Automatic quartz ring lettering device

A quartz and automatic technology, applied in auxiliary devices, auxiliary welding equipment, welding equipment, etc., can solve the problems of high scrap rate of product lettering, inconvenient positioning of quartz ring lettering, and difficult operation, so as to achieve accurate and reliable lettering position and reduce scrapping of lettering Accurate and reliable effect of high rate and positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

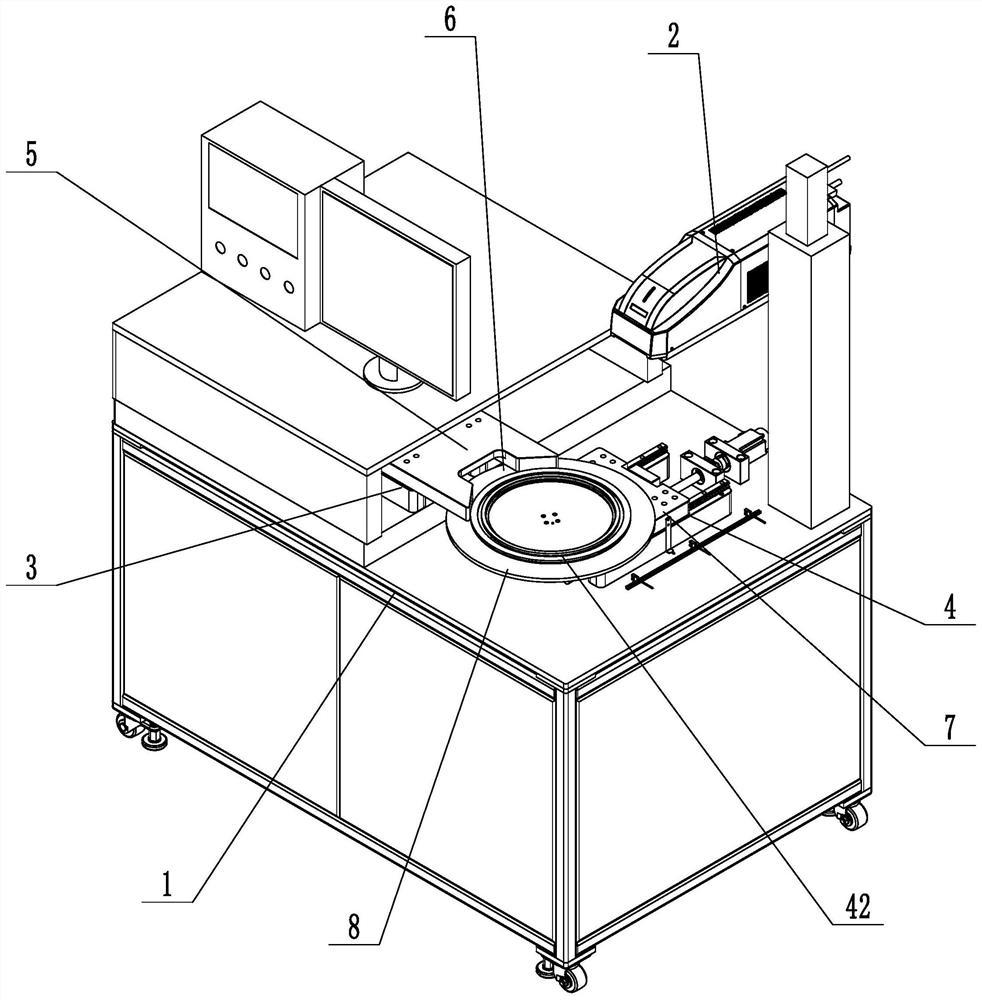

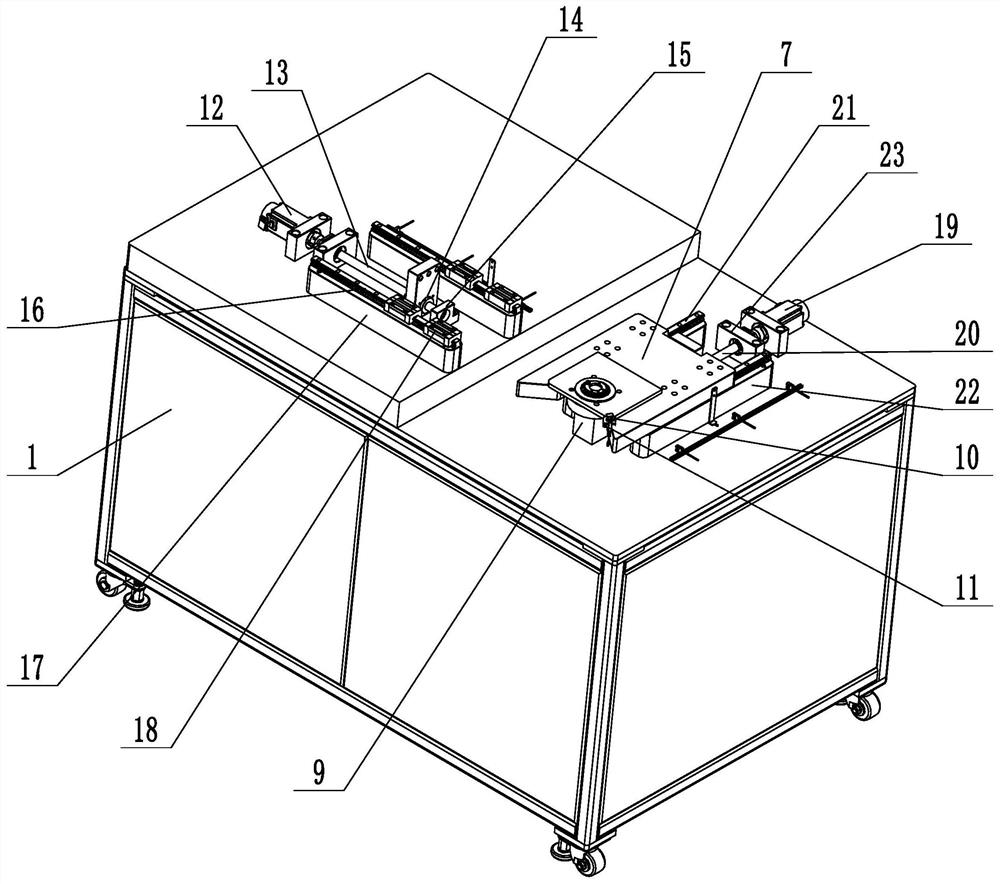

[0029] Embodiment 1: A kind of quartz ring automatic lettering device (see attached figure 1 , attached figure 2 ), including the fuselage 1, the laser engraving assembly 2 installed on the fuselage, the centering mechanism 3 and the handling mechanism 4 are installed on the fuselage, the centering mechanism includes a centering push block 5, which is used to drive the centering push block to move The driving assembly of the centering push block is provided with a V-shaped centering groove 6; the transport mechanism includes a moving block 7, a power unit for driving the moving block to move, a rotatable turntable 8 is installed on the moving block, and a quartz ring 42 Placed on the turntable, the centering push block can be moved to the top of the turntable, the outer wall of the quartz ring and the side wall of the centering groove are fitted and positioned so that the center of the quartz ring coincides with the rotation center of the turntable, and the power unit drives ...

Embodiment 2

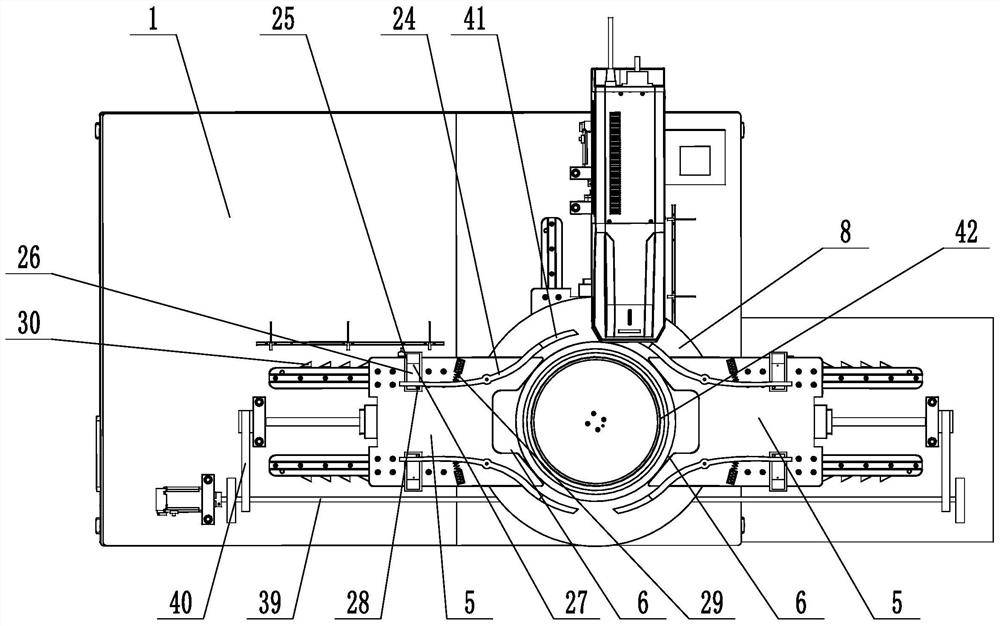

[0033] Embodiment 2: A kind of quartz ring automatic lettering device (see attached image 3 to attach Figure 5 ), its structure is similar to that of Embodiment 1, the main difference is that in this embodiment, two centering mechanisms are installed symmetrically on the left and right sides of the transport mechanism on the fuselage, and the front parts of the centering push blocks of the two centering mechanisms are equipped with dials The toggling mechanism comprises two toggling rods 24, the two toggling rods are respectively hinged on both sides of the centering push block, one end of the toggling rod extends out of the edge of the centering groove, and the centering push block corresponds to the other end of the toggling rod. Position limit groove 25 is installed, and slide block 26 is installed in the limit groove, and push rod 27 and abutment rod 28 are connected on the slide block, and return spring 29 is connected between positioning push block and toggle lever, un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com