Automatic quartz crystal oscillator inserting equipment

A technology of quartz crystal oscillators and crystal oscillators, applied in the direction of electrical components, impedance networks, etc., can solve problems such as low work efficiency, high labor intensity, damage, etc., and achieve the effect of convenient grasping and improving operation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations.

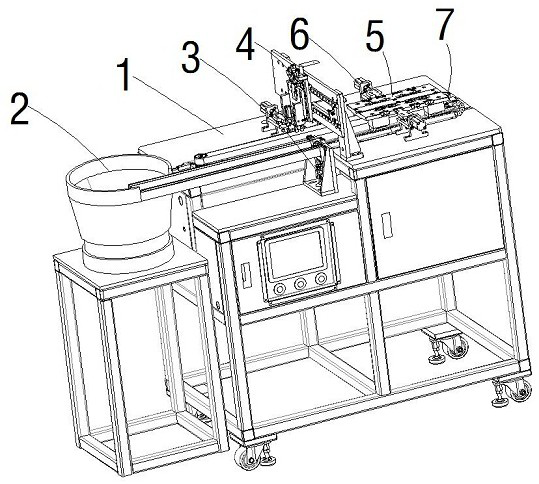

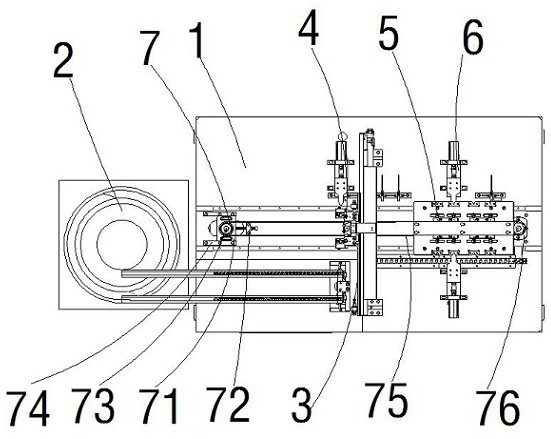

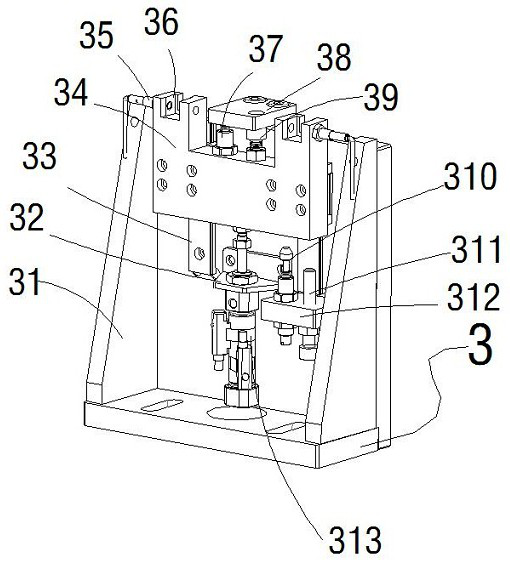

[0033] like Figure 1-2 The automatic inserting equipment for quartz crystal oscillators shown includes an inserting processing platform 1 for providing an operating table, and a vibrating feeder for centrally placing the pins of crystal oscillators and placing them on the feeding track 2. A pushing mechanism 3 for pushing the pins of the crystal oscillator to the inserting mechanism 4, an inserting mechanism 4 for grabbing the pins of the crystal oscillator from the pushing mechanism 3 and inserting them into the base of the crystal oscillator, a A crystal oscillator base fixing mechanism 5 for fixing the crystal oscillator base, a positioning mechanism 6 for fixing the crystal oscillator base fixing mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com