Excavator bucket for constructional engineering

A technology for construction engineering and excavators, which is applied in construction, mechanically driven excavators/dredgers, earth movers/shovels, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

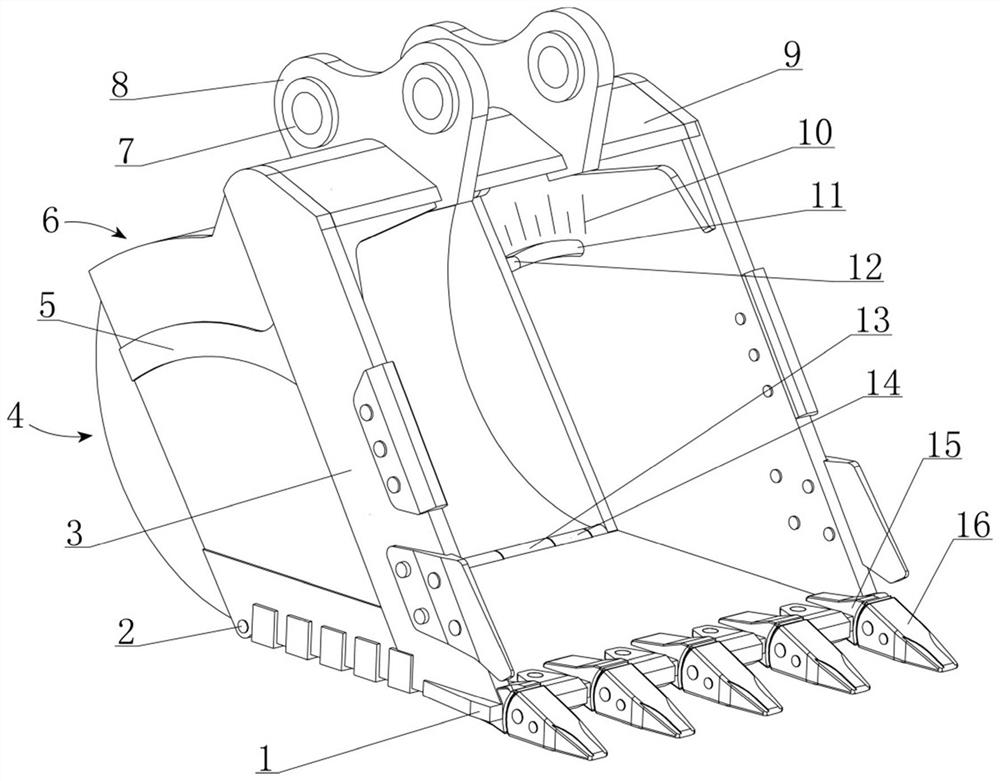

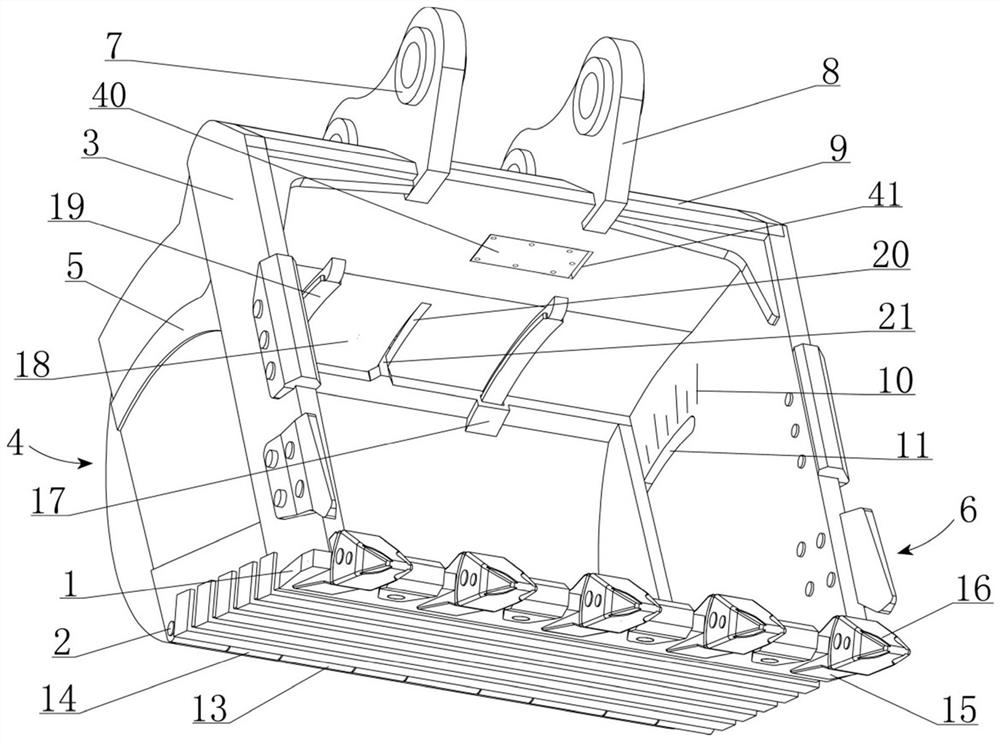

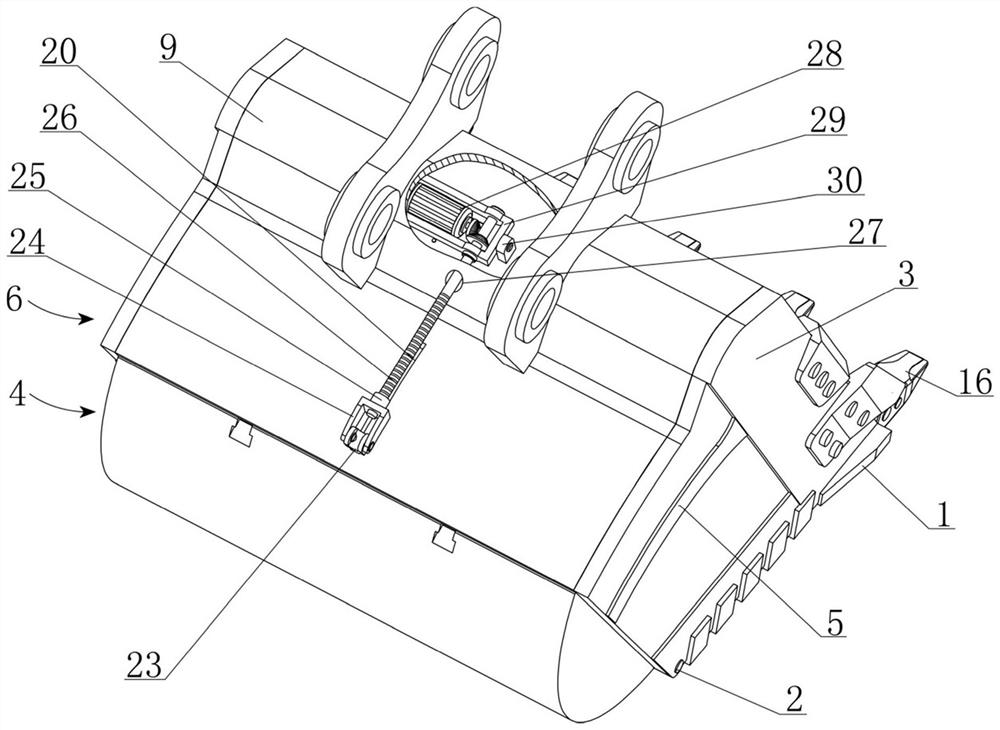

[0032] see Figure 1-6As shown, a kind of excavator bucket for construction engineering disclosed by the present invention includes a bucket body 6 and a bottom cover 4 arranged at the rear of the bucket body 6; the bucket body 6 has an inner cavity, and the bucket body 6. The rear end is open and is in the shape of a frame transparent front and back. The lower part of the front end of the bucket body 6 is fixed with a tooth seat plate 1, which is also called a knife plate. The upper side of the body 6 is fixed with a back plate 9 and a bucket ear plate 8, the rear lower end of the bucket body 6 is provided with a first hinged portion 13, the upper inner side wall of the bucket body 6 has an arc portion 18, and the middle part of the upper wall of the bucket body 6 has a front and rear joint. The extended guide groove 20, the geometric central axis of the arc portion 18 coincides with the first hinge portion 13 and extends along the left and right direction, the front side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com