Automatic quartz crucible feeding and forming system

An automatic feeding and quartz crucible technology, which is applied in glass forming, ceramic forming machines, manufacturing tools, etc., can solve the problem of uneven distribution of quartz sand in forming molds, reduced success rate of semiconductor single crystallization, and reduced utilization of quartz crucibles, etc. Problems, to achieve the effect of being close to each other, reducing gaps, improving quality and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

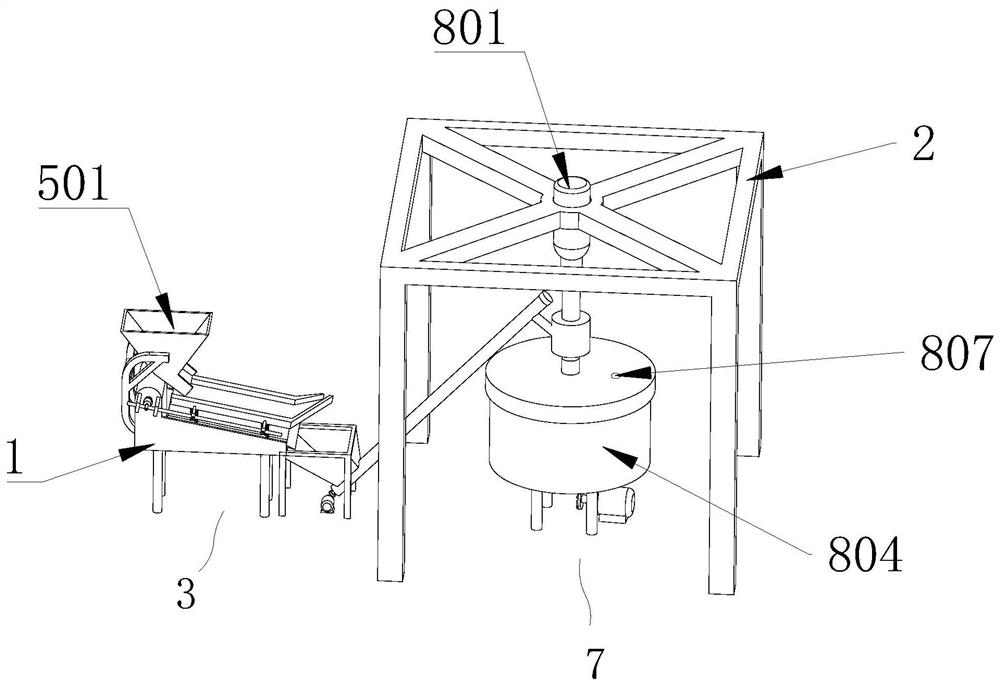

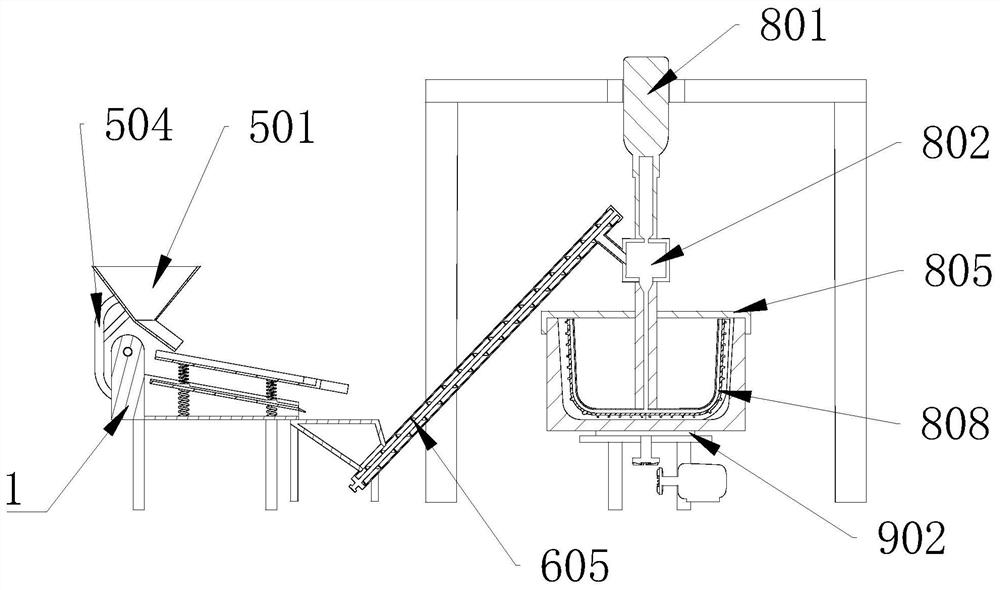

[0031] Example: such as Figure 1-2As shown, a quartz crucible automatic feeding forming system includes a base 1, a fixed frame 2, a screening feeding mechanism 3 located above the base 1, and a spray forming mechanism 7 located at the lower end of the fixed frame 2;

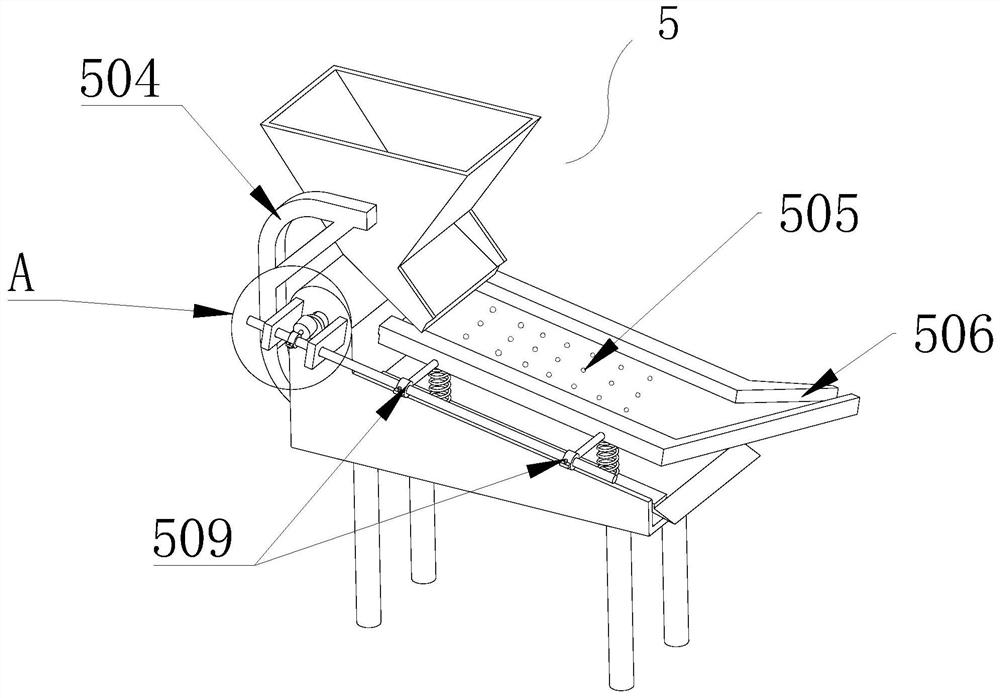

[0032] Such as Figure 3-7 As shown, the screening feeding mechanism 3 includes a vibrating assembly 4, a screening assembly 5 and a feeding assembly 6, and the vibrating assembly 4 includes a first motor 401, a first transmission shaft 402, a circular turntable 403 and a transmission rod 404, so One end of the first rotating shaft is connected to the first motor 401, and the circular turntable 403 is located at the other end of the first rotating shaft. A connecting ball 405 is arranged at an eccentric position on the surface of the circular turntable 403, and the tail of the transmission rod 404 is One end of the connecting sleeve 406 is provided with a connecting sleeve 406, one end of the connecting sleeve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com