Method for producing paperboards and paper tubes

A technology for paper tubes and cardboards, which is applied in the field of pulp and paper making, using steam explosion technology to produce cardboards and paper tubes, which can solve the problems of consuming large cellulose resources, affecting the quality of papermaking, and producing chemical waste products, etc., and achieves simple processes and strong bonding Enhanced, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

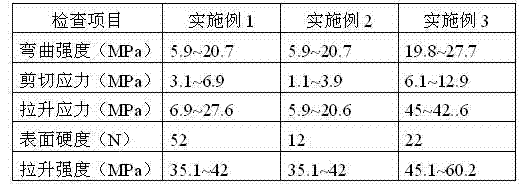

Embodiment 1

[0030] The present invention is implemented according to the following steps:

[0031] (1) Plant waste such as rice straw, corn stalk, wheat straw, bamboo and wood processing industry scraps and waste materials, old materials in the packaging industry and publishing industry, waste paper, etc., are subjected to steam explosion treatment and jet crushing treatment to obtain raw material A, The particle size distribution of raw material A is: the mass fraction of plant particles with a particle size of 1 to 100 nanometers accounts for 6%, and the mass fraction of plant particles with a particle size of 0.1 to 100 microns accounts for 94%;

[0032] (2) Steam explosion treatment of old clothes, old quilts, waste leather, waste packaging bags and waste plastic bags to obtain raw material B;

[0033] (3) Prepare a sodium silicate solution with a mass concentration of 15% to obtain raw material C;

[0034] (4) Evenly mix 84% of raw material A, 9% of raw material B, 6% of raw m...

Embodiment 2

[0036] (1) Plant waste such as rice straw, corn stalk, wheat straw, bamboo and wood processing industry scraps and waste materials, old materials in the packaging industry and publishing industry, waste paper, etc., are subjected to steam explosion treatment and jet crushing treatment to obtain raw material A, The particle size distribution of raw material A is: the mass fraction of plant particles with a particle size of 1 to 100 nanometers accounts for 10%, and the mass fraction of plant particles with a particle size of 0.1 to 100 microns accounts for 90%;

[0037] (2) Steam explosion treatment of old clothes, old quilts, waste leather, waste packaging bags, waste plastic bags, animal hair, crab shells, and shrimp shells to obtain raw material B;

[0038] (3) Prepare a sodium silicate solution with a mass concentration of 14% to obtain raw material C;

[0039] (4) Evenly mix 86% of raw material A, 6% of raw material B, 6% of raw material C and 2% of waste phenolic res...

Embodiment 3

[0041] (1) Plant waste such as rice straw, corn stalk, wheat straw, bamboo and wood processing industry scraps and waste materials, old materials in the packaging industry and publishing industry, waste paper, etc., are subjected to steam explosion treatment and jet crushing treatment to obtain raw material A, The particle size distribution of raw material A is: the mass fraction of plant particles with a particle size of 1 to 100 nanometers accounts for 14%, and the mass fraction of plant particles with a particle size of 0.1 to 100 microns accounts for 86%;

[0042] (2) Steam explosion treatment of old clothes, old quilts, waste leather, waste packaging bags, waste plastic bags, and animal hair to obtain raw material B;

[0043] (3) Prepare a sodium silicate solution with a mass concentration of 12% to obtain raw material C;

[0044] (4) Evenly mix 85% of raw material A, 8% of raw material B, and 7% of raw material C, adopt the continuous production method of preparing linea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com