Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50results about How to "Will not silt" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

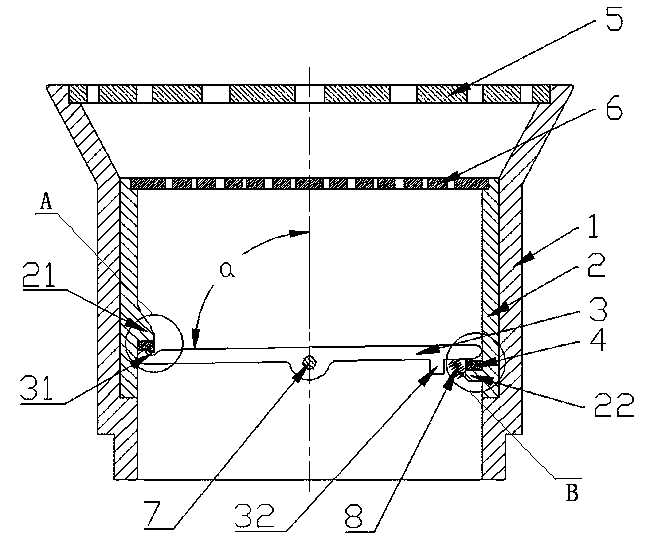

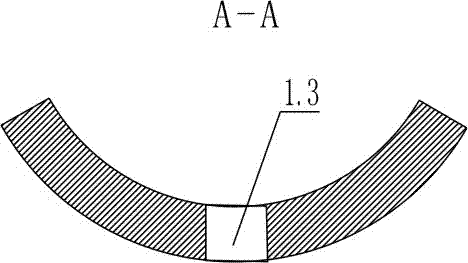

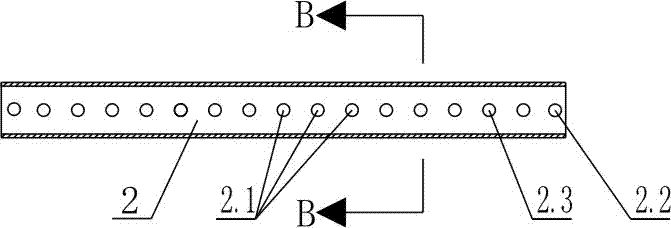

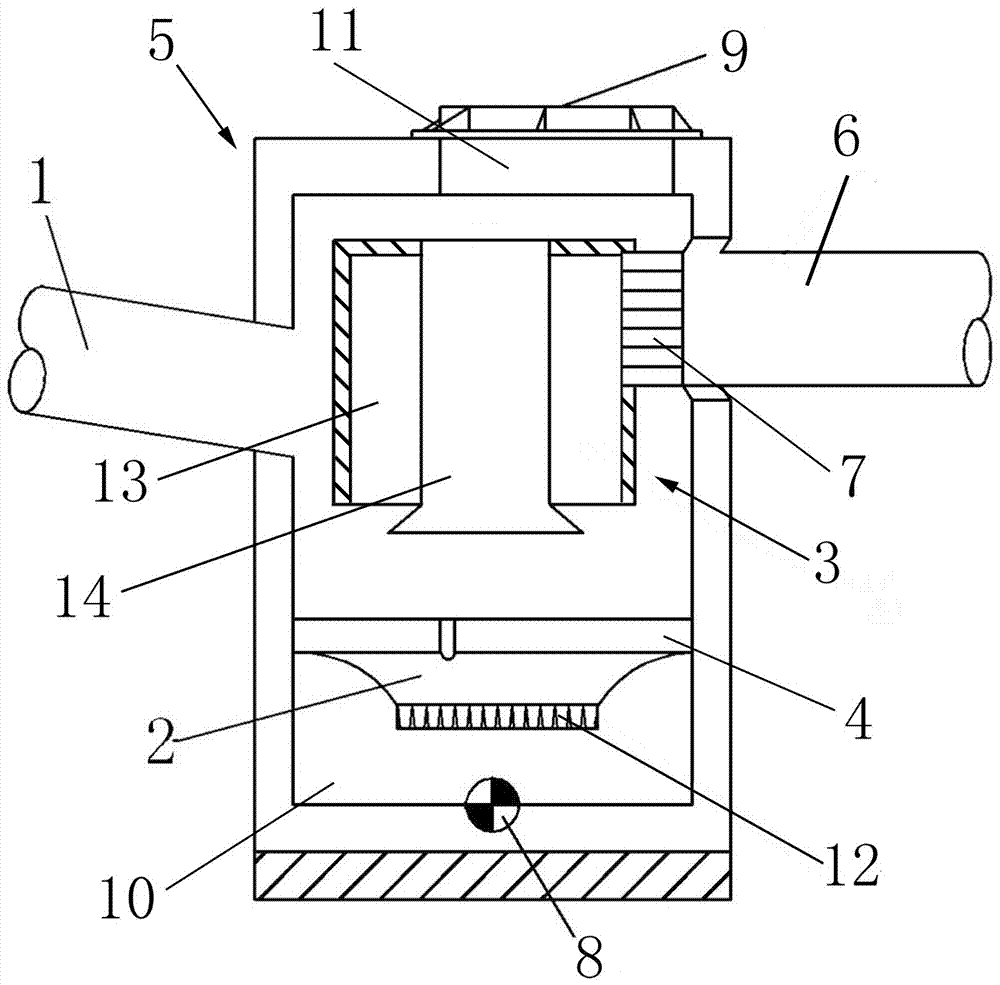

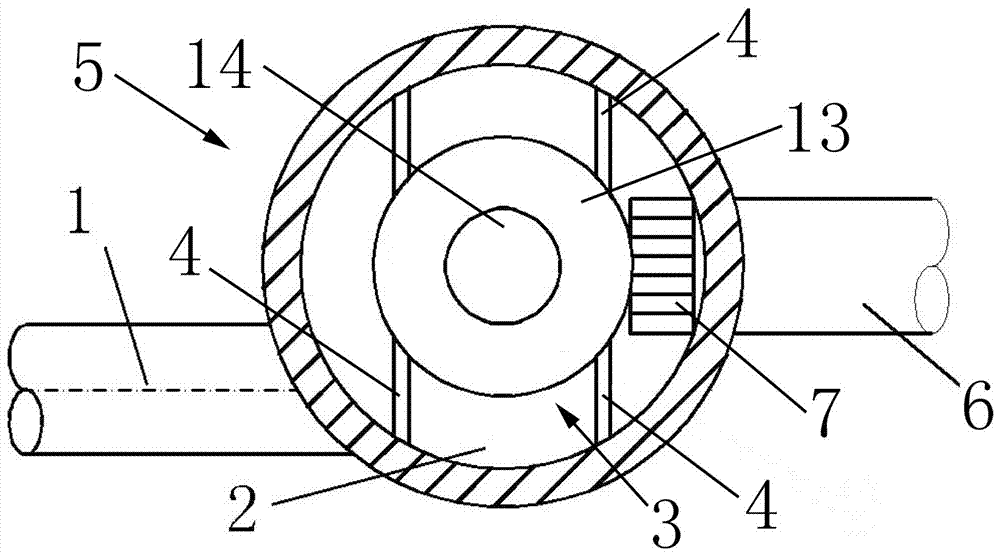

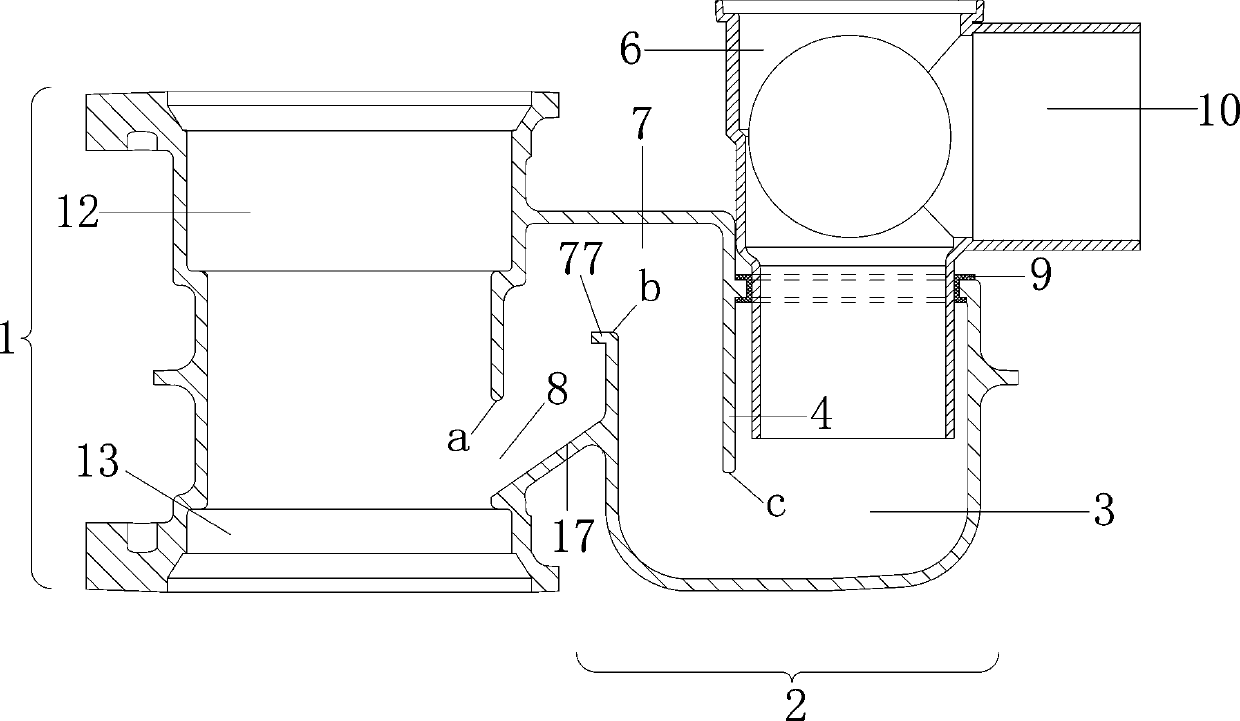

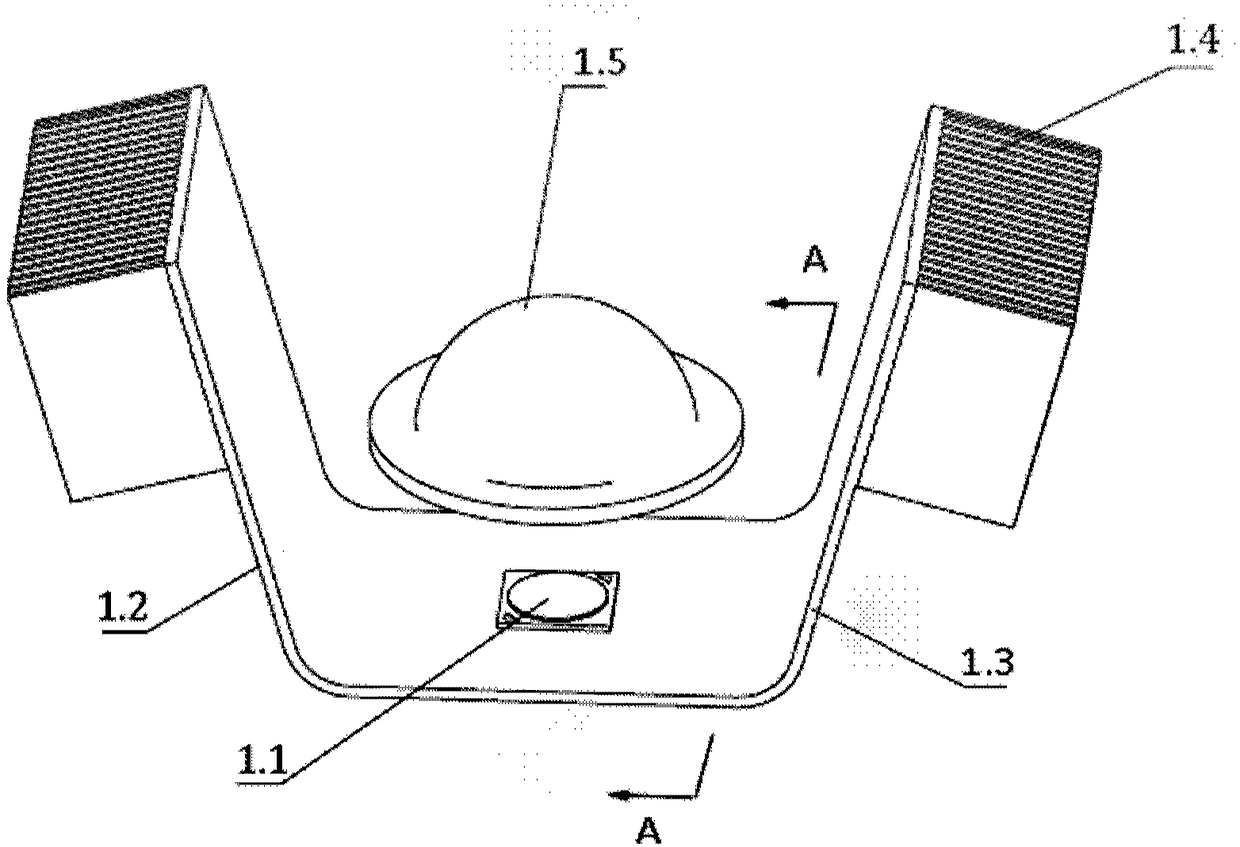

Self-sealing type floor drain

InactiveCN103410214AAchieve anti-odorPrevent the phenomenon of not being able to return effectivelyFatty/oily/floating substances removal devicesSewerage structuresAgricultural engineering

Owner:GUANGDONG LIANSU TECH INDAL

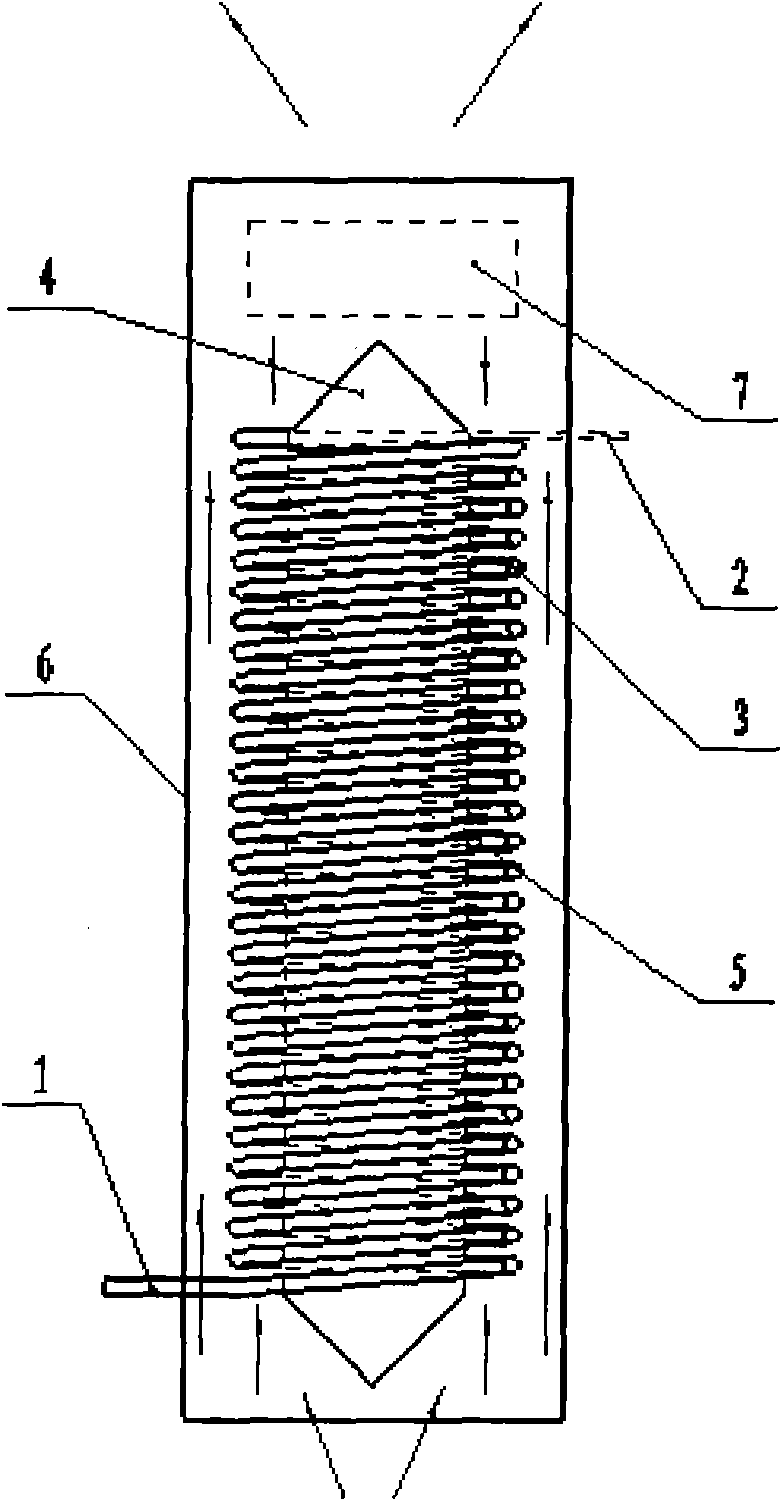

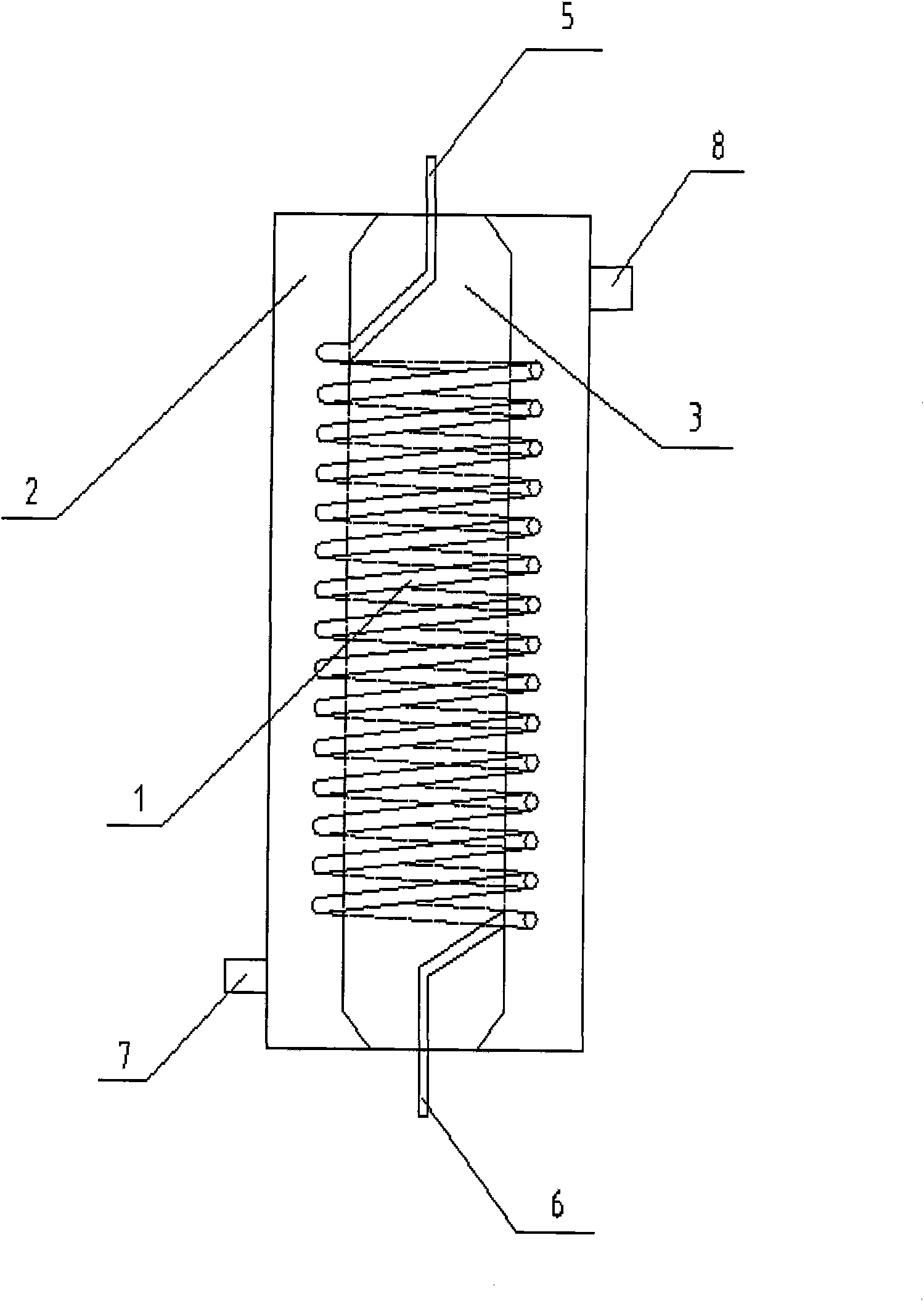

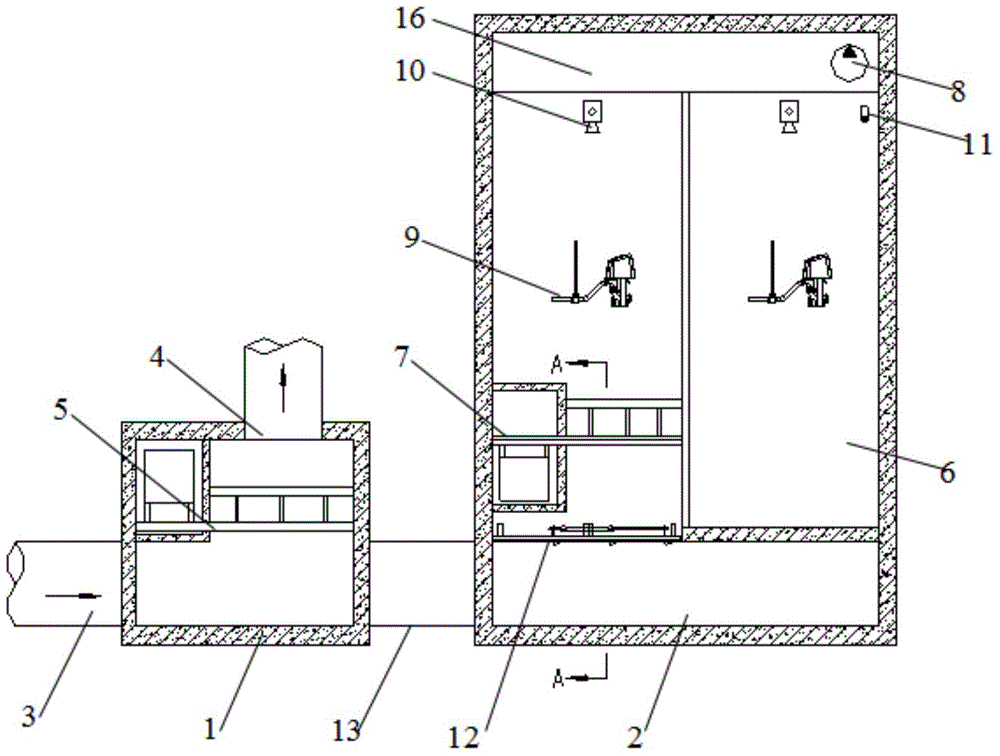

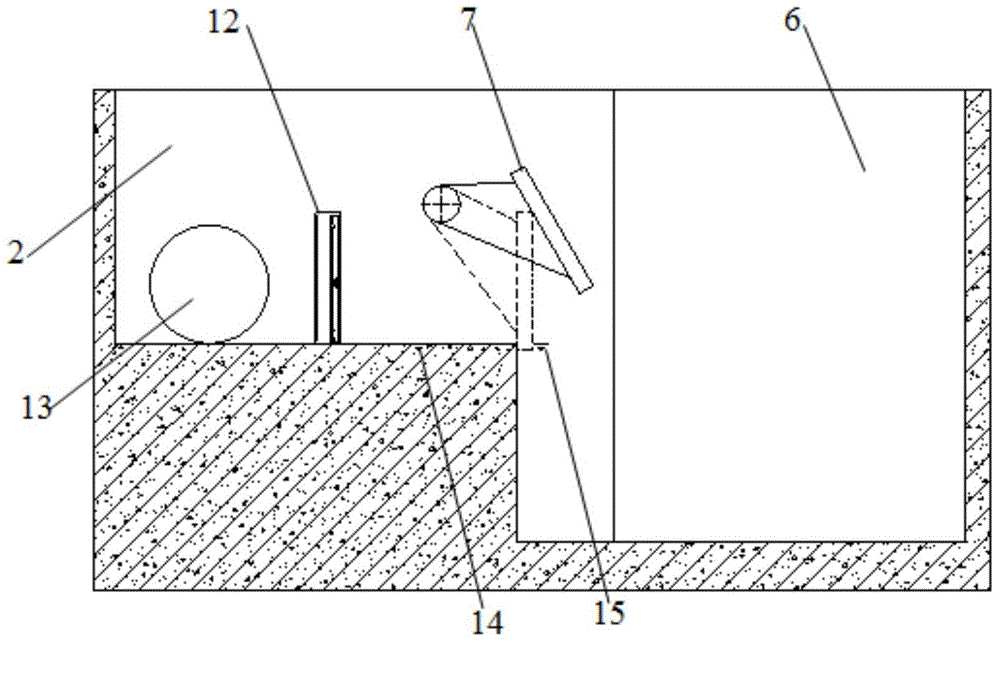

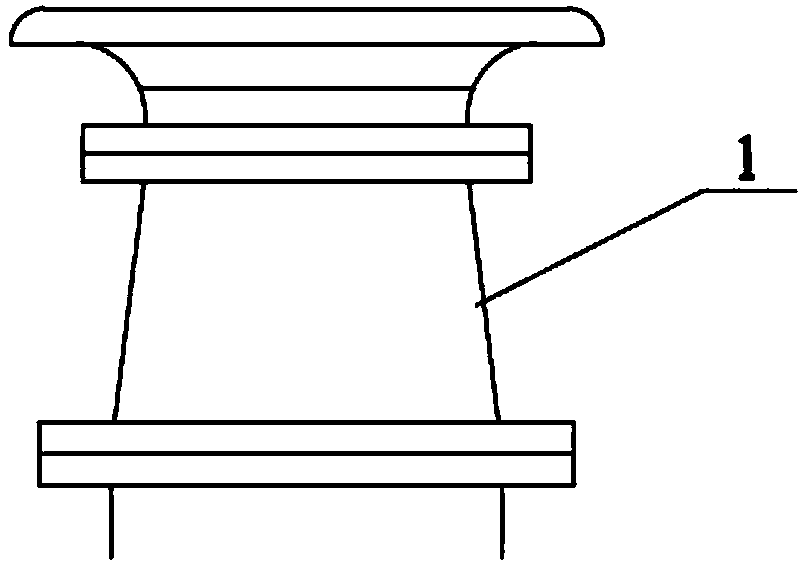

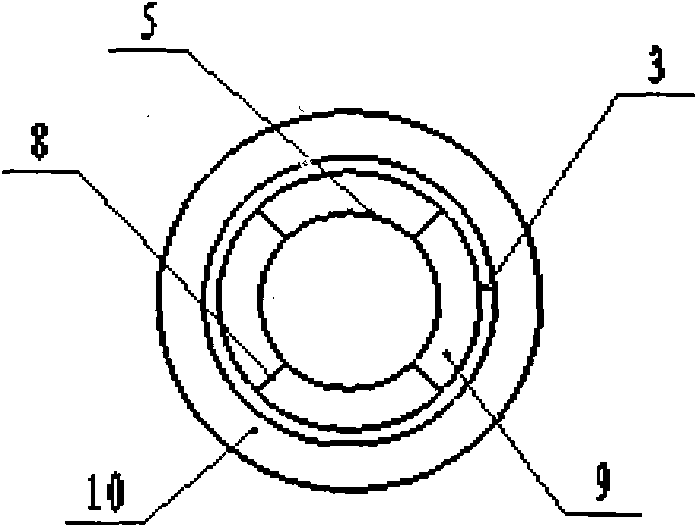

Heat exchanger with corrugated pipe coil structure provided with internal duct and external duct

InactiveCN101619944ASmooth heat convectionModularElectrolysis componentsChemical industryLiquid mediumEngineering

The invention discloses a heat exchanger with a corrugated pipe coil structure provided with an internal duct and an external duct, which comprises an inlet, an outlet, a corrugated pipe, a dome, an internal ring bushing, an external ring bushing, a fan and a bracket. When fluid media to be in heat exchange flow in the corrugated pipe in the heat exchanger from the inlet, form a turbulent flow in a pipe wall with a corrugated structure and carry out heat exchange with air in the internal duct and the external duct outside the corrugated pipe via the wall of the corrugated pipe, the fan discharges air in the internal duct and the external duct, and the fluid media are discharged from the outlet after the heat exchange performed in the corrugated pipe in a spiral way. The heat exchanger has the advantages of high heat exchanger effectiveness, simple structural technology, light weight, integration, and the like, and the fluid media in the pipe coil after the heat exchange have even temperature, thereby the heat exchanger can be used for heat exchange of air, liquid and air-liquid mixing substances. When the corrugated pipe adopts resistant materials, the heat exchanger can be used for heat exchange for corrosive liquid media.

Owner:南京容宇能源科技有限公司

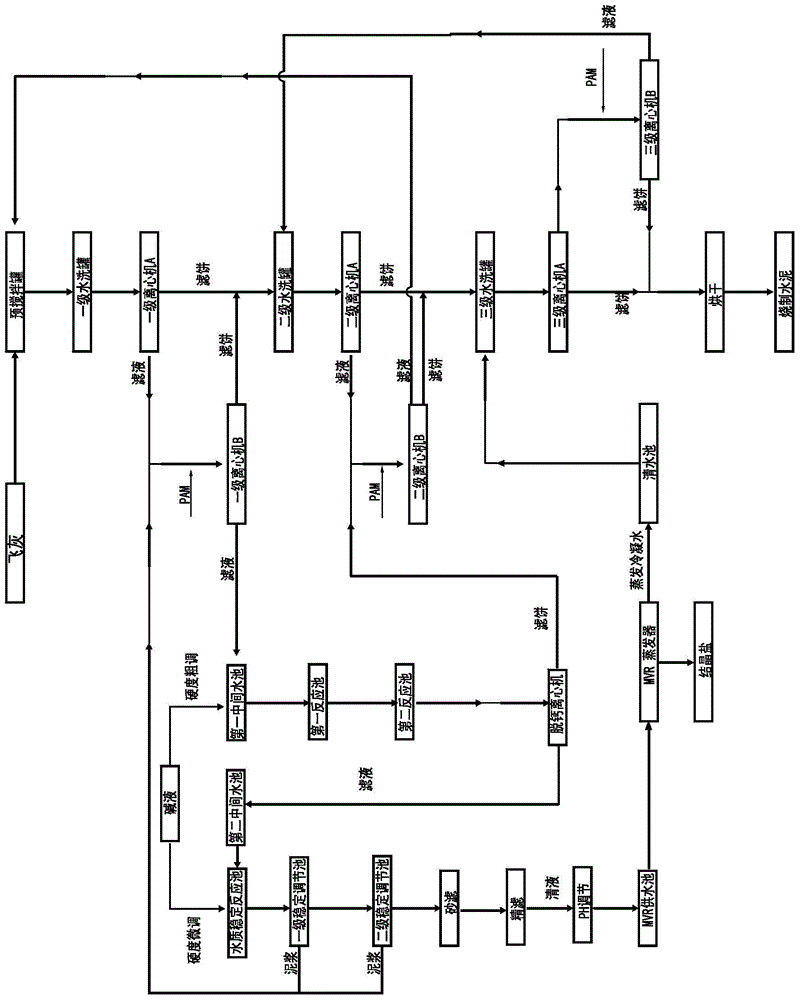

Washing softening technology for MSWI (Municipal Solid Waste Incineration) fly ash

ActiveCN104803537ASolving Excessive Chlorine ProblemsGuaranteed qualityWater/sewage treatment by centrifugal separationSludge treatmentWater qualityTherapeutic effect

The invention discloses a washing softening technology for MSWI (Municipal Solid Waste Incineration) fly ash. The technology comprises the following steps of performing primary washing on the fly ash; performing primary centrifugal dewatering on the washed fly ash after the washing operation is completed; adding a PAM (Polyacrylamide) solution into the separated filter liquor and uniformly blending; feeding the mixture into a first-level centrifugal machine B for performing secondary centrifugal dewatering; feeding the filter liquor separated from the first-level centrifugal machine B into a decalcified centrifugal machine for centrifuging after the filter liquor is subjected to hardness coarse-adjustment and heavy metal removal treatment; finely adjusting the hardness of the filter liquor separated from the decalcified centrifugal machine, sequentially precipitating and filtering the filter liquor, and adjusting the PH value of the filter liquor to be 7-8; finally feeding the filter liquor to an MVR (Mechanical vapor recompression) evaporator. According to the washing softening technology for the MSWI (Municipal Solid Waste Incineration) fly ash, the washing treatment effect is good, and the effluent quality is stable; a filter cake separated from the decalcified centrifugal machine is mixed with the filter liquor discharged by a second-level centrifugal machine A, and then the mixture is subjected to subsequent treatment, so that the mixture can be washed twice again, therefore the content of chloride ions in the filter cake is smaller than 0.5%, and the problem of high chlorine content in the filter cake is solved, and the cement quality is guaranteed.

Owner:BEIJING ZKGR ENVIRONMENTAL PROTECTION TECH CO LTD

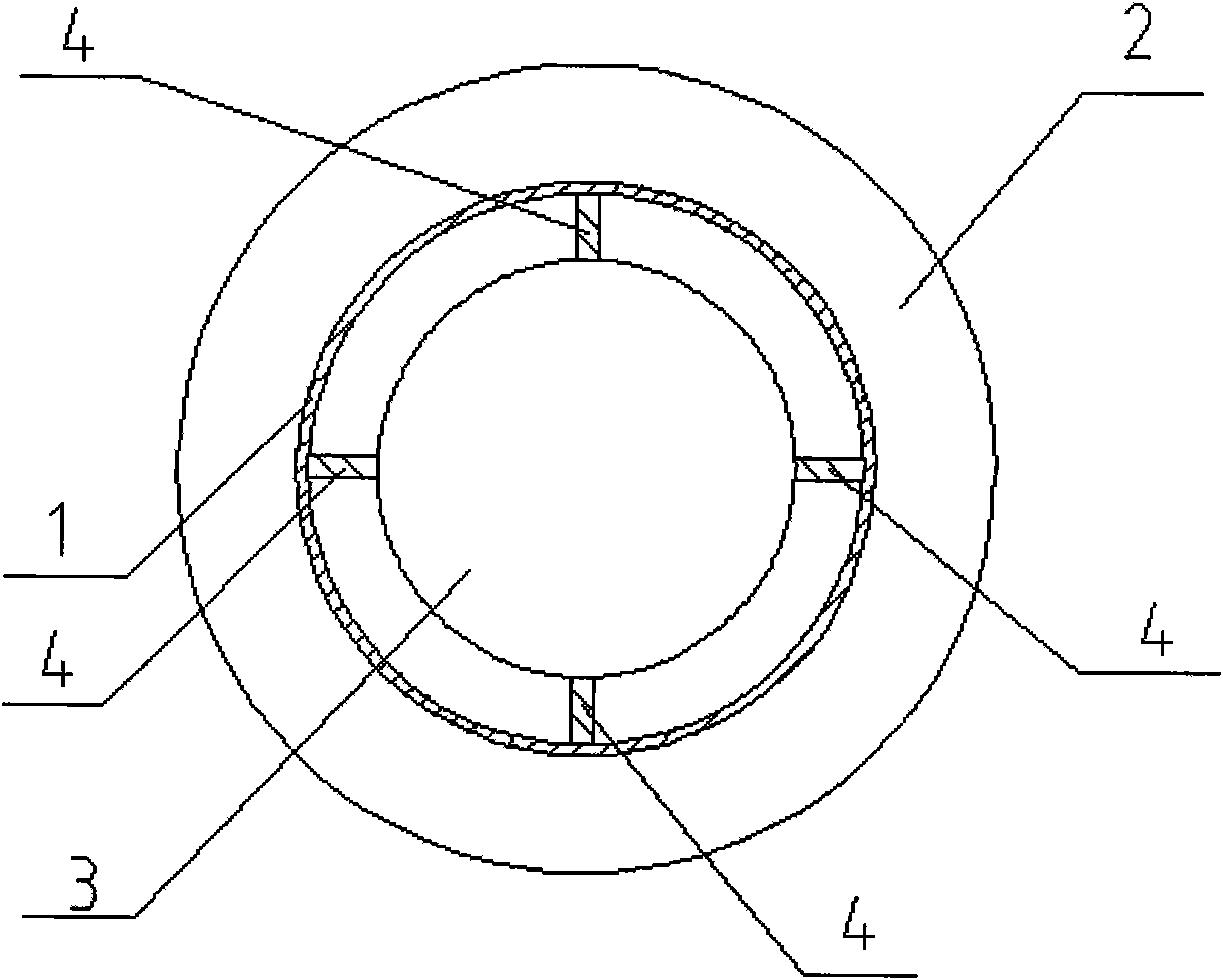

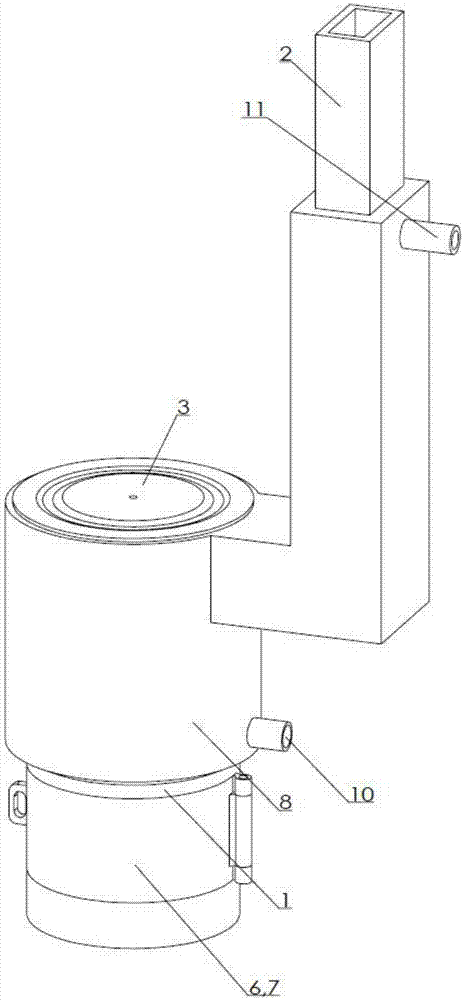

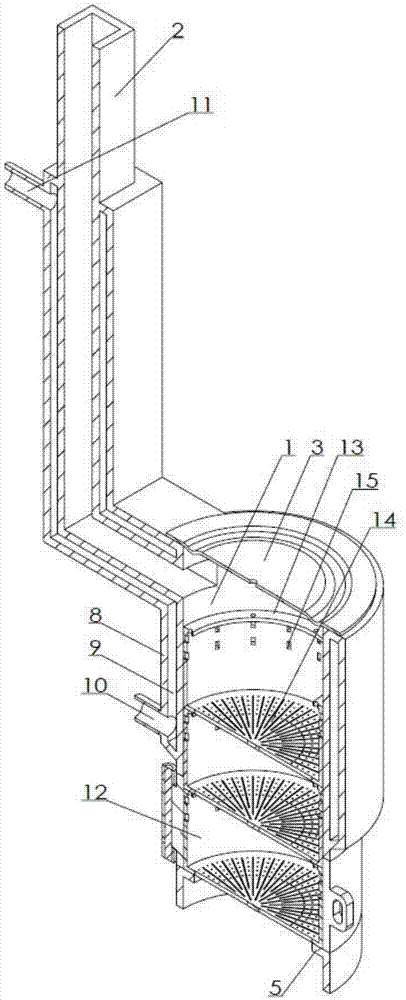

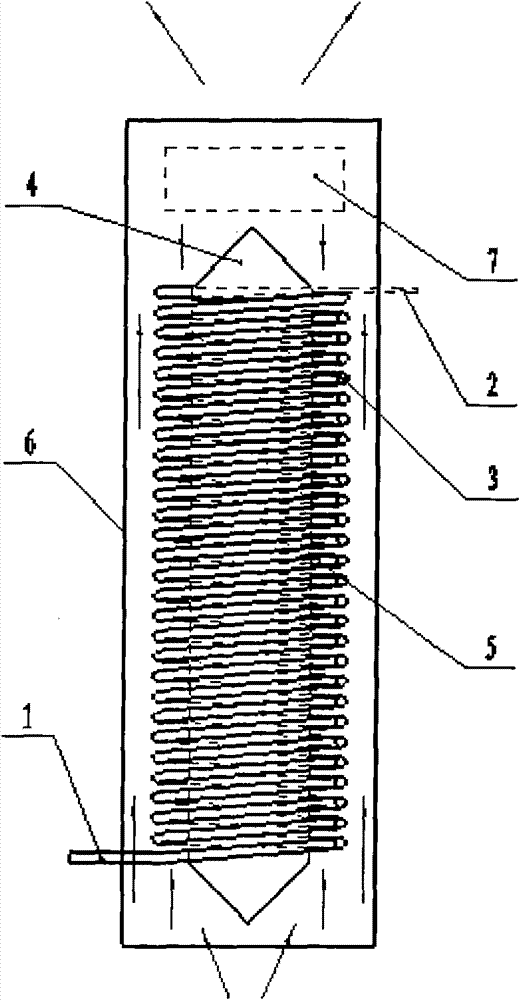

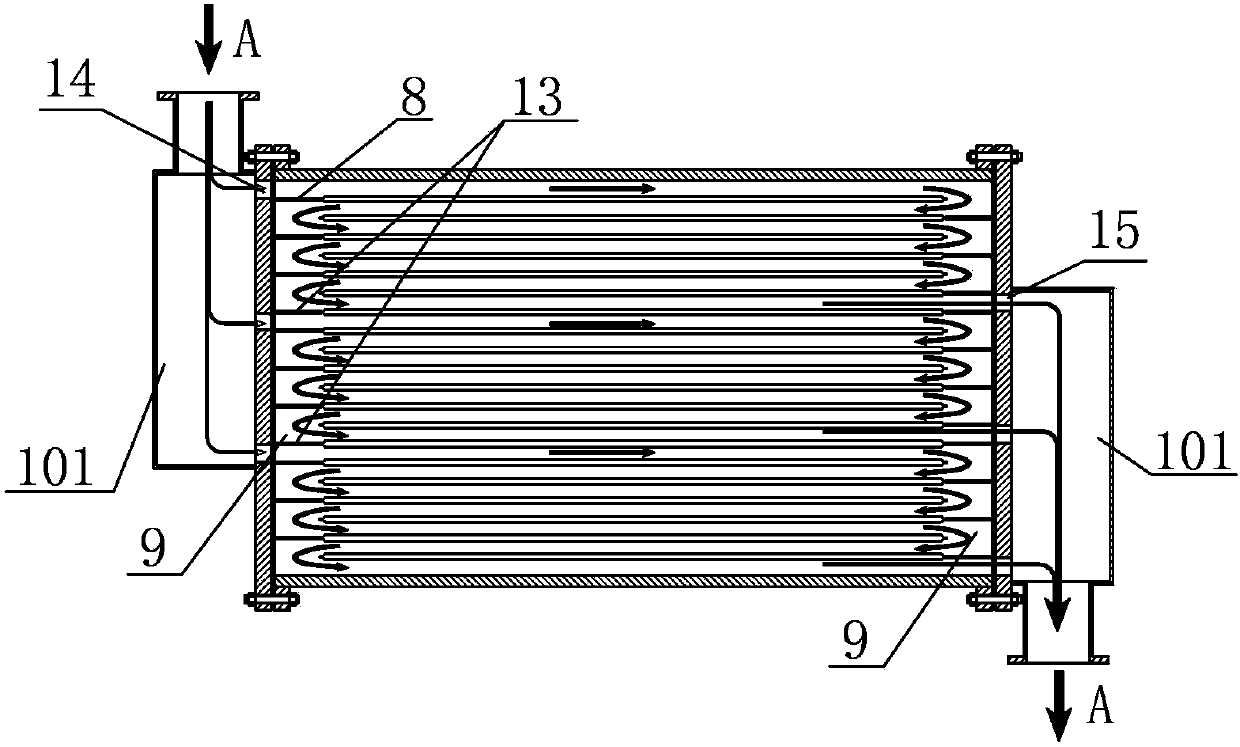

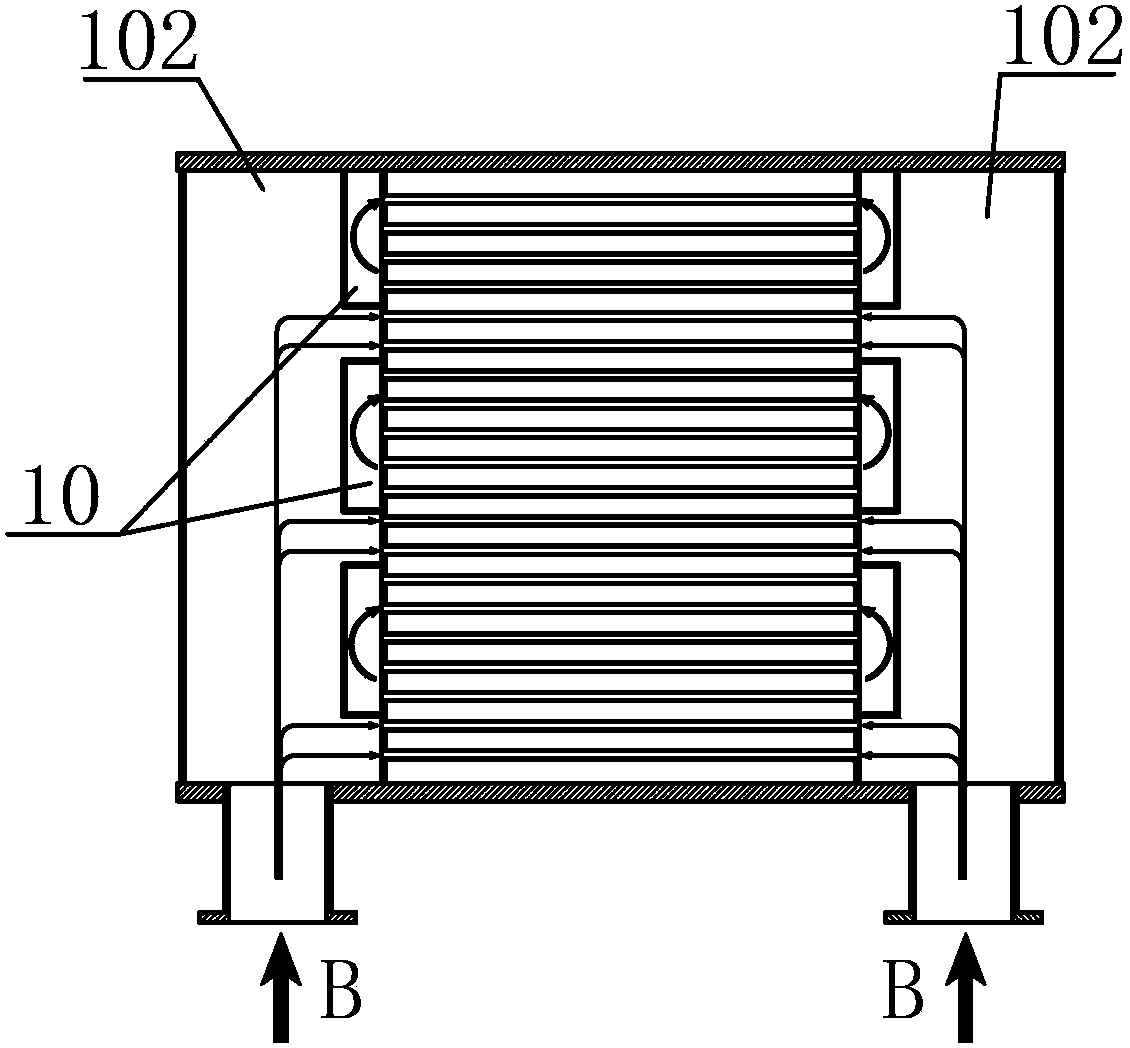

Liquid-cooled heat exchanger based on spiral structure

InactiveCN101625207AWill not siltAvoid easy cloggingElectrolysis componentsStationary tubular conduit assembliesHydrogenCooling chamber

The invention relates to a liquid-cooled heat exchanger based on a spiral structure, solving the problems of effectively reducing the temperature of an electrolyzed gas-liquid mixture and preventing device corrosion when hydrogen and oxygen are prepared by electrolytic water. The heat exchanger comprises a cooling chamber, a radiating pipe, an inner pipe and a bracket, wherein the cooling chamber is a sealed container, and both ends of the cooling chamber are provided with an inlet and an outlet; the radiating pipe is positioned in the cooling chamber, both ends of the radiating pipe are respectively used as an inlet and an outlet, and both the inlet and the outlet extend out of the cooling chamber by through holes of the cooling chamber; a body of the radiating pipe is in a ripple structure, and both the inner surface and the outer surface of the pipe are provided with ripples; the part of the radiating pipe, which is positioned in the cooling chamber, is in a spiral structure and is positioned between the inlet and the outlet of the cooling chamber; and the radiating pipe as well as the inlet and the outlet of the radiating pipe are made of steel or stainless steel. The liquid-cooled heat exchanger has favorable radiating effect and is difficult to interfere by the external environment.

Owner:南京容宇能源科技有限公司

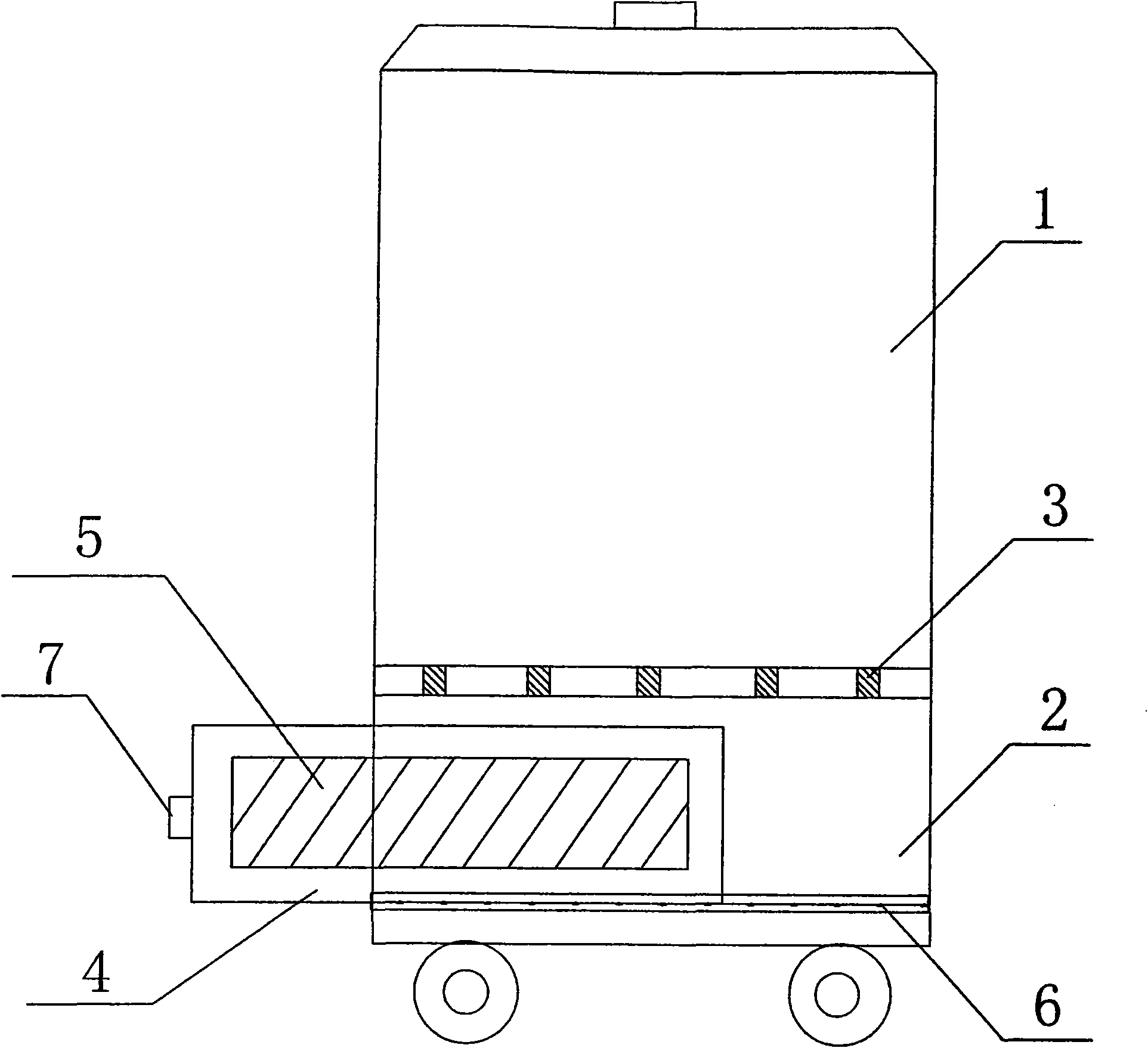

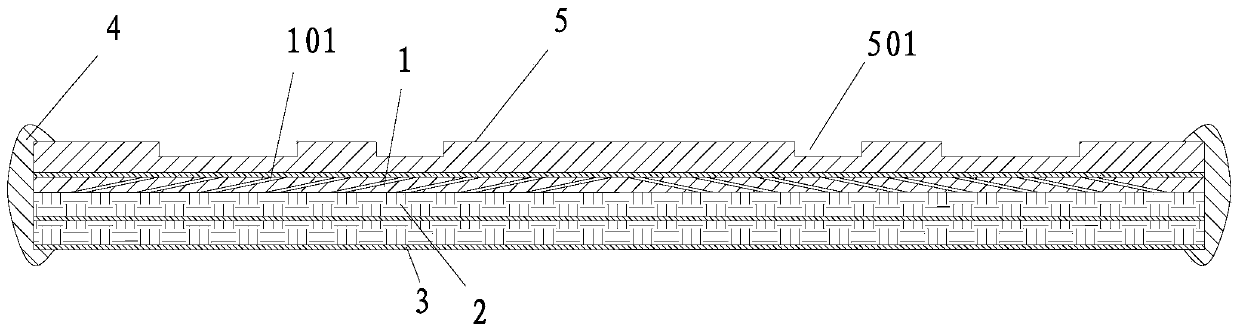

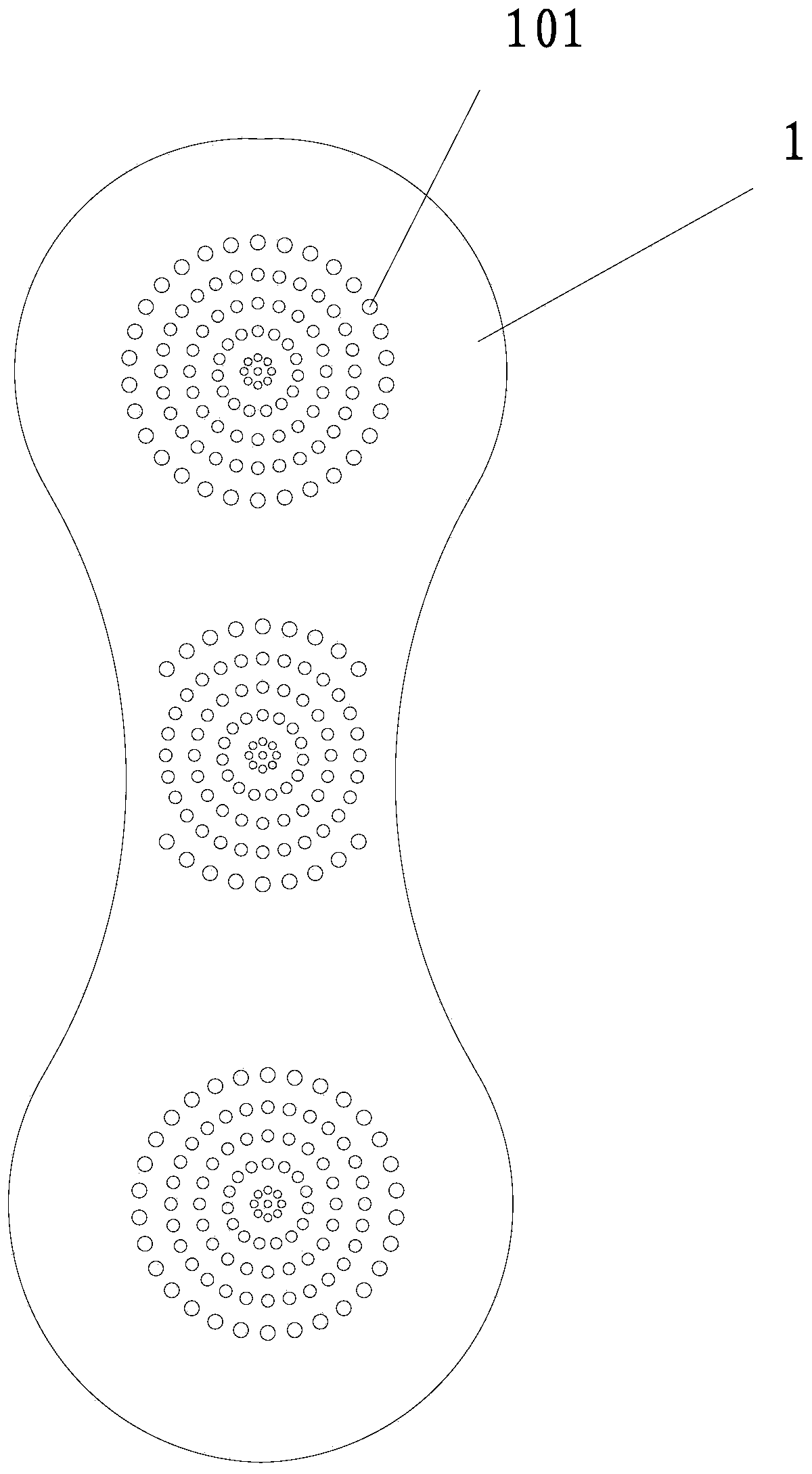

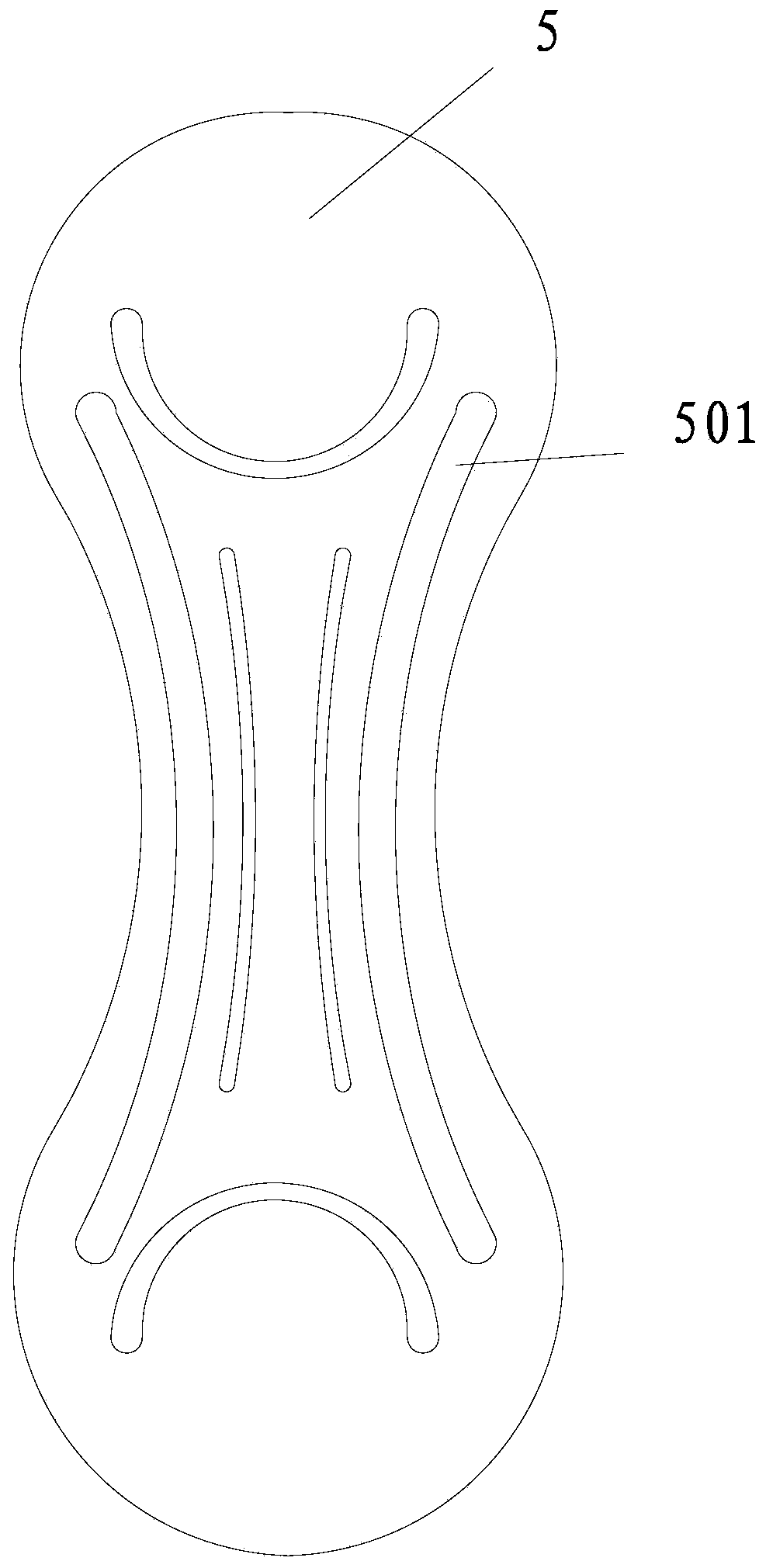

Novel environment-friendly garbage bin with sewage collecting box

The invention relates to a novel environment-friendly garbage bin with a sewage collecting box, which comprises a bin body, and is characterized in that the bin body is divided into an upper part and a lower part, the upper part is a garbage storing bin (1), and the lower part is the sewage collecting box (2); the bottom of the garbage storing bin is provided with a plurality of pores (3), so that sewage in the garbage storing bin (1) can flow into the sewage collecting box (2) through the pores (3); a storage case (4) is arranged in the sewage collecting box (2); and the storage case (4) is withdrawn from an opening of the sewage collecting box (2), and a sewage absorption bag (5) which is filled with powdery or fine granular absorbing substances is arranged in the storage case (4). The garbage can collect the sewage in the garbage bin, so that the sewage cannot flow out of the garbage bin; the garbage bin not only can protect the environment, but also is convenient to clean; and the garbage bin has the advantages of simple structure, convenient modification, and easy implementation and popularization.

Owner:陆洪兴

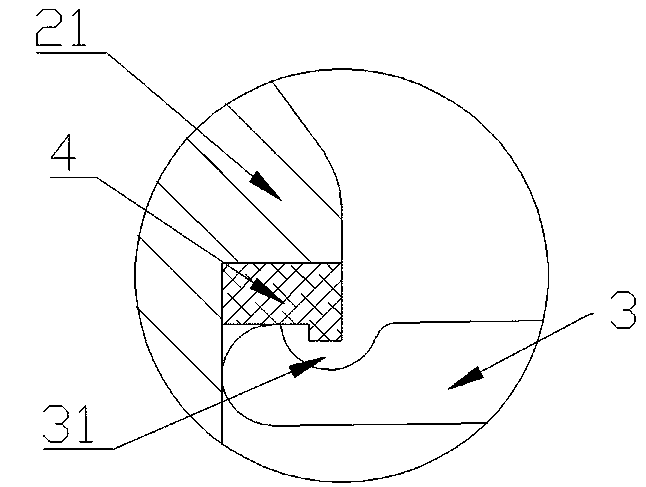

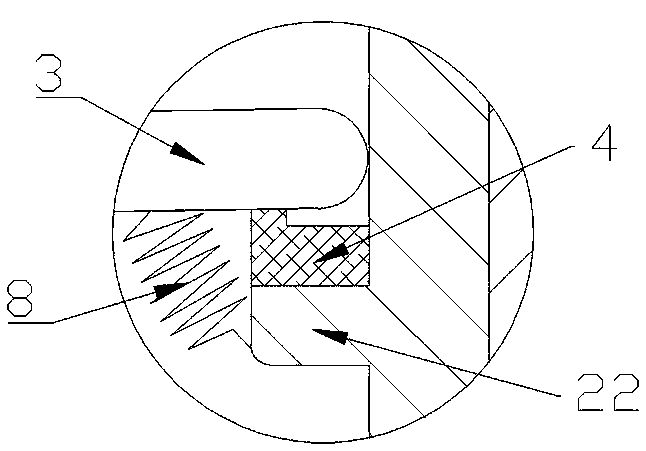

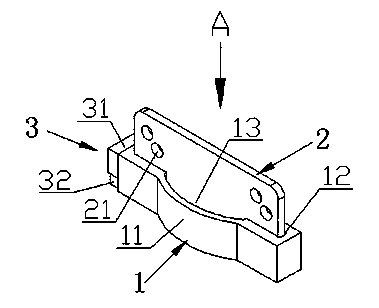

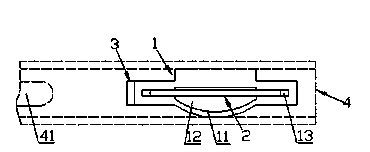

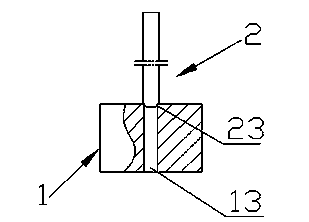

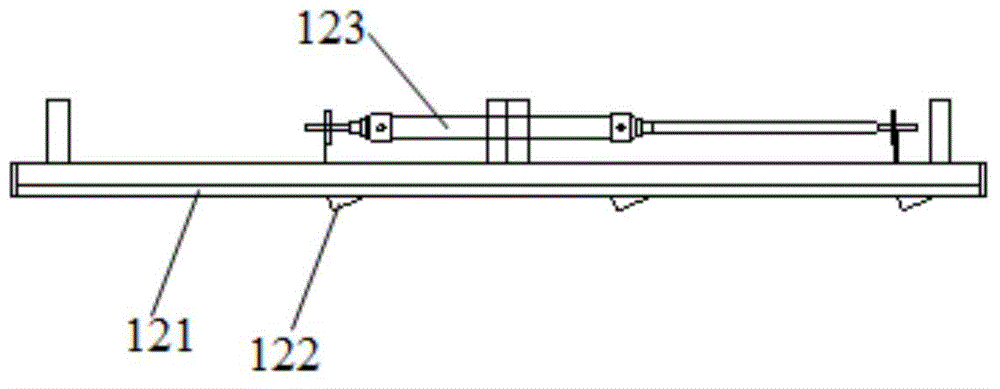

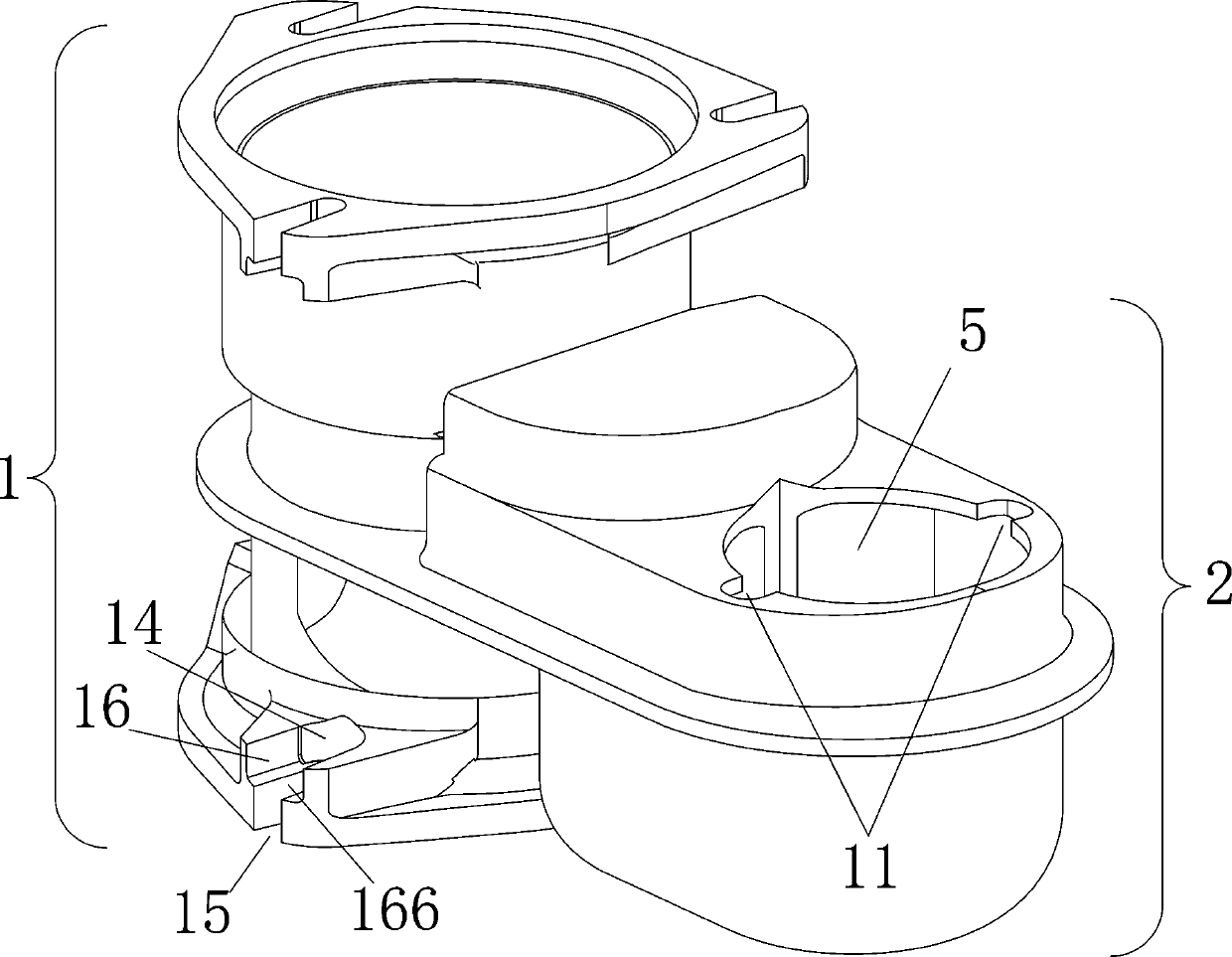

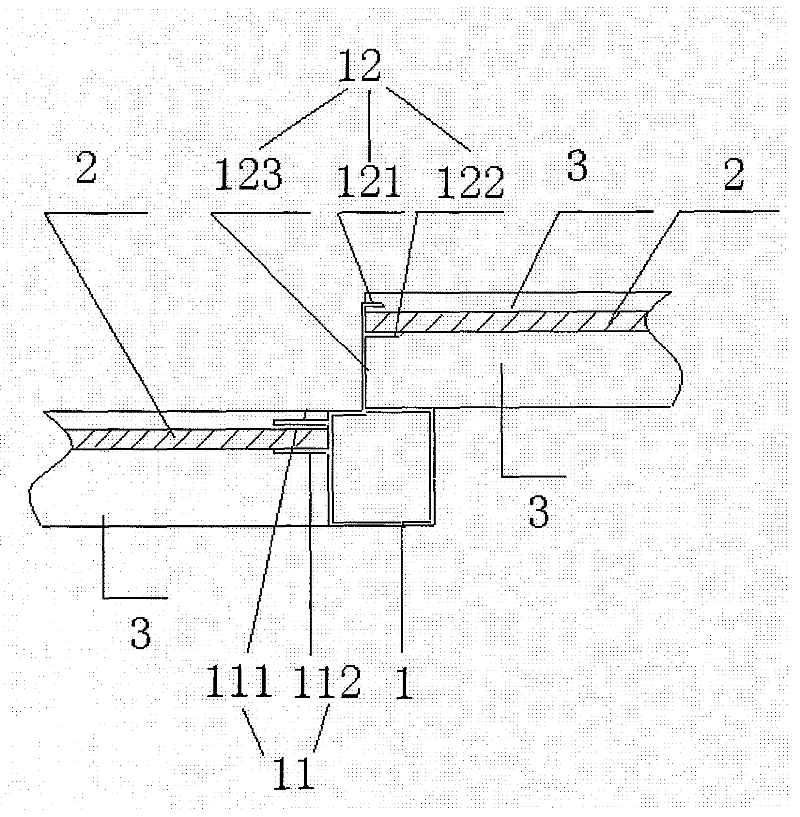

Sill slider device of elevator door

The invention relates to a sill slider device of an elevator door. The sill slider device is arranged in a sill groove of an elevator and comprises a sill slider and a connecting plate. The connecting plate is connected to the slider; the sill slider is arranged in the sill groove, at least one side, which corresponds to a groove surface of the sill groove, of the sill slider is provided with an elastic border, the borders are in contact with the corresponding groove surfaces of the sill groove in a pressure manner and accordingly movably elastically deform towards the inner sides of the borders, and the sill slider can be seamlessly slidably connected into the sill groove. The sill slider device has the advantages that the sill slider is provided with the elastically deformable borders, and can be seamlessly slidably connected into the sill groove, seams between the slider and the sill groove can be constantly and assuredly prevented even if the corresponding borders are abraded due to frequent sliding of the slider, and the elevator door can assuredly stably run without noise; the sill groove can be cleaned under the sliding action of a cleaning element, so that jamming faults due to garbage deposits in the sill groove can be prevented; the cleaning element is quite convenient to replace.

Owner:SPECIAL EQUIP SAFETY SUPERVISION INSPECTION INST OF JIANGSU PROVINCE

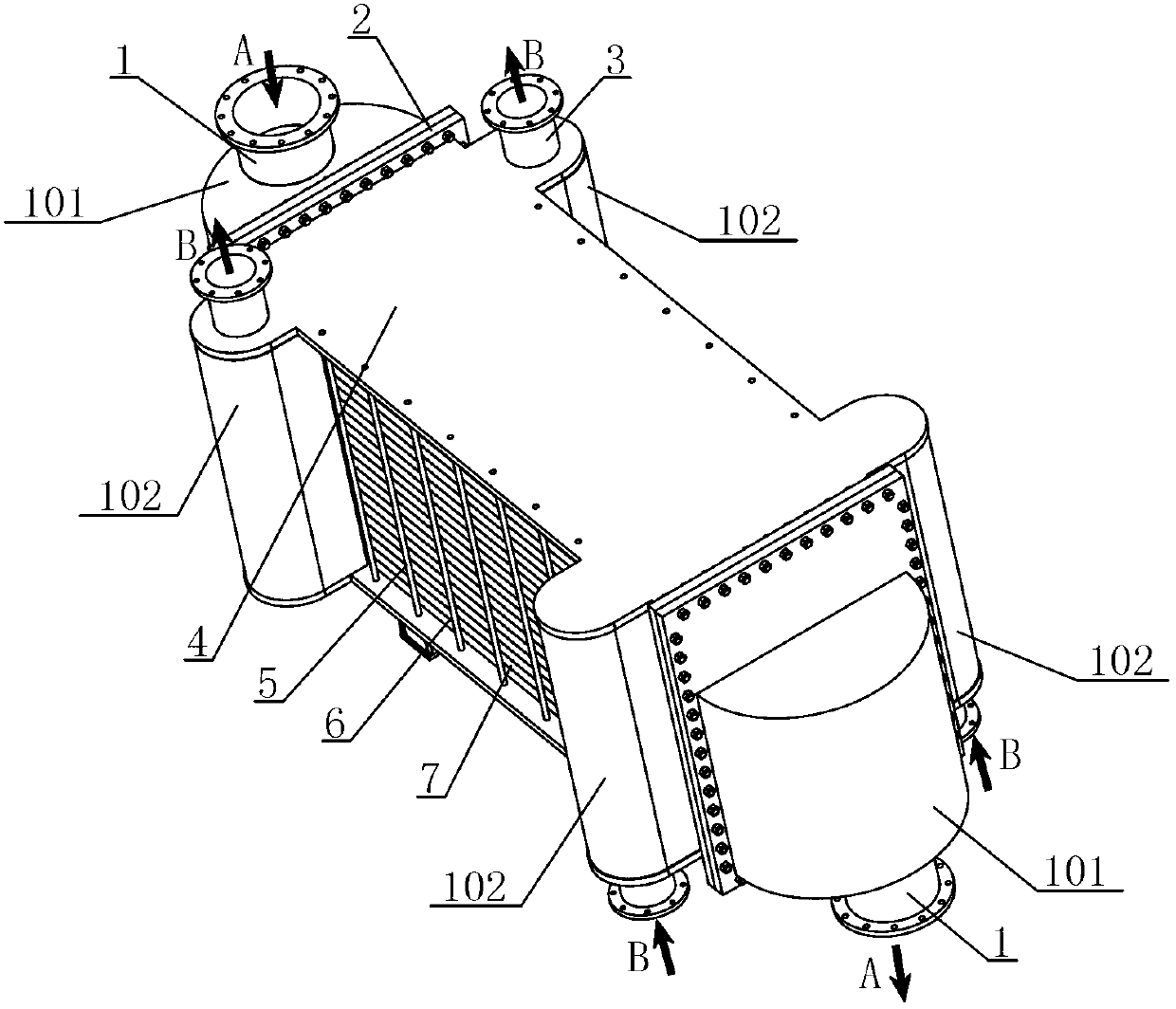

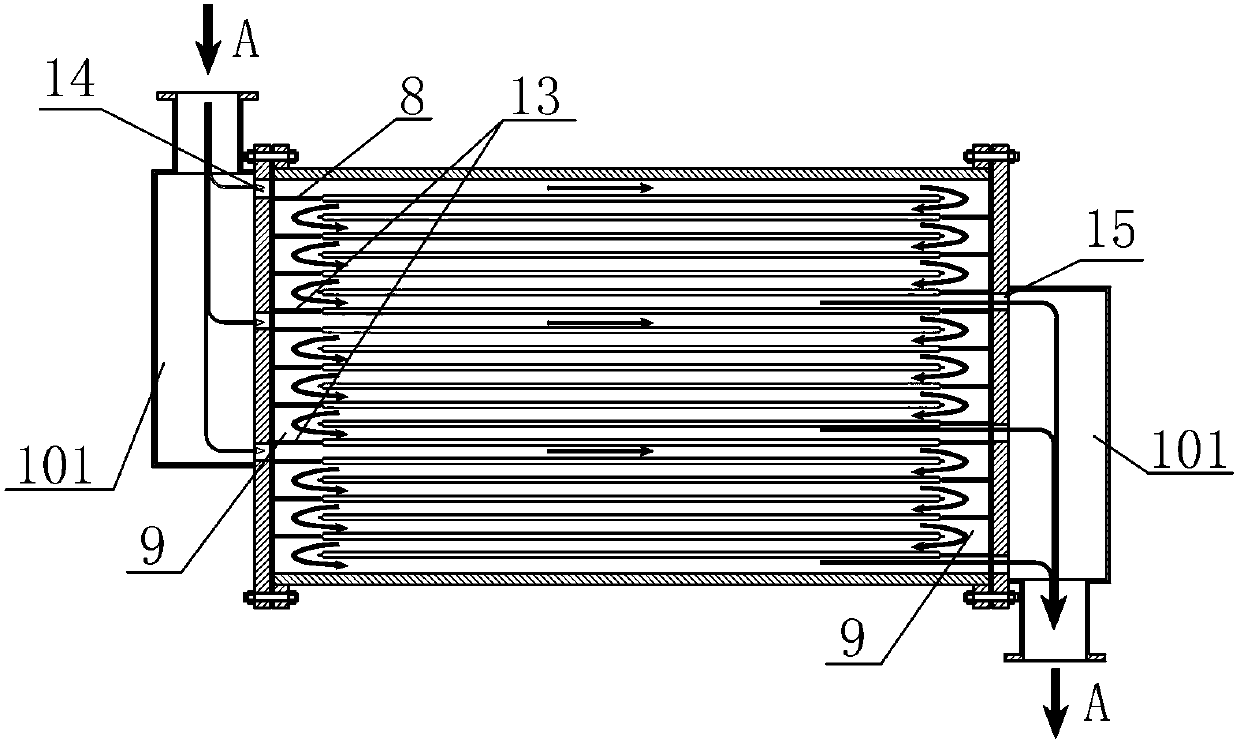

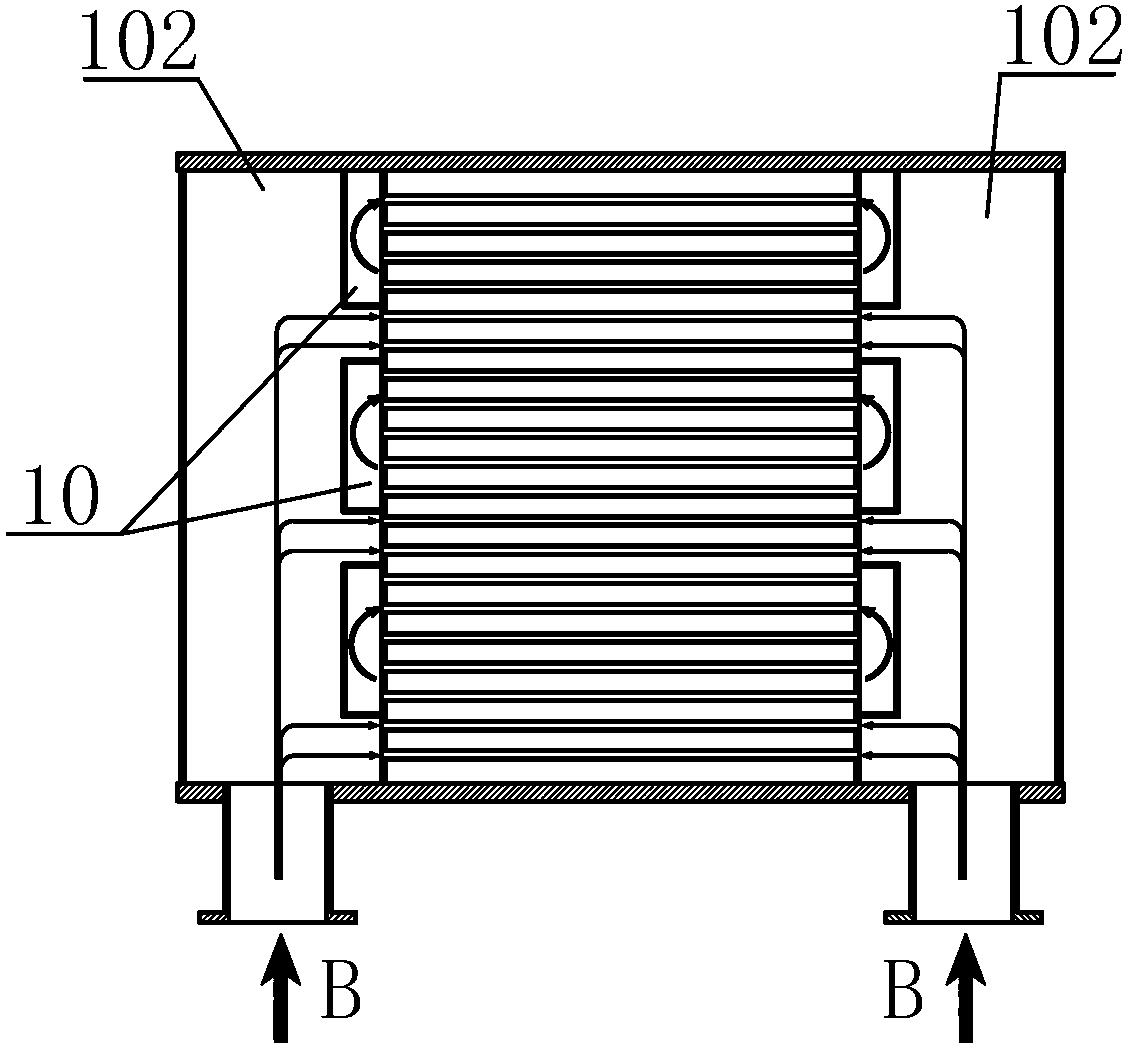

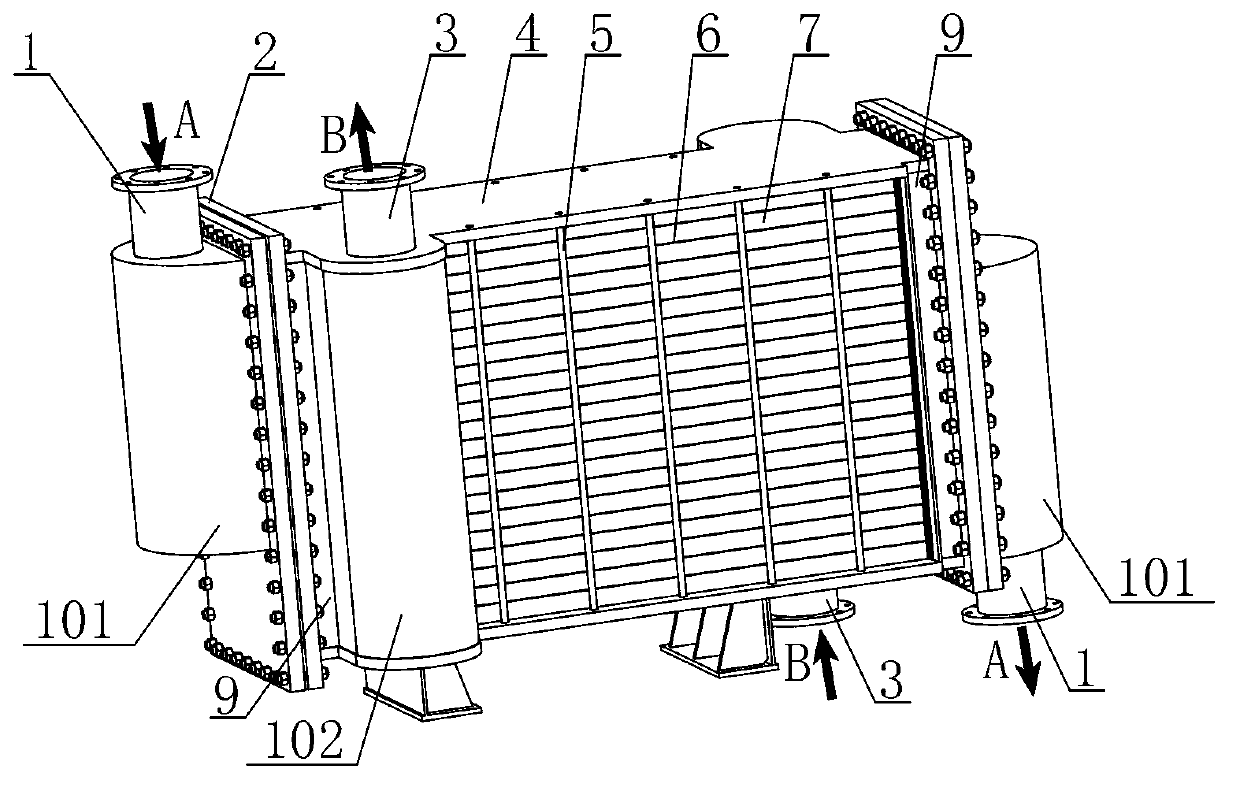

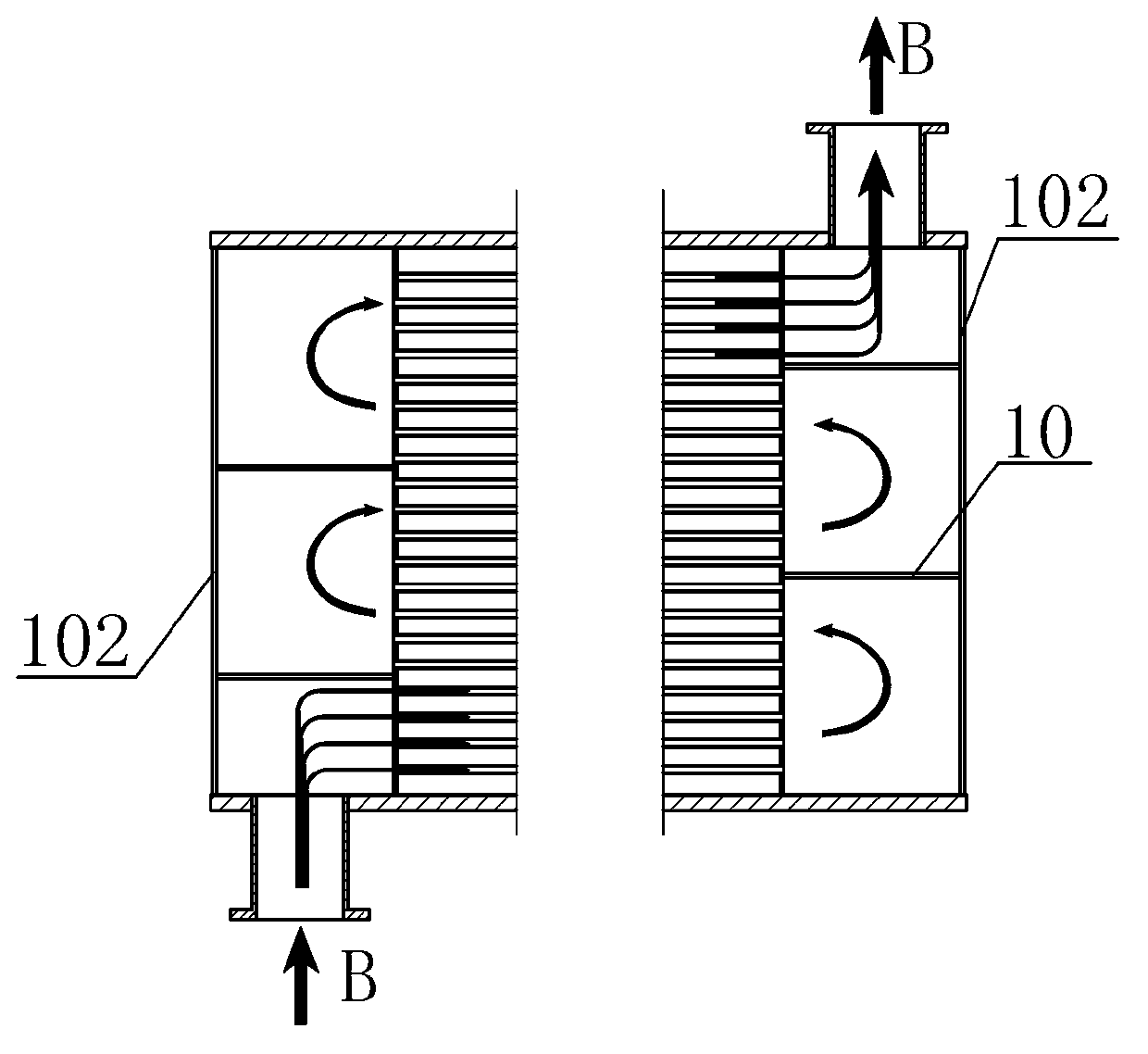

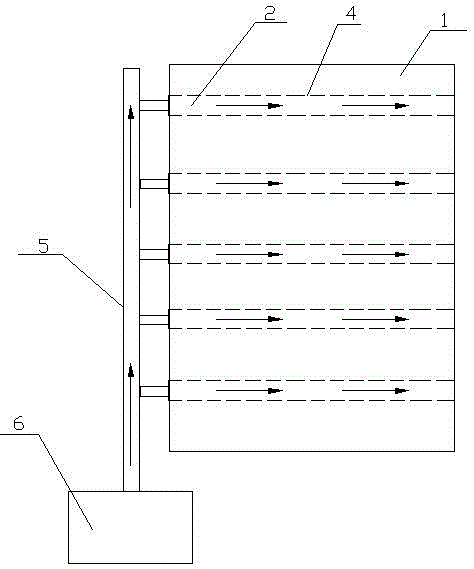

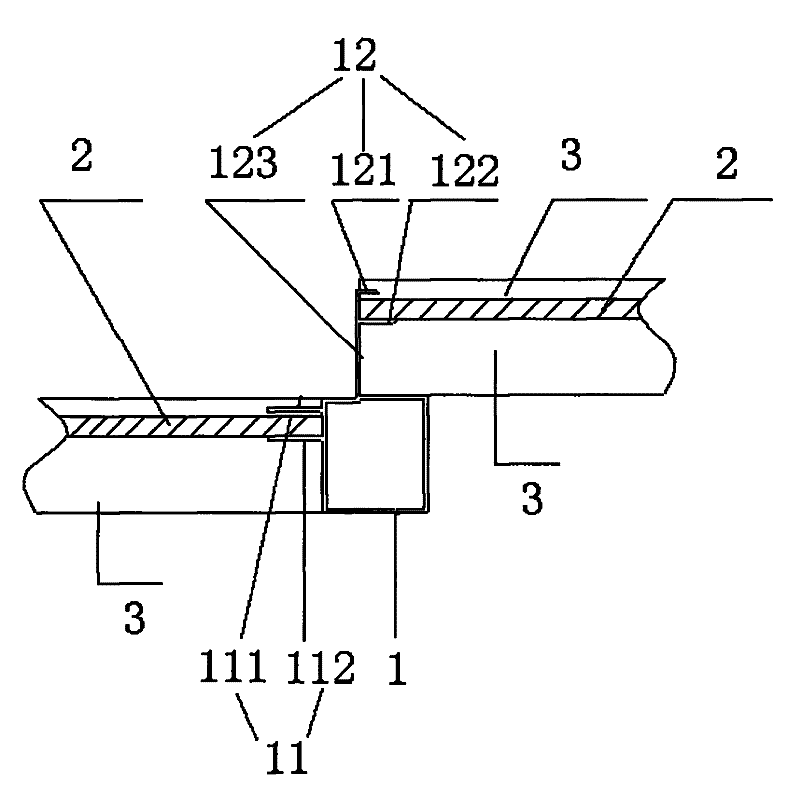

Multi-path heat exchanger for blast furnace slag flushing water

The invention relates to a multi-path heat exchanger for blast furnace slag flushing water, and the multi-path heat exchanger is of a welding plate structure. Multiple heat exchange units are assembled and stacked into a heat exchange plate bundle, each heat exchange unit comprises multiple horizontally-placed heat transfer plates, one side of the heat transfer plate is provided with a slag flushing water channel, the other side of the heat transfer plate is provided with a secondary water channel, one side of the slag flushing water channel is contactless, each slag flushing water channel is folded through slag flushing water pipe boxes connected to the two ends of the heat exchange plate bundle so as to form a contactless single-channel slag flushing water heat exchange flow path, and the heat exchange plate bundle assembled and stacked by multiple heat exchange units forms multiple contactless single-channel slag flushing water heat exchange flow paths which are connected in parallel; the outer side of a flat cover of each slag flushing water pipe box is provided with a slag flushing water diversion box, and the slag flushing water diversion box realizes the functions of flow diversion, flow collection, adapter tube importing and exporting, disassembling and flushing through an inlet and an outlet of a slag flushing water channel on the flat cover of the pipe box; and two pairs of secondary water pipe boxes are arranged on both sides of the heat exchange plate bundle. The structure of the heat exchanger can be used for solving the blocking problem caused by slag flushing water; and the heat exchanger is long in operation cycle, convenient to flush, compact in structure and high in heat transfer efficiency.

Owner:TIANJIN HUASAIER HEAT TRANSFER EQUIP

Separate system type initial rainwater regulation and storage pool

ActiveCN104975649APrevent backflowReduce sediment contentSewerage structuresSewer cleaningAutomatic controlWater flow

The invention discloses a separate system type initial rainwater regulation and storage pool. The separate system type initial rainwater regulation and storage pool is characterized by comprising a natural water drainage unit and a buffer regulation and storage unit which are arranged in the water flow direction, the natural water drainage unit comprises a first buffer pool and a first hydraulic automatic tilting gate, a water inlet pipe is arranged on the upstream part of the first hydraulic automatic tilting gate in the first buffer pool, a natural water drainage outlet is formed in the downstream part of the first hydraulic automatic tilting gate in the first buffer pool, the buffer regulation and storage unit comprises a second buffer pool communicated with the first buffer pool, and a regulation and storage pool body, and the second buffer pool is communicated with the regulation and storage pool body through a second normally-open hydraulic automatic gate. According to the separate system type initial rainwater regulation and storage pool, initial rainwater separation is achieved, rainwater drainage is controlled and regulated according to the different rainfall amount, pollution caused when initial rainwater is directly drained and water accumulation in towns are effectively prevented, the structure is simple, the cost is low, full-automatic control can be achieved, manual operation is not needed, and regulation and storage are safe and reliable.

Owner:WUHAN SHENGYU DRAINING SYST

Blast furnace cinder flushing water multipath heat exchanger

ActiveCN103134359AWon't clogSolve the clogging problemStationary plate conduit assembliesContact freeWater channel

The invention relates to a blast furnace cinder flushing water multipath heat exchanger of a welding plate type structure. The heat exchanger is characterized in that a heat exchanging plate beam is formed by stacking multiple heat exchanging units, each heat exchanging unit comprises multiple horizontal heat transmitting plate pieces, cinder flushing water channels are arranged on one sides of the heat transmitting plate pieces, and secondary water channels are arranged on the other sides of the heat transmitting plate pieces, no contact exists on one sides of the cinder flushing water channels, each cinder flushing water channel realizes process returning through cinder flushing water pipe boxes connected at two ends of the heat exchanging plate beam to form a single-channel cinder flushing water heat exchanging process, the heat exchanging plate beams formed by stacking the multiple heat exchanging units forms multiple parallel-connected contact-free single-channel cinder flushing water heat exchanging processes, cinder flushing water branching boxes are arranged on outer sides of flush covers of the cinder flushing water pipe boxes and realize functions of flow branching, flow collecting, connecting pipe guiding in and out and demounting flushing through in and out of cinder flushing water channel ports arranged on the pipe box flush covers, and the two secondary water pipe boxes are arranged on two sides of the heat exchanging plate beam. The heat exchanger of the structure solves the problem of blockage of cinder flushing water and is long in operating period, convenient to flush, compact in structure and high in heat transmitting efficiency.

Owner:TIANJIN HUASAIER HEAT TRANSFER EQUIP

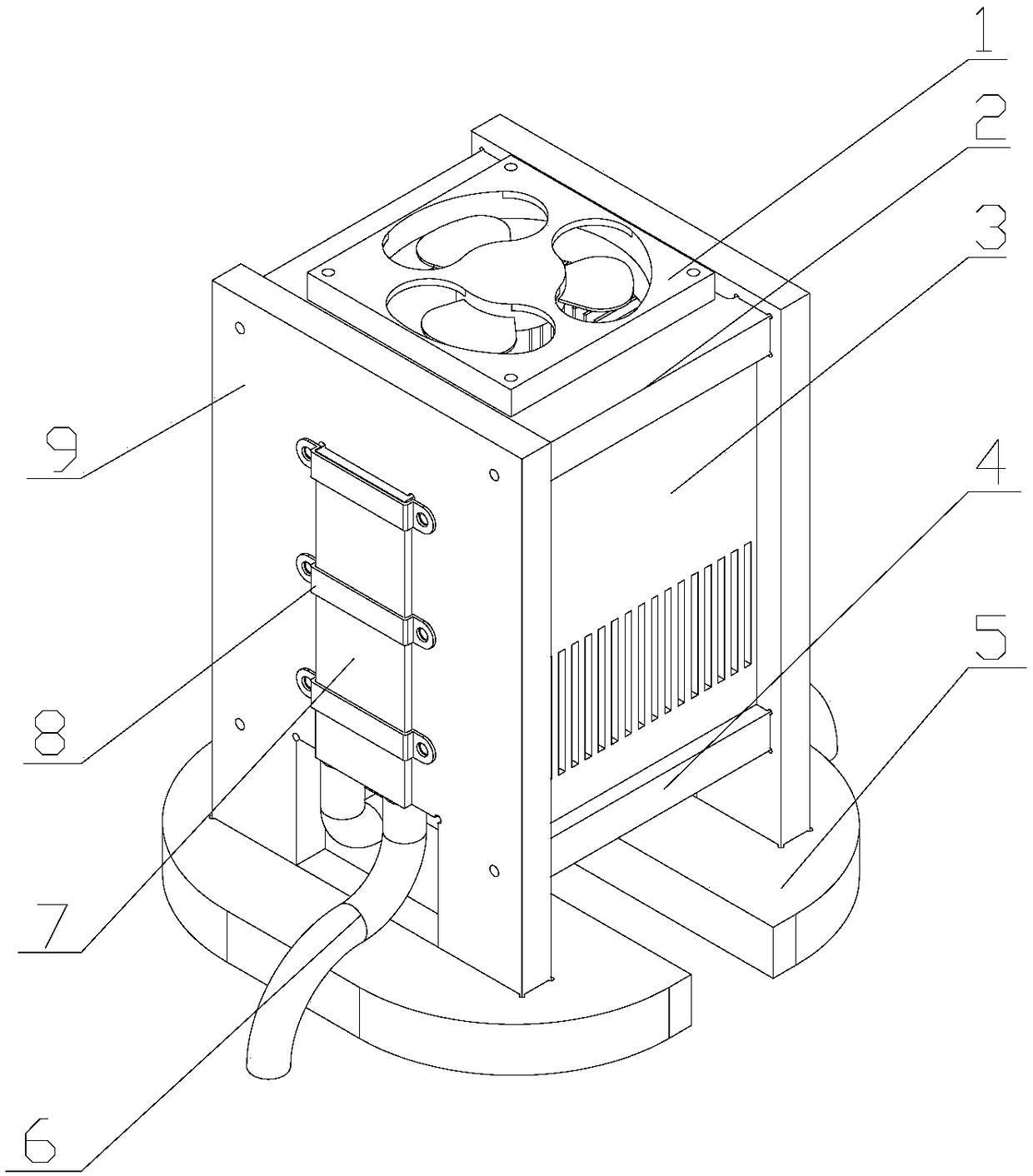

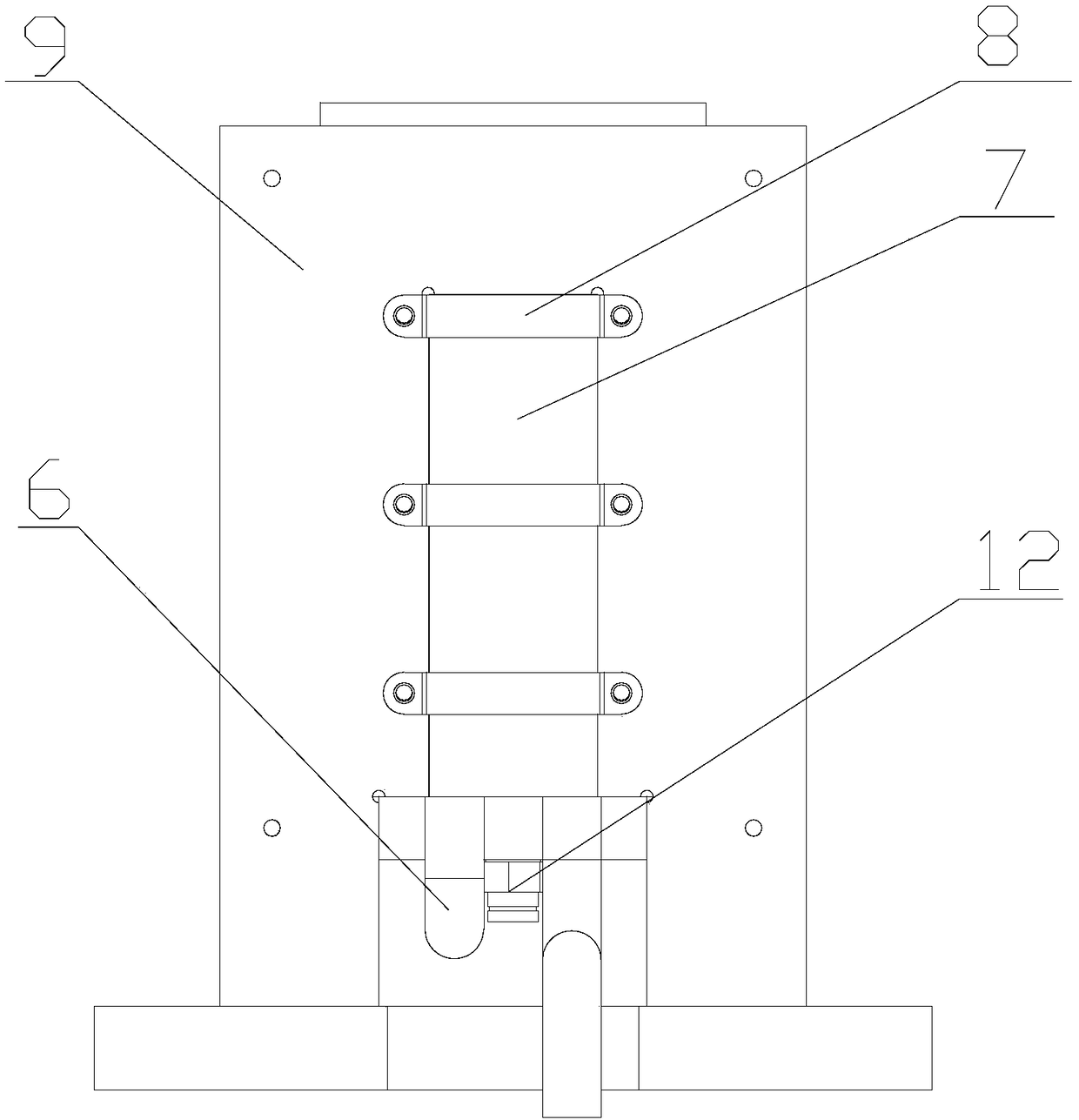

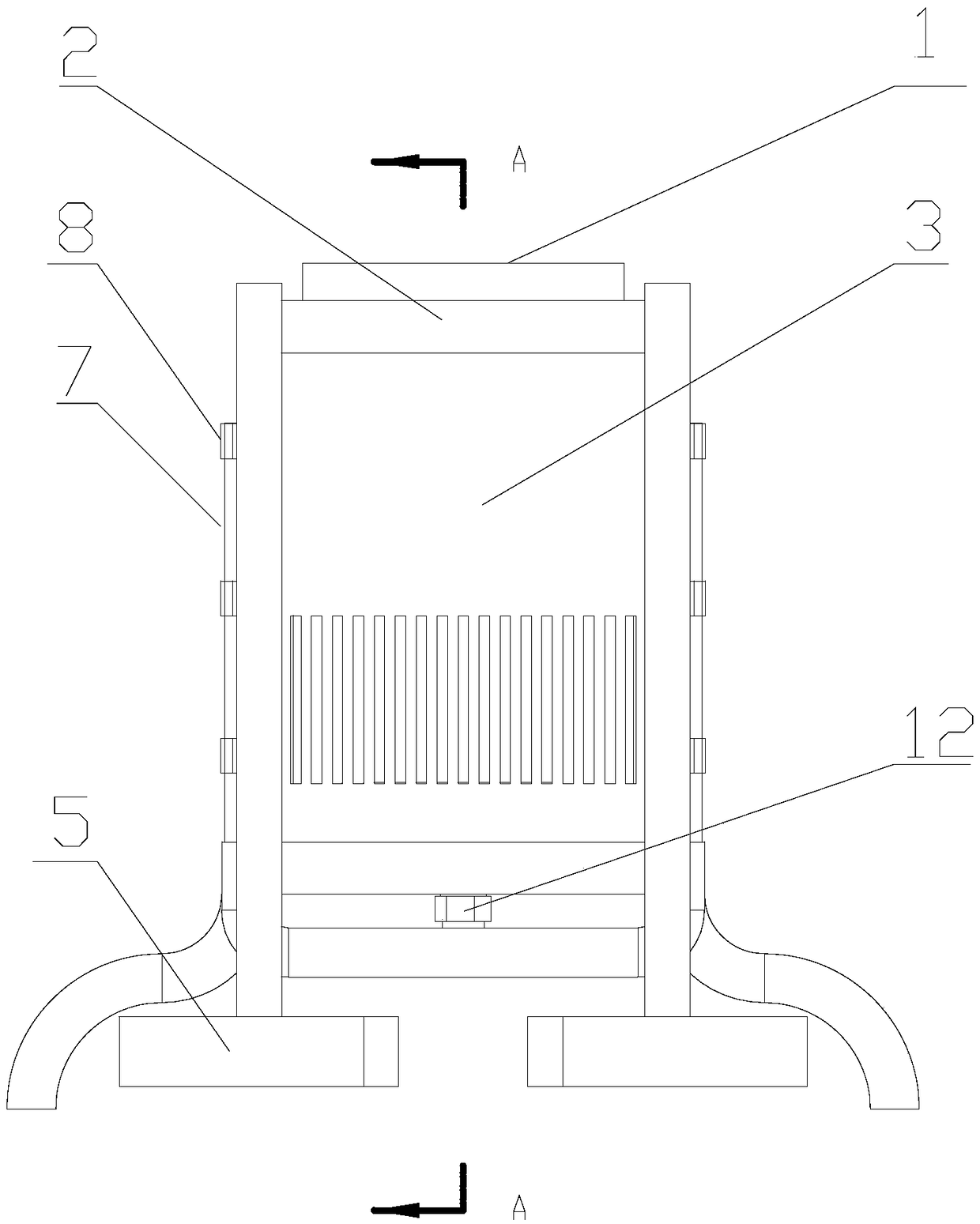

Condensation dehumidification device for control cabinet cooled by water cooling

PendingCN109412051AImprove cooling effectSimple structureSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsClosed loopEngineering

The invention discloses a condensation dehumidification device for a control cabinet cooled by water cooling. The technical scheme is that a water-cooling fixing plate is provided with a water-coolinghead, the inner side of the water-cooling head is provided with a semiconductor refrigeration sheet, and the inner side of the semiconductor refrigeration sheet is provided with a heat-dissipating sheet. A cold end of the semiconductor refrigeration sheet is attached to the heat-dissipating sheet, and a hot end is attached to the water-cooling head. The two water-cooling heads respectively on thetwo water-cooled fixing plates are connected in series, and water inlet and outlet of the water-cooling head are connected with a water pipe by a clamp, and the water pipe and a water tank form a closed loop. A fan is mounted on a top connecting plate, and a ventilation duct is arranged on a top connecting plate below the fan and is used for blowing air in the control cabinet to a tank. A water collecting plate is provided with a pipe joint fixing hole, and a pipe joint is fixed in the pipe joint fixing hole. The device can realize condensation and dehumidification of the air in the control cabinet, and can discharge heat generated by the hot end of the semiconductor refrigeration sheet to the control cabinet to prevent a condensation effect from being reduced caused by poor heat dissipation of the hot end.

Owner:HANGZHOU E ENERGY ELECTRIC POWER TECH +2

Waterproof and leakage-proof expansion joint for roof

ActiveCN113585496AMalleableWill not siltRoof covering insulationsSnow trapsArchitectural engineeringLap joint

The invention discloses a waterproof and leakage-proof expansion joint for a roof, and belongs to the technical field of constructional engineering. The waterproof and leakage-proof expansion joint comprises constructional joint parapet walls, an aluminum alloy panel, an aluminum alloy water guide groove and a water stop belt, the aluminum alloy panel is formed by connecting a fixed side plate, an inclined panel and an eave shielding side plate, the inner side of the aluminum alloy panel is further connected with a movable partition plate device, the water stop belts is arranged on the structural joint parapet walls in a lap joint mode, the aluminum alloy water guide groove presses the two sides of the water stop belt and is fixed to the structural joint parapet walls, the fixed side plate is fixed to the first parapet wall, the inclined face plate covers gaps between the two corresponding structural joint parapet walls, the eave shielding side plate extends out and is suspended outside the outer side wall of the second parapet wall, and meanwhile, the movable partition plate device is placed on the upper surface of the second parapet wall, so that the waterproof and leakage-proof expansion joint for the roof is formed. The waterproof and leakage-proof expansion joint for the roof has the beneficial effects that a three-stage waterproof structure and an anti-deformation structure are adopted, deposition and leakage can be avoided, and a structural body is allowed to deform along with the deformation of the expansion joint.

Owner:浙江协晟建设有限公司

Tunnel side wall drainage net

InactiveCN103089303AAdaptableLow requirements for site and construction conditionsDrainageViscous resistancePoint location

The invention provides a tunnel side wall drainage net which is composed of a plurality of arc-liked vertical pipe pieces, a plurality of arc-like horizontal pipe pieces, a plurality of four-way connectors and a plurality of drainage tubes, wherein the plurality of arc-like vertical pipe pieces are covered with water hole belts, and the plurality of arc-like horizontal pipe pieces are covered with water hole strips. The four-way connectors are formed by vertical connecting pipes and horizontal connecting pipes. The vertical pipe pieces are connected with the vertical connecting pipes of the four-way connectors, and the horizontal pipe pieces are connected with the horizontal connecting pieces. A grid structure is formed by combining and splicing of the plurality of vertical pipe pieces, the plurality of horizontal pipe pieces and the four-way connectors. The vertical pipe piece at the lowest end of the grid structure is connected with the drainage tubes, wherein two ends of the drainage tubes are not sealed. The tunnel side wall drainage net has the advantages that seepage deposited on a side wall is avoided due to an open type grid, and underground construction operating safety is improved. An included angle formed by the horizontal pipe pieces and the side wall can be adjusted, symmetrical water flow can be fast guided, and over large point location seepage pressure of the side wall can be prevented. The drainage tubes are clear in guiding, dewatering is thorough, shock strength is high, fluid viscous resistance is low, the assembly is simple, and use is convenient.

Owner:WUHAN UNIV OF TECH

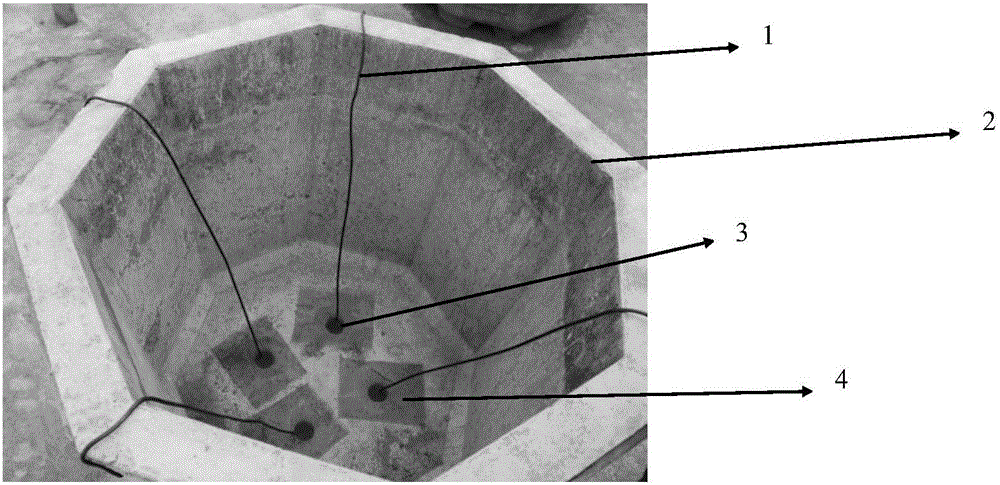

Rainwater runoff pollution sewage interception facility and sewage interception operation method

InactiveCN106948467AHigh cut-offImprove processing efficiencyFatty/oily/floating substances removal devicesSewerage structuresForeign matterSlag

The invention relates to a rainwater runoff pollution sewage interception facility and a sewage interception operation method. An integrated facility main body is in a barrel shape. Two sides of the upper part of the facility main body are provided with a water inlet pipe and a water outlet pipe. The water inlet pipe has an inclination angle and is inserted in the facility main body, and is tangent with the peripheral body of the facility main body and is inserted into an inner wall. A supporting frame in the facility main body is provided with a guide cylinder. Rainwater forms an eddy state between the inner wall of the facility main body and the guide cylinder, to generate centrifugal force. Foreign matters in rainwater fall into a sediment collecting region from a lower ventage of a guide plate, and the foreign matters are discharged after a slag-drip opening is opened. The facility is simple in structure, good in reliability, and simple in installation and maintenance. Improvement on an original initial rainwater sewage interception device improves interception and processing efficiency of rainwater runoff pollution, and a filter layer in a water outlet pipe can fully filter surplus pollutants, and the improved facility main body still keeps integrated. The facility is convenient in installation and overhaul, and just needs regular checking and dredging and pollution discharge.

Owner:TIANJIN WATER RESOURCES RES INST

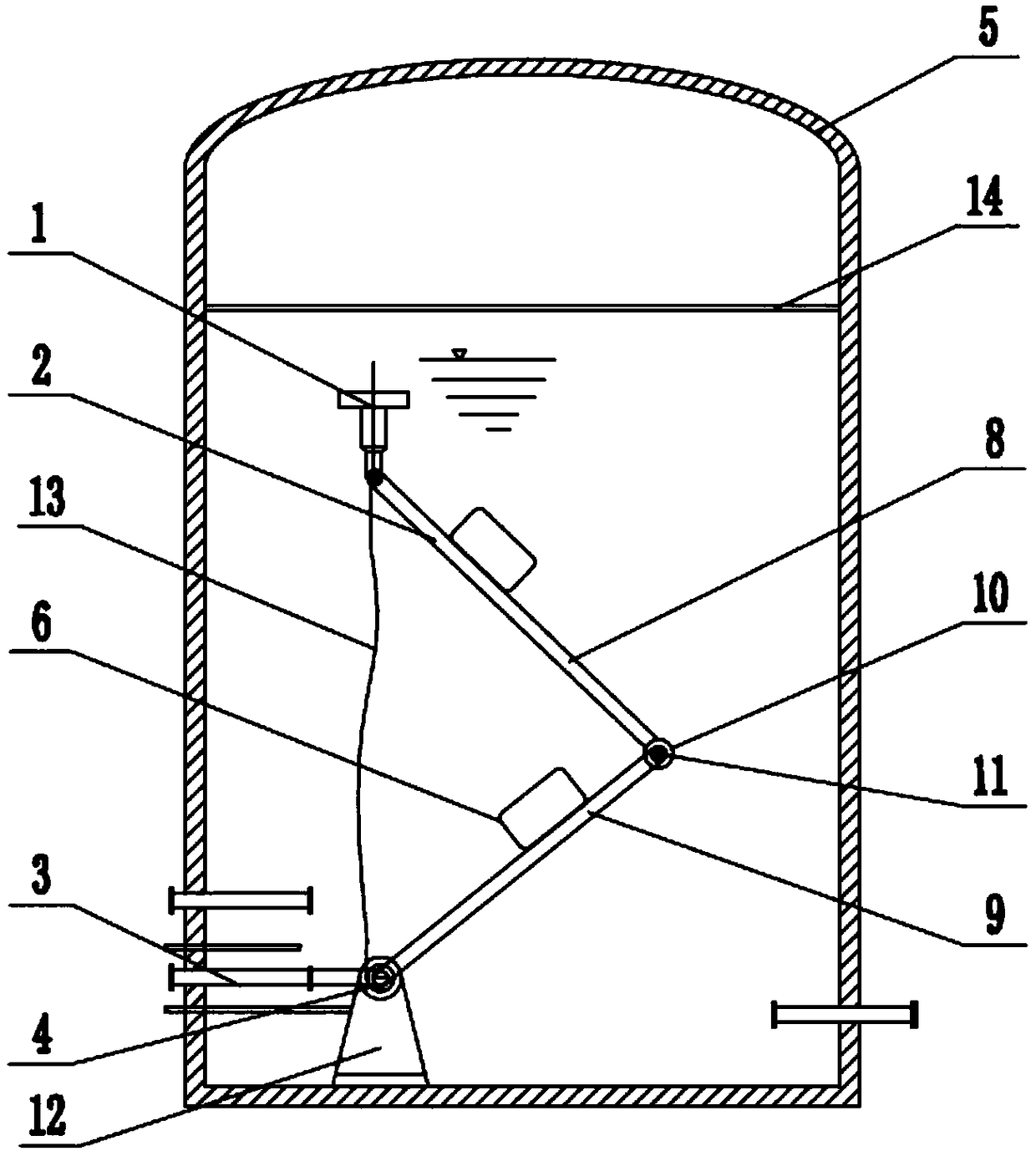

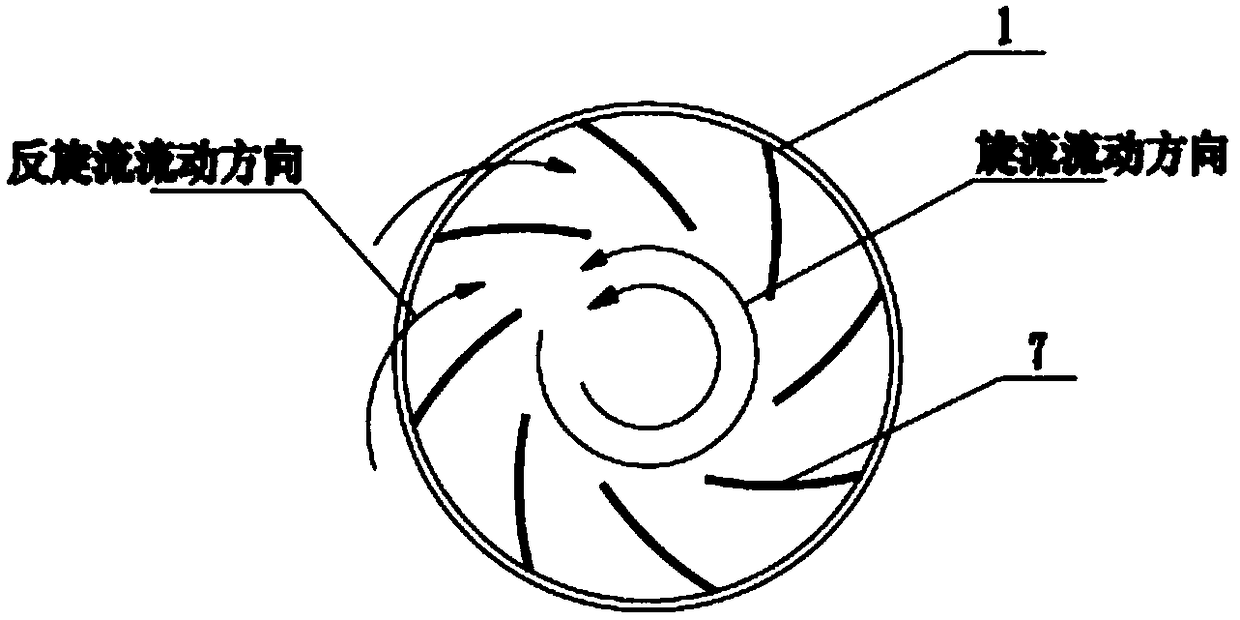

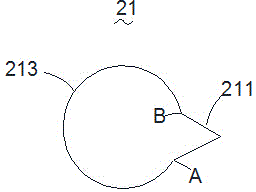

Fluid suction device

PendingCN108298493AWill not siltSmooth oil absorptionLiquid transferring devicesEngineeringRotational flow

The invention discloses a fluid suction device. The fluid suction device comprises an oil suction port, an oil suction arm, an oil outlet pipe, a rolling device and a controller. The top end of the oil suction port is arranged at the bottom of the liquid face in an oil tank. The bottom end of the oil suction port is connected with the top end of the oil suction arm. The bottom end of the oil suction arm is connected with the oil outlet pipe. The rolling device is arranged between the oil suction arm and the oil outlet pipe. An arm body of the oil suction arm is further provided with a buoyancyoil barrel. The controller is connected with the rolling device and can control the rolling device to limit the position of the oil suction arm. According to the provided fluid suction device, the oil suction port is formed below the liquid face, an oil liquid suction-in port is arranged upwards, and the oil suction port is internally provided with a plurality of reverse rotational flow blades; and meanwhile, the rolling device and a rotation device are further arranged, and the beneficial effects that the oil suction efficiency is high, and the device stability is good are achieved.

Owner:大连鸿泽泵业有限公司

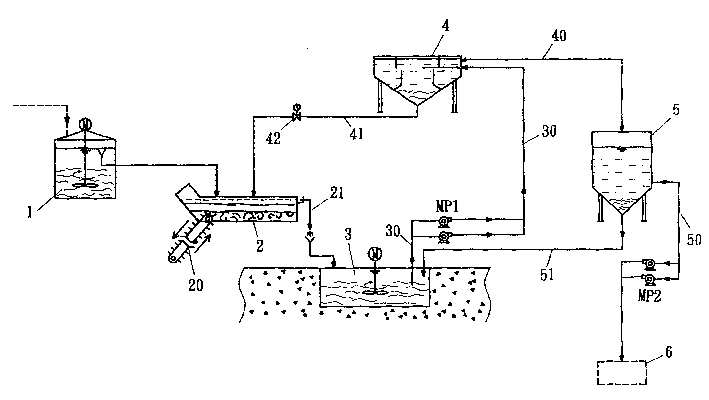

Treatment system for waste water from exhaust gas desulfurization in gas-electricity generating device

InactiveCN1521130AUnique designSave spaceWater/sewage treatment by flocculation/precipitationSedimentation settling tanksSludgeElectric power

The present invention provides one unique practical system for treating waste water from desulfurizing water gas of steam and electric power co-producing apparatus, separating suspended solid from water and making effluent reach drainage standard. The treating system includes oxidizing tank, boiler water seal tank, bottom ash stirring pond, fast bottom ash depositing pond and waste water tank, and treats the waste water through unique process and control to separate the waste water containing magnesium sulfate and ash sludge into water and sludge. The drained water is suitable for sewage disposal yard to further treat and the ash sludge for reuse.

Owner:LONG CHEN PAPER

Leakage prevention oil can nozzle device

InactiveCN104433891AWill not siltFully consider the fluid characteristicsKitchen equipmentSanitationPetroleum engineering

The invention relates to kitchen supplies, in particular to a leakage prevention oil can nozzle device. The leakage prevention oil can nozzle device comprises an oil can nozzle body, a secondary oil can nozzle and an oil leakage hole, wherein the oil can nozzle body is in a hollow cylindrical shape; the secondary oil can nozzle is detachably buckled in the oil can nozzle body; a slightly inwards protrusive structure is arranged at the buckling position of the oil can nozzle body and is arc; the included angle between the tangent line, at the junction with the inner wall of the oil can nozzle body, of the protrusive structure and the inner wall of the oil can nozzle body ranges from 0 degree to 5 degrees; the secondary oil can nozzle comprises an upper end, a middle part and a lower end; the middle part is small while the two ends are large; the periphery of the lower end is also in a small arc shape and tightly attached to the protrusive structure; the oil leakage hole is formed in the upper portion of the lower end of the secondary oil can nozzle. The leakage prevention oil can nozzle device has the advantages that oil is effectively prevented from being left at the oil can nozzle when poured, oil is poured conveniently, and sanitation is achieved.

Owner:王子川

Automatic sand screening device

The invention relates to an automatic sand screening device, in particular to an automatic sand screening device used for a construction site. The automatic sand screening device is composed of a support, a motor, a rotating turbine, a feeding port, a machine barrel, screening cloth, a collecting chamber and a discharging port. Compared with the prior art, the automatic sand screening device is simple in structure, high in efficiency and easy to maintain, accessories are replaceable, and operation is not affected by weather.

Owner:JIANGSU HAIJIAN

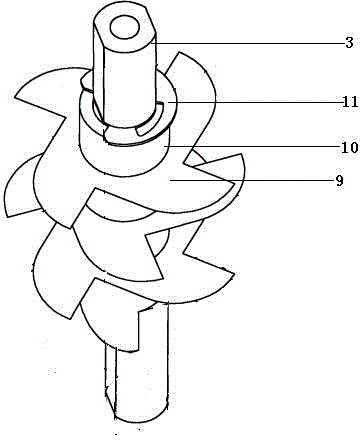

A battery plate cleaning device

InactiveCN104485446BImprove the transportation environmentBeneficial removal effectLead-acid accumulator electrodesCleaning using gasesEngineeringAir compressor

The invention discloses a novel storage battery plate clearing device which comprises a bracket, a rotating shaft and a water spray nozzle, wherein the rotating shaft which drives a polar plate to transport is arranged on the bracket; the water spray nozzle is arranged on a rack and is used for cleaning the polar plate; the interior of the rotating shaft is hollow; air outlet holes with uniform distribution are formed in the rotating shaft; an air delivery pipe is arranged on the bracket and is connected to each rotating shaft; the other end of the air delivery pipe is connected to an air compressor; and a limiting plate is arranged above the rotating shaft. According to the device disclosed by the invention, the residual plaster on the polar plate is cleared in a mode of combining the operation of performing air injection on the polar plate from the interior of the rotating shaft and the operation of spraying water outside the polar plate, the clearing effect is beneficial, and the clearing device does not need to be replaced, so that the production cost is low. Moreover, the residual plaster is not deposited on the rotating shaft by virtue of air pressure, so that the rack is clean, the polar plate transport environment is improved, and the residual plaster can be collected and reutilized by virtue of a recycling box.

Owner:TIANNENG BATTERY WUHU

Multilayer biofuel heating furnace

InactiveCN105444208AFast ignitionWon't crushLighting and heating apparatusStove/ranges for heating waterWater pipeEngineering

The invention discloses a multilayer biofuel heating furnace. The multilayer biofuel heating furnace is characterized by comprising a furnace cavity and a smoke discharge pipe; the furnace cavity is cylindrical; a furnace cover is arranged in an upper opening; the wall, near the upper opening, of the furnace cavity is connected with the smoke discharge pipe communicated with the internal; the inner wall, near a lower opening, of the furnace cavity is provided with an annular baffle plate; an opening 180 is formed in the side wall of the furnace cavity in the upper part of the annular baffle plate; a door is arranged in the opening; outer walls are connected to the side wall of the furnace cavity of the upper part of the opening and the outer side of the wall of the smoke discharge pipe, and form a water accommodating cavity; the lower part of the water accommodating cavity is connected with a water inlet pipe; the upper part of the water accommodating cavity is connected with a water outlet pipe; 3-5 fuel boxes are stacked on the annular baffle plate; the fuel boxes have circular side walls bonded on the inner wall of the furnace cavity; inner flanges are arranged at the upper ends of the circular side walls; bottoms with holes are connected to the lower parts of the circular side walls; side holes are formed in the circular side walls; and the heights of the fuel boxes are 4 / 5 to 2 / 3 of the height of the opening. The multilayer biofuel heating furnace cannot accumulate dust for long-time use, reduces non-burnt particles to be mixed in the dust for leakage, and is high in combustion efficiency.

Owner:CHONGQING HUAWANLUN BIOLOGICAL NEW ENERGY TECH CO LTD

Indoor pot culturing method for tea-oil tree bare roots

InactiveCN106665265AWill not siltMeet growth needsGrowth substratesCulture mediaTree rootCamellia oleifera

The invention discloses an indoor pot culturing method for tea-oil tree bare roots. The method comprises the following steps: (1) selecting a corresponding transplanting container according to the size of the tea-oil tree root system, placing a plastic gauze element above a hole of the container and penetrating an aluminum wire through the hole in the bottom of the container; (2) paving argils in different sizes in the container; (3) putting a tea-oil tree into the center of the container, filling a base material to a certain height, fixing an aluminum wire by using a pincer and then filling the base material till reaching the original height of the root system; (4) covering the tree with a white transparent plastic film and tightening; and (5) after watering, putting the planted tree into a shading shed. According to the method disclosed by the invention, the survival rate of the potted tea-oil tree is increased and the problems of rotten stock roots and delayed rooting of the root system of the potted tea-oil tree are solved.

Owner:湖南多彩生态农林有限公司

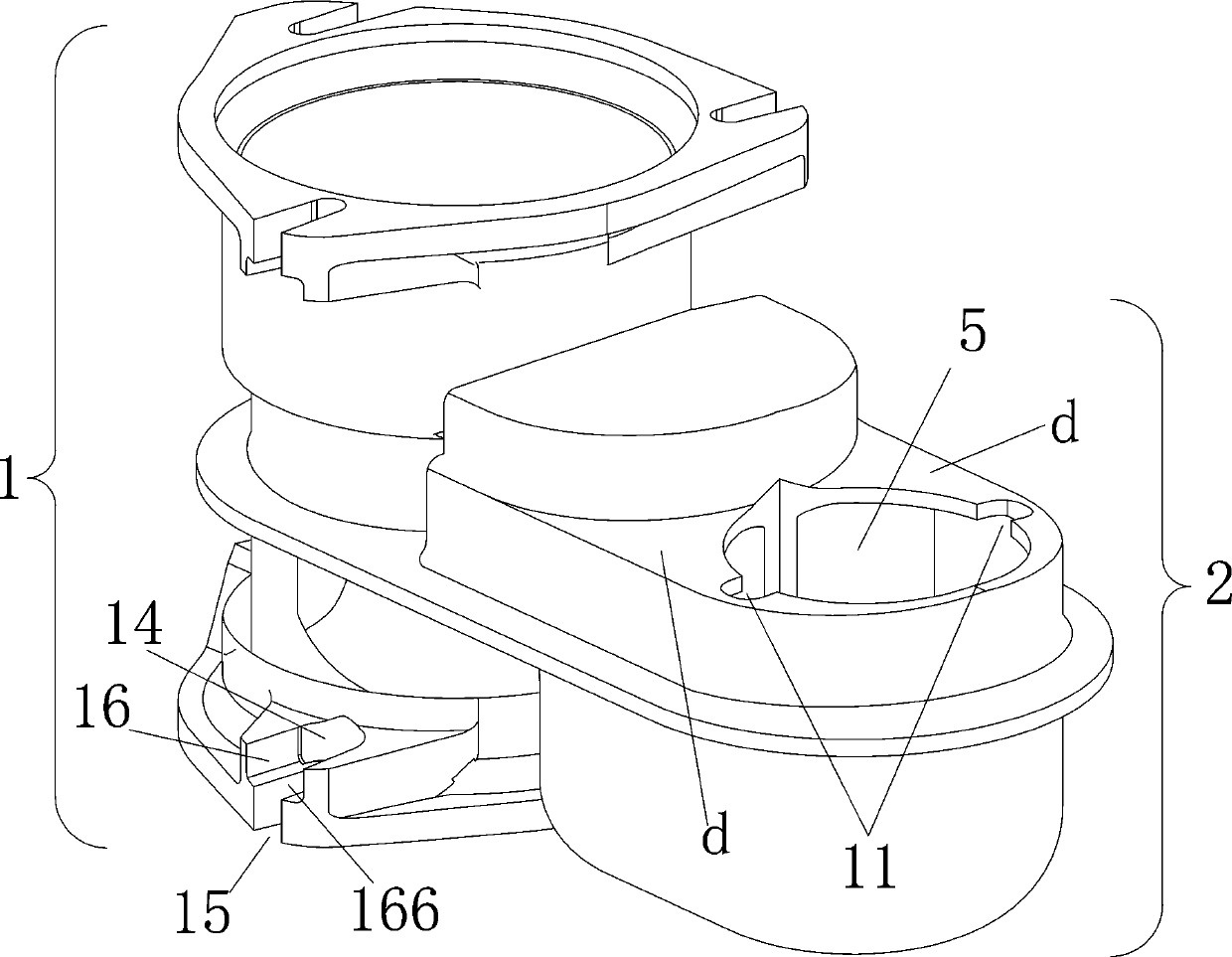

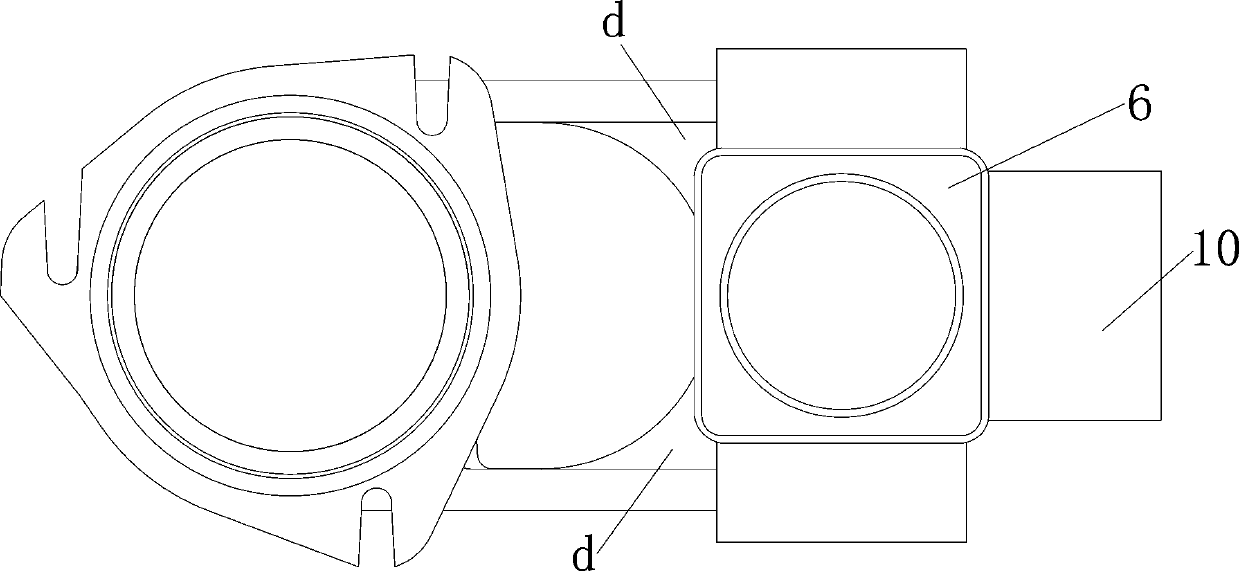

Fabricated building same-floor drainage pipe fitting

PendingCN110565753ASimple structureReduce occupancyDomestic plumbingBranching pipesPipe fittingHorizontal branch

The invention discloses a fabricated building same-floor drainage pipe fitting. The fabricated building same-floor drainage pipe fitting is composed of a vertical pipe joint and a horizontal pipe joint, the upper part of the vertical pipe joint communicates with the lower part of the vertical pipe joint, and horizontal pipe joint is located on one side of the vertical pipe joint and communicates with the vertical pipe joint; the horizontal pipe joint is composed of a water seal groove, a water seal baffle, a horizontal pipe drainage inlet and a branch pipe joint-port; the water seal groove isclosed with the outer surface of the vertical pipe joint and communicates with the inner wall of the vertical pipe joint, the lower end of the water seal groove is closed, an opening is formed in theside wall, close to the vertical pipe joint, of the upper end of the water seal groove, the length of the opening in the longest transverse position is larger than that in the longest vertical position, and the communicating port of the opening and the vertical pipe joint has difference of level. The provided fabricated building same-floor drainage pipe fitting has the advantages that the water seal connecting all drainage appliances is not easy to dry, the drainage safety can be improved, the drainage smoothness can also be improved, the replacement, removal and installation of pipelines areconvenient, the use amount of drainage horizontal branch pipes is saved, a sanitary room can be prevented from water accumulation for any reason, unpleasant odor is not prone to being generated, and the occupation of building plane space of products can be reduced.

Owner:贵州群之英屋业科技有限公司

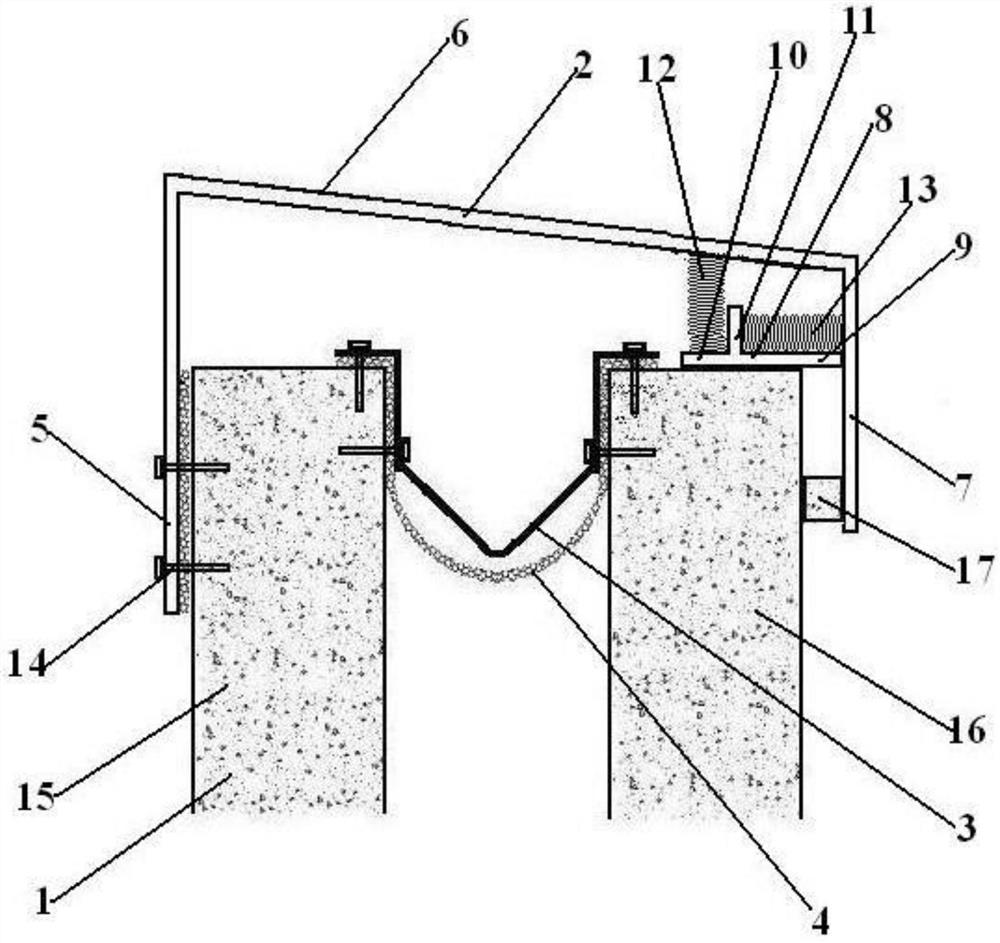

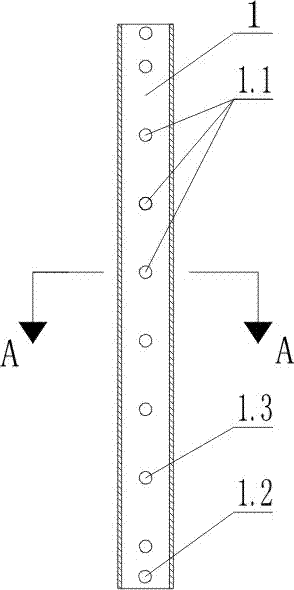

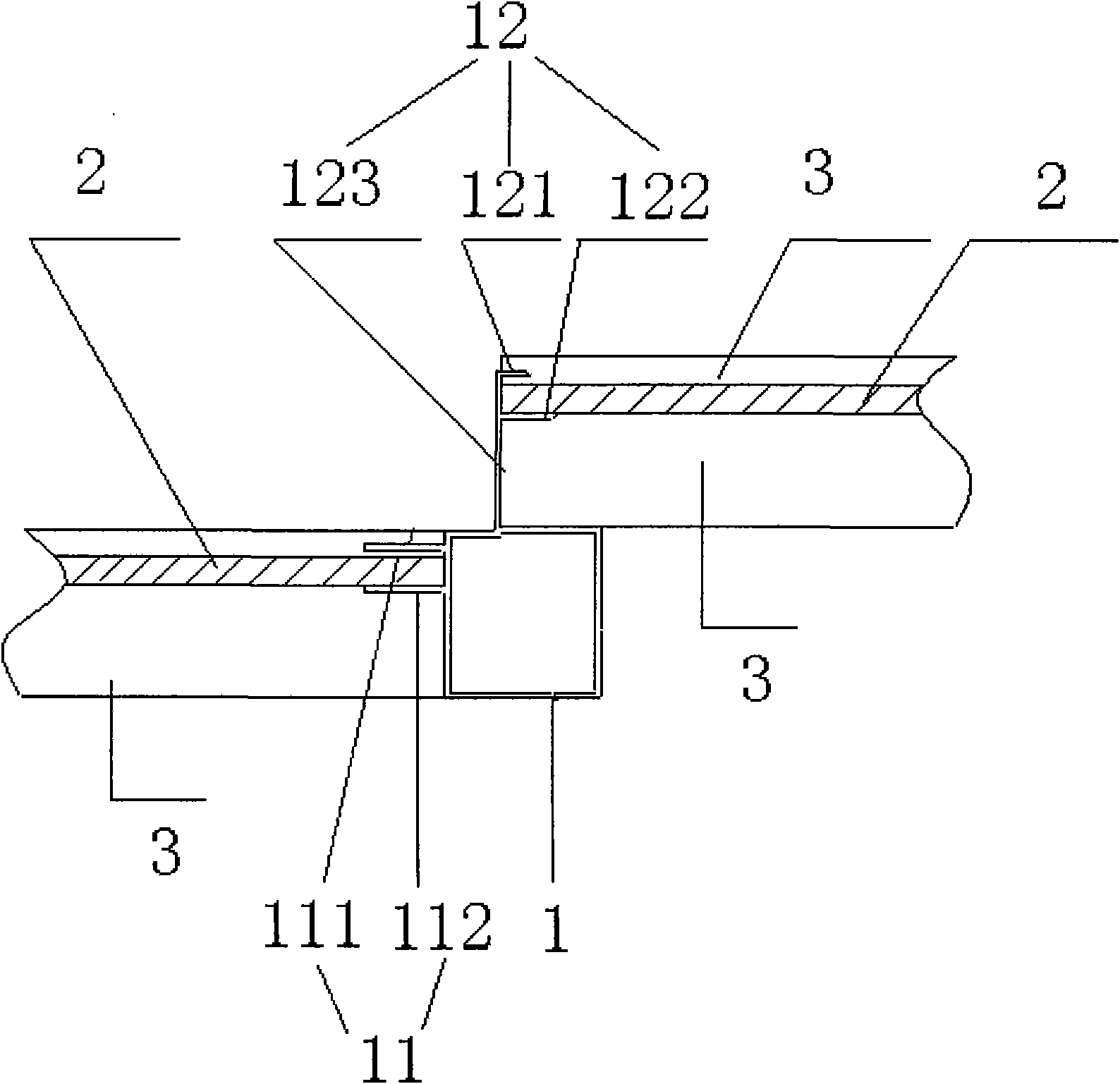

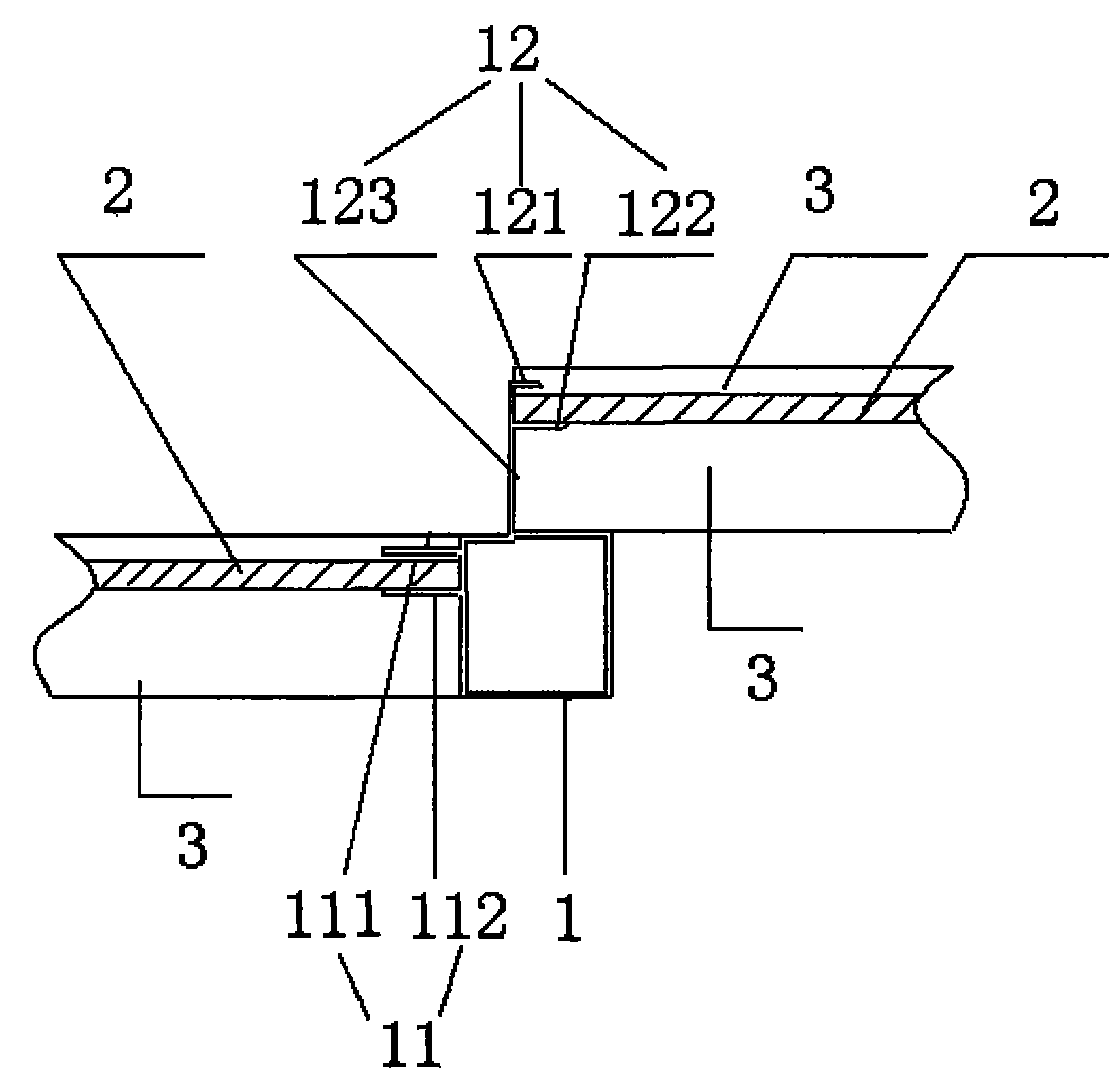

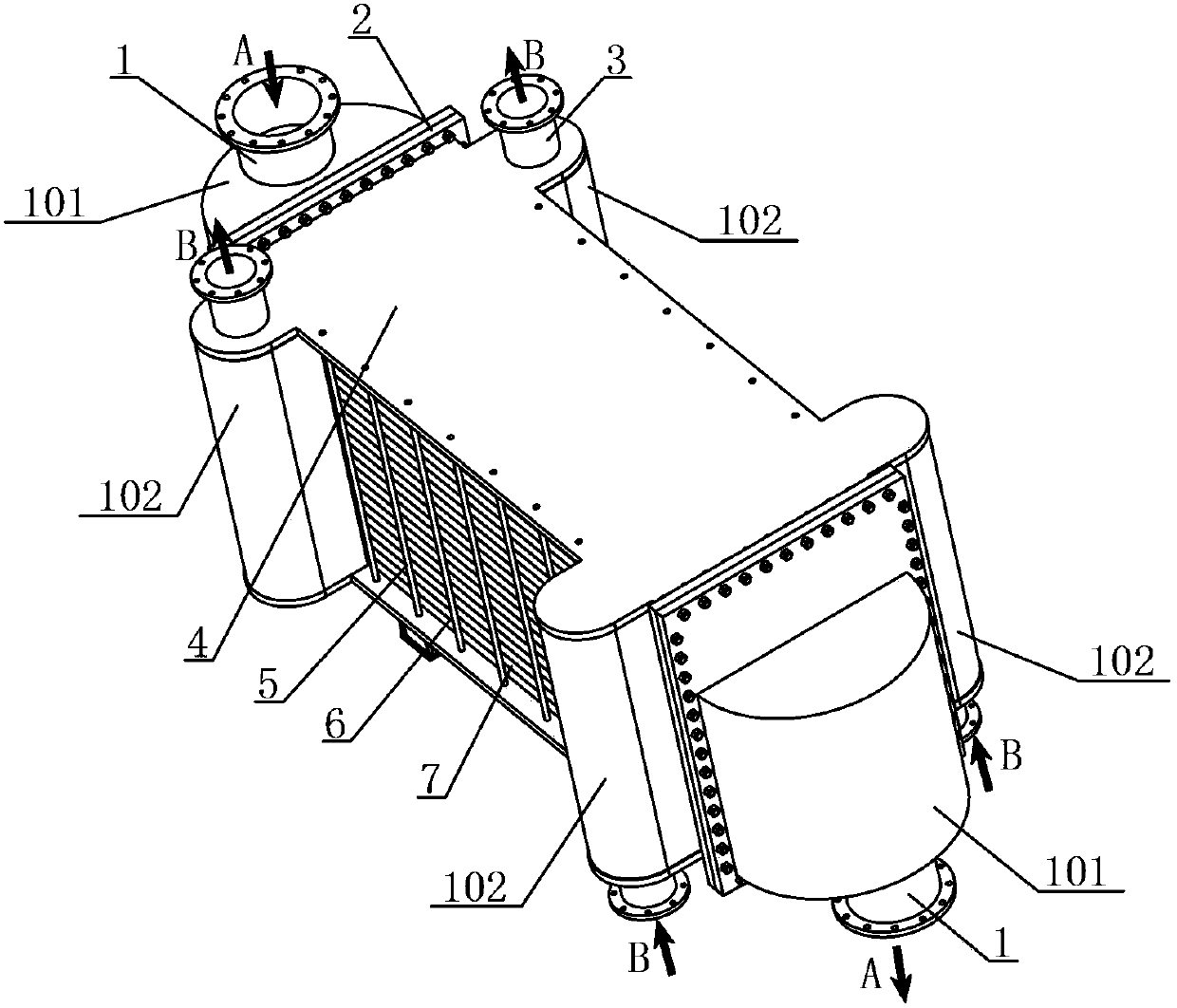

Connection structure of over-long roof of greenhouse

ActiveCN101824858ATo connectWill not siltClimate change adaptationBuilding constructionsGreenhouseStructural engineering

The invention discloses a connection structure of an over-long roof of a greenhouse. The connection structure comprises glass, roof lathes, a connecting piece, lower crosspieces and upper crosspieces, wherein the glass is provided with the roof strips at positions close to the edge; the connecting piece, the upper crosspieces and the lower crosspieces form an integrated structure; one side of the connecting piece is provided with the lower crosspieces for accommodating the glass edge, while the other side is provided with the upper crosspieces for accommodating the glass edge; the upper and lower crosspieces are arranged in parallel; the upper crosspieces are F-shaped and comprise a support bar, an upper crosspiece I and an upper crosspiece II, and the glass is arranged between the upper crosspiece I and the upper crosspiece II; and the lower crosspieces comprise a lower crosspiece I and a lower crosspiece II between which the glass is arranged. A stepped installation method introduced by the invention plays a part in connection through the connecting pieces, the lower crosspieces and the upper crosspieces, so large roof of the glass greenhouse can be designed and installed, wherein the large roof cannot accumulate water and has a water discharge function; and simultaneously, the method plays a part in enhancing the effect of supporting the large roof of the glass greenhouse.

Owner:SHANGHAI DUSHI GREEN ENG

Prefabricated building same-layer drainage pipe fitting

PendingCN110578352AReduce thicknessDoes not affect runner widthDomestic plumbingBranching pipesVertical tubePipe fitting

The invention discloses a prefabricated building same-layer drainage pipe fitting which comprises a stand pipe joint and a transverse pipe joint; the stand pipe joint is in up-down communicating; thetransverse pipe joint is arranged on one side of the stand pipe joint and communicates with the stand pipe joint; the transverse pipe joint is formed by a water seal groove, a water seal baffle plate,a cross pipe drainage inlet and a branch pipe interface; the water seal groove is closed with the outer wall of the stand pipe joint and communicates with the inner wall of the stand pipe joint; thelower end of the water seal groove is closed; the side wall, close to the stand pipe joint, of the upper end of the water seal groove is provided with a through hole; a length of a transverse longestpart of the through hole is larger than a length of a vertical longest part of the through hole; and a length of a transverse longest part of a communication hole is larger than a length of a verticallongest part of the communication hole. The prefabricated building same-layer drainage pipe fitting has the advantages that by providing the prefabricated building same-layer drainage pipe fitting, water seals for connecting all drainage devices can not be dried easily, the drainage safety and the drainage smoothness can be both improved, a pipeline is convenient to change, disassemble and mountat the same time, the use amount of drainage transverse branch pipes can be saved, water accumulation can be avoided in a toilet for any reason, and peculiar smell can not be easily produced in toilet.

Owner:KUNMING QUNZHIYING TECH

Flow guide layer for sanitary napkins or diapers

InactiveCN110279525AInfiltration realizationPrevent infiltrationSanitary towelsBaby linensEngineeringHot-melt adhesive

The invention relates to the technical field of sanitation, in particular to a flow guide layer for sanitary napkins or diapers. The flow guide layer comprises a diffusion layer, diffusive sponge layers, a one-way liquid guide membrane and hydrophobic sealing edges, wherein multiple inclined pores with inclination angle of 125-165 degrees are circumferentially formed in the diffusion layer, and the diffusion layer is located above the diffusive sponge layers; multiple diffusive sponge layers made of polyurethane sponge are stacked, and longitudinal pores and transverse pores are formed in the polyurethane sponge; the one-way liquid guide membrane is arranged at the bottom of the diffusive sponge layers; the hydrophobic sealing edges are bonded to edges of the multiple diffusive sponge layers through hot melt adhesive. The invention provides the flow guide layer which is used for sanitary napkins or diapers and has simple structure, low price and excellent diffusion performance to solve technical problems.

Owner:DADDY BABY

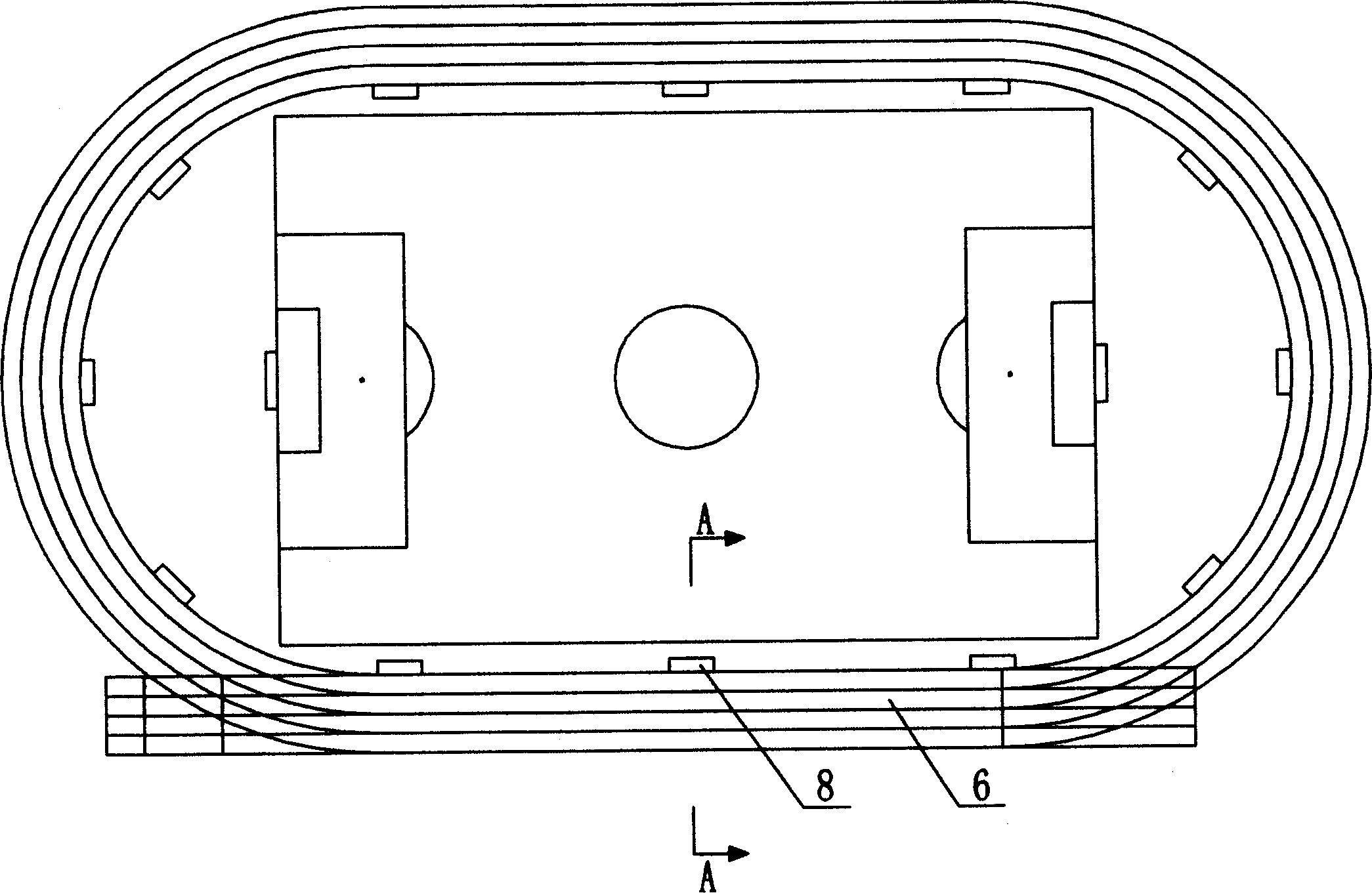

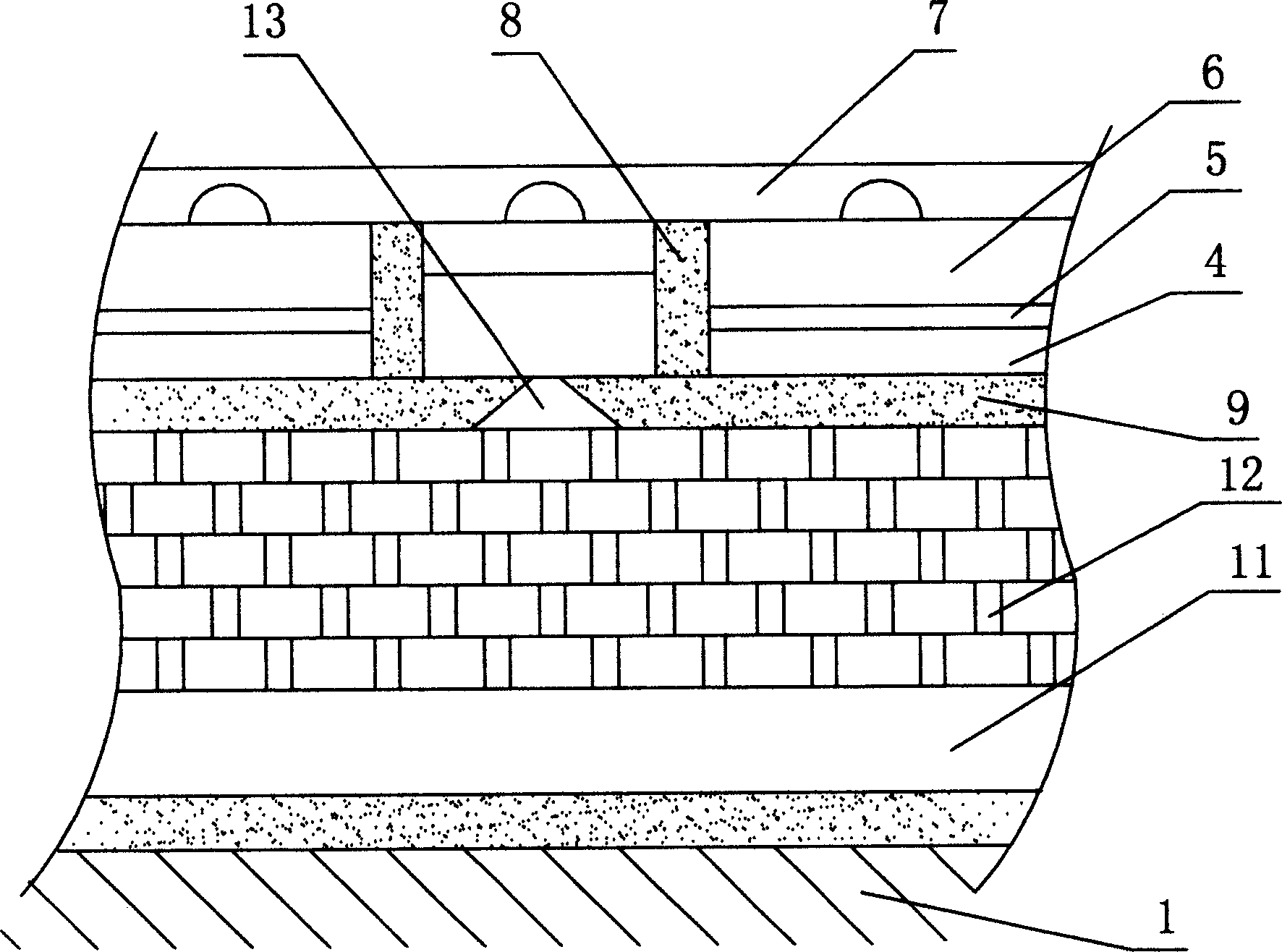

Structural layer for playground track and materials used for track pavings

InactiveCN1888314AImprove permeabilityNot easy to accumulate waterSolid waste managementGround pavingsBrickSurface layer

The present invention discloses a structure layer of track of sports field and material of track surface layer. Said structure layer includes basis ground layer, ragstone layer, crushed stone layer, breeze layer, straw layer and red brick dregs-sawdust track surface layer from bottom to top. It is characterized by that the lower portion of the inner side of said circular track is equipped with a covered ditch for drainage, so that said invention has good drainage function and moisture-retention function.

Owner:李镇维

Laminating machine waste scrap recycling mixing device

The invention relates to a recycling and stirring device for slitter edge offcuts of a film laminating machine. The recycling and stirring device comprises an offcut hopper, a mixing bin, a feeding screw, a stirring device and a driving device, wherein the offcut hopper is arranged in the center of the mixing bin; the driving device is arranged in the center of the outer side of the upper part of the offcut hopper; the feeding screw is fixedly connected with the front end of the driving device and is directly inserted to the bottom of the mixing bin; stirring strips are fixed at the top of the feeding screw; a side hopper is fixedly arranged on the side surface of the offcut hopper and is inserted into the mixing bin. The recycling and stirring device for the slitter edge offcuts of the film laminating machine has the benefits as follows: in an on-line composite slitter edge recycling process, the condition that the offcuts and aggregates cannot be sufficiently stirred and form blockage at an inlet is avoided; in the on-line composite slitter edge recycling process, a motor driving the feeding screw can synchronously ascend and descend at the linear velocity of composite, and accordingly, the offcuts in a charging basket cannot be deposited.

Owner:常州市永明机械制造有限公司

Heat exchanger with corrugated pipe coil structure provided with internal duct and external duct

InactiveCN101619944BSmooth heat convectionImprove cooling effectElectrolysis componentsChemical industryLiquid mediumEngineering

The invention discloses a heat exchanger with a corrugated pipe coil structure provided with an internal duct and an external duct, which comprises an inlet, an outlet, a corrugated pipe, a dome, an internal ring bushing, an external ring bushing, a fan and a bracket. When fluid media to be in heat exchange flow in the corrugated pipe in the heat exchanger from the inlet, form a turbulent flow ina pipe wall with a corrugated structure and carry out heat exchange with air in the internal duct and the external duct outside the corrugated pipe via the wall of the corrugated pipe, the fan discharges air in the internal duct and the external duct, and the fluid media are discharged from the outlet after the heat exchange performed in the corrugated pipe in a spiral way. The heat exchanger hasthe advantages of high heat exchanger effectiveness, simple structural technology, light weight, integration, and the like, and the fluid media in the pipe coil after the heat exchange have even temperature, thereby the heat exchanger can be used for heat exchange of air, liquid and air-liquid mixing substances. When the corrugated pipe adopts resistant materials, the heat exchanger can be used for heat exchange for corrosive liquid media.

Owner:南京容宇能源科技有限公司

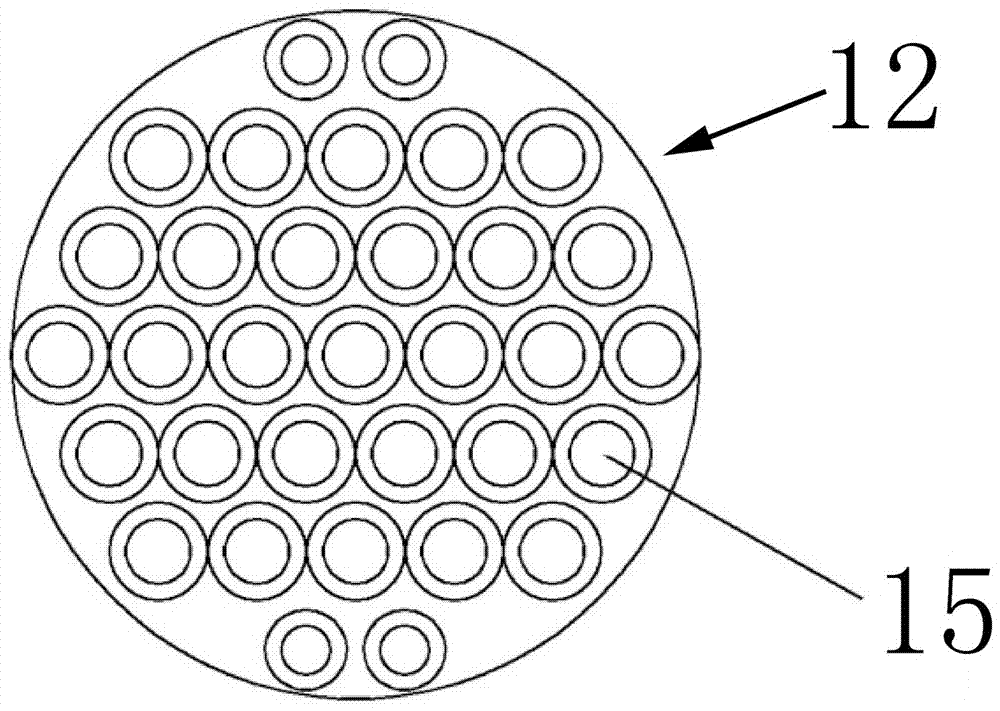

LED lamp with concurrent flow vapor chamber radiator

PendingCN108119775AImprove cooling effectTo achieve the effect of heating without power consumptionLighting heating/cooling arrangementsSemiconductor devices for light sourcesHeat conductingMiniaturization

The invention discloses an LED lamp with a concurrent flow vapor chamber radiator. The LED lamp with the concurrent flow vapor chamber radiator includes an LED light source and the concurrent flow vapor chamber radiator. The concurrent flow vapor chamber radiator includes a concurrent flow vapor chamber, and the concurrent flow vapor chamber includes a flat tube and at least one heat conducting piece. The flat tube is a flat sealing tube with two planes on the upper and lower face and a gap in the middle. The heat conducting piece is arranged in the flat tube and connected with the upper and lower wall of the flat tube, and penetrates through the both ends of the flat tube. The flat tube is divided into a plurality of cavities by the heat conducting piece. Liquid heat conducting working medium is filled into the cavities. The LED light source is arranged on the upper surface of the concurrent flow vapor chamber. The concurrent flow vapor chamber radiator further includes heat conducting fins, and the heat conducting fins are fixed on the outer side of the upward bending position of the concurrent flow vapor chamber. The LED lamp with the concurrent flow vapor chamber radiator has good heat dissipation performance, and is conducive to the miniaturization and lightweight design of the LED lamp of single power source.

Owner:中科龙祥科技有限公司

Connection structure of over-long roof of greenhouse

ActiveCN101824858BTo connectWill not siltClimate change adaptationBuilding constructionsGreenhouseStructural engineering

The invention discloses a connection structure of an over-long roof of a greenhouse. The connection structure comprises glass, roof lathes, a connecting piece, section 1 and section 2, wherein the glass is provided with the roof strips at positions close to the edge; the connecting piece, the section 2 and the section 1 form an integrated structure; one side of the connecting piece is provided with the section 1 for accommodating the glass edge, while the other side is provided with the section 2 for accommodating the glass edge; the section 2 and the section 1 are arranged in parallel; the section 2 are F-shaped and comprise a support bar, an upper crosspiece I and an upper crosspiece II, and the glass is arranged between the upper crosspiece I and the upper crosspiece II; and the section 1 comprise a lower crosspiece I and a lower crosspiece II between which the glass is arranged. A stepped installation method introduced by the invention plays a part in connection through the connecting pieces, the section 1 and the section 2, so large roof of the glass greenhouse can be designed and installed, wherein the large roof cannot accumulate water and has a water discharge function; and simultaneously, the method plays a part in enhancing the effect of supporting the large roof of the glass greenhouse.

Owner:SHANGHAI DUSHI GREEN ENG

Multi-path heat exchanger for blast furnace slag flushing water

ActiveCN103103301BWon't clogSolve the clogging problemStationary plate conduit assembliesSlagWater flow

The invention relates to a multi-path heat exchanger for blast furnace slag flushing water, and the multi-path heat exchanger is of a welding plate structure. Multiple heat exchange units are assembled and stacked into a heat exchange plate bundle, each heat exchange unit comprises multiple horizontally-placed heat transfer plates, one side of the heat transfer plate is provided with a slag flushing water channel, the other side of the heat transfer plate is provided with a secondary water channel, one side of the slag flushing water channel is contactless, each slag flushing water channel is folded through slag flushing water pipe boxes connected to the two ends of the heat exchange plate bundle so as to form a contactless single-channel slag flushing water heat exchange flow path, and the heat exchange plate bundle assembled and stacked by multiple heat exchange units forms multiple contactless single-channel slag flushing water heat exchange flow paths which are connected in parallel; the outer side of a flat cover of each slag flushing water pipe box is provided with a slag flushing water diversion box, and the slag flushing water diversion box realizes the functions of flow diversion, flow collection, adapter tube importing and exporting, disassembling and flushing through an inlet and an outlet of a slag flushing water channel on the flat cover of the pipe box; and two pairs of secondary water pipe boxes are arranged on both sides of the heat exchange plate bundle. The structure of the heat exchanger can be used for solving the blocking problem caused by slag flushing water; and the heat exchanger is long in operation cycle, convenient to flush, compact in structure and high in heat transfer efficiency.

Owner:TIANJIN HUASAIER HEAT TRANSFER EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com