Full-automatic quartz wafer appearance sorting machine

A quartz wafer, fully automatic technology, used in testing crystals, measuring devices, material analysis by optical means, etc., can solve the problems of judgment error, slow detection speed, low work efficiency, etc., and achieve the effect of high detection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

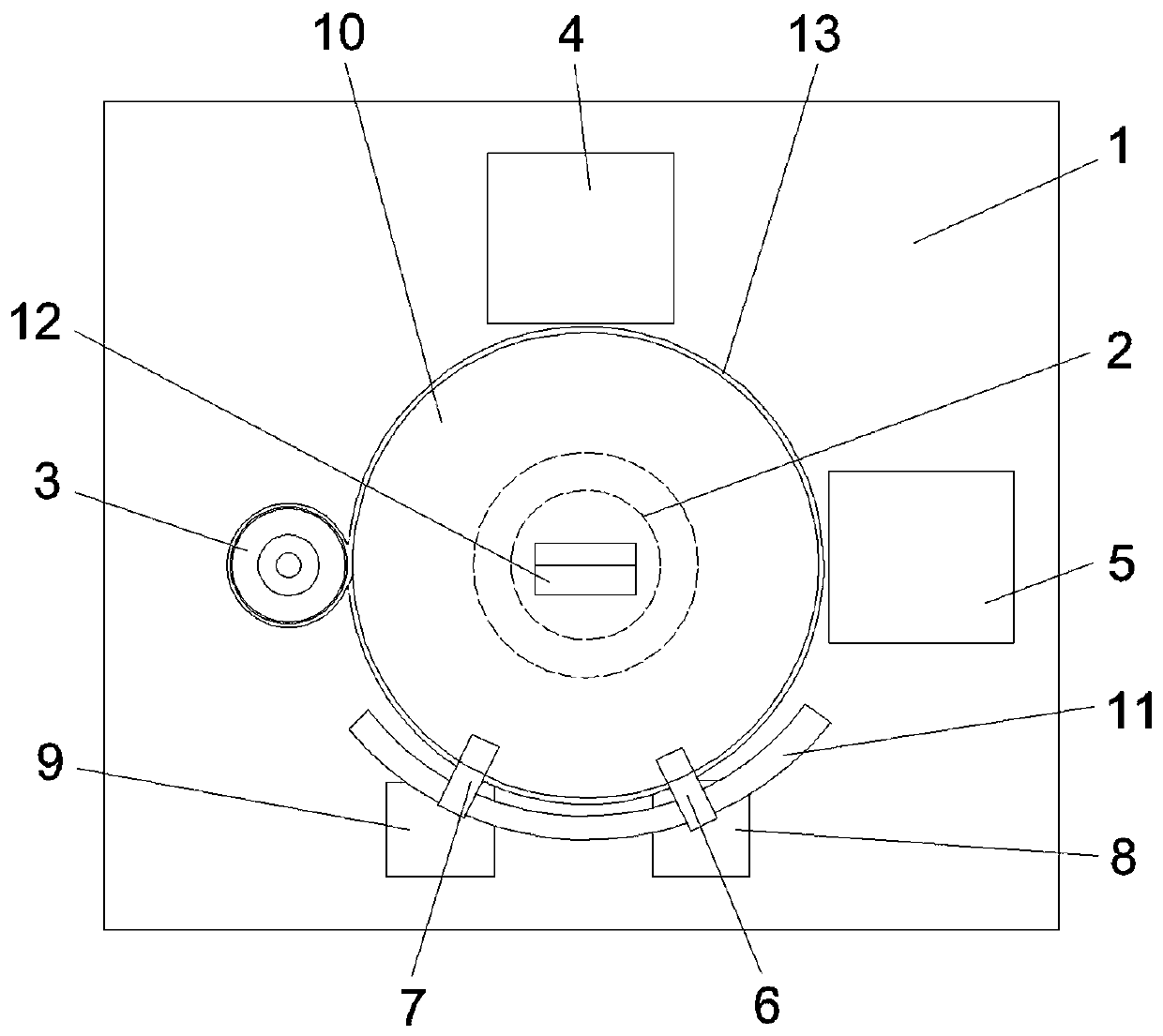

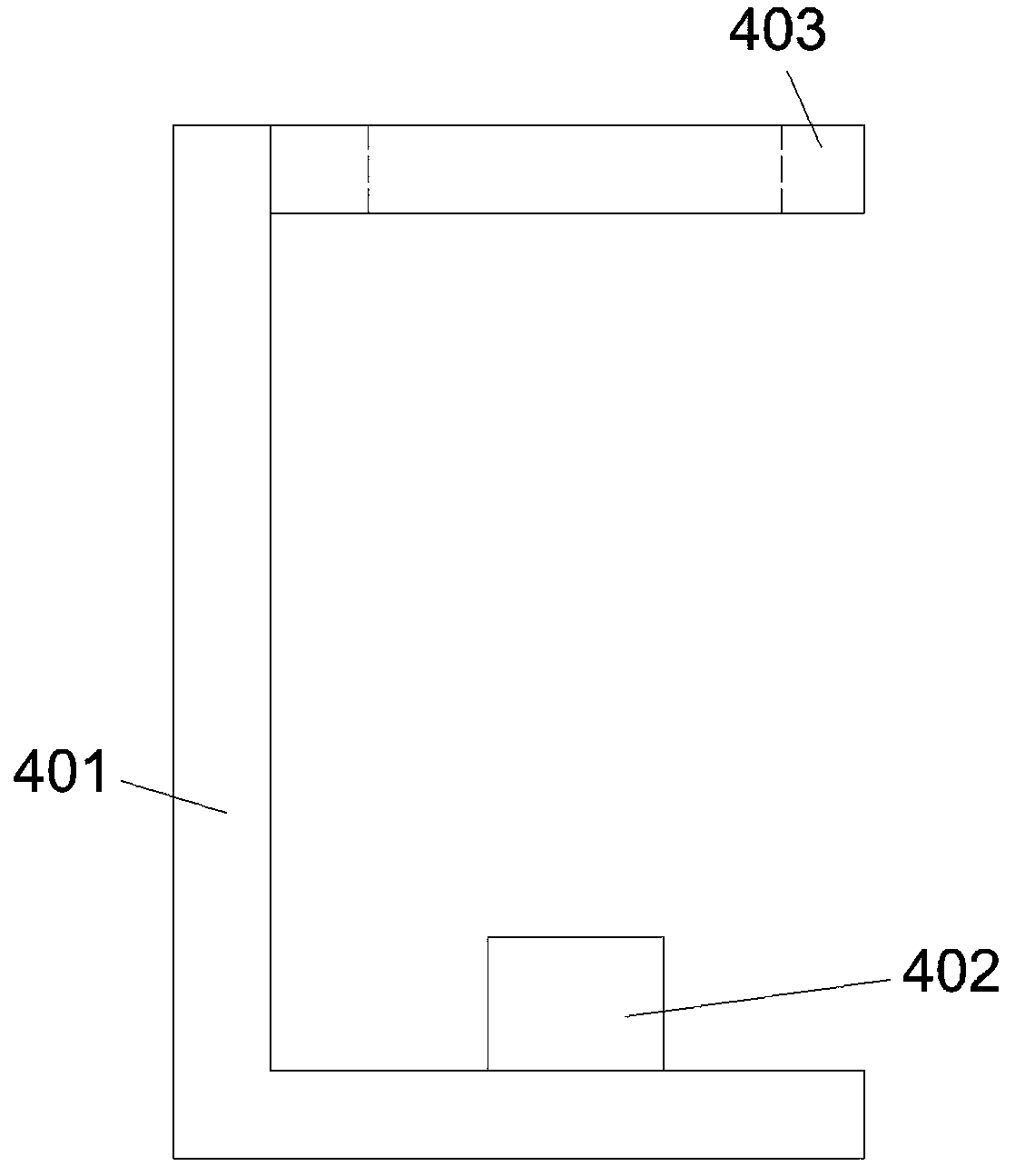

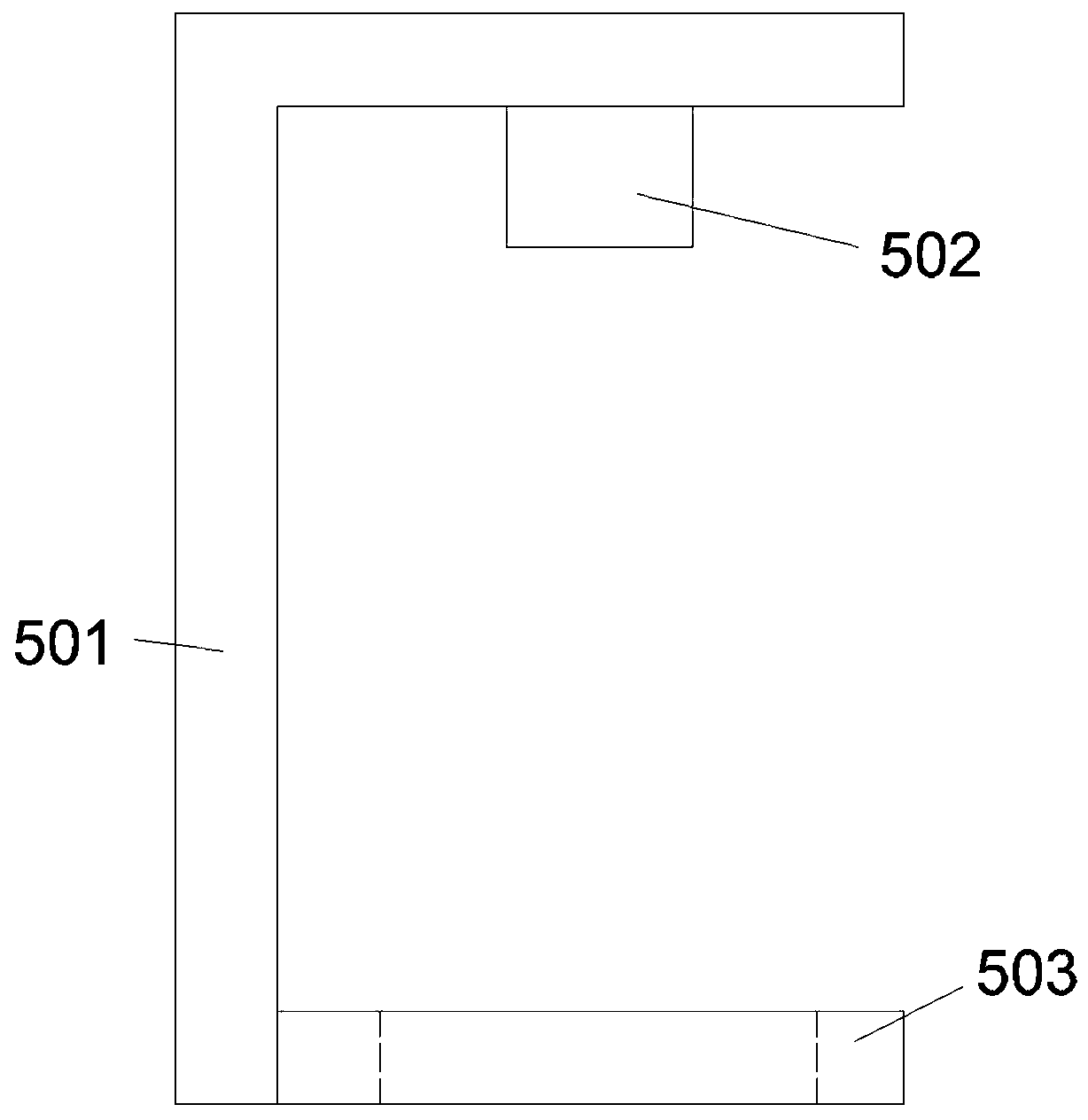

[0014] Such as Figure 1 to Figure 3 As shown, in the present embodiment, the present invention includes a machine platform 1, and the machine platform 1 is provided with a rotating motor 2, a vibrating feeding tray 3, a wafer front detection mechanism 4, a wafer reverse surface detection mechanism 5, a first blanking Blowing mechanism 6, second blanking blowing mechanism 7, good product unloading tray 8 and defective product unloading tray 9, said rotary motor 2 is equipped with a turntable 10, said vibrating feeding tray 3, said wafer The front detection mechanism 4, the wafer reverse detection mechanism 5, the good product unloading tray 8 and the defective product unloading tray 9 are sequentially arranged on the outside of the turntable 10, and the first unloading air blowing mechanism 6 , The second material blowing mechanism 7 is located above the turntable 10, and cooperates with the good product discharge tray 8 and the defective product discharge tray 9 respectively....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com