Die bonding method for automatic quartz alignment by image recognition

An automatic image and die-bonding technology, applied in semiconductor/solid-state device manufacturing, electrical components, comprehensive factory control, etc., can solve the problems of die-bonding accuracy and speed constraints, poor stability, low efficiency of artificial die-bonding, etc. The effect of high efficiency, cost saving, and improvement of die bonding speed and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

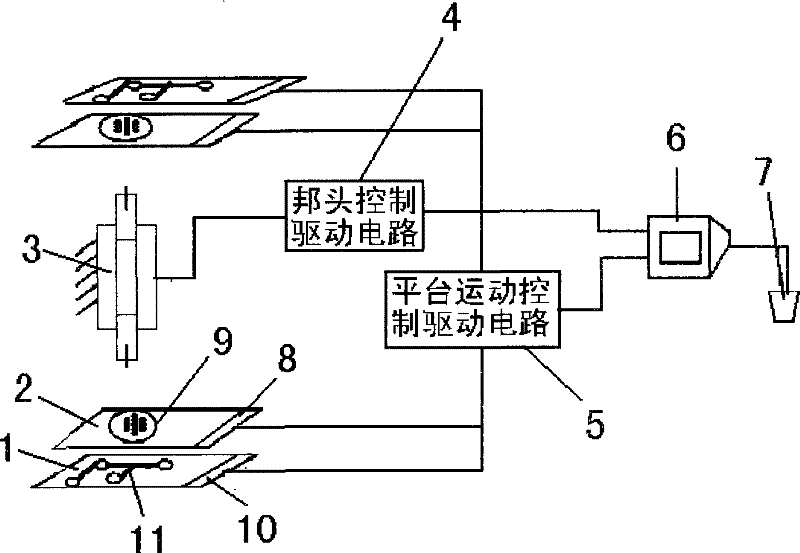

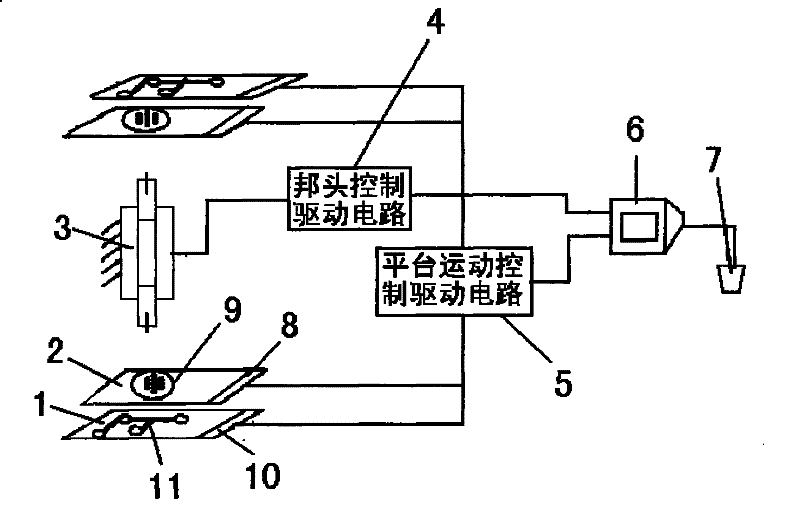

[0015] First, adjust the wafer platform fixture and circuit board platform fixture to an appropriate distance according to the height of the wafer, so that the distance from the wafer film to the circuit board solid point is slightly greater than the height of the wafer, and then respectively fix the wafer and the circuit board in the same group. On the wafer platform fixture and the circuit board platform fixture, and glue the end of the wafer to prepare for solid crystal, use the camera to take pictures of the wafer platform fixture and the circuit board platform fixture respectively, input the image data into the computer, and the computer Analyze, calculate and process the captured image, so that the wafers on the wafer ring and the corresponding die-bonding positions on the circuit board are automatically matched one by one, and the coordinate deviation value of each corresponding point is calculated. In order to have a calculation and analysis benchmark, Set a reference p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com