Automatic quartz sand distribution control system

A control system, quartz sand technology, applied in electrical program control, program control in sequence/logic controllers, manufacturing tools, etc., can solve problems such as small thermal expansion coefficient, unfavorable modernization requirements, and heavy mold repair work, and achieve investment The effect of low cost, improving production speed and processing technology level, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

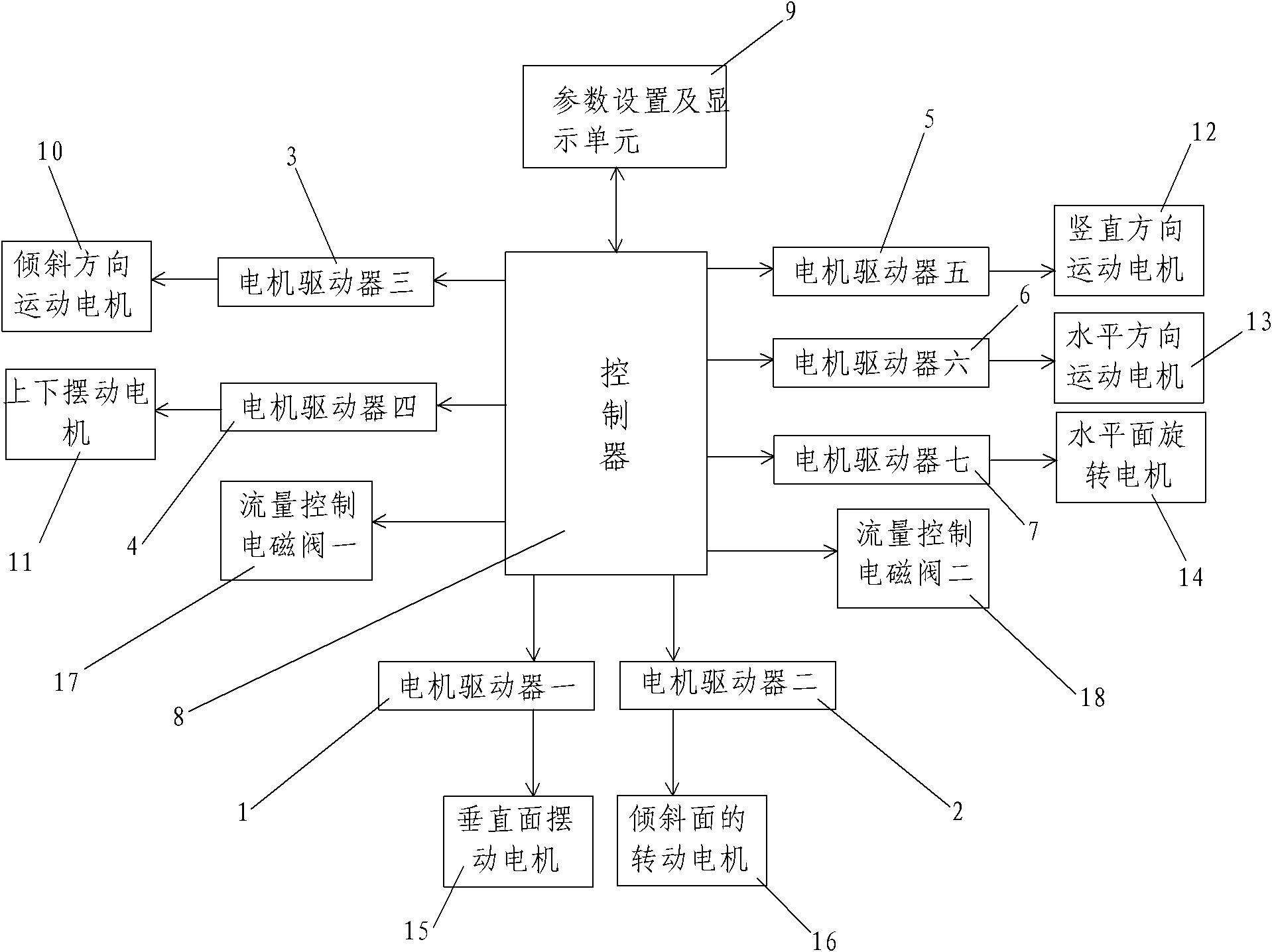

[0019] Such as figure 1 As shown, the present invention includes a controller 8, a parameter setting and a display unit 9 connected with the controller 8, a side wall automatic material distribution movement unit, a bottom automatic material distribution movement unit, and a quartz cone mold movement unit; The wall automatic distributing movement unit includes the tilt direction motion motor 10 driven by the motor driver 3 3 under the control of the controller 8, the up and down swing motor 11 driven by the motor driver 4 4 under the control of the controller 8 and connected with the controller 8 The flow control valve one 17; the bottom automatic distributing motion unit includes a vertical motion motor 12 driven by the motor driver five 5 under the control of the controller 8, and a horizontal motor driven by the motor driver six 6 under the control of the controller 8 Directional motion motor 13, the horizontal plane rotating motor 14 driven by motor driver seven 7 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com