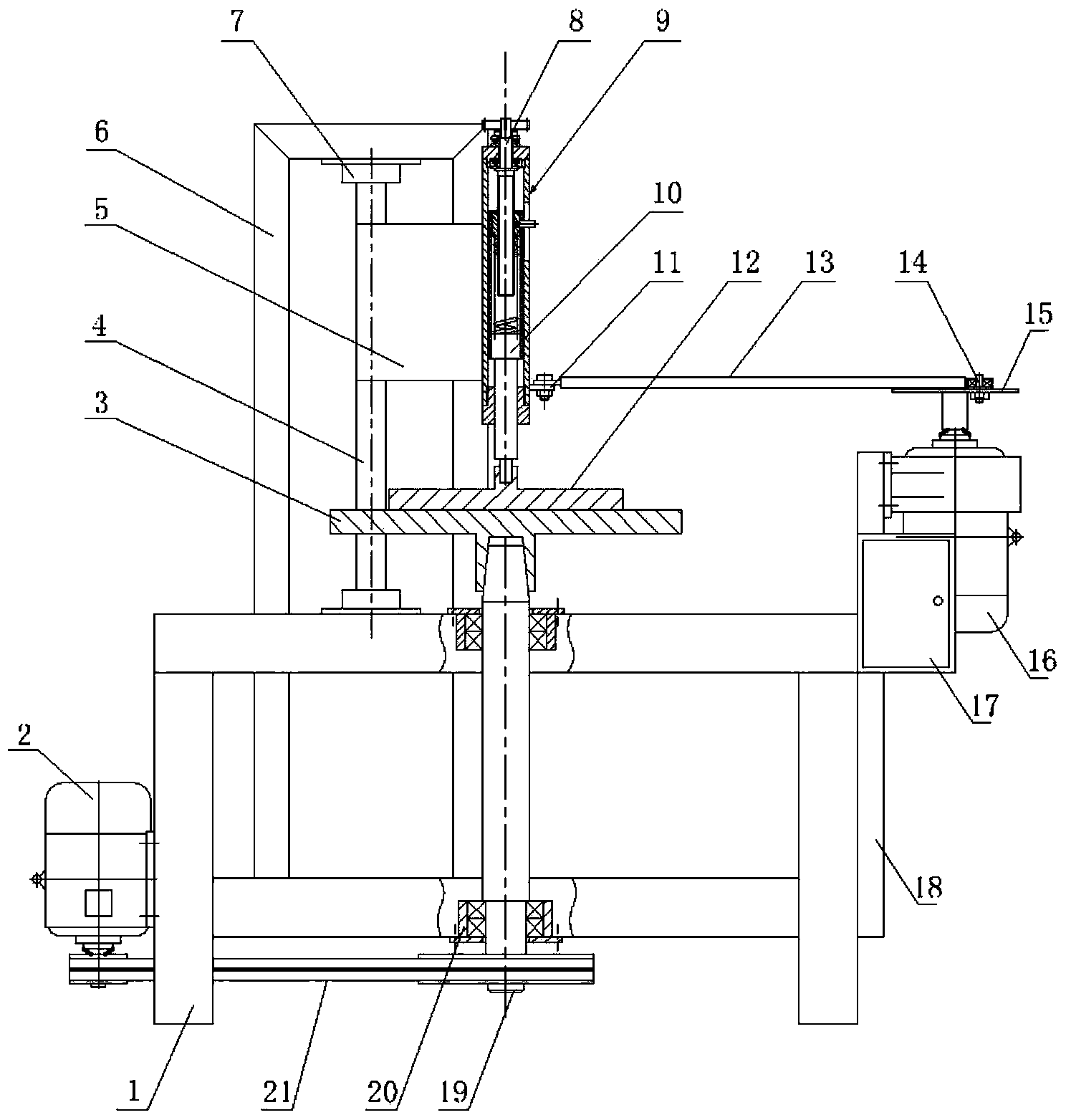

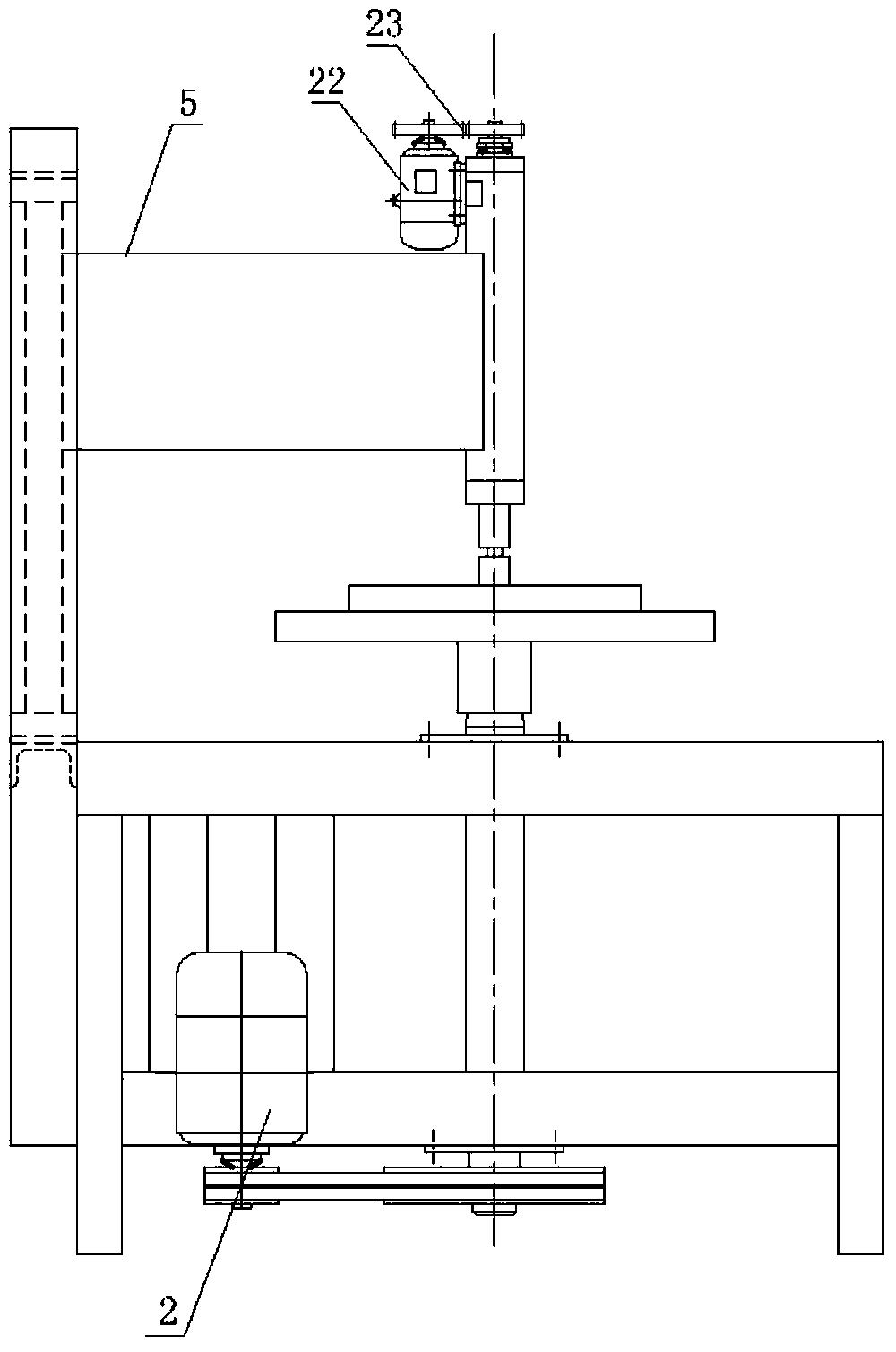

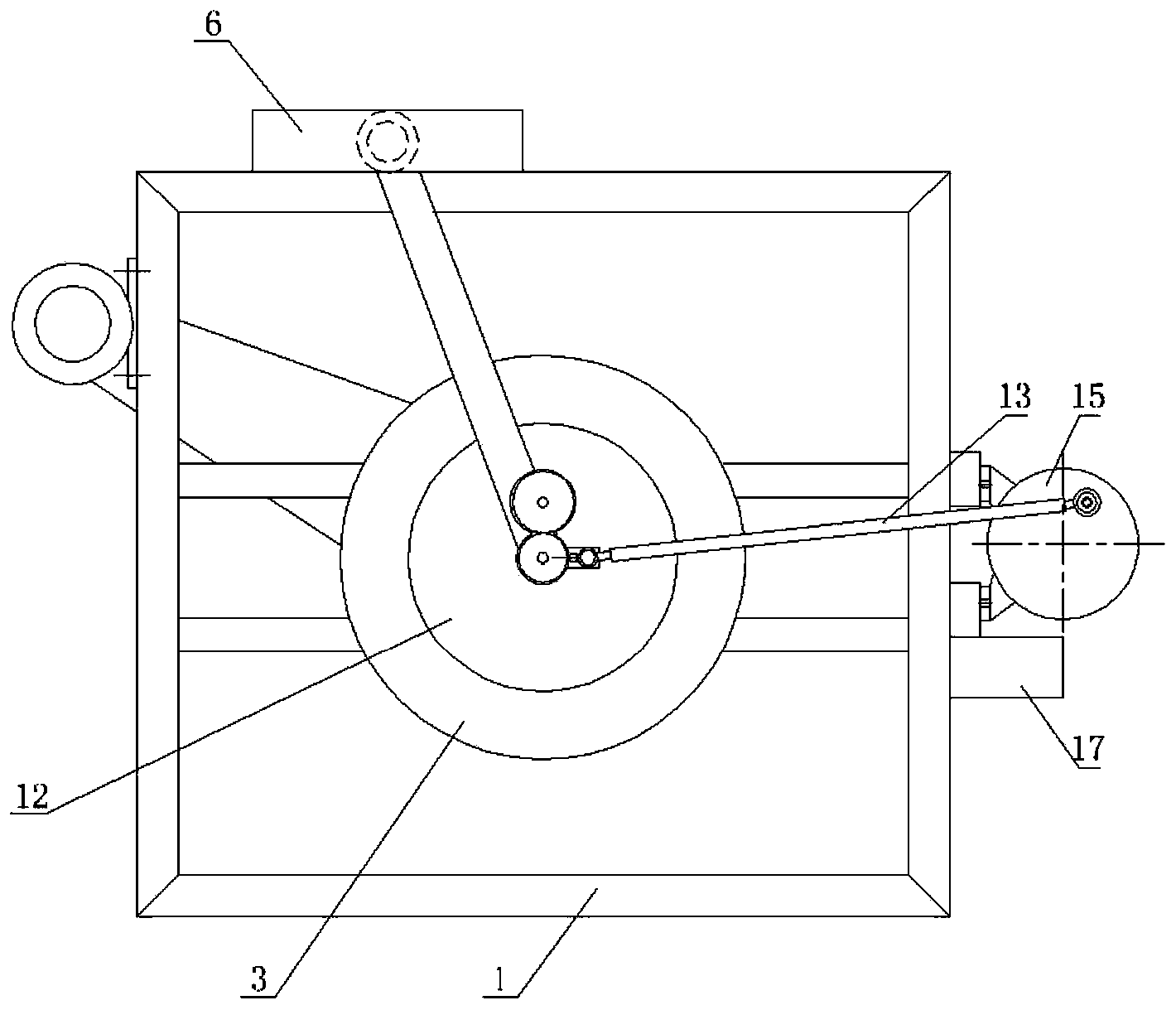

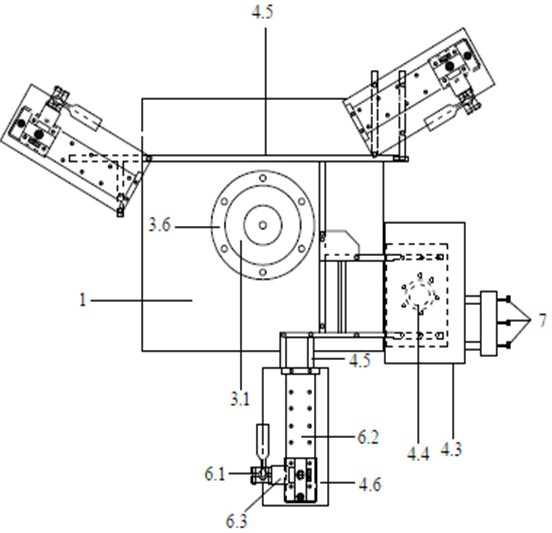

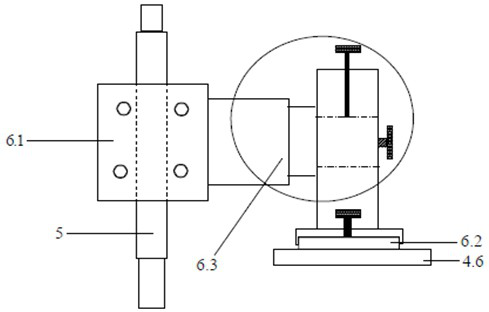

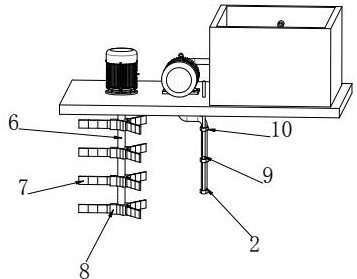

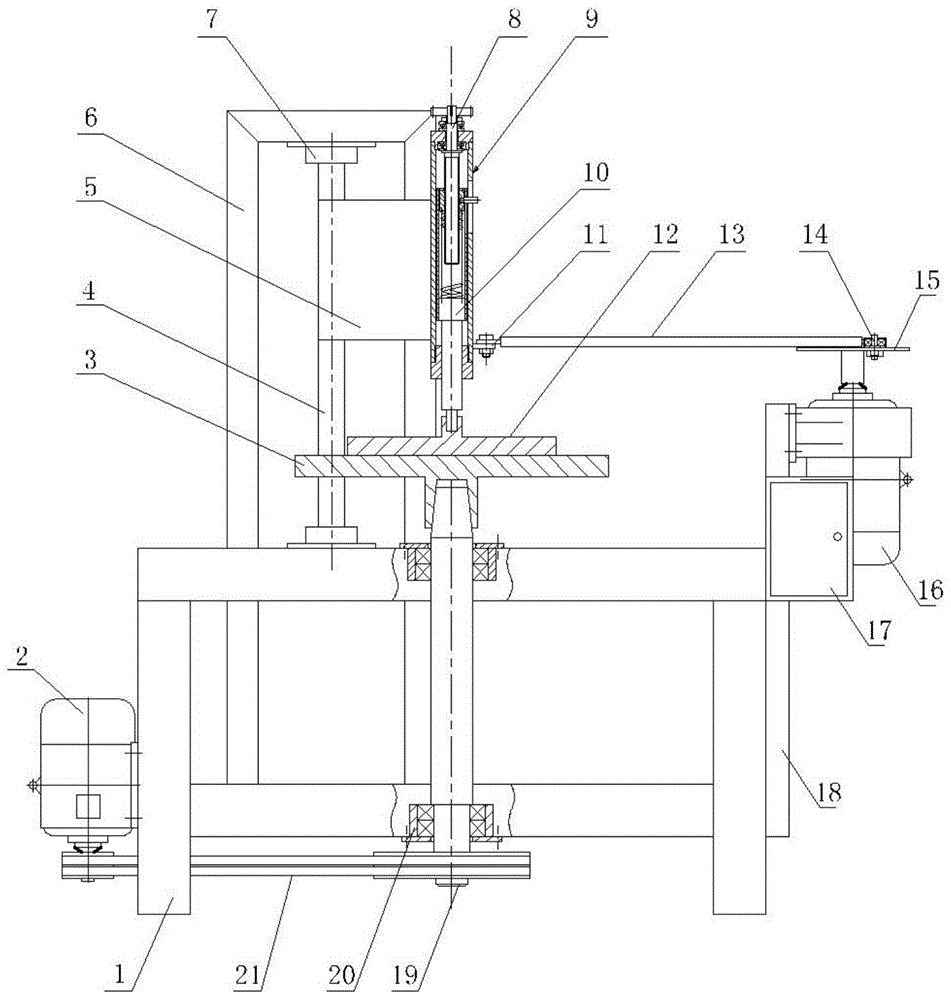

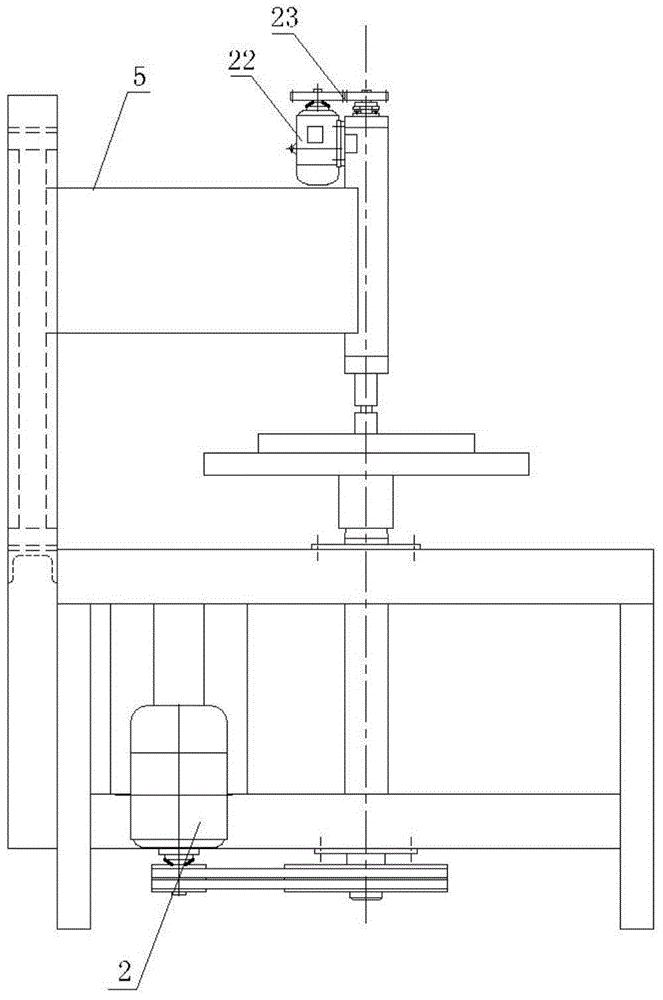

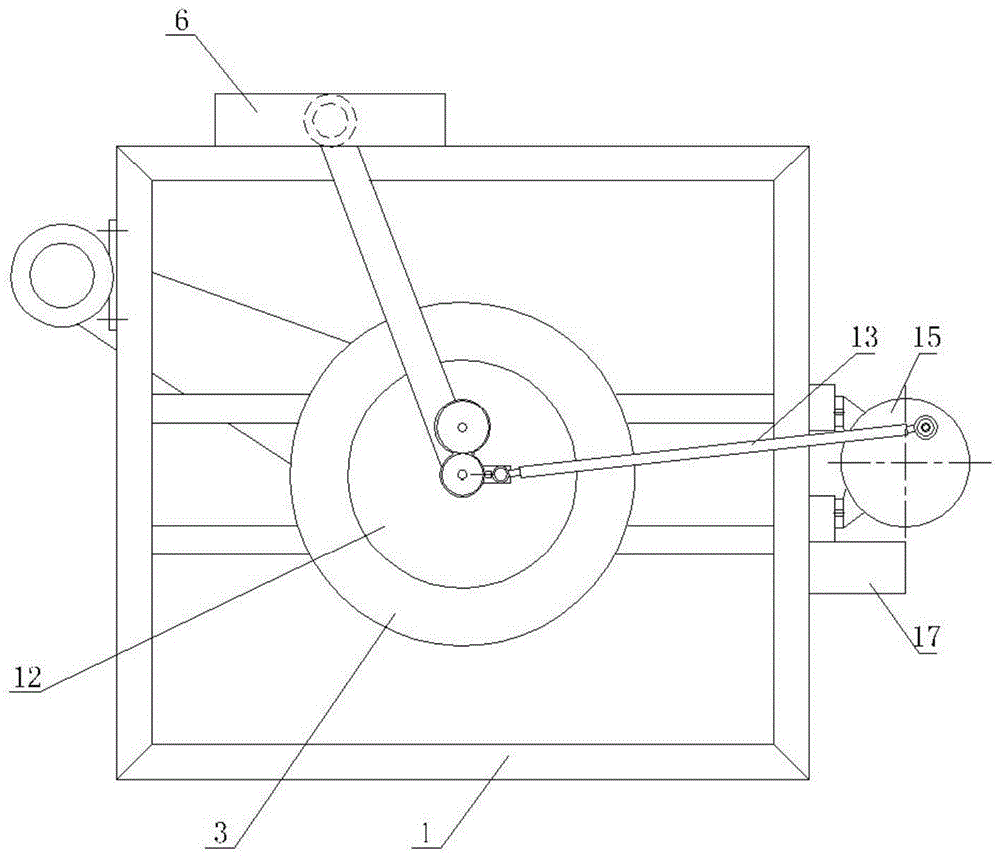

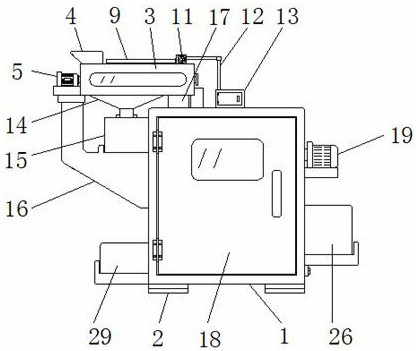

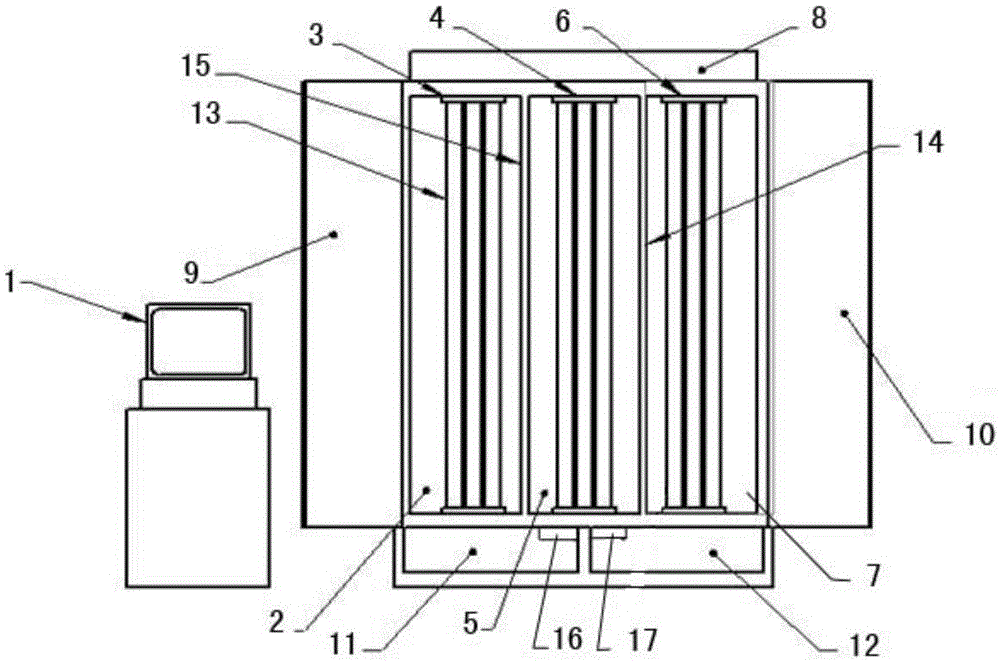

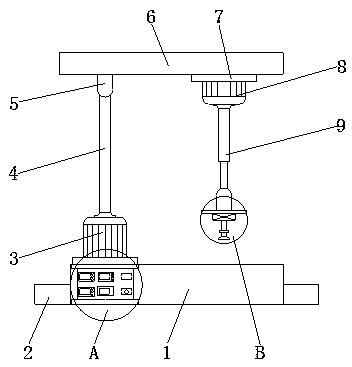

Full-automatic quartz glass polishing machine

InactiveCN104029108AReduce torqueSimple structurePolishing machinesGrinding drivesAutomatic controlAutomatic quartz

The invention discloses a full-automatic quartz glass polishing machine which comprises a framework. A main motor and a spindle are arranged on the framework and are connected with each other by a first transmission mechanism, a polishing support plate is mounted at the upper end of the spindle, a base plate is supported on the polishing support plate, a swing shaft is mounted on a side of the framework, a swing arm is fixed to the upper portion of the swing shaft, a plate press device is fixedly connected to a free end of the swing arm, a miniature motor is arranged on the outer side of the upper portion of the plate press device, an output shaft of the miniature motor is connected with an adjusting lead screw by a second transmission mechanism, the adjusting lead screw is arranged at the upper end of the plate press device, and a positioning output shaft at the lower end of the plate press device is inserted into a center hole of the base plate; a gear motor is arranged on a side of the framework and is connected with a mounting jacket of the plate press device by a crank connecting rod mechanism. The full-automatic quartz glass polishing machine has the advantages that the full-automatic quartz glass polishing machine can be reasonably stressed, torsion on the swing shaft during work can be greatly reduced, accordingly, long-term fault-free continuous work can be guaranteed, and the full-automatic quartz glass polishing machine is long in service life; full-automatic control effects can be realized, and the full-automatic quartz glass polishing machine is high in quartz glass sheet replacing speed and work efficiency.

Owner:广东盈锋实业有限公司

Automatic quartz stone welding equipment

PendingCN107553741AGuaranteed to workAccurate control of hole sizeFine working devicesStone-like material working toolsAutomatic quartzWork in process

An automatic quartz stone welding equipment, including a feeding mechanism, a welding mechanism, and a fixed platform. The feeding mechanism and the welding mechanism are connected together. Gas pipeline, the acetylene intake pipeline is four placed side by side, the acetylene intake pipeline is connected together with the flow valve through the pipeline, the flow valve is connected together with the welding mechanism through the pipeline, the fixed platform A man-machine dialogue window is installed in the top edge of the man-machine dialogue window, and the man-machine dialogue window is placed on the periphery of the welding mechanism. The invention automatically performs acetylene opening and annular acetylene welding on the semi-finished quartz stone through the welding mechanism and the feeding mechanism. It is processed into finished products and taken out automatically, saving labor costs.

Owner:苏州苏汀达自动化科技有限公司

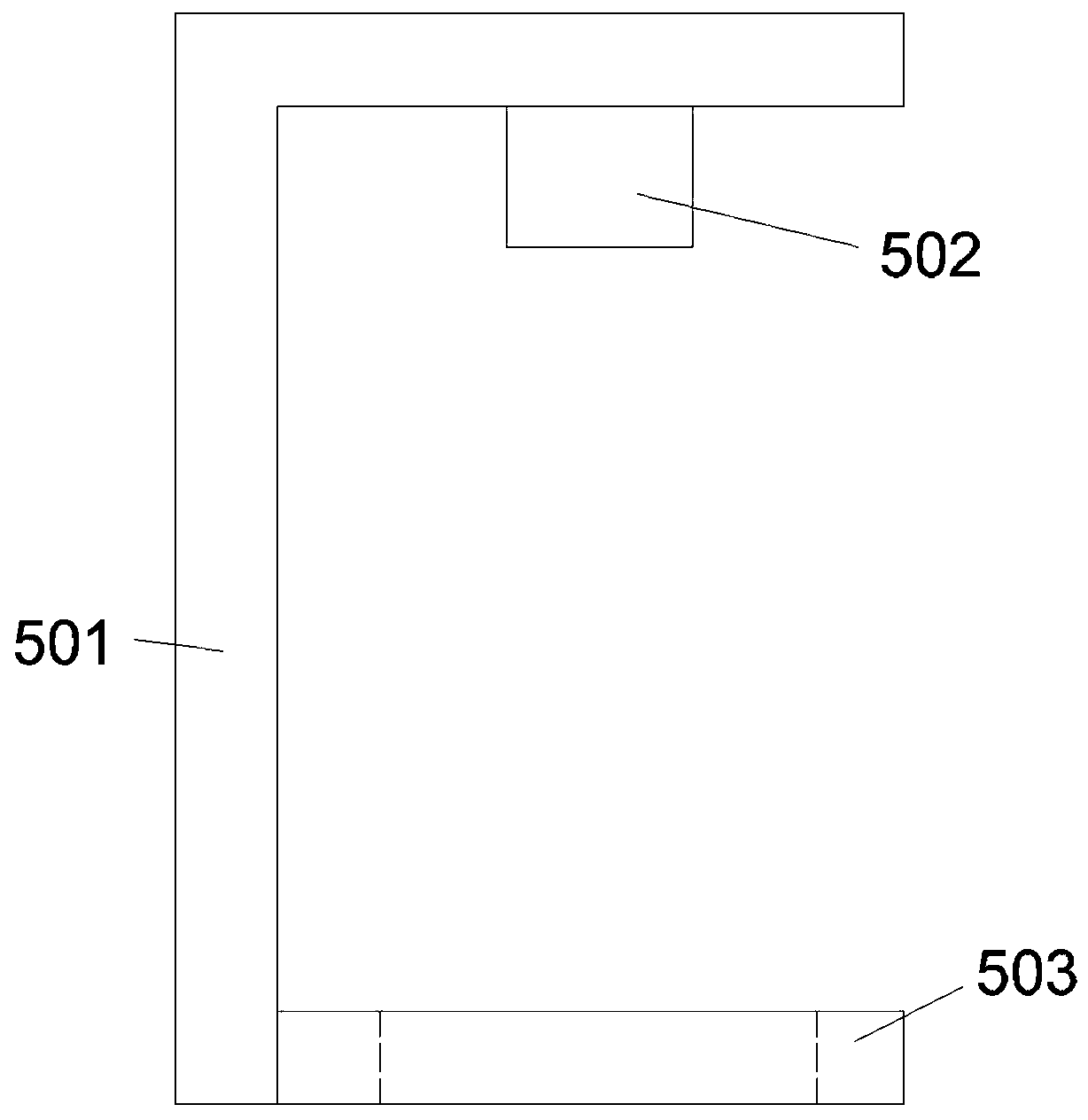

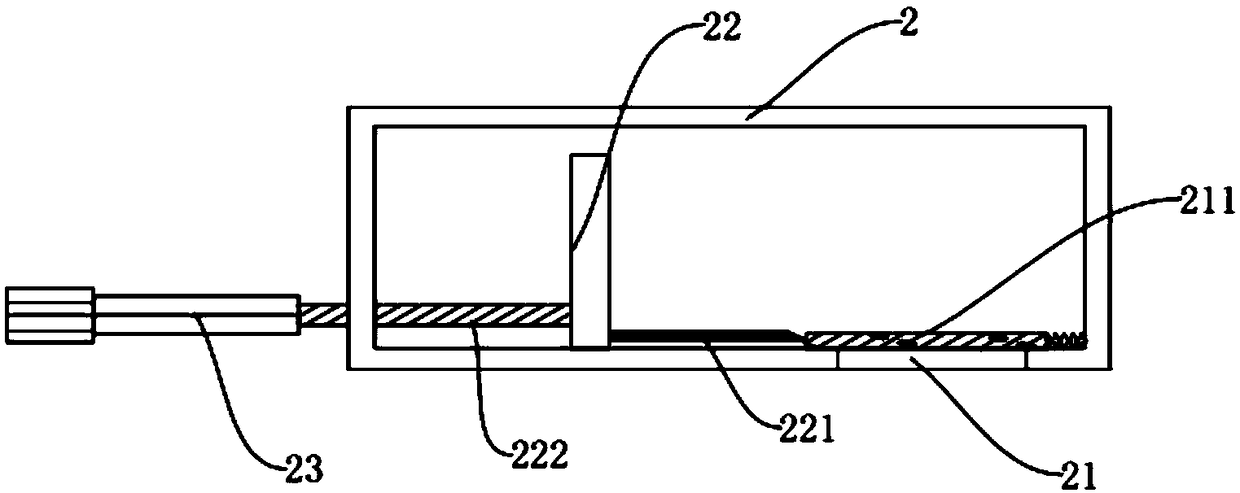

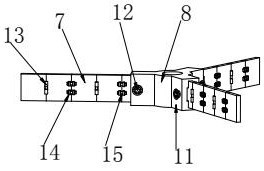

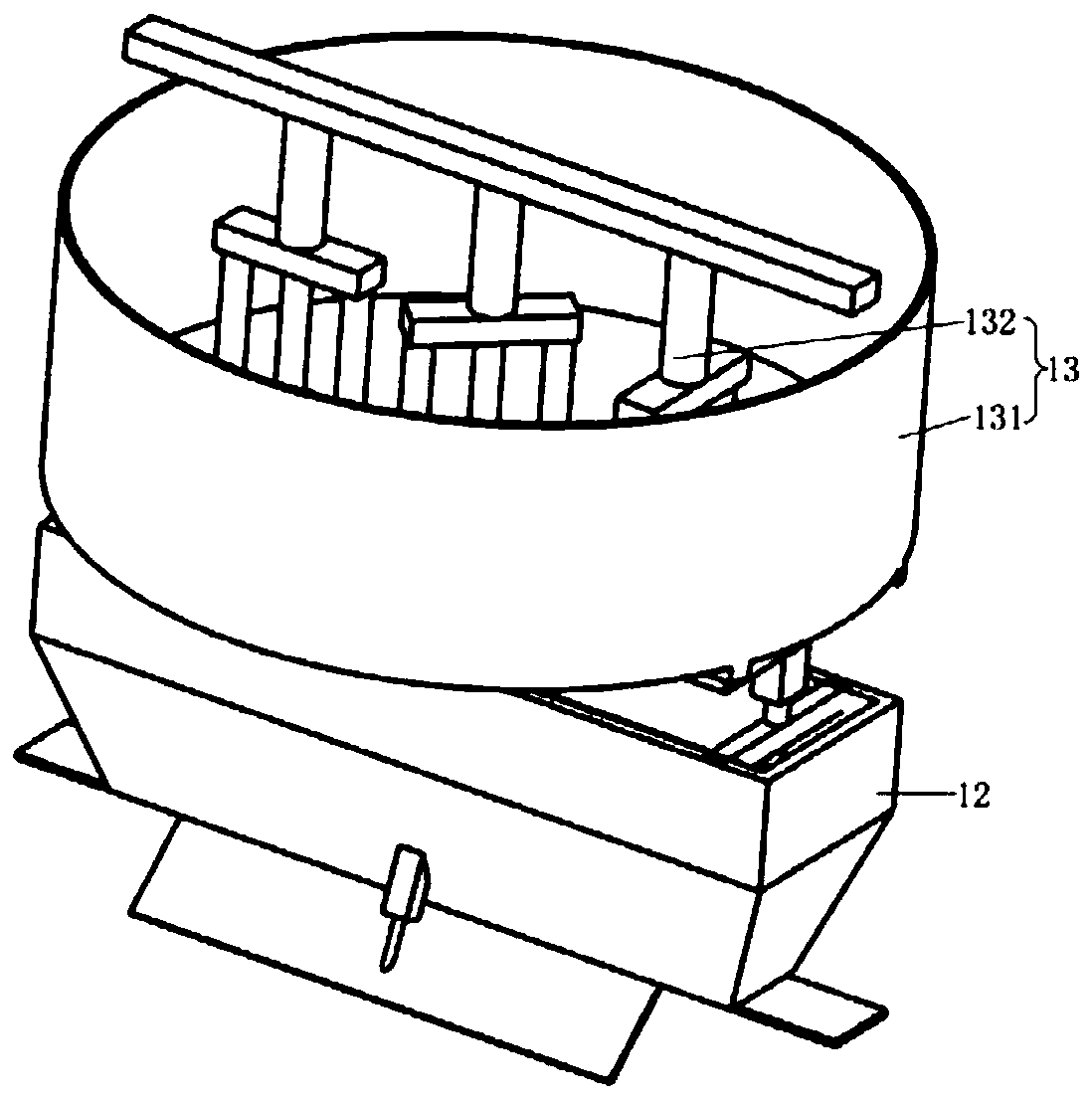

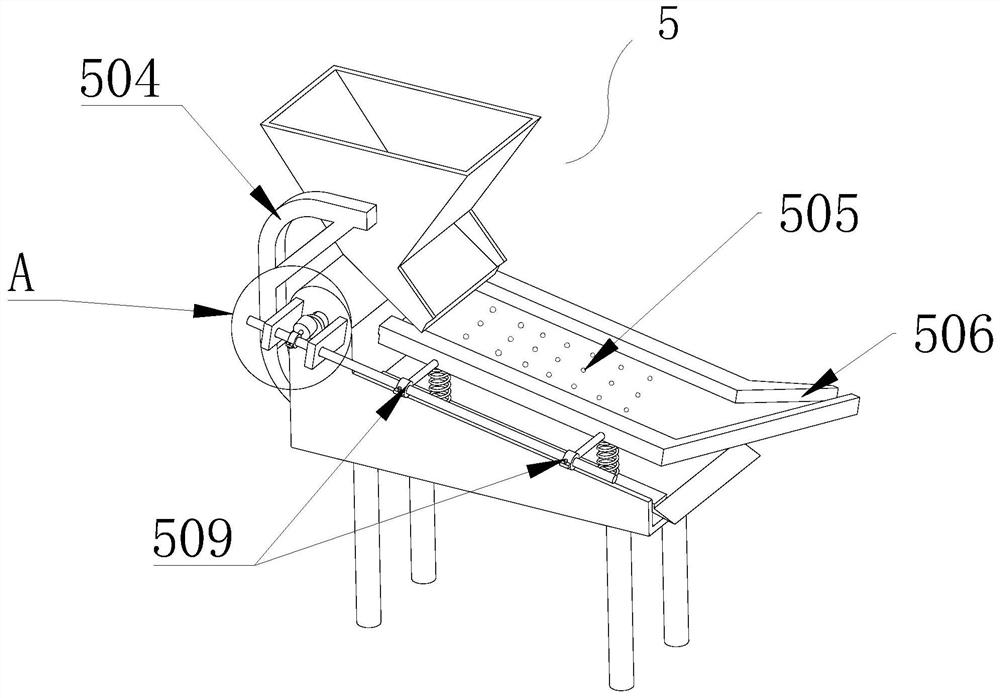

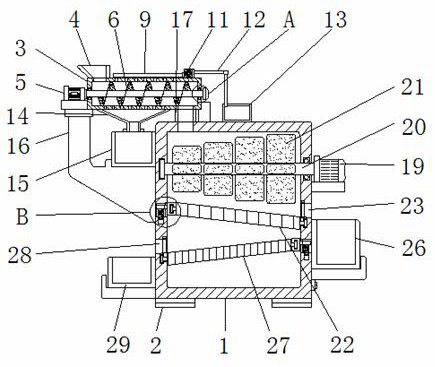

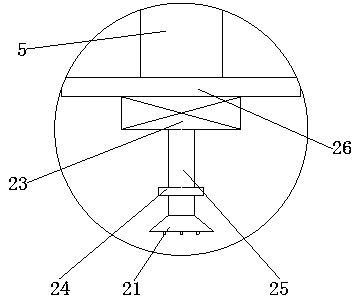

Automatic quartz wafer angle sorting device

PendingCN110102479AIt will not be scattered on the groundGuaranteed stabilityGradingAgricultural engineeringAutomatic quartz

The invention discloses an automatic quartz wafer angle sorting device which comprises a box body, screening plates and a base. An upright post, a supporting rod, an adjusting cylinder and a placing frame are arranged at the upper end of the base, the box body is arranged at the upper end of the upright post, the adjusting cylinder is arranged on the left side of the placing frame, the supportingrod is arranged on the left part of the adjusting cylinder, the upright post is arranged on the left part of the supporting rod, and screening plates are arranged at the upper ends of the supporting rod and the adjusting cylinder. A sliding groove is formed in the left part of the upper end of each screening plate, a screening groove is formed in the right part of the upper end of each screening plate, mounting grooves are formed in the positions, close to the screening grooves, on the two sides of the inner parts of the screening grooves, and first cylinders are arranged at the positions, corresponding to the side walls of the outer sides of the screening plates, of the mounting grooves. By arranging the first cylinders and the adjusting cylinder, the problems that the quartz wafer sorting device does not have the function of angle adjustment and residual quartz wafers stay on the device due to the fact that the residual quartz wafers often cannot be sorted.

Owner:马鞍山荣泰科技有限公司

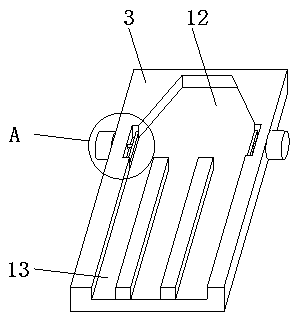

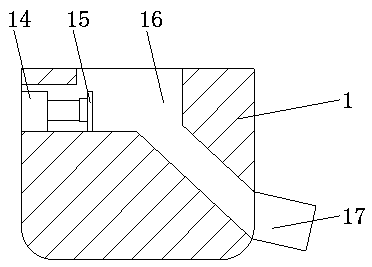

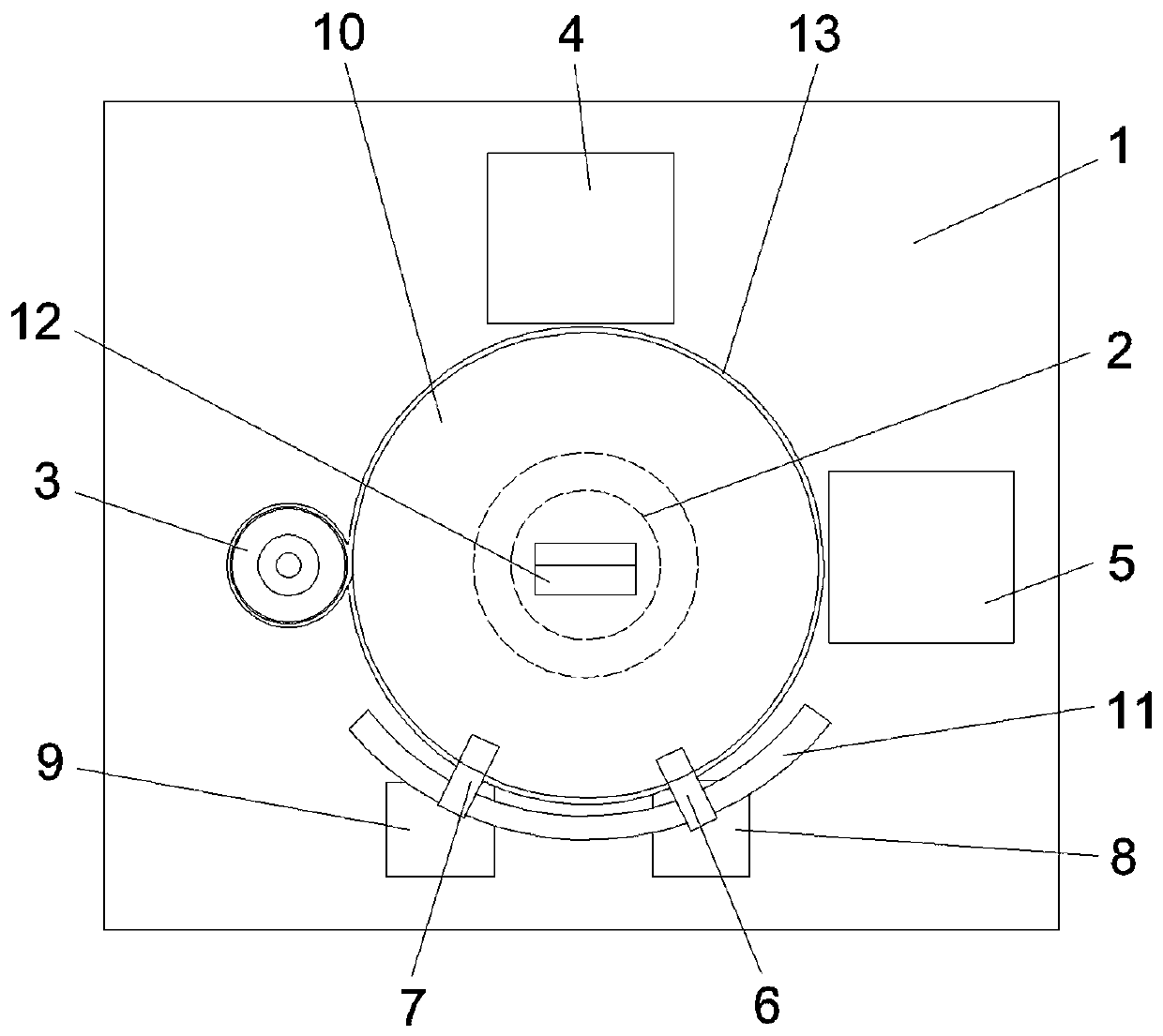

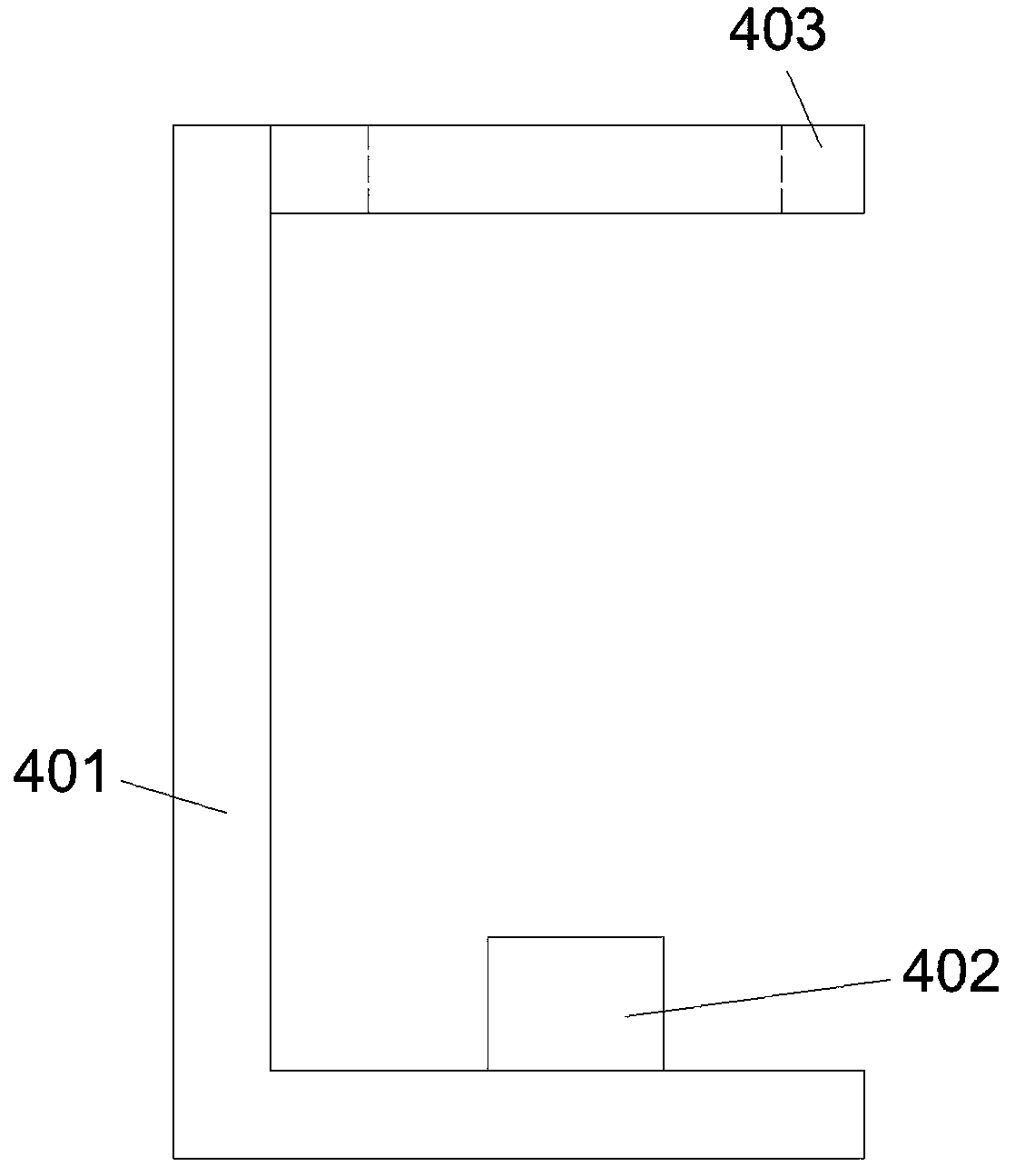

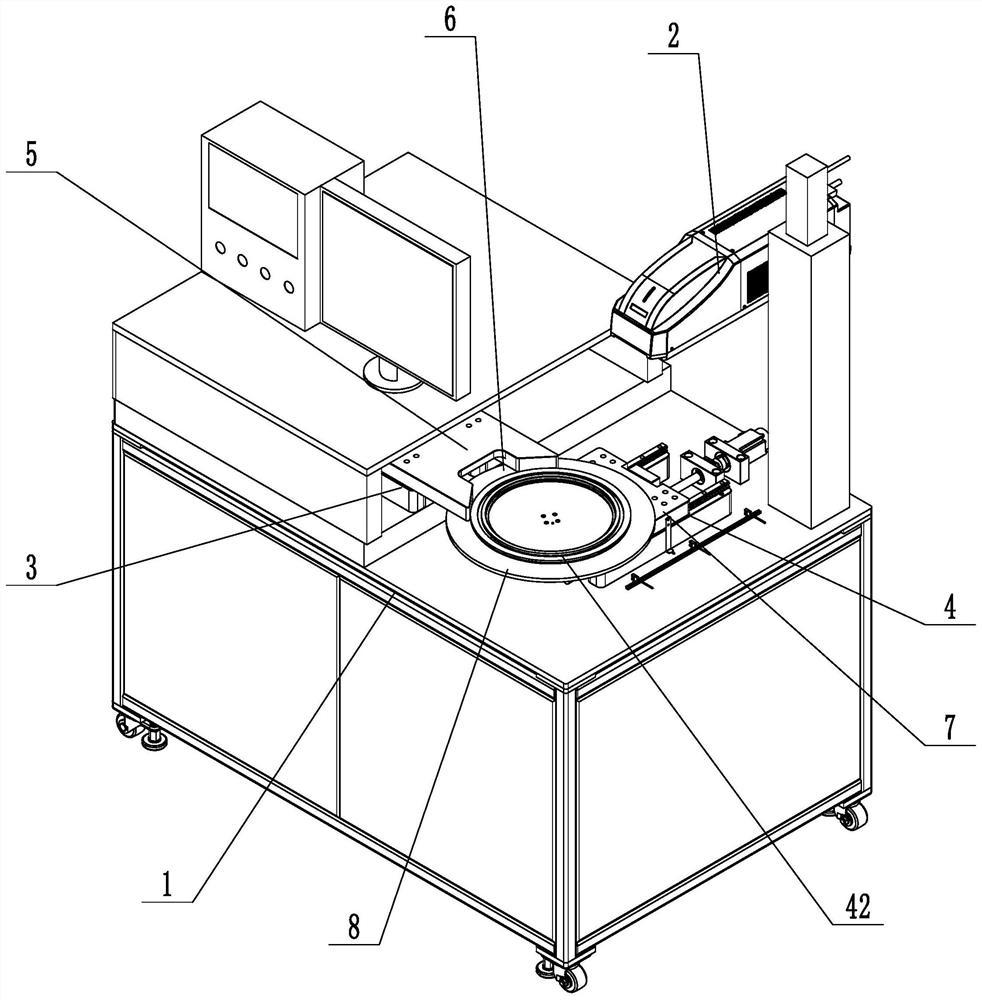

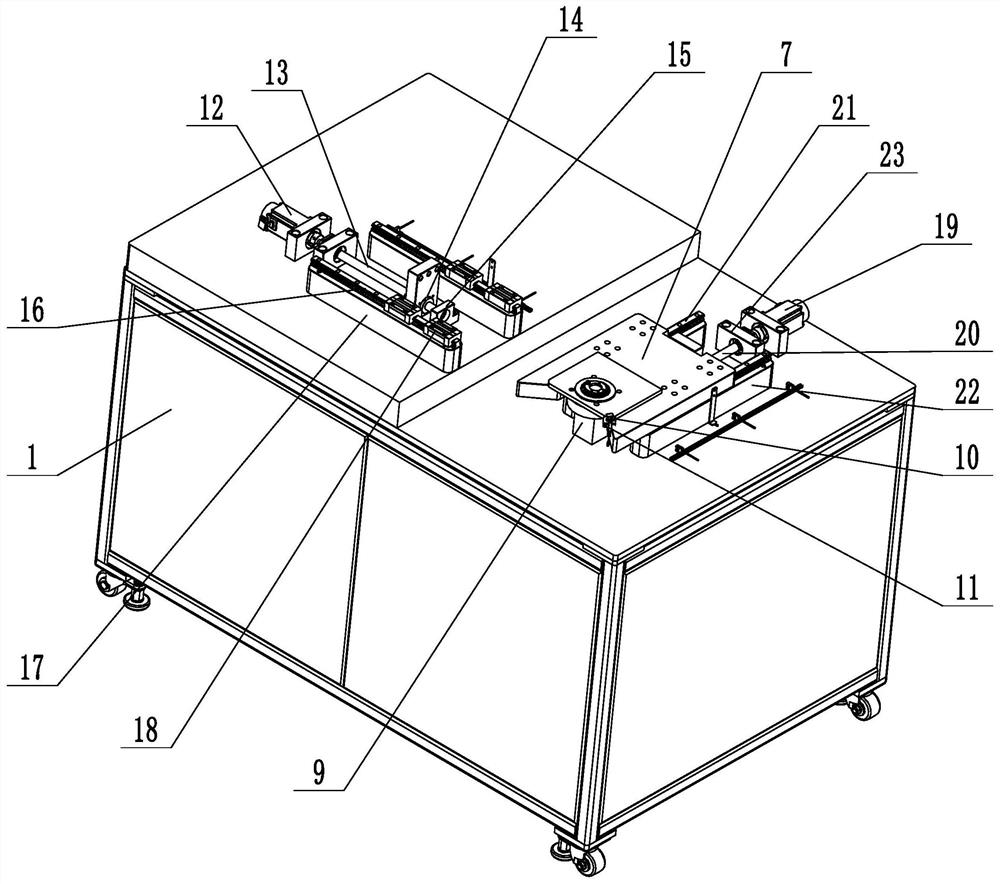

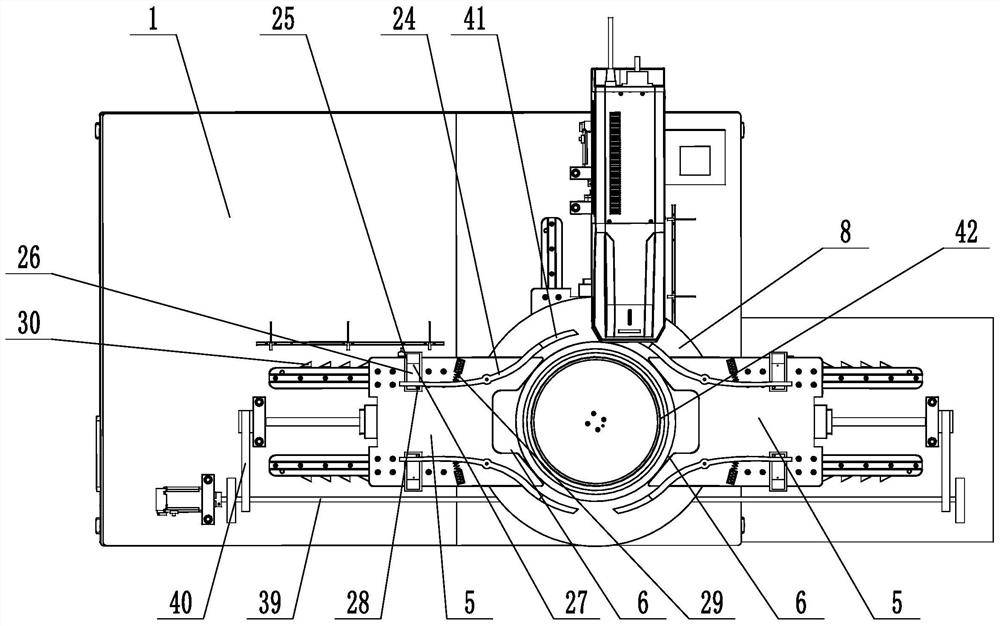

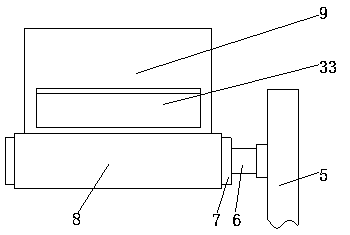

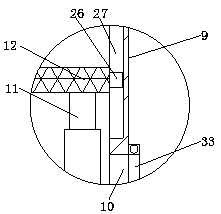

Full-automatic quartz wafer appearance sorting machine

PendingCN110865085AImprove detection efficiencyInvestigating crystalsOptically investigating flaws/contaminationWaferingElectric machine

The invention discloses a full-automatic quartz wafer appearance sorting machine, and aims to provide a full-automatic quartz wafer appearance sorting machine with high detection efficiency. The device comprises a machine table; a rotary motor, a vibration feeding disc, a wafer front face detection mechanism, a wafer back face detection mechanism, a first discharging blowing mechanism, a second discharging blowing mechanism, a good product discharging disc and a defective product discharging disc are arranged on the machine table. A rotating disc is arranged on the rotating motor in a matchedmanner; the vibration feeding disc, the wafer front face detection mechanism, the wafer back face detection mechanism, the good product discharging disc and the defective product discharging disc aresequentially arranged outside the rotating disc in a matched mode. The first discharging air blowing mechanism and the second discharging air blowing mechanism are both located above the rotating discand matched with the good product discharging disc and the defective product discharging disc respectively. The invention is applied to the technical field of quartz wafer appearance picking machines.

Owner:珠海东锦石英科技有限公司

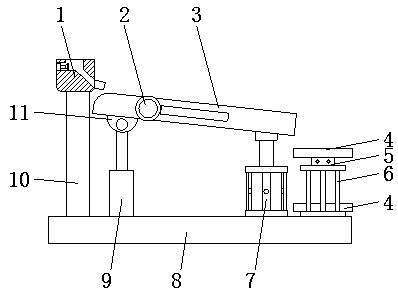

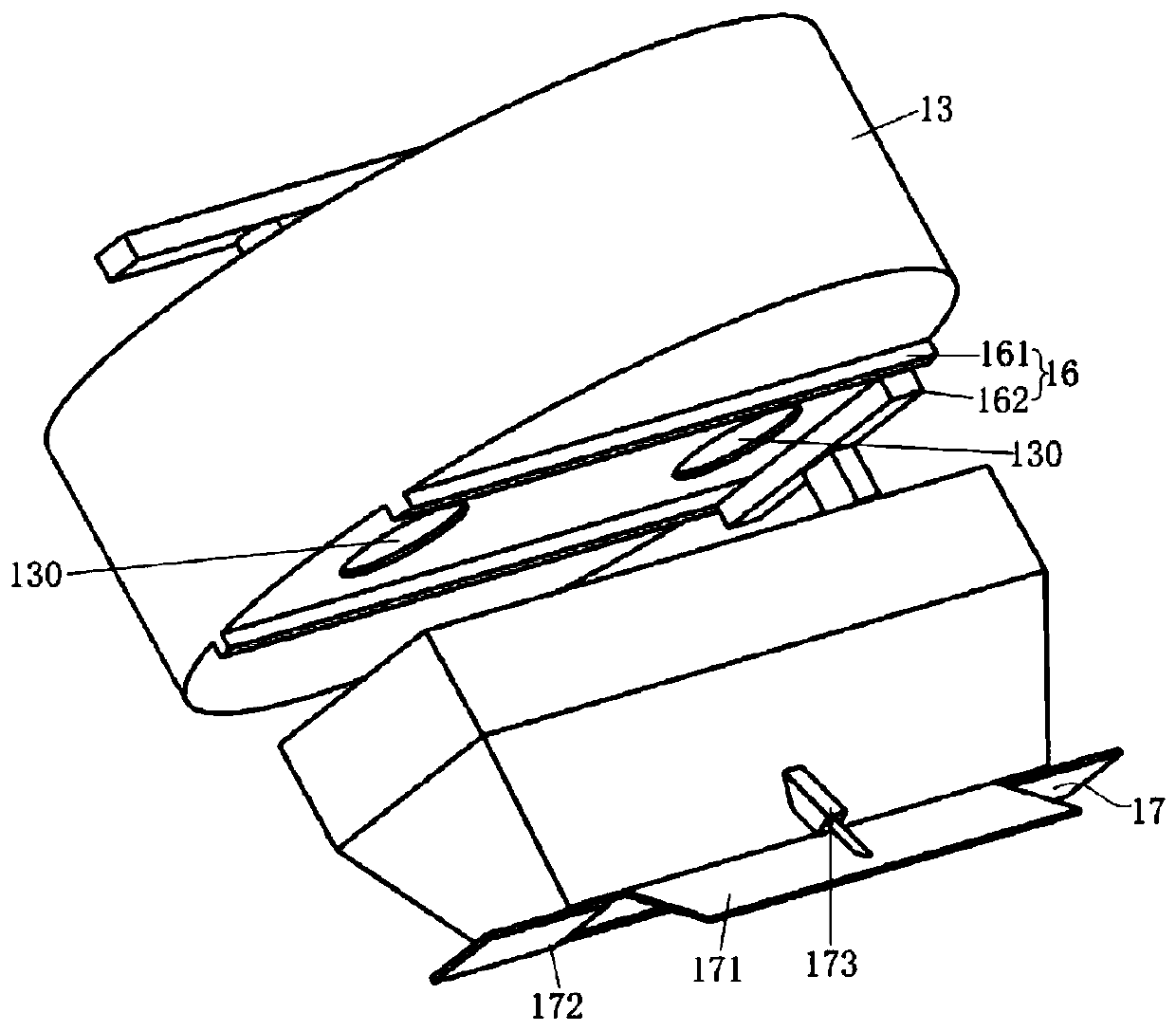

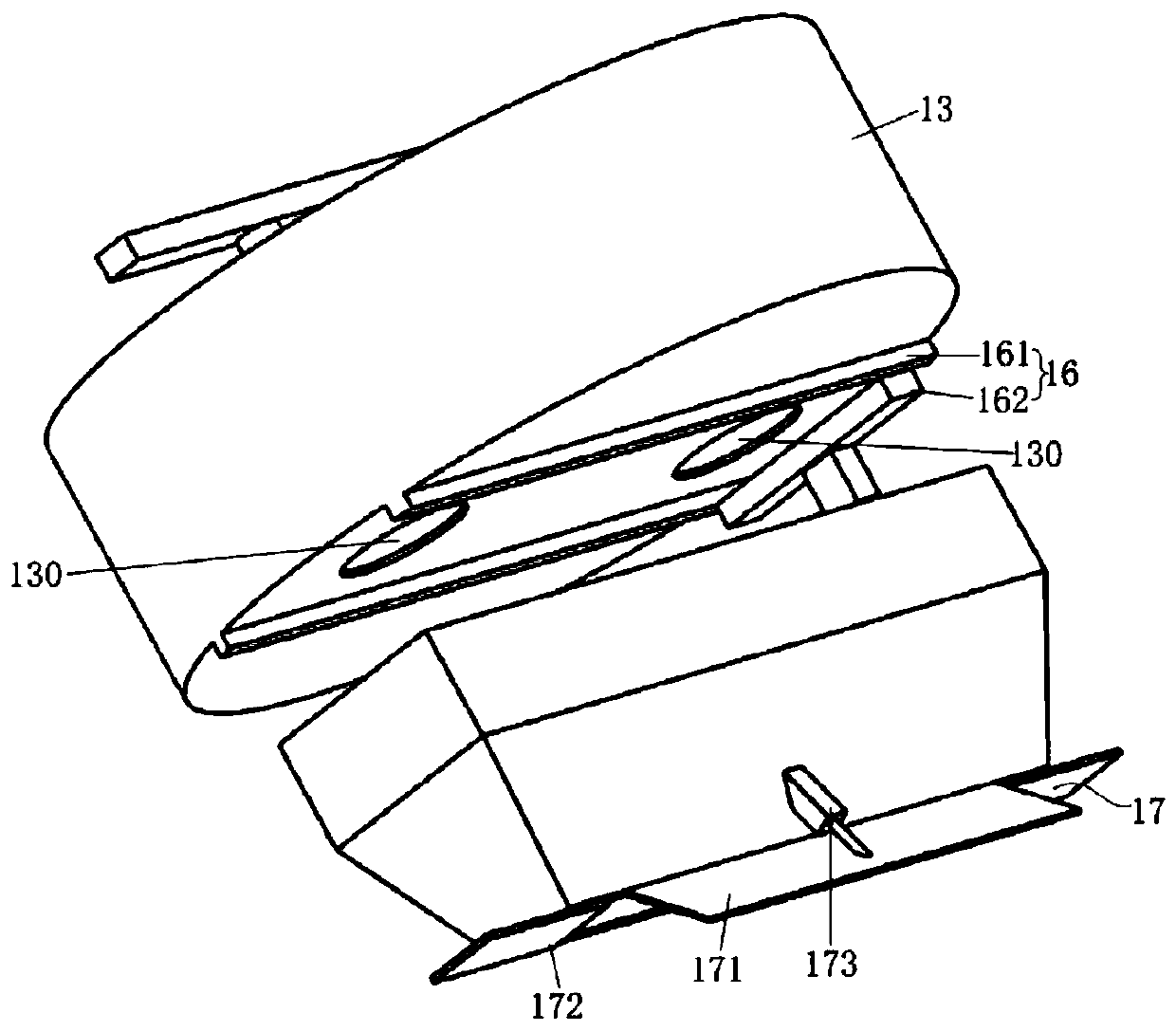

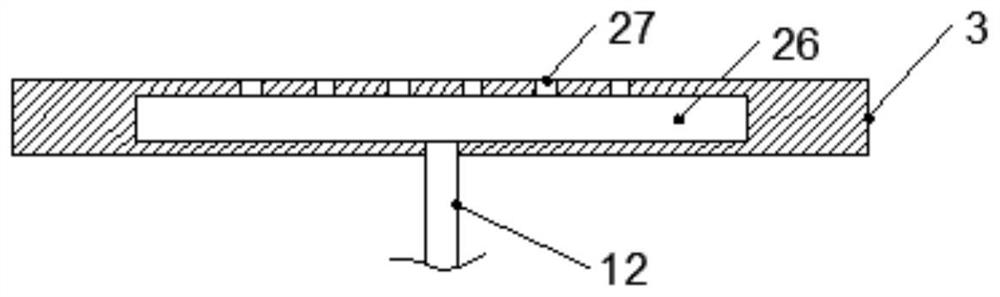

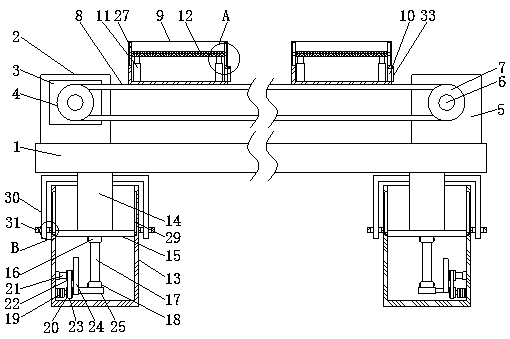

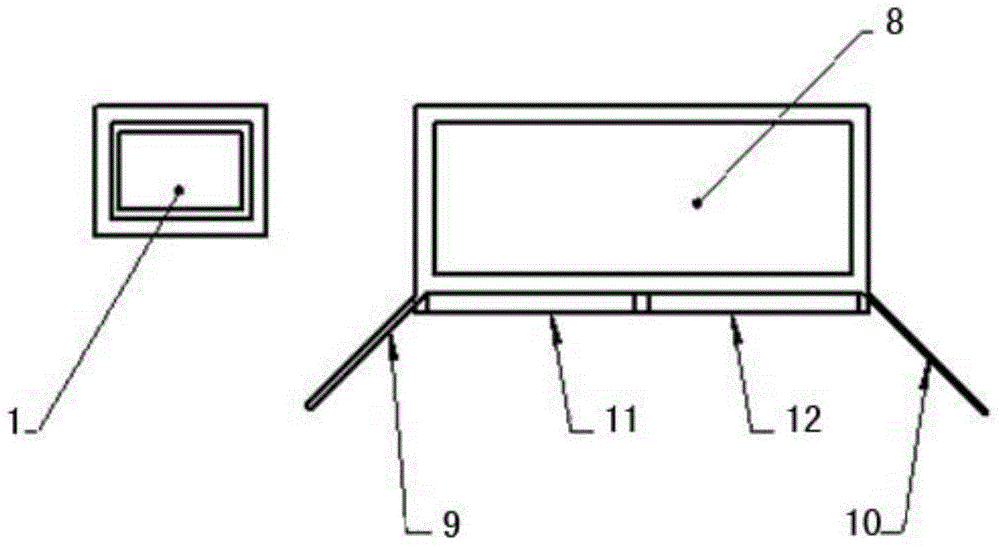

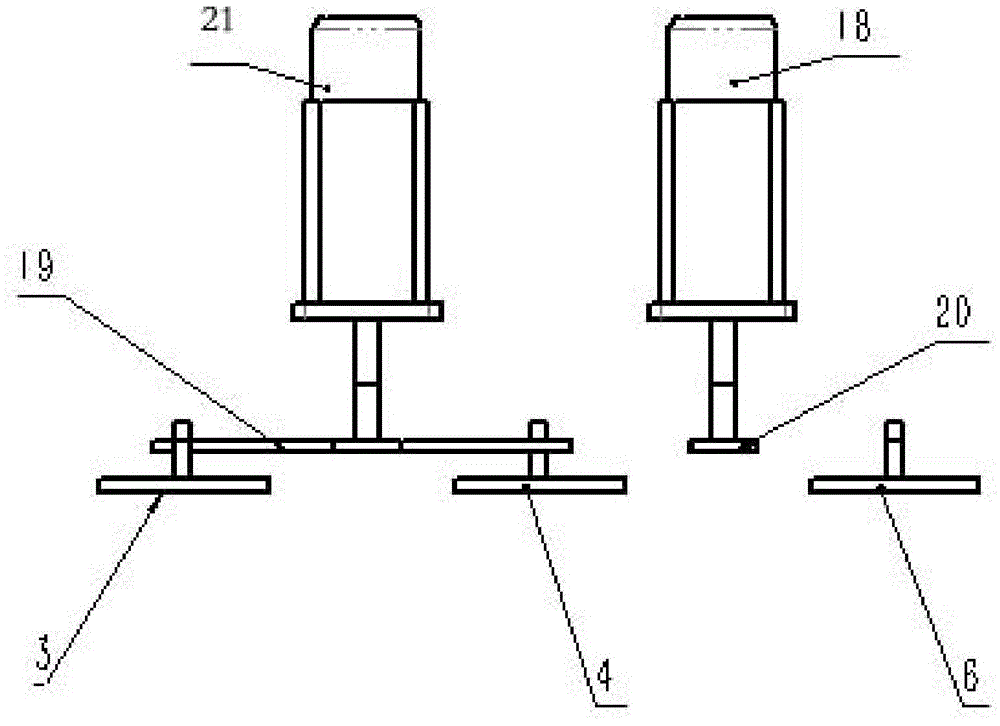

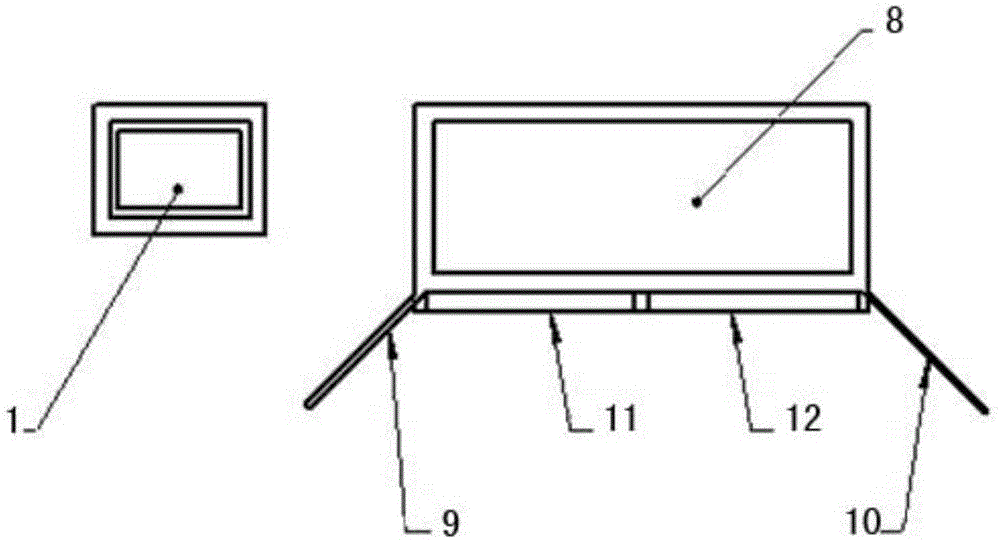

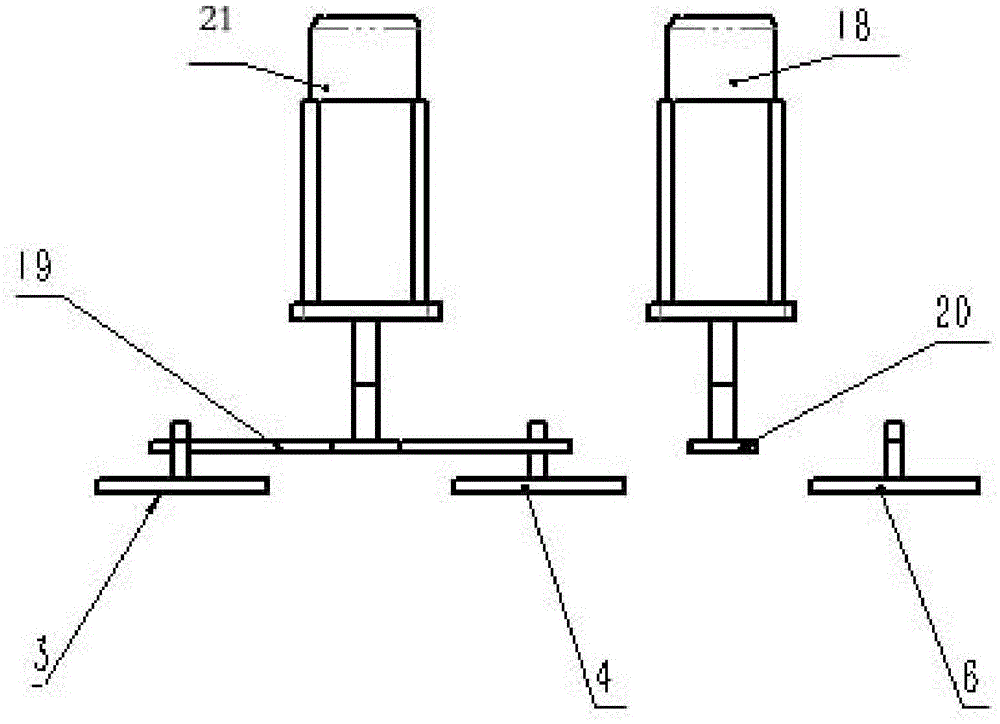

Automatic quartz plate loading system

PendingCN110790008AEasy to moveMeet the needs of feedingConveyor partsClassical mechanicsAutomatic quartz

The invention relates to an automatic quartz plate loading system which comprises a feeding sliding table and a transfer device. The feeding sliding table comprises a magazine base and an air cylindermounted on a bottom plate, a first guide rail mounted on the magazine base, a second guide rail of a first material table mounted on the magazine base, a first slide block mounted on the first guiderail, a magazine mounted on the first slide block and a baffle plate matched with the magazine and the second guide rail to use jointly to form a quartz plate holding cavity. The transfer device comprises a servo motor mounted on the bottom plate, a back swing arm, a front swing arm and a transfer material table, wherein one end of the back swing arm is fixedly connected to an output shaft of theservo motor while the other end of the back swing arm is fixedly connected to a cylinder block of a swing air cylinder, one end of the front swing arm is fixedly connected to the output end of the swing arm air cylinder while the other end of the front swing arm is fixedly connected to a sucking disc, and the transfer material table is mounted on the bottom plate. The automatic quartz plate loading system is simple in structure and convenient to use, can transfer and load quartz plates automatically, and not only improves the work efficiency of an enterprise, but also meets the demand on automatic production of the enterprise.

Owner:北京石晶光电科技股份有限公司

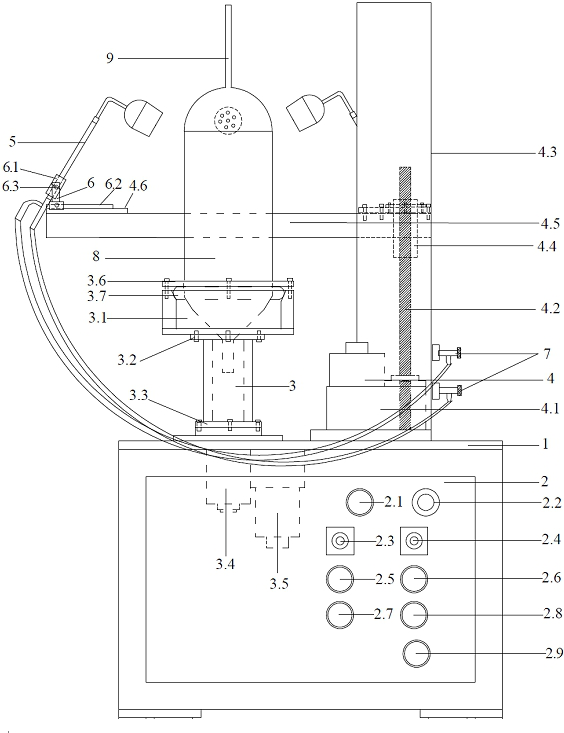

Automatic quartz tube welding device and method

PendingCN112520989AEvenly heatedImprove growth qualityGlass reforming apparatusTemperingAutomatic quartz

The invention discloses an automatic quartz tube welding device and method. The device comprises an operation table, a control panel, an objective table rotating apparatus, an oxyhydrogen welding gunmoving apparatus, oxyhydrogen welding guns, oxyhydrogen welding gun adjusting apparatuses and oxyhydrogen gas valves. The method includes: placing a quartz tube filled with a polycrystalline materialand other auxiliary materials on an objective table; placing a quartz cap at the upper port of the quartz tube and performing aligning; adjusting the concentricity of the quartz tube; adjusting the positions of the oxyhydrogen welding guns according to the diameter of the to-be-welded quartz tube; and performing igniting to adjust the flame size of the oxyhydrogen welding gun, and sintering the joint of the quartz tube and the quartz cap to finish the welding of the two. The method has the following advantages that: the flame of each oxyhydrogen welding gun is independently controlled, and therisk of welding failure caused by single-gun tempering is avoided; the welding process is simple in operation and high in efficiency, the three welding guns are used for sintering at the same time, the quartz tube is heated more evenly by combining rotation, the welding quality is better than that of manual operation, the problem that stress tube cracking is prone to occurring in the manual operation is solved, and the personal safety of operators can be well guaranteed.

Owner:CHINA ELECTRONICS TECH GRP NO 46 RES INST

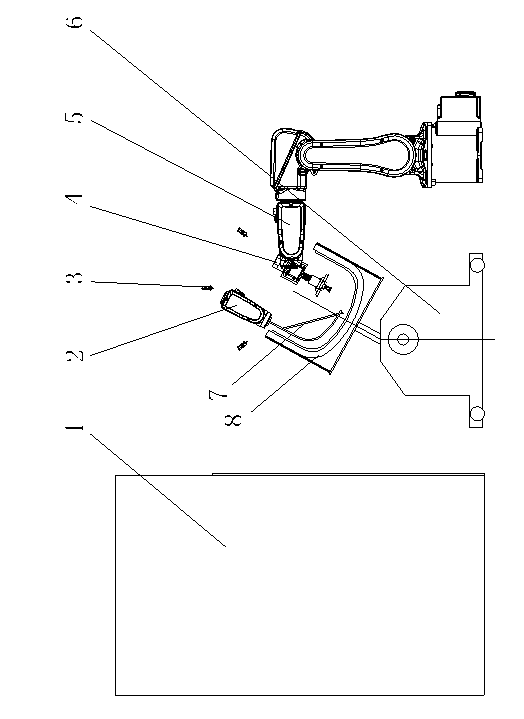

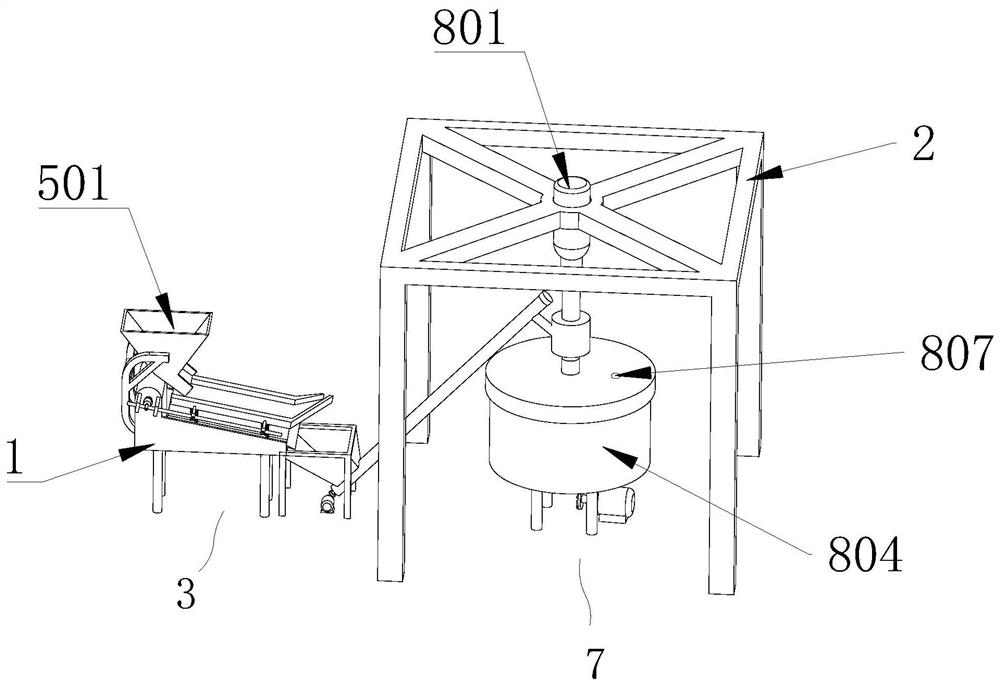

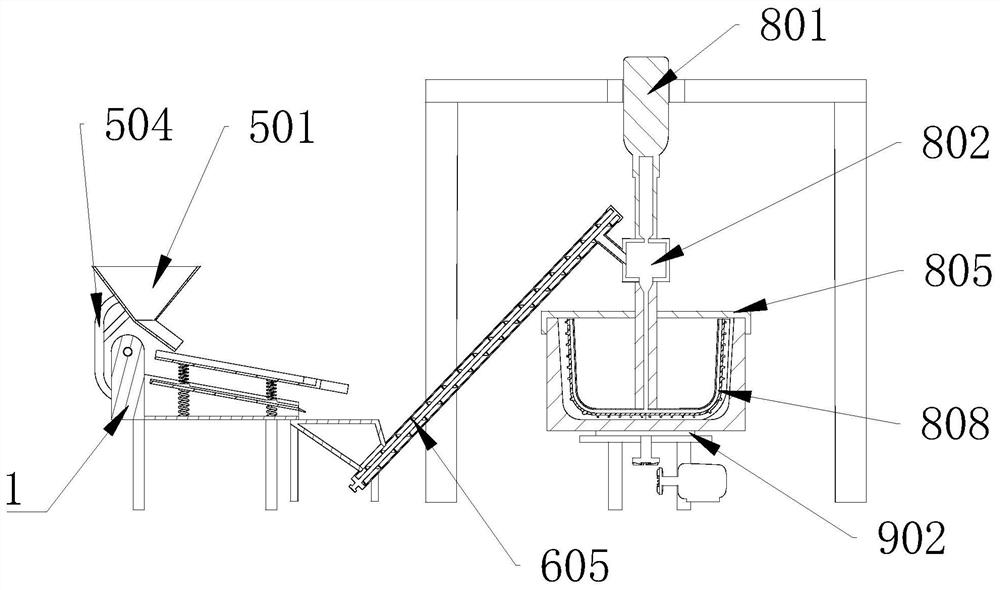

Automatic quartz crucible material feeding molding system

InactiveCN102992595AUniform movementUniform qualityGlass shaping apparatusAutomatic quartzManipulator

The present invention discloses an automatic quartz crucible material feeding molding system, which comprises a rotation crucible melting furnace, a quartz crucible melting chamber, a laser type position calculation photoelectric tube, an optical positioning camera, a pneumatic material loading machine, a material feeding mechanical arm, a quartz crucible molding mechanical arm and a molding rod, wherein both sides of the rotation crucible melting furnace are respectively provided with the quartz crucible melting chamber and the material feeding mechanical arm, the material feeding mechanical arm is provided with the pneumatic material loading machine, the laser type position calculation photoelectric tube and the optical positioning camera are arranged above the rotation crucible melting furnace, a quartz crucible is filled inside the rotation crucible melting furnace, and the molding rod is arranged inside the quartz crucible, and is connected with the quartz crucible molding mechanical arm. With the present invention, quartz crucible molding quality can be increased. In addition, compared to the conventional quartz crucible manufacturing process, the automatic quartz crucible material feeding molding system of the present invention has the following advantages that: product quality can be effectively improved, labor can be saved, and mass of the fed material is precise.

Owner:江苏华尔石英材料科技有限公司

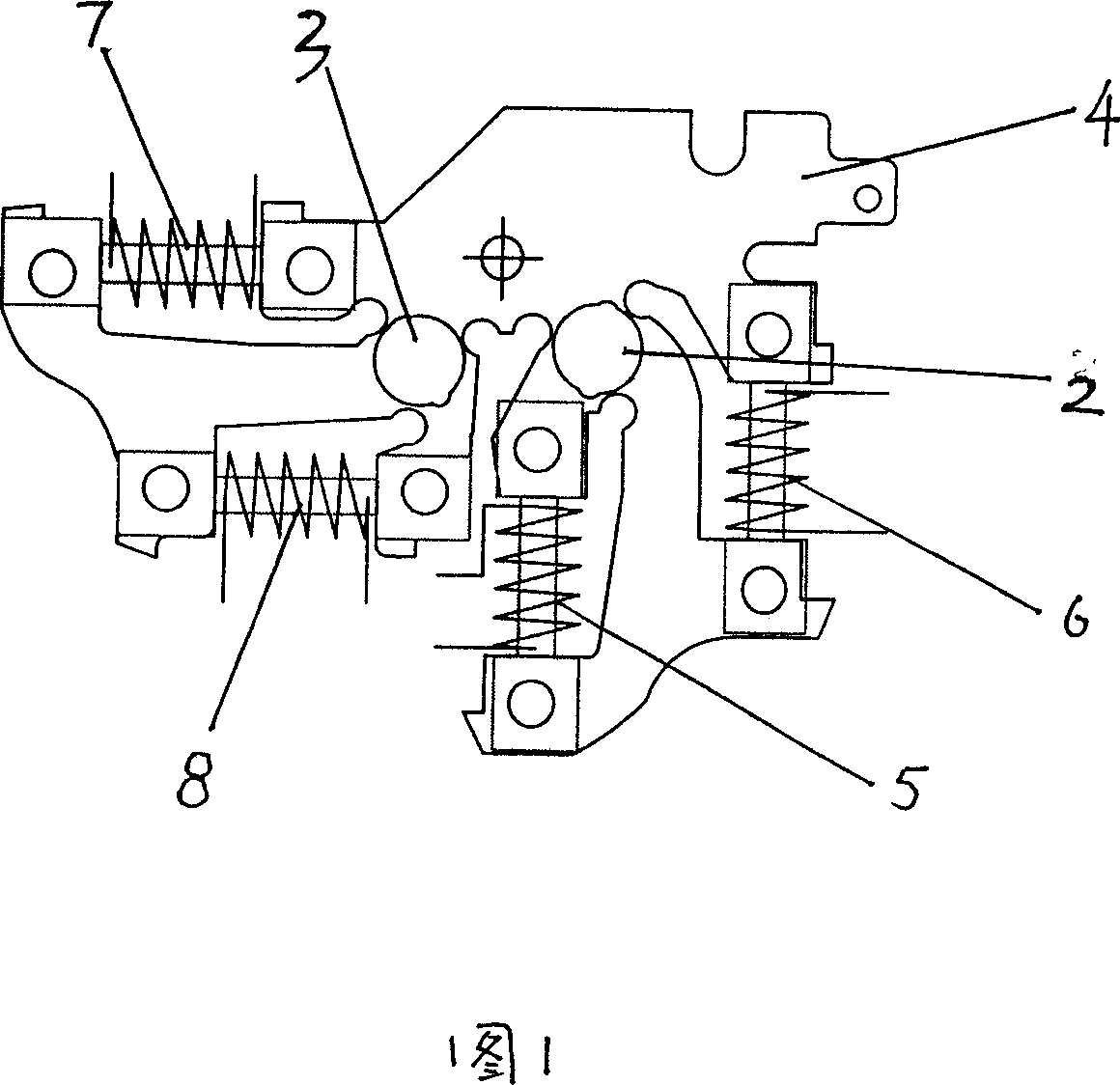

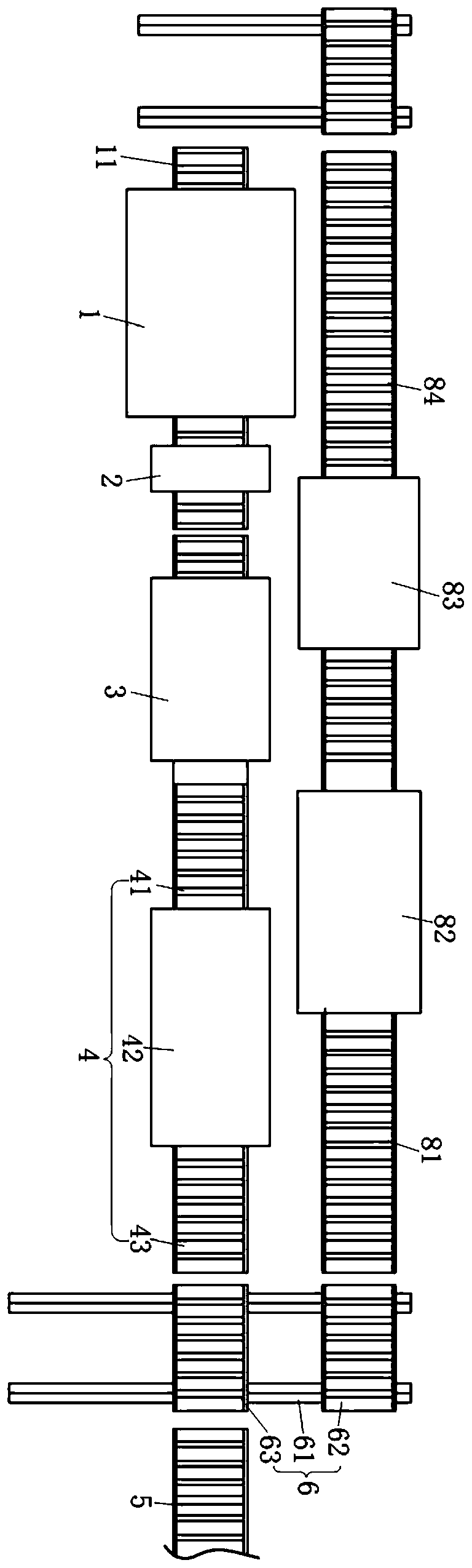

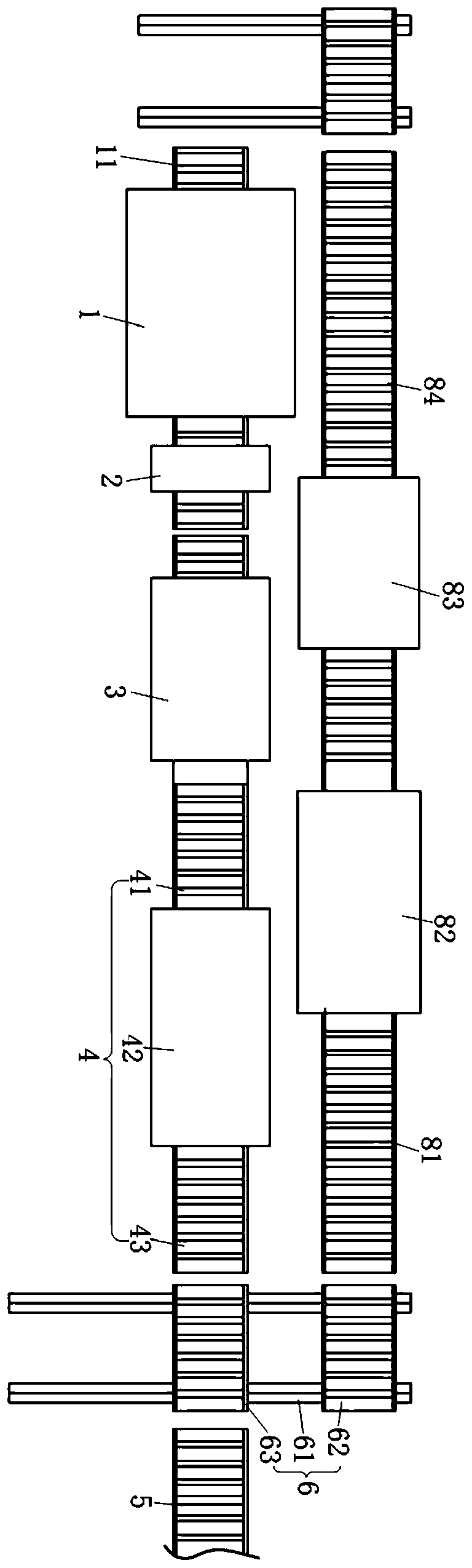

Automatic quartz clock stepping motor

InactiveCN1992485AQuick zeroStandard Time Quick RecoveryElectric windingDynamo-electric machinesAutomatic quartzStepper

The invention relates to an automatic quartz crystal clock stepper motor, belonging to the timing device area, particularly in relation to the stepper motor used on a quartz crystal clock, and it comprises the rotor, the stator slice and the driven coil, and on the stator slice equipped two or more rotors, on the stator slice equipped the driven coil, and two or more rotors installed in a shared stator slice, and each rotor has the driven coil, and the rotors respectively matching the stator slice, and the driving coil is installed and fixed on the stator slice through the standing. The invention has novel structure, cleverly conceived, and the stepper motor directly and separately controls hour hand and minute hand, the machine core with simple structure and with only two stepper motors, no other drive machine in the machine core, it can achieve normal walking and rapid execution of the various functions.

Owner:广州市番禺大石军科电子厂

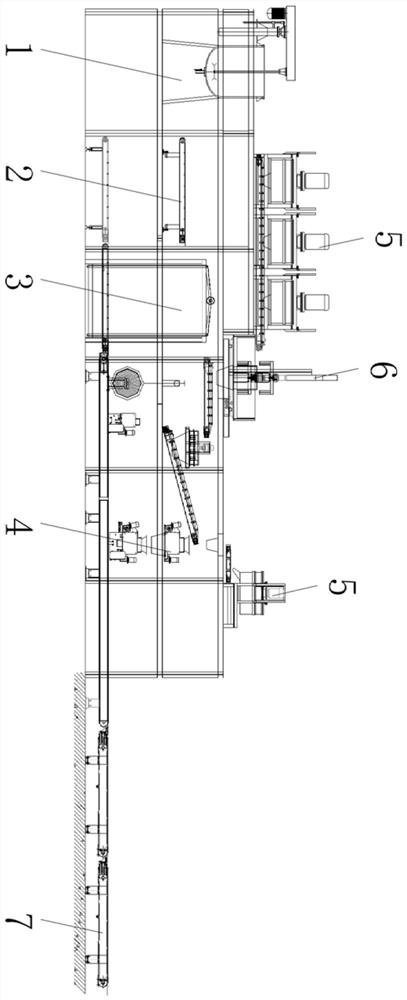

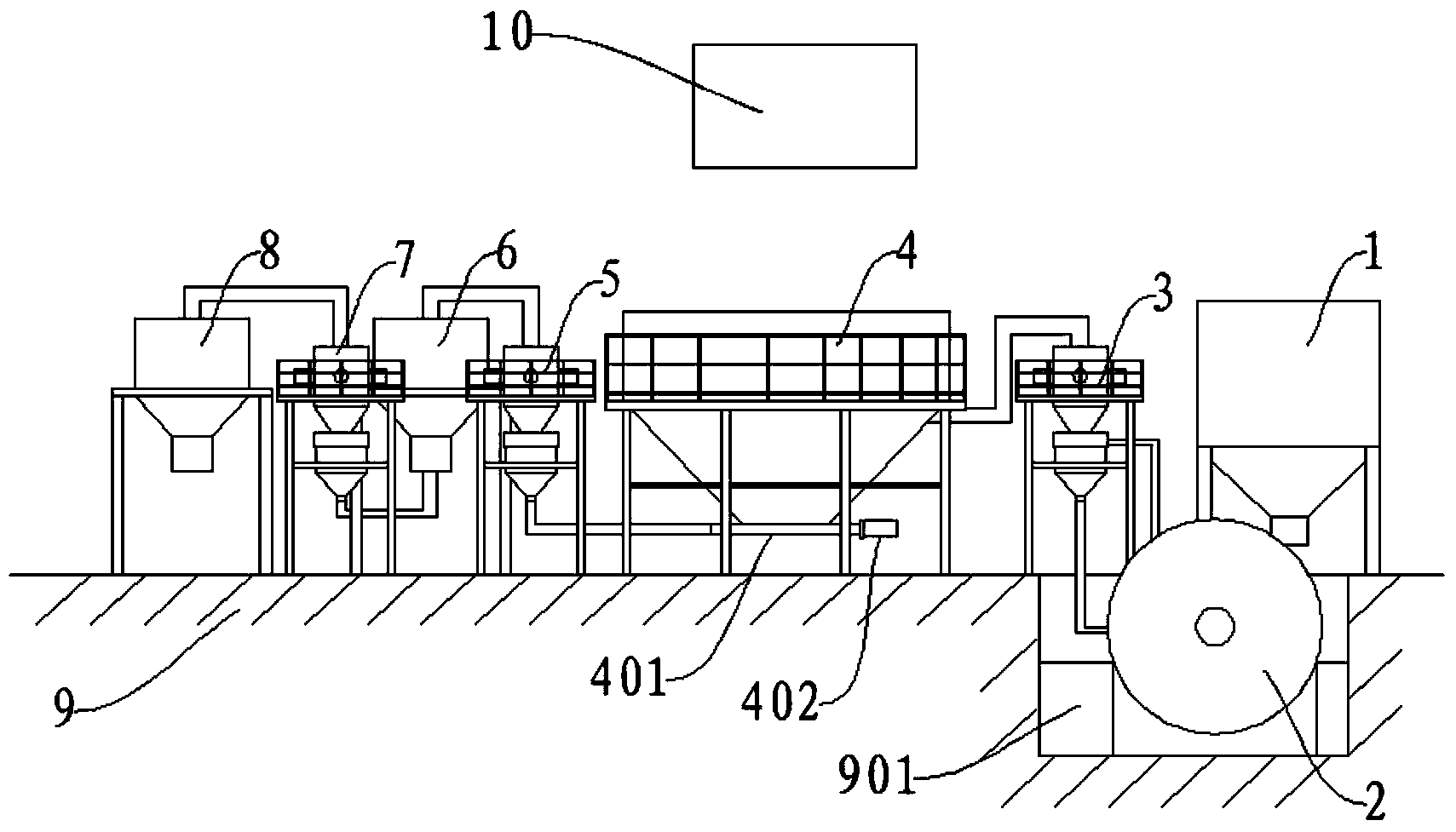

Automatic quartz stone plate production line

ActiveCN109760193AEvenly distributedRealize automatic clothCeramic shaping plantsFeeding arrangmentsProduction lineAutomatic quartz

The invention discloses an automatic quartz stone plate production line. The production line comprises a mixing and material distribution device, an automatic paper spreading device, a vacuum air compressor, a drying device and a surface treatment device which are sequentially arranged, wherein the mixing and material distribution device comprises a first conveying line used for conveying formingmolds, a material distribution bin arranged right above the first conveying line and a mixing and stirring mechanism arranged right above the material distribution bin, the mixing and stirring mechanism is used for mixing and uniformly stirring a raw material, the lower end of the mixing and stirring mechanism is provided with discharging ports corresponding to the material distribution bin, the material distribution bin is of a long-strip-shaped structure matched with the width of the first conveying line, a horizontal push plate is installed in the material distribution bin, the horizontal push plate is driven to move up and down through a lifting driving mechanism, the horizontal push plate is driven by a horizontal driving mechanism to horizontally reciprocate along the length direction of the material distribution bin, and the lower end of the material distribution bin is provided with a long-strip-shaped lower opening and a switch mechanism used for opening and closing the loweropening. According to the automatic quartz stone plate production line, automatic material distribution of plates can be realized, and the material distribution efficiency is improved.

Owner:YUNFU OPALY NEW MATERIALS TECH CO LTD

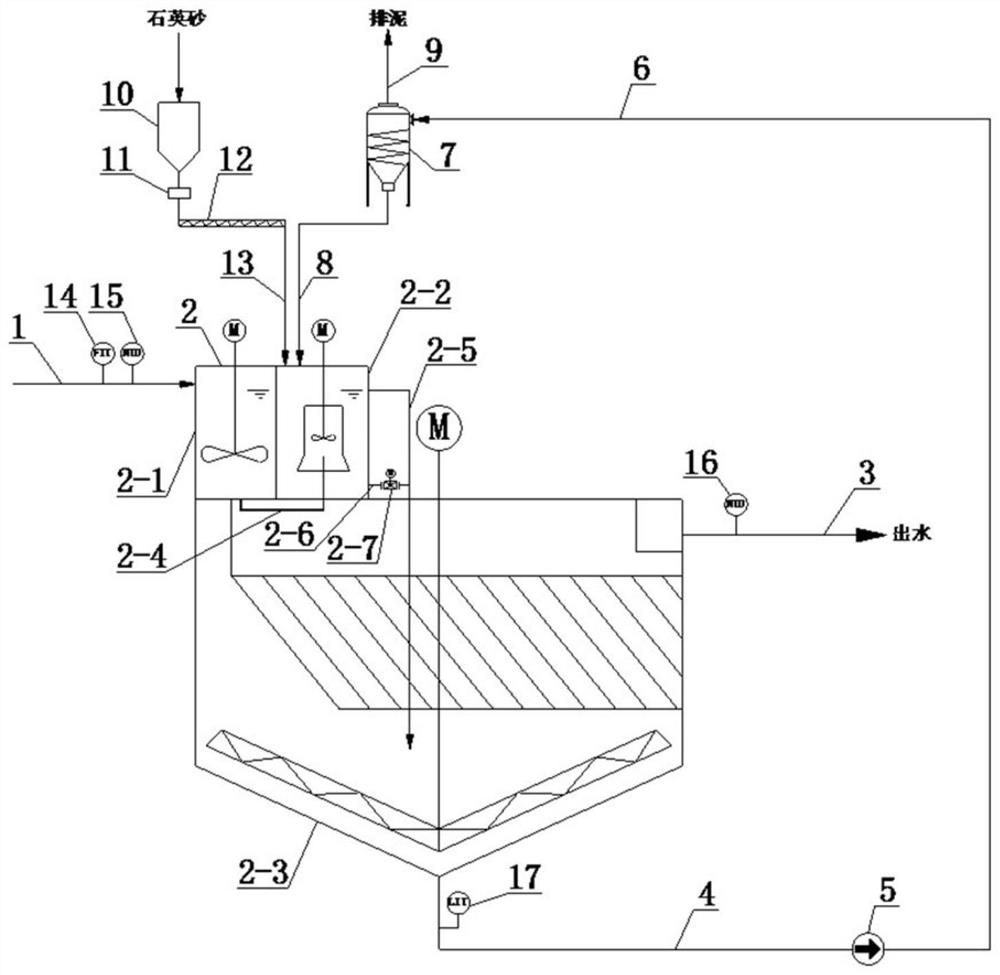

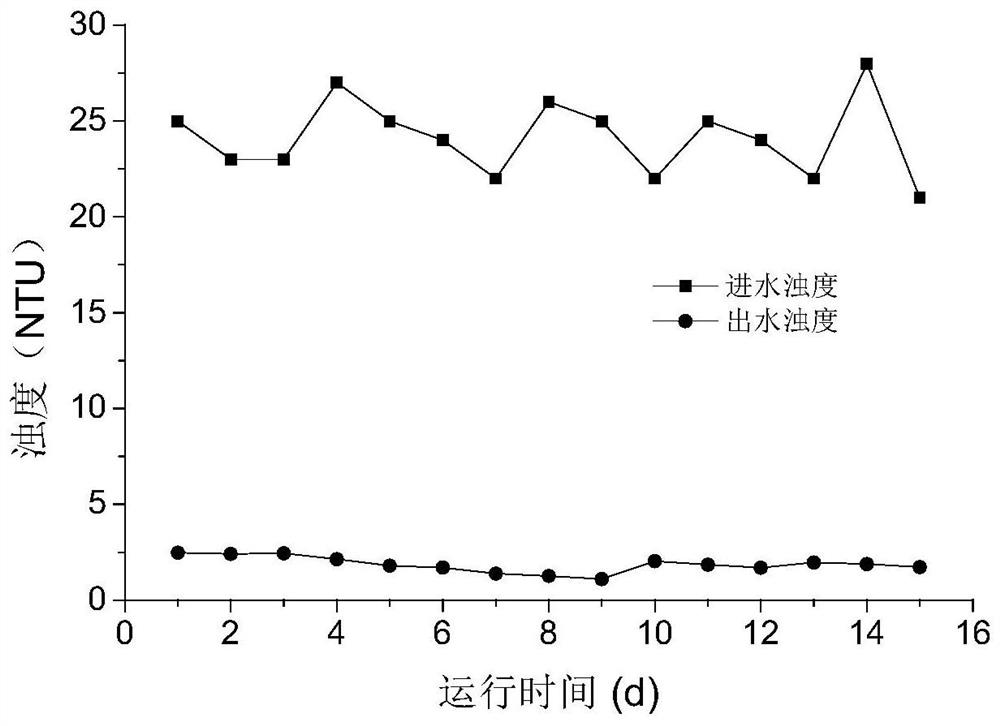

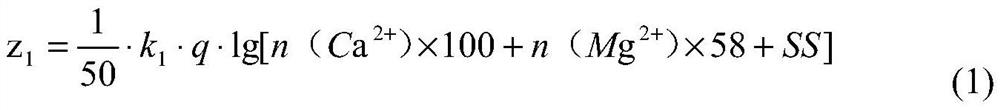

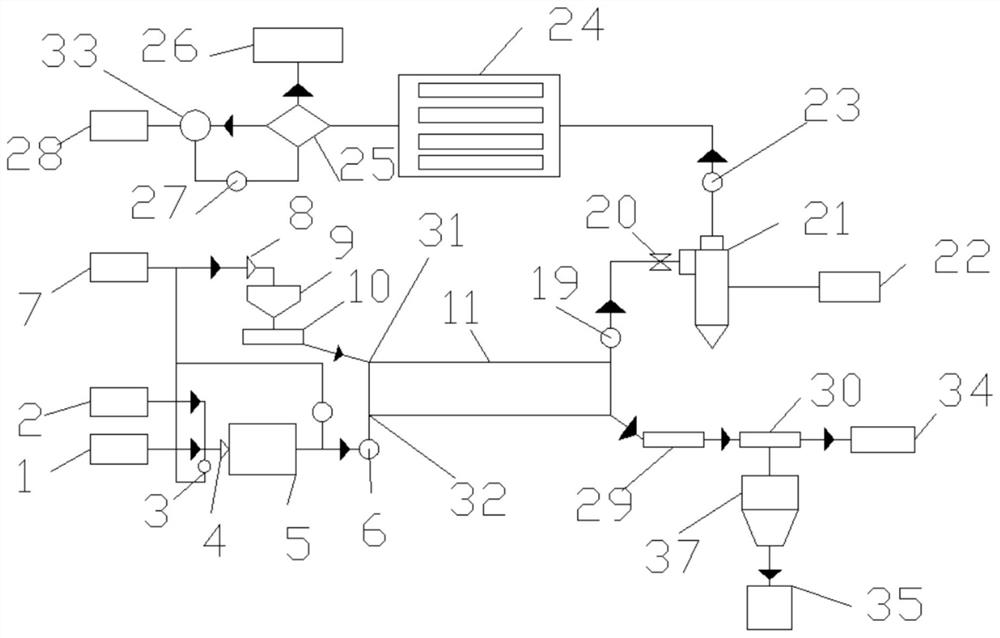

Quartz sand type dense medium efficient coagulation and clarification system and method

PendingCN113880213AReduce supplementationDosingGeneral water supply conservationSettling tanks feed/dischargeSludgePhysical chemistry

The invention discloses a quartz sand type dense medium efficient coagulation and clarification system and method. The system comprises an efficient coagulation and clarification unit and an automatic quartz sand adding unit, wherein the efficient coagulation and clarification unit comprises a coagulation tank, a flocculation tank and a clarification tank; a quartz sand rotational-flow recovery unit comprises a quartz sand rotational-flow recoverer, a quartz sand return pipe and a residual sludge discharge pipe; the coagulating tank is connected with the clarification tank through the flocculation tank; a top outlet of the clarification tank is provided with a water outlet pipe; a clarification tank sludge discharge pipe is arranged at the bottom of the clarification tank; the clarification tank sludge discharge pipe is connected with an inlet of the quartz sand rotational-flow recoverer through a sludge reflux pump; a top outlet of the quartz sand rotational-flow recoverer is connected with a residual sludge discharge pipe; a bottom outlet of the quartz sand rotational-flow recoverer is connected with the quartz sand return pipe; the quartz sand return pipe is connected with the flocculation tank; and the automatic quartz sand adding unit is connected with the flocculation tank. According to the invention, sludge in the clarification tank can be discharged in time, effluent quality is ensured, proper backflow quartz sand concentration can be controlled, and coagulation and clarification effect is enhanced.

Owner:XIAN TPRI WATER & ENVIRONMENTAL PROTECTION

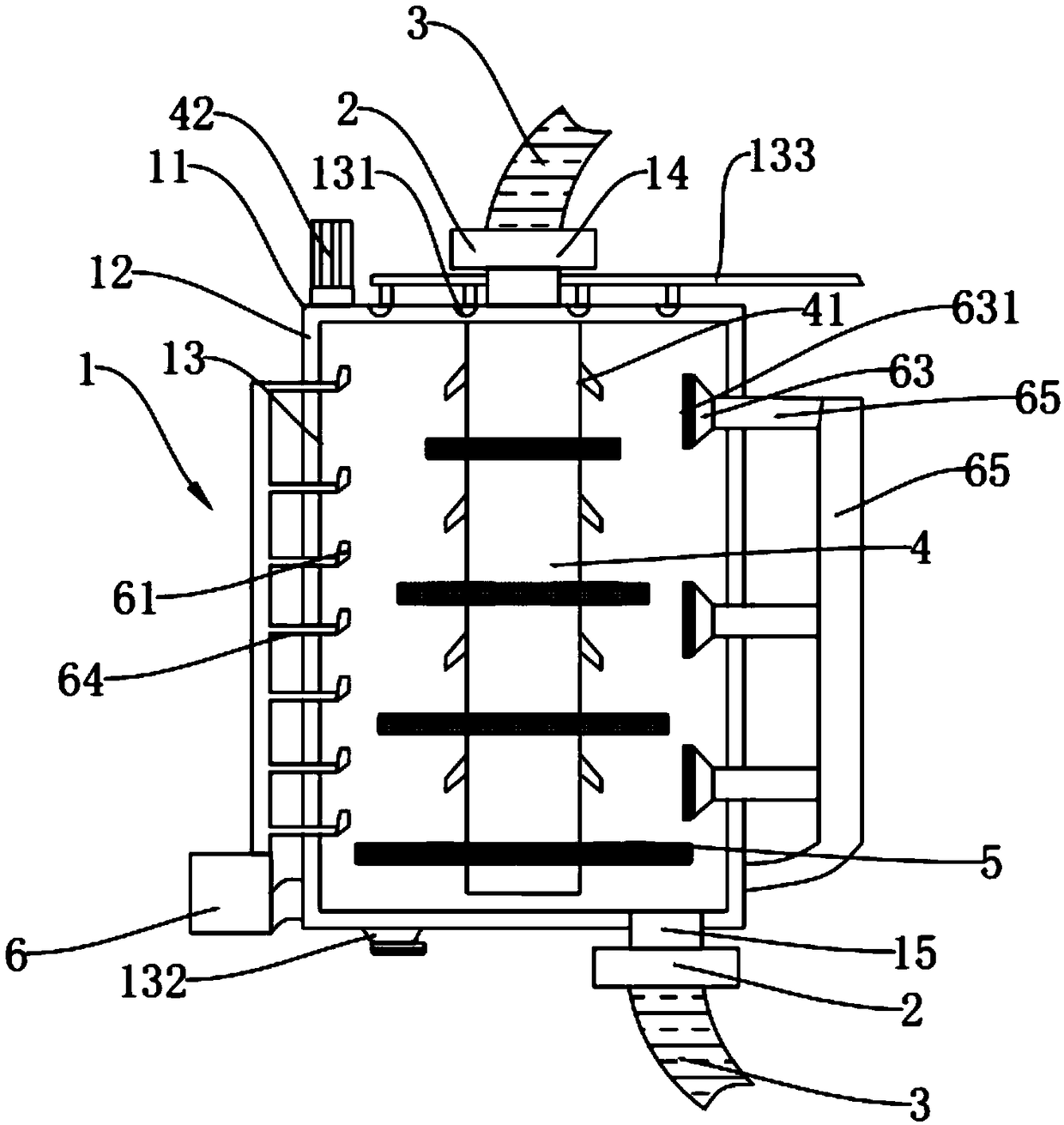

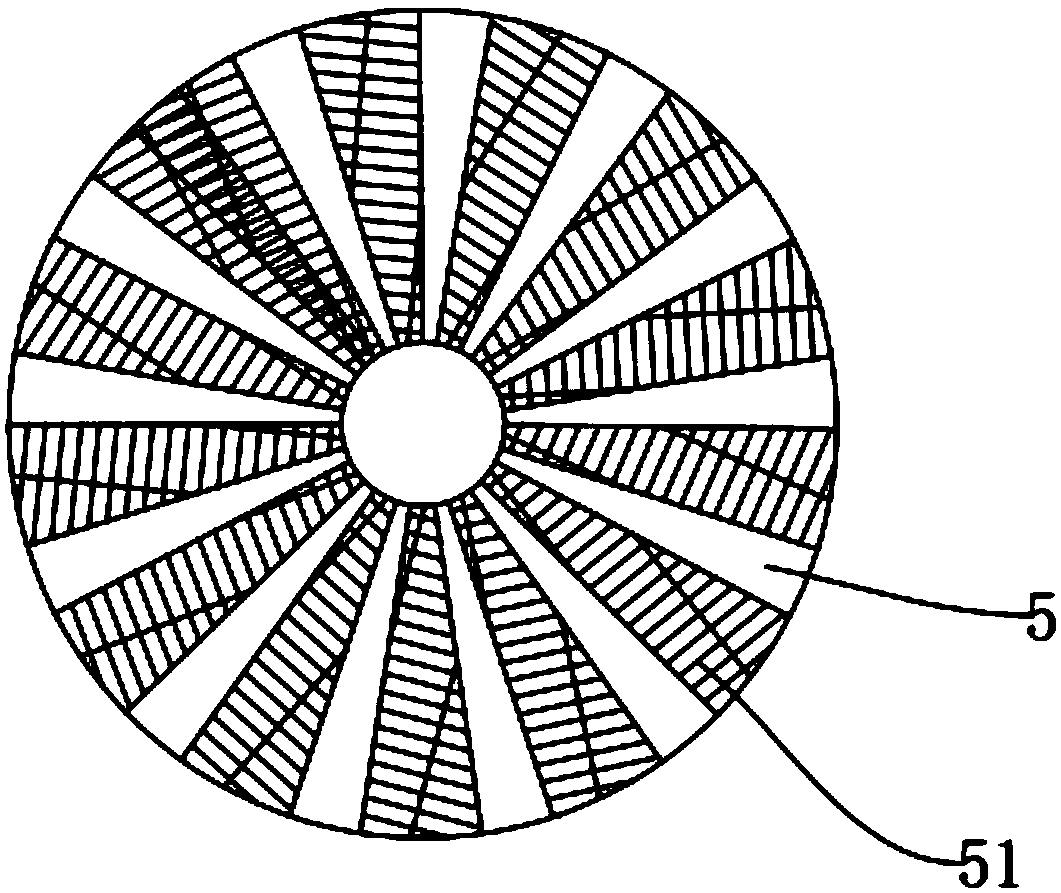

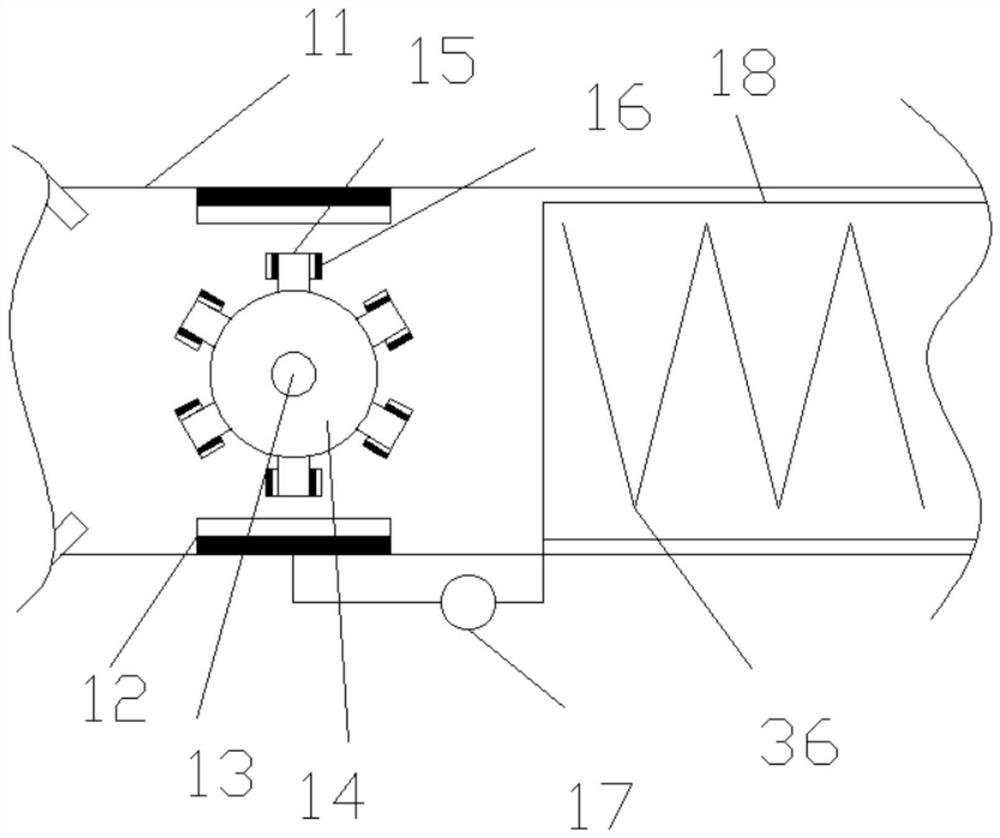

Environment-friendly type automatic quartz sand drying device and quartz sand drying method

PendingCN109357518AImprove drying efficiencyHigh degree of automationSand dryingDrying solid materials with heatCircular discAutomatic quartz

The invention discloses an environment-friendly type automatic quartz sand drying device and a quartz sand drying method. The environment-friendly type automatic quartz sand drying device comprises adrying chamber; a feeding inlet is formed in the top of the drying chamber, a discharging outlet is formed in the bottom of the drying chamber, and the feeding inlet and the discharging outlet are both provided with dedusting cavities and material chutes connected with the dedusting cavities; the drying chamber is internally provided with a feeding barrel connected with the feeding inlet, and a plurality of distribution discs arranged with the feeding barrel as the center; the distribution discs are sequentially arranged in the vertical direction according to the diameter from small to large;and the portions, corresponding to the space formed by the adjacent distribution discs, of the inner wall of the drying chamber are provided with a plurality of air blowing ports and the like. The environment-friendly type automatic quartz sand drying device has the unique layered air blowing drying, closed dust prevention, washing cleaning and other designs, the drying efficiency is high, the automation degree is high, environment pollution is small, practicability is high, and the environment-friendly type automatic quartz sand drying device is suitable for application and popularization.

Owner:徐州赛诺石英有限公司

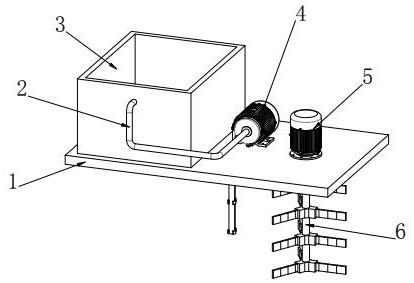

Accurate batching and stirring mechanism for full-automatic production of quartz plates

PendingCN114797564AWill not stir the operation is not thoroughRotary stirring mixersTransportation and packagingAutomatic quartzElectric machinery

The invention relates to the technical field of quartz stone plate production, in particular to a precise batching and stirring mechanism for full-automatic quartz plate production, which comprises a bottom plate, one side of the upper surface of the bottom plate is connected with a trough, one side, close to the trough, of the upper surface of the bottom plate is connected with a material pump, and the output end of the material pump is connected with a material pipe. A motor is connected to the other side of the upper surface of the bottom plate, and a rotating shaft is connected to the position, corresponding to the motor, of the lower surface of the bottom plate; through the arrangement of the stirring blades, the hinges and the fixing buckles, the stirring blades are formed by splicing a plurality of stirring blades through mutual connection and limitation of the fixing buckles and the buckles, so that the length of the stirring blades extending out of the folding box can be adjusted according to the number of the stirring blades; a worker can adjust the length of the stirring blade according to the space size of the stirring position, so that the situation that the stirring operation cannot be carried out because the stirring blade is too large is avoided, and the situation that the stirring operation on the stirring position is not thorough because the stirring blade is too small is avoided.

Owner:枣庄市永益新材料科技股份有限公司

Automatic quartz plate production process

InactiveCN112062501AReduce occupancyAvoid safety hazardsFlat articlesAutomatic quartzPhysical chemistry

The invention discloses an automatic quartz plate production process, which comprises the steps of weighing quantitative raw materials including 36.28kg of resin, 135kg of quartz sand, 98.72kg of silica powder, 1.68kg of titanium dioxide, 0.38kg of a coupling agent and 0.38kg of a curing agent through electronic weighing equipment, storing for later use through a storage device, and preparing a compact filling mixture from quartz sand, powder and particles according to a color ratio; fully and uniformly mixing through a stirring pot and a 3M mixing pot, and accurately weighing each component for later use through an automatic weighing device. Through the arrangement of the stirring kettle, the multiple groups of stirring pots and the mixing pot, various different raw materials are efficiently and uniformly mixed at different stages at the same time, so that the uniform mixing effect is improved, the quality and excellent characteristics of the plate are ensured, the time consumed by raw material treatment is shortened, and the production period of the plate is shortened.

Owner:安徽弗仕通实业有限公司

Automatic Quartz Glass Polishing Machine

InactiveCN104029108BReduce torqueSimple structurePolishing machinesGrinding drivesAutomatic controlAutomatic quartz

The invention discloses a full-automatic quartz glass polishing machine which comprises a framework. A main motor and a spindle are arranged on the framework and are connected with each other by a first transmission mechanism, a polishing support plate is mounted at the upper end of the spindle, a base plate is supported on the polishing support plate, a swing shaft is mounted on a side of the framework, a swing arm is fixed to the upper portion of the swing shaft, a plate press device is fixedly connected to a free end of the swing arm, a miniature motor is arranged on the outer side of the upper portion of the plate press device, an output shaft of the miniature motor is connected with an adjusting lead screw by a second transmission mechanism, the adjusting lead screw is arranged at the upper end of the plate press device, and a positioning output shaft at the lower end of the plate press device is inserted into a center hole of the base plate; a gear motor is arranged on a side of the framework and is connected with a mounting jacket of the plate press device by a crank connecting rod mechanism. The full-automatic quartz glass polishing machine has the advantages that the full-automatic quartz glass polishing machine can be reasonably stressed, torsion on the swing shaft during work can be greatly reduced, accordingly, long-term fault-free continuous work can be guaranteed, and the full-automatic quartz glass polishing machine is long in service life; full-automatic control effects can be realized, and the full-automatic quartz glass polishing machine is high in quartz glass sheet replacing speed and work efficiency.

Owner:广东盈锋实业有限公司

Die bonding method for automatic quartz alignment by image recognition

InactiveCN101488552BImprove Die Bonding EfficiencyLow costSemiconductor/solid-state device manufacturingProgramme total factory controlAutomatic quartzDie bonding

Owner:NANCHANG HANGKONG UNIVERSITY

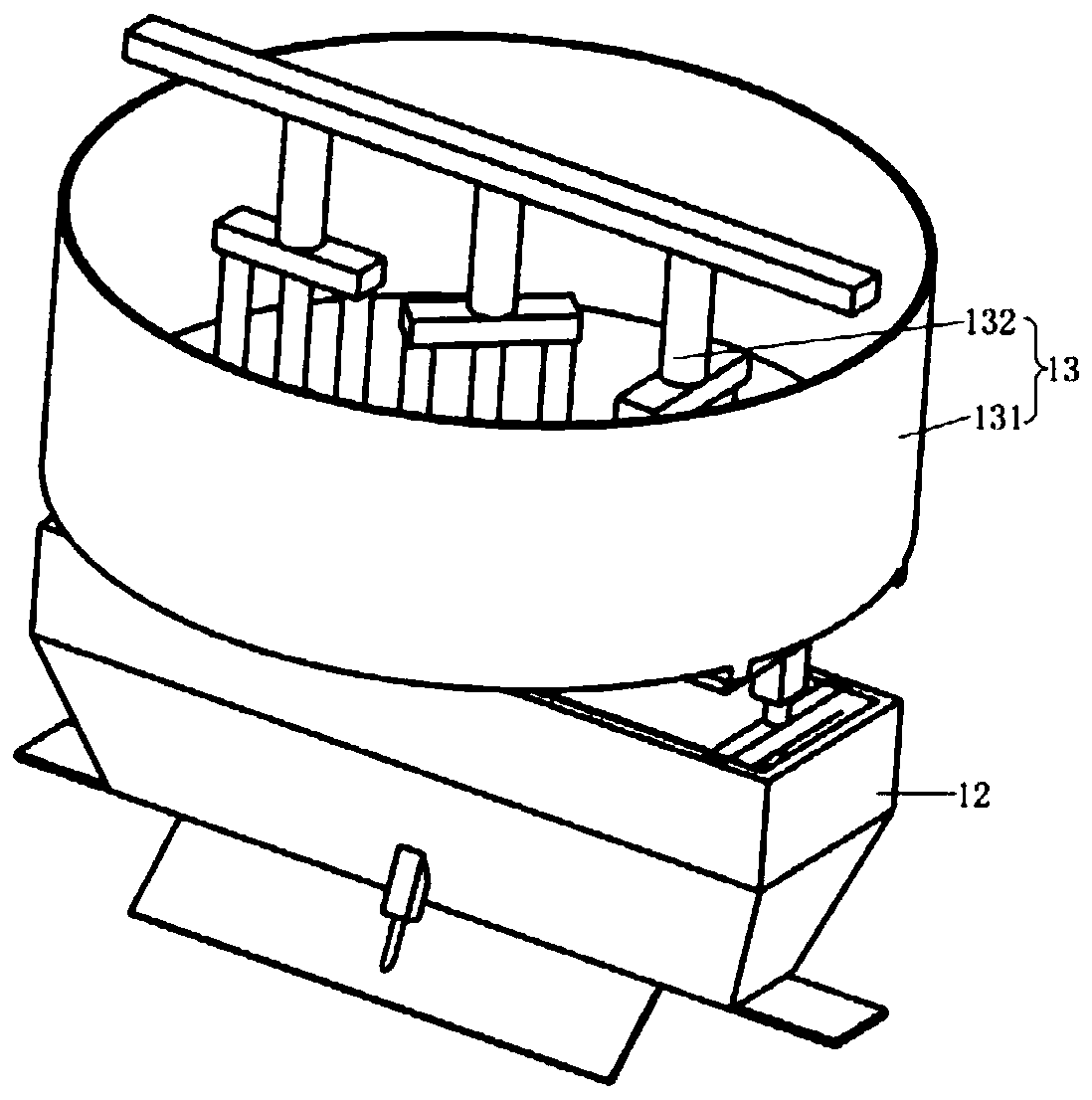

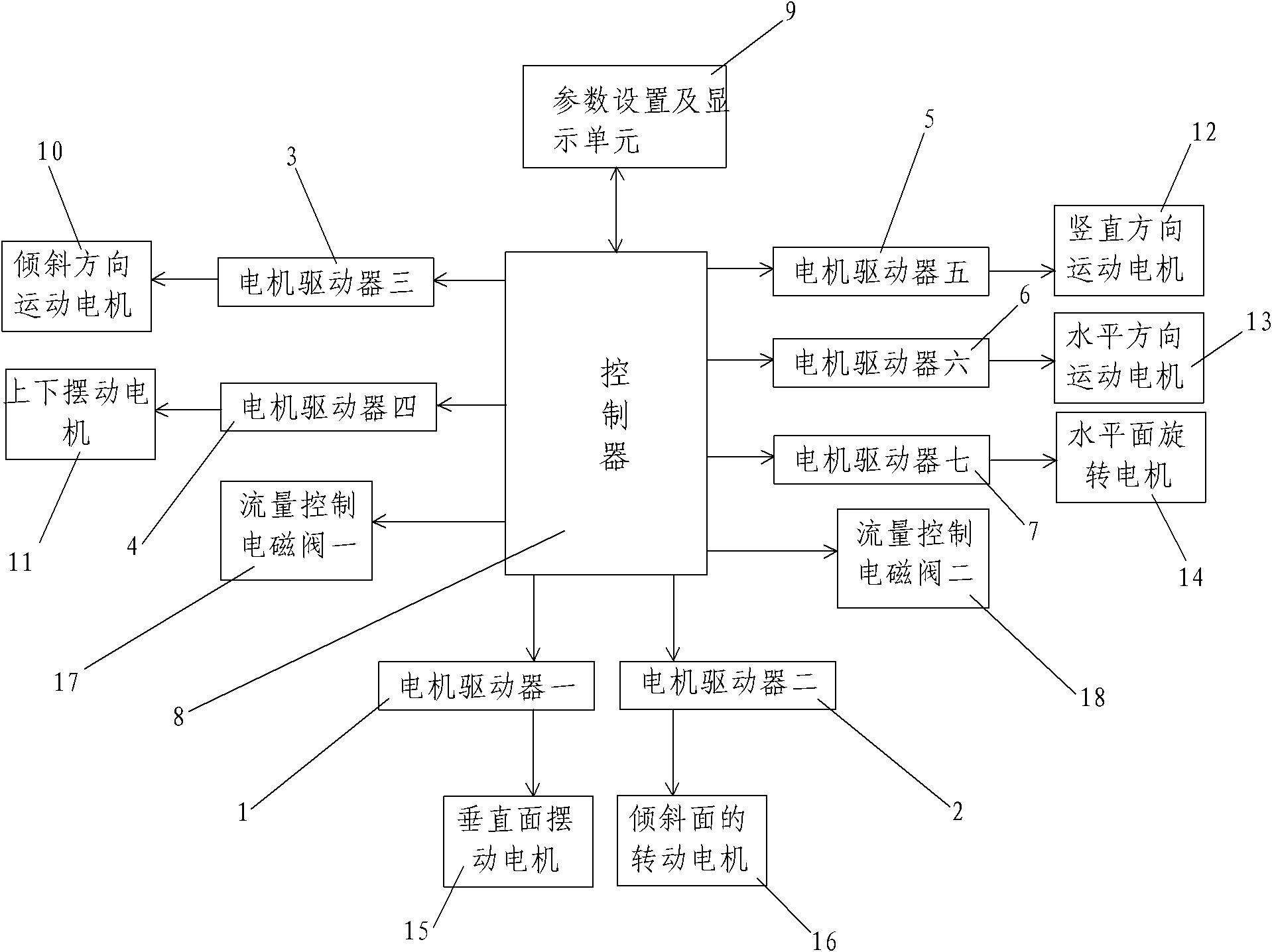

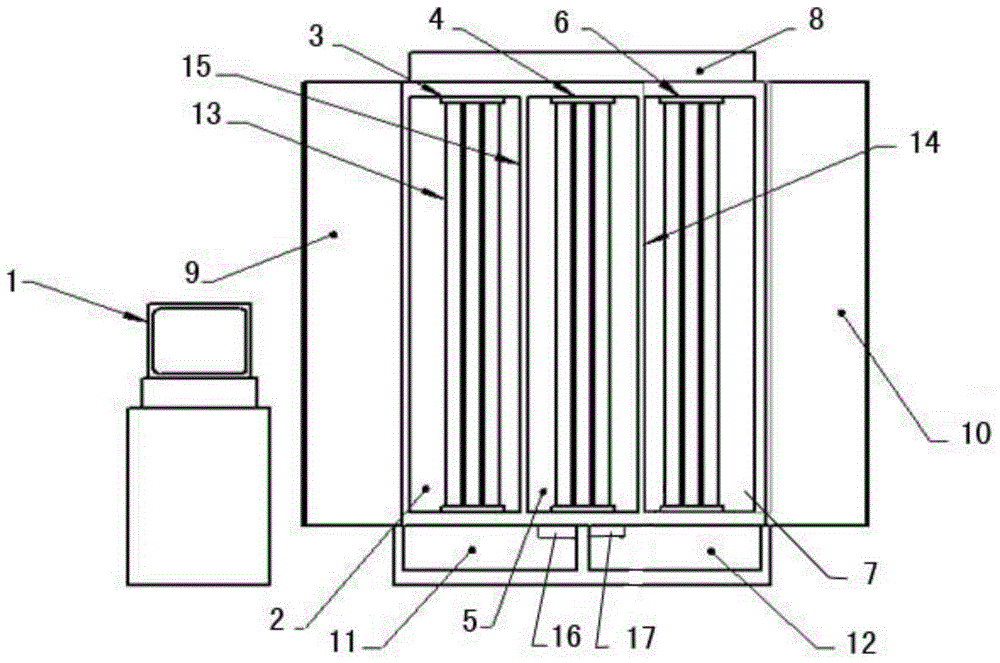

Automatic quartz sand distribution control system

InactiveCN103176422ASimple structureEasy to operateGlass shaping apparatusProgramme control in sequence/logic controllersDistribution controlVertical plane

The invention discloses an automatic quartz sand distribution control system. The automatic quartz sand distribution control system comprises a controller, a parameter setting and display unit connected with the controller, an automatic side wall distribution movement unit, an automatic bottom distribution movement unit and a quartz cone mould movement unit, the automatic side wall distribution movement unit comprises an inclined movement motor, an up-down swing motor and a first flow control valve connected with the controller, the automatic bottom distribution movement unit comprises a vertical movement motor, a horizontal movement motor, a horizontal plane rotating motor and a second flow control valve connected with the controller, and the quartz cone mould movement unit comprises a vertical plane swing motor and an inclined plane rotating motor. The automatic quartz sand distribution control system is simple in structure, convenient to use and operate and low in input cost, production speed and processing technological level are increased, and complicated labor intensity is relieved.

Owner:陕西银星科技有限公司

Drying device of waste quartz sand filter material regeneration processor

InactiveCN112268428AFully automatedFull dehumidificationDrying gas arrangementsDrying chambers/containersAutomatic quartzEnvironmental engineering

The invention discloses a drying device of a waste quartz sand filter material regeneration processor. The drying device comprises an air tank and a natural gas tank, and is characterized in that theright sides of the air tank and the natural gas tank are electrically connected with an exhaust fan; an automatic quartz sand drying device is arranged on the right side of the exhaust fan; the automatic quartz sand drying device comprises an air inlet adjusting valve fixedly mounted on the right side of the exhaust fan; a gas smoke furnace is fixedly mounted on the right side of the air inlet adjusting valve; a first high-temperature measuring meter is arranged on the right side of the gas smoke furnace; the right side of the first high-temperature measuring meter is connected with an automatic quartz sand dryer through a pipe; a wet quartz sand storage box is fixedly mounted above the natural gas tank; a feed adjusting valve is arranged on the right side of the wet quartz sand storage box; and a quartz sand buffer bin is fixedly mounted below the feed adjusting valve. The drying device has the characteristics of quick and automatic drying, improvement of the quartz sand drying efficiency and reduction of the labor force.

Owner:JIANGSU JINENGDA ENVIRONMENTAL ENERGY SCI & TECH

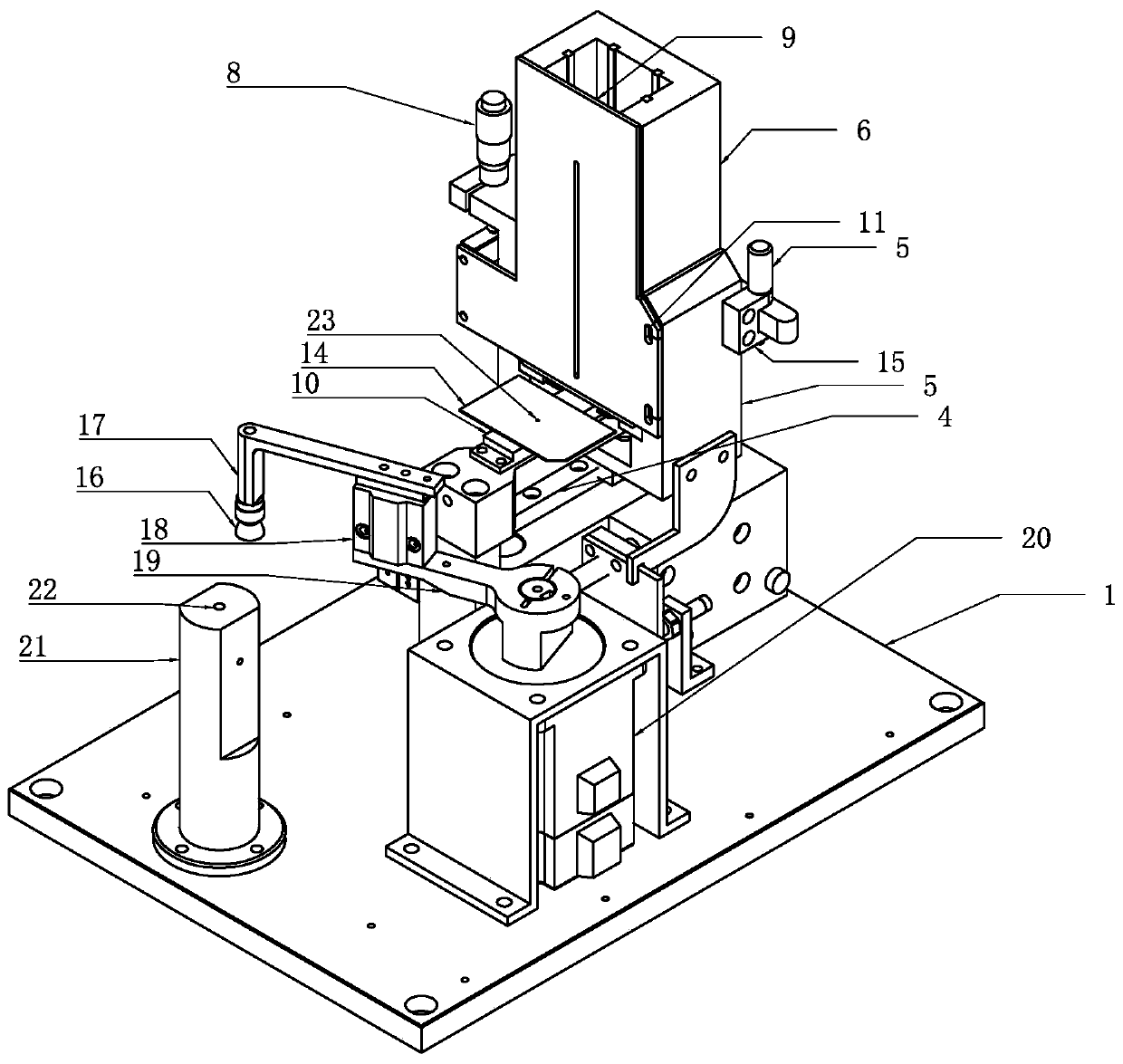

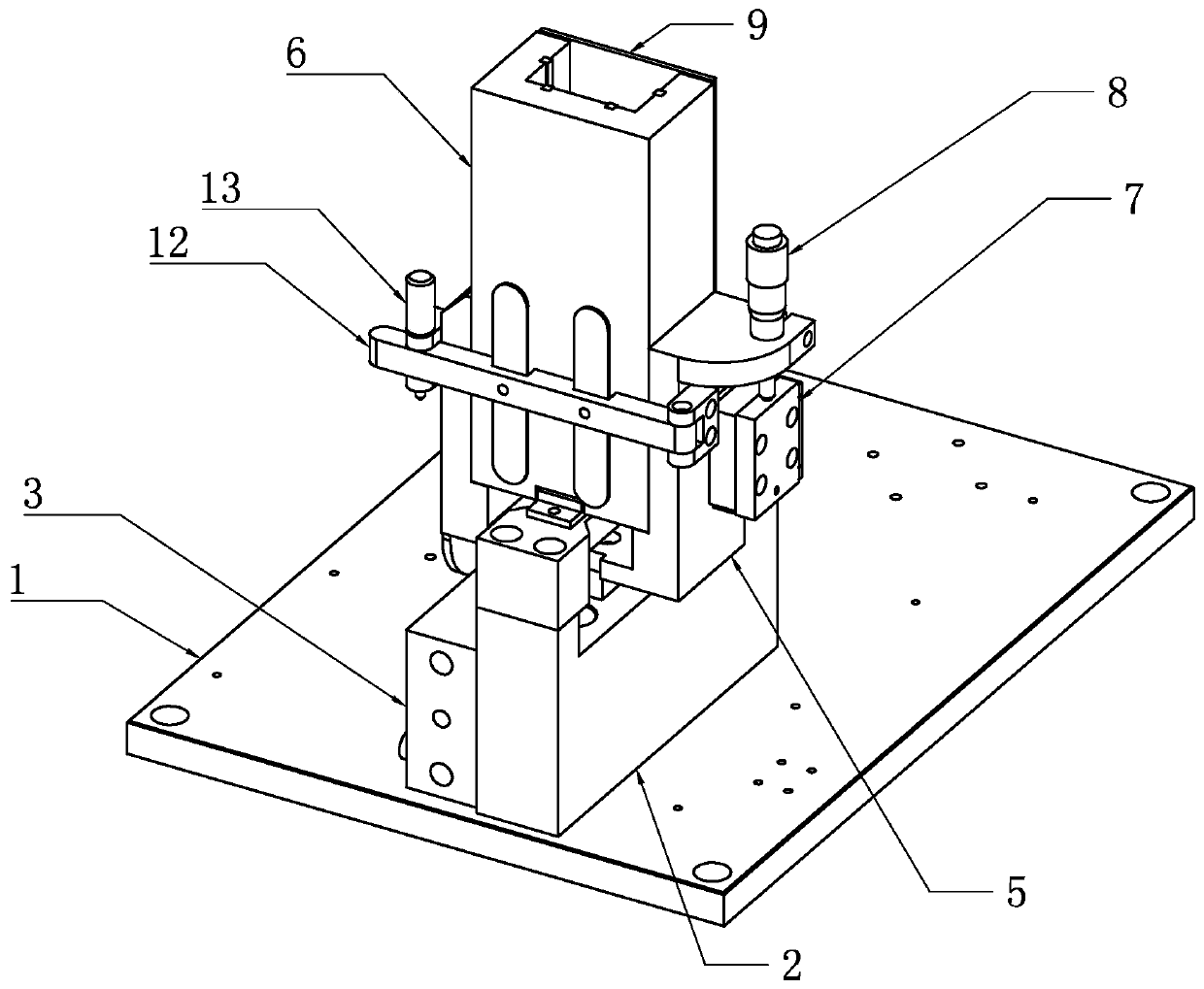

Automatic quartz ring lettering device

ActiveCN113305442APrecise positioningEasy positioningWelding/cutting auxillary devicesAuxillary welding devicesAutomatic quartzEngineering

The invention discloses an automatic quartz ring lettering device, and aims to overcome the defect that the positioning effect is unsatisfactory during quartz ring lettering. The automatic quartz ring lettering device comprises a device body and a laser lettering assembly installed on the device body, and is characterized in that a centering mechanism and a carrying mechanism are installed on the device body; the centering mechanism comprises a centering push block and a driving assembly used for driving the centering push block to move, and a V-shaped centering groove is formed in the front portion of the centering push block; the carrying mechanism comprises a moving block and a power unit used for driving the moving block to move, and a rotating disc capable of rotating is installed on the moving block; and a quartz ring is arranged on the rotating disc, the centering push block can move to the position above the rotating disc, the outer wall of the quartz ring is attached to the side wall of the centering groove for positioning so that the circle center of the quartz ring can coincide with the rotation center of the rotating disc, and the power unit drives the moving block to move so that the quartz ring can move to the position below the laser lettering assembly. The automatic quartz ring lettering device has a good quartz ring positioning effect, the lettering position is accurate and reliable, and the product lettering rejection rate is greatly reduced.

Owner:HANGZHOU DAHE THERMO MAGNETICS CO LTD

Quartz Stone Plate Automatic Production Line

ActiveCN109760193BEvenly distributedRealize automatic clothCeramic shaping plantsFeeding arrangmentsProduction lineAutomatic quartz

Owner:YUNFU OPALY NEW MATERIALS TECH CO LTD

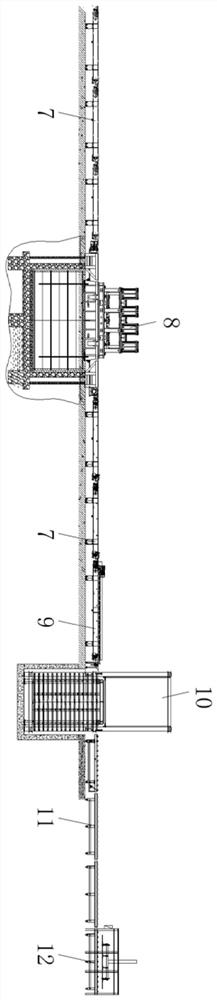

Full-automatic quartz sand production line

The invention discloses a full-automatic quartz sand production line. The full-automatic quartz sand production line comprises an assembling floor; the assembling floor is sequentially provided with a storage silo, a multifunctional airflow classifier I, a pulse dust catcher I, a multifunctional airflow classifier II, a pulse dust catcher II, a multifunctional airflow classifier III and a pulse dust catcher III; the assembling floor between the storage silo and the multifunctional airflow classifier I is provided with a pit; a ball mill is arranged in the pit; the pieces of equipment are connected to the same control box. The full-automatic quartz sand production line overcomes the defects in the prior art and is reasonable in design structure; the airflow magnitude is adjusted according to the crystal structure of quartz sand ore and different densities of components, and quartz sand with high concentration is separated; an air floatation principle pure physical method is utilized for design, so that the produced quartz sand has few impurities and is low in cost; in second-level airflow classification and third-level airflow classification, the granularity is completely adjustable and controllable by controlling vortex airflow generated by classifying impellers, and the application range is wide.

Owner:安徽东阳矿业科技有限公司

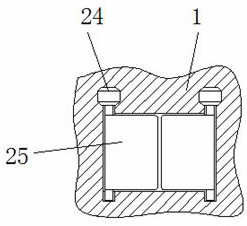

Full-automatic quartz crucible separation device

PendingCN112010538AImprove efficiencyReduce labor hazardsGlass shaping apparatusAutomatic quartzEngineering

The invention provides a full-automatic quartz crucible separation device. The full-automatic quartz crucible separation device comprises a control cabinet, a base, a protective cover, transverse sliding tables, longitudinal sliding tables, a first servo motor, a second servo motor and a knocking device, wherein two parallel transverse sliding tables are arranged on the surface of the top of the base; the first servo motor is arranged on the part, in the center of the bottom of a supporting seat, of the base; the protective cover is arranged on the side face of the supporting seat; two parallel longitudinal sliding tables are arranged on the surface of the top of the supporting seat; a fixed seat is connected to a longitudinal sliding block; the second servo motor is arranged on the part,located at the bottom of one end of the fixed seat, of the supporting seat; and the knocking device is arranged on the surface of the top of the fixed seat. By arranging the control cabinet, the base,the protective cover, the transverse sliding tables, the longitudinal sliding tables, the first servo motor, the second servo motor and the knocking device, automation is achieved, manpower is replaced, workers are reduced, labor intensity is lowered, and cost is saved.

Owner:山东益立申节能技术有限公司

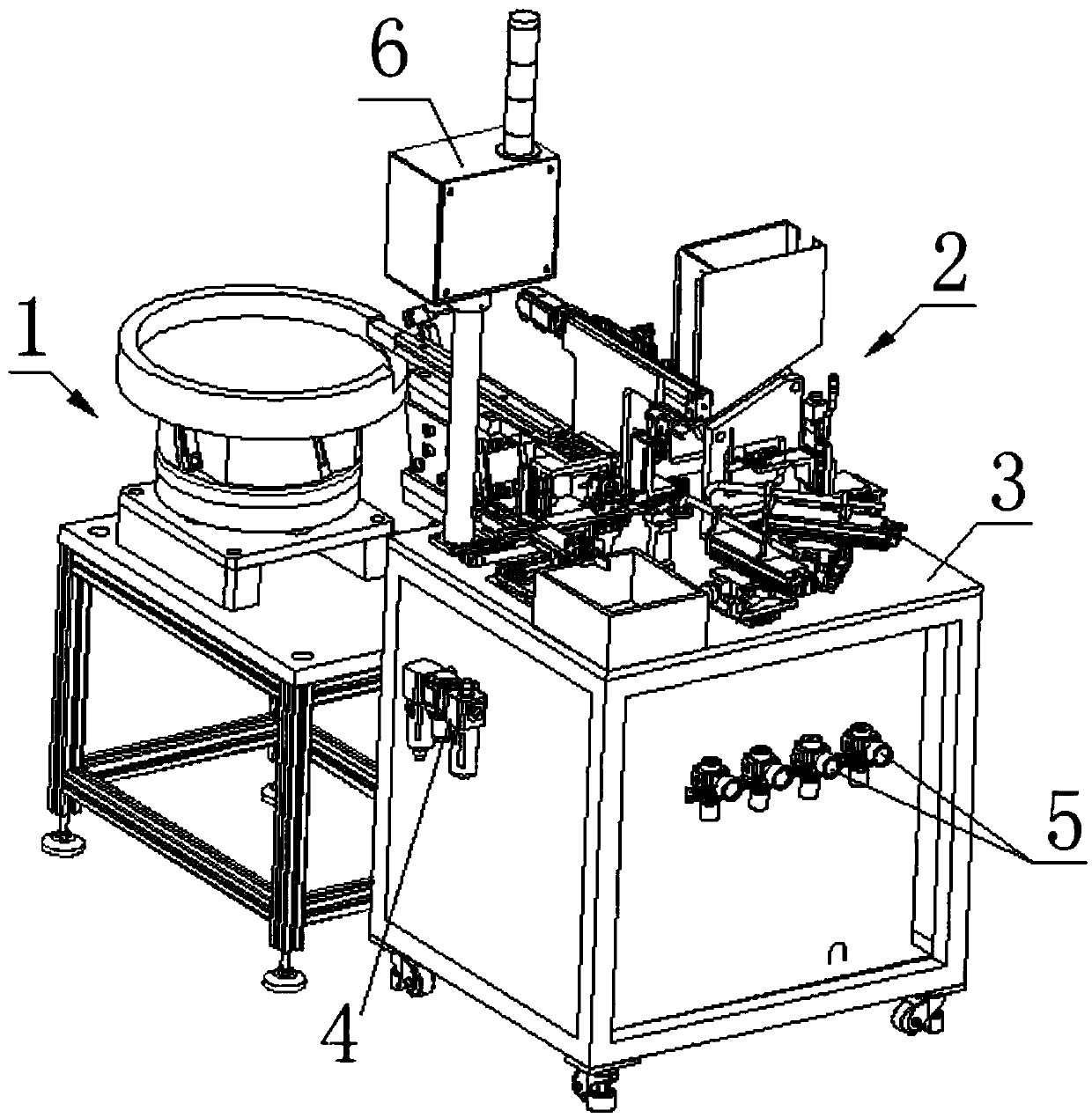

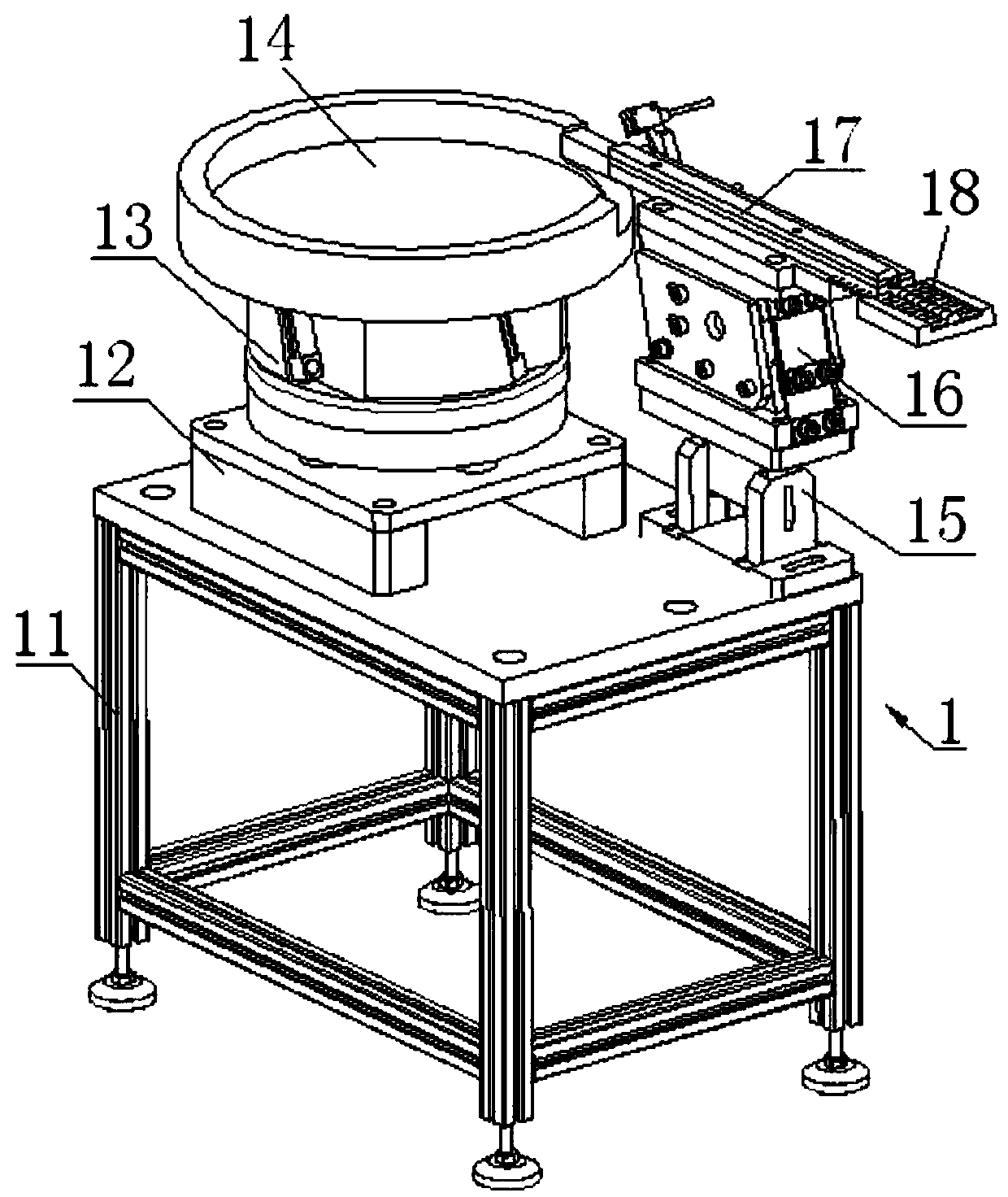

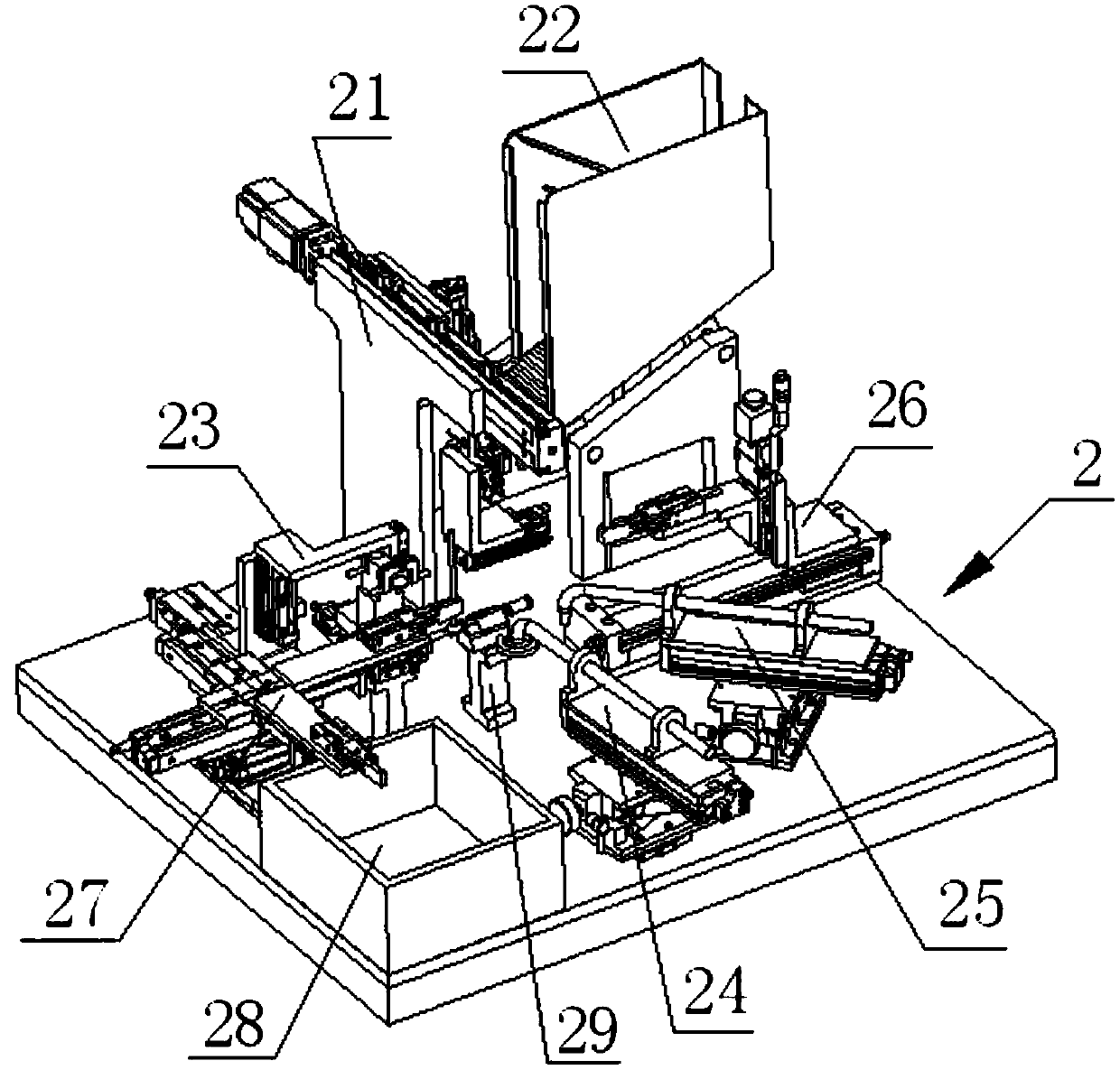

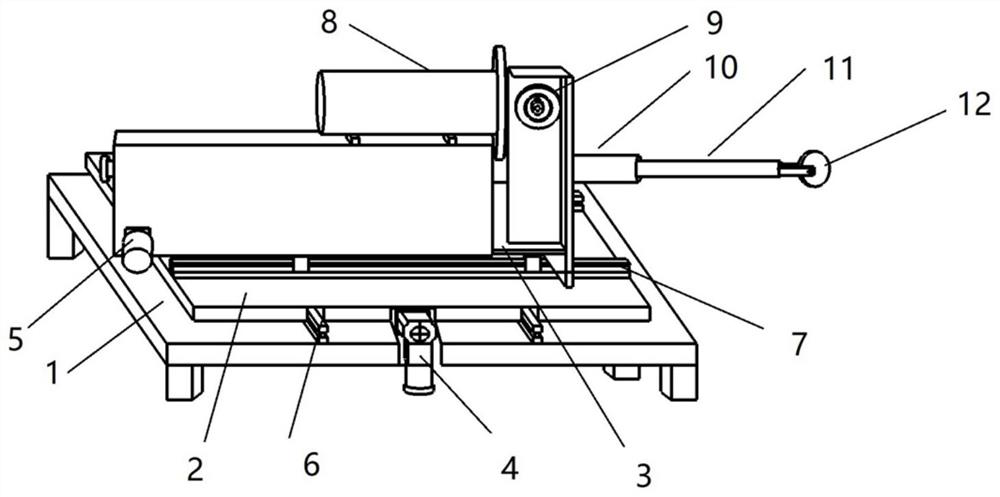

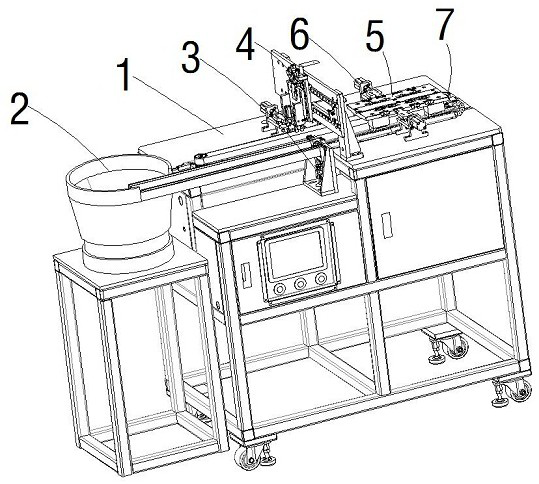

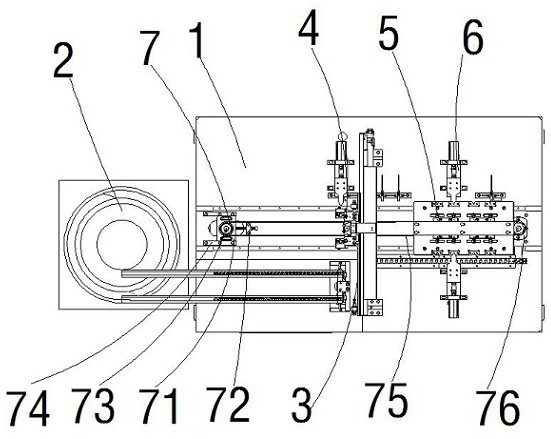

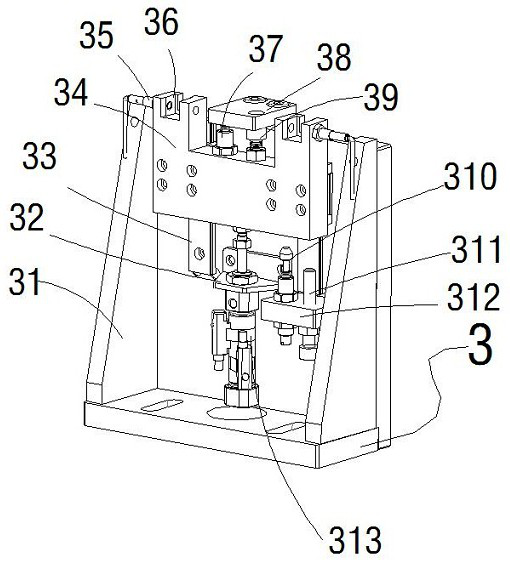

Automatic quartz crystal oscillator inserting equipment

InactiveCN114070226AEasy to grabRealize mass production operationsImpedence networksReciprocating motionAutomatic quartz

The invention discloses automatic quartz crystal oscillator inserting equipment. A vibrating feeder is placed on the side face of an insertion piece machining platform. The vibrating feeder is in butt joint with a pushing mechanism through a feeding track, the pushing mechanism is fixed on the insertion piece machining platform and placed on the side face of an insertion piece mechanism, a crystal oscillator base fixing mechanism capable of moving in a reciprocating mode is arranged in the middle of the lower portion of the insertion piece mechanism, and the crystal oscillator base fixing mechanism is connected with a conveying mechanism. After a wafer inserting gripper grabs crystal oscillator wafer pins, the wafer inserting gripper horizontally moves to a middle operation area under the action of a wafer inserting transverse moving air cylinder and moves downwards under the action of a wafer inserting downward moving air cylinder to install the crystal oscillator wafer pins into a crystal oscillator base, and batch production operation can be achieved through reciprocating motion.

Owner:马鞍山成聚电子科技有限公司

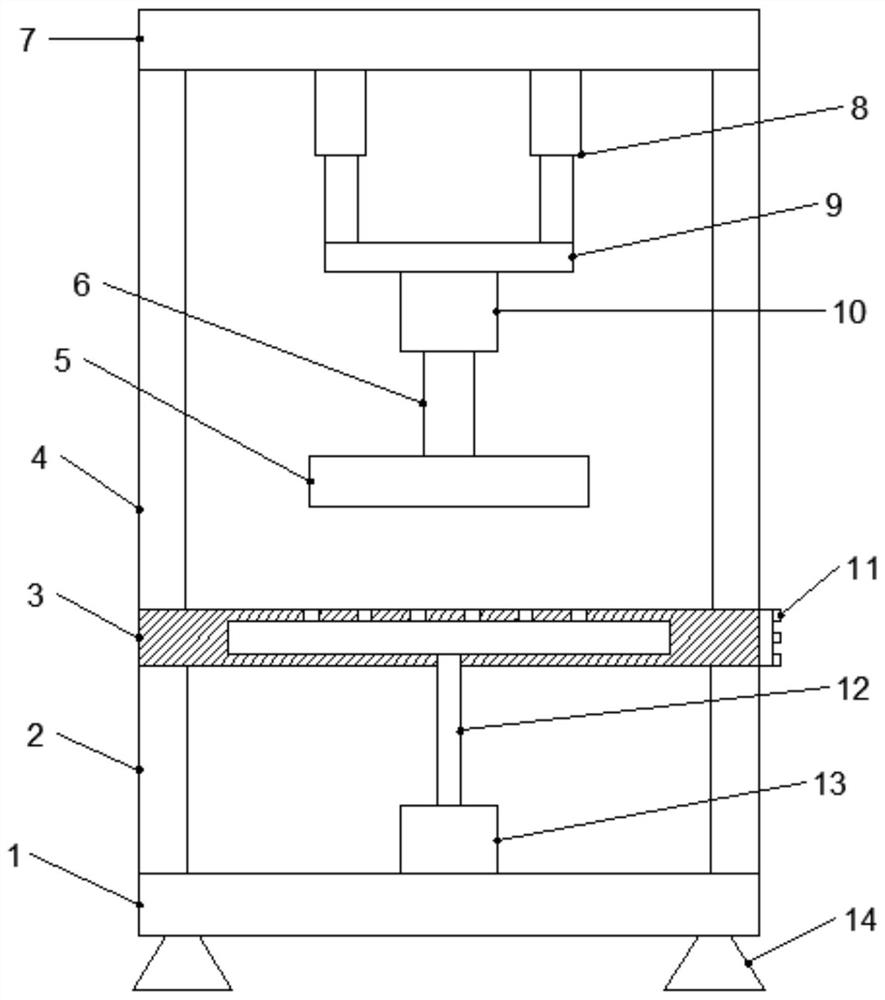

Full-automatic quartz glass polishing machine

PendingCN113829172AEasy to fixAvoid damageSievingOptical surface grinding machinesAutomatic quartzElectric machinery

The invention discloses a full-automatic quartz glass polishing machine. The full-automatic quartz glass polishing machine comprises a base, wherein supporting legs are connected to the top of the base, a workbench is fixedly connected to the top ends of the supporting legs, supporting rods are connected to the top of the workbench, a top plate is fixedly connected to the top ends of the supporting rods, hydraulic telescopic rods are fixedly connected to the bottom of the top plate, and a connecting plate is fixedly connected to the bottom ends of the hydraulic telescopic rods; a first motor is fixedly connected to the bottom of the connecting plate, a first rotating shaft is connected to the output end of the first motor, a polishing disc is fixedly connected to the bottom end of the first rotating shaft, a vacuum pump is arranged on the top of the base and connected with an air pipe, a cavity is formed in the workbench, the air pipe is connected with the cavity, and multiple sets of adsorption holes are formed in the top of the workbench; and a dust collection assembly is arranged at the rear side of the top of the workbench. According to the full-automatic quartz glass polishing machine, the interior of the cavity is vacuumized through the vacuum pump, quartz glass is adsorbed to the workbench through the adsorption holes, and glass is fixed, so that the glass fixing effect is good, damage to the glass can be avoided, and meanwhile powder generated during polishing is treated through the dust collection assembly.

Owner:新沂市铭达玻璃有限公司

Automatic quartz crucible feeding and forming system

ActiveCN113305980ARealize vibration separation operationUniform volumeGlass shaping apparatusFeeding arrangmentsMolding machineAutomatic quartz

Owner:XINYI ZHONGXIN OPTOELECTRONICS TECH CO LTD

Automatic quartz crystal conveying and sorting device

The invention discloses an automatic quartz crystal conveying and sorting device. The device comprises a bottom plate, wherein mounting plates I are fixedly connected to the left side of the top of the bottom plate, and motors I are fixedly arranged on the front surfaces of the mounting plates I; the output ends of the motors I are fixedly connected with rollers I, and mounting plates II are fixedly connected to the right side of the top of the bottom plate; the front surfaces of the mounting plates II are movably connected with rotating columns I through bearings; the ends, far away from themounting plates II, of the rotating columns I are fixedly connected with rollers II; and the rollers I and the rollers II are in transmission connection through a conveyor belt, and sorting boxes arefixedly connected to the top of the conveyor belt. According to the device, adjusting rods, lifting plates, linking rods, motors II, belt wheels I, rotating columns II, belt wheels II, belts, rotatingrods and connecting rods are arranged in a cooperating mode, the height of the adjusting rods can be increased or reduced, and therefore the height of the bottom plate and the height of the conveyorbelt can be adjusted, the situation that the device is butt joint with different equipment is facilitated, and quartz crystal is convenient to transport.

Owner:TONGLING RIKE ELECTRONICS

Full-automatic classified screening equipment for quartz stone production

InactiveCN112871658AAchieve screeningAchieve removalGas current separationMagnetic separationElectric machineryAutomatic quartz

The invention discloses a full-automatic classified screening equipment for quartz stone production. The equipment comprises a machine body shell, a servo motor, an air suction machine body, a material leakage pipe, a supporting frame, a driving motor, a first screening plate, a rotary blocking door, a first material collecting box body and a second material collecting box body, the first screening plate is installed in the machine body shell, and a first discharging through hole is formed at the right side of the machine body shell; and a small motor is installed in the machine body shell, the rotary blocking door is installed in the first discharging through hole, a limiting sliding groove and a cylindrical through hole are formed in the machine body shell, and a limiting column is installed in the limiting sliding groove. The full-automatic classified screening equipment for quartz stone production is provided with a magnetic block, in the using process, a rotating cylinder can rotate through operation of the driving motor, so that the magnetic block rotates, the magnetic block can attract scrap iron in quartz stone, and therefore the scrap iron in the quartz stone can be removed; and the functionality of the equipment is improved.

Owner:湖北钊晟新材料科技有限公司

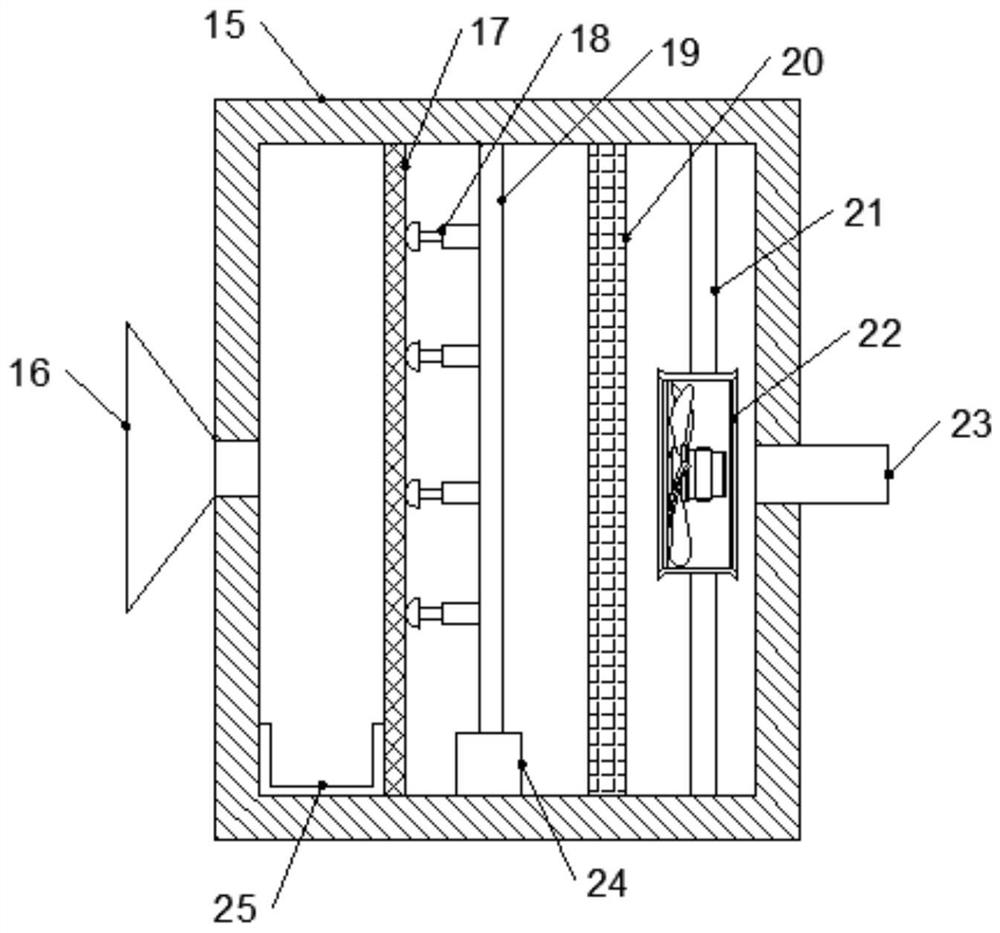

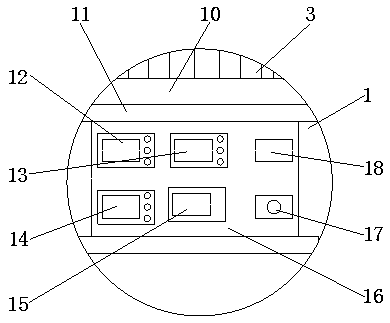

Automatic quartz reaction tube cleaning machine and automatic tube cleaning method thereof

ActiveCN104624571AWon't leakIncrease flexibilityHollow article cleaningProgrammable logic controllerAutomatic quartz

The invention discloses an automatic quartz reaction tube cleaning machine and an automatic tube cleaning method thereof. The automatic quartz reaction tube cleaning machine comprises a housing divided into an upper chamber and a lower chamber, a rotation switching mechanism is arranged at the top of the housing, the left side and the right side of the upper chamber are provided with a pipe inlet door and a pipe outlet door respectively, a first automatic door and a second automatic door are arranged in the upper chamber sequentially from left to right, the upper chamber is divided into a to-be-cleaned area, a cleaning area and a drying area by the first automatic door and the second automatic door from left to right, a first holder plate, a second holder plate and a third holder plate are arranged in the to-be-cleaned area, the cleaning area and the drying area respectively, the lower chamber is provided with a cleaning tank inside, and the cleaning area is communicated with the cleaning tank through an openable flushing door. The rotation switching mechanism controls the first, the second and the third holder plate to move according to a certain sequence by commands transmitted by a PLC (programmable logic controller). The automatic quartz reaction tube cleaning machine has the advantages that labor operation and halt time of equipment are reduced, cleaning is more convenient and efficient, high-efficiency operation of equipment is realized, and production requirements of successive process are well met.

Owner:WUHAN FIBERHOME RUITUO TECH CO LTD

Quartz reaction tube automatic washing machine and automatic washing method thereof

ActiveCN104624571BWon't leakIncrease flexibilityHollow article cleaningProgrammable logic controllerAutomatic quartz

The invention discloses an automatic quartz reaction tube cleaning machine and an automatic tube cleaning method thereof. The automatic quartz reaction tube cleaning machine comprises a housing divided into an upper chamber and a lower chamber, a rotation switching mechanism is arranged at the top of the housing, the left side and the right side of the upper chamber are provided with a pipe inlet door and a pipe outlet door respectively, a first automatic door and a second automatic door are arranged in the upper chamber sequentially from left to right, the upper chamber is divided into a to-be-cleaned area, a cleaning area and a drying area by the first automatic door and the second automatic door from left to right, a first holder plate, a second holder plate and a third holder plate are arranged in the to-be-cleaned area, the cleaning area and the drying area respectively, the lower chamber is provided with a cleaning tank inside, and the cleaning area is communicated with the cleaning tank through an openable flushing door. The rotation switching mechanism controls the first, the second and the third holder plate to move according to a certain sequence by commands transmitted by a PLC (programmable logic controller). The automatic quartz reaction tube cleaning machine has the advantages that labor operation and halt time of equipment are reduced, cleaning is more convenient and efficient, high-efficiency operation of equipment is realized, and production requirements of successive process are well met.

Owner:WUHAN FIBERHOME RUITUO TECH CO LTD

Automatic quartz wafer mounting device

InactiveCN110482226AAchieve installationSolve low work efficiencyCharge manipulationConveyor partsProximity sensorAutomatic quartz

The invention discloses an automatic quartz wafer mounting device which comprises a bottom block, a first motor, a top plate and a second motor. The first motor is mounted at the upper left end of thebottom block, and a rotary shaft is mounted at the upper end of the first motor. The upper end of the rotary shaft is connected with the top plate. The second motor is mounted at the right bottom endof the top plate. An electric telescopic rod is mounted at the bottom end of the second motor, and the lower end of the electric telescopic rod is connected with a pump. According to the automatic quartz wafer mounting device, by arranging the first motor, the rotary shaft, the second motor, the electric telescopic rod, a first controller, a second controller, a third controller, a microprocessor, a proximity detector, a suction seat, the pump, a connecting sleeve and an air guide pipe structure, the problems that a quartz wafer is mounted through a manual method at present, and consequentlythe work efficiency is low; and at present, the position of a quartz wafer grabbing structure in an existing quartz wafer mounting device cannot be adjusted, the shape of the grabbed quartz wafer is single, and consequently the existing quartz wafer mounting device is limited in use range are solved.

Owner:马鞍山荣泰科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com