High-bending-strength high-modulus light epoxy composite board and preparation method thereof

A flexural strength and high modulus technology, applied in the field of high flexural strength and high modulus lightweight epoxy composite panels and their preparation, can solve the problems of high cost and low flexural modulus, and achieve low cost and high flexural strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

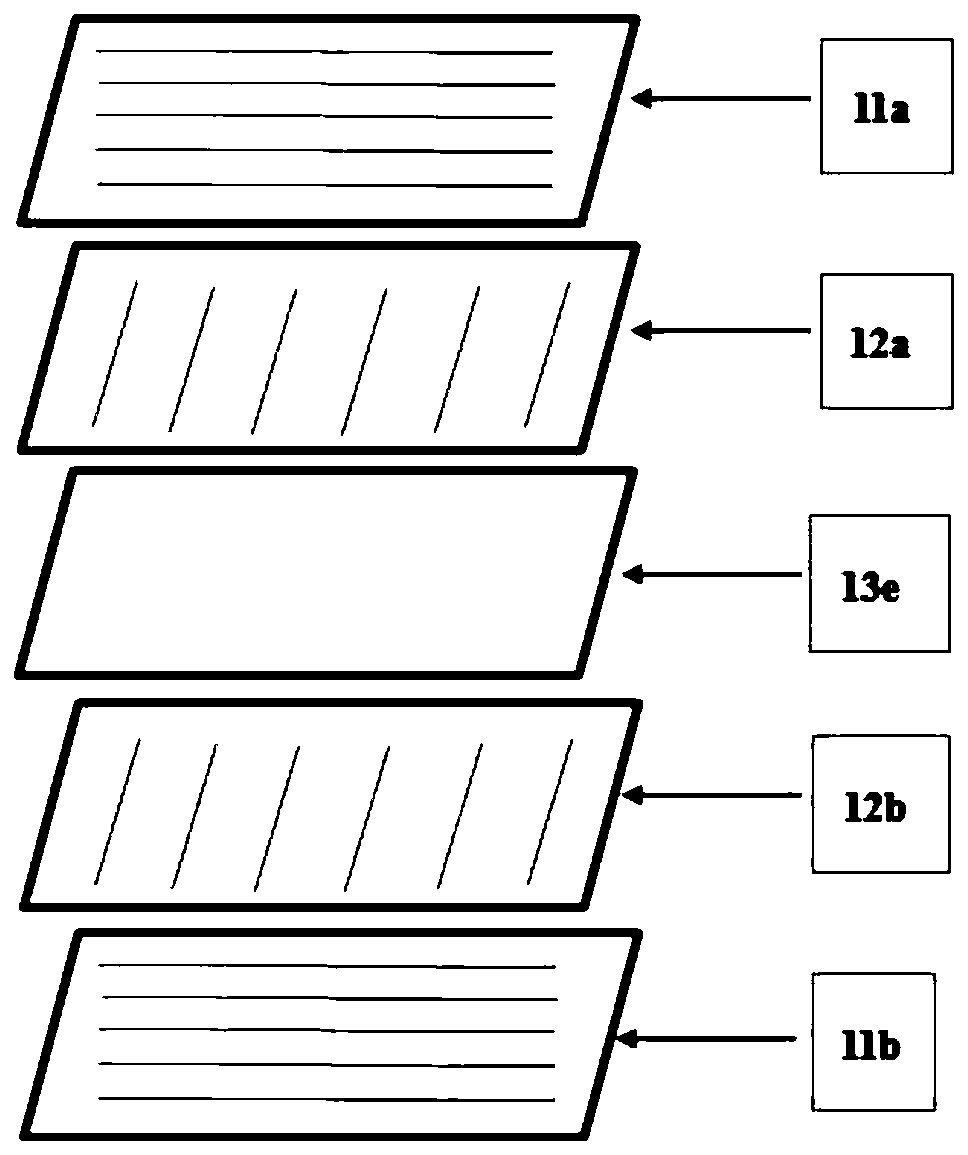

[0032] Such as figure 1 As shown, take two sheets of FAW for 150g / m 2 , RC is 35% carbon fiber UD prepreg 11a, 11b, two FAW is 75g / m 2 , RC is 35% carbon fiber UD prepreg 12a, 12b, and a density of 0.72g / cm 3 , a lightweight epoxy board 13e with a thickness of 0.60mm, a carbon fiber UD prepreg 11a and a carbon fiber UD prepreg 12a, a carbon fiber UD prepreg 11b and a carbon fiber UD prepreg 12b in advance Stacked vertically at 0° / 90°, and then stacked with a lightweight epoxy board 13e, carbon fiber UD prepregs 11a, 12a and carbon fiber UD prepregs 11b, 12b are arranged on both sides of the lightweight epoxy board 13e , and relative to the lightweight epoxy board 13e, it is symmetrical in relative position and symmetrical in the UD direction. After stacking, add release film up and down, at a temperature of 170-200°C and a pressure of 10-30kg / cm 2 Under the condition of hot pressing for 150min, then at 5Kgf / cm 2 The pressure is cold pressed for 60 minutes to obtain a ligh...

Embodiment 2

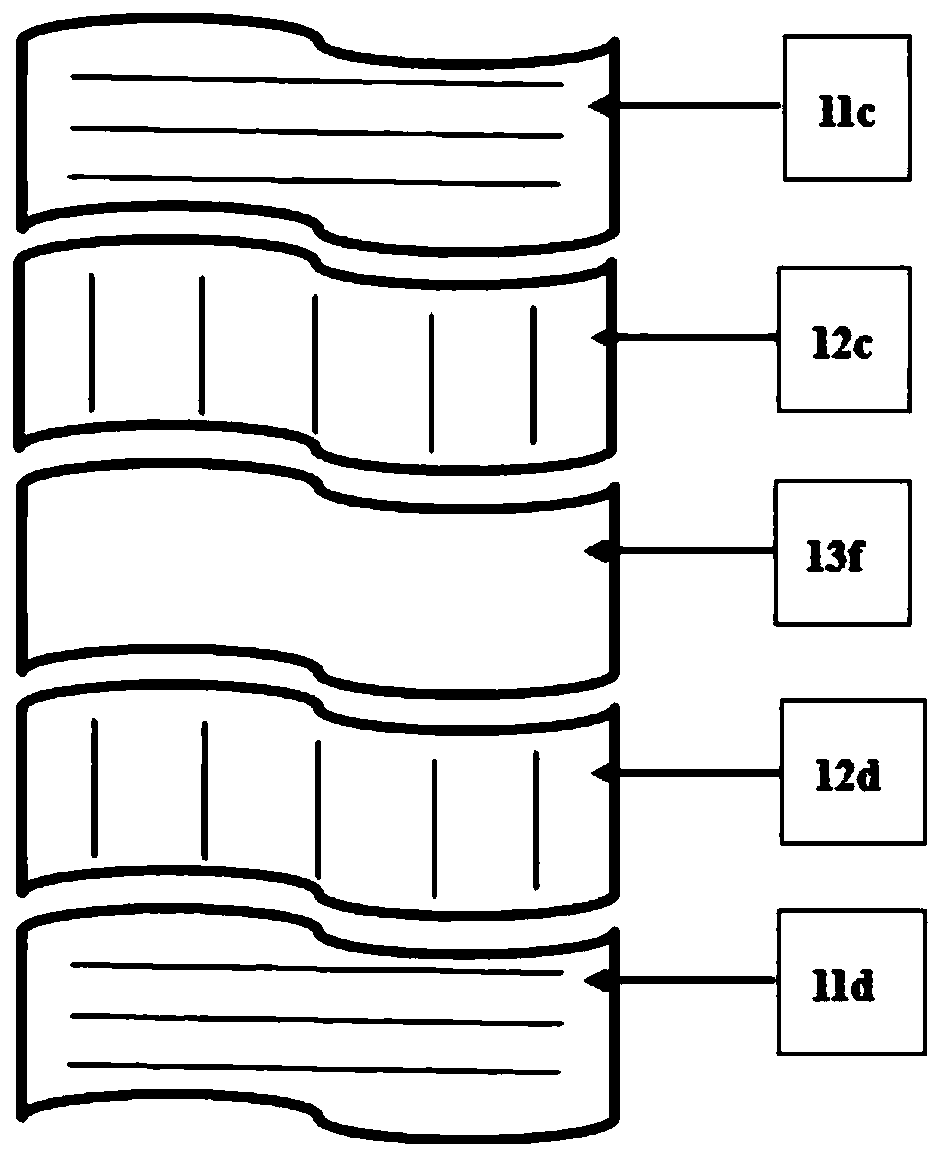

[0034] Such as figure 2 As shown, take two sheets of FAW for 150g / m 2 , RC is 30% glass fiber UD prepreg 11c, 11d, two FAW is 65g / m 2 , RC is 30% glass fiber UD prepreg 12c, 12d, and a density of 0.8g / cm 3, a light weight epoxy board 13f with a thickness of 0.75mm, a piece of glass fiber UD prepreg 11c and a piece of glass fiber UD prepreg 12c, a piece of glass fiber UD prepreg 11d and a piece of glass fiber UD The prepregs 12d are stacked vertically at 0° / 90°, and then stacked with a lightweight epoxy board 13f, the glass fiber UD prepregs 11c, 12c and the glass fiber UD prepregs 11d, 12d are arranged in a light ring The two sides of the oxygen board 13f, and relative to the lightweight epoxy board 13f, are symmetrical in relative position and symmetrical in the UD direction. After stacking, add release film up and down, at a temperature of 170-200°C and a pressure of 10-30kg / cm 2 Under the condition of hot pressing for 150min, then at 5Kgf / cm 2 The pressure is cold pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com