Automatic quartz clock stepping motor

A technology of stepping motors and quartz clocks, applied to electromechanical clocks, clocks, electrical components, etc., can solve the problems of slow time adjustment, inability to rotate counterclockwise, and many transmission mechanisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing.

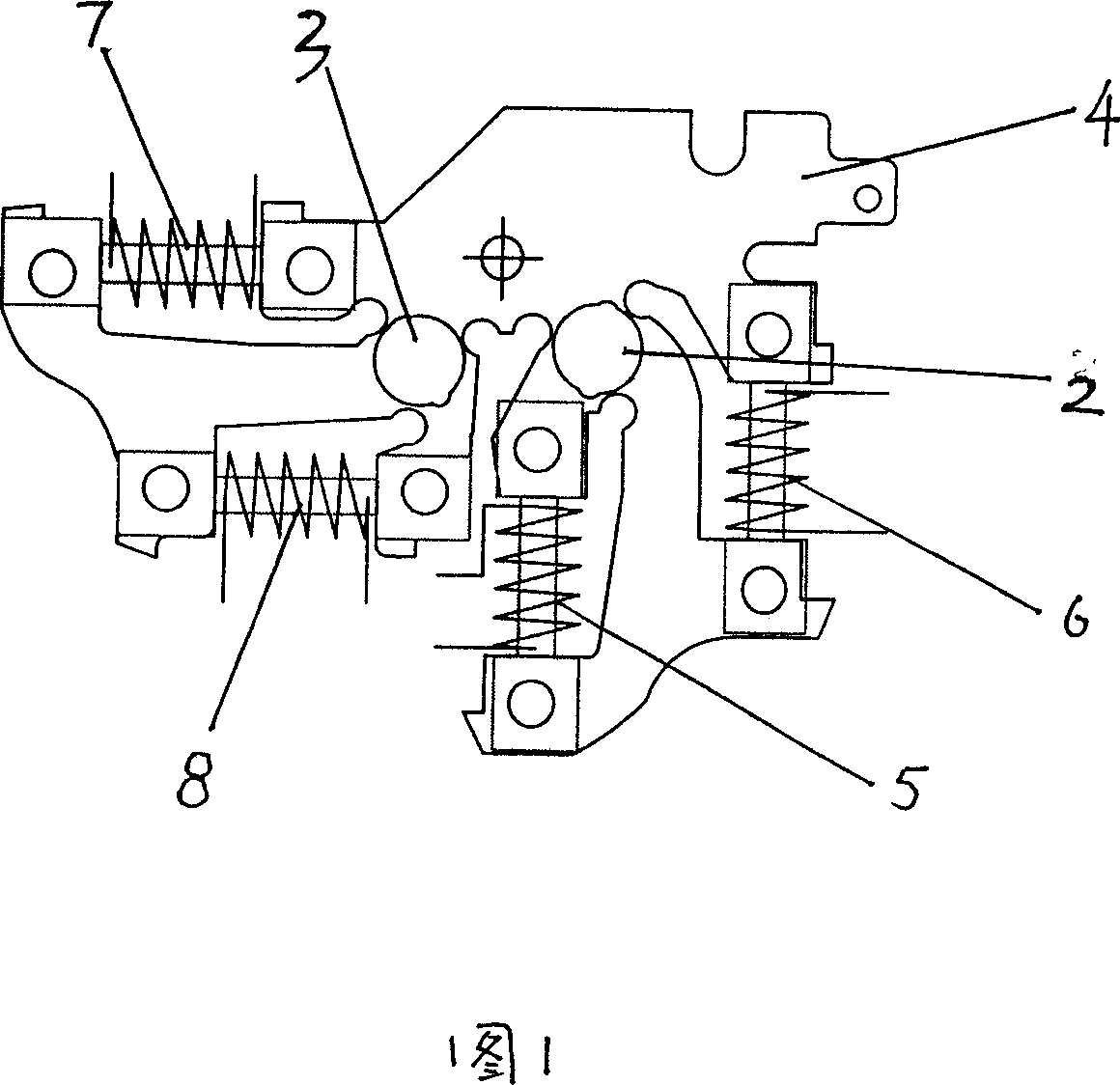

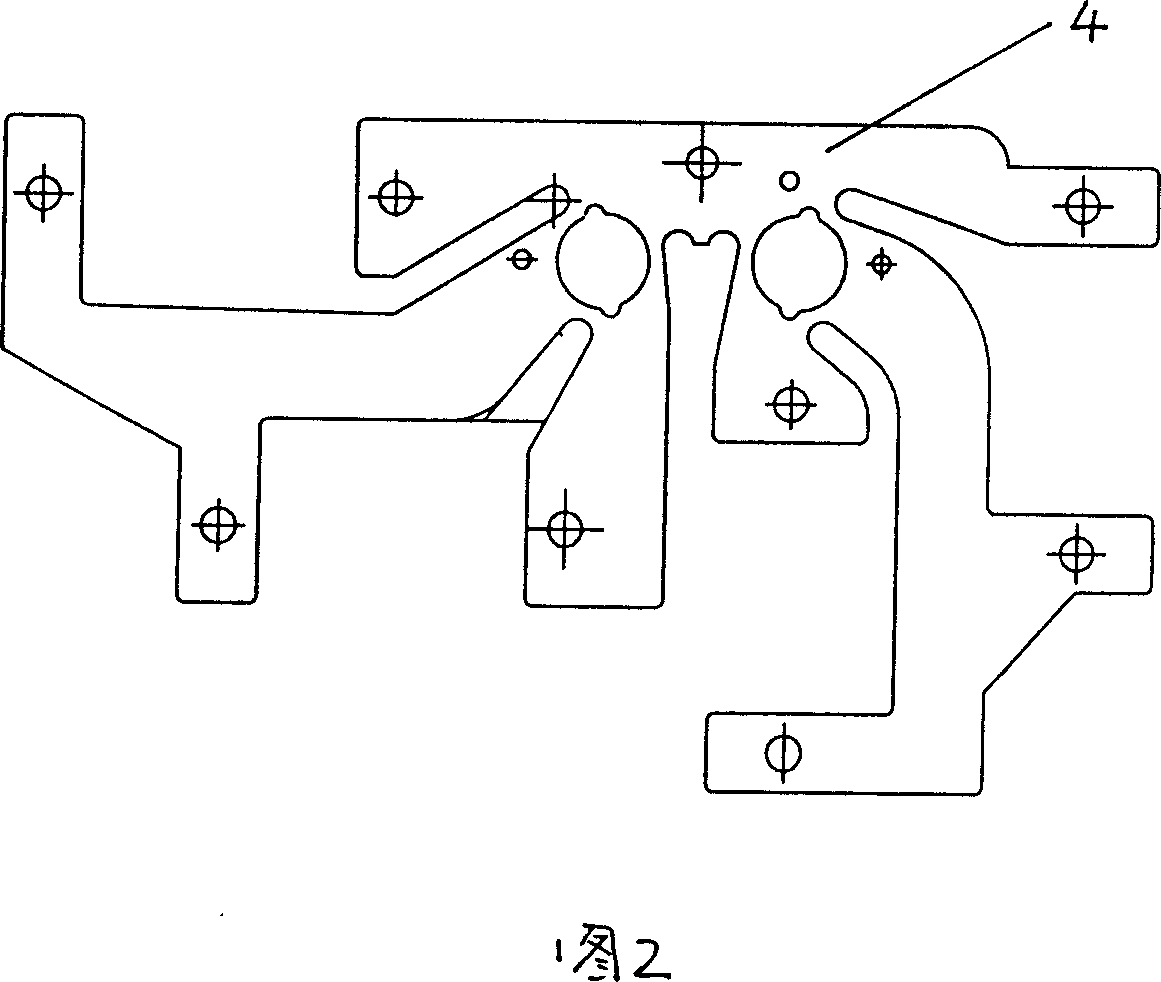

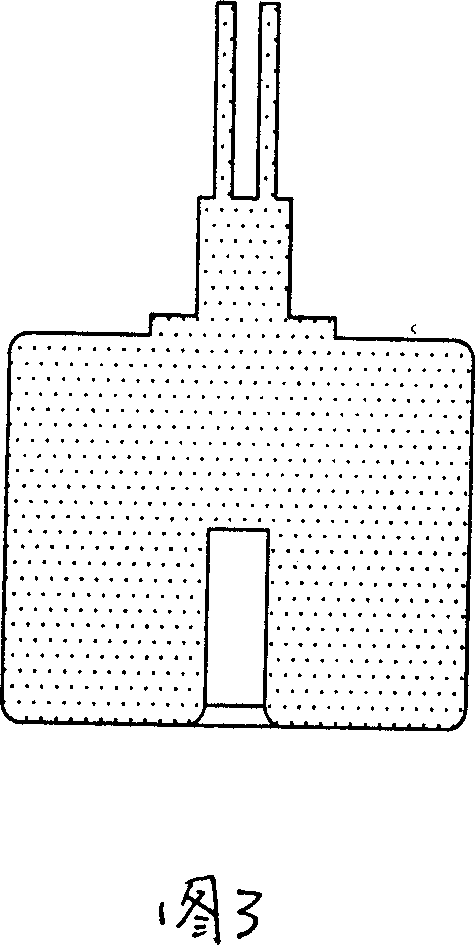

[0023] As shown in accompanying drawing 1, stepper motor of the present invention is made up of rotor, stator plate and drive coil, is provided with two rotors on stator plate, minute hand rotor 3 and hour hand rotor 2, and two rotors are installed in a common stator On sheet 4, the hour hand rotor and the minute hand rotor cooperate with the stator sheet respectively to form an hour hand stepping motor and a minute hand stepping motor. On the chip, the hour hand driving coil is divided into forward rotating hour hand driving coil 5 and reverse rotating hour hand driving coil 6, and the minute hand driving coil is arranged on the stator sheet, and the minute hand driving coil is divided into forward rotating minute hand driving coil 7 and reverse rotating minute hand driving coil 8. And it is connected with the printed circuit board, and the printed circuit board is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com