Automatic quartz stone welding equipment

A technology of automatic welding and quartz stone, which is applied in the direction of stone processing equipment, stone processing tools, fine working devices, etc., can solve the problems of increased labor costs, cumbersome operations, and low operating efficiency, and achieve the effect of saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

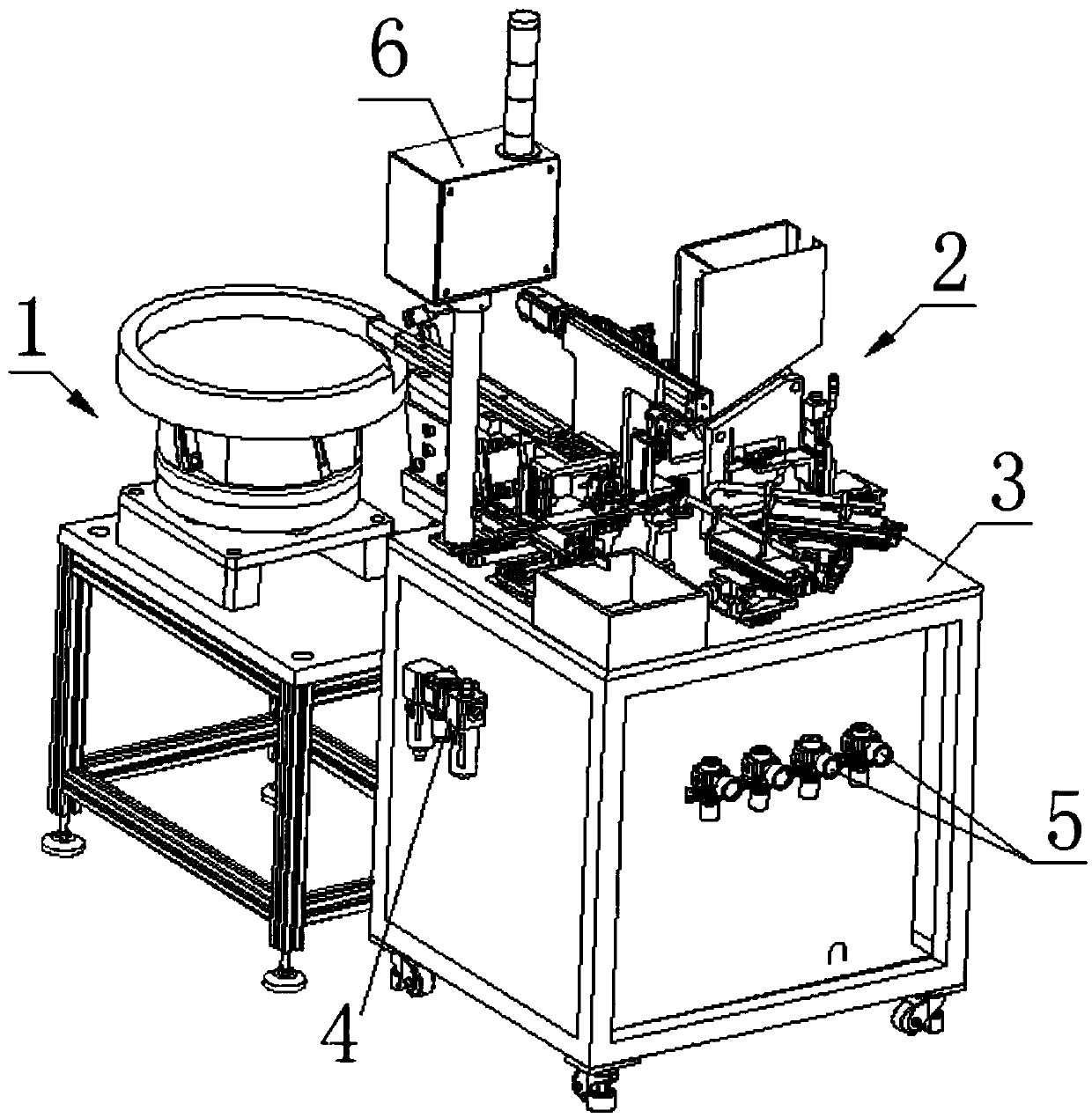

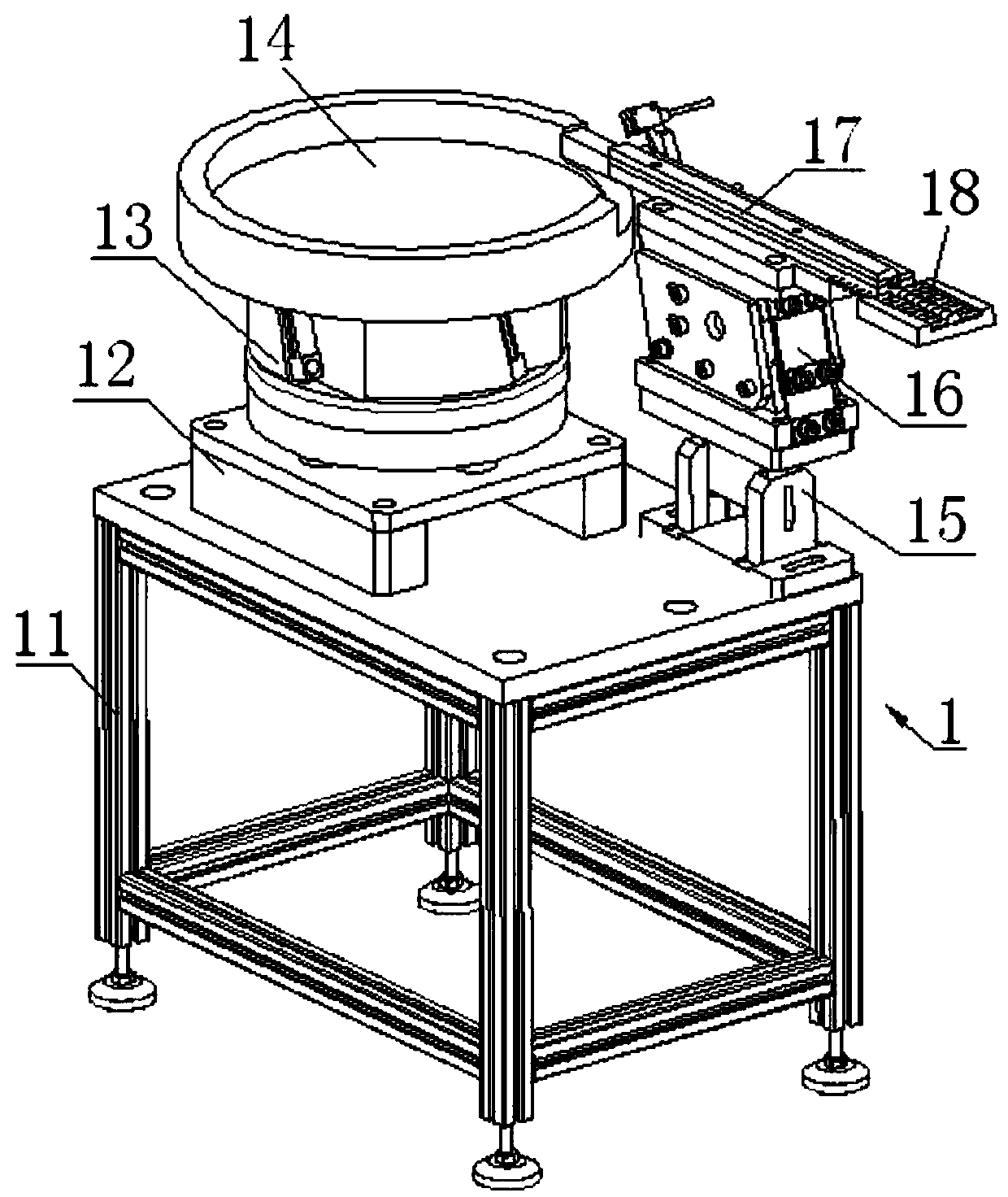

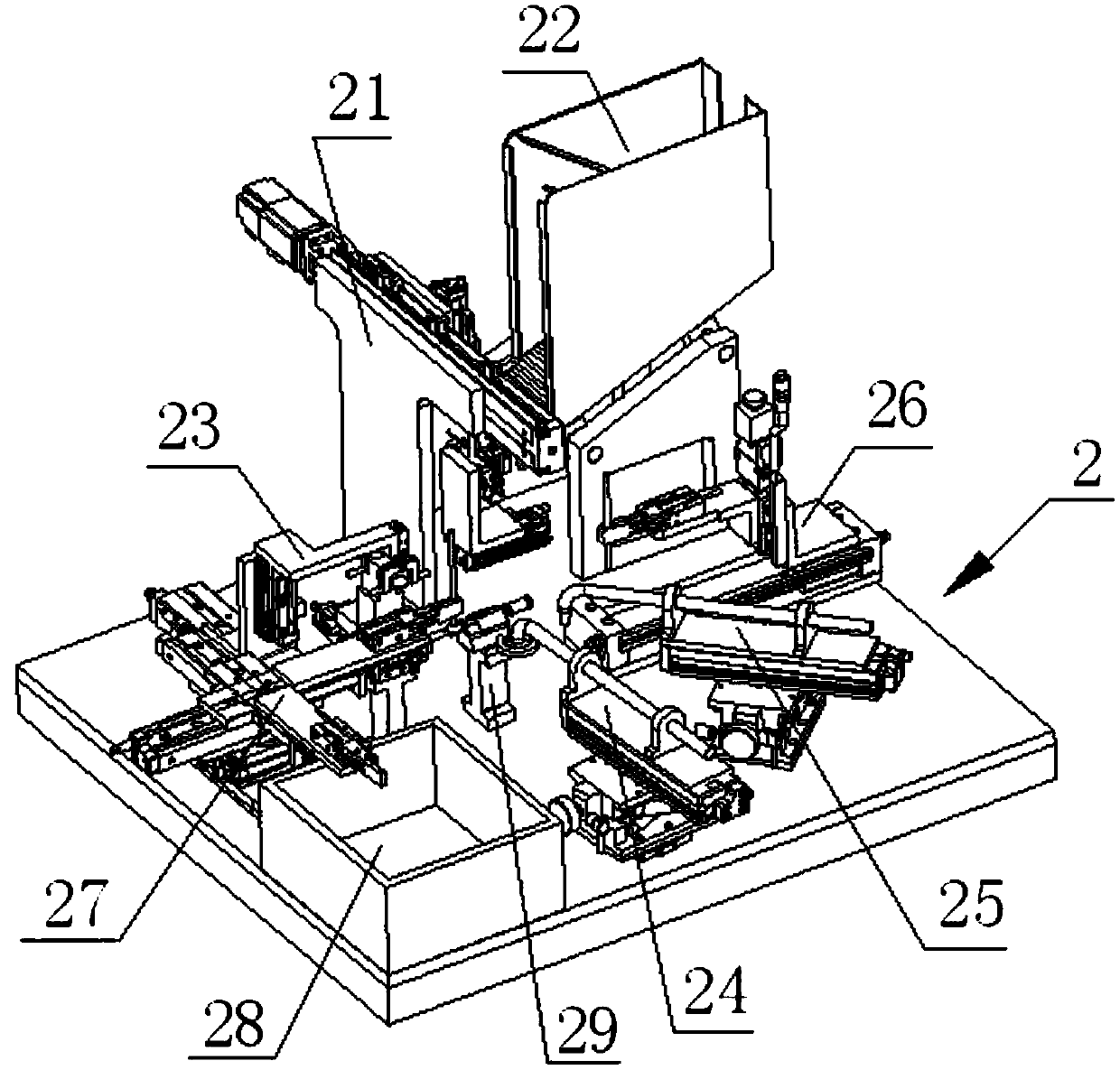

[0018] refer to Figure 1~3 , an automatic quartz stone welding equipment, including a feeding mechanism 1, a welding mechanism 2, a fixed platform 3, a flow valve 4, an acetylene intake pipeline 5, and a man-machine dialogue window 6, and the shape of the fixed platform 3 is a closed square box , the bottom of the fixed platform 3 is equipped with universal wheels (not marked), the fixed platform 3 can be adjusted to the best position through the free rotation of the universal wheels, a side of the fixed platform 3 is placed with a feeding mechanism 1, The welding mechanism 2 is fixedly installed on the top plane of the fixed platform 3. The feeding mechanism 1 and the welding mechanism 2 are connected together. There are four air intake pipelines 5 placed side by side. The acetylene intake pipeline 5 is connected to the flow valve 4 through the pipeline, and the flow valve 4 is connected to the welding mechanism 2 through the pipeline. Machine-machine dialogue window 6, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com