Full-automatic quartz glass polishing machine

A quartz glass and polishing machine technology, which is applied to surface polishing machine tools, grinding/polishing equipment, grinding drive devices, etc., can solve the problems of slow speed of quartz glass sheets, damage to reciprocating drive mechanisms, and low work efficiency, and achieve Simple structure, high working efficiency and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

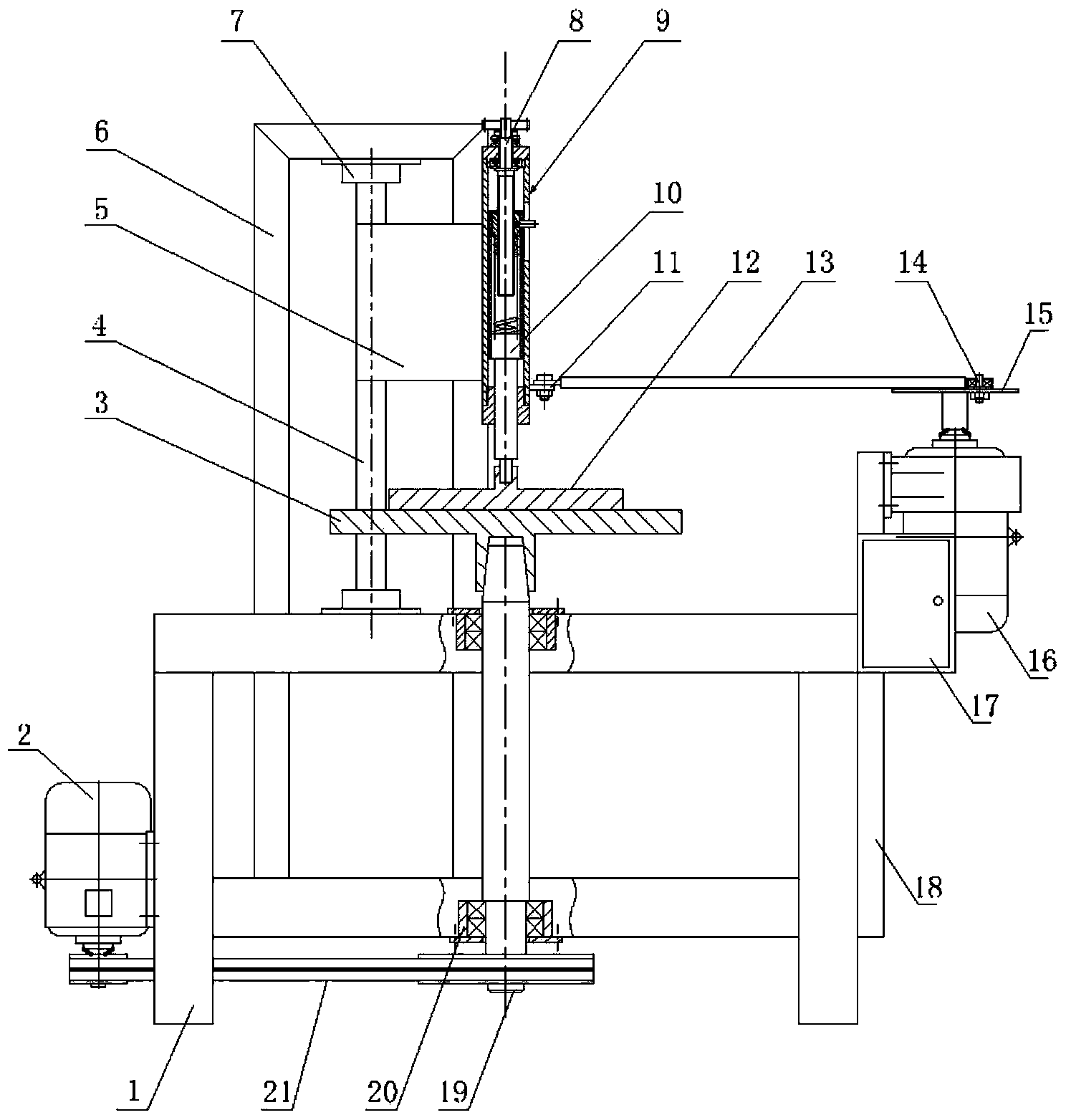

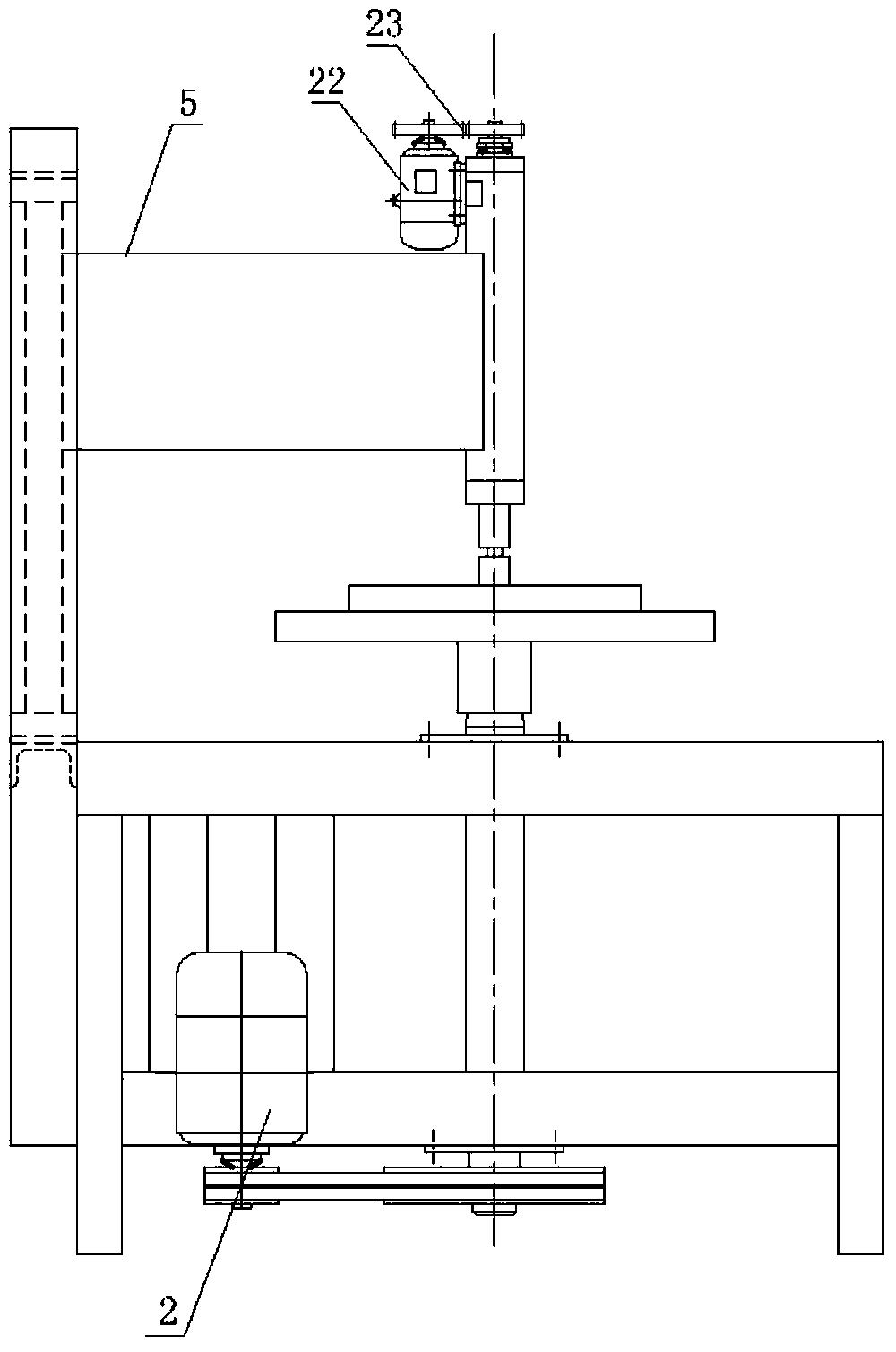

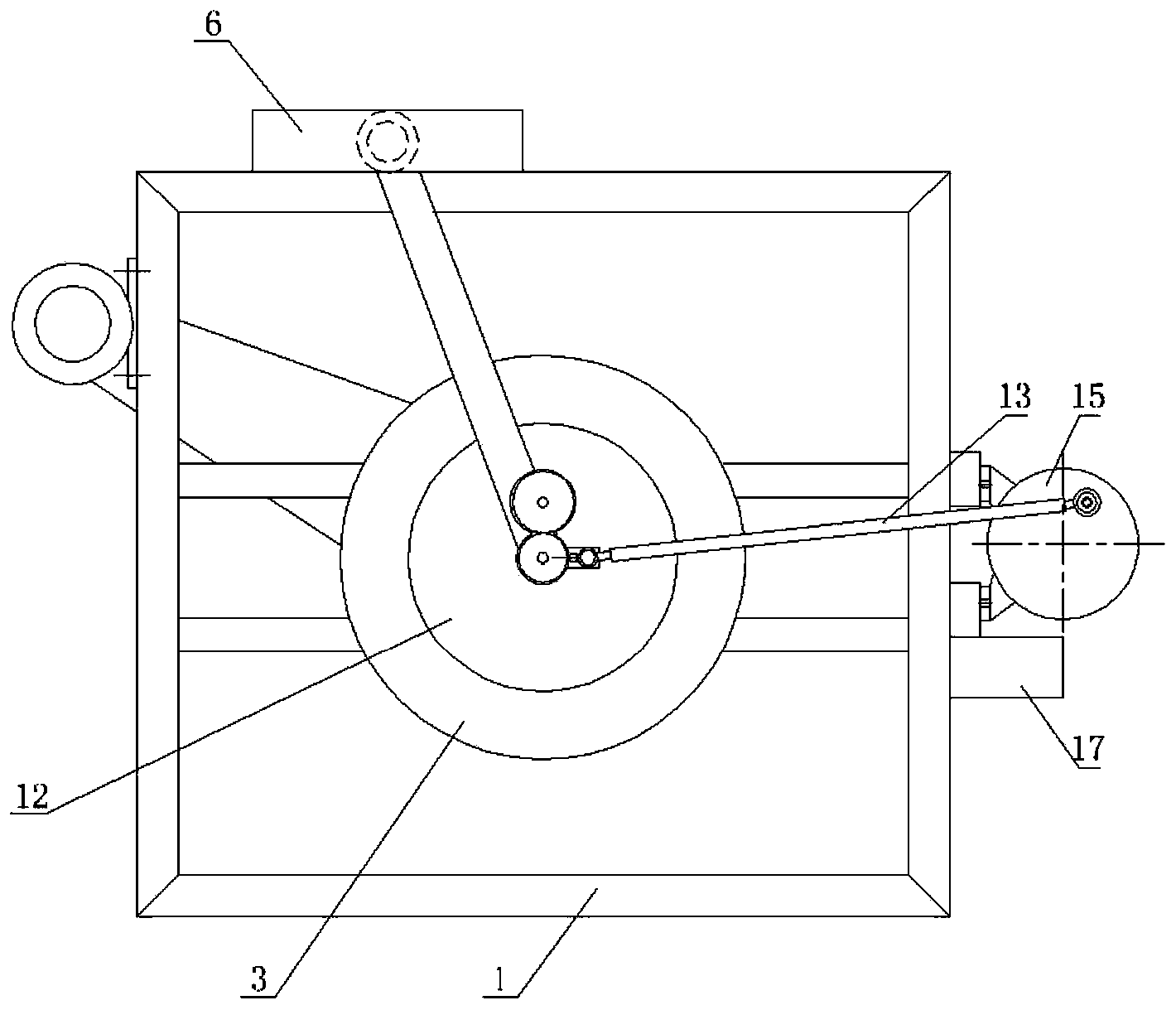

[0022] As shown in the figure, the full-automatic quartz glass polishing machine involved in the present invention includes a frame 1, the frame 1 is welded by channel steel, and a main motor 2 is vertically installed on the left side of the frame 1 through bolts. Frame 1 center place is vertically installed with rotatable main shaft 19, main shaft 19 top and bottom are installed on the frame 1 by a bearing seat 20 and two cover bearings respectively, and described bearing seat 20 is fixed on the frame 1 by bolt. The main motor 2 is connected to the main shaft 19 through a first transmission mechanism 21. Preferably, the first transmission mechanism 21 is a belt transmission mechanism, and a chain transmission or other transmission mechanisms may also be used.

[0023] On the upper end of the main shaft 19, a polishing support disc 3 is inserted through a conical surface, and a base plate 12 is supported on the polishing support disc 3 . A swing shaft mounting frame 6 is welde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com