Flow guide layer for sanitary napkins or diapers

A diversion layer and diaper technology, applied in the sanitary field, can solve problems such as large rewet volume, gel blocking, complex manufacturing process, etc., and achieve good permeability, avoid rewet, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

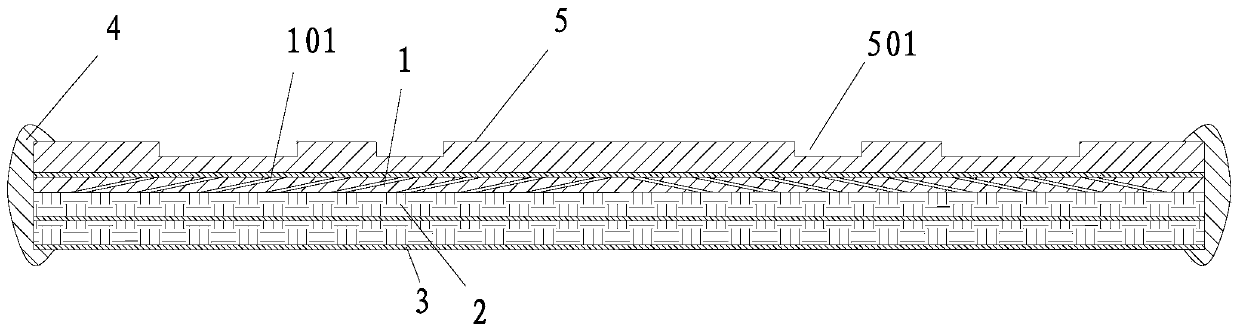

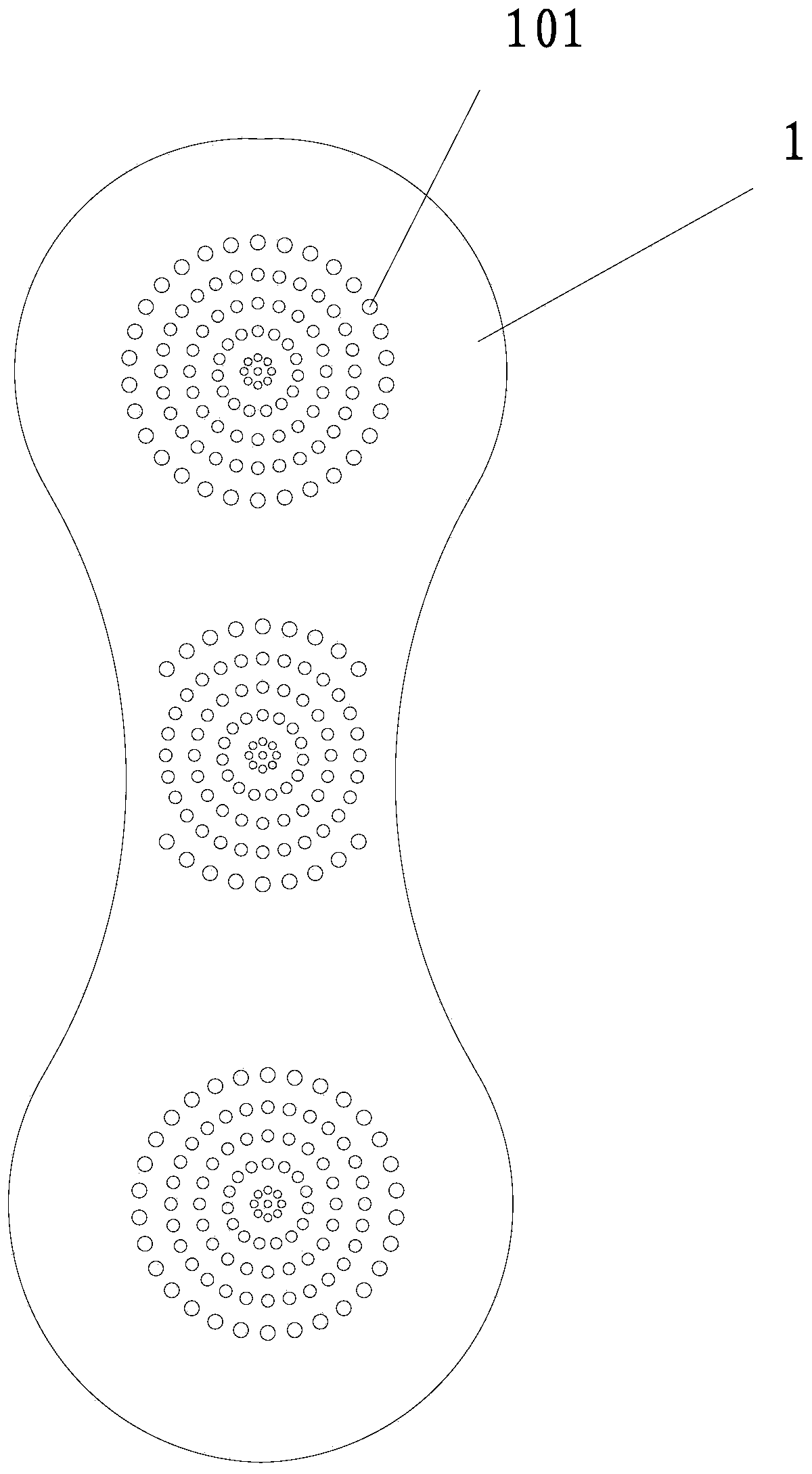

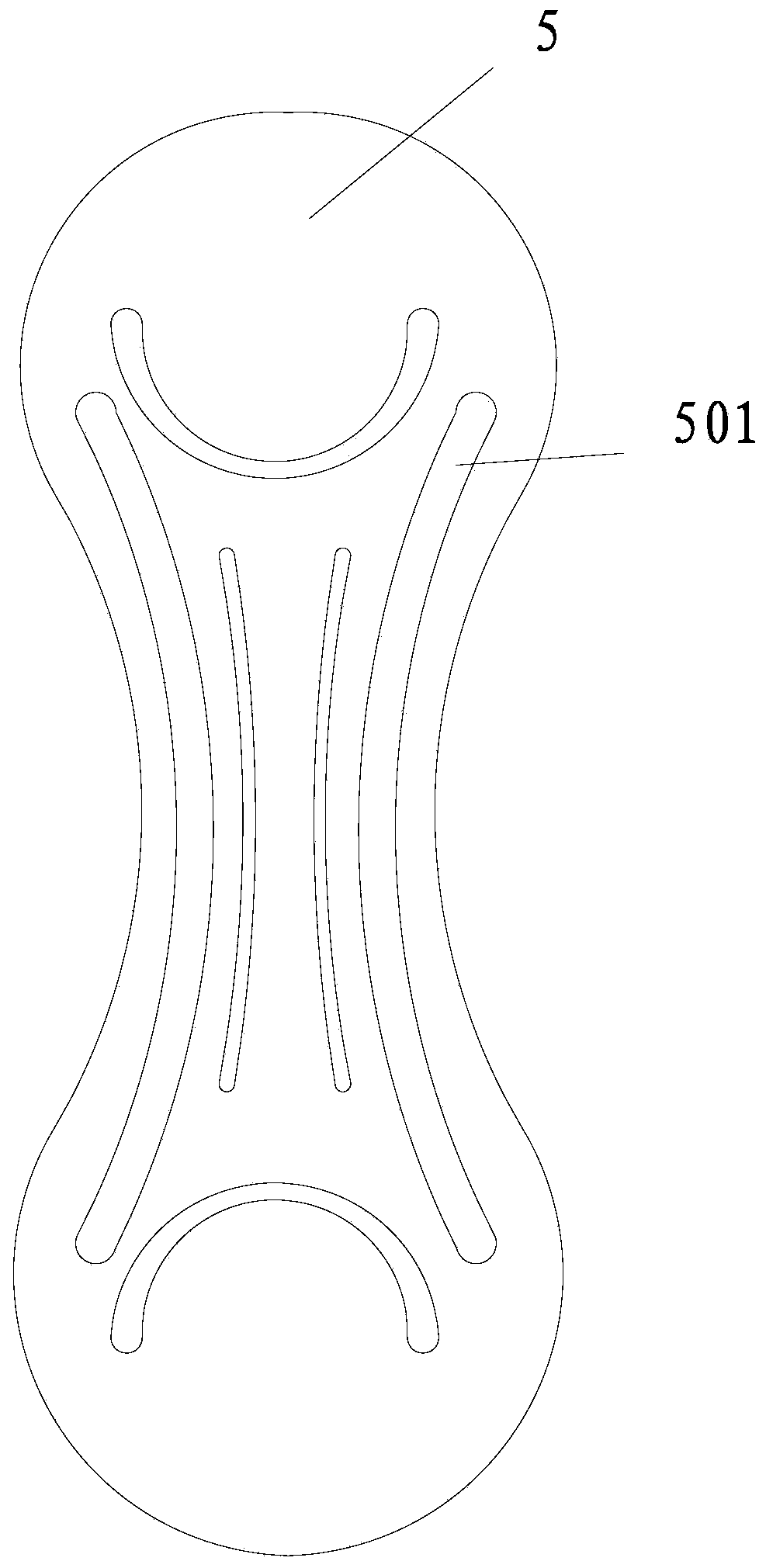

[0048] A flow guiding layer for sanitary napkins or diapers, comprising a diffusion layer 1, a diffusing sponge layer 2, a unidirectional liquid-conducting film 3 and a hydrophobic edge 4; the diffusion layer 1 is located on the top of the flow guiding layer; A number of inclined channels 101 are arranged along the circumference of the layer 1; the diffusible sponge layer 2 is located on the lower surface of the diffusive layer 1; the diffusible sponge layer 2 is arranged in multiple layers, and the material of the diffusible sponge layer 2 is polyurethane sponge , The diffusible sponge layer 2 has longitudinal and transverse pores, and the top of the diffusible sponge layer 2 has wavy folds; each layer of the diffusible sponge layer 2 is provided with a unidirectional liquid film 3; the hydrophobic The edge sealing 4 is bonded to the edge side of the diffusion layer 1, the diffusing sponge layer 2 and the unidirectional liquid conducting film 3 by hot melt glue. The density of...

Embodiment 2

[0056] A flow guiding layer for sanitary napkins or diapers, comprising a diffusion layer 1, a diffusing sponge layer 2, a unidirectional liquid-conducting film 3 and a hydrophobic edge 4; the diffusion layer 1 is located on the top of the flow guiding layer; A number of inclined channels 101 are arranged along the circumference of the layer 1; the diffusible sponge layer 2 is located on the lower surface of the diffusive layer 1; the diffusible sponge layer 2 is arranged in multiple layers, and the material of the diffusible sponge layer 2 is polyurethane sponge , The diffusible sponge layer 2 has longitudinal and transverse pores, and the top of the diffusible sponge layer 2 has wavy folds; each layer of the diffusible sponge layer 2 is provided with a unidirectional liquid film 3; the hydrophobic The edge sealing 4 is bonded to the edge side of the diffusion layer 1, the diffusing sponge layer 2 and the unidirectional liquid conducting film 3 by hot melt glue. The density of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com