Multilayer biofuel heating furnace

A biofuel and heating stove technology, applied in the field of multi-layer biofuel heating stoves, can solve problems such as affecting combustion, waste, and aggravating environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

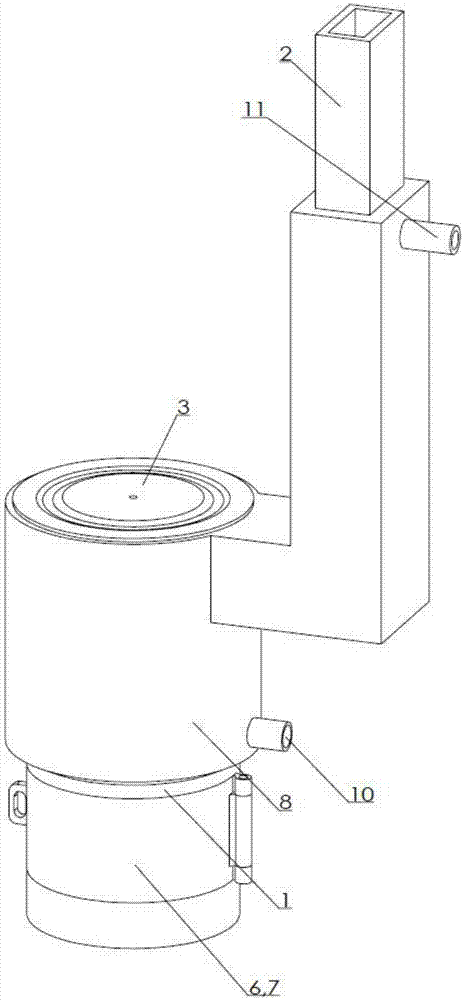

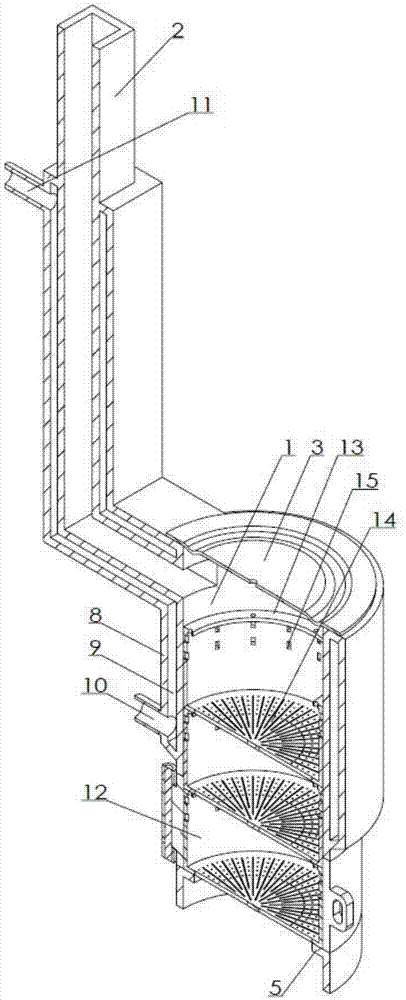

[0011] Examples of the present invention figure 1 , 2 As shown, the multi-layer biofuel heating furnace is provided with a furnace cavity 1 and a smoke exhaust pipe 2; the furnace cavity is a cylindrical combustion chamber, and the upper opening is provided with a circular furnace cover 3, and the furnace cover is provided with an annular depression, which coincides with On the edge of the upper opening, the furnace cavity wall is connected with a smoke exhaust pipe connected to the interior near the upper opening. The inner wall of the furnace cavity is provided with an annular baffle 5 near the lower opening, and 180 openings 6 are arranged on the side wall of the upper furnace cavity of the annular baffle. There is an opening door 7, which is hinged on one side of the opening and can be opened and closed. An outer wall 8 is connected to the outer side of the furnace chamber side wall and the smoke exhaust pipe wall at the upper part of the opening to form a water holding ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com