Prefabricated building same-layer drainage pipe fitting

A same-layer drainage and assembly technology, which is applied in the direction of construction, pipes/pipe joints/fittings, pipes, etc., can solve the problems of reduced drainage safety, unsmooth drainage, and peculiar smell, so as to facilitate disassembly of products and reduce drilling Process and yield improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

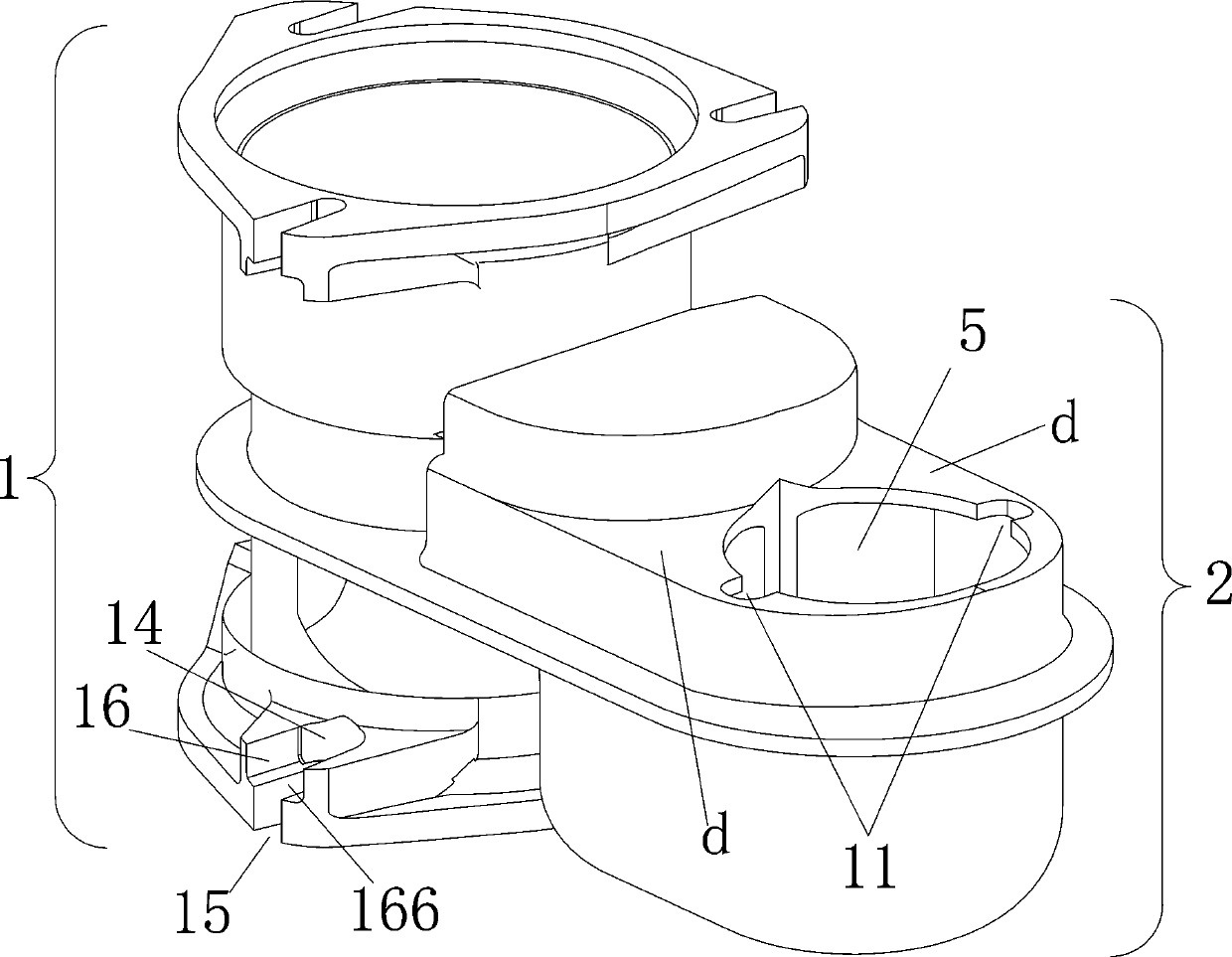

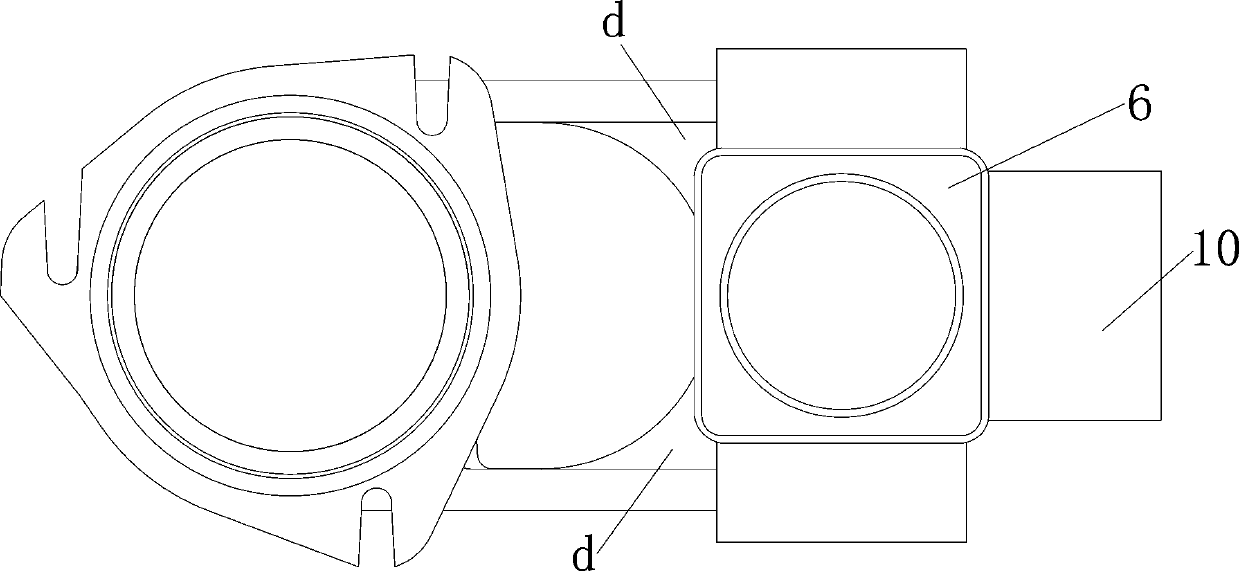

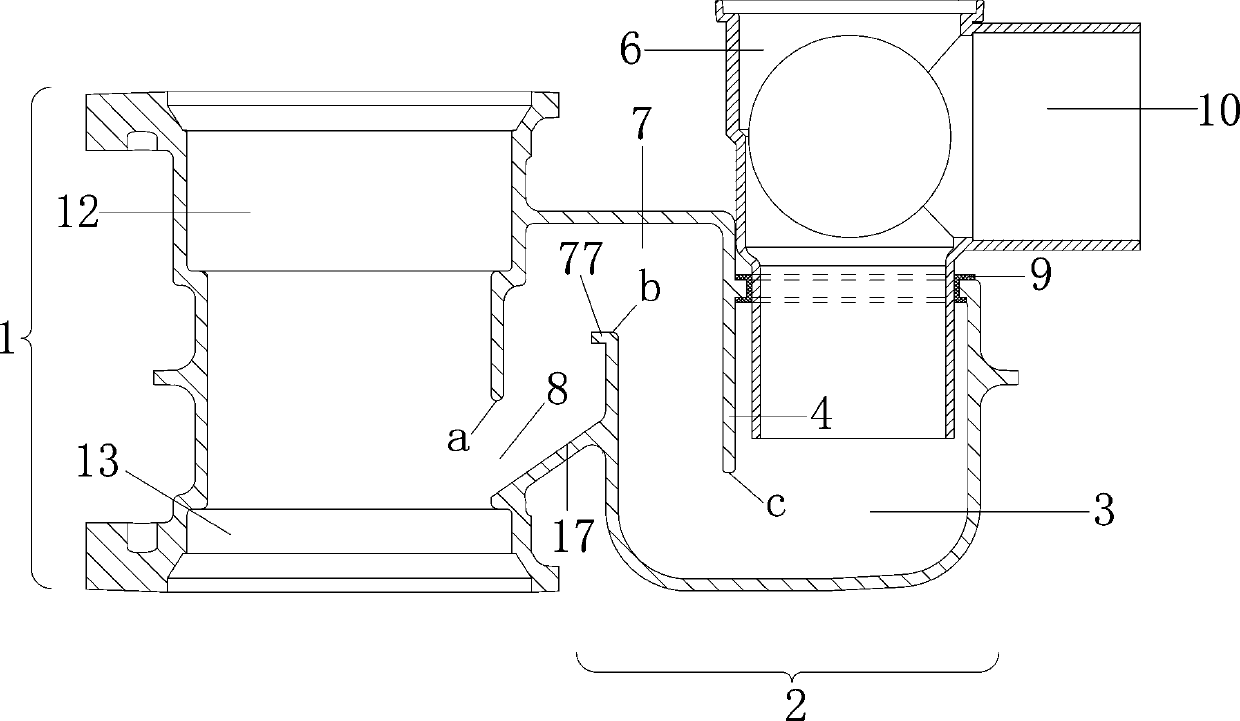

[0016] Such as figure 1 , 3 , 4, the prefabricated building same-floor drainage pipe fitting of the present invention is composed of a riser joint 1 and a horizontal pipe joint 2. The riser joint 1 is connected up and down, and the horizontal pipe joint 2 is located on one side of the riser joint 1 and connected with the riser joint 1; the horizontal pipe joint 2 is composed of a water seal groove 3, a water seal baffle 4, a horizontal pipe drainage inlet 5 and a branch pipe interface 6 components; the outer wall of the water seal groove 3 is closed and the inner wall is connected with the riser joint 1, the lower end of the water seal groove 3 is closed, and the upper end is close to the side wall of the riser joint 1. The length of the connection port 8 is 100mm, and the length of the longest vertical point is 30mm. is 30mm. The highest point a of the communication port 8 is 20mm lower than the lowest point b of the port 7; Seal baffle 4, the lowest end c of water seal b...

Embodiment 2

[0018] Such as figure 1 , 2 , 3, and 4, the prefabricated building same-floor drainage pipe fitting of the present invention is composed of a riser joint 1 and a horizontal pipe joint 2. The riser joint 1 is connected up and down, and the horizontal pipe joint 2 is located on one side of the riser joint 1 and connected with the riser joint 1; the horizontal pipe joint 2 is composed of a water seal groove 3, a water seal baffle 4, a horizontal pipe drainage inlet 5 and a branch pipe interface 6 components; the outer wall of the water seal groove 3 is closed and the inner wall is connected with the riser joint 1, the lower end of the water seal groove 3 is closed, and the upper end is close to the side wall of the riser joint 1. The length of the connecting port 8 is 90mm, the length of the longest vertical point is 35mm, the drop between the port 7 and the connecting port 8 of the riser joint 1 is 25mm, the length of the longest horizontal point of the narrowest part of the co...

Embodiment 3

[0020] Such as figure 1 As shown, in the same-floor drainage pipe fitting of the prefabricated building described in the present invention, there is an accumulated water discharge port 11 on the horizontal pipe drainage inlet 5 on the upper part of the water seal tank 3, and the accumulated water discharge port 11 is located at the water seal baffle 4 away from the riser joint Any position in 1 side, all the other are the same as embodiment 1,2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com