Multi-path heat exchanger for blast furnace slag flushing water

A blast furnace slag flushing water and multi-process technology is applied in the field of blast furnace slag flushing water narrow plate multi-process heat exchangers to achieve the effects of increased processing capacity, convenient flushing, and improved heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

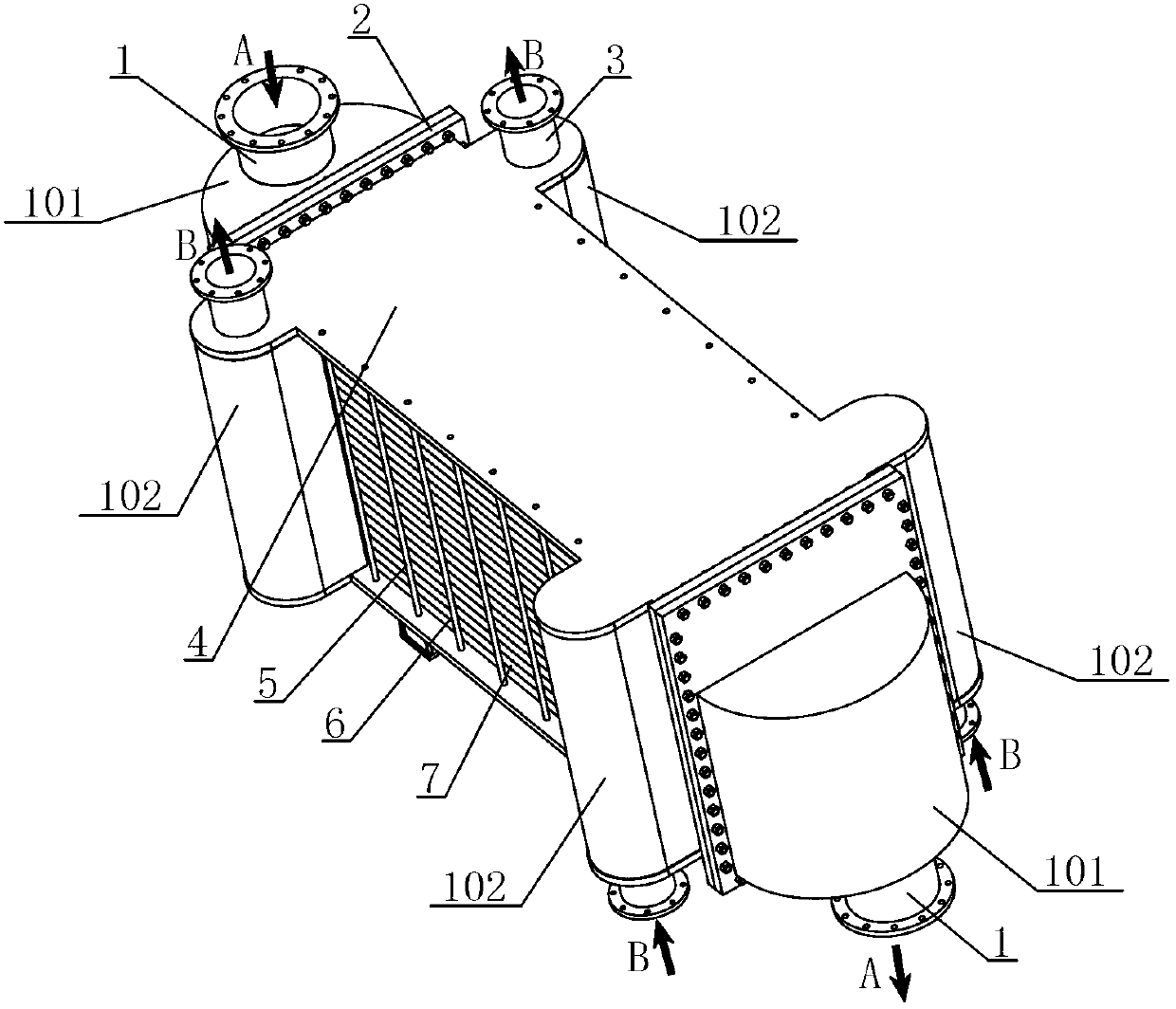

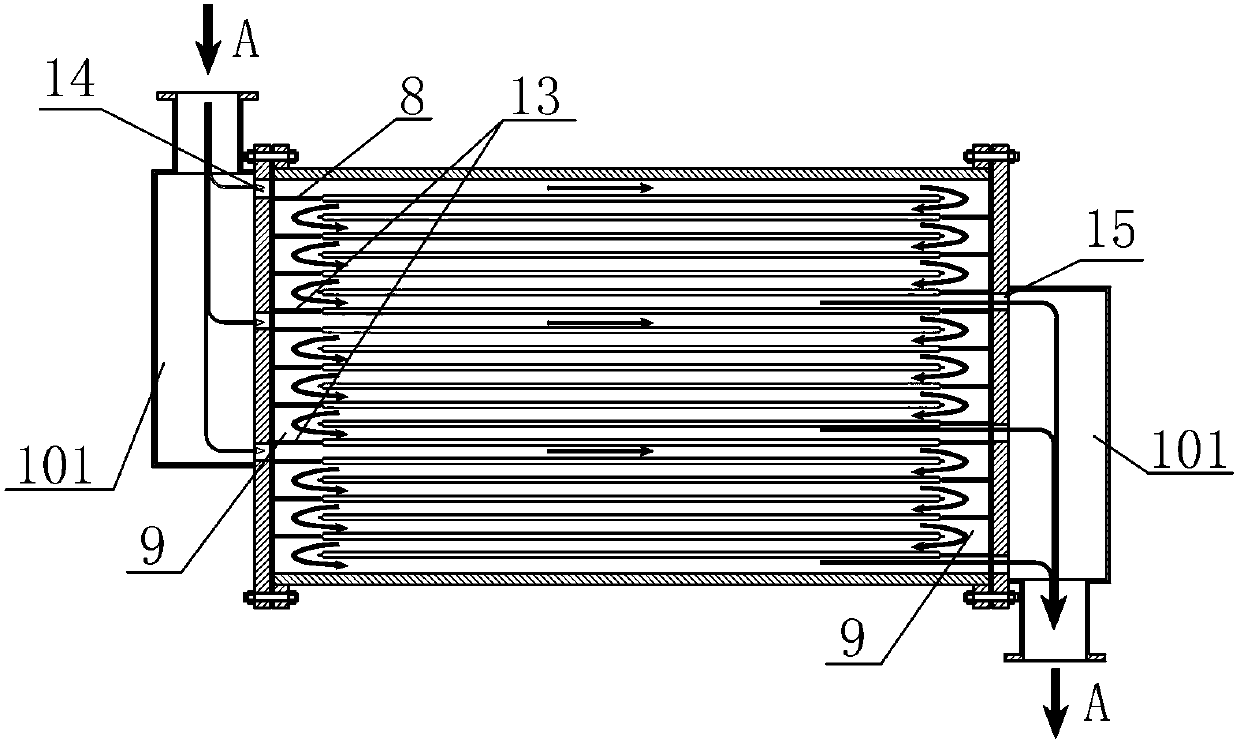

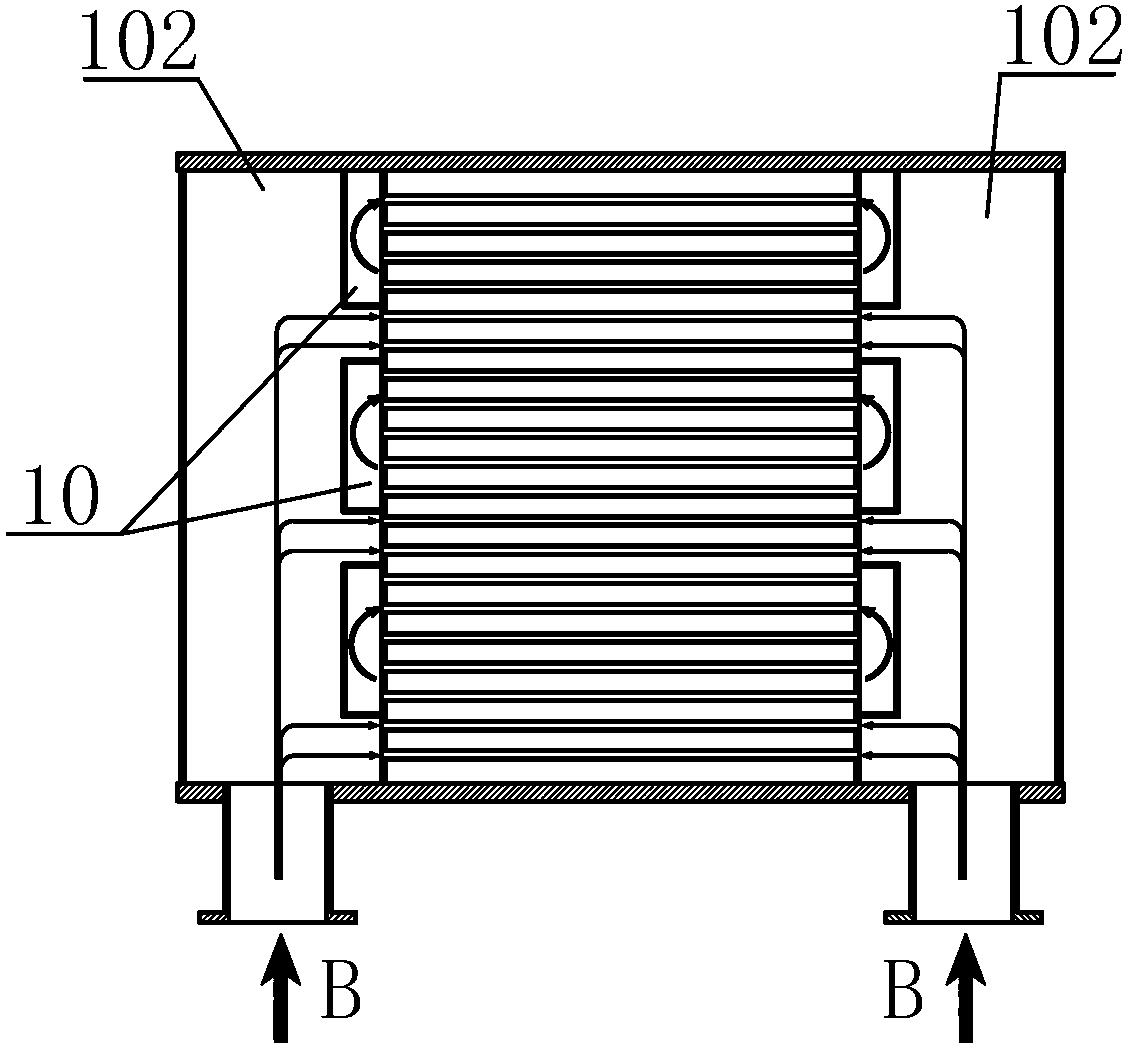

[0023] As shown in the figure, the present invention includes a pair of slag flushing water connection pipes 1 and two pairs of secondary water connection pipes 3 arranged at the upper and lower ends, two slag flushing water pipe boxes 9 arranged at both ends, and two slag flushing water pipe boxes 9 connected to each other. The flat cover 2 of the slag flushing water pipe box and its splitter box 101, two pairs of secondary water pipe boxes 102 at both ends of both sides, the heat exchange plate bundle and the clamping heat exchange plate bundle arranged between the slag flushing water pipe box and the secondary water pipe box The compression plate 4 and the tie rod 5, the heat exchange plate bundle includes a plurality ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com