Excavator bucket

A technology for excavators and buckets, applied in the field of buckets for excavation machinery, can solve the problems of time-consuming and laborious, difficult to adjust bucket capacity, and high soil density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

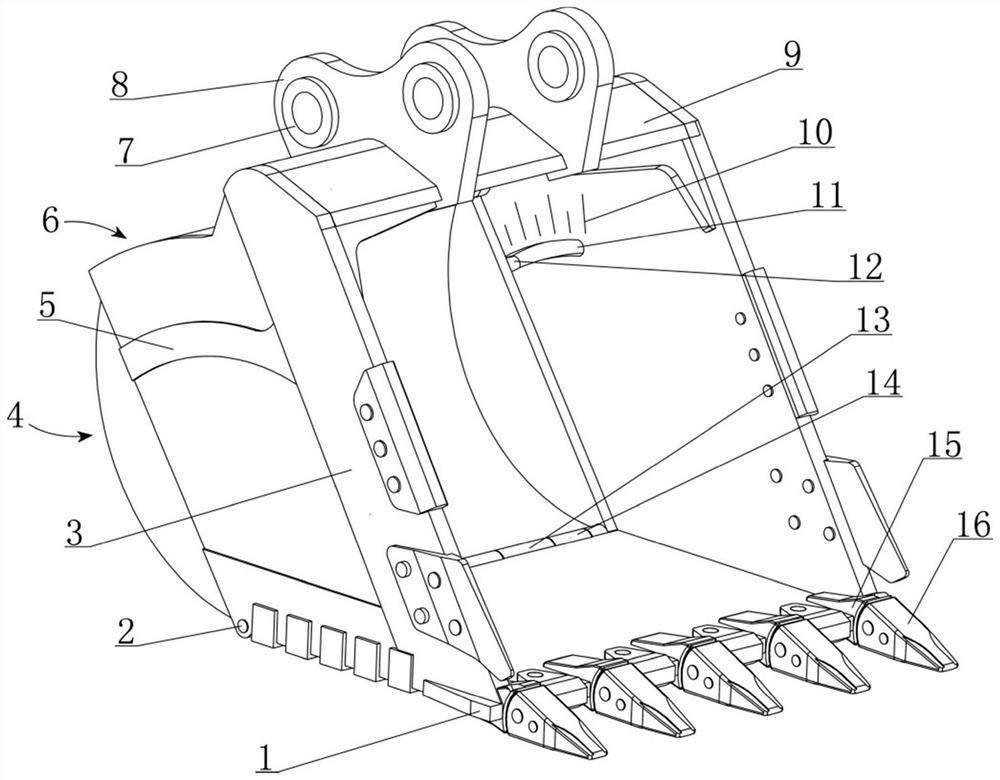

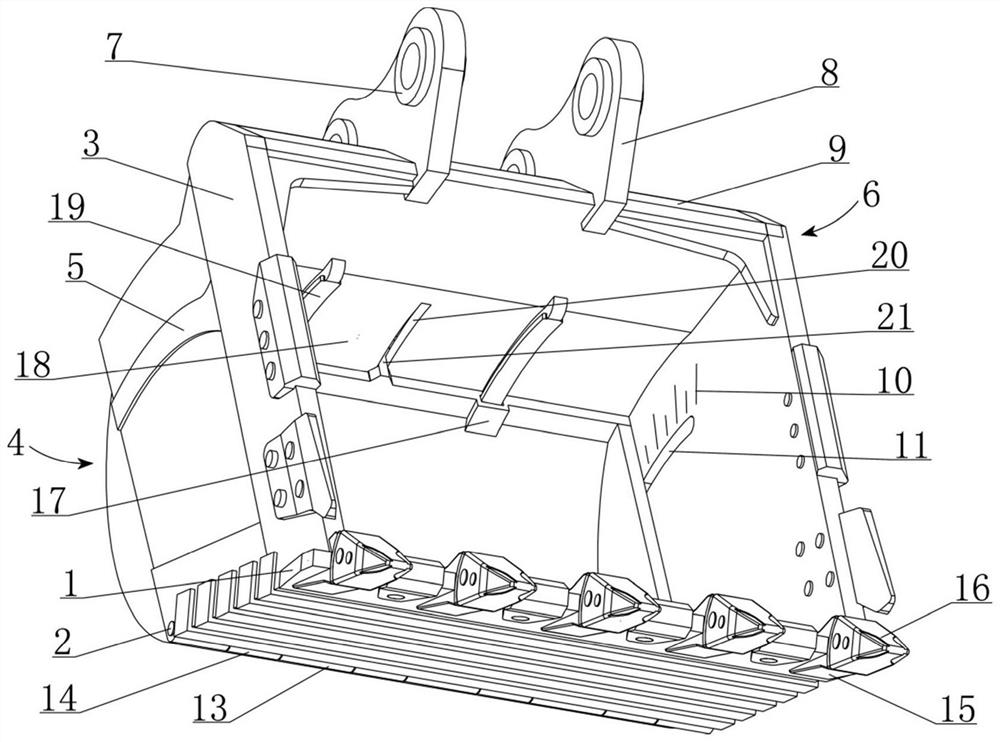

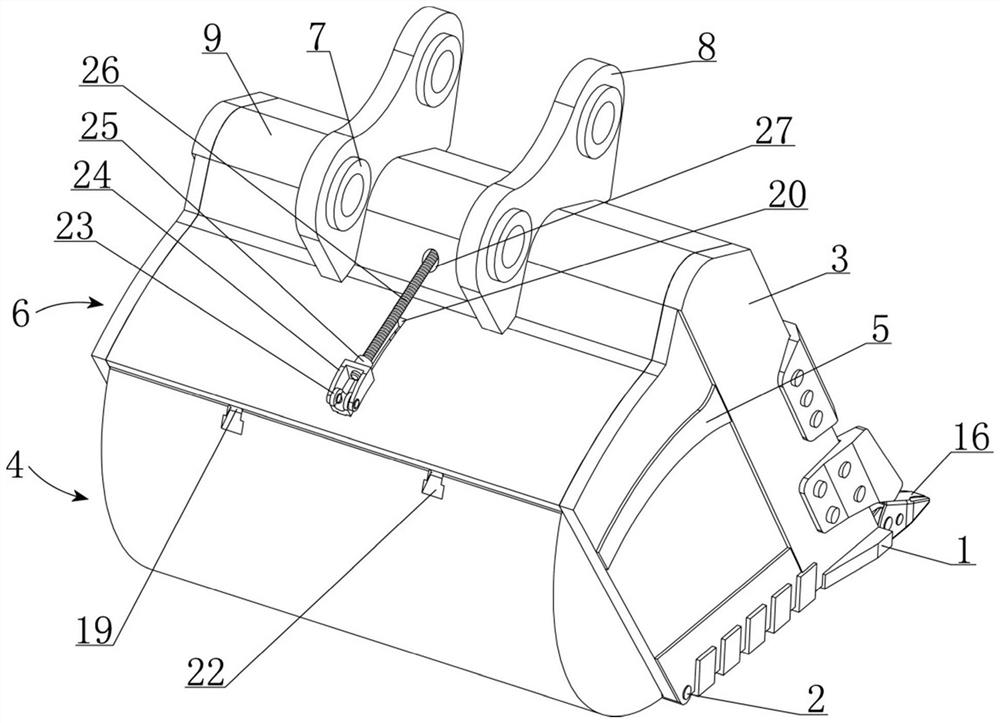

[0030]SeeFigure 1-6As shown, an excavator bucket disclosed in the present invention includes a bucket body 6 and a bottom cover 4 arranged at the rear of the bucket body 6; the bucket body 6 has an inner cavity with an opening at its rear end It is in the shape of a front and rear transparent frame. The lower part of the front end is fixed with a tooth seat plate 1, also called a knife plate. The left and right sides are respectively fixed with side plates 3, also called side knife plates. The upper side is fixed with a back plate 9 and The ear plate 8 has a first hinged portion 13 at its rear and lower end, an arc-shaped portion 18 on its upper inner side wall, and a guide groove 20 extending forward and backward in the middle of its upper wall. The arc-shaped portion 18 is connected to the first The geometrical central axes of the two hinge parts 13 coincide and extend in the left-right direction. The front side of the tooth seat plate 1 is provided with a tooth seat 15, and the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com