Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "With support" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

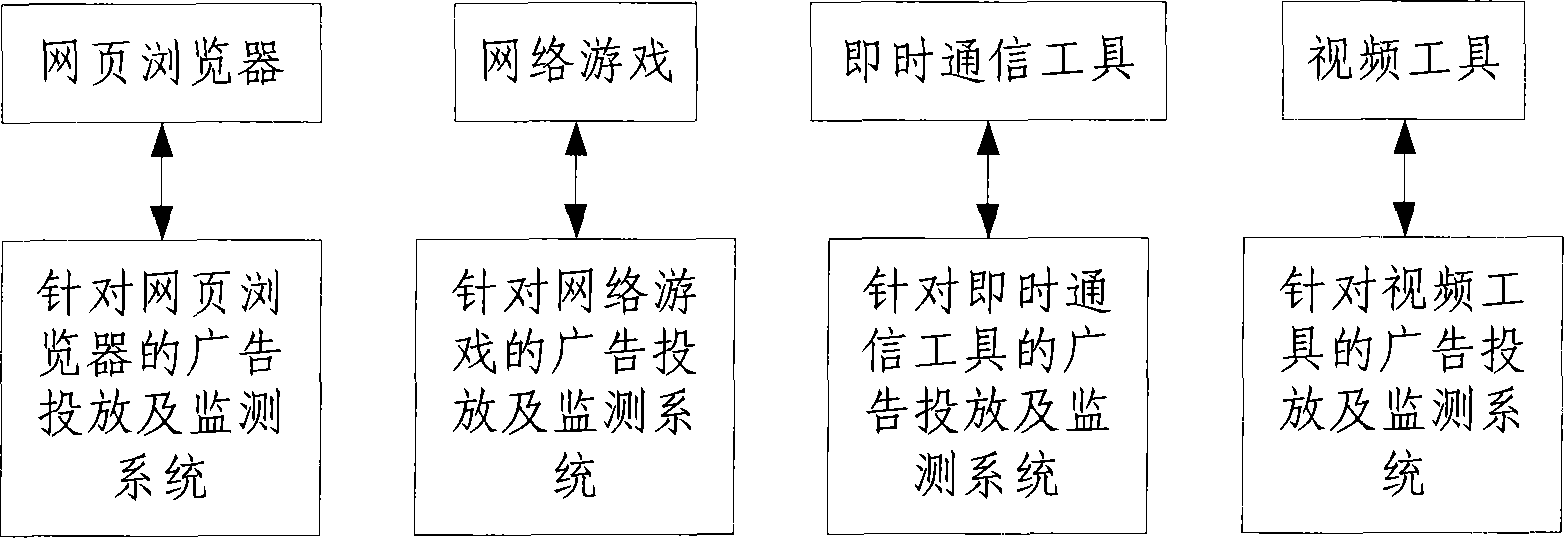

Method, system and related device for implementing on-line advertisement launching

ActiveCN101119223AImplement functions such as advertisingStrong scalabilitySpecial service provision for substationData switching by path configurationThe InternetClient-side

The present invention discloses a realizing method, a system and related devices of the on-line advertisement broadcast. An on-line advertisement request with a type label is sent to an advertisement service terminal in an advertisement client terminal, in correspondence to an advertisement type adapter of the present internet application platform. The advertisement service terminal receives the on-line advertisement request which is from the advertisement type adapter, determines the internet application platform type according to the type label which is carried by the advertisement request, and provides an on-line advertisement document, which corresponds to the internet application platform, for the corresponding advertisement type adapter in advertisement client terminal. The advertisement type adapter which aims at different internet application platform can screen the difference of the on-line advertisements on the internet application platform on the advertisement service, so as to achieve the function of advertisement broadcast, etc. through the uniform advertisement service.

Owner:TENCENT TECH (SHENZHEN) CO LTD

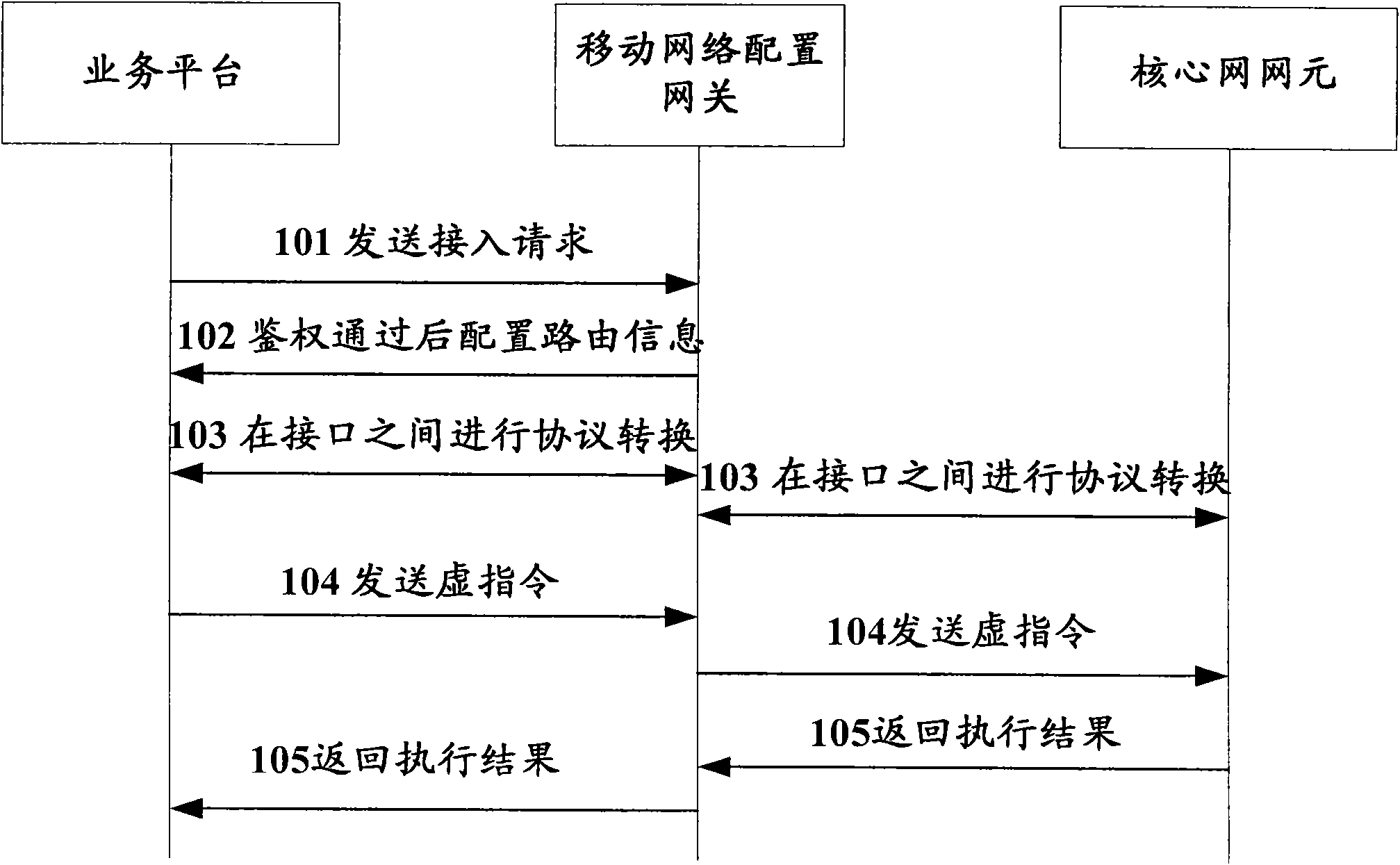

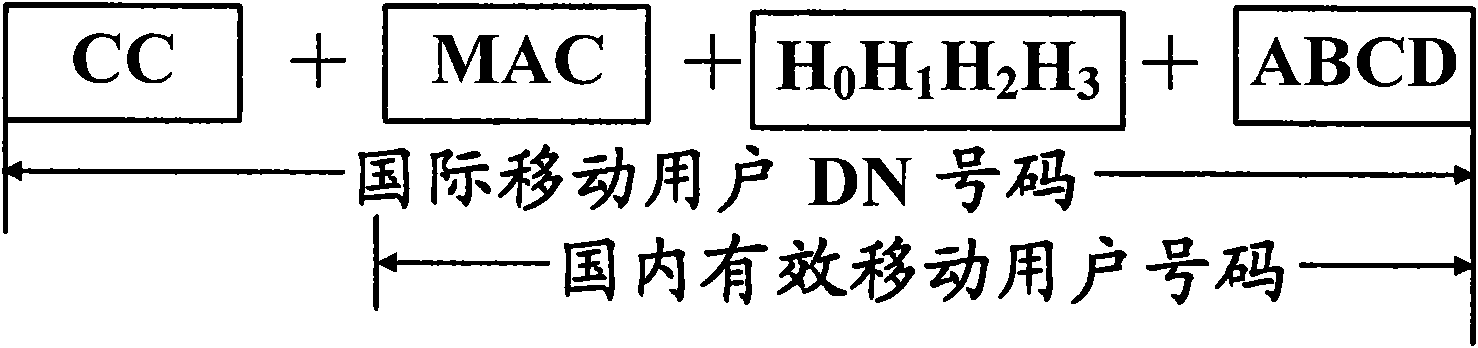

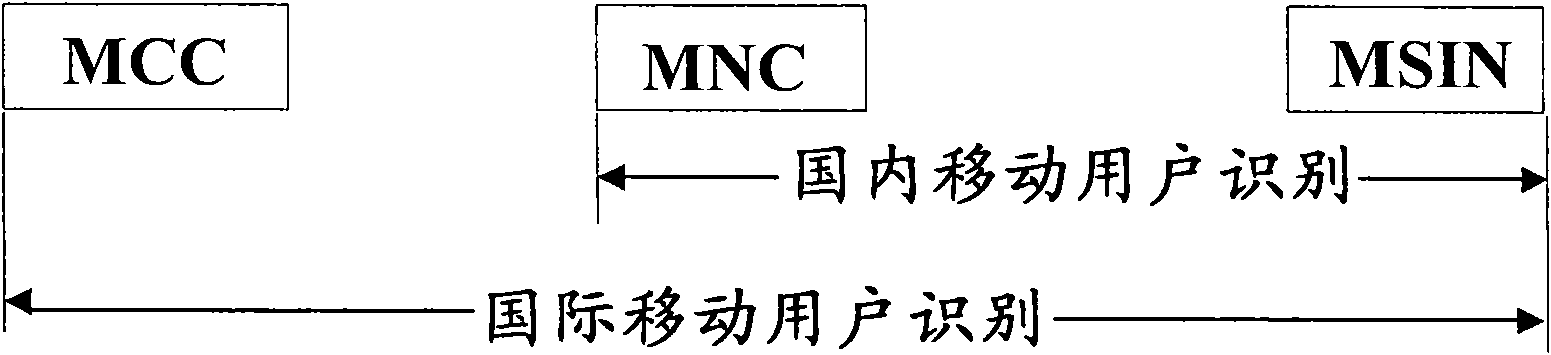

A user data configuration method, system and mobile line configuration gateway

ActiveCN101552989AEnsure safetyBlock direct accessConnection managementSecurity arrangementPasswordService configuration

The invention puts forward a user data configuration method, system and mobile line configuration gateway, which includes the following functions as: the mobile line configuration gateway carrying through authentication with the account number and password when the service platform sends or receives requests containing account number, password and identification information of network element of the core network, fixing on the network element of the core network needed to be carried through service configuration based on the aforementioned identification information after the authentication passed and configuring the aforementioned service platform with routing information based on the essential information of the network element of the core network, establishing communication connection and carrying through protocol transformation between the service platform connector and the connector of network element of the core network, the aforementioned service platform sending deficiency instruction to the network element of the core network through the mobile line configuration gateway, and carrying through service configuration with the aforementioned network element of the core network. This invention implements the service configuration and service query between the frontend service platform and the after end network element for actually storing user data with the increased mobile line configuration gateway.

Owner:CHINA TELECOM CORP LTD

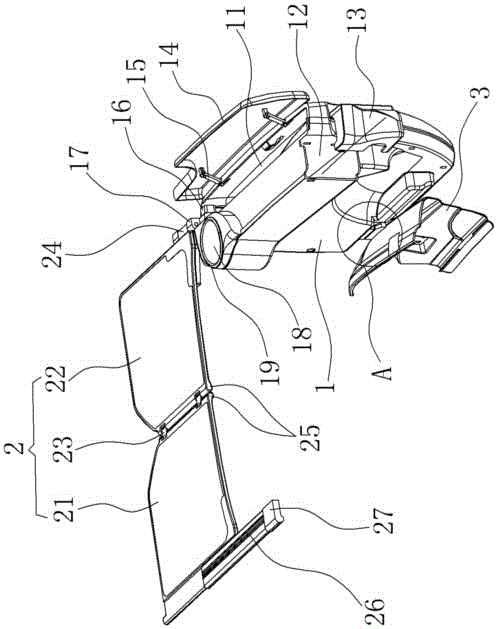

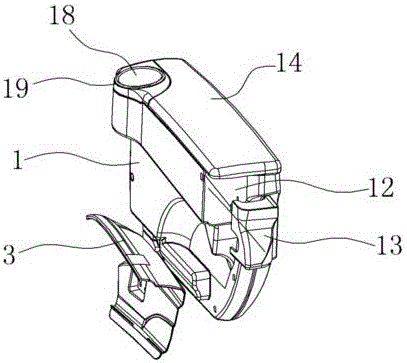

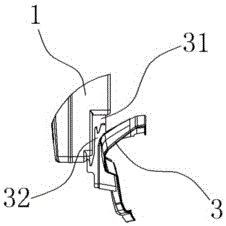

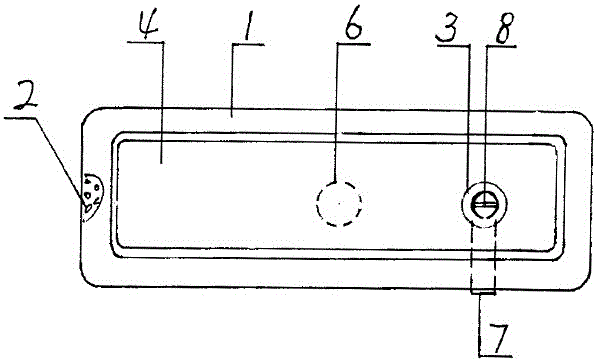

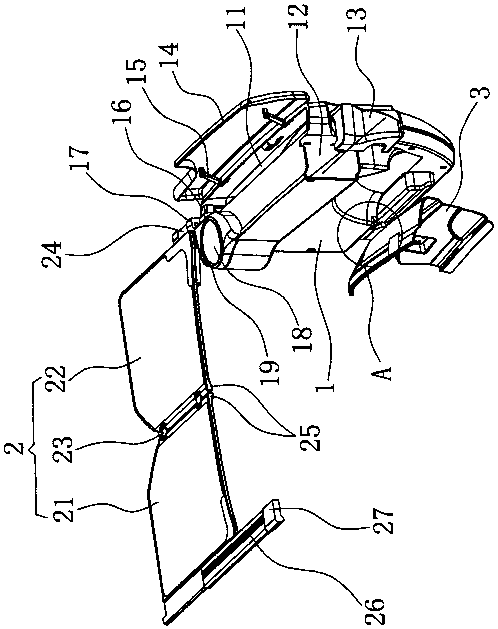

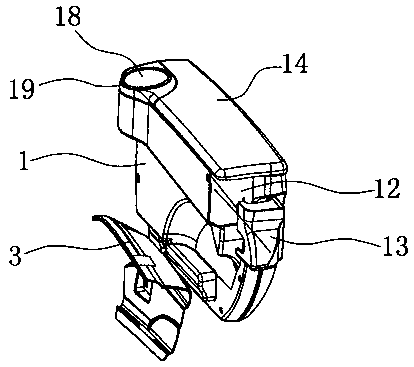

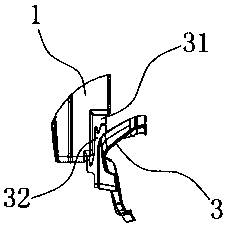

Hidden folding table for automobile

InactiveCN105711463AIncreased load-bearing capacityUse will not affectVehicle arrangementsWeight-bearingHandrail

The invention discloses a hidden folding table for an automobile. The hidden folding table structurally comprises a main body, a table plate groove, a folding table plate and the like, and is mainly characterized in that the upper part of the back end of the main body is additionally provided with an installing hole which is used for anastomotically sheathing an armrest of an automobile seat; then, the inner side of the main body is provided with a clamp tooth assembly which is detachably clamped and arranged at the side surface of the automobile seat; through the design of the installing hole and the clamp tooth assembly, the main body can be stably and firmly arranged at one side of the automobile seat; meanwhile, the folding table plate uses double table plates in open and close design, so that the hiding function is not influenced, and the use area is also increased; one hanging end of the folding table plate is also provided with a supporting rod for supporting, so that the two ends of the folding table plate have supporting force; the weight bearing force of the folding table plate is greatly enhanced; the improved structure can carry more articles in the use process and bear computer placement during work; during folding, the folding table plate is completely hidden in the main body; the use of the seating space of the automobile seat cannot be influenced, so that the temporary use requirements such as dining or working in the automobile can be fully met.

Owner:NINGHAI COUNTY HUAMENG MOLD CO LTD

Grafted protein hydrogel biological material and its preparing process

The invention relates to an aquagel material used to recover hurt nerve center. Wherein, it uses nerve center cross method to graft the layer adhesive protein (Laninin) with nerve grow activity to the molecule skeleton of transparent acid aquagel, to rpare the aquagel frame, which can accelerate the regeneration of nerve axon.

Owner:首都医科大学北京神经科学研究所

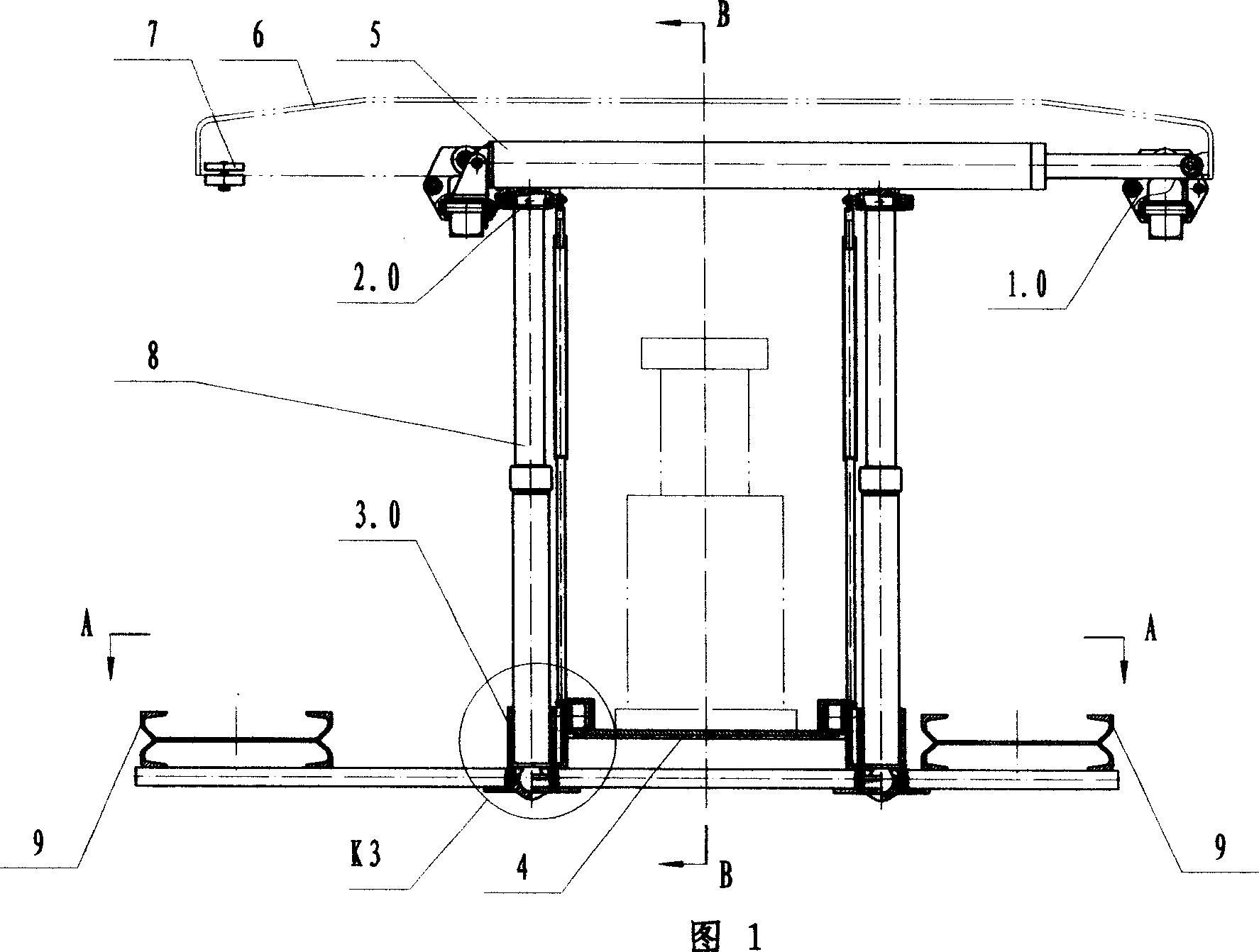

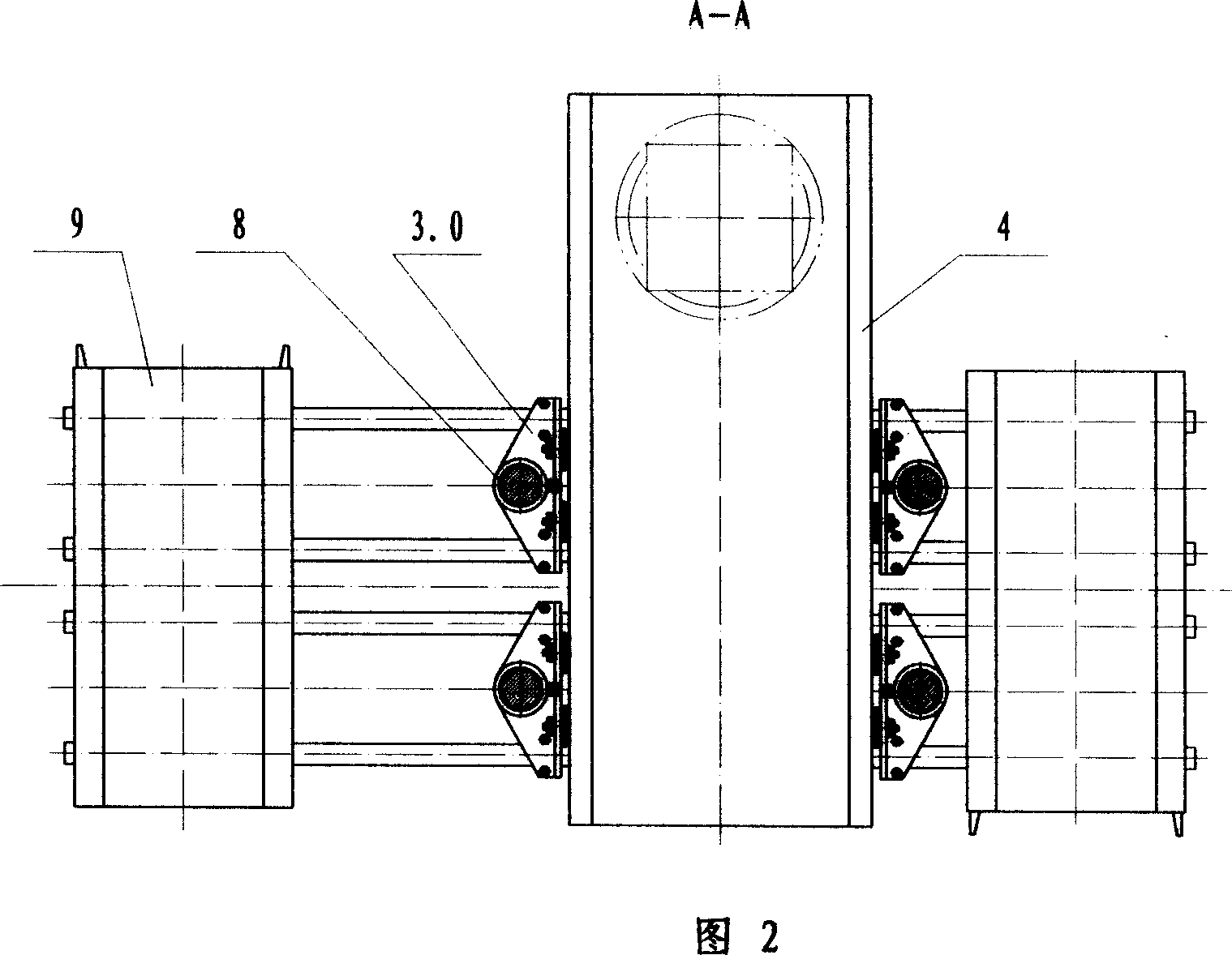

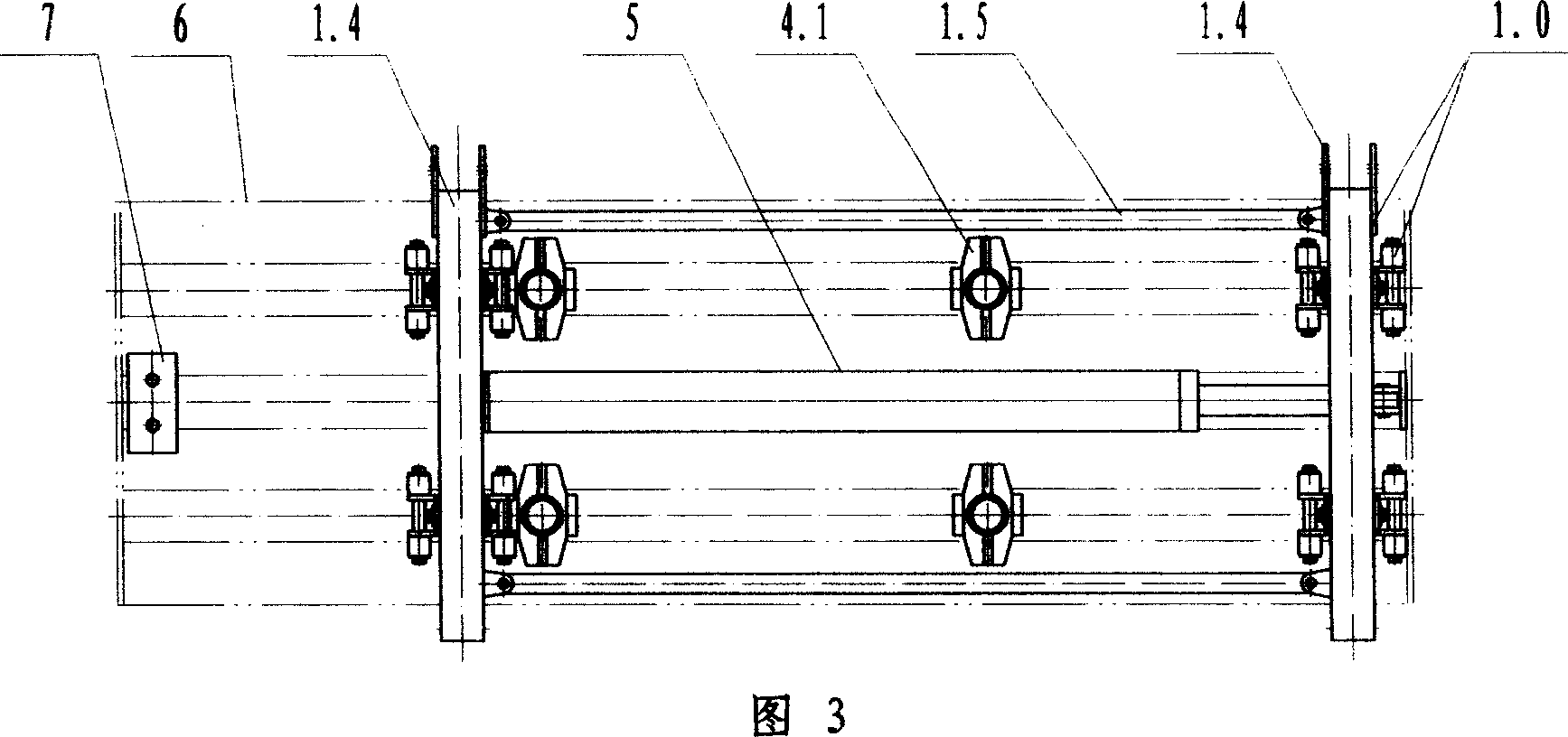

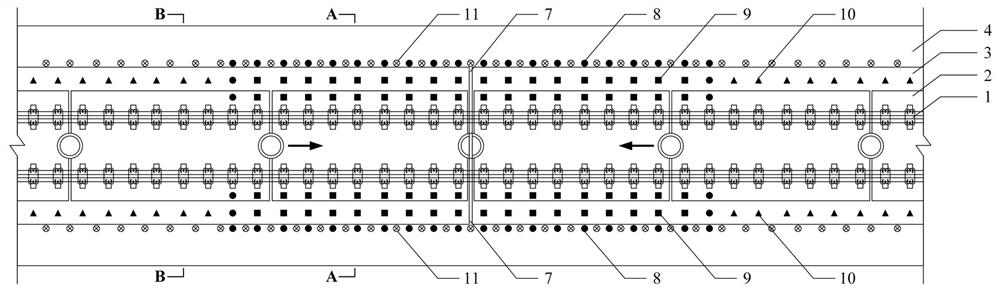

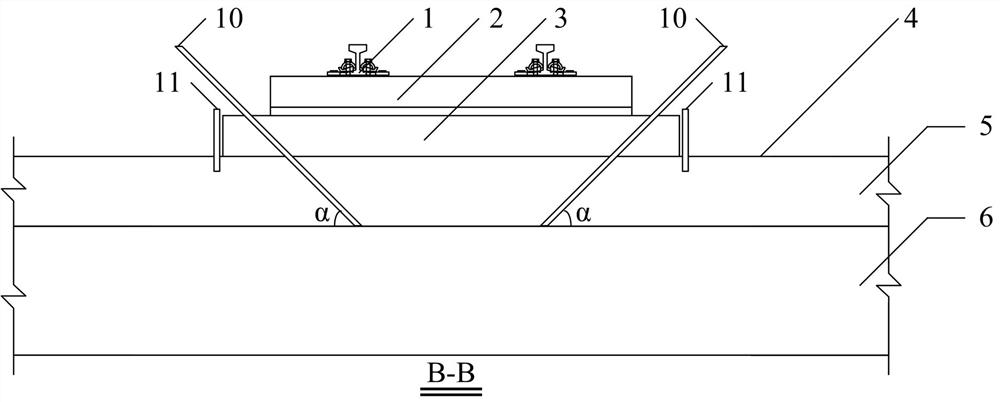

Combined suspension moving hydraulic support with universal upper bracket and lower hanging beam

InactiveCN101063409AReduce processing and manufacturing costsImprove integrityProps/chocksHydraulic cylinderEngineering

The invention relates to an assembled hanging hydraulic support with a universal upper holder and a lower hanging beam, comprising a top beam, a step-type hydraulic cylinder, a hydraulic prop, a step size adjusting location baffle, the universal upper holder, the lower hanging beam and a picking flat car, characterized in that the universal upper holder comprises a roller holder and a holder, while the lower hanging beam comprises a beam, a hanger rod and a leg ring, and the picking flat car is equipped with a lifting tool capable of rotating, and the hydraulic prop is connected with the top beam via a three-axis and four-rope suspension second ball-hole, wherein the prop is lifted and moves in step with a drag conveyer. The invention has the advantages of simple structure, easy production and convenient assembling and repairing.

Owner:王振孝

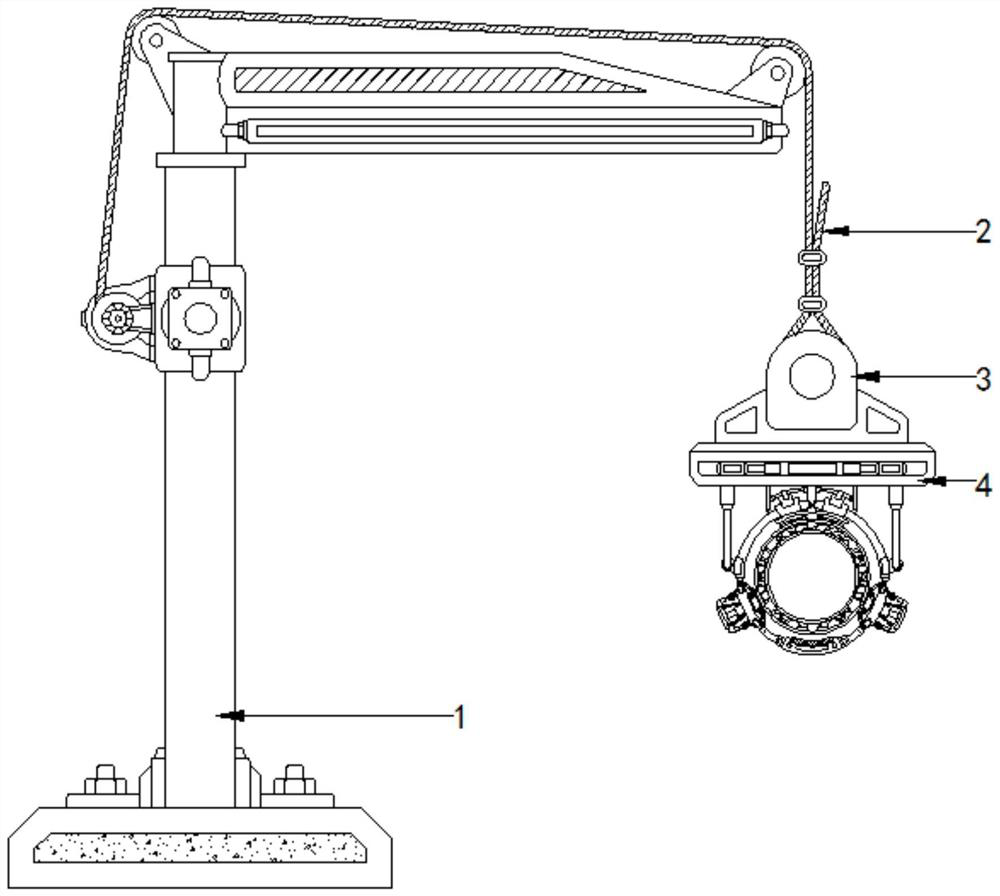

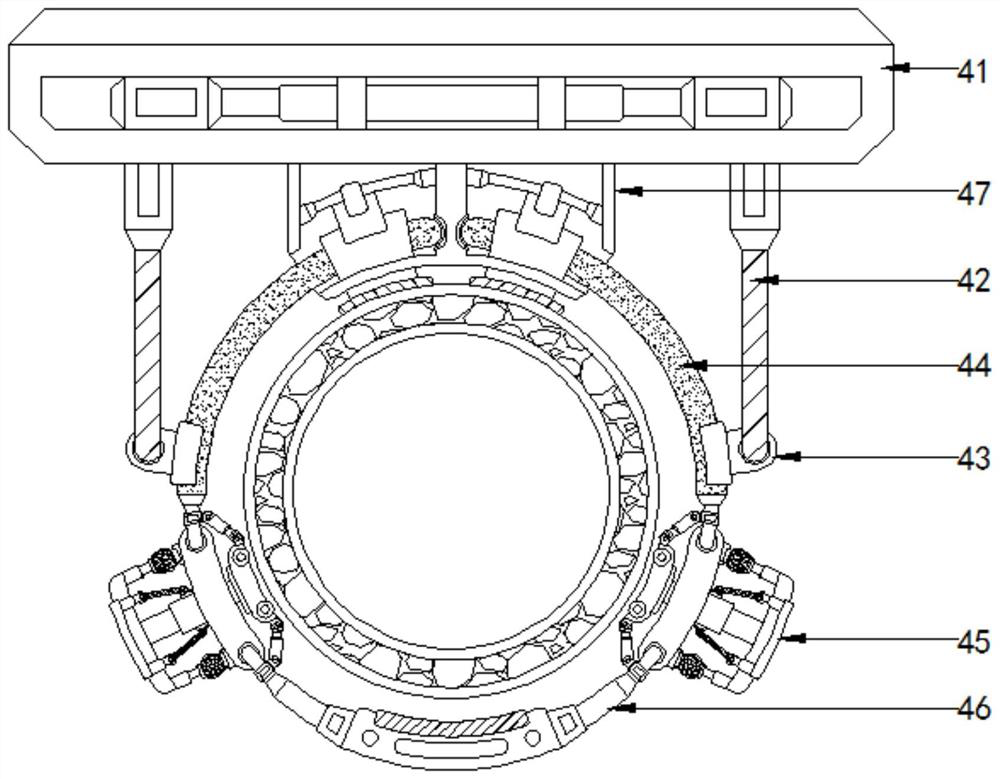

Hoisting device for cement pipeline hoisting

The invention relates to the technical field of hoisting devices, and discloses a hoisting device for cement pipeline hoisting. The hoisting device comprises a main body and a hoisting assembly, the outer wall of the top of the main body is movably connected with a steel cable, and the bottom of the right side of the steel cable is fixedly provided with a connector. According to hoisting device for cement pipeline hoisting, the cement pipeline is placed on a support plate. Then the steel cable is lifted, a mounting head and arc plates are tightened inward under the action of gravity, a connecting rod moves and a pneumatic rod shrinks, and meanwhile, a supporting assembly is folded inward, so that a limiting plate has a certain supporting force, and the supporting force acts on a supporting plate, so as to produce a certain supporting force for the cement pipeline; and then the two arc plates rotate towards the opposite sides and are inserted into extrusion heads, due to the fact that the extrusion heads are provided with mounting grooves, the extrusion heads can move downwards under the action of the arc plates, and meanwhile, the extrusion plates move downwards, extrusion force is generated on the cement pipeline, and then the effect that the cement pipeline bears uniform supporting force is achieved.

Owner:桐庐红狮水泥有限公司

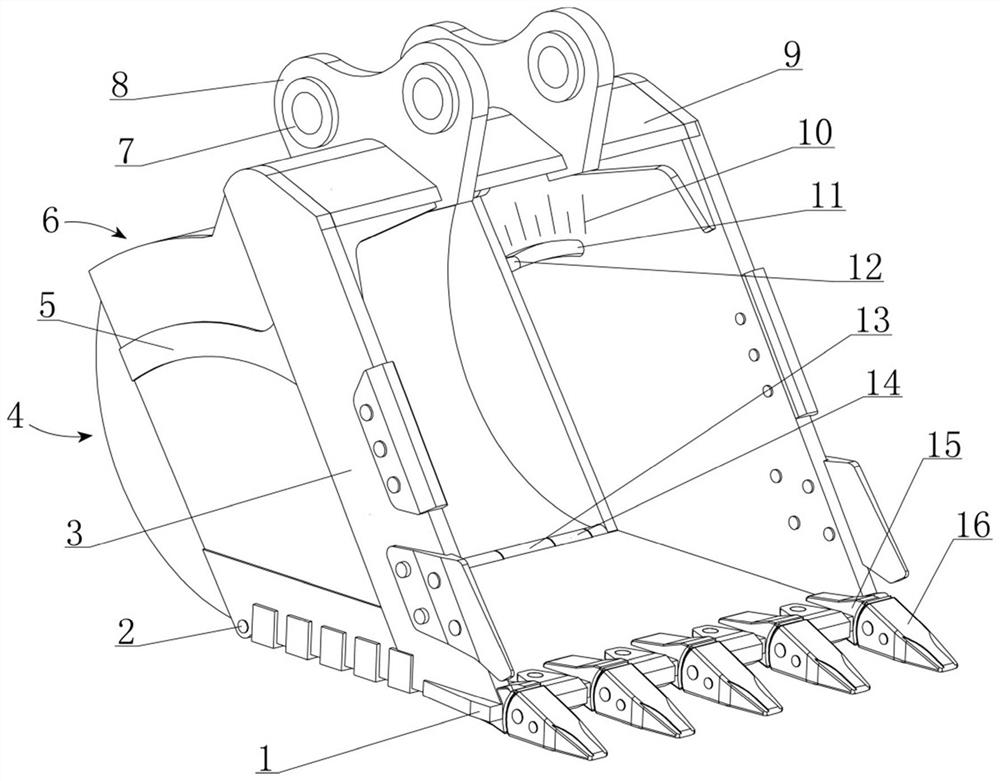

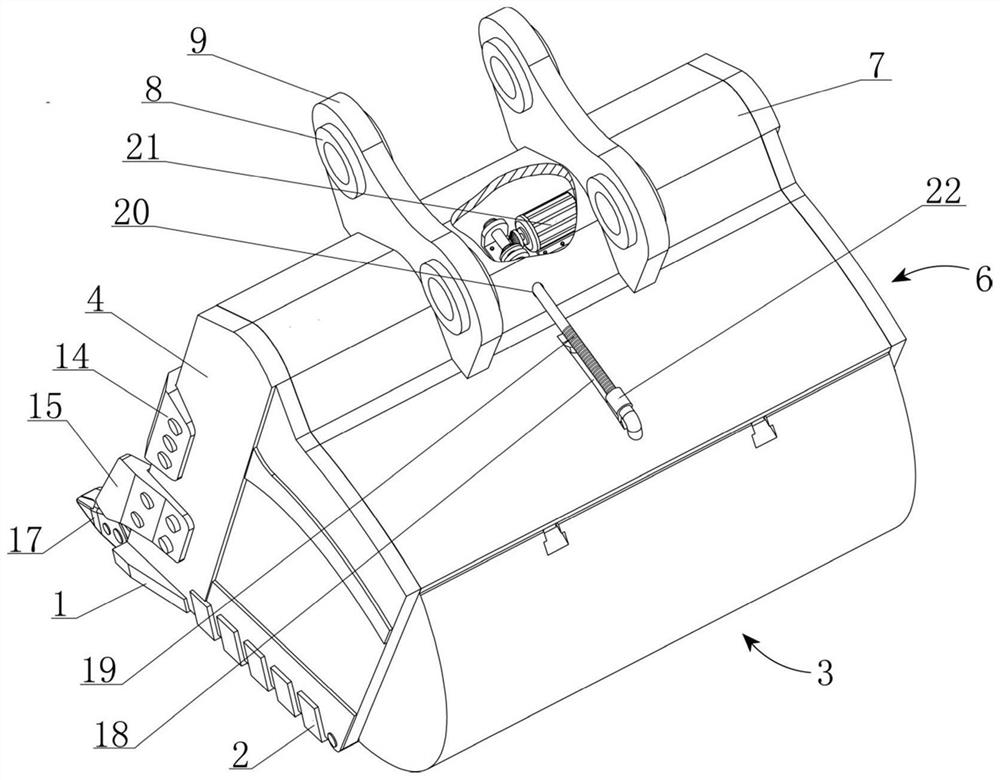

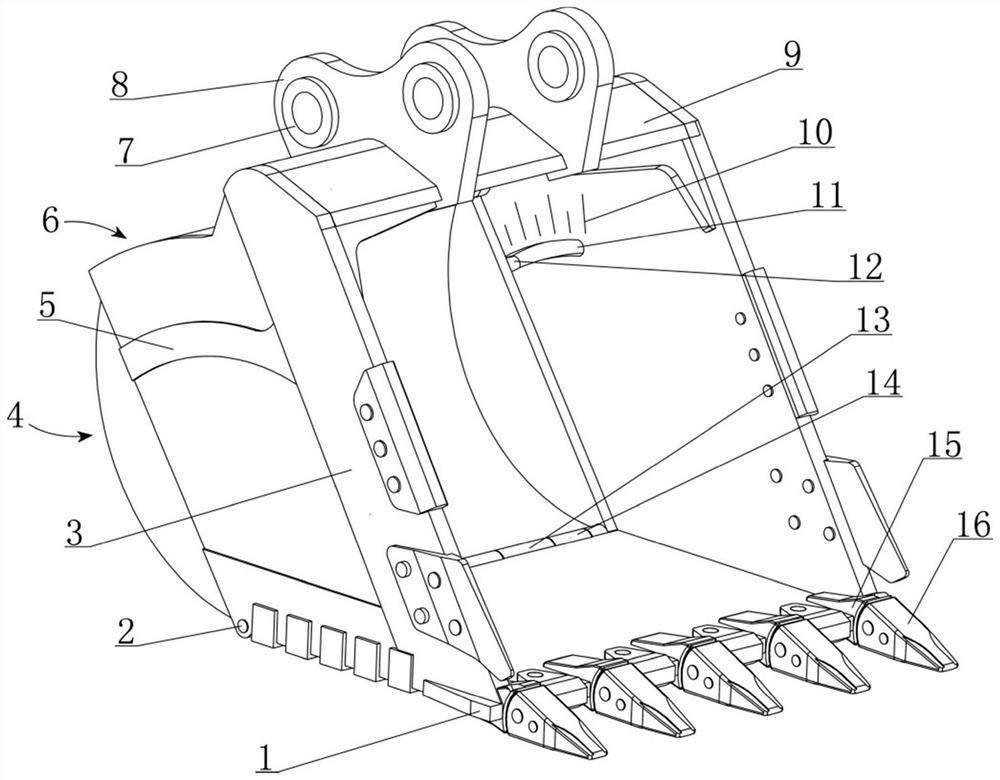

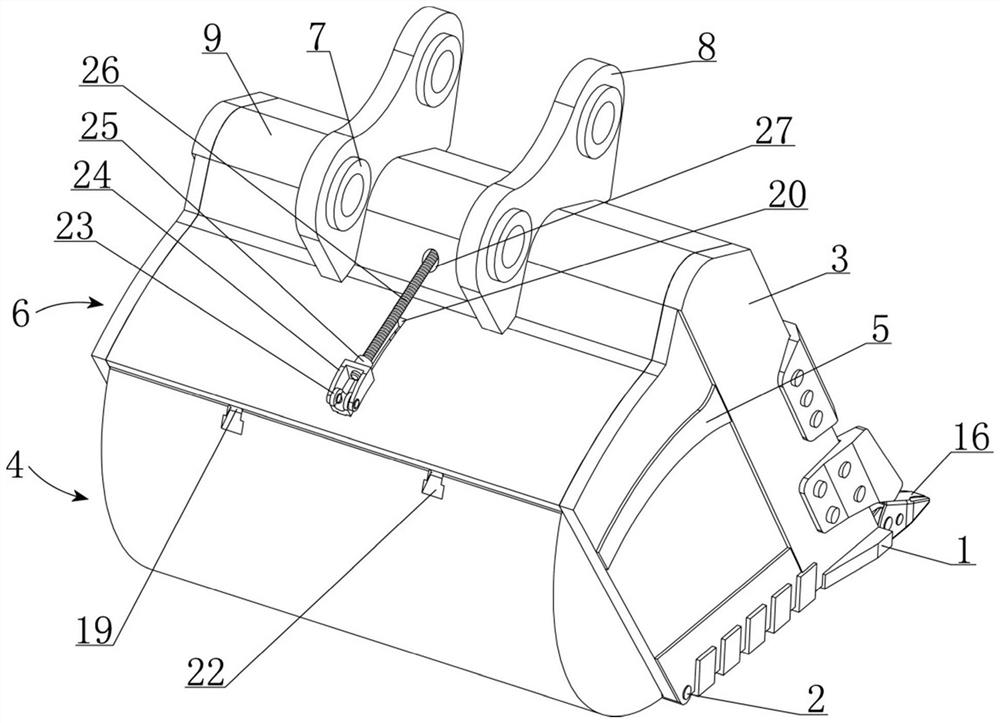

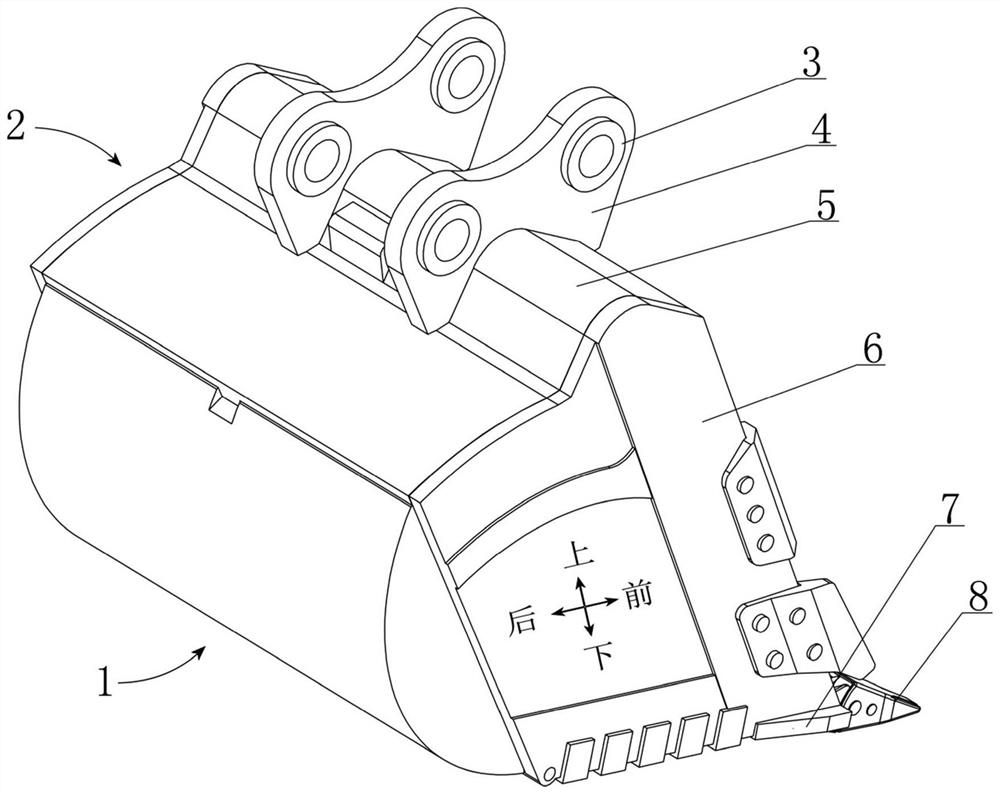

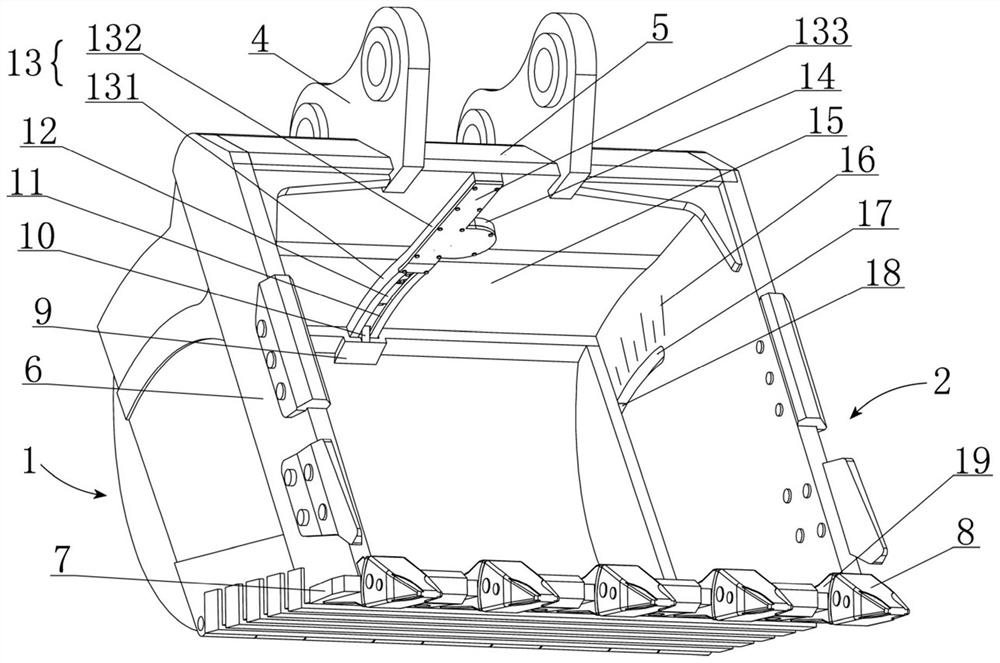

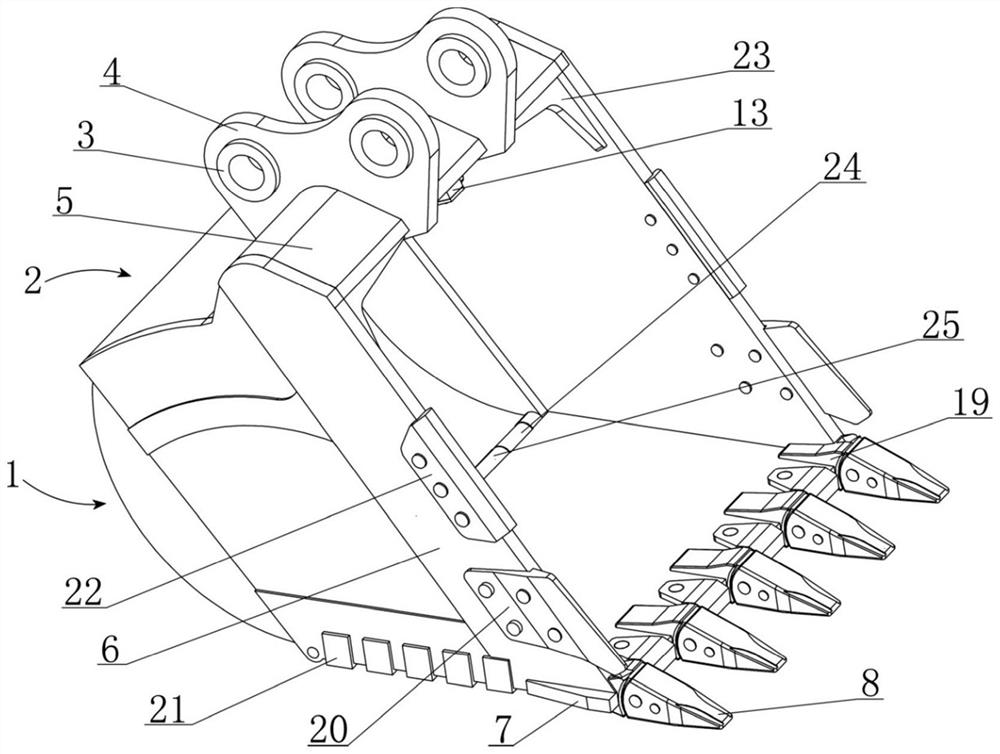

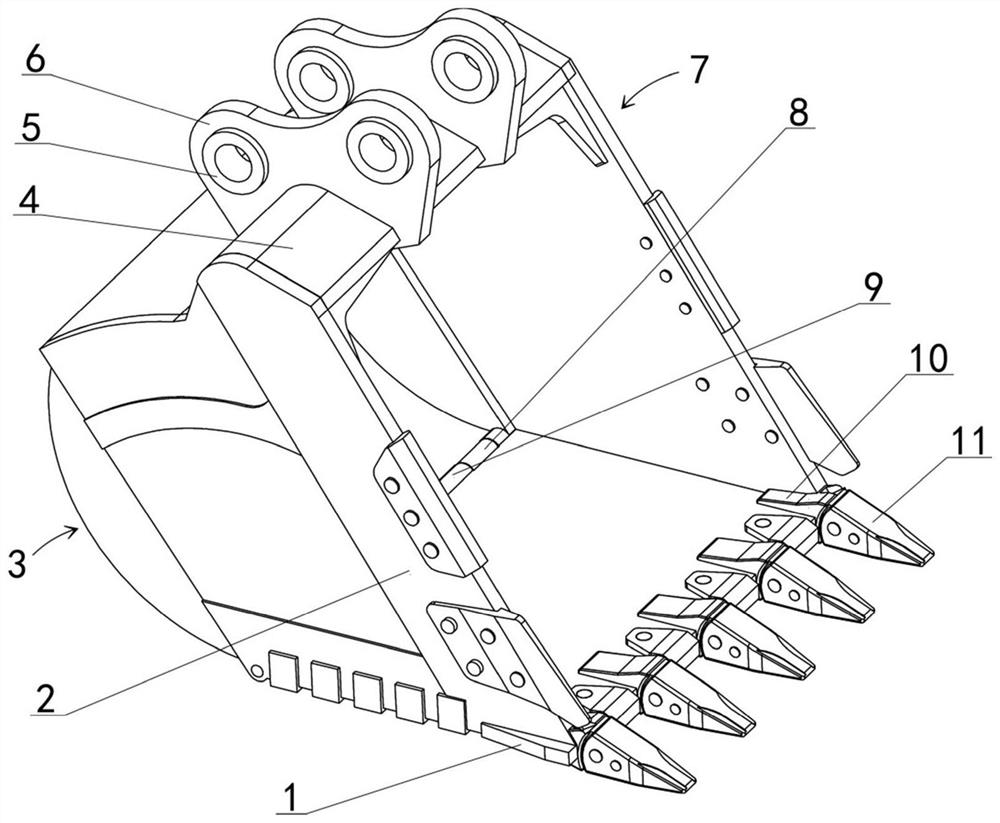

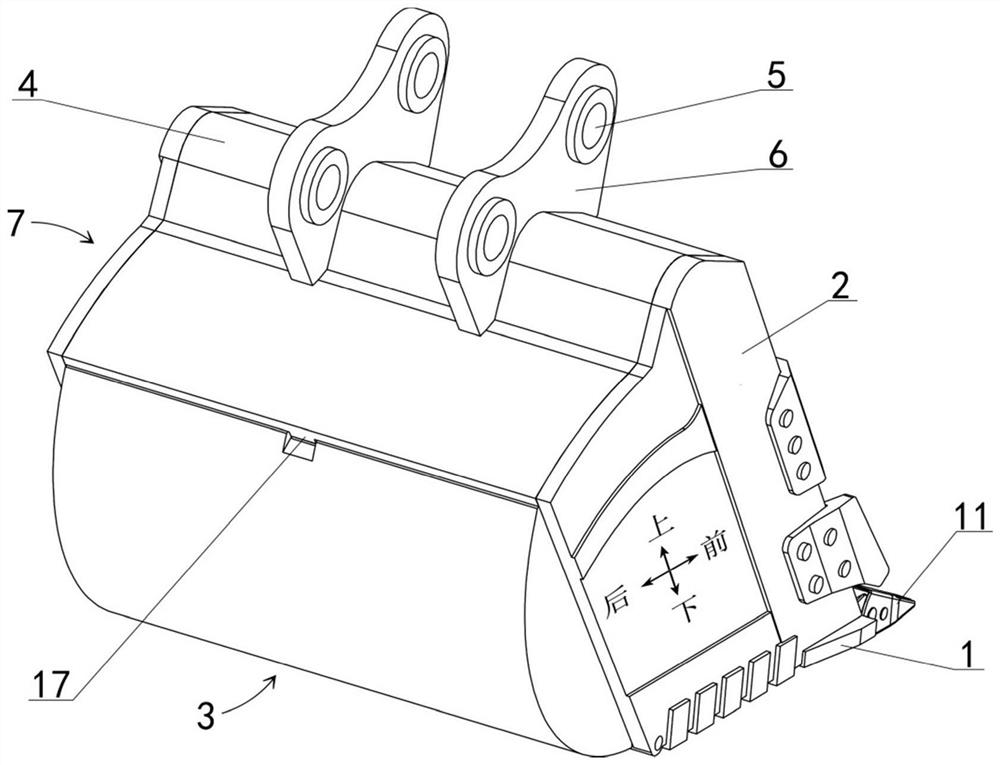

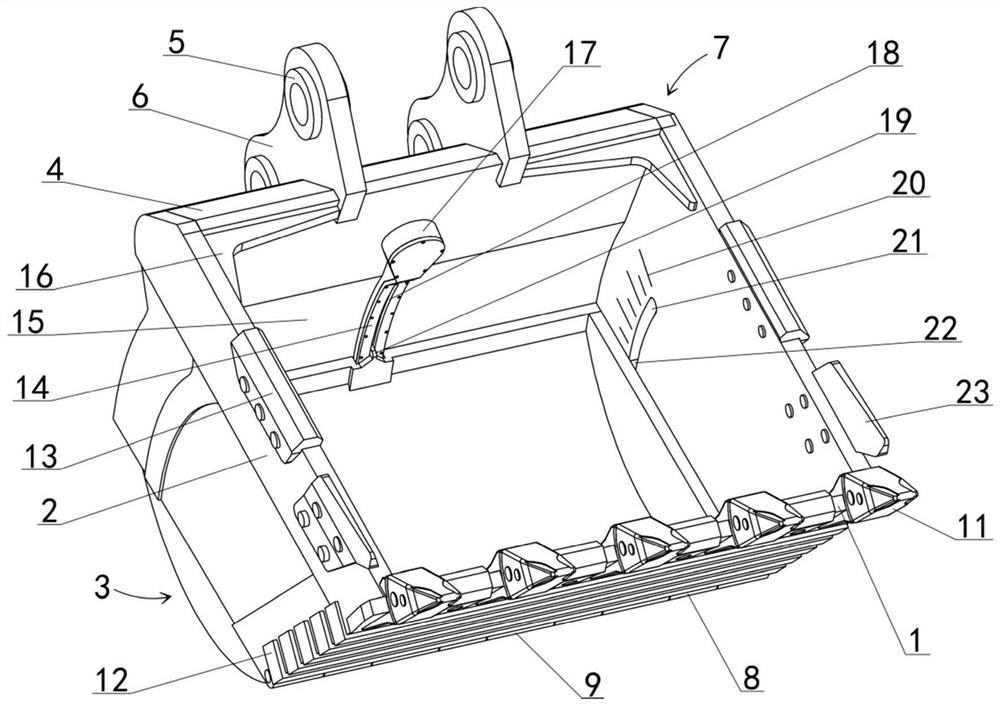

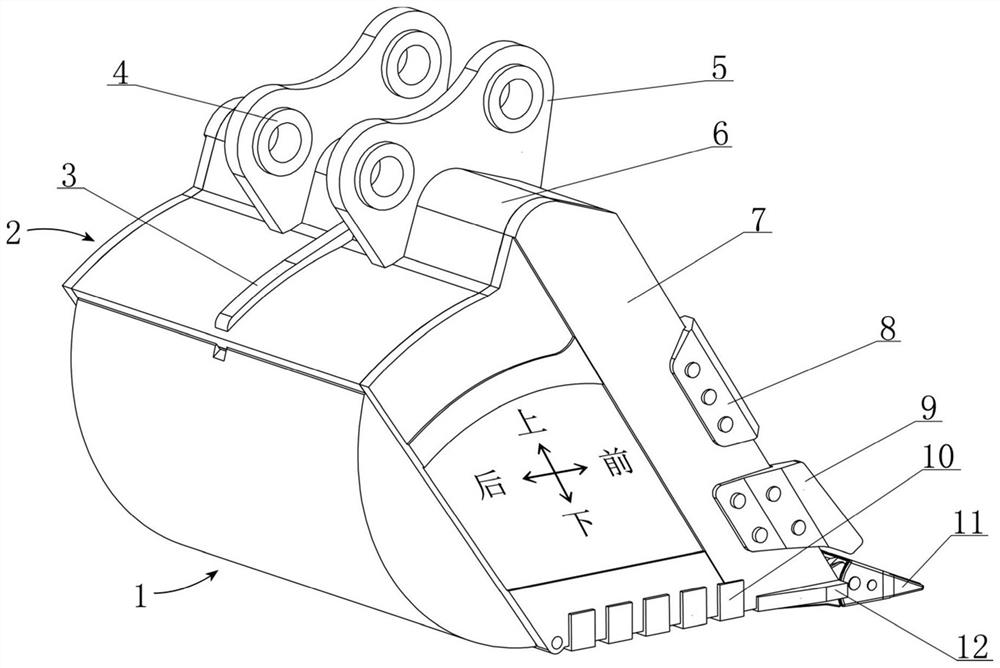

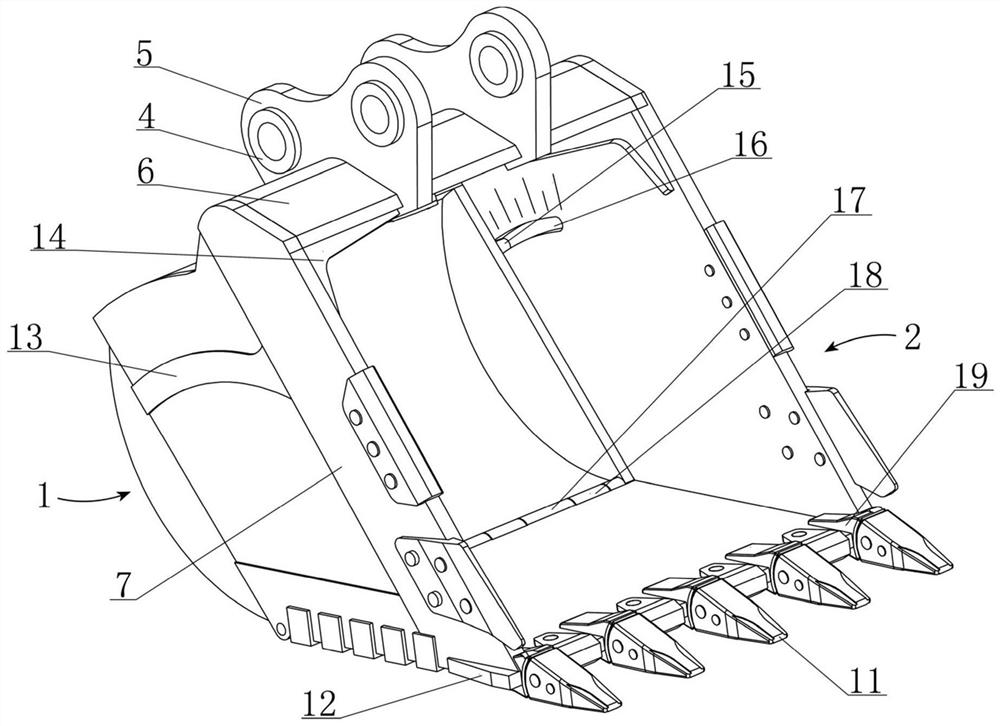

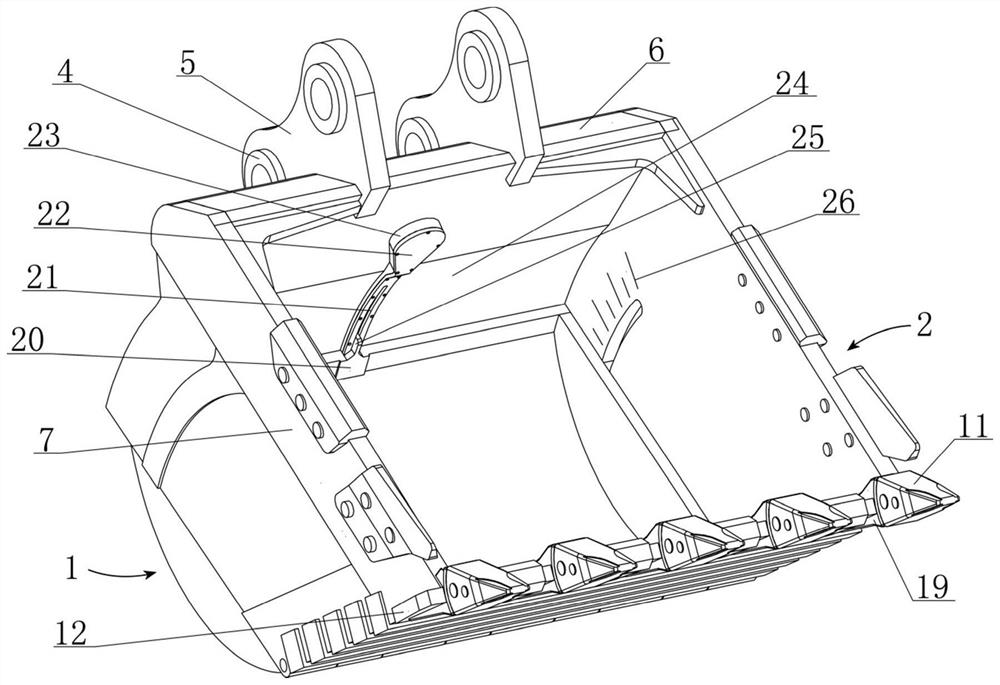

Excavator bucket for constructional engineering

PendingCN112281947AWith capacity adjustment functionStable jobMechanical machines/dredgersElectric machineryExcavator

The invention relates to an excavator component, and particularly discloses a bucket. The bucket comprises a bucket body with an opening in the rear end, a guide groove is formed in the upper wall ofthe bucket body, the rear lower end of the bucket body is hinged to a bottom cover, a guide block matched with the guide groove is arranged at the upper end of the bottom cover, the bottom cover rotates forwards, the bucket capacity is reduced, and otherwise, the bucket capacity is increased; and a traction base is arranged at the outer end of the guide block and hinged to a traction arm, and a threaded sleeve is arranged at the other end of the traction arm. A swing seat and a motor device are arranged above the bucket body, a main shaft driven by a motor device is arranged on the swing seat,and the main shaft is matched with the threaded sleeve so that the position of the bottom cover can be adjusted through rotation to achieve bucket capacity adjustment. The bucket has a bucket capacity adjusting function and can be adjusted according to actual working conditions, and the operation efficiency can be improved to the maximum extent on the premise that stable work of an excavator is guaranteed; the bucket capacity is convenient and fast to adjust, and time and labor are saved; and a spare bucket is not required to be arranged, so that the equipment acquisition cost is reduced, andthe defects of labor consumption, operation efficiency reduction and the like of the spare bucket in transportation, disassembly and assembly are overcome.

Owner:黄付银

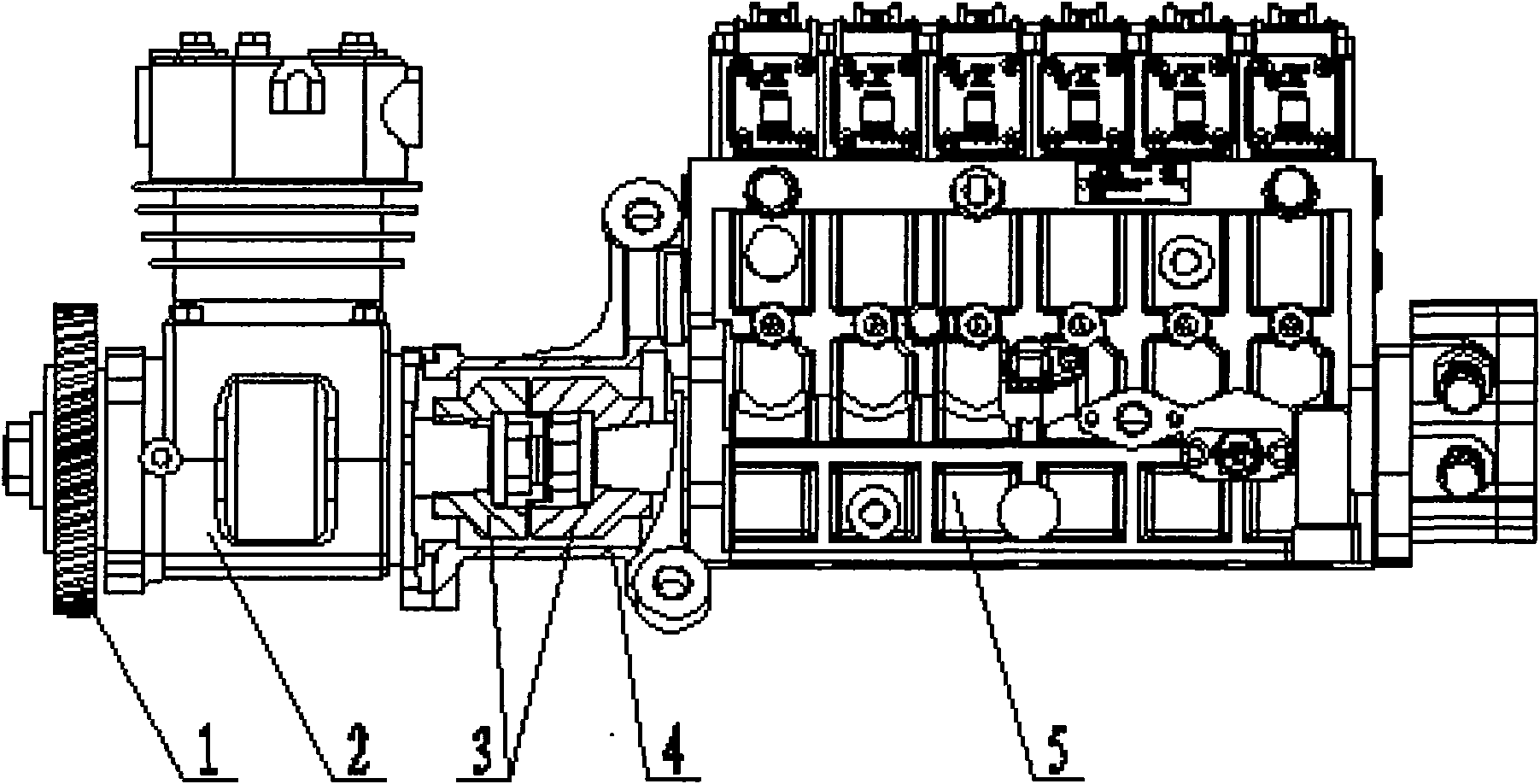

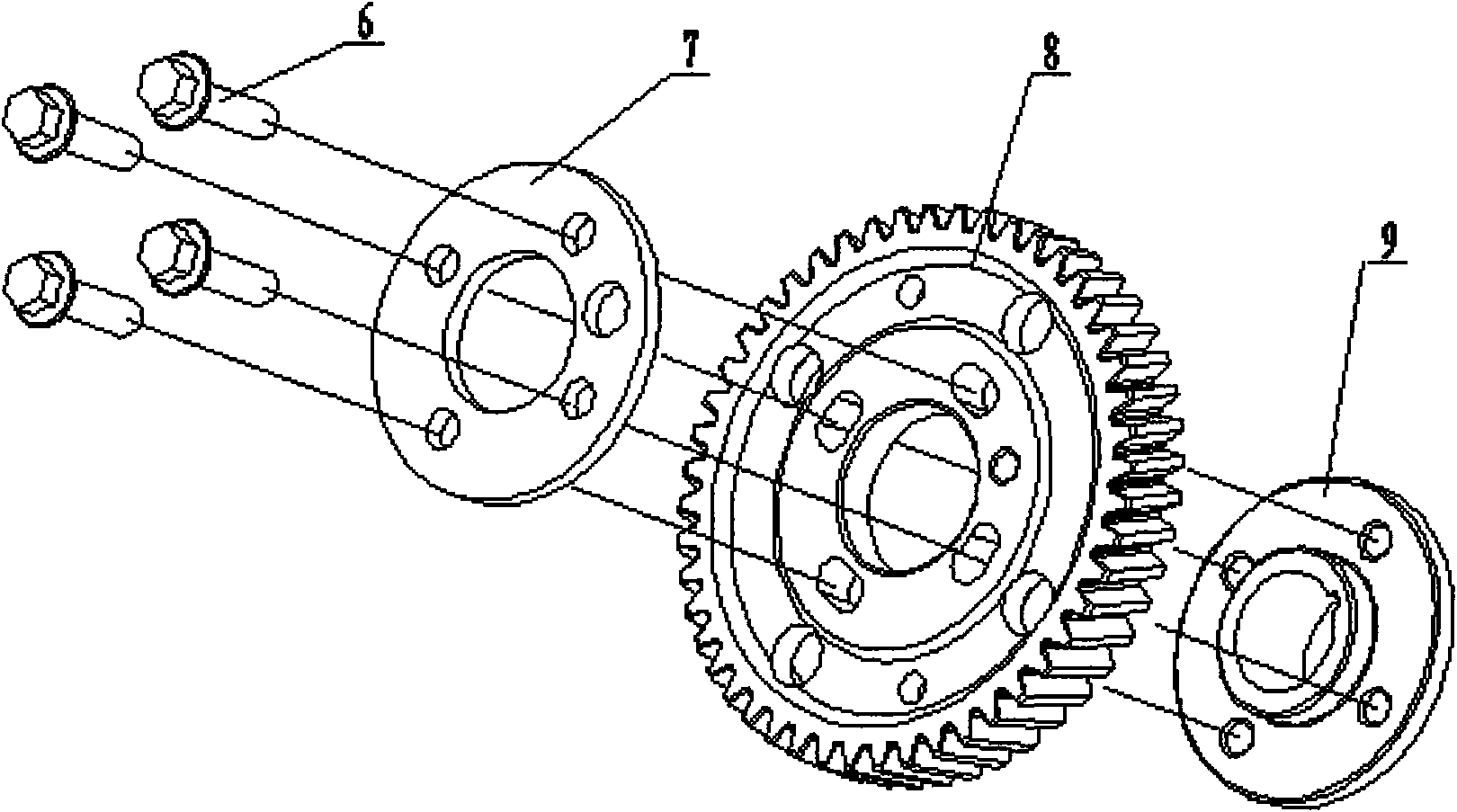

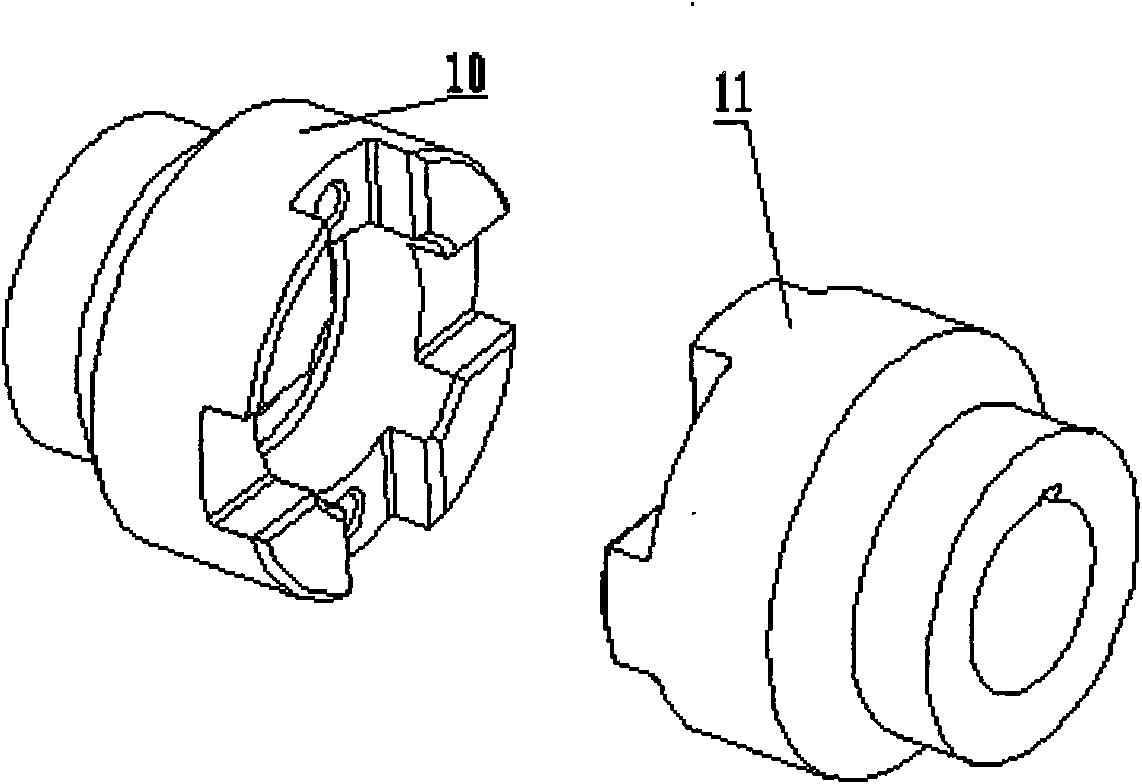

Large-torque driving device of engine

InactiveCN101968005ASimple structureLarge transmission torqueFuel injection apparatusCouplings for rigid shaftsGear driveGear wheel

The invention discloses a large-torque driving device used for an engine. The driving device comprises a gear component, driving pawl components and a driving cover, wherein the gear component is engaged with a gear system of the engine; through gear driving, the gear component drives an air compressor; the air compressor drives an electronic fuel injection pump through the drive pawl components; the drive pawl components are respectively arranged on the shaft of the air compressor and the shaft of the electronic fuel injection pump; through the engagement of two driving pawls, the air compressor drives the electronic fuel injection pump to rotate; and the driving cover is used for sealing and lubricating the driving pawl components and simultaneously supporting and positioning the installation of the electronic fuel injection pump. The large-torque driving device has the advantages of simple structure, driving torque up to 570N.m, and high reliability, can adjust a timing phase angle of the electronic fuel injection pump, and can be widely used in the field of manufacturing engines of which the emission is up to over national standard 3.

Owner:GUANGXI YUCHAI MASCH CO LTD

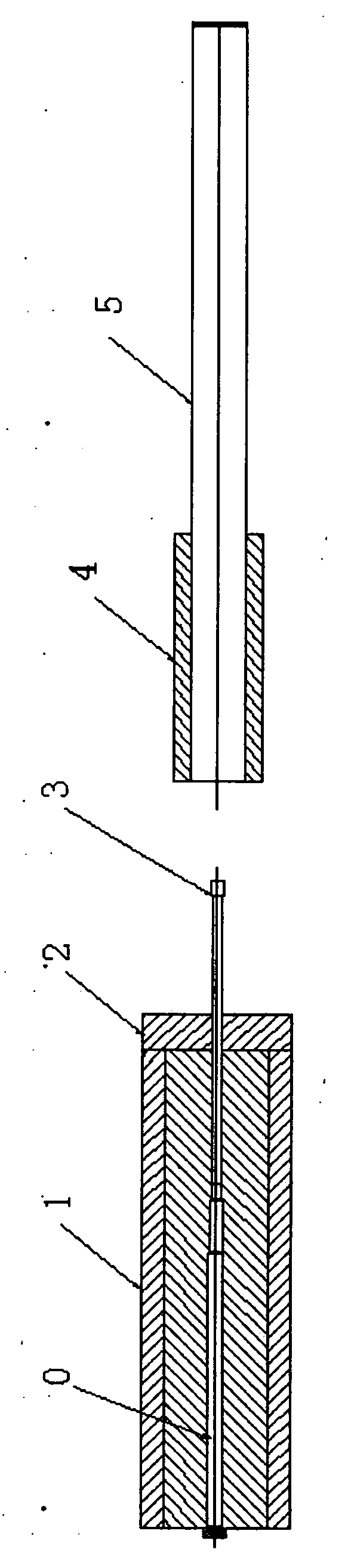

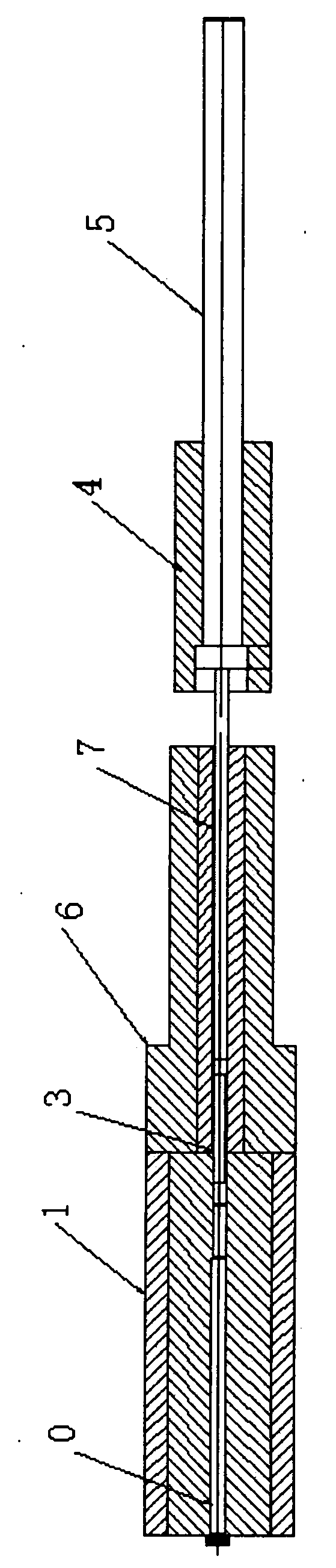

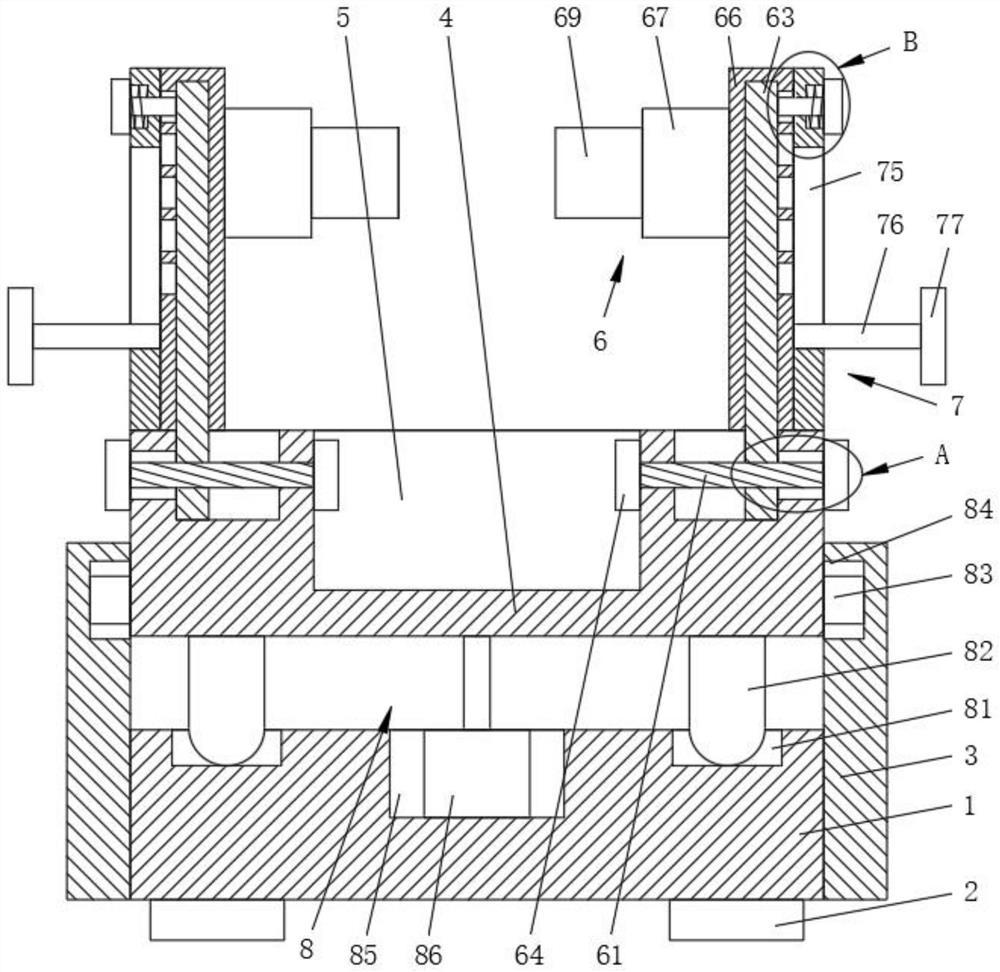

Cold upsetting forming die of slender bolt

InactiveCN101927311AShorten the lengthIncrease the outer diameterBoltsForging/hammering/pressing machinesEngineering

The invention discloses a cold upsetting forming die of a slender bolt. The forming die comprises a female die, a dredging bar, a backrack big screw and a back movable connection rod; one end of the dredging bar is arranged in the cavity of the female die; the back part of the female die is provided with the backrack big screw; and the back movable connection rod is arranged at the center of the backrack big screw. The invention is characterized in that the back of the female die is also provided with a safety protection pipe; the safety protection pipe is sleeved on the other end of the dredging bar; and the central hole of the safety protection pipe is opposite to the cavity of the female die. As the safety protection pipe is arranged on the periphery of the dredging bar and the central hole of the safety protection pipe is opposite to the cavity of the female die, the length of the female die can be set to be shorter; as the external diameter of the dredging bar is increased and the dredging bar is supported, the dredging bar is difficult to bend or crack in the driving or retreating process and the work efficiency can not be influenced; and as a starting tringle is added on the front part of the back movable connection rod, the length of the back movable connection rod can be shortened, the weight can be lightened and the defect that the back movable connection rod is difficult to process can be overcome.

Owner:MORGAN HARDWARE KUSN

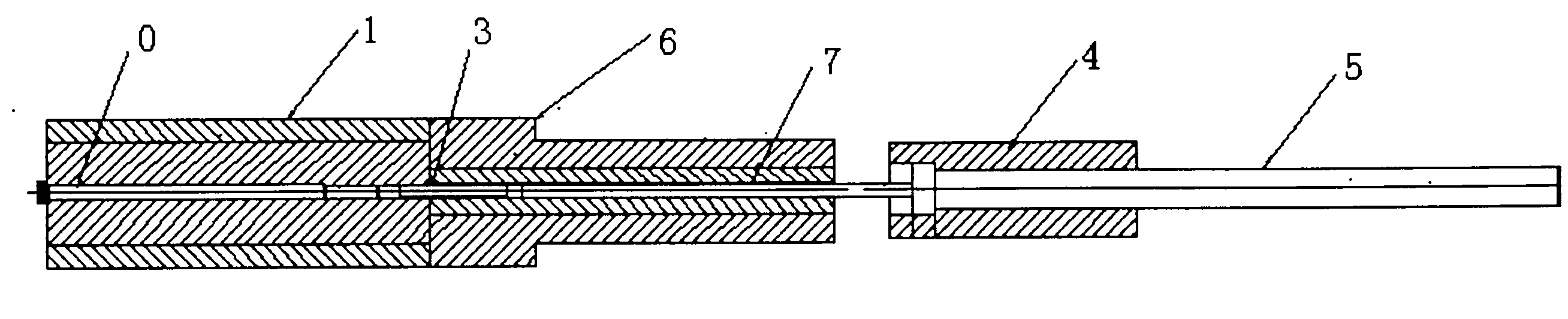

High polymer grouting repair method for treating ballastless track foundation bed mud pumping

The invention discloses a high polymer grouting repair method for treating ballastless track foundation bed mud pumping, which is characterized in that residual accumulated water and mud in a foundation bed surface layer in a mud pumping disease area are squeezed and discharged in a high-pressure grouting manner, and pores in the foundation bed surface layer and a void area at the bottom of a base plate are fully filled, so that the stress condition of the foundation bed surface layer is improved; the whip effect of the track structure under the train operation load effect is relieved; and meanwhile, grouting is conducted on the junction of the side edge of the base plate and the concrete sealing layer, and rainwater is prevented from intruding into the channel. And after high polymer grouting is completed, sealing glue is adopted for sealing expansion joints in the ends of the base plates and cracks in the side edges of the base plates correspondingly, and rainwater is further prevented from invading the channel. According to the method, the supporting rigidity of the surface layer of the foundation bed in the disease area is enhanced, the stress characteristic of the track structure is improved, a rainwater invasion channel is effectively blocked finally, the long-term service performance of the repaired foundation bed is guaranteed, and the frost boiling and mud emitting diseases of the ballastless track foundation bed of the high-speed railway can be well treated.

Owner:ZHEJIANG UNIV

Manufacturing method of pad 3D monofilament structure non-fabric composite elastic material

The invention relates to a manufacturing method of a pad 3D monofilament structure non-fabric composite elastic material. The manufacturing method comprises the following steps: a solid nomofilament or a hollow monofilament is pressed out, randomly or deliberately swings by using the height of the distance from mold stripping to the water surface, and is bonded to form a non-fabric structure before incomplete cooling; a foaming agent and a base material are filled in the formed non-fabric structure, and foaming objects thereof are fully filled in gaps of the non-fabric to finish a composite elastic material blank; the non-fabric structure is put in a mold, the foaming agent and the base material are injected, and foaming objects thereof are fully filled in the mold for cooling and mold stripping to finish a finished blank; and the finished blank is finished through a cold pressing or hot pressing technology. The manufacturing method has the following beneficial effects: a new composite elastic material is formed by injection foaming as a pad filling material, and has the advantages of ventilation, support force, lightness, easy molding, water washing and bacteria resistance in a traditional material; the atmospheric damage by PU sponge foaming can be reduced; and the purpose of recycling is achieved.

Owner:胡润屏

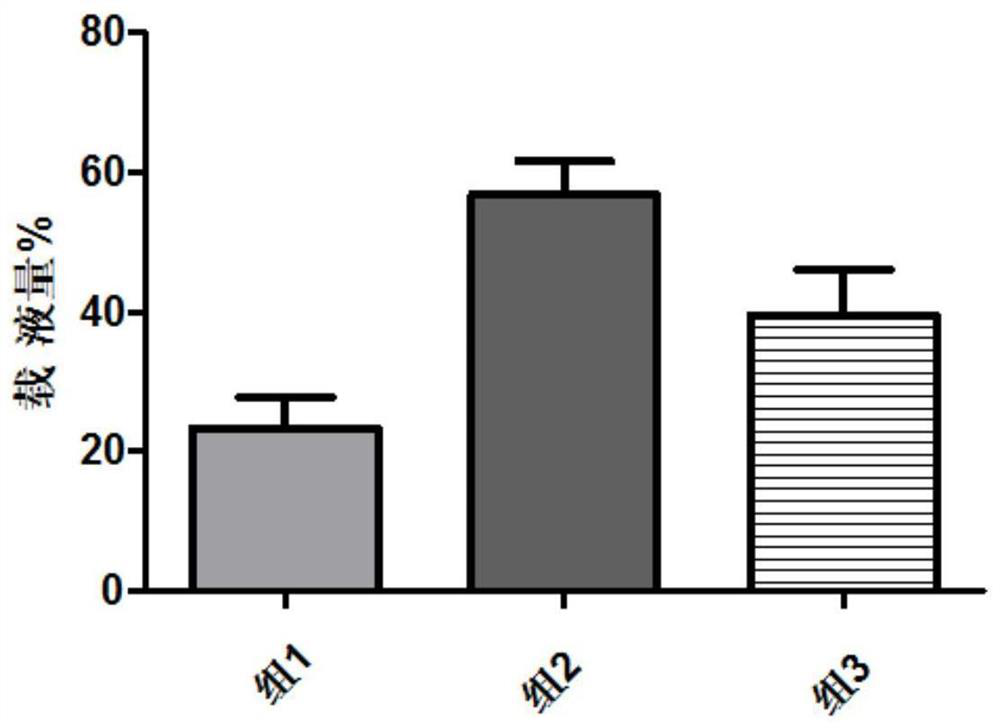

Tissue engineering material for inhibiting inflammation and promoting alveolar bone repair as well as preparation method and application thereof

ActiveCN112121229APromotes self-cell colonization and regenerationPeriodontal disease controlTissue regenerationProsthesisTissue engineeringPolyglutamic acid

The invention discloses a tissue engineering material for inhibiting inflammation and promoting alveolar bone repair as well as a preparation method and application thereof, and aims to solve the problem of influence of existing alveolar bone repair materials due to non-ideal periodontal disease control effect. The tissue engineering material for inhibiting inflammation and promoting alveolar bonerepair comprises an sPL platelet factor preparation, poly-gamma-glutamic acid and hyaluronic acid. The preparation method of the tissue engineering material for inhibiting inflammation and promotingalveolar bone repair comprises the following steps: 1, preparing the sPL platelet factor preparation; 2, adding poly-gamma-glutamic acid into the sPL platelet factor preparation, and carrying out uniform stirring; and then, adding hyaluronic acid, and carrying out uniform stirring so as to obtain a mixed solution, namely the tissue engineering material for inhibiting inflammation and promoting alveolar bone repair. The tissue engineering material for inhibiting inflammation and promoting alveolar bone repair disclosed by the invention is capable of controlling further absorption of the alveolar bone, as well as promoting autologous cell colonization so as to allow regeneration of the alveolar bone; and thus, alveolar bone regeneration can be effectively realized while controlling periodontal diseases. The tissue engineering material is used for repairing the alveolar bone.

Owner:天晴干细胞股份有限公司

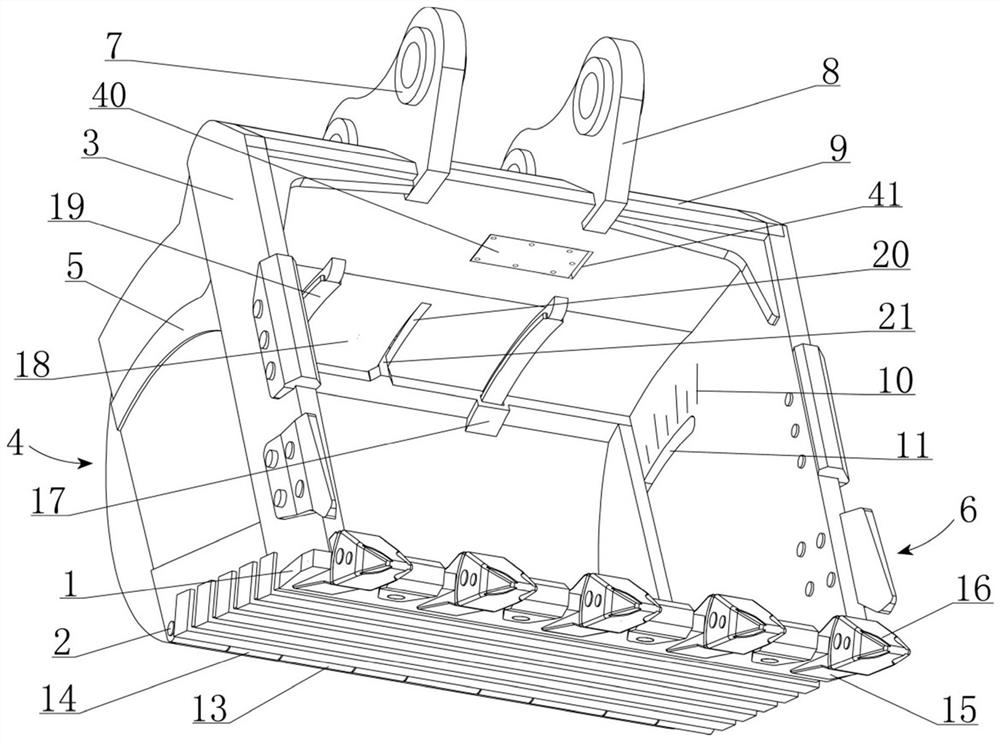

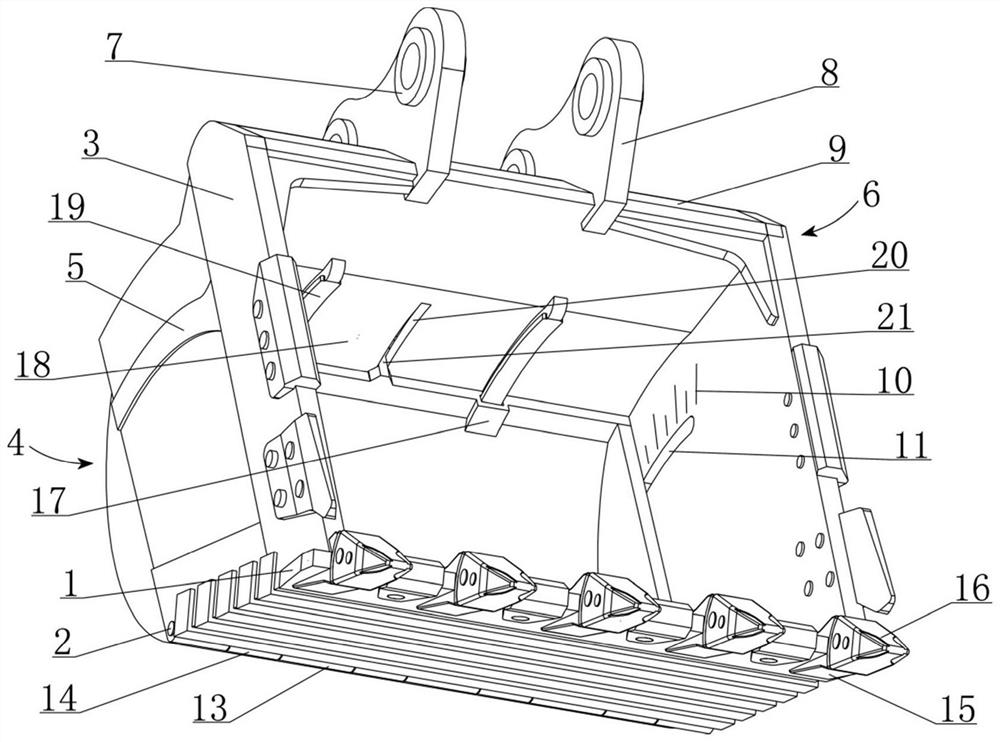

Excavator bucket for excavator

InactiveCN112281945AStable jobWith capacity adjustment functionMechanical machines/dredgersControl engineeringAgricultural engineering

The invention relates to an excavator component and particularly discloses an excavator bucket which comprises a bucket body with an opening in the rear end, a guide groove is formed in the upper wallof the bucket body, the rear lower end of the bucket body is hinged to a bottom cover, the bucket capacity is reduced when the bottom cover rotates forwards, and the bucket capacity is increased whenthe bottom cover rotates backwards; a main shaft is arranged above the bucket body, and a thread sleeve is arranged on the main shaft and connected with the bottom cover via a connecting rod arm; anda motor device is arranged in the back plate, the front end of the main shaft is connected with the motor device. In the process that the motor device drives the main shaft to rotate, the thread sleeve drags the bottom cover to rotate forwards and backwards via the connecting rod arm to achieve bucket capacity adjustment. The excavator bucket has the bucket capacity adjusting function, the bucketcapacity can be adjusted according to actual working conditions, and the operation efficiency can be improved to the maximum extent on the premise that stable work of the excavator is guaranteed; thebucket capacity is convenient and fast to adjust, and both time and labor are saved; and a spare excavator bucket is not required to be arranged, so that the equipment acquisition cost is reduced, and the defects of labor consumption, operation efficiency reduction and the like caused in the transportation, dismounting and mounting process of the spare excavator bucket are eliminated.

Owner:黄付银

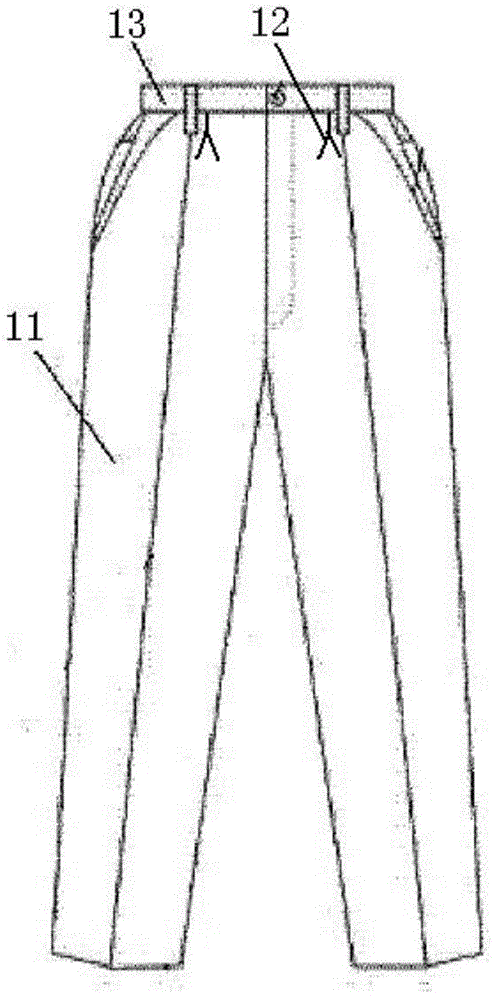

Arc-waist crease-resist trousers

The invention provides a pair of arc-waist crease-resist trousers. The pair of arc-waist crease-resist trousers comprises front trouser pieces, rear trouser pieces and a trouser waist, wherein the trouser waist comprises a rear waist, a left front waist and a right front waist. The pair of arc-waist crease-resist trousers is characterized in that both the left front waist and the right front waist are arc waist pieces which are formed by cutting a whole fabric; a front waist formed by the left front waist and the right front waist is concaved downwards; the distance between the lowest position of a central top line of the front waist and a top line of a rear waist is 2.5-5 cm; the upper ends of the front trouser pieces adopt an arc shape which is matched with the left front waist and the right front waist; and the two front trouser pieces are sewed with the left front waist and the right front waist in a crease-free manner respectively. According to the pair of the arc-waist crease-resist trousers, the three-dimensional trouser waist adapts to the shape of the waist of a human body through a three-dimensional cutting manner; the abdomen waist parts of western style trousers and casual trousers are straight, good in shape and free from creases; even if the trousers are worn or washed repeatedly for a long time, the trousers can keep the original shapes and are not deformed; and the processing technology is simple, the manufacturing cost is saved, and the qualified rate of products is high.

Owner:姚兰英

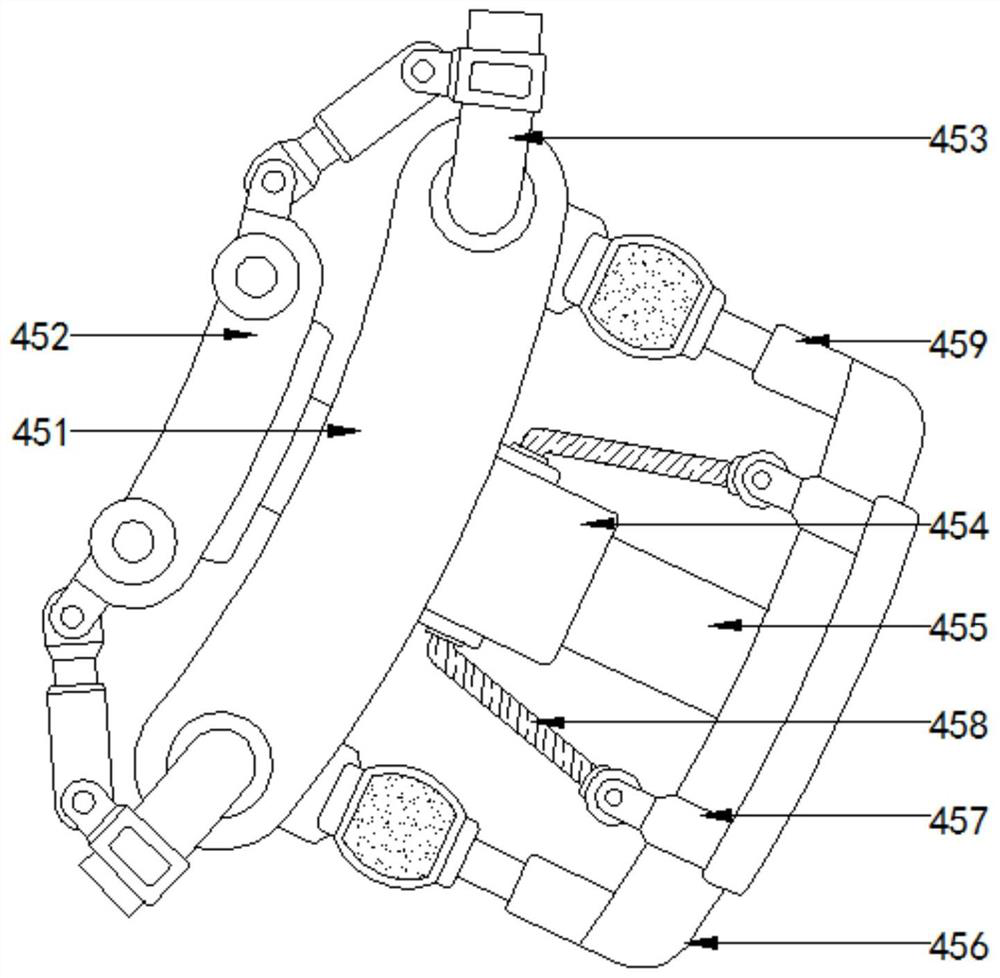

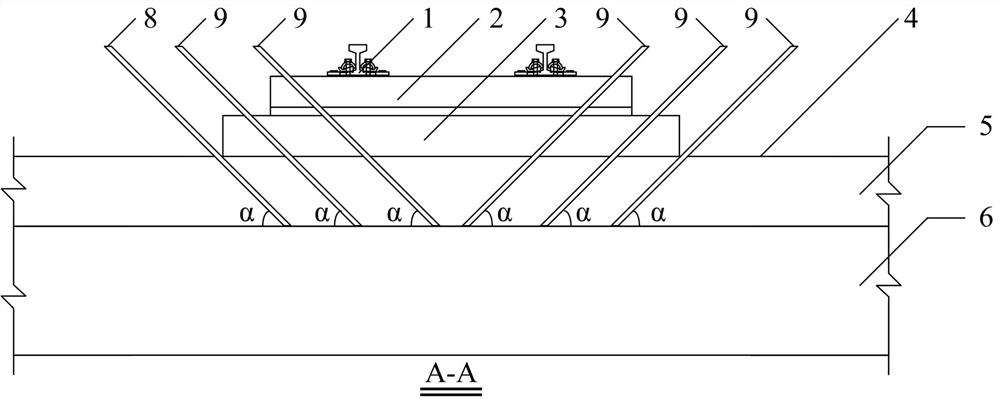

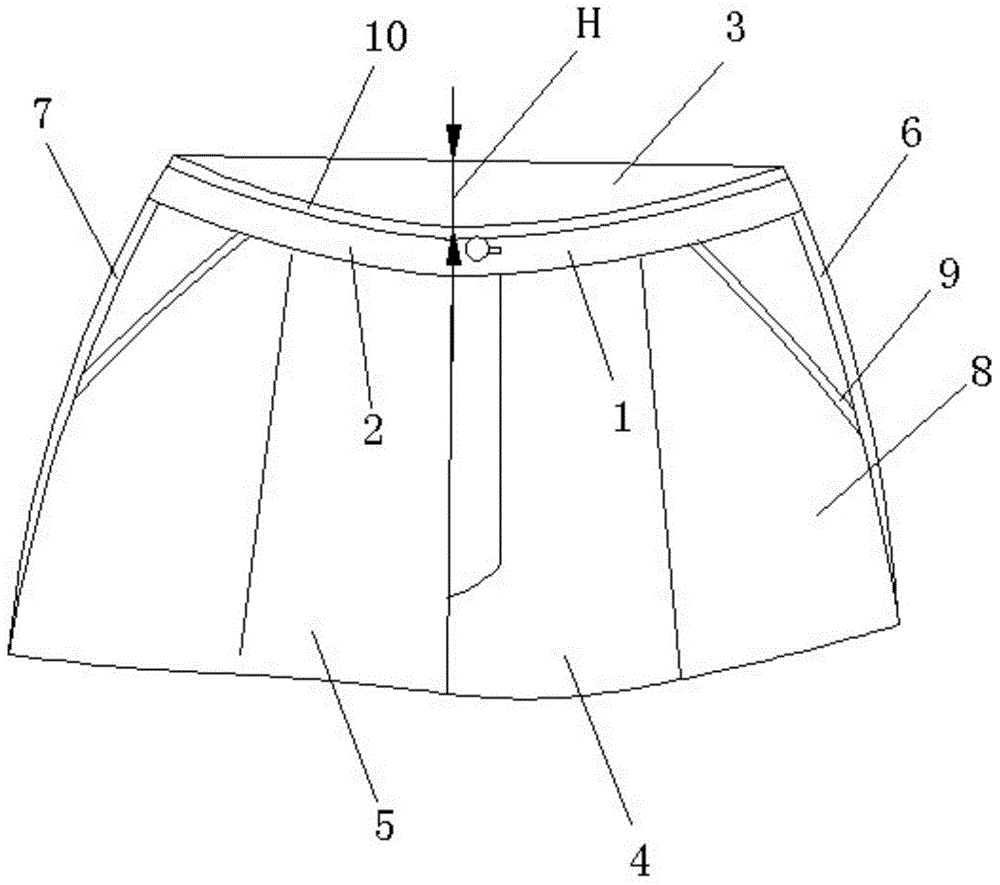

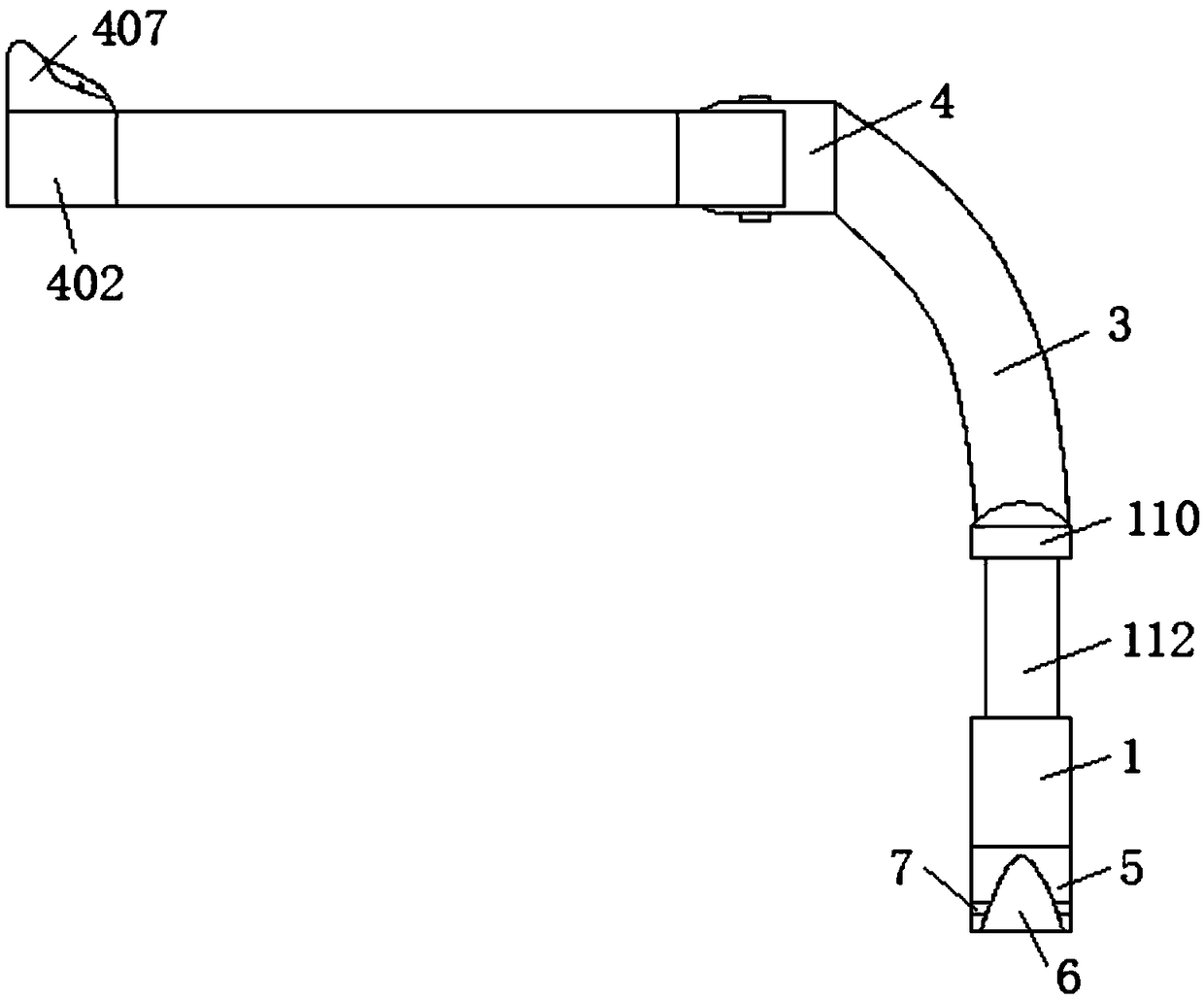

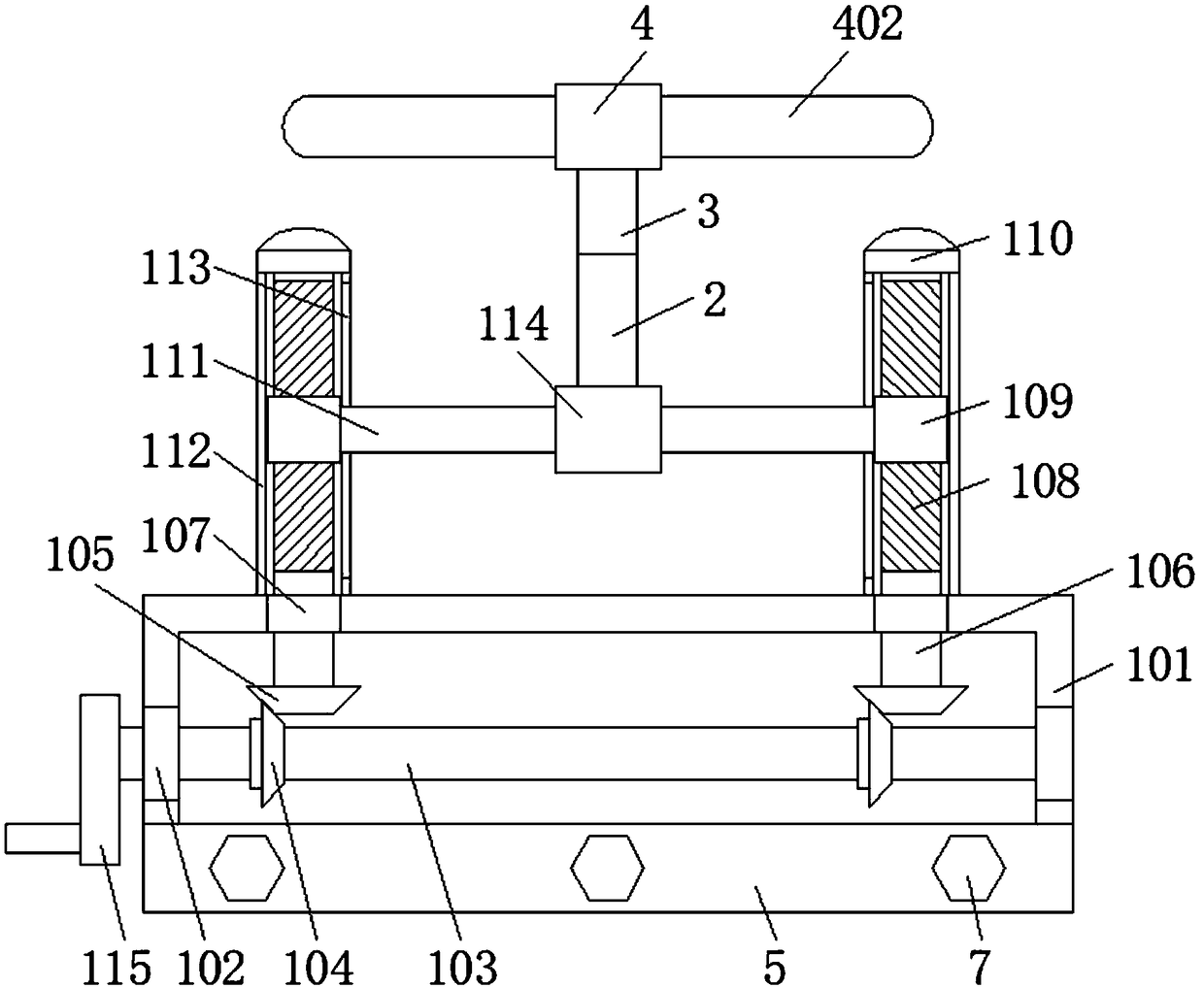

Flexible and adjustable one-full-year infant hairdressing auxiliary device

ActiveCN108784102AWith supportSolve the problem of easily twisting the head and causing ear injuryStoolsHairdressersEngineeringAssistive device

Owner:吴小敏

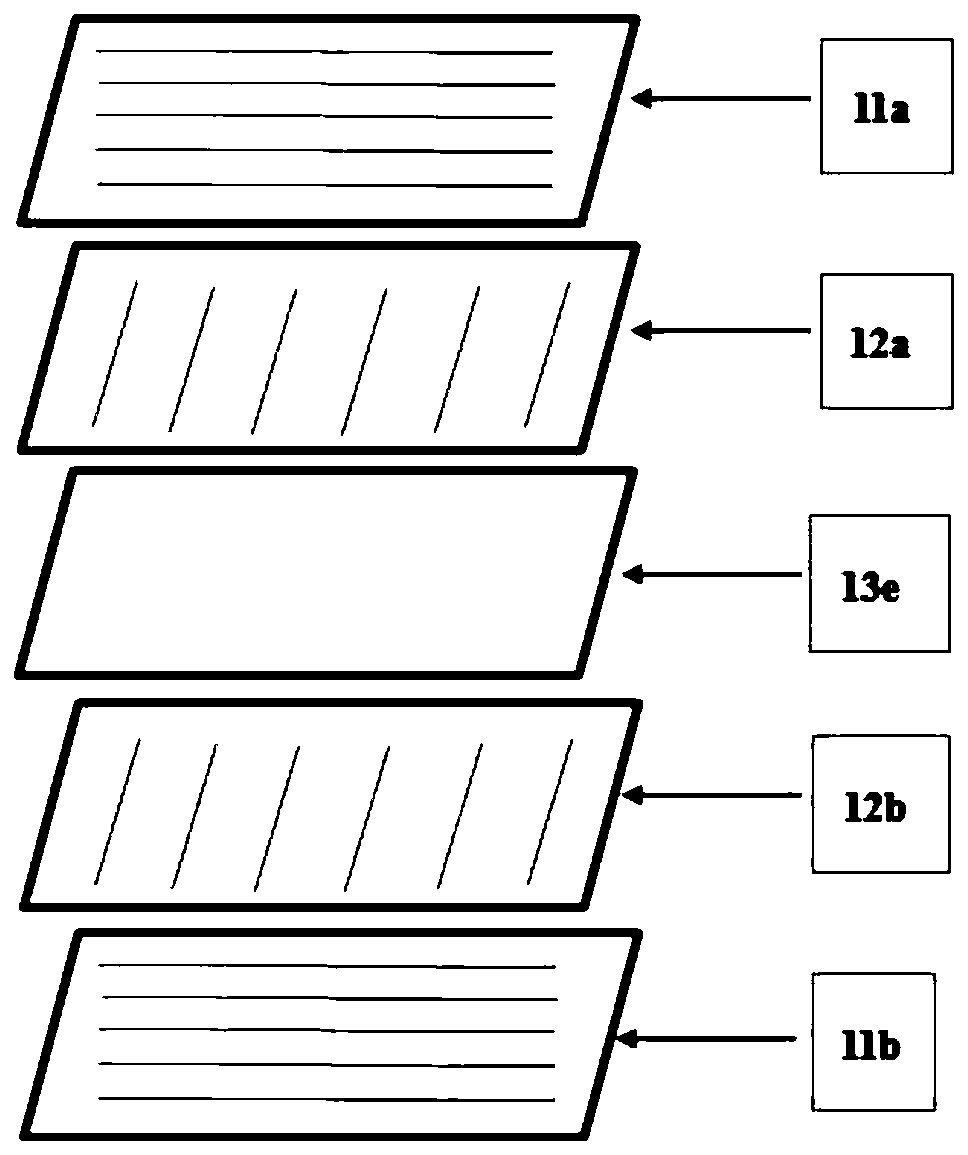

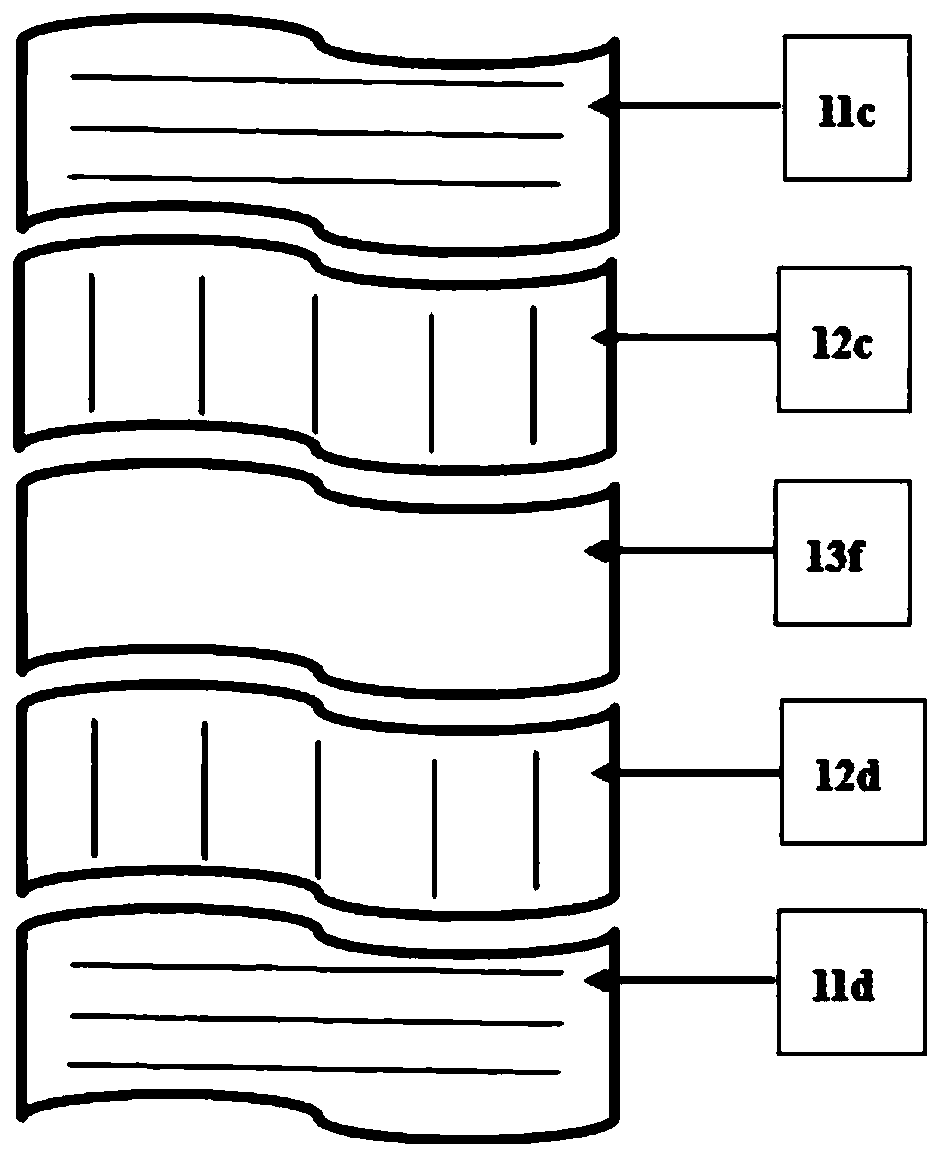

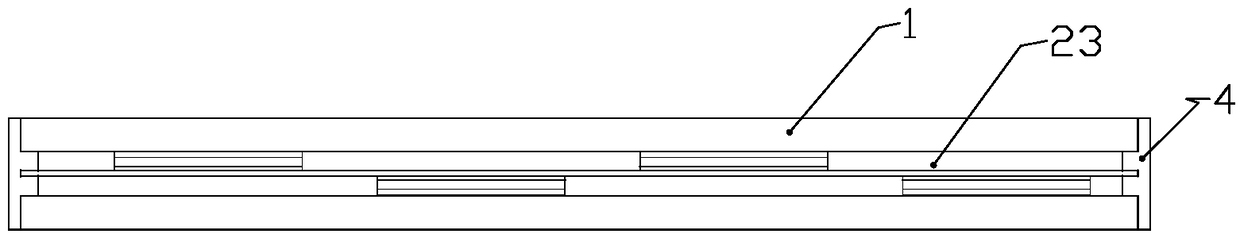

High-bending-strength high-modulus light epoxy composite board and preparation method thereof

PendingCN111251670AImprove bending strengthLow costSynthetic resin layered productsLaminationFlexural strengthHot pressing

The invention discloses a high-bending-strength high-modulus light epoxy composite board and a preparation method thereof. The high-bending-strength high-modulus light epoxy composite board is obtained by respectively and symmetrically arranging a plurality of UD prepregs on two sides of a light epoxy board in opposite positions and in the UD direction, superposing the prepregs, hot-pressing the prepregs and then cold-pressing the prepregs. According to the high-bending-strength high-modulus light epoxy composite board, the basic characteristics of a light epoxy board are reserved, the functions of insulation, supporting and the like are achieved, and the characteristics of high bending strength, high modulus, light weight and low cost are further achieved.

Owner:中科威禾科技(肇庆)股份有限公司

Method, system and related device for implementing on-line advertisement launching

ActiveCN101119223BImplement functions such as advertisingImprove scalabilitySpecial service provision for substationData switching by path configurationThe InternetClient-side

The present invention discloses a realizing method, a system and related devices of the on-line advertisement broadcast. An on-line advertisement request with a type label is sent to an advertisement service terminal in an advertisement client terminal, in correspondence to an advertisement type adapter of the present internet application platform. The advertisement service terminal receives the on-line advertisement request which is from the advertisement type adapter, determines the internet application platform type according to the type label which is carried by the advertisement request,and provides an on-line advertisement document, which corresponds to the internet application platform, for the corresponding advertisement type adapter in advertisement client terminal. The advertisement type adapter which aims at different internet application platform can screen the difference of the on-line advertisements on the internet application platform on the advertisement service, so as to achieve the function of advertisement broadcast, etc. through the uniform advertisement service.

Owner:TENCENT TECH (SHENZHEN) CO LTD

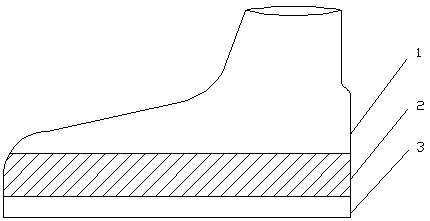

Easily cleaned sneaker upper fabric

InactiveCN108116024AImprove protectionExtended service lifeSynthetic resin layered productsUpperFiberPolyester

The invention relates to the field of textile fabrics, in particular to an easily cleaned sneaker upper fabric and aims at solving the problem that a sneaker upper fabric is not easily cleaned before.The easily cleaned sneaker upper fabric structurally comprises a first fabric main body at the upper side of a shoe sole; the first fabric main body is connected with a second fabric main body through a hook and loop fastener; a hook and loop fastener sticky hook is arranged on the outer surface of the first fabric main body; a hook and loop fastener substrate is arranged on the inner surface ofthe second fabric main body; the second fabric main body comprises a waterproof layer; a polyester fiber layer is arranged on the inner side of the waterproof layer; a first plastic sheet layer is arranged on the inner side of the polyester fiber layer; and a metal net layer is arranged on the inner side of the first plastic sheet layer. The easily cleaned sneaker upper fabric is simple in structure and convenient to use and is suitable for various places.

Owner:苏州市莱盎纺织有限公司

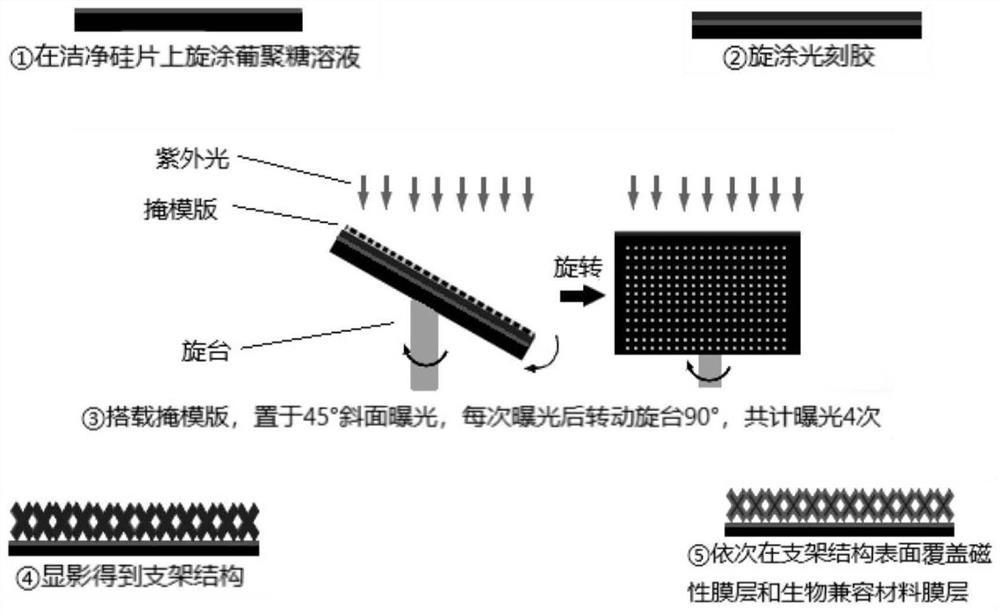

Achiral magnetic control micro-stent robot as well as preparation method and application thereof

PendingCN113440726AReduce manufacturing costProtectiveMedical devicesSurgical manipulatorsMechanical engineeringTargeted therapy

The invention provides an achiral magnetic control micro-stent robot as well as a preparation method and application thereof. The achiral magnetic control micro-stent robot comprises a net-shaped stent main body, a magnetic film layer located on the outer layer of the net-shaped stent main body and a biological compatibility film layer located outside the magnetic film layer. The achiral magnetic control micro-stent robot stent structure can be used for attachment, growth, proliferation and differentiation of stem cells, has the effect of protecting and supporting the stem cells, can achieve directional movement under the control of a rotating magnetic field, and further can achieve targeted therapy on the affected part of osteoarthritis.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

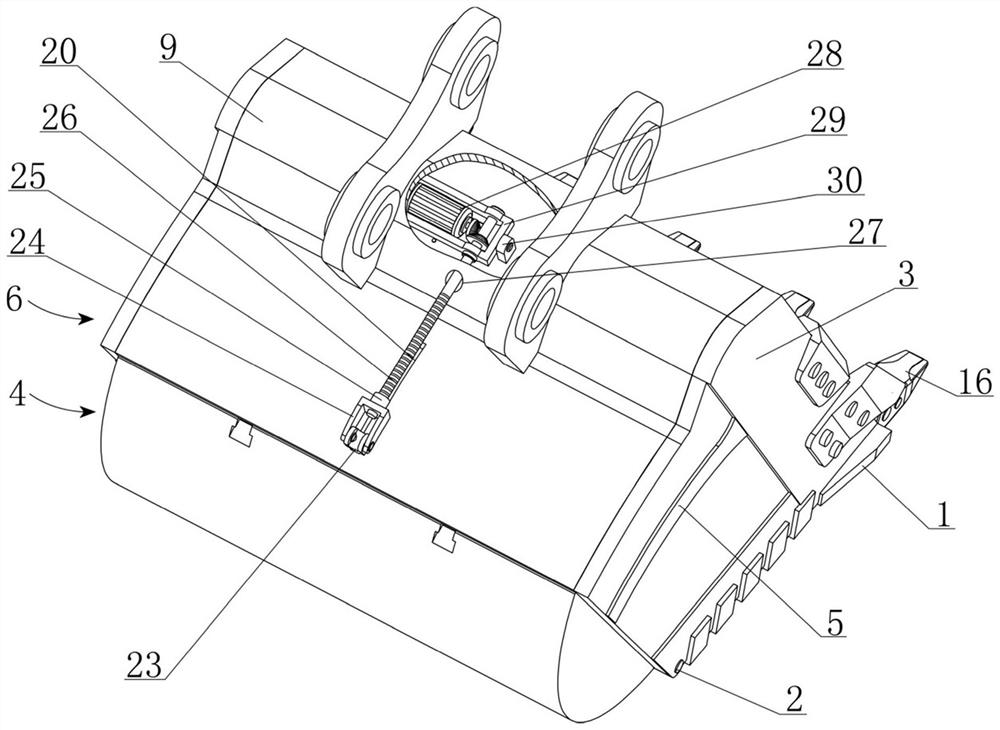

Excavator bucket

PendingCN112281950AStable jobWith capacity adjustment functionMechanical machines/dredgersControl engineeringElectric machinery

The invention relates to an excavator component, and particularly discloses a bucket. The bucket comprises a bucket body with an opening in the rear end, wherein a guide groove is formed in the upperwall of the bucket body, the rear lower end of the bucket body is hinged to a bottom cover, a guide block matched with the guide groove is arranged at the upper end of the bottom cover, and the bucketcapacity is reduced when the bottom cover rotates forwards, and is increased otherwise; a traction base is arranged at the outer end of the guide block and is hinged to a traction arm, and a threadedsleeve is arranged at the other end of the traction arm; and a swing seat is arranged above the bucket body, a main shaft and a motor device are arranged on the swing seat, and the main shaft is matched with the threaded sleeve so that the position of the bottom cover can be adjusted through rotation to adjust the bucket capacity. The bucket has the bucket capacity adjusting function and can be adjusted according to actual working conditions, and therefore the operation efficiency can be improved to the maximum extent on the premise that stable work of an excavator is guaranteed; the bucket capacity is convenient and fast to adjust, so that time and labor are saved; and a spare bucket is not required to be arranged, so that the equipment acquisition cost is reduced, and the defects of labor consumption, operation efficiency reduction and the like of the spare bucket in transportation, disassembling and assembling are eradicated.

Owner:黄付银

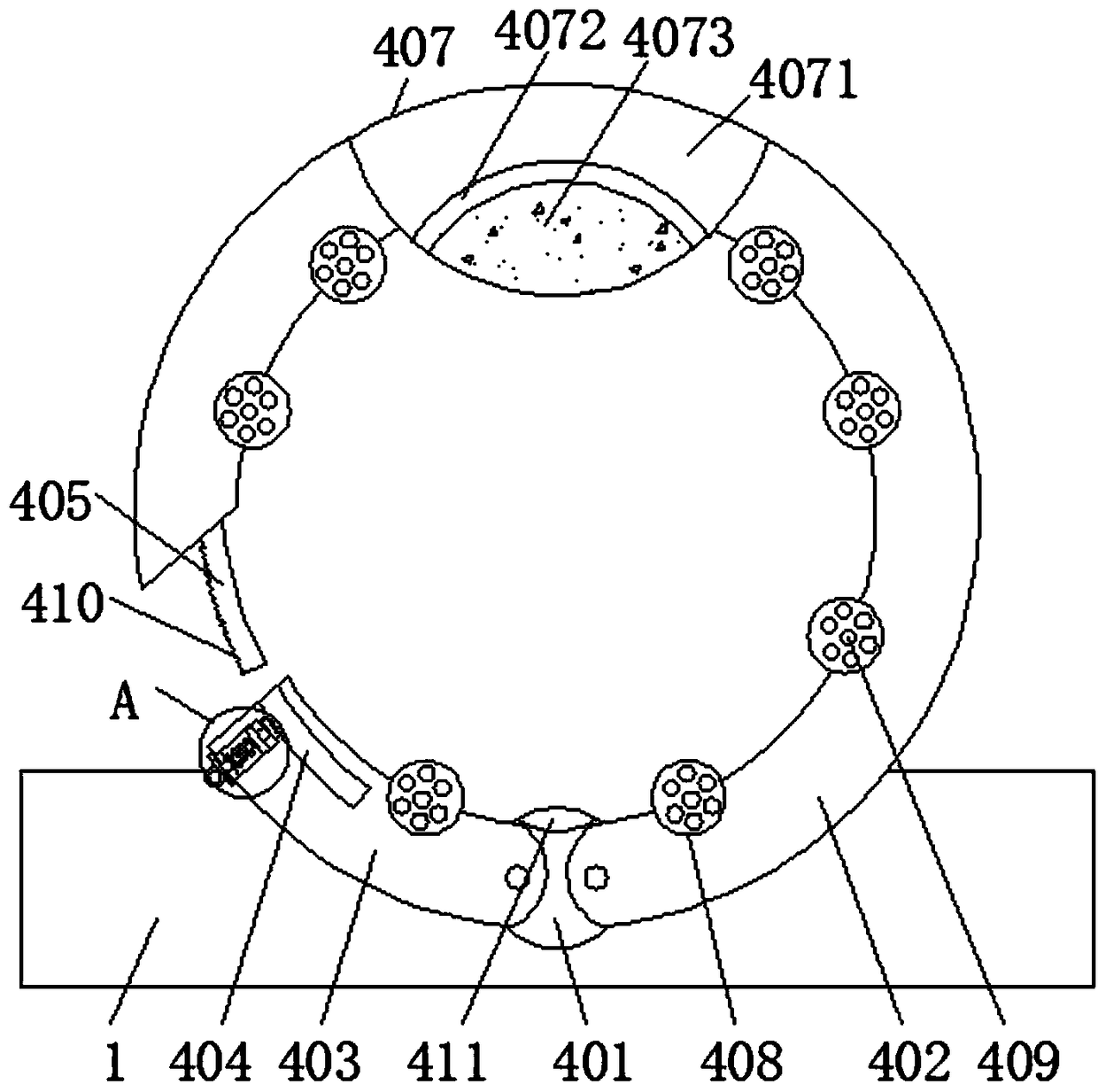

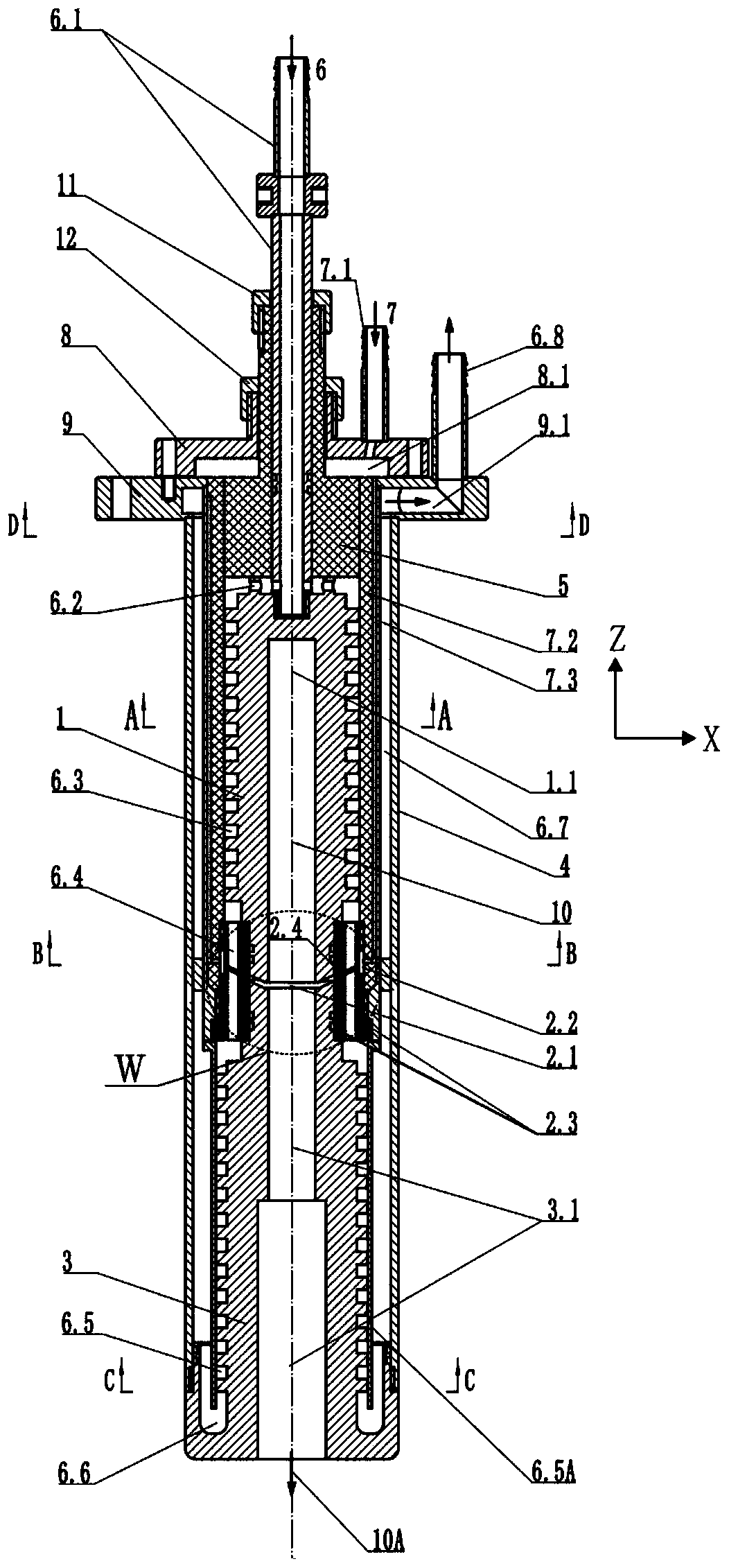

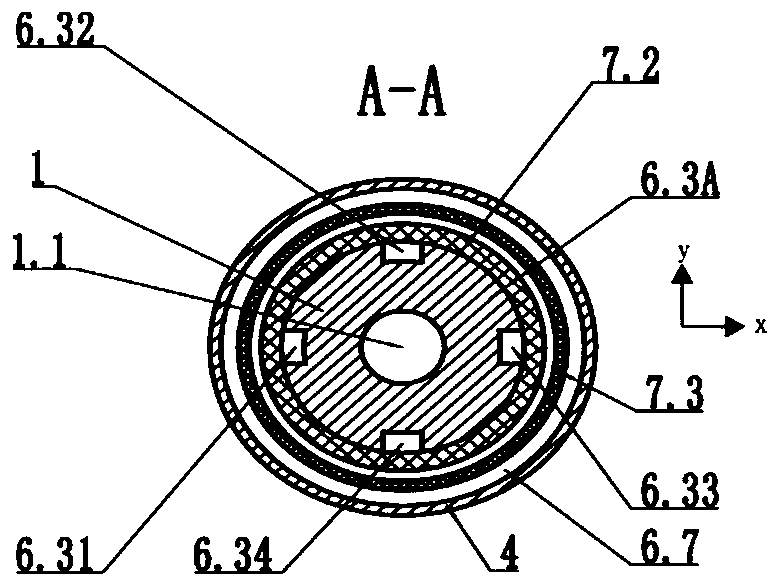

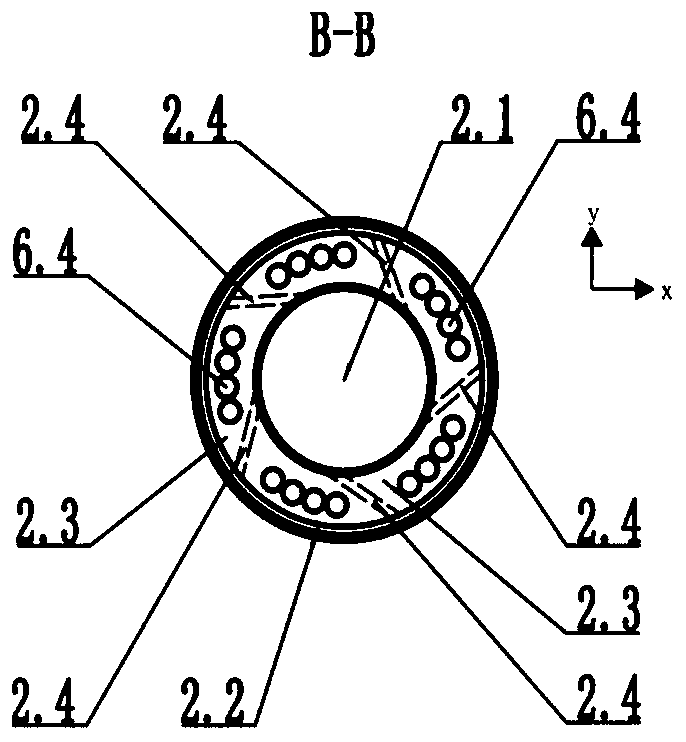

Air cylindrical plasma generator gap structure

The invention discloses an air cylindrical plasma generator gap structure. A cathode and an anode are hollow cylindrical bodies arranged at the middle lower end; a gap is located at the junction of two electrodes. A gas ring cylinder is arranged at the gap, and W inclined gas guide through holes are formed in the gas ring cylinder; meanwhile, W groups of gap vertical water inlet pipes are arrangedand are circumferentially and uniformly distributed at intervals. The gap arc striking is performed, and the functions of water guiding, air guiding, positioning and the like are achieved, thereby meeting the requirement for overall design of the cylindrical cathode and anode. An electric arc moves on the inner walls of the two cylinders, so the heating surface is greatly increased, the temperature of the cylinder wall directly cooled by water is low, the electrodes are not easy to burn out, and the temperature of the sprayed electric arc is as high as 3,000 DEG C; and the requirement of longservice life of high-temperature treatment is met. A water cooling system is reversely discharged from an upper end water inlet pipe, a cathode spiral water channel, a gap water inlet pipe, an anodespiral water channel and a lower water return tank through the annular water outlet channel and the water outlet pipe. The two spiral water channels and the two cooling heat exchange surfaces are large, so that the cooling effect is extremely optimized. The invention not only solves the problems of expensive inert gas material, high cost, short structural life and difficult maintenance in the prior art, but also solves the problem of long service life in high-temperature treatment, especially the treatment of industrial hazardous wastes.

Owner:CHENGDU JINCHUANGLI SCI & TECH

Excavator bucket for constructional engineering

PendingCN112281949AWith capacity adjustment functionStable jobMechanical machines/dredgersGear wheelElectric machinery

The invention relates to an excavator component, and particularly discloses a bucket. The bucket comprises a bucket body with an opening in the rear end, wherein a guide box and a gear seat are arranged on the upper side wall of the bucket body, the rear lower end of the bucket body is hinged to a bottom cover, a traction part is arranged at the upper end of the bottom cover, and the bucket capacity is reduced when the bottom cover rotates forwards, and is increased otherwise; and a joint rack is arranged in the guide box, a gear is arranged in the gear seat, the rear end of the joint rack isconnected with the traction part, the front portion of the joint rack is meshed with the gear, a worm wheel coaxial with the gear, a worm matched with the worm wheel and a motor device driving the worm to rotate are arranged in a back plate, and the motor device can drive the bottom cover to rotate so as to adjust the bucket capacity. The bucket has the bucket capacity adjusting function and can be adjusted according to actual working conditions, and therefore the operation efficiency can be improved to the maximum extent on the premise that stable work of an excavator is guaranteed; the bucket capacity is convenient and fast to adjust, so that time and labor are saved; and a spare bucket is not required to be arranged, so that the equipment acquisition cost is reduced, and the defects oflabor consumption, operation efficiency reduction and the like of the spare bucket in transportation, disassembling and assembling are eradicated.

Owner:黄付银

High-quality jaboticaba tree potting breeding device and cultivation method

PendingCN114651665AFor the purpose of clamping and positioningTo achieve the effect of anti-lodgingCultivating equipmentsFruit treeAnimal science

The invention discloses a high-quality jaboticaba tree potted plant breeding device which comprises a base, four evenly-distributed supporting seats are fixedly connected to the base, connecting seats are fixedly connected to the supporting seats, fixing seats are in contact with the connecting seats, grooves are formed in the fixing seats, supporting mechanisms are arranged on the fixing seats, and the supporting mechanisms are arranged on the fixing seats. An adjusting mechanism is arranged on the fixing seat, and a rotating mechanism is arranged on the base. The invention relates to a high-quality jaboticaba tree potting breeding device, which has the characteristics of sapling supporting and sapling sunshine receiving position adjusting.

Owner:福建金永鹏农业科技有限公司

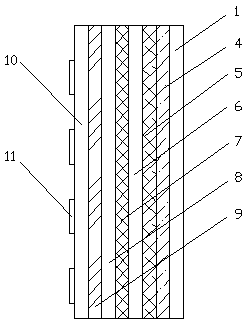

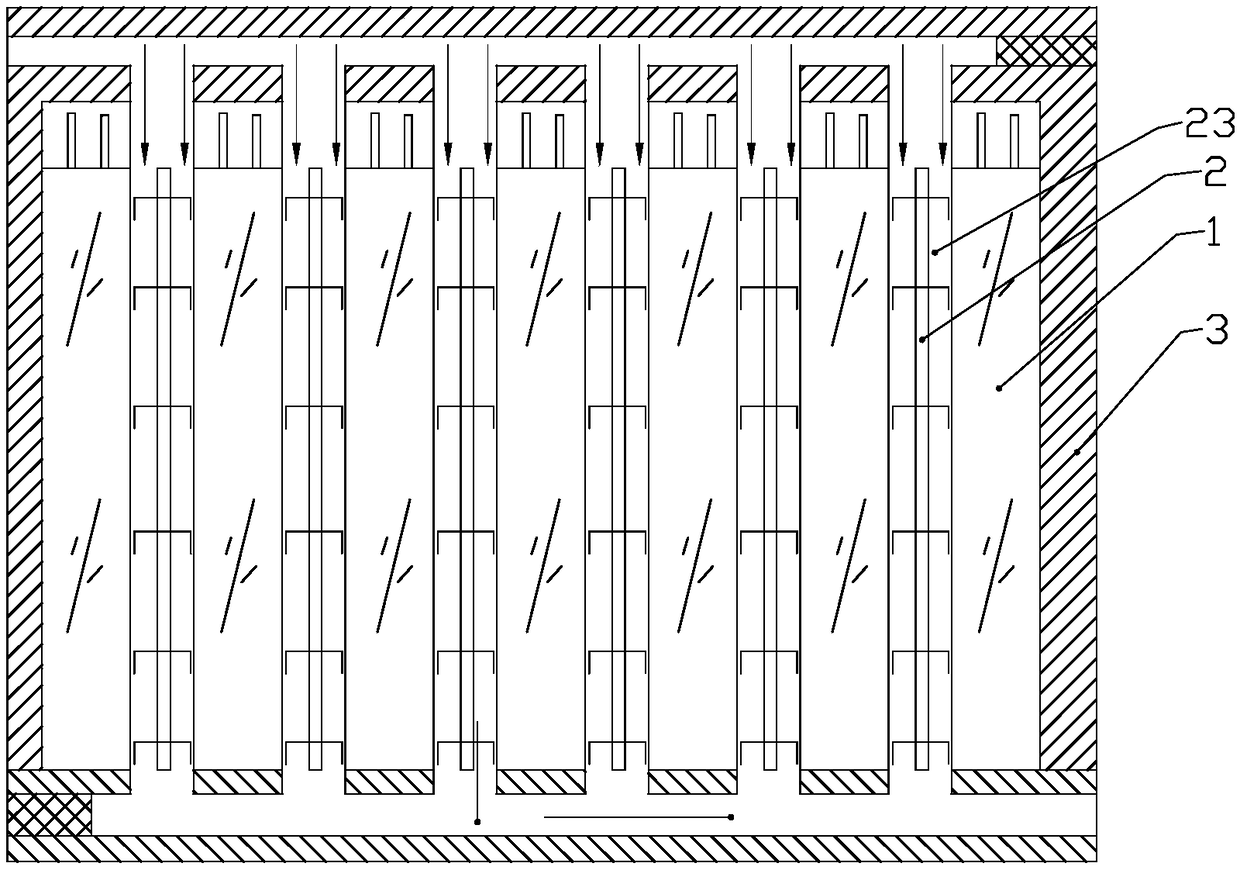

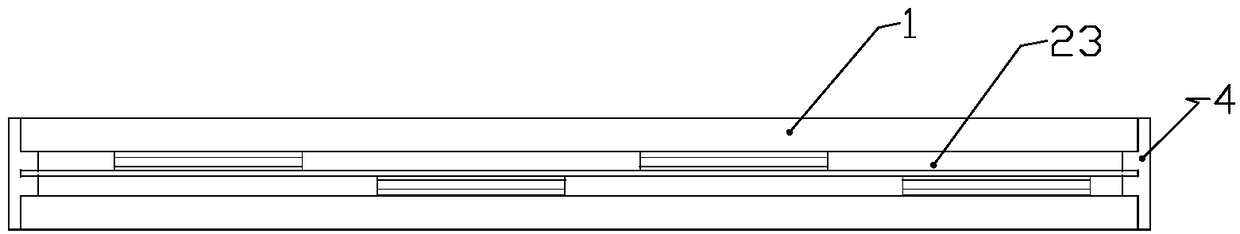

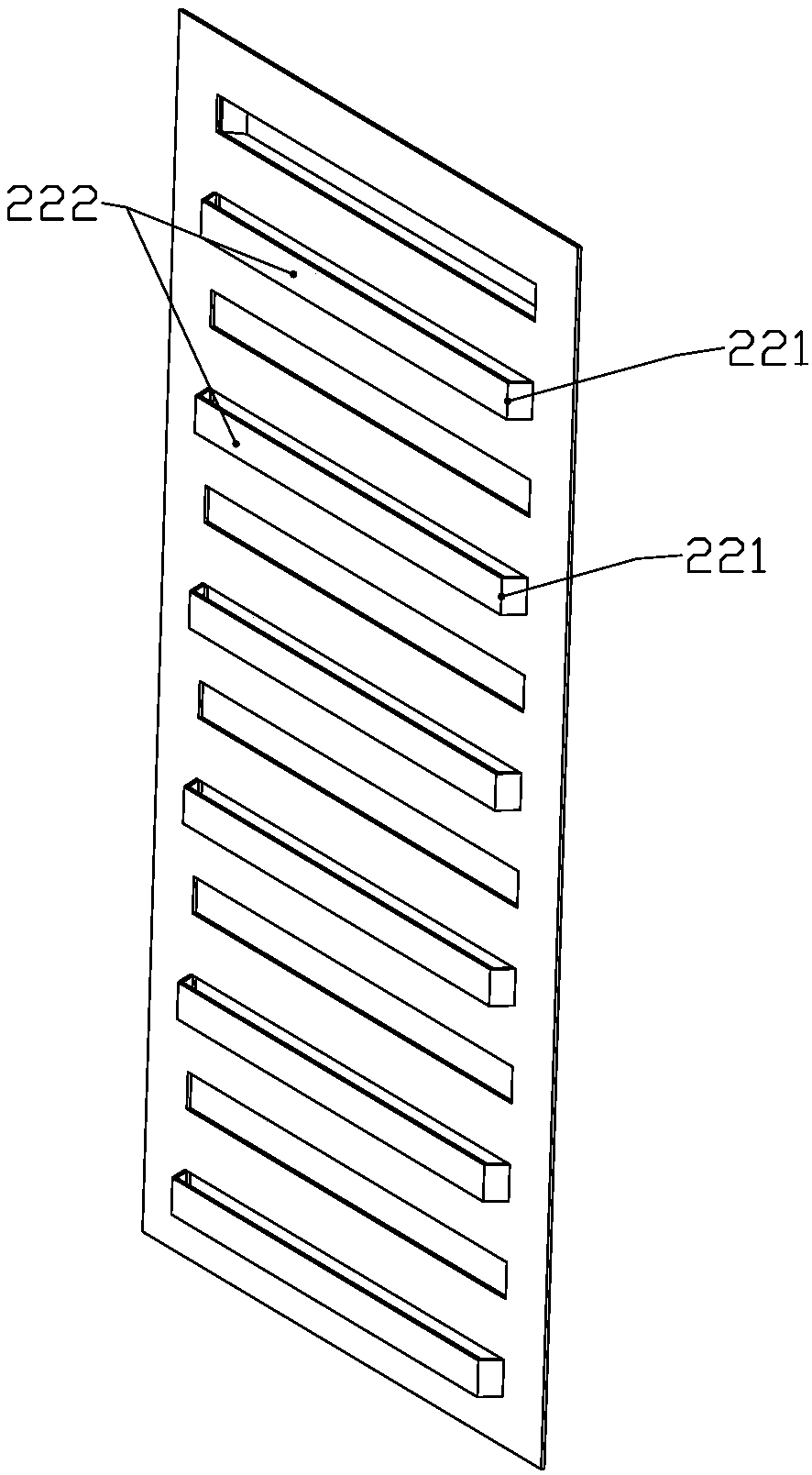

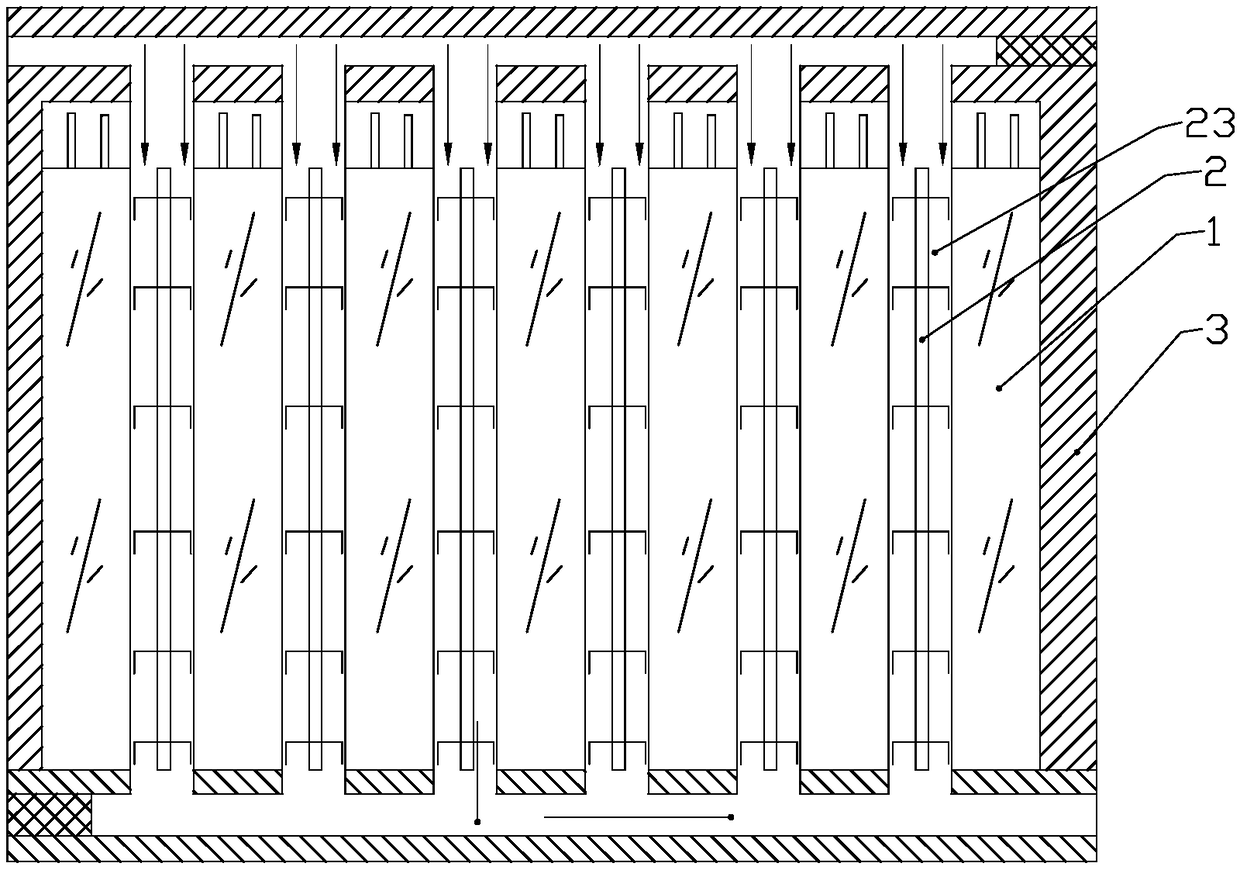

Lithium battery separator and lithium battery pack

ActiveCN106328874BSimple structureEasy to implementCell seperators/membranes/diaphragms/spacersLi-accumulatorsEngineeringSupport point

The invention discloses a lithium battery separator and a lithium battery pack, wherein the lithium battery separator includes a foam body and a skeleton, the skeleton is a metal stamping part, and is formed on both sides by stamping on the skeleton Evenly arranged Z-shaped bending, the end of the Z-shaped bending is a planar support point for matching with the battery; the foam is compounded on the skeleton and the main surfaces on both sides of the foam are located at the Z inside of the bend. The separator combines the dual advantages of inorganic foam and metal plate. The metal plate has the functions of impact resistance, elasticity and support. The inorganic foam has the performance requirements of anti-explosion and has a wide application space.

Owner:江苏科耐尔新能源科技有限公司

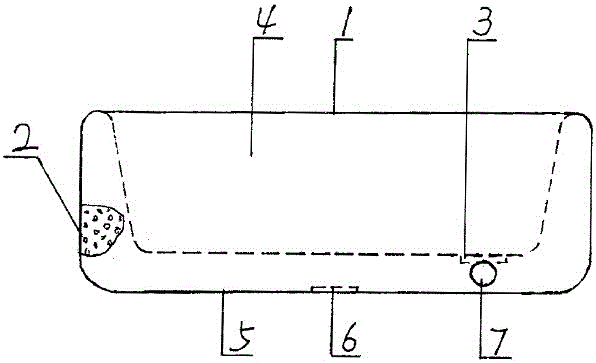

Manufacturing and application method of plastic bathtub

Disclosed is a manufacturing and application method of a plastic bathtub. The plastic bathtub comprises a shell, foam and a valve, the shell is a plastic shell formed by injection molding, a basin is arranged in the middle of the shell, the valve for draining water is arranged at the bottom of the basin of the shell, a bottom board is connected to the bottom of the shell and used for sealing the bottom surface of the shell, the foam is injected into the shell via an injection molding hole in the bottom board, and the solidified foam has (filling) supporting and heat-insulation effects on the shell.

Owner:张七龙

A kind of warping type thermosetting epoxy board and preparation method thereof

ActiveCN110202876BAvoid breakingKeep basic featuresSynthetic resin layered productsLaminationEpoxyThermal dilatation

Owner:广东裕丰威禾新材料科技股份有限公司

Lithium battery separator and manufacturing method thereof

ActiveCN106299221BSimple structureEasy to implementCell seperators/membranes/diaphragms/spacersSurface layerPortland cement

The invention discloses a lithium battery core partition plate and a manufacturing method thereof. The lithium battery core partition plate comprises a foaming body and a framework. The framework is a metal stamping part, evenly-arranged Z-shaped bends are formed towards the two sides of the framework in a stamping mode, and the ends of the Z-shaped bends are planer supporting points used for being matched with battery cores. The foaming body is attached to the framework, and the main surfaces of the two sides of the foaming body are located in the Z-shaped bends. The foaming body is a foaming plate formed by ordinary Portland cement, iron aluminate cement, glass beads, mountain flour, hydrogen peroxide, a water reducing agent, water and rubber powder according to the standard through a foaming process, wherein the foaming plate has a certain thickness. A fabric supporting layer is arranged on main surface layers on the two sides of the foaming body. A coating layer is sprayed on the surface of the foaming body. The partition plate integrates the advantages of the inorganic foaming body and the advantages of a metal plate, the metal plate has impact resistance, elasticity and a supporting effect, the inorganic foaming body has the antiknock property, and the partition plate has wide use space.

Owner:JIANGSU HENGTONG LIGHTING GRP CO LTD

Excavator bucket for engineering construction

PendingCN112281953AStable jobWith capacity adjustment functionMechanical machines/dredgersElectric machineryTraction cord

The invention relates to an excavator component, and particularly discloses an excavator bucket for engineering construction. The excavator bucket for engineering construction comprises a frame-shapedbucket body, a rope box is fixedly arranged in the bucket body, a rope wheel and a traction rope are arranged in the rope box, a bottom cover is rotatably and fixedly arranged at the rear end of thebucket body, a traction part is arranged at the upper end of the bottom cover, the traction part is connected with the traction rope, the bottom cover rotates forwards, the bucket capacity is reduced,otherwise, the bucket capacity is increased, a wheel shaft of the rope wheel is connected with a worm wheel, a worm which meshes with the worm wheel and a motor device which drives the worm to rotateare arranged in an inner cavity of a back plate, and bucket capacity adjustment can be achieved when the motor device drives the worm to rotate. The excavator bucket has the bucket capacity adjustingfunction, adjusting can be carried out according to actual working conditions, the operation efficiency can be improved to the maximum extent on the premise that stable work of a excavator is guaranteed; the adjusting operation of the bucket capacity is convenient and fast, time-saving and labor-saving; and a spare bucket is not required to be arranged, so that the equipment acquisition cost is reduced, and the defects of labor consumption, operation efficiency reduction and the like of the spare bucket in transportation, disassembly and assembly are overcome.

Owner:黄付银

Excavator bucket for engineering construction

InactiveCN112281951AStable jobWith capacity adjustment functionMechanical machines/dredgersElectric machineryTraction cord

The invention relates to an excavator component, and particularly discloses an excavator bucket for engineering construction. The excavator bucket comprises a bucket body, a main shaft and a pulley are arranged on the bucket body, a first rope wheel, a second rope wheel and a worm wheel are fixed on the main shaft, a traction rope bypasses the rear side of the pulley, and two ends of the tractionrope are wound on the first rope wheel and the second rope wheel respectively; a bottom cover is rotationally fixed to the rear end of the bucket body, a traction part is arranged at the upper end ofthe bottom cover and connected with the traction rope, and the bucket capacity is decreased when the bottom cover rotates forwards or increased otherwise; and a worm and a motor device are arranged inan inner cavity of a back plate, and the motor device drives the worm to rotate to achieve bucket capacity adjustment. The bucket has a bucket capacity adjusting function and can be adjusted according to actual working conditions, and the operation efficiency can be improved to the maximum extent on the premise that stable work of an excavator is guaranteed; the bucket capacity is convenient andfast to adjust, and the time and labor are saved; and a spare bucket is not required to be arranged, so that the equipment acquisition cost is reduced, and the defects of labor consumption, operationefficiency reduction and the like of the spare bucket in transportation, disassembly and assembly are overcome.

Owner:黄付银

Hidden Car Folding Table

InactiveCN105711463BIncreased load-bearing capacityUse will not affectVehicle arrangementsEngineeringWeight-bearing

The invention discloses a hidden folding table for an automobile. The hidden folding table structurally comprises a main body, a table plate groove, a folding table plate and the like, and is mainly characterized in that the upper part of the back end of the main body is additionally provided with an installing hole which is used for anastomotically sheathing an armrest of an automobile seat; then, the inner side of the main body is provided with a clamp tooth assembly which is detachably clamped and arranged at the side surface of the automobile seat; through the design of the installing hole and the clamp tooth assembly, the main body can be stably and firmly arranged at one side of the automobile seat; meanwhile, the folding table plate uses double table plates in open and close design, so that the hiding function is not influenced, and the use area is also increased; one hanging end of the folding table plate is also provided with a supporting rod for supporting, so that the two ends of the folding table plate have supporting force; the weight bearing force of the folding table plate is greatly enhanced; the improved structure can carry more articles in the use process and bear computer placement during work; during folding, the folding table plate is completely hidden in the main body; the use of the seating space of the automobile seat cannot be influenced, so that the temporary use requirements such as dining or working in the automobile can be fully met.

Owner:NINGHAI COUNTY HUAMENG MOLD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com