Waterproof and leakage-proof expansion joint for roof

An expansion joint, leak-proof technology, applied in the direction of roof insulation materials, snow traps, building components, etc., can solve the problems of rainwater leakage, the inability of roof expansion joints to adapt to misalignment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

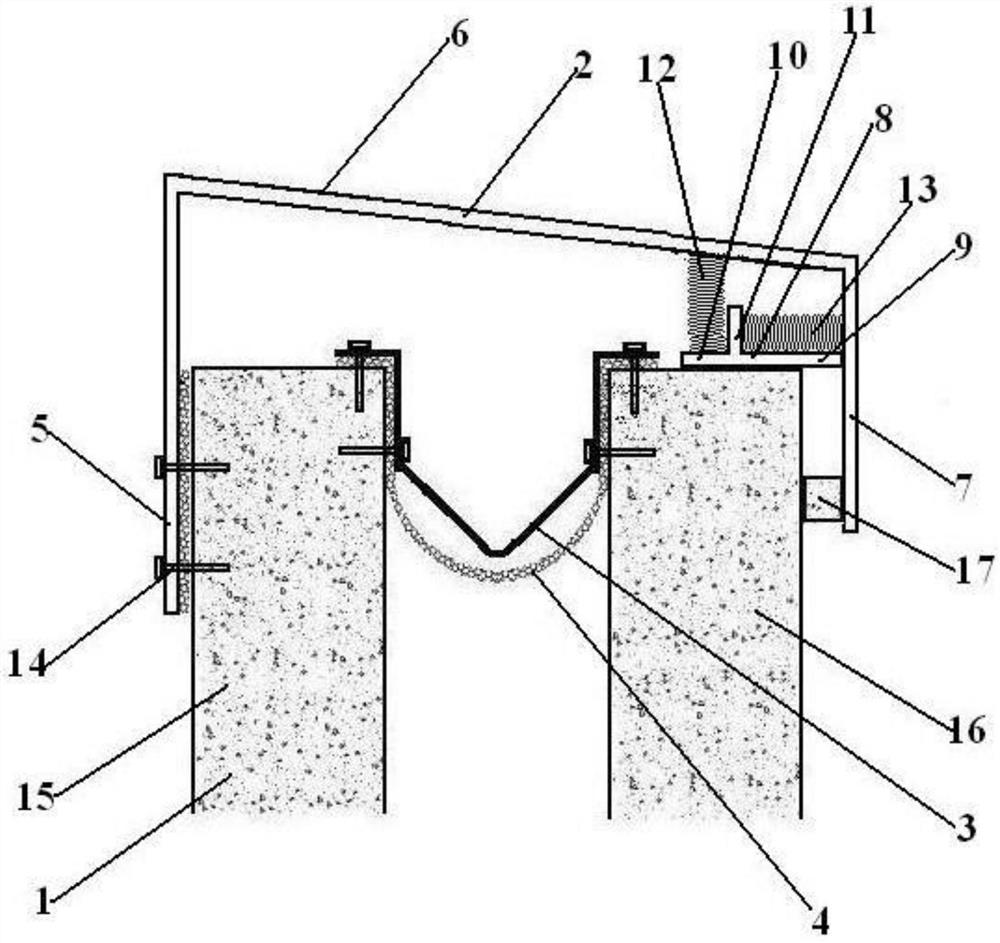

[0028] Such as figure 1 As shown, the roof waterproof and leak-proof expansion joint construction is carried out on a structural seam parapet with high and low spans. The structure joint parapet 1 is two corresponding parapets, which are respectively called the first parapet 15 and the second parapet 16; the aluminum alloy panel 2 is composed of a fixed side plate 5, an inclined panel 6 and 7 are fixedly connected sequentially, wherein the fixed side panel 5 is parallel to the eaves side panel 7, the inclined panel 6 is connected to the eaves side panel 7 at an angle greater than 90°, and the fixed side panel 5 and the inclined panel 6 is connected at an angle greater than 90°, the fixed side plate 5 and the eaves side plate 7 are respectively on both sides of the inclined panel 6, and the angle formed by the two and the inclined panel 6 is equal; the inner side of the aluminum alloy panel 2 Also be connected with movable partition device 8, described movable partition device...

Embodiment 2

[0034] Such as figure 2 As shown, a roof waterproof and leak-proof expansion joint construction is performed on a contoured structural seam parapet, the expansion joint includes a structural seam parapet 1, an aluminum alloy panel 2, an aluminum alloy water guide 3 and a water stop 4; The structural seam parapet 1 is two corresponding parapets, called the first parapet 15 and the second parapet 16 respectively; It is fixedly connected in turn, wherein the fixed side panel 5 is parallel to the eaves side panel 7, the fixed side panel 5 is connected to the inclined panel 6 at an angle less than 90°, and the fixed side panel 5 and the eaves side panel 7 are in the The same side of the inclined panel 6, and the angle formed by the two and the inclined panel 6 is a supplementary angle to each other.

[0035] The fixed side panel 5 is connected to the inclined panel 6 at an angle greater than 90°, the fixed side panel 5 and the eaves side panel 7 are respectively on both sides of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com