Automatic quartz reaction tube cleaning machine and automatic tube cleaning method thereof

A reaction tube and quartz technology, applied in cleaning methods and utensils, chemical instruments and methods, cleaning hollow objects, etc., can solve the problems of low automation of reaction tube cleaning devices, reduce manual operation and equipment downtime, and process specifications , the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The invention provides an automatic washing machine for quartz reaction tubes and an automatic washing method thereof, which have a simple structure and a high degree of automation. The present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

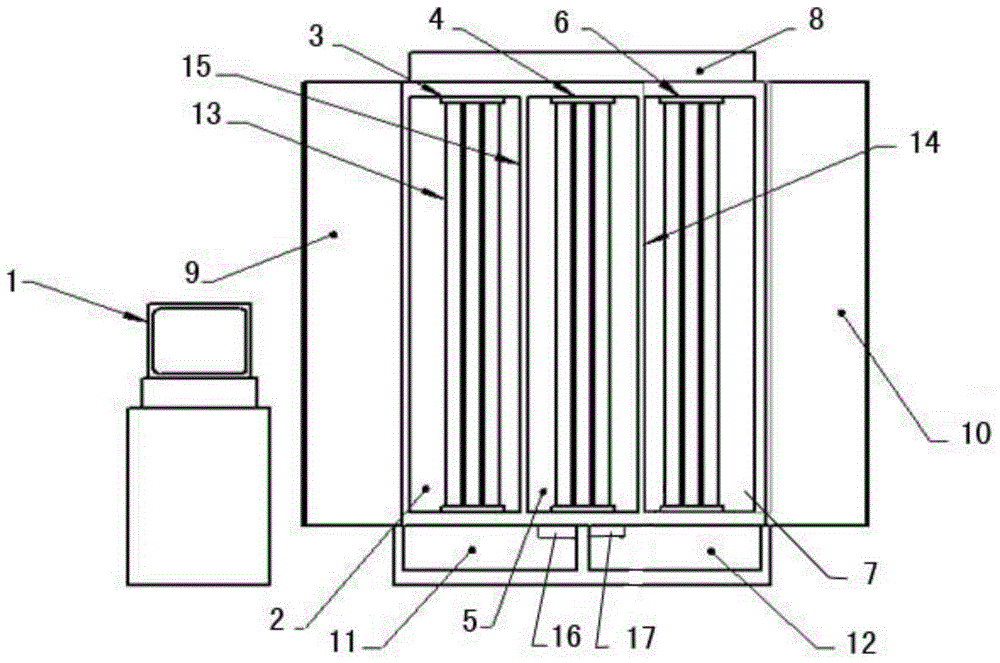

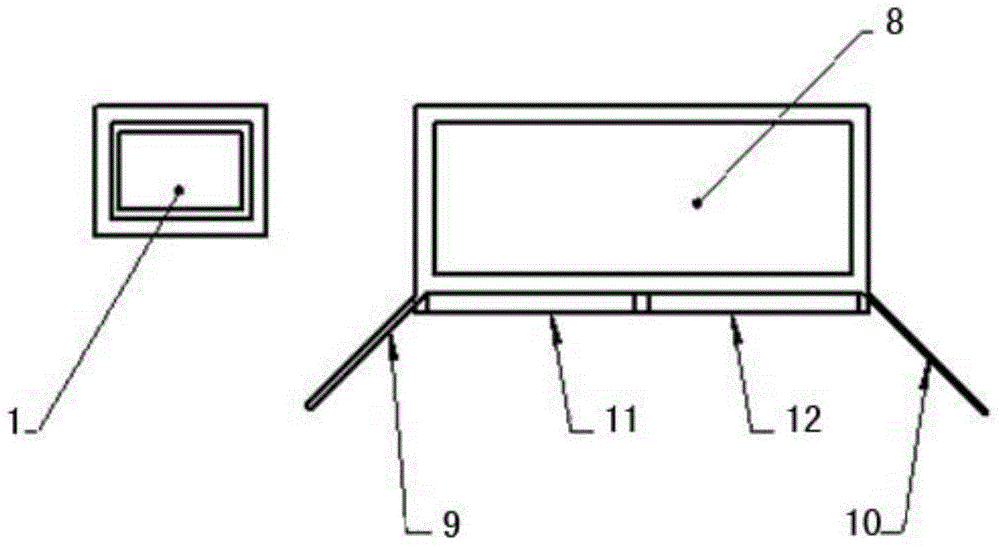

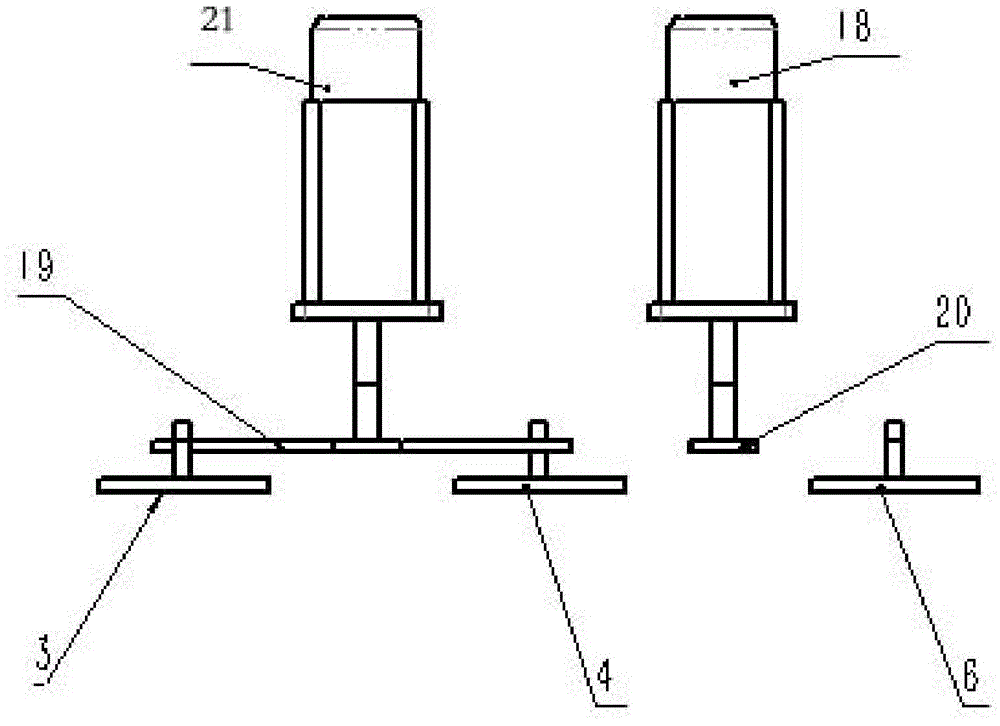

[0029] Such as figure 1 and figure 2 As shown, the quartz reaction tube automatic washing machine provided by the present invention includes a housing, which is divided into two closed upper and lower chambers, the upper chamber is a cleaning area, and the lower chamber is a cleaning pool, controlled by a PLC controller. 1 controls the cleaning step, and the PLC controller 1 is connected with the quartz reaction tube automatic tube washing machine through a cable.

[0030] The top of the housing is provided with a rotating switching mechanism 8, and the left and right sides of the upper chamber are respectively provided with an inlet door 9 and an outlet door 10, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com