Cold upsetting forming die of slender bolt

A technology for forming dies and bolts, applied in the direction of bolts, manufacturing tools, threaded fasteners, etc., can solve the problems of inability to return, difficult to process, easy to bend, etc., to achieve shortened length, difficult to bend or break, and lighter weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

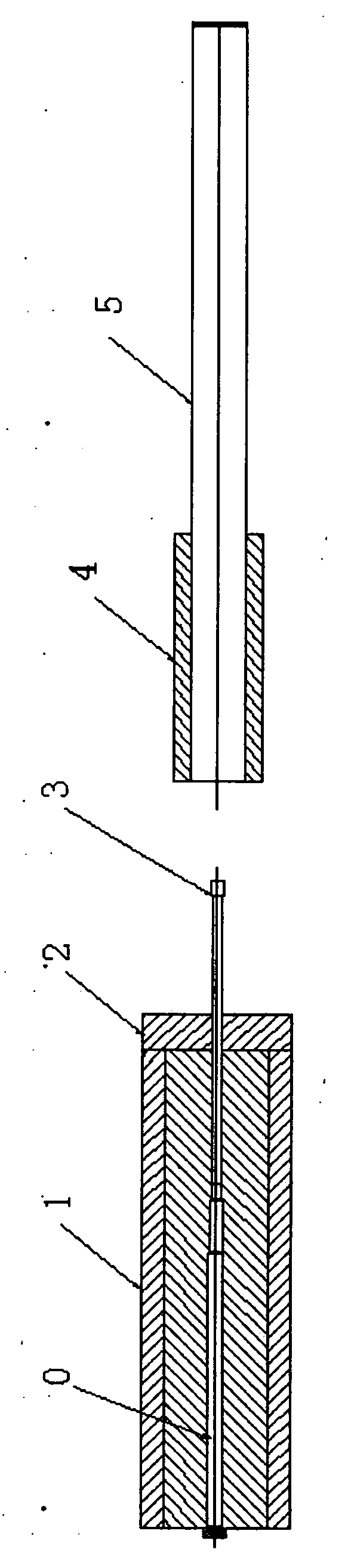

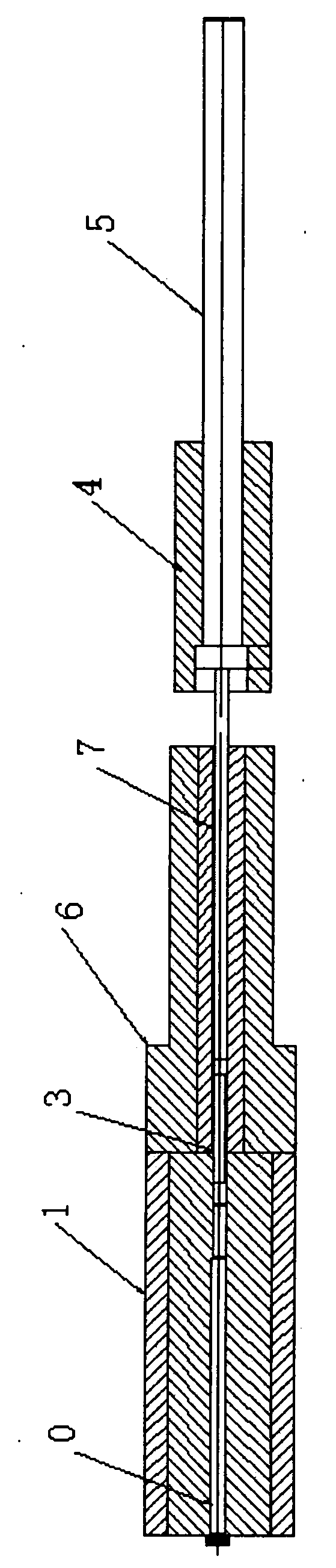

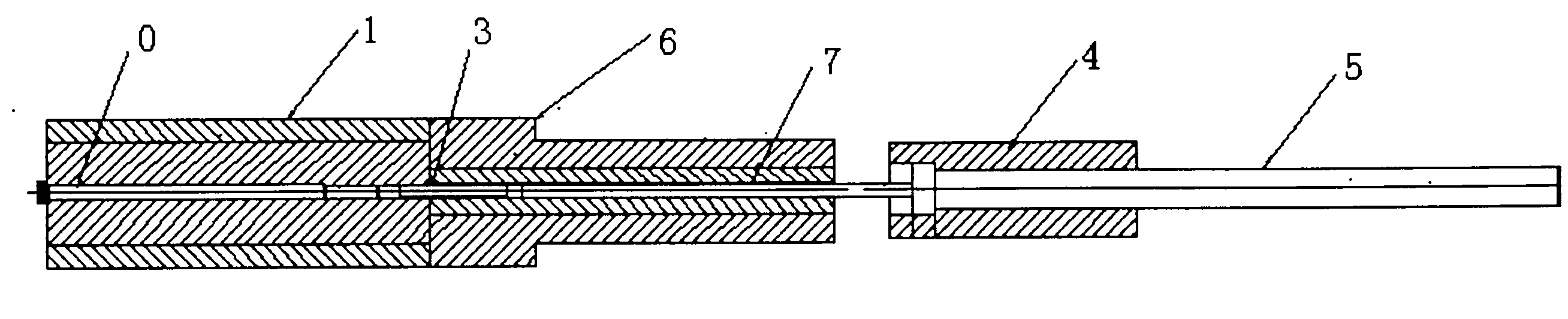

[0015] figure 2 It is a structural schematic diagram of an embodiment of the present invention.

[0016] like figure 2 Shown: a slender bolt cold heading forming mold, including a master mold 1, a feeding rod 3, a large rear support screw 4 and a rear moving connecting rod 5. One end of the feeding rod 3 is set in the cavity of the female mold 1, and its The rear part is the back supporting large screw 4, and the rear moving connecting rod 5 is located at the center of the rear supporting large screw 4. It is characterized in that a safety protection tube 6 is also arranged at the rear of the master mold 1, and the safety protection tube 6 is set in the through The other end of the material rod 3, and the central hole of the safety protection tube 6 corresponds to the cavity of the master mold, and the head of the rear moving connecting rod 5 is also connected with a mold opening lever 7, and the front end of the mold opening lever 7 extends into to the center hole of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com