Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "The hole position is accurate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

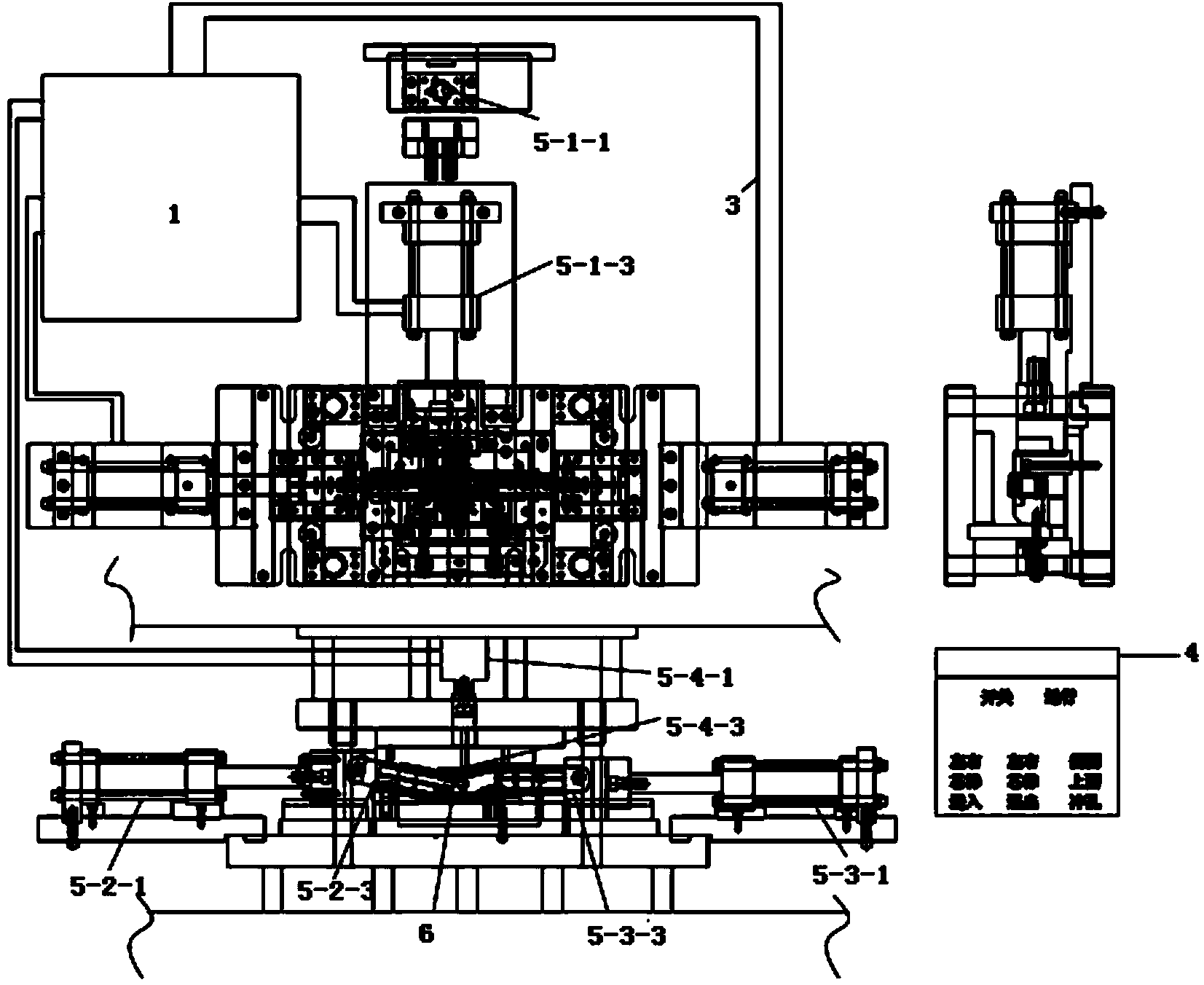

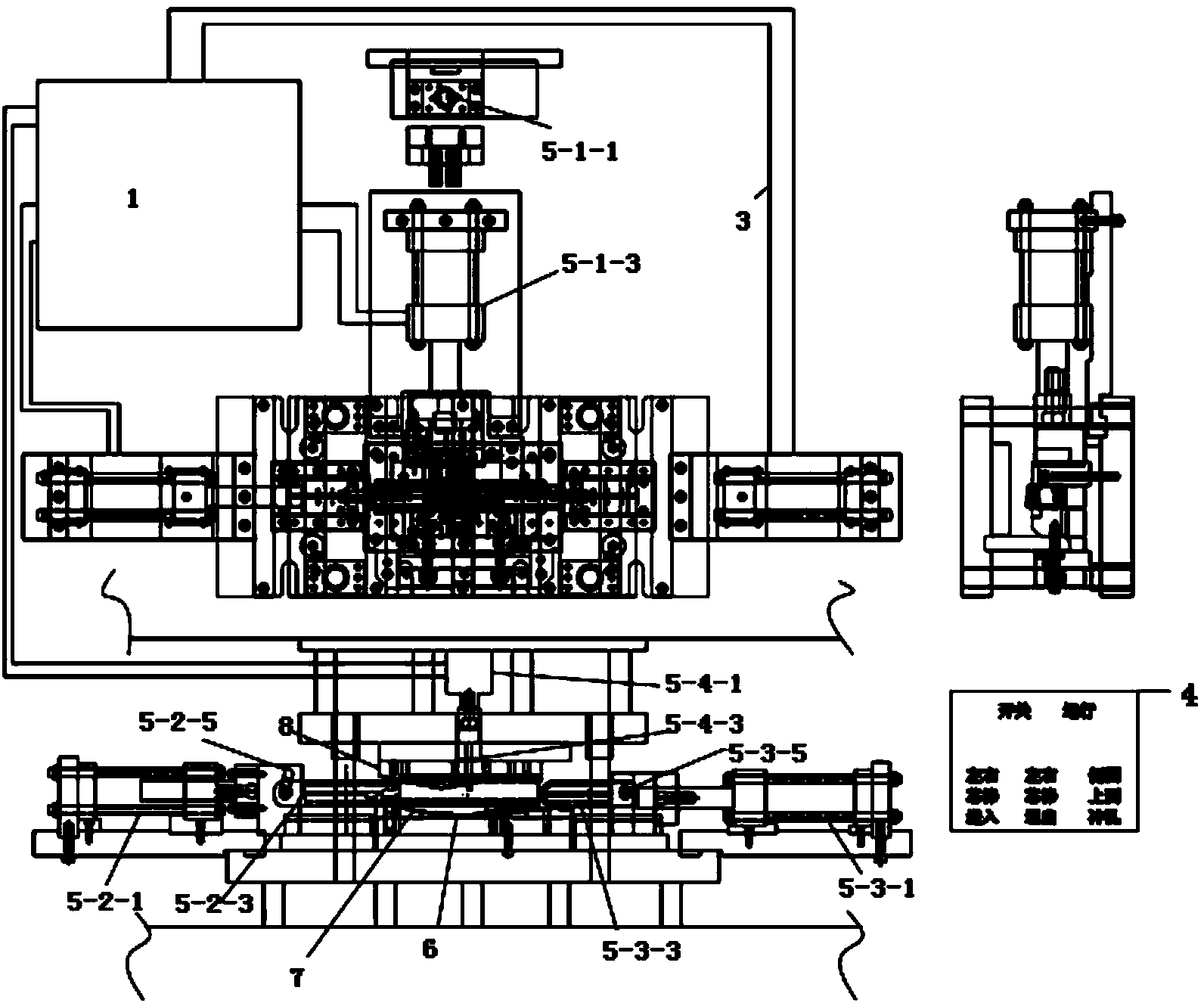

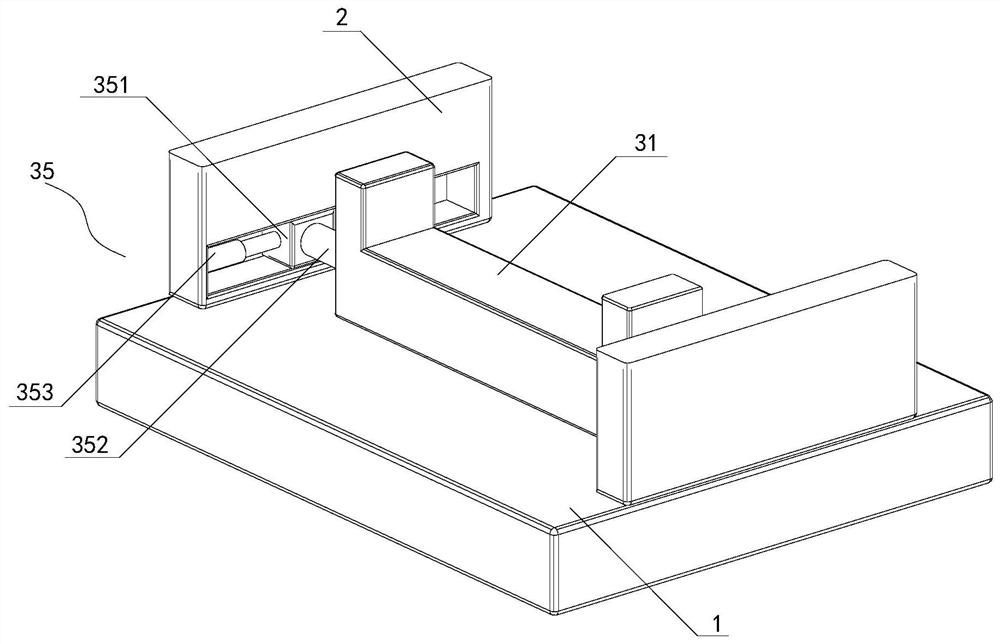

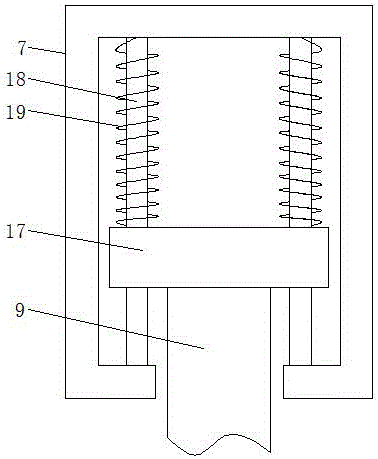

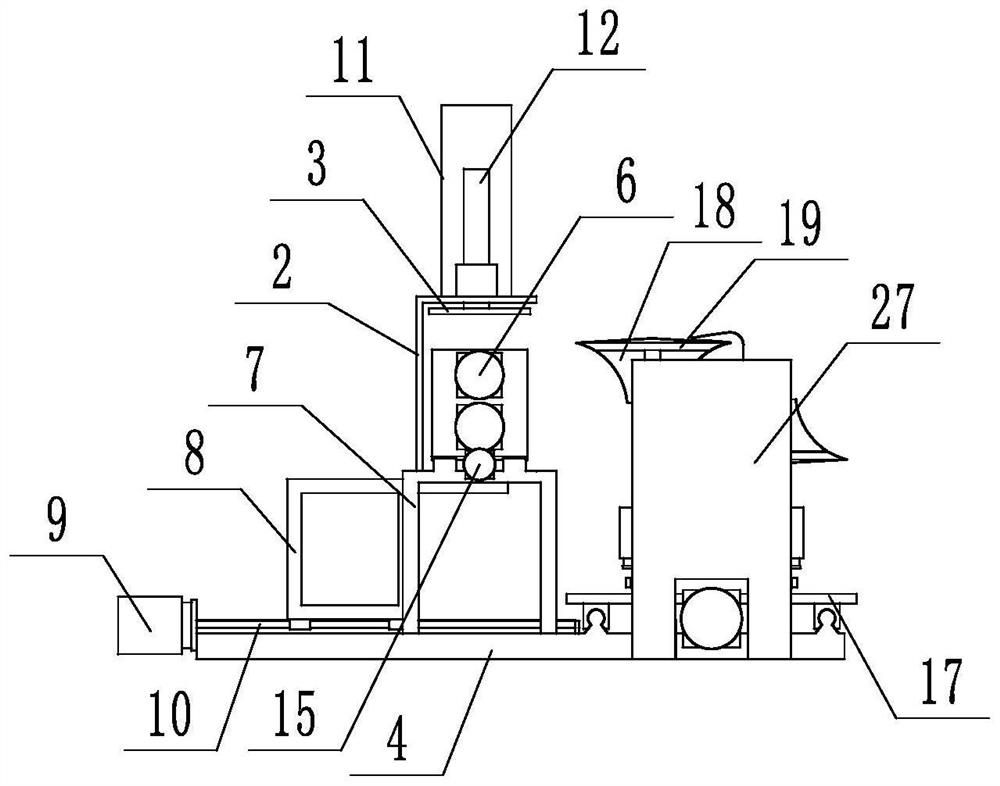

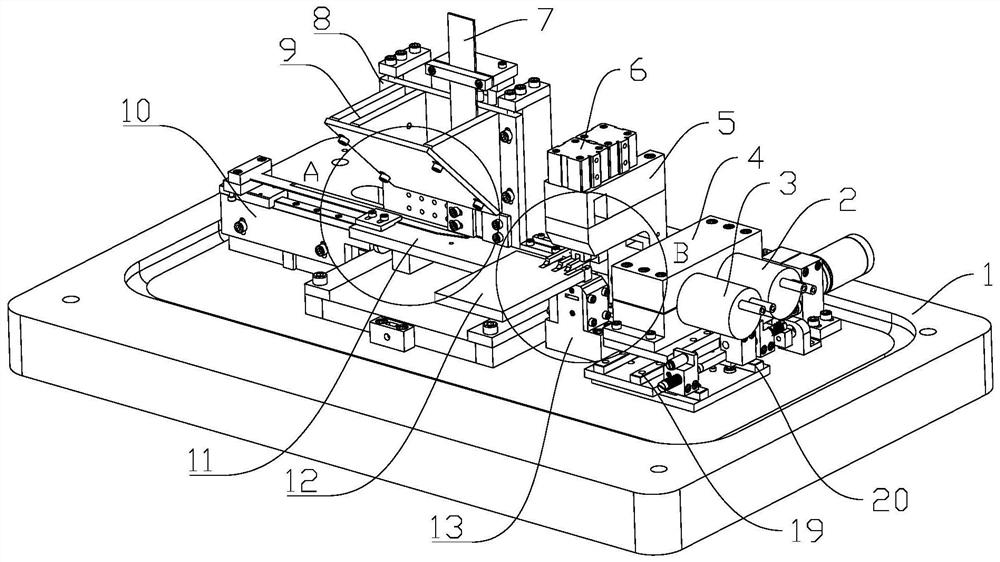

Multi-station automobile aluminum alloy profile bending and punching system

ActiveCN103521606AThe hole position is accurateShaping toolsPerforating toolsPunchingElectrical control

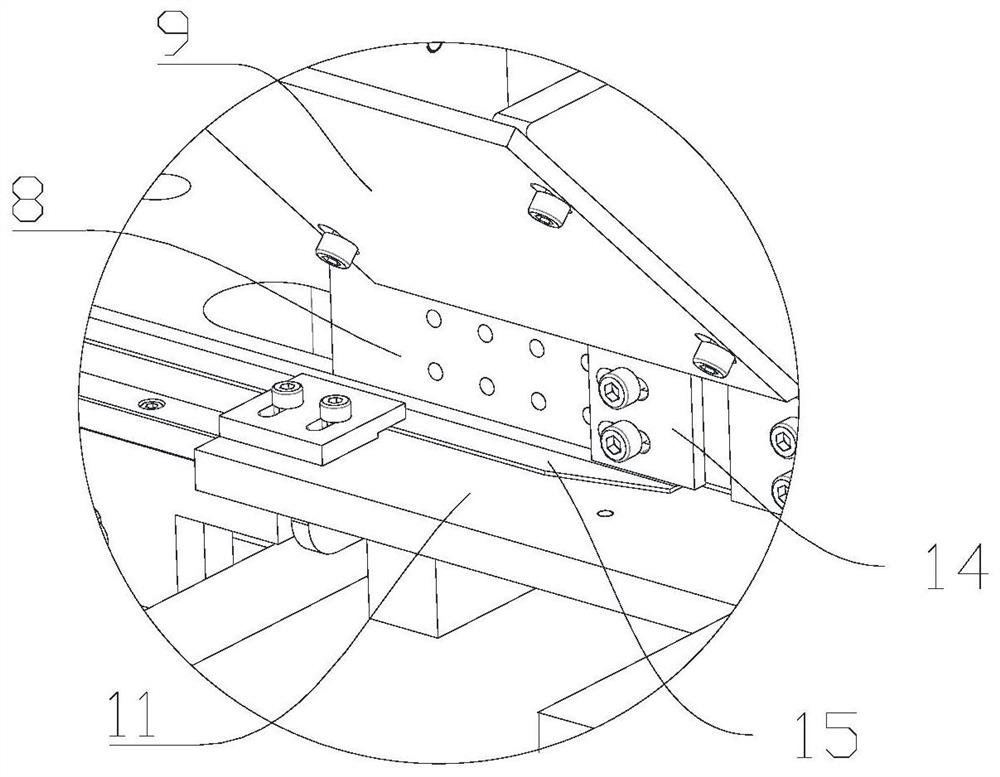

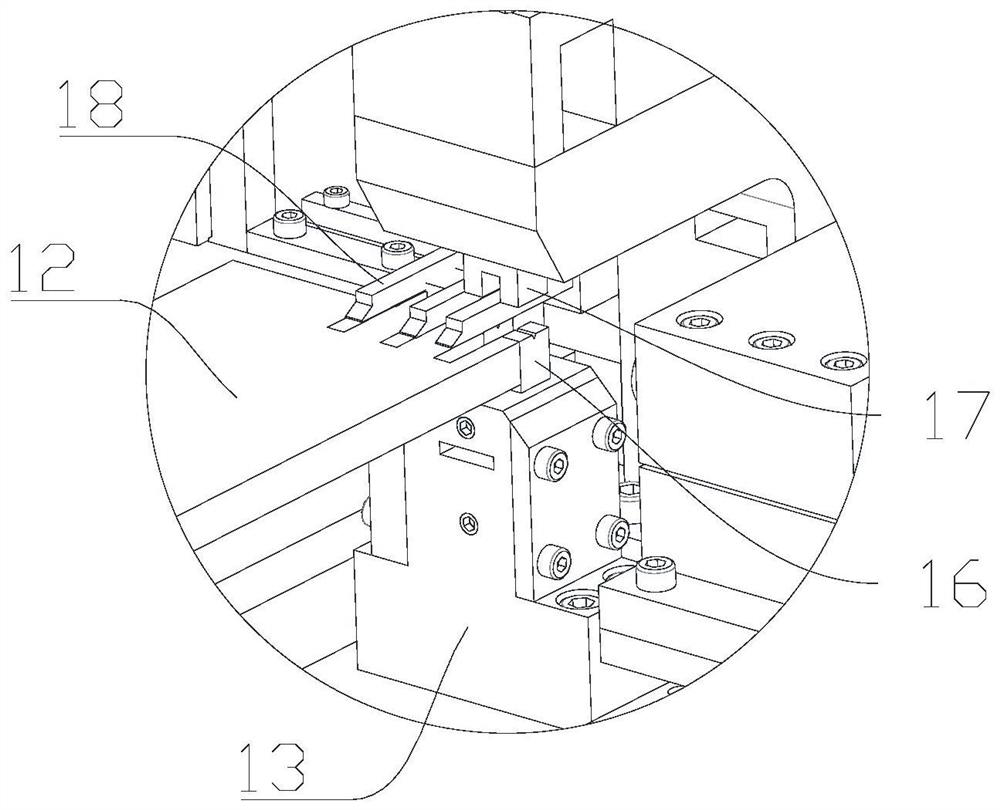

The invention discloses a multi-station automobile aluminum alloy profile bending and punching system. The multi-station automobile aluminum alloy profile bending and punching system comprises a hydraulic pressure station, an oil pipe, an electrical control cabinet and a die, wherein the hydraulic pressure station is connected with the die through the oil pipe, the electrical control cabinet is connected with and controls the hydraulic pressure station and the die, and the die is composed of a lateral punching oil cylinder device, a left core-pulling oil cylinder device, a right core-pulling oil cylinder device and an upper punching oil cylinder device. According to the multi-station automobile aluminum alloy profile bending and punching system, core insertion forming is conducted before punching is conducted, the operation can be completed through one die without replacing the standard, and the position of a hole is accurate.

Owner:SHANGHAI UNISON ALUMINUM PRODS

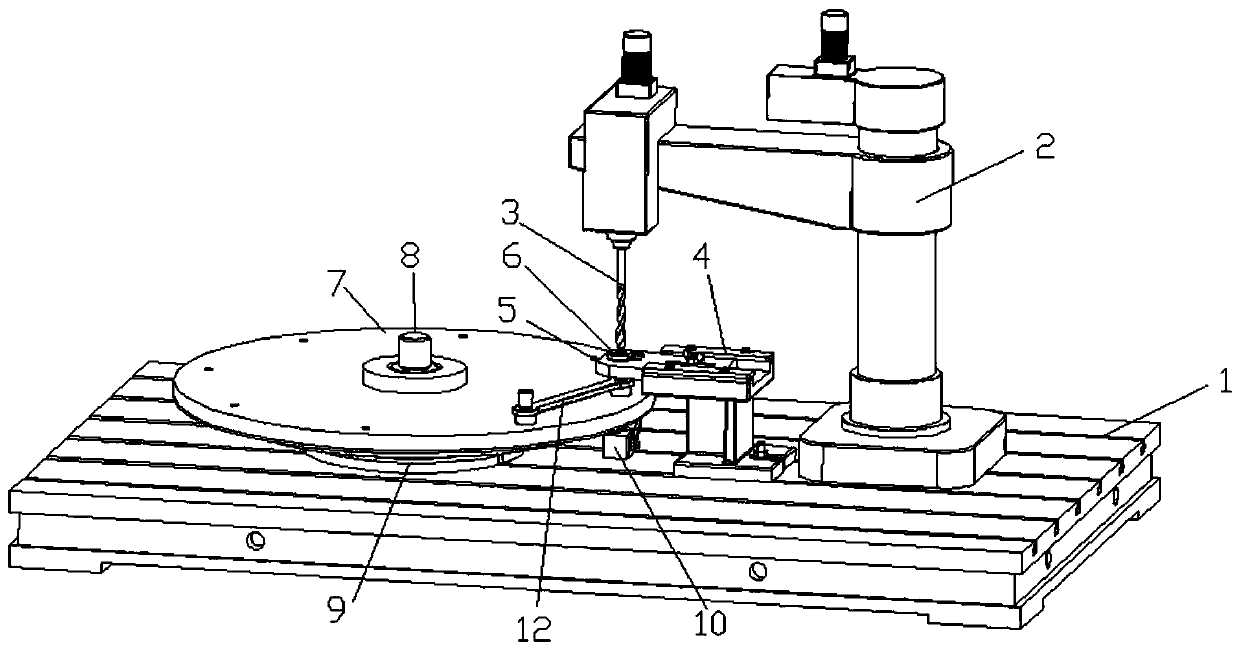

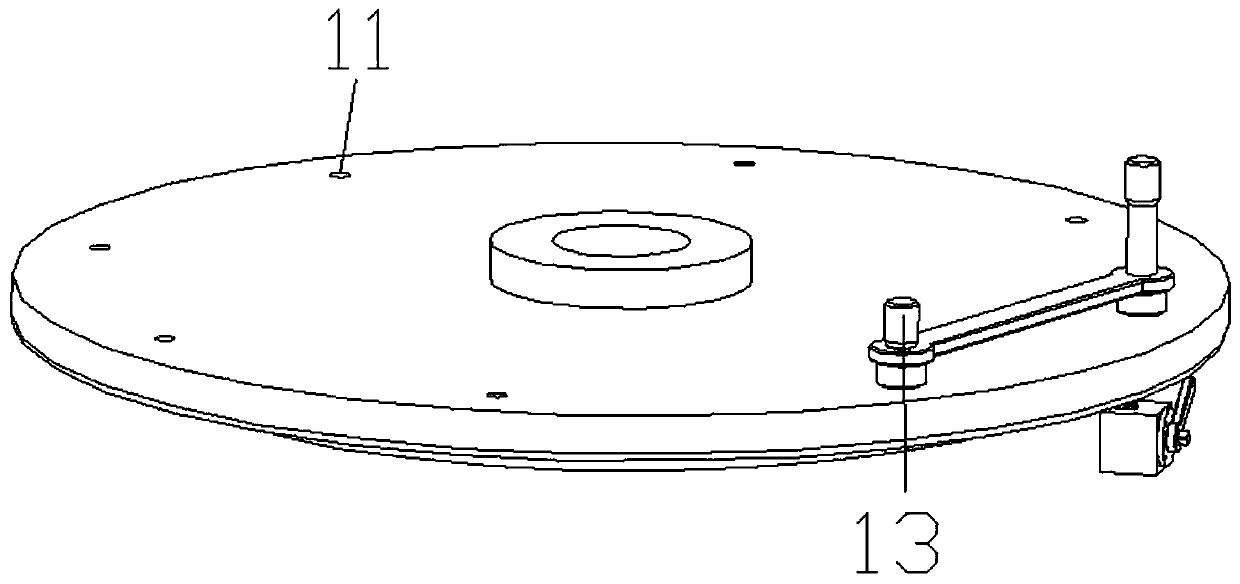

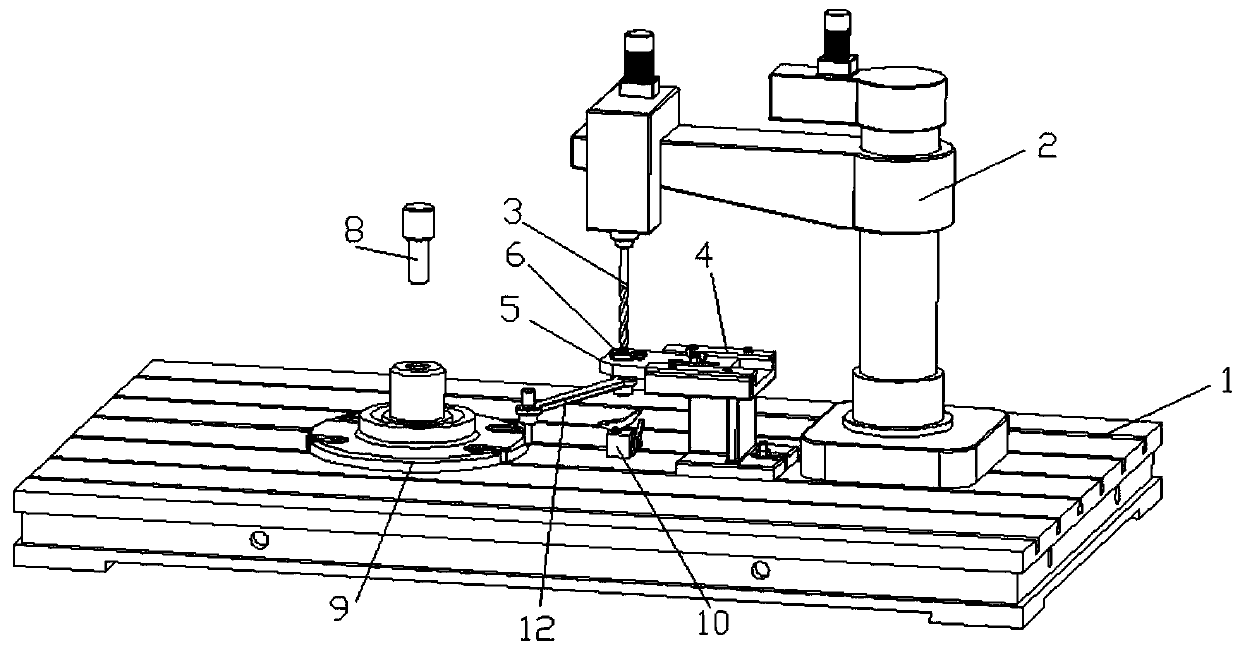

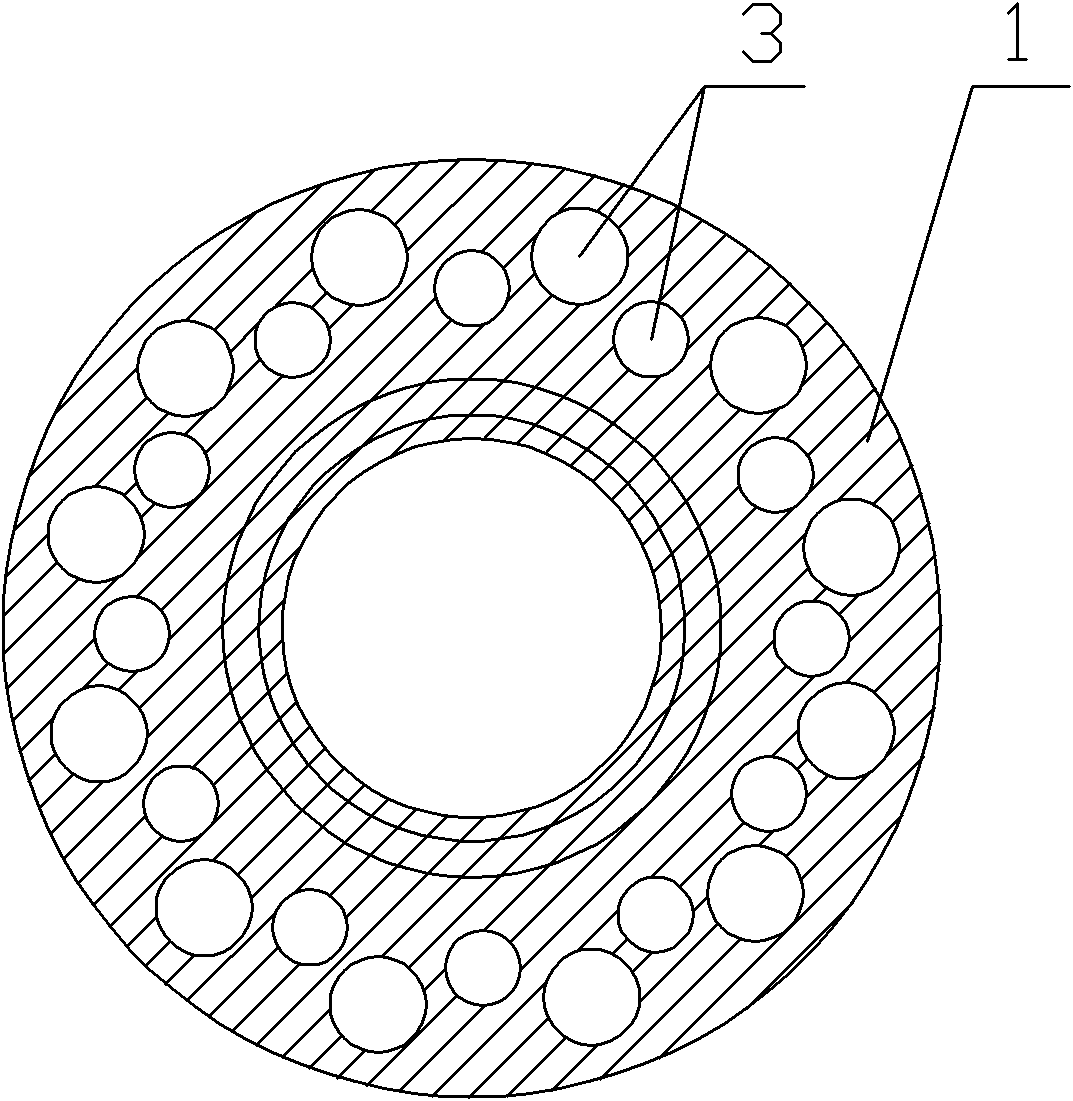

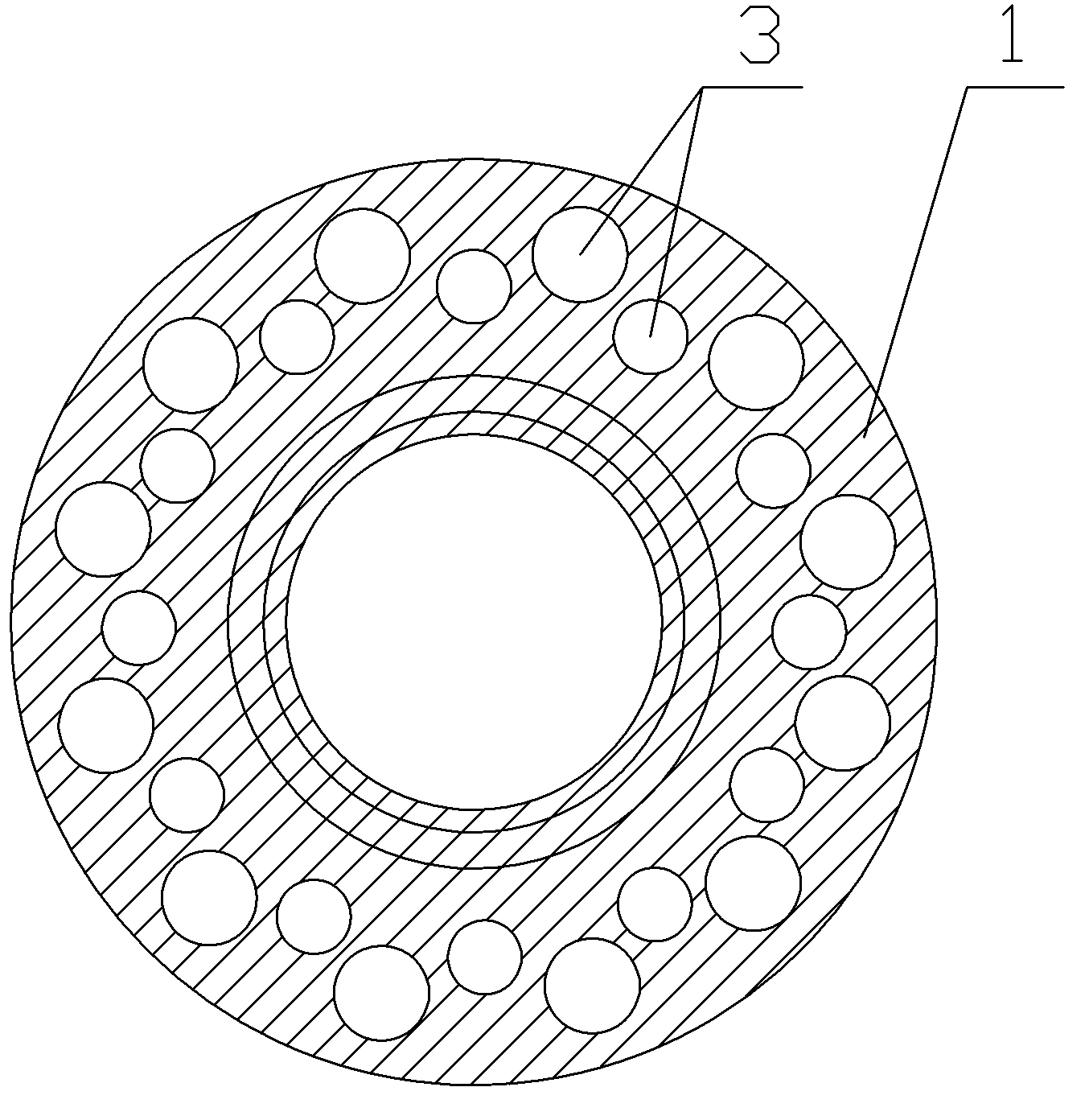

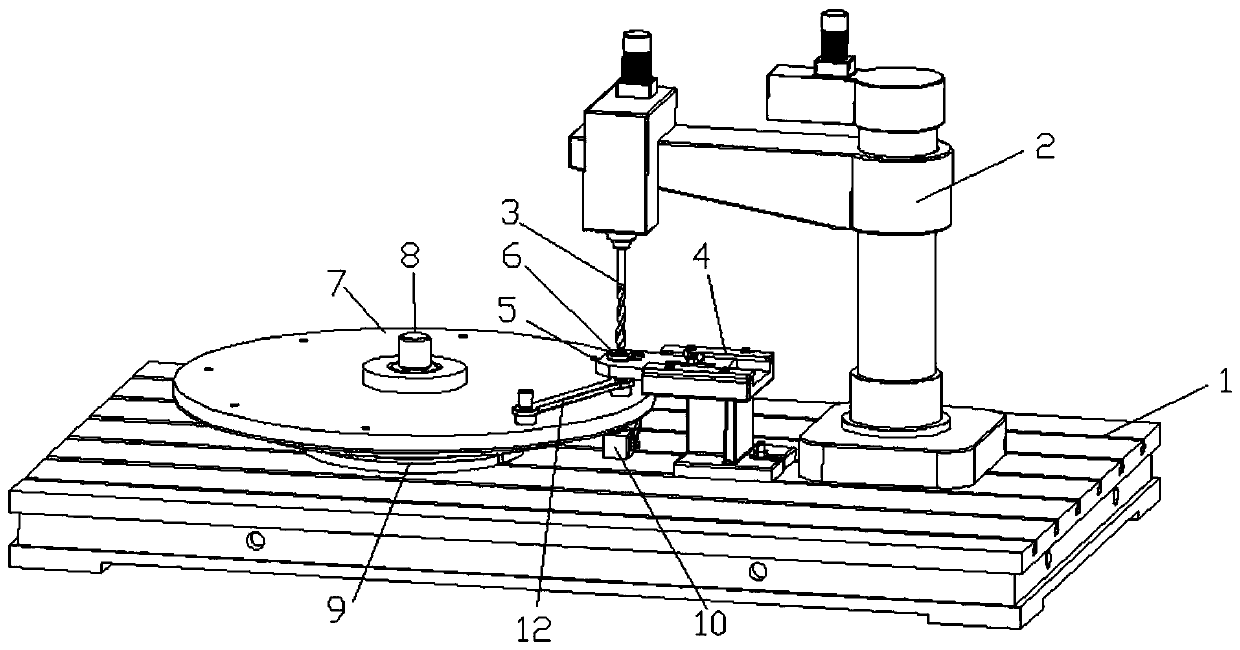

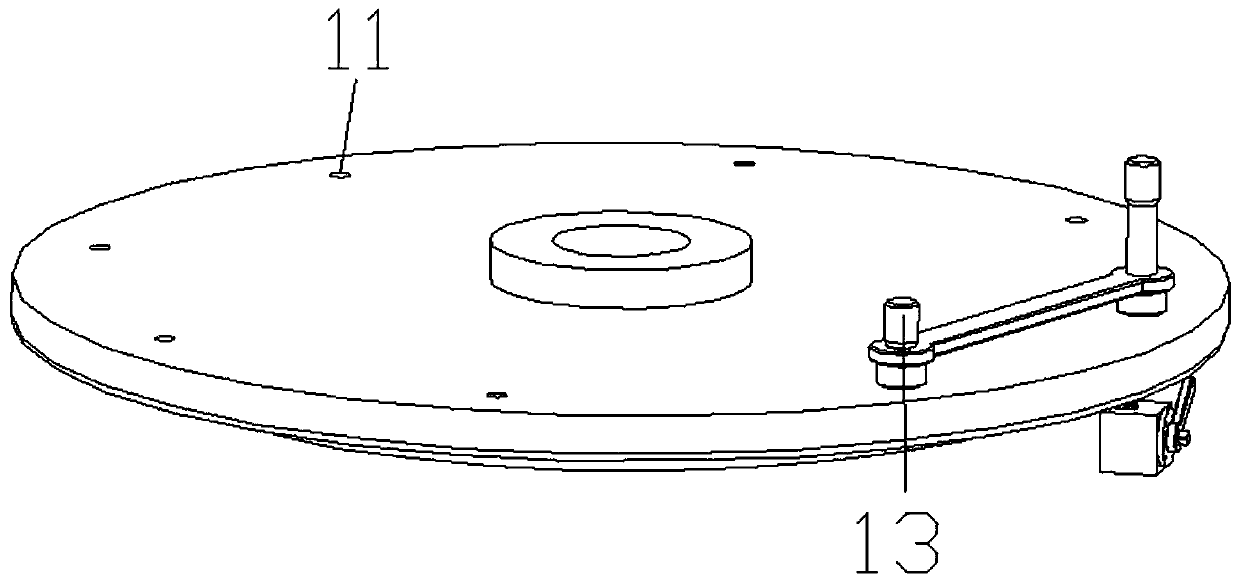

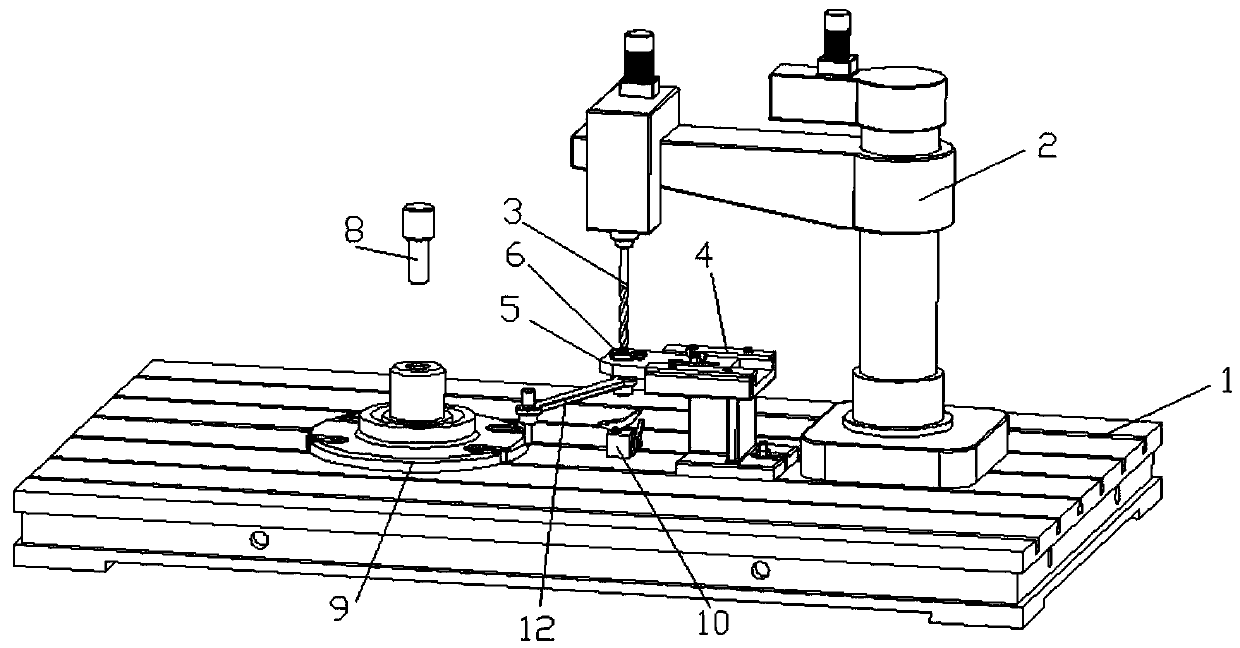

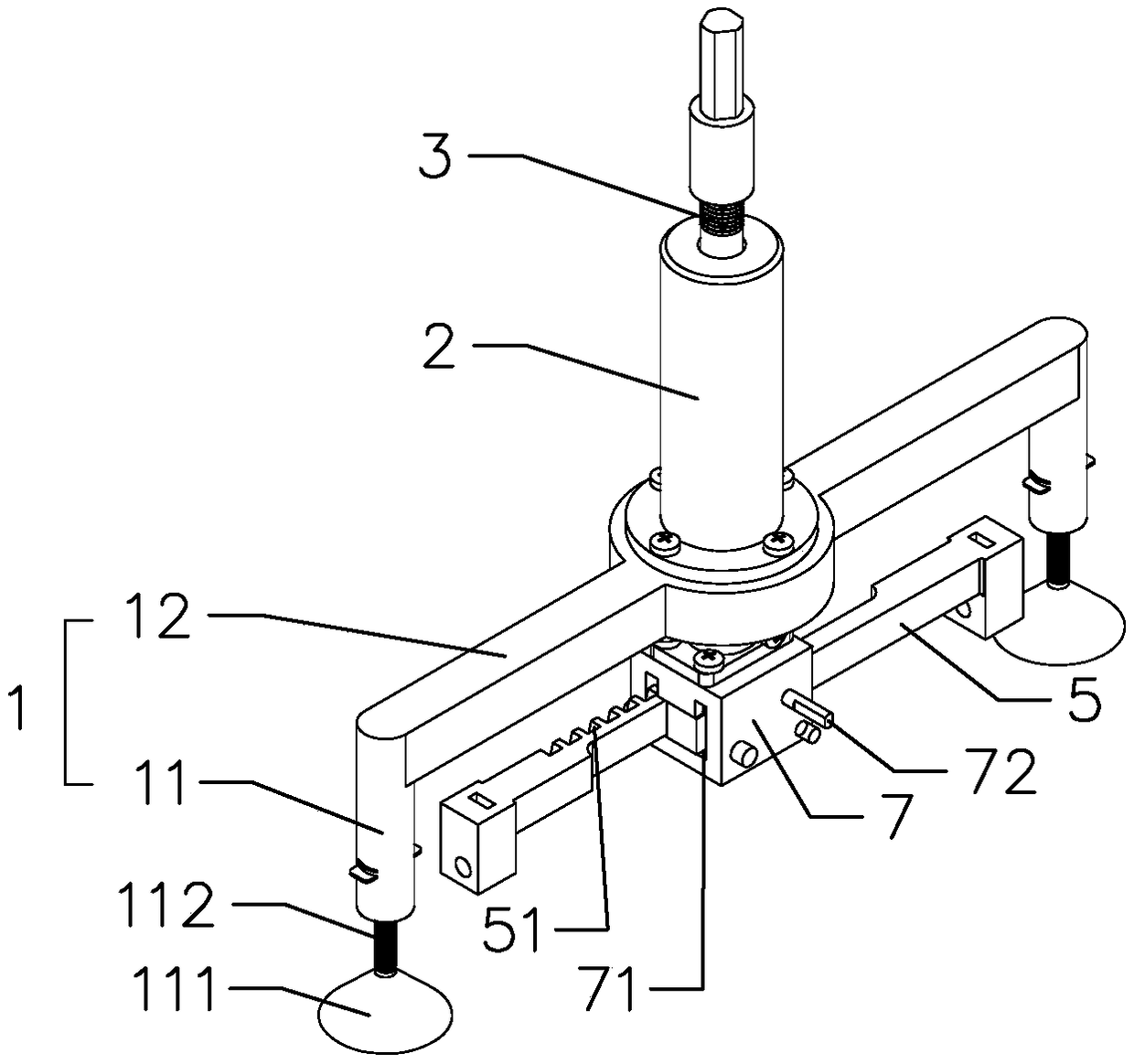

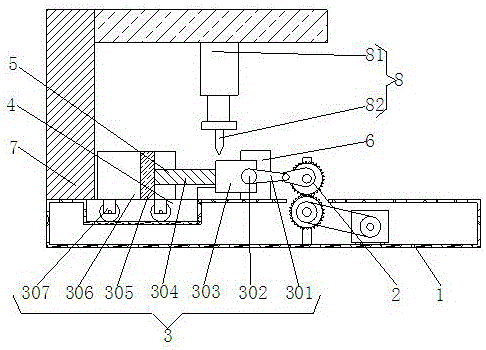

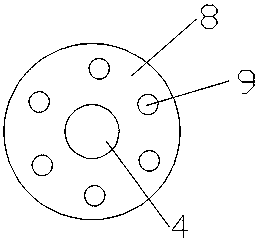

Large-scale flange type workpiece punching positioning device

InactiveCN110421195AUniform Position AccuracyGuaranteed positioning accuracyPositioning apparatusMetal-working holdersEngineeringMechanical engineering

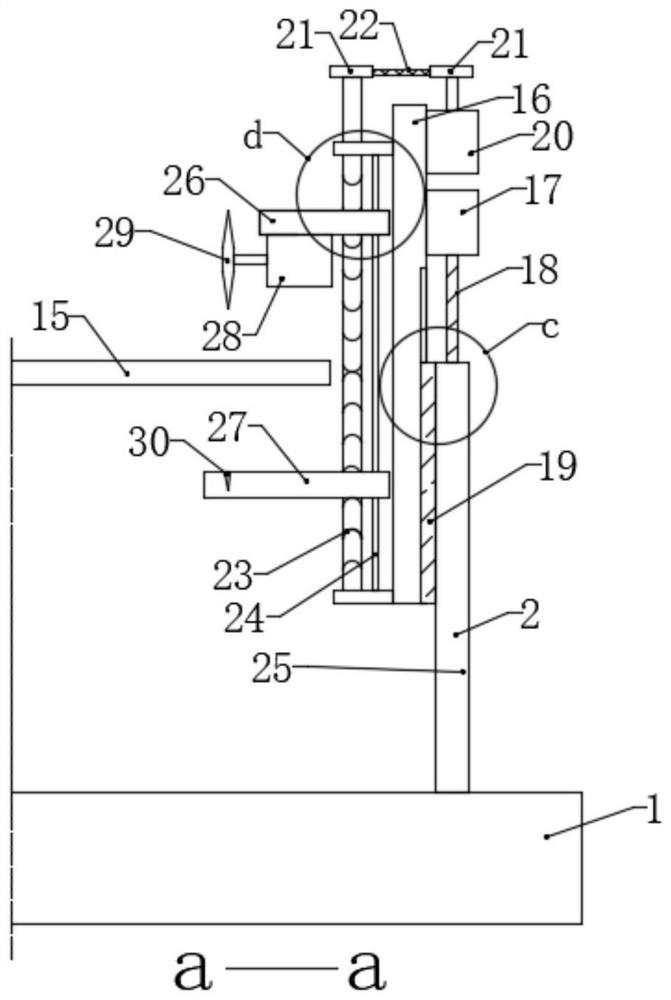

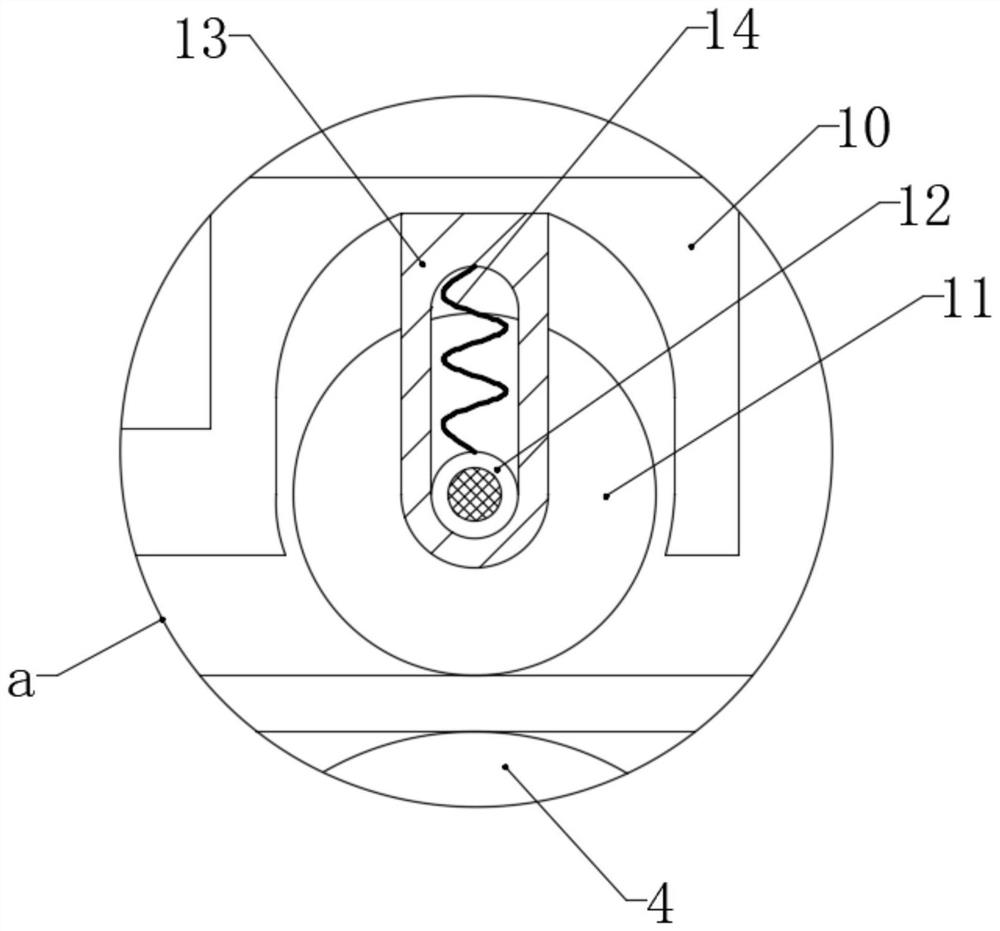

The invention discloses a large-scale flange type workpiece punching positioning device. The device comprises a horizontally arranged worktable; a vertically arranged drilling machine is arranged on the right side of the top surface of the worktable; a vertical positioning plate support is arranged on the left side of the drilling machine; a horizontal positioning plate is arranged in the positioning plate support; a positioning sleeve is arranged at the left part of the positioning plate; a round flange plate support is arranged at the left part of the positioning plate support; a flange plate is arranged at the upper part of the flange plate support; a central positioning pin is arranged at the center of the top surface of the flange plate; a horizontally arranged positioning rod is arranged at a relative position at the top of the flange plate; vertical through holes are formed in both ends of the positioning rod; a plurality of machining holes are uniformly formed in the circumferential direction of the flange plate; and an auxiliary support is arranged at a relative position at the lower part of the flange plate. The device has the beneficial effects of punching holes with accurate positions in the large-scale flange type workpieces and being simple to operate.

Owner:ZHENGZHOU UNIV

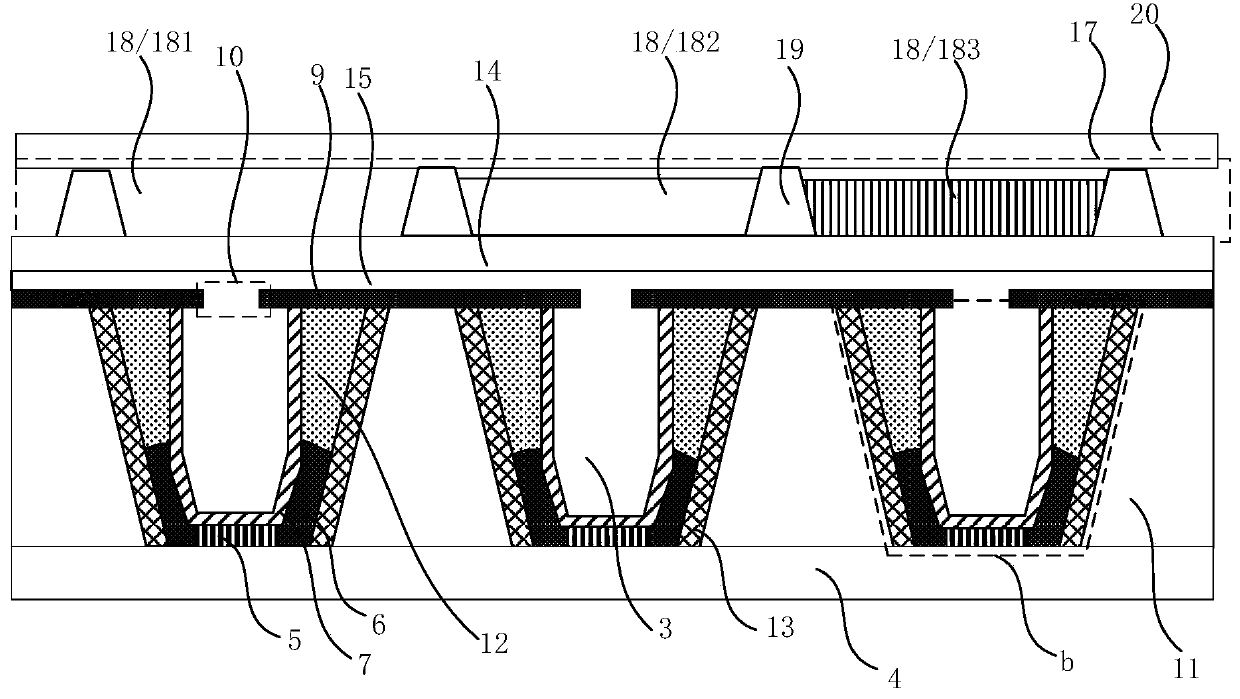

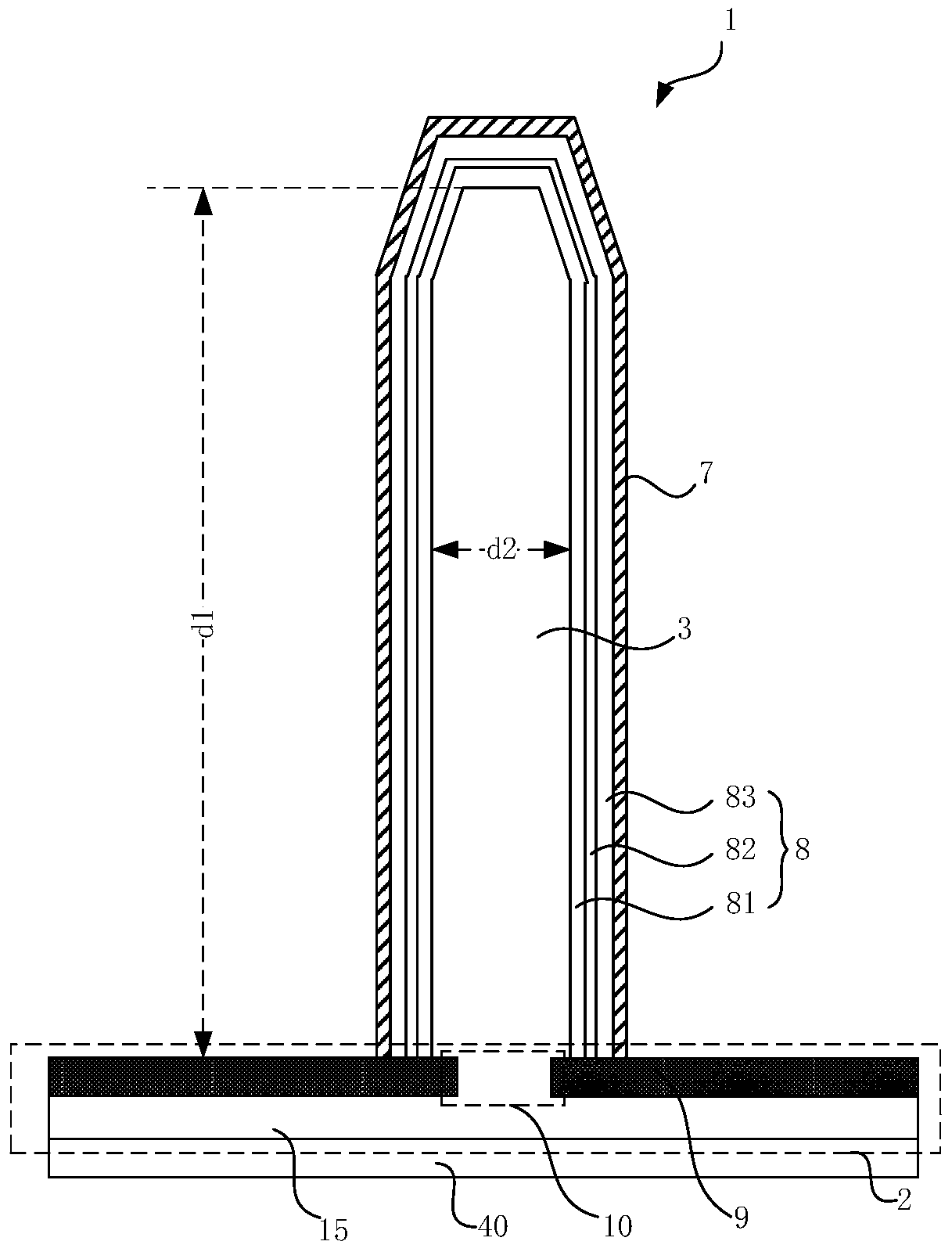

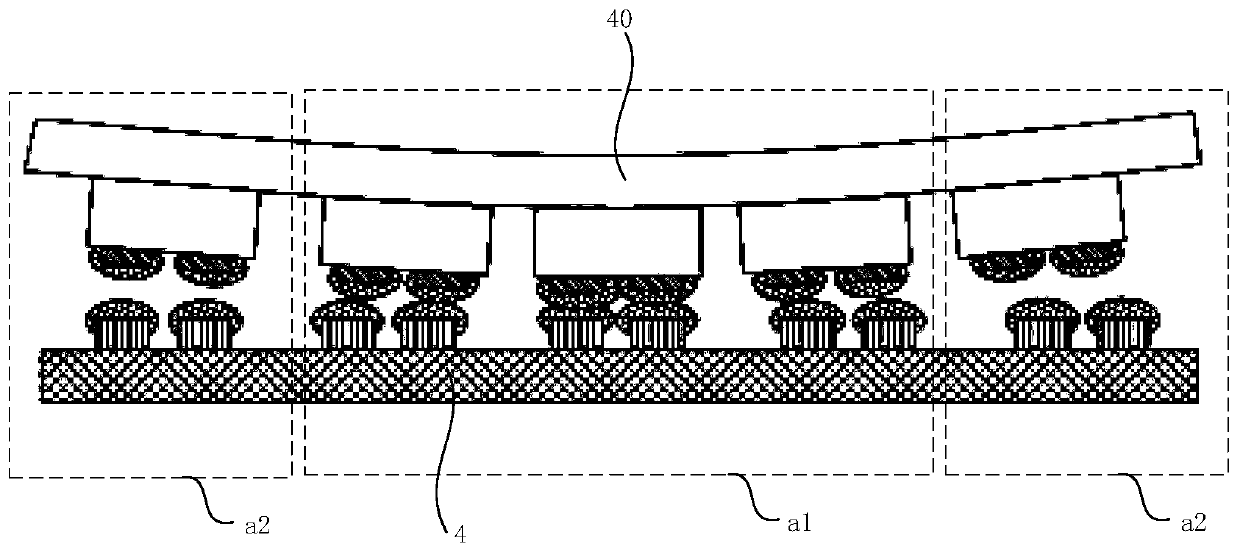

Display panel and display device

ActiveCN110444562ALarge luminous areaReduce dislocation densitySolid-state devicesIdentification meansDisplay deviceEngineering

The invention discloses a display panel and a display device. The display panel comprises a plurality of light-emitting devices each of which comprises a planar film layer and a columnar structure protruding from the planar film layer; and a driving backplane provided with bonding pad corresponding to the light-emitting devices one to one and covered by a flexible conductive structure, wherein thecolumnar structures of the light-emitting devices are inserted into the flexible conductive structure to electrically connect metal electrodes wrapping the columnar structures with the correspondingbonding pads. The display panel greatly reduces the influence of wafer warpage on the binding yield, and avoids the binding misalignment caused by the thermal mismatch between the driving backplane and the light-emitting device substrate.

Owner:CHENGDU VISTAR OPTEOLECTRONICS CO LTD

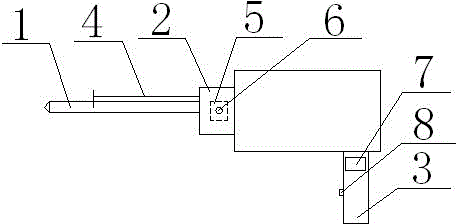

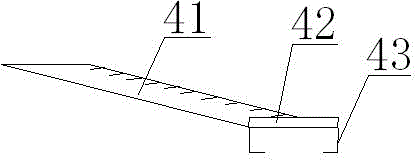

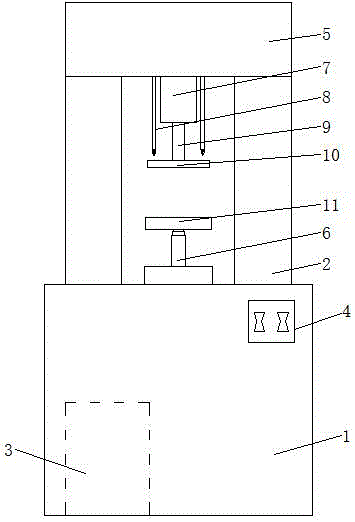

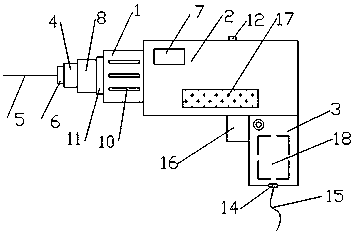

Electric drill with accurately locating function

InactiveCN104625166AThe hole position is accurateDrilling/boring measurement devicesPortable drilling machinesLaser rangingMeasurement device

The invention provides an electric drill with an accurately locating function. The electric drill comprises a drill bit, a drill bit installation portion and a handle. A drilling depth locating device is arranged on the front portion of the drill bit installation portion and comprises a measuring ruler, a pulling plate and a fixing button. The measuring ruler is connected with the drill bit installation portion through a reel. A laser range finder is arranged in the drill bit installation portion and connected to a power circuit of the electric drill in series. A laser emitting hole is formed in the surface of the drill bit installation portion. A distance display screen is arranged on the handle which is further provided with a laser range finder control switch. The distance display screen and the laser range finder control switch are connected with the laser range finder in series. Due to the fact that the electric drill is provided with the drilling depth measuring device and the position locating device, the hole depth can be accurately determined, the hole position can be accurately located, multiple drilled holes are uniform, and a hung piece can be set right.

Owner:XIAN SHUZHENG ELECTRONICS TECH

New fixture

InactiveCN110757201AEasy to fixEasy to clamp and fixMeasurement/indication equipmentsPositioning apparatusEngineeringMechanical engineering

Owner:天津世创机械制造有限公司

Drilling mould for flange connection hole at side of butterfly valve

InactiveCN101941091AGuaranteed interchangeabilityMeet the needs of drillingPositioning apparatusMetal-working holdersMating connectionButterfly valve

The invention relates to a drilling mould for a flange connection hole at the side of a butterfly valve, mainly comprising a ring-shaped drilling mould body and a drilling jig, wherein the ring-shaped surface of the drilling mould body is evenly distributed with drilling jig connection holes in cooperative connection with the drilling jig; and the concentric circle at one side of the drilling mould body is provided with a step table round spigot matched with the inner hole diameter of the butterfly valve body. The invention brings the beneficial effects of saving the labor and time consuming benchwork lining process and completing the drilling via directly installing the mould, guaranteeing the correct position of each hole and ensuring the interchangeability of the flange connection hole at the side of the butterfly valve. A double-row drilling jig connection hole design is adopted to satisfy the drilling demand of two flange connection holes with different specifications at the side of the butterfly valve, enlarge the using range and save the manufacturing cost.

Owner:天津津通瓦特阀门制造有限公司

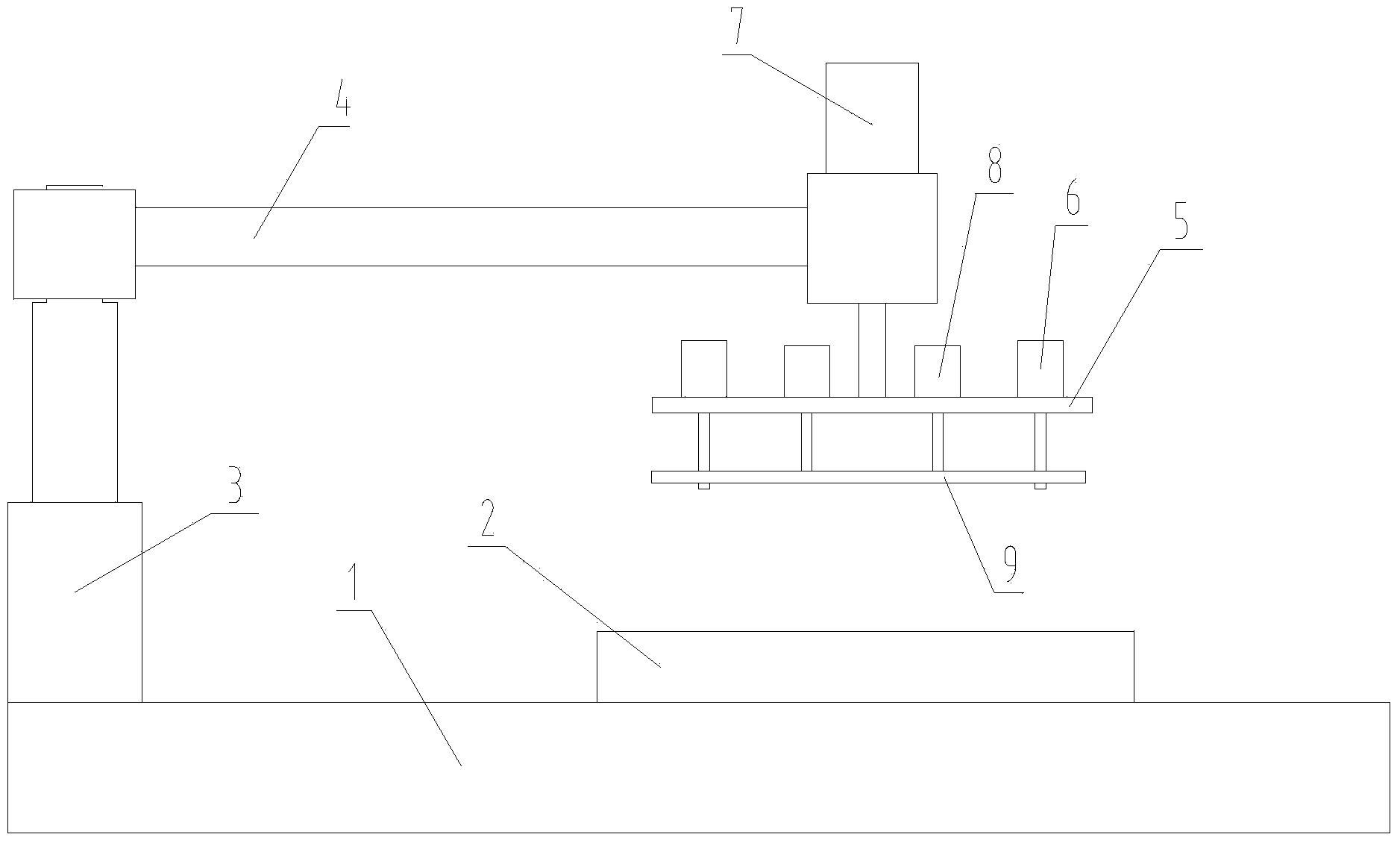

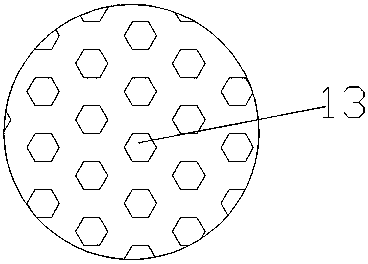

Wheel hub drilling device with accurate positioning

InactiveCN104209552AThe overall structure is simple and reliableThe hole position is accurateWheelsBoring/drilling machinesAxis cylinderHydraulic cylinder

The invention provides a wheel hub drilling device with accurate positioning, and belongs to the field of wheel hub manufacturing equipment. The device comprises a base, wherein a positioning base is arranged on the base; one side of the base is provided with an axis cylinder; a rotating rod sleeves on the axis cylinder; the front end of the rotating rod is provided with a disk; a plurality of holes are formed in the disk; a motor is arranged on the surface of the disk; the motor is connected with a drill to penetrate through the hole on the disk; the front end of the rotating rod is provided with a hydraulic cylinder; a hydraulic rod on the hydraulic cylinder is connected with the disk to stretch the height of the disk so as to be suitable for the wheel hub with different thicknesses. The device is simple and reliable in structure; one drill is aligned with the hole on the wheel hub, the disk is pressed, the other drills begin drilling so as to ensure that the position of the hole on the wheel hub is exact, the positioning is accurate; multiple holes can be processed for the wheel hub, and the efficiency is high.

Owner:安徽省巢湖市宏顺机械铸造有限公司

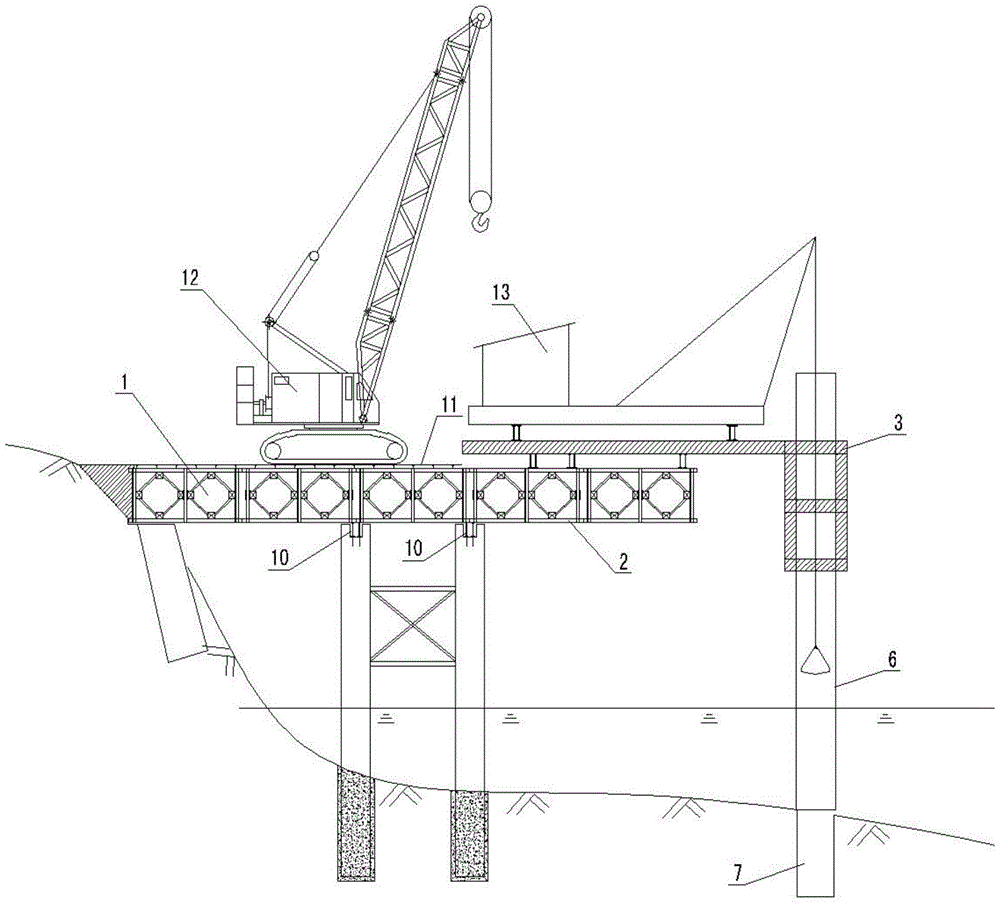

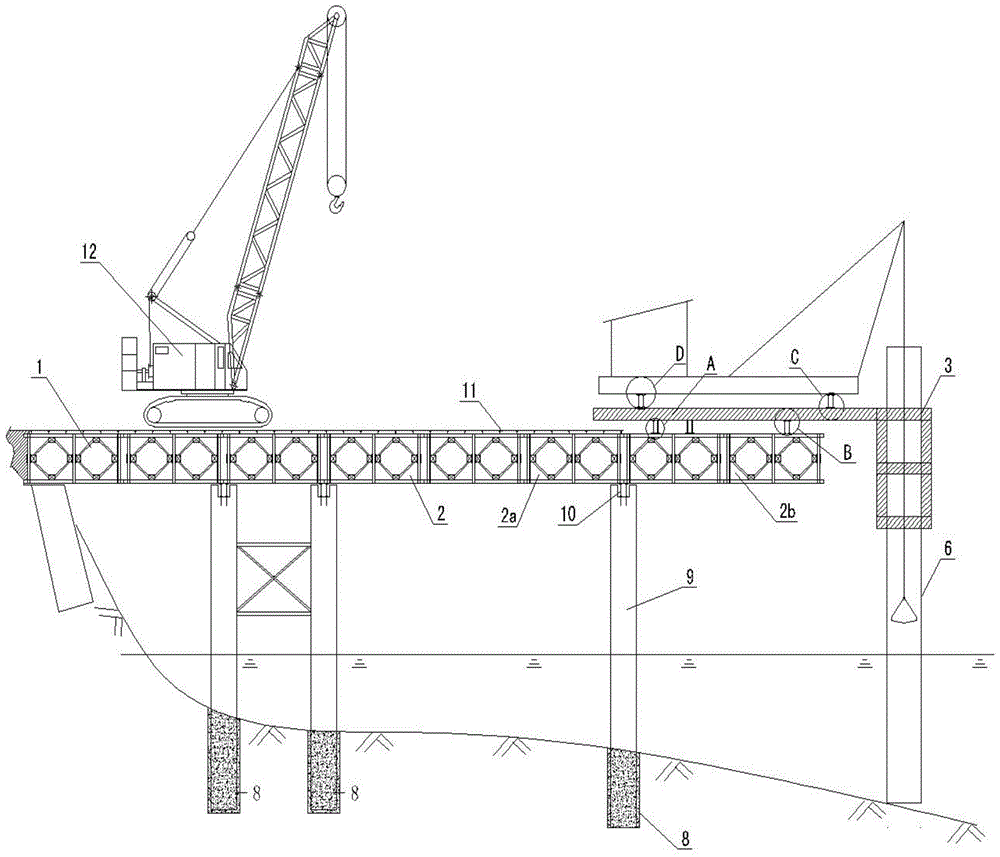

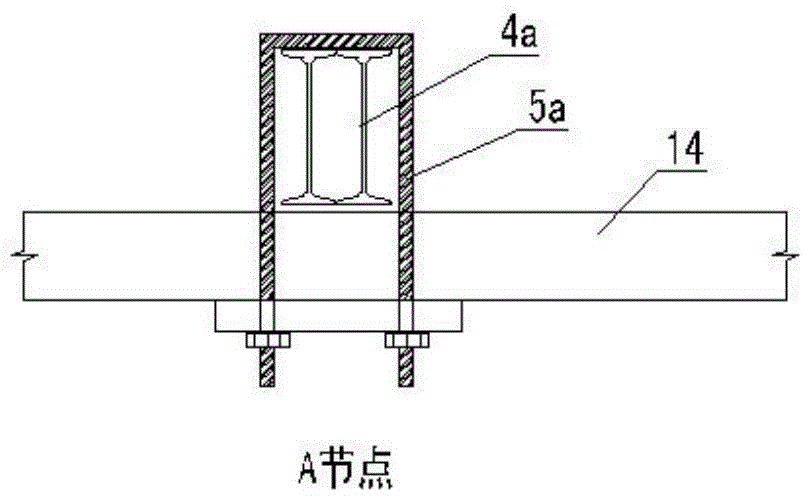

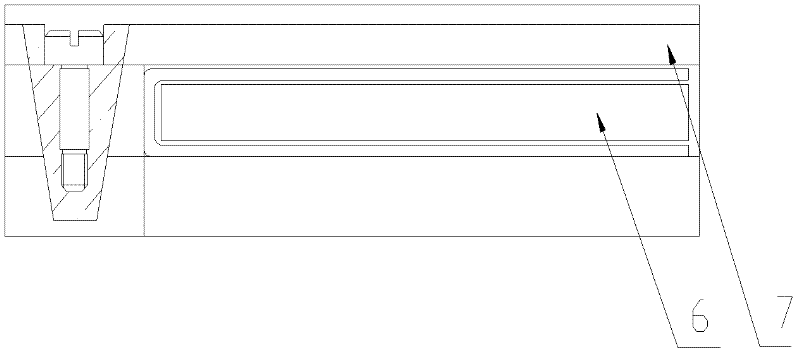

Construction method and facilities of steel trestle bridge with percussion drilling limit hole implantation combined with crawler crane

ActiveCN105133506BAvoid safety hazardsEnsure construction safetyBridge erection/assemblyBulkheads/pilesEngineeringCantilever

The invention discloses a steel trestle construction method and facility with percussion drill limiting pore-forming implantation and a crawler crane combined. The construction method comprises the steps that construction is carried out from one end of a steel trestle to the other end of the steel trestle one by one so that the complete trestle can be constructed, and the next span of cantilever beret piece beam is formed on the previous span of steel trestle which has already been constructed; a limiting rack and a percussion drill are fixed to the next span of cantilever beret piece beam through double-buckling H-steel and deformed steel bar U-shaped clamps, and accordingly the plane position of the overhung limiting rack is located at the plane position of the next span of steel pipe piles of the steel trestle; a steel casing is placed in the limiting rack, and a hammer of the percussion drill hammers bedrock in the steel casing so that pile holes can be formed. According to the steel trestle construction method and facility, under the construction conditions of heavy flow of water and oblique river bed rock surfaces, there is no need for operators to drill a trestle pipe pile foundation by blasting through underwater operation, overwater equipment such as a ship does not need to enter the scene, the potential safety risks of operation by the operators and the ship under the condition of heavy flow of water are avoided, engineering cost is lowered, and construction safety is improved.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD

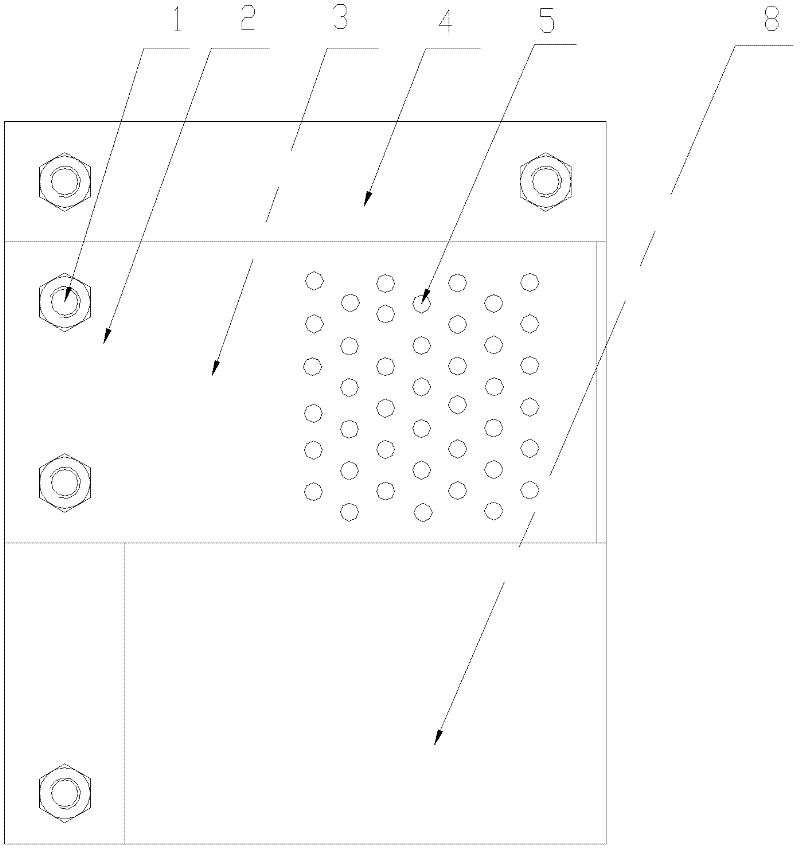

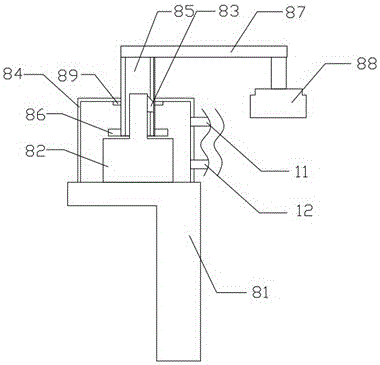

Strip bar flat cable clamp perforating tool for generator stator

InactiveCN102377293AEasy to manufactureAccurate locationManufacturing dynamo-electric machinesCost savingsStator

The invention relates to a strip bar flat cable clamp perforating tool for a generator stator, and belongs to the technical field of generators. The strip bar flat cable clamp perforating tool for the generator stator is characterized by comprising a positioning plate, a shim plate, an aperture plate and a bottom plate, wherein the aperture plate is fixed on the bottom plate by bolts; the positioning plate for perforating and positioning of a flat cable clamp is fixed on the bottom plate; and the shim plate is arranged in the flat cable clamp. The tool has the advantages of light weight, simplicity, easiness in manufacturing, accurate hole position, good concentricity, cost saving, accurate data, time and labor saving, high efficiency and the like.

Owner:TIANJIN TIRNFR HEAVY HYDROELECTRIC FRCILITY CO LTD

A large flange type workpiece drilling positioning device

InactiveCN110421195BUniform Position AccuracyGuaranteed positioning accuracyPositioning apparatusDrill jigsStructural engineeringMechanical engineering

The invention discloses a large-scale flange type workpiece punching positioning device. The device comprises a horizontally arranged worktable; a vertically arranged drilling machine is arranged on the right side of the top surface of the worktable; a vertical positioning plate support is arranged on the left side of the drilling machine; a horizontal positioning plate is arranged in the positioning plate support; a positioning sleeve is arranged at the left part of the positioning plate; a round flange plate support is arranged at the left part of the positioning plate support; a flange plate is arranged at the upper part of the flange plate support; a central positioning pin is arranged at the center of the top surface of the flange plate; a horizontally arranged positioning rod is arranged at a relative position at the top of the flange plate; vertical through holes are formed in both ends of the positioning rod; a plurality of machining holes are uniformly formed in the circumferential direction of the flange plate; and an auxiliary support is arranged at a relative position at the lower part of the flange plate. The device has the beneficial effects of punching holes with accurate positions in the large-scale flange type workpieces and being simple to operate.

Owner:ZHENGZHOU UNIV

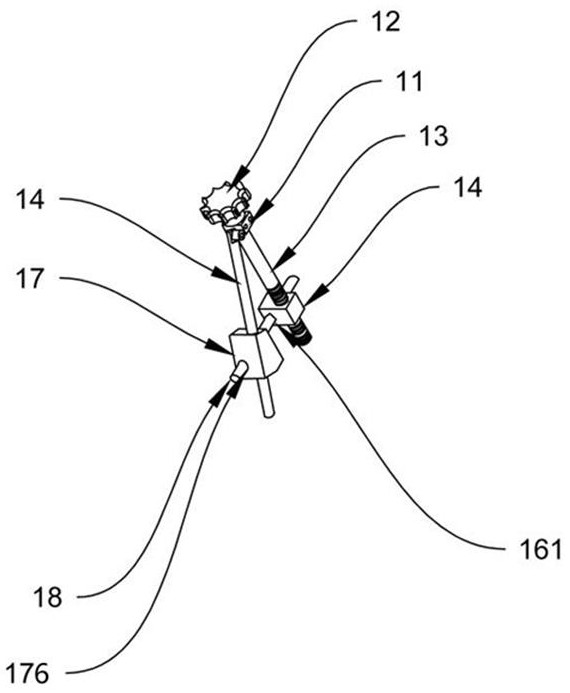

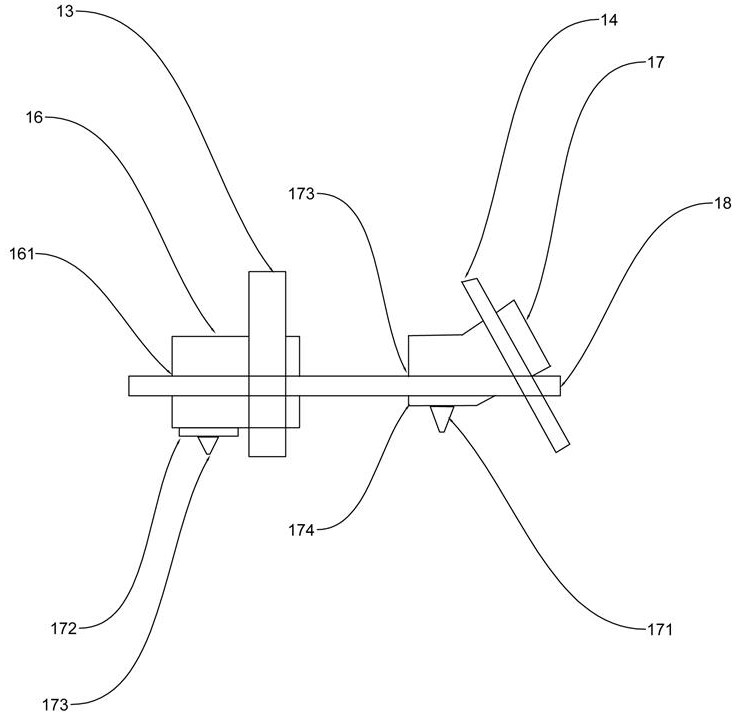

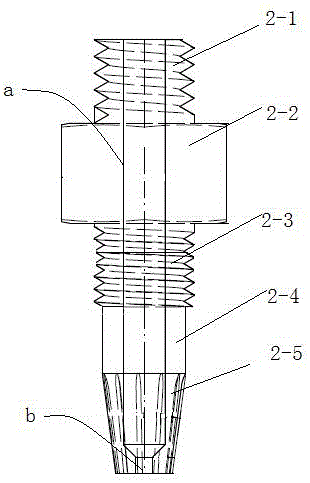

Trepanning device used for copper bar insulation sleeve and use method thereof

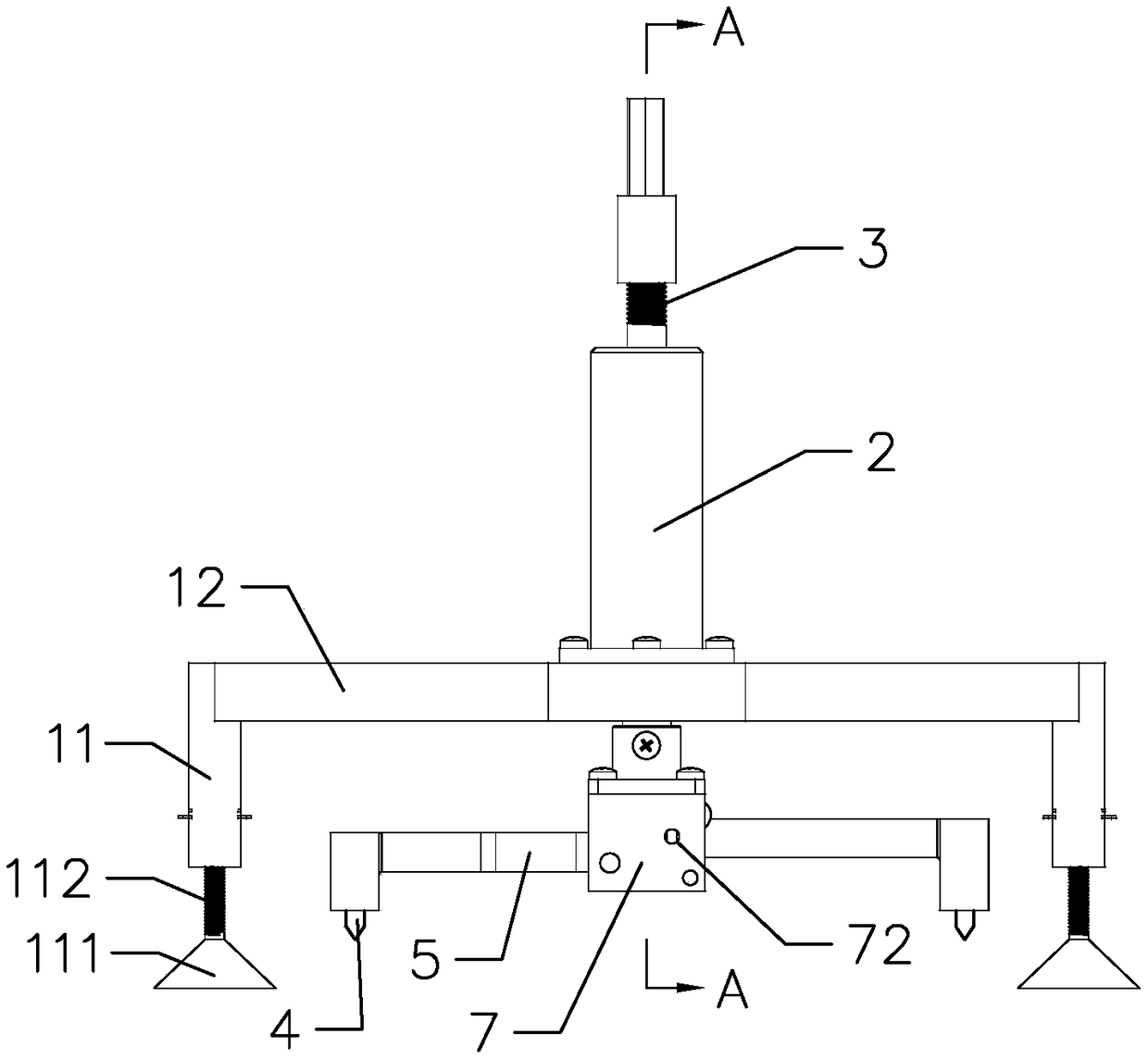

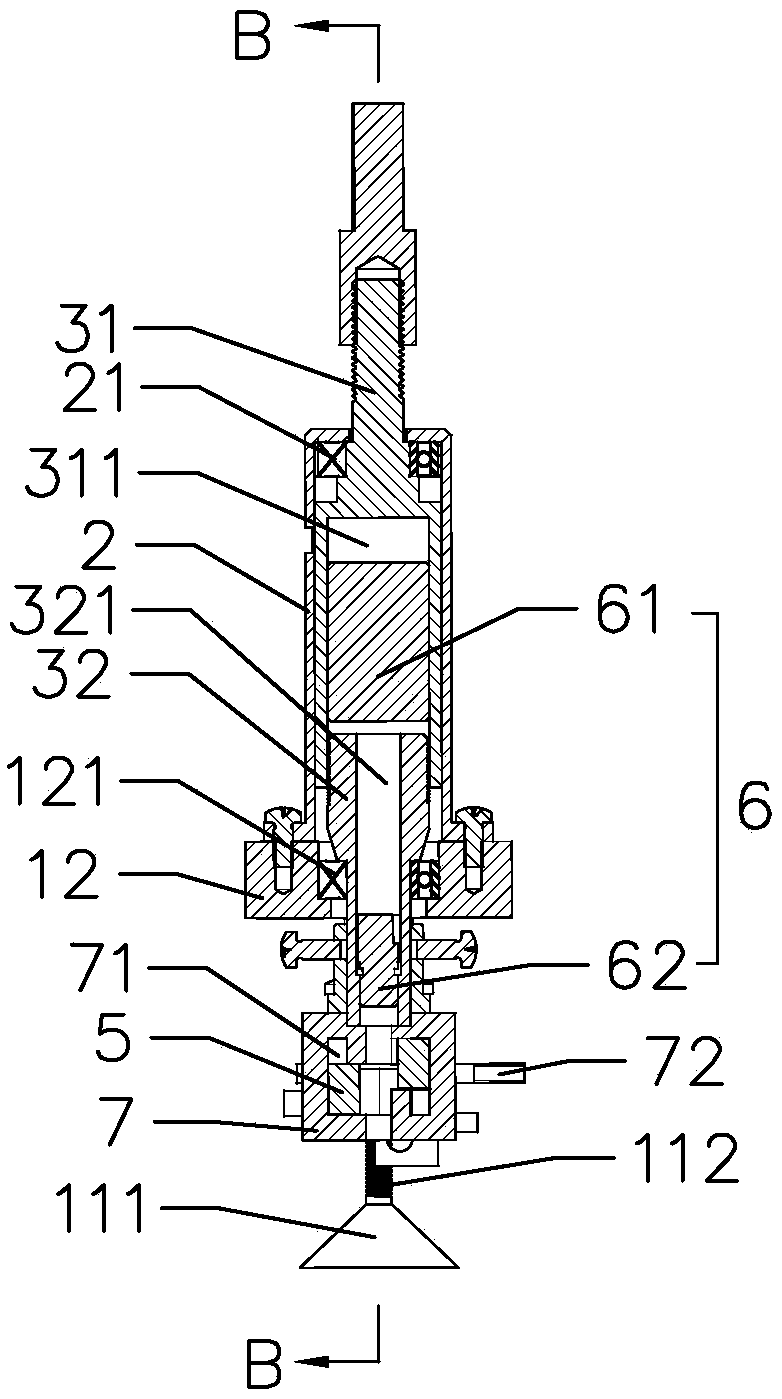

PendingCN108746745AEven by forceAvoid scratchesDrilling/boring measurement devicesLarge fixed membersEngineeringCopper

The invention provides a trepanning device used for a copper bar insulation sleeve. The device comprises a mounting frame and a trepanning device; the mounting frame comprises two supporting feet anda cross beam for connecting the two supporting feet, the trepanning device comprises a sleeve, a connecting screw rod and trepanning knives, the trepanning knives are vertically placed, knife bits face downwards, the two trepanning knives are arranged and are symmetrically arranged along the connecting screw rod, the lowest points of the knife bits of the two trepanning knives are located on the same horizontal plane, the trepanning knives and the connecting screw rod are connected through connecting strips, the connecting strips are horizontally arranged and move in the length direction, theinteriors of the connecting screw rod is hollow to form a mounting cavity, a laser assembly is arranged in the mounting cavity, when the two trepanning knives rotate, the cutting thicknesses of the insulation sleeve are the same, in the trepanning process, the copper bar stress is uniform, a zinc coating of the copper bar is prevented from being scratched, and use is reliable. The invention further provides a use method of the trepanning device. The rotating type trepanning work is adopted, and in the trepanning process, the damage to the zinc coating of the copper bar is avoided.

Owner:杭州电力设备制造有限公司临安恒信成套电气制造分公司 +2

Frame punching device and method for advertising board manufacturing

PendingCN113681633ANot easy to shiftThe hole position is accurateMetal working apparatusEngineeringWorkbench

The invention relates to the technical field of advertising, in particular to frame punching device and method for advertising board manufacturing. A advertising board is placed on a bottom plate, a pressing plate moves up and down through adjustment of an adjusting component, so that the pressing plate fixes the advertising board in the height direction, a side face limiting block moves left and right on the bottom plate through adjustment of the adjusting component, and therefore the side face limiting block limits the side face of the advertising board, the advertising board is fixed to a workbench, and the advertising board is perforated through the work of a perforating assembly, so that the advertising board is not prone to displacement in the perforating process, and the perforating position is accurate.

Owner:HUZHOU QINGMI MEDIA TECH CO LTD

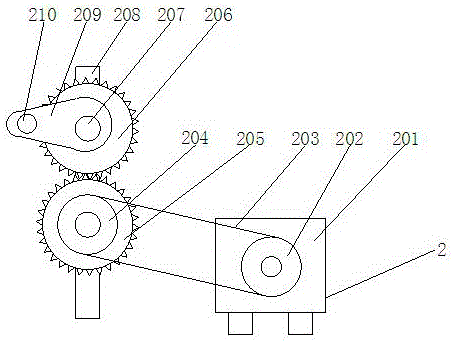

Punching machine with fixing function

InactiveCN106042054AThe hole position is accurateAvoid damage and wasteMetal working apparatusPush and pullExtrusion

The invention discloses a punching machine with a fixing function. The punching machine comprises a base. A drive device is fixedly connected to the inner wall of the base and comprises a motor. The motor is fixedly connected to the inner wall of the base. A first belt wheel is fixedly connected to a rotating shaft of the motor and movably connected with the surface of a second belt wheel through a belt. The second belt wheel is fixedly connected to the surface of a first gear. According to the punching machine with the fixing function, through matched usage of the motor, the first belt wheel, the belt, the second belt wheel, the first gear and a second gear, an object can be well fixed during punching, and the situation that in the object punching process, due to the fact that fixation is not adopted, deviation of the punching position happens is avoided; and through the arrangement of a connecting plate, a connecting block, a push and pull rod and a movable extrusion block, the object cannot swing in the punching process, and therefore the position of a hole of the object is more accurate in the punching process, and the object is prevented from being damaged and wasted.

Owner:无锡博成洋超声设备有限公司

Perforating device for garment production

ActiveCN112089144ASimple tensioning processUniform tension surfaceClothes making applicancesElectric machineryStructural engineering

The invention discloses a perforating device for garment production, and belongs to the field of garment production. The perforating device comprises a base; a plurality of fixing plates are fixed inthe middle of the top wall of the base; two tensioning transmission mechanisms and two buffer pressing mechanisms are symmetrically arranged on the top wall of the base by taking the plurality of fixing plates as the center; a lifting plate is arranged above one side of each fixing plate in a sliding mode; a second motor is fixed to the upper portion, close to one side of the corresponding fixingplate, of each lifting plate; a one-way threaded rod is installed at the driving end of each second motor; the bottom end of each one-way threaded rod is inserted into the top end of the correspondingfixing plate and is in threaded connection with the corresponding fixing plate; and a third motor is fixed to one side of the corresponding lifting plate and located above the corresponding second motor. According to the scheme, cloth can be conveniently and efficiently tensioned, and tensioning force is uniform, so that wrinkles of the cloth cannot be caused; and a to-be-punched point of the cloth can be supported during punching, so that the to-be-punched point of the cloth is prevented from deviating, and the punching position is more accurate.

Owner:EASTERN LIAONING UNIV

Punching device with relatively high drilling efficiency for hardware connecting piece

InactiveCN105834479AImprove drilling efficiencySimple structureBoring/drilling machinesPunchingControl switch

The invention discloses a punching device with relatively high drilling efficiency for a hardware connecting piece. The punching device comprises a workbench, wherein a storage battery is fixedly connected inside the workbench; a control switch fixing plate is fixedly connected on the front surface of the workbench; an electric telescopic rod is fixedly connected at the middle end of the top of the workbench; a hardware connecting piece placing plate is fixedly connected at the telescopic end of the electric telescopic rod; a hardware connecting piece placing groove is formed in the front surface of the hardware connecting piece placing plate; a bracket is fixedly connected on the back surface of the workbench; a work box is fixedly connected on the bracket; and a motor is fixedly connected inside the work box. According to the punching device with relatively high drilling efficiency for the hardware connecting piece, the structure is simple, the operation is convenient, a punching position of the hardware connecting piece is limited in advance, a drill pipe can directly perform punching operation on the hardware connecting piece, the punching position is more precise, the location selection is more accurate, the punching speed is increased, and the working efficiency of the punching device is improved.

Owner:CHANGZHOU JINHAIJI MACHINERY MFG

A Multifunctional Electric Drill Capable of Precise Positioning

ActiveCN106346048BEasy to store and placeSimple structureDrilling/boring measurement devicesPortable power-driven toolsLaserDrill bit

The invention provides a multifunctional electric drill capable of accurately positioning. The multifunctional electric drill comprises an electric drill body, wherein the electric drill body comprises a swivel, an electric drill main body and a handle; a chuck is coaxially arranged at the front end of the swivel; a drill bit is clamped on the chuck; a positioning device is arranged on the chuck; a positioning display screen is arranged on the electric drill main body; a dust collection device is further arranged at the front end of the swivel and is arranged between the chuck and the swivel; a plurality of dust suction holes are uniformly formed in the front end surface of the dust collection device; a plurality of dust discharging rails are uniformly arranged on the side surface of the swivel along the periphery; an illumination device is arranged between the dust collection device and the swivel; a heat dissipation hole is formed in the rear end of the electric drill main body; a storage battery is arranged in the handle; a charging wiring hole is formed in the bottom of the handle; and the charging wiring hole is connected with a power line. The multifunctional electric drill capable of accurately positioning is simple in structure and reasonable in design and can be used for absorbing generated dust when being used for drilling; and the multifunctional electric drill is provided with a laser positioning device, so that hole depth and hole position can be accurately positioned.

Owner:扬州市国凤工艺品有限公司

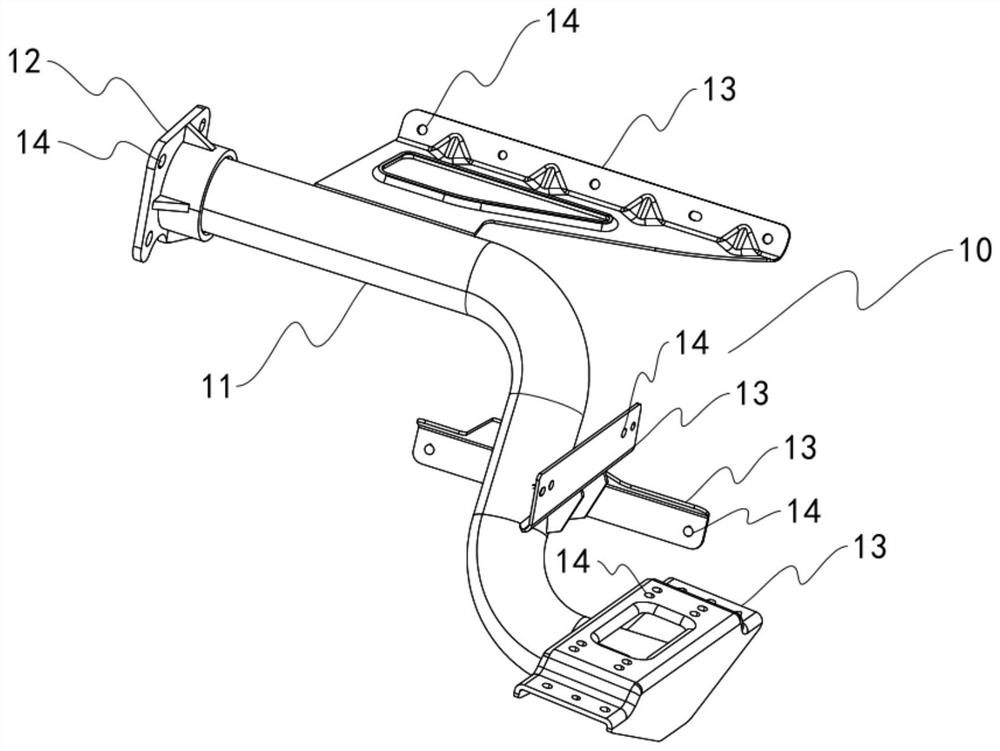

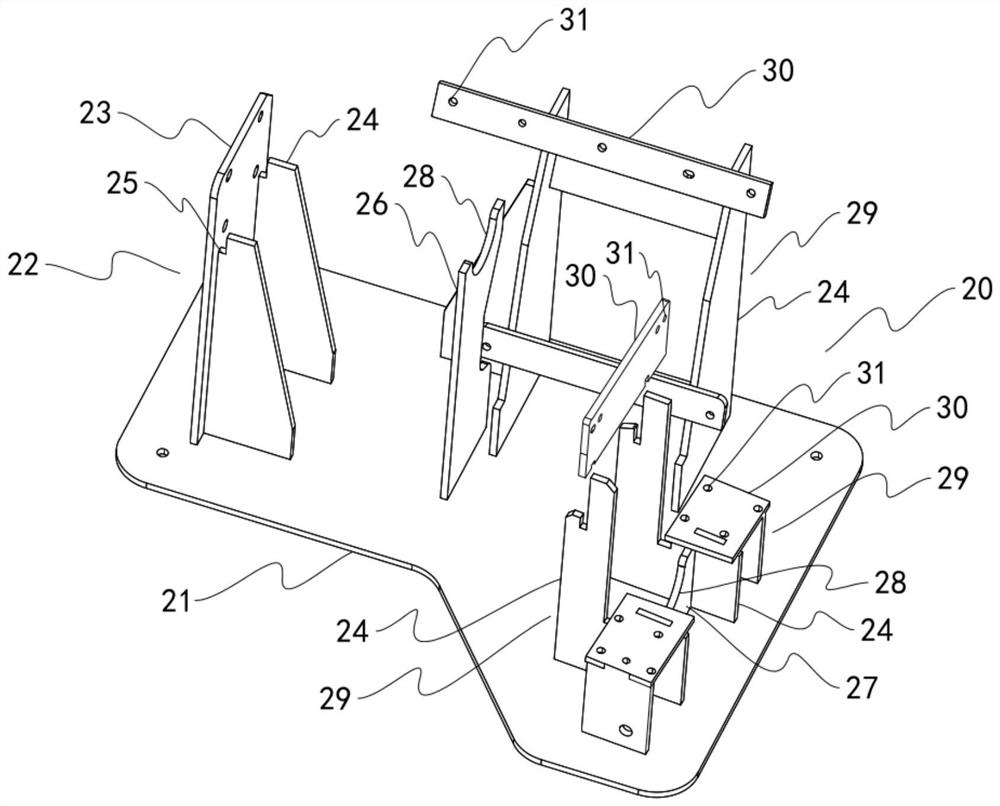

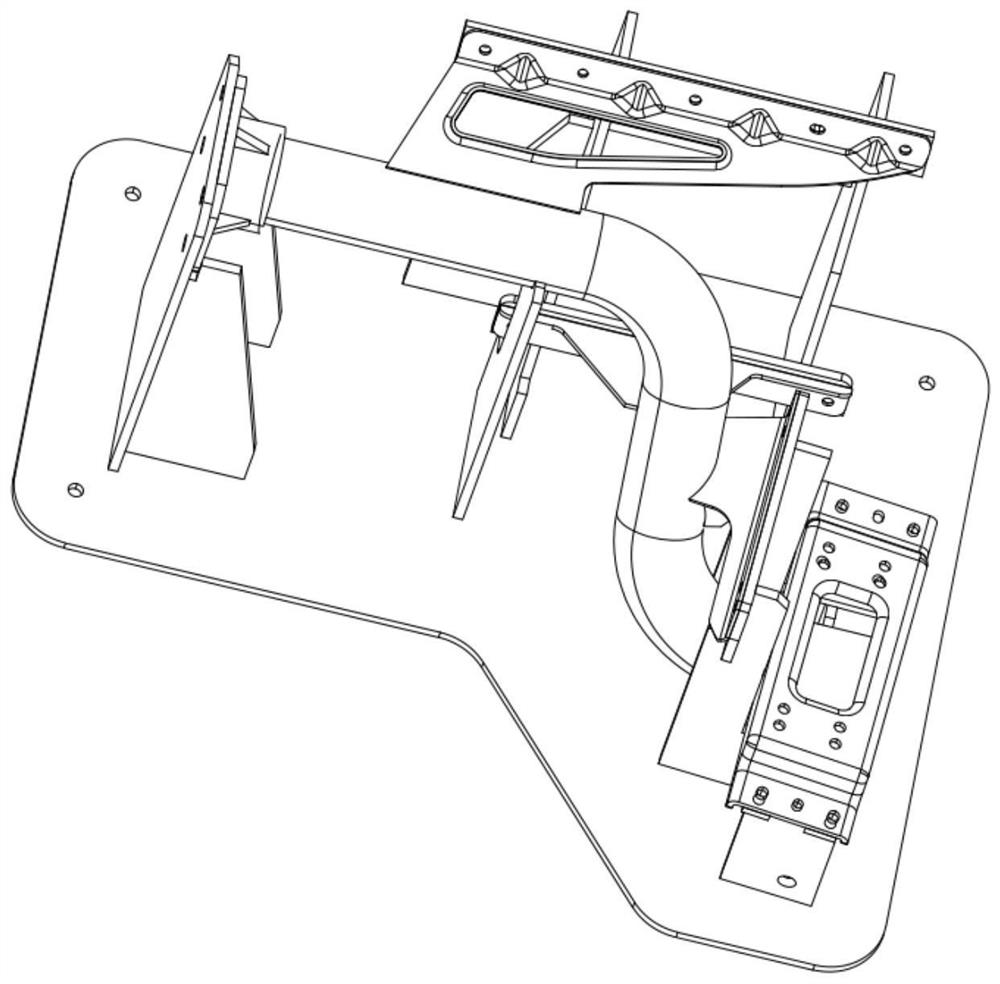

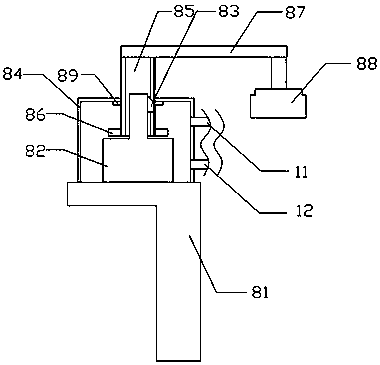

Step tubular beam welding fixture

PendingCN111843337AImprove welding efficiencyImprove welding precisionWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention discloses a step tubular beam welding fixture. The step tubular beam welding fixture comprises an S-shaped tube body and multiple supports, wherein the supports are arranged from the front end to the rear end of the tube body in sequence. A flange is further connected with the front end of the tube body. The welding fixture comprises a base. A front-end tube body supporting piece corresponding to the front end of the tube body is arranged on the base, a middle tube body supporting piece corresponding to the position, close to the middle, of the front end of the tube body is arranged on the base, and a rear-end tube body supporting piece corresponding to the rear end of the tube body is arranged on the base. The front-end tube body supporting piece is as high as the middle tube body supporting piece. The rear-end tube body supporting piece is lower than the front-end tube body supporting piece and the middle tube body supporting piece. A rectangular clamping groove in cooperative positioning with the side edge of the flange is formed in the front-end tube body supporting piece. Arc-shaped clamping grooves in cooperative positioning with the tube body are formed in themiddle tube body supporting piece and the rear-end tube body supporting piece respectively. Multiple support supporting pieces corresponding to the supports are arranged on the base. Connecting plateswhich correspond to the supports and are used to fix the supports are arranged on the support supporting pieces respectively.

Owner:四川丰科汽车部件有限公司

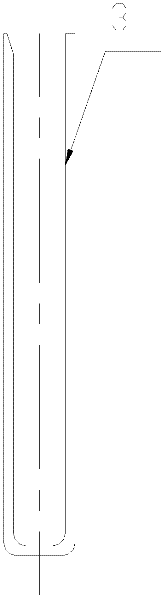

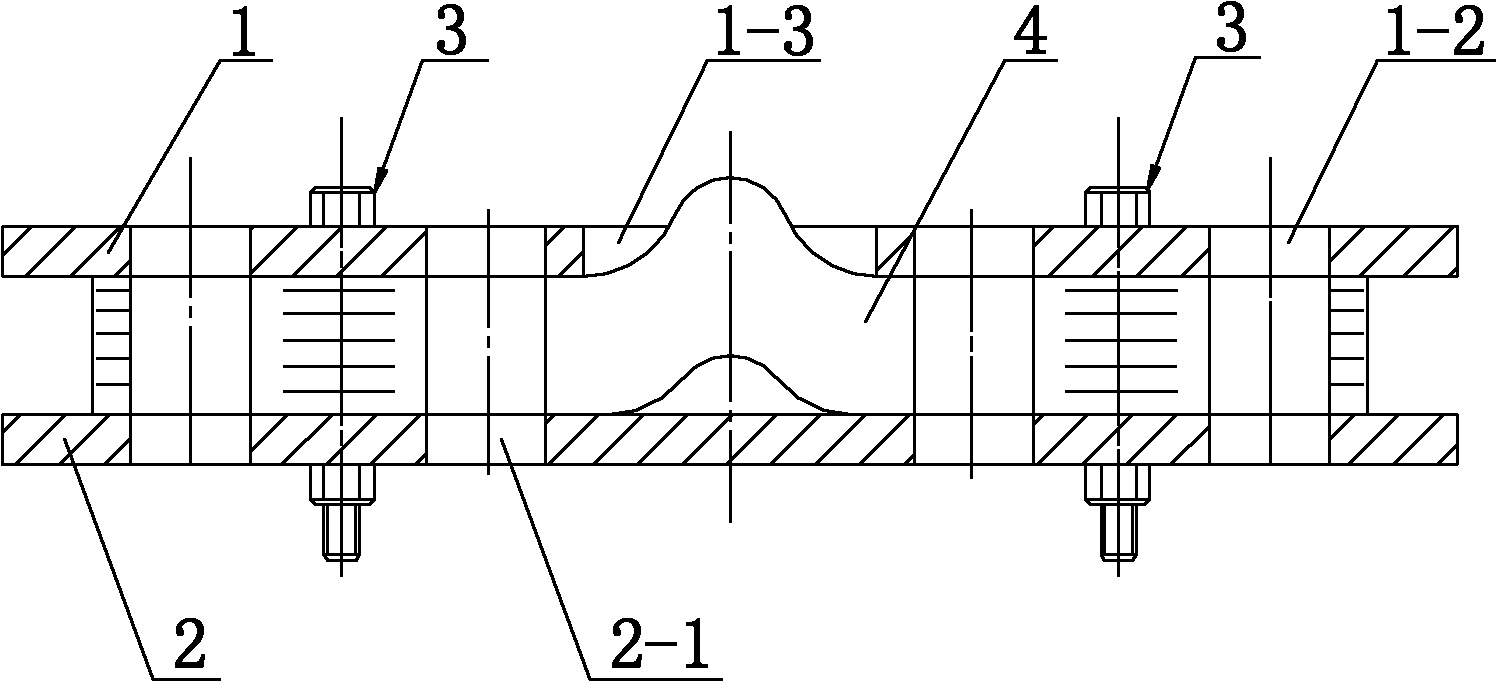

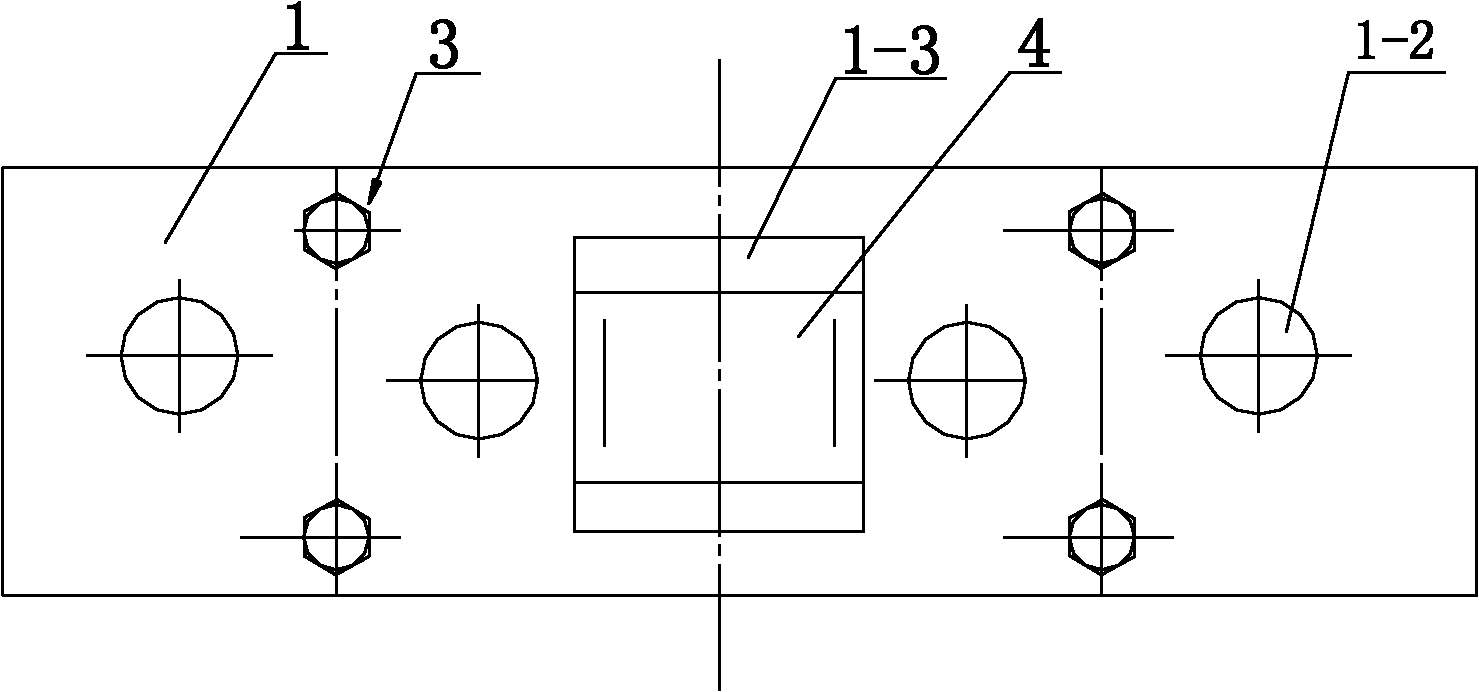

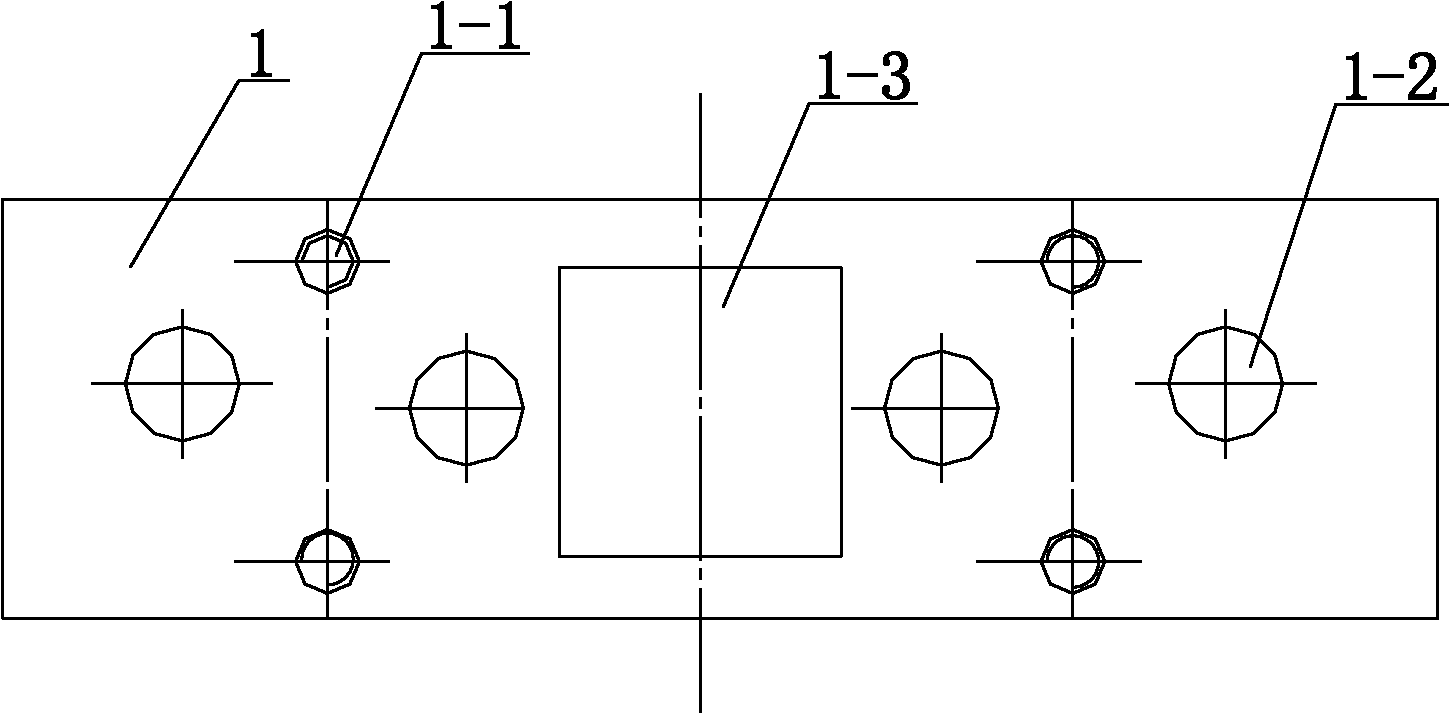

Large-scale hydro-generator rotor connecting sheet punching tool

InactiveCN102013769AThe hole position is accurateHigh concentricityManufacturing stator/rotor bodiesPunchingEngineering

The invention relates to a large-scale hydro-generator rotor connecting sheet punching tool. The large-scale hydro-generator rotor connecting sheet punching tool is characterized by comprising an upper pressing plate, a lower pressing plate and fastening components, wherein the fastening component is connected with the upper pressing plate and the lower pressing plate; screwed holes through which fasteners pass and preset holes for processing are formed on the upper pressing plate; the hollow distance between the preset holes is required to be consistent with the pitch of the connected sheet which is punched; a preset opening of a connecting sheet dome is accommodated in the center of the upper pressing plate; screwed holes and preset holes which correspond to those of the upper pressing plate are formed on the lower pressing plate; and the fastening components are arranged in the corresponding screwed holes. The large-scale hydro-generator rotor connecting sheet punching tool has the advantages of accurate position, high concentricity and no deformation of holes drilled on the rotor connecting sheet, no popup of the connecting sheet, simpleness in operation, cost saving, accurate data, time saving, labor saving, high efficiency and the like.

Owner:TIANJIN TIRNFR HEAVY HYDROELECTRIC FRCILITY CO LTD

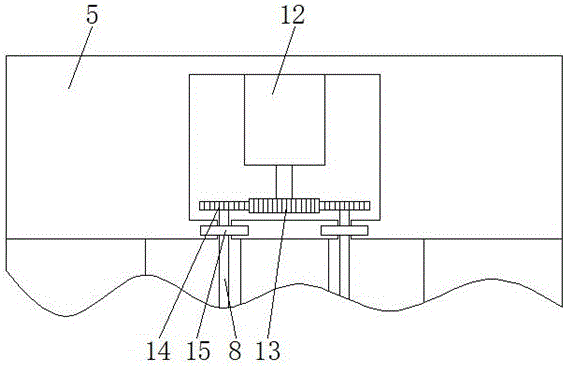

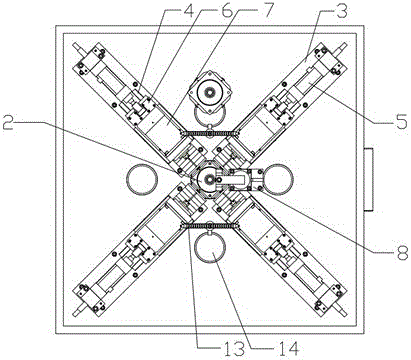

Motor blade cover drilling device

ActiveCN106424816AImprove work efficiencyThe hole position is accurateBoring/drilling componentsBoring/drilling machinesEngineeringMechanical engineering

The invention relates to a motor blade cover drilling device. The motor blade cover drilling device comprises a workbench and further comprises a material bearing frame and drilling device bodies. The material bearing frame is in a cylinder shape of which the top surface is provided with an opening, and four through holes are formed in the same height position of the middle-lower portion of the material bearing frame in a circumference array mode. The material bearing frame is fixedly installed in the center of the workbench. Each drilling device body comprises a base, a linear guide rail, an air cylinder and a drilling power head. Each base is fixedly installed on the workbench. Each linear guide rail is fixed to the end, close to the material bearing frame, of the corresponding base and is parallel to the axis line of the corresponding through hole. Each drilling power head is slidably installed on the corresponding linear guide rail, and the axis line of each drilling power head is aligned to the axis line of the corresponding through hole. Each air cylinder is fixedly installed at the end, away from the material bearing frame, of the corresponding base. The top of each air cylinder is fixedly connected to the tail end of the corresponding drilling power head. The four drilling device bodies are fixed to the workbench around the material bearing frame and are aligned to the four through holes of the material bearing frame correspondingly. The working efficiency is greatly improved, and in addition, the hole positions are also accurate, so that substandard products are not produced.

Owner:浙江佳雪微特电机有限公司

A rapid positioning and opening device for radiotherapy thermoplastic film

ActiveCN111617392BAvoid stabbingImprove comfortMetal working apparatusX-ray/gamma-ray/particle-irradiation therapyThermoplasticPatient comfort

The invention discloses a rapid positioning and opening device for a thermoplastic film for radiotherapy, which comprises a sleeve with an open lower end; the sleeve is also provided with a liftable blade mounting plate and barbs, and there are multiple barbs. Each barb is located outside the blade mounting plate; a plurality of side pressure plates telescopic to the center of the sleeve are also installed on the side wall of the sleeve, and a detachable cutting blade and a lower pressure plate are installed on the blade mounting plate, and the lower pressure plate Located on the inside of the cutting blade. In the process of opening holes in the low-temperature thermoplastic memory film, the invention does not need to wait for the low-temperature thermoplastic memory film to cool, harden, and shape the patient's body surface, and can realize "online" hole opening at any position on the patient's body surface, and the low-temperature heat The plastic memory film is far away from the patient's body surface during the cutting process, and the patient's comfort is better; at the same time, the invention can quickly complete the opening process, reducing the waiting time of the patient and the workload of the technician, so that after the low-temperature thermoplastic memory film is opened The incision is regular and smooth, and the structure is simple and easy to operate.

Owner:SICHUAN MIANYANG 404 HOSPITAL

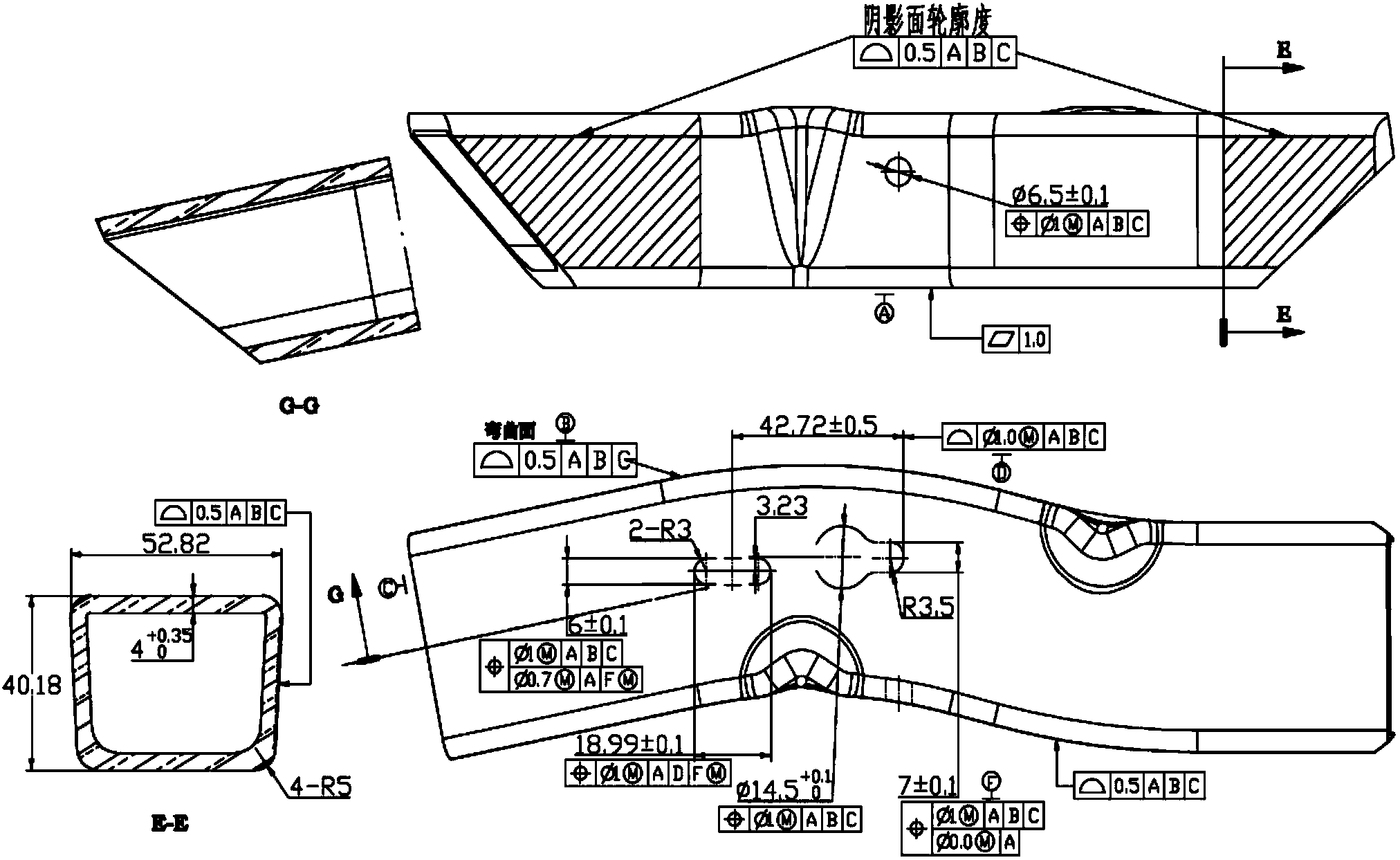

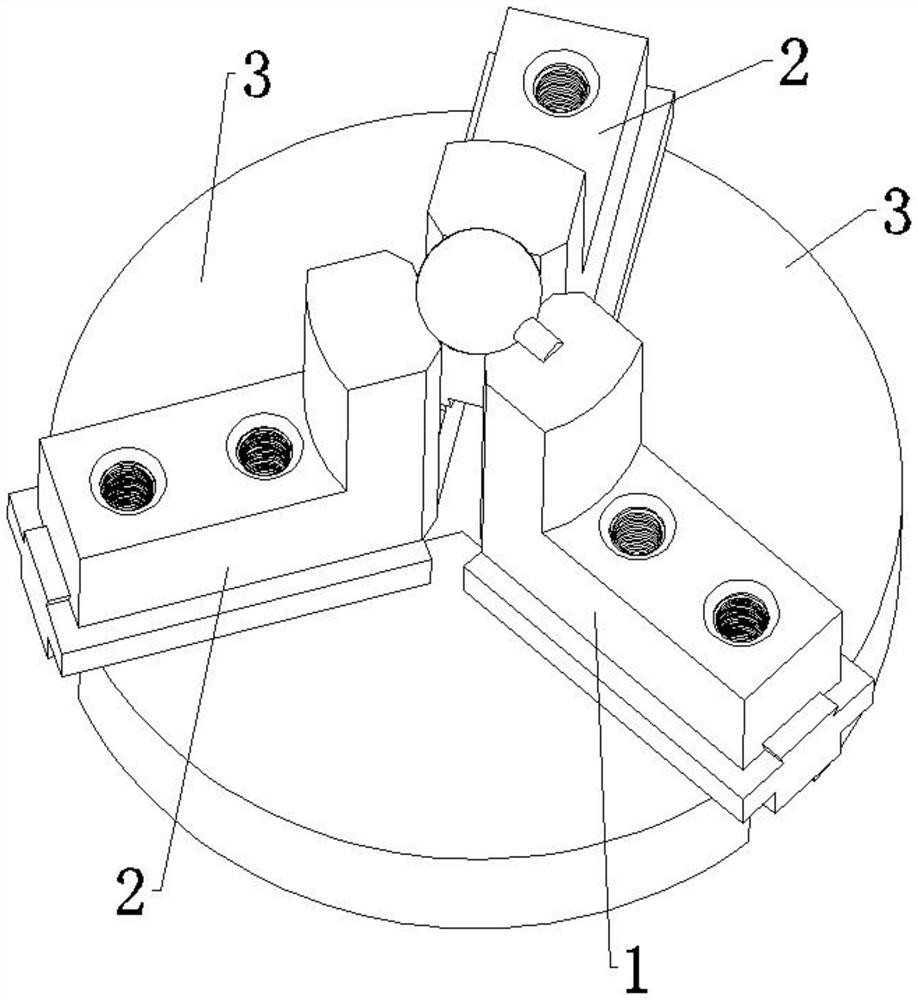

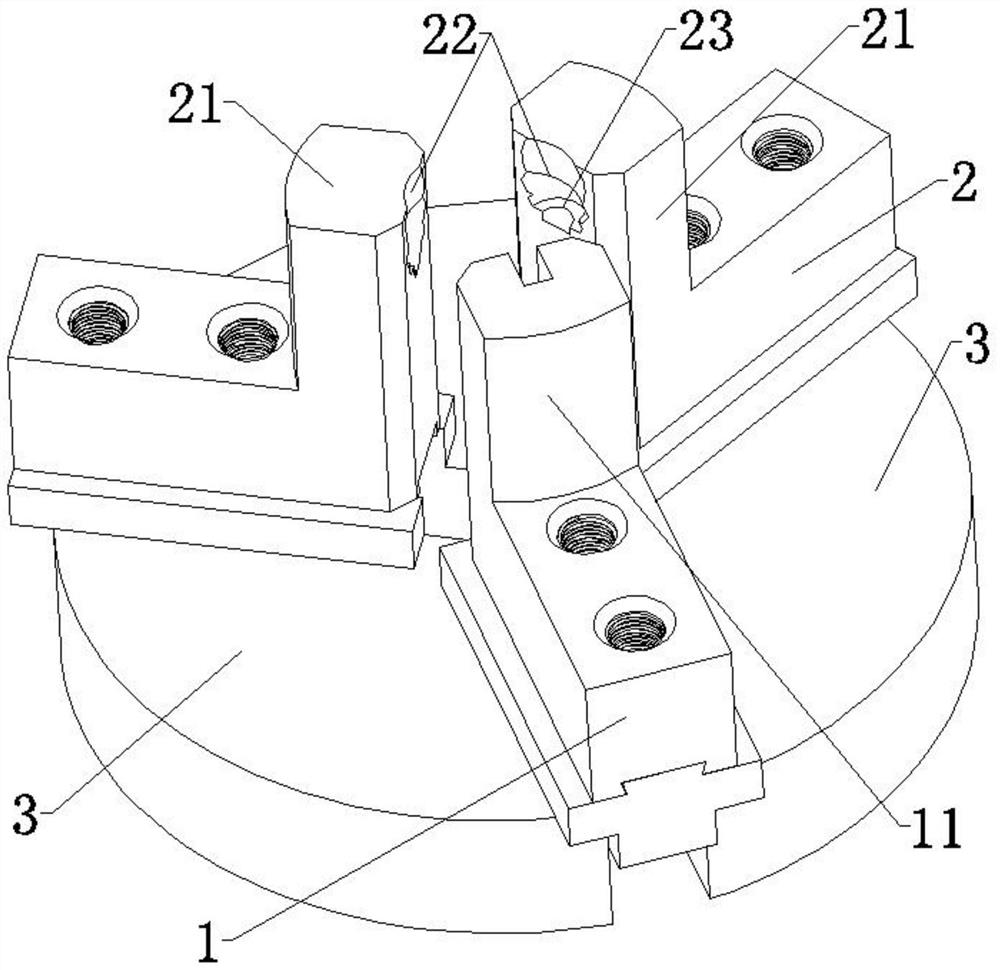

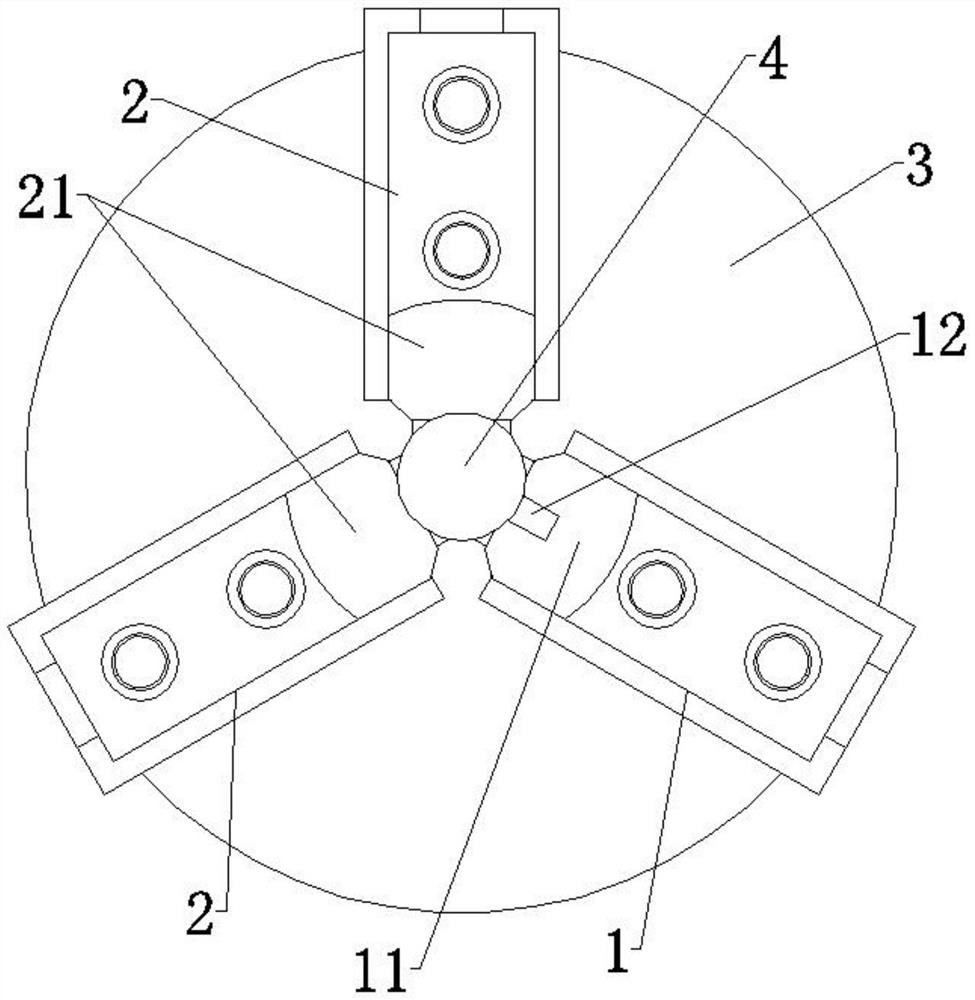

Double-face integrated machining clamp of pumping connector and machining method of double-face integrated machining clamp

The invention discloses a double-face integrated machining clamp of a pumping connector and a machining method of the double-face integrated machining clamp, and belongs to the technical field of pumping connector machining. The double-face integrated machining clamp comprises a connecting rod clamping jaw, two ball clamping jaws and a chuck, and the connecting rod clamping jaw, the two ball clamping jaws and the chuck form a three-jaw chuck. Through the device, the two end faces can be machined together by clamping raw materials of the pumping connector at a time, the parallelism of the two end faces is ensured, an inner hole of the pumping connector is machined together without disassembling the connector, and the perpendicularity of the axis of the inner hole of a ball and the two end faces is ensured; and the device can clamp the pumping connector, the position precision of a connecting rod and an opening of the ball is ensured, machining in a turning mode is realized, the machining precision is high, the circular arc of the inner hole is smoother, the hole surface precision is high, and the hole diameter precision is better controlled, so that the machining method based on the device not only ensures the machining precision, but also improves the efficiency.

Owner:福州臻宝金属有限公司

Louver blade machining device for wind resistance and noise reduction

ActiveCN114290060AGuaranteed machining accuracyRealize automatic processingOther manufacturing equipments/toolsMotor driveClassical mechanics

The shutter blade machining device for wind resistance and noise reduction comprises a clamping mechanism and a drilling mechanism, the clamping mechanism comprises a clamping groove used for supporting a blade and a pressing plate used for pressing the blade, and the drilling mechanism comprises drill bits which are symmetrical up and down; the device further comprises a cutting mechanism and a supporting mechanism, the cutting mechanism comprises a second sliding plate, a first cutter and a second cutter, and the supporting mechanism comprises a supporting column matched with the pin shaft hole. When the blade is machined, firstly, the blade is placed in the clamping groove, the first motor drives the drill bit to rotate and move inwards, and pin shaft holes are drilled in the two ends of the blade; and then, a first driving mechanism drives a clamping groove to move backwards, a fourth driving mechanism drives a supporting column to penetrate into a pin shaft hole, a third driving mechanism drives a second sliding plate to move leftwards, and a clamping groove in the blade is machined. Automatic machining of the blade clamping groove is achieved, and the machining precision of the blade can be guaranteed.

Owner:济南国宏建材有限公司

A punching device for switch accessories for motorcycles

The invention discloses a punching device for switch accessories for motorcycles, which includes a punching part for punching holes, the punching part includes a fixed head, a rotating handle, a main punching rod provided with external threads, and a fixed head A secondary punching rod hinged at an acute angle, an AC motor used to drive the rotation handle, a first slider passing through the main punching rod, a second sliding block passing through the secondary punching rod, the first sliding block and The second slider is movably connected through a connecting rod. The first slider is provided with an internal thread that matches the external thread of the main punching rod. Punching, opening large holes with high precision and high efficiency, less damage to switch accessories materials.

Owner:FUZHOU THREEGOLD VEHICLE PARTS CO LTD

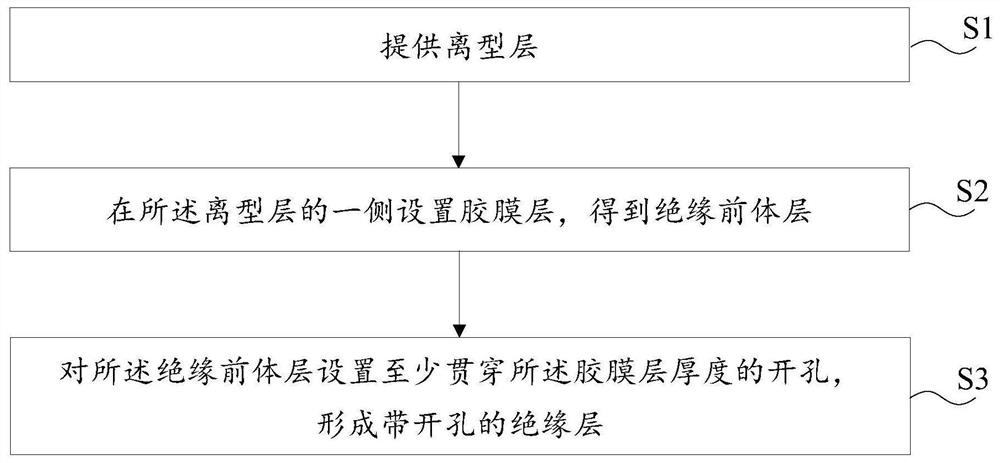

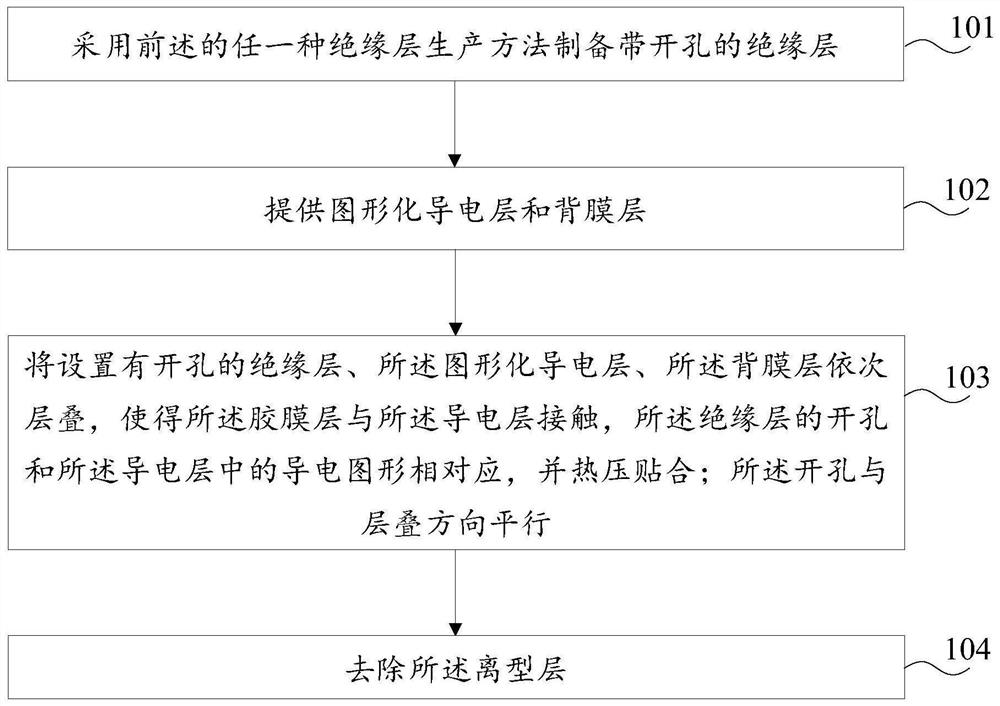

Insulating layer production method, insulating layer, conductive backboard production method and conductive backboard

PendingCN111864000AHigh strengthLimit creepFilm/foil adhesives without carriersPhotovoltaic energy generationOpen cellElectrically conductive

The invention provides an insulating layer production method, an insulating layer, a conductive backboard production method and a conductive backboard, and relates to the technical field of photovoltaics. The insulating layer production method comprises the following steps: providing a release layer; arranging an adhesive film layer on one side of the release layer to obtain an insulating precursor layer; and forming an open pore at least penetrating through the thickness of the adhesive film layer in the insulating precursor layer to form an insulating layer with the open pore. The release layer has good dimensional stability and certain strength, therefore, the insulating precursor layer has good dimensional stability and certain strength; the release layer can fully limit creep, deformation and the like of the adhesive film layer in the tapping process; the deviation of an adhesive film in the tapping process is reduced; the hole size and position of the obtained adhesive film layerare accurate, the alignment and connection reliability can be improved, repeated re-punching is not needed, the precision and production efficiency can be improved, the production cost is reduced, only the adhesive film layer needs to be arranged on one side of the release layer, the release layer needs to be removed after hole forming, and the process is simple.

Owner:LONGI SOLAR TECH (TAIZHOU) CO LTD

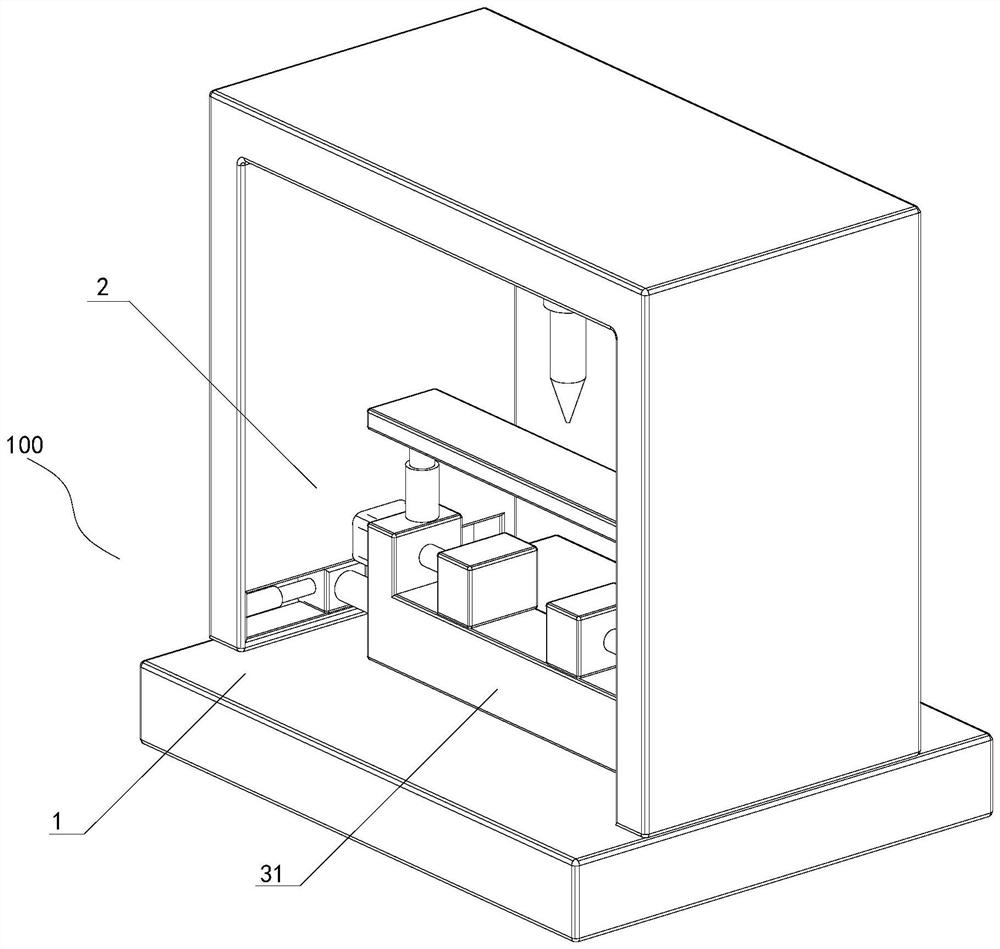

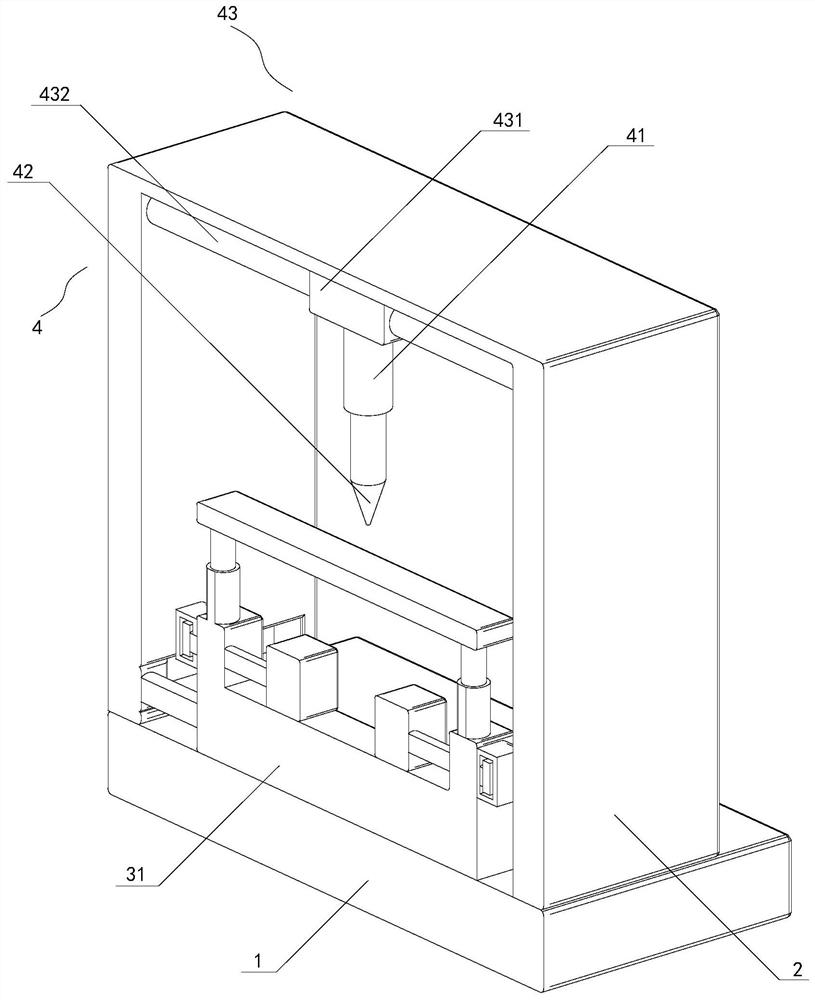

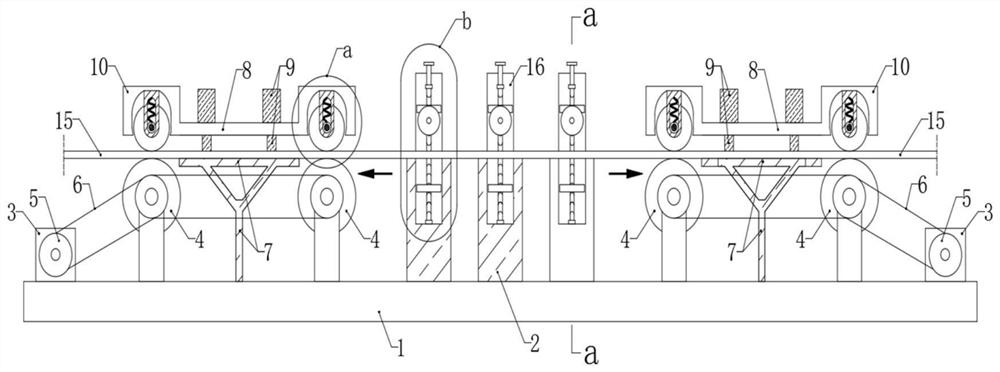

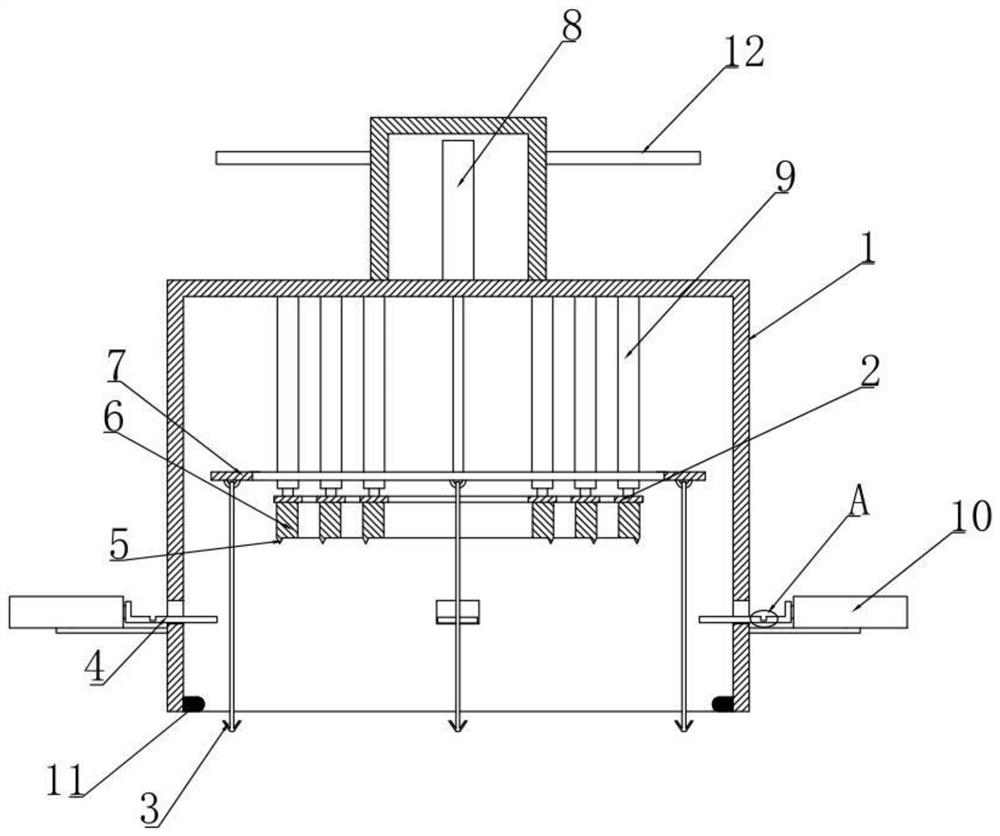

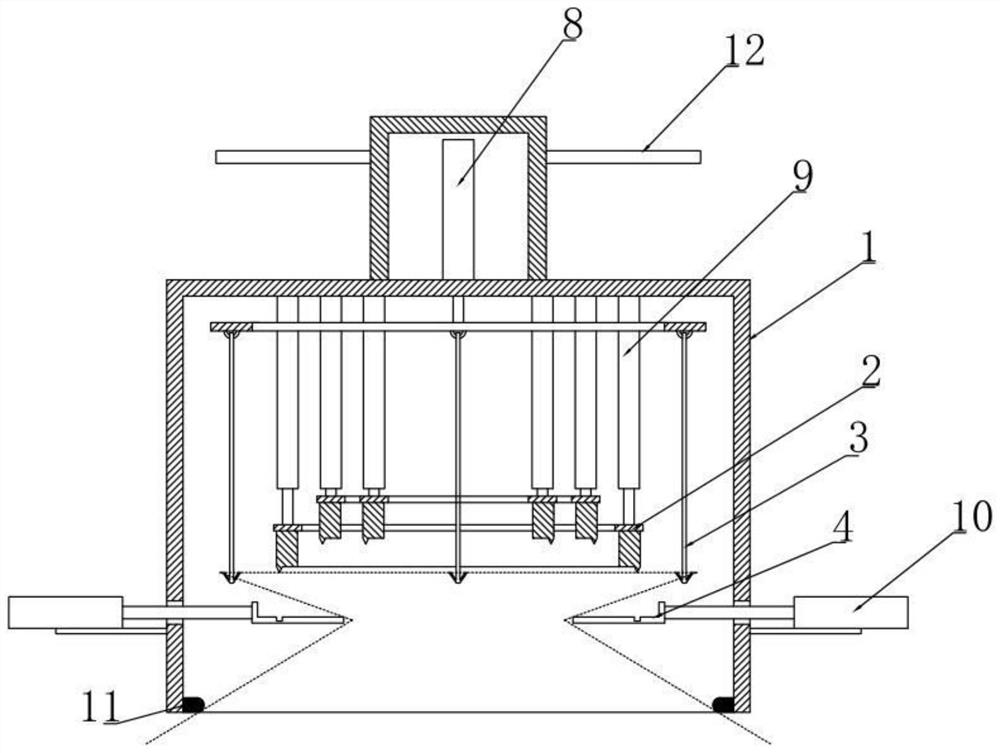

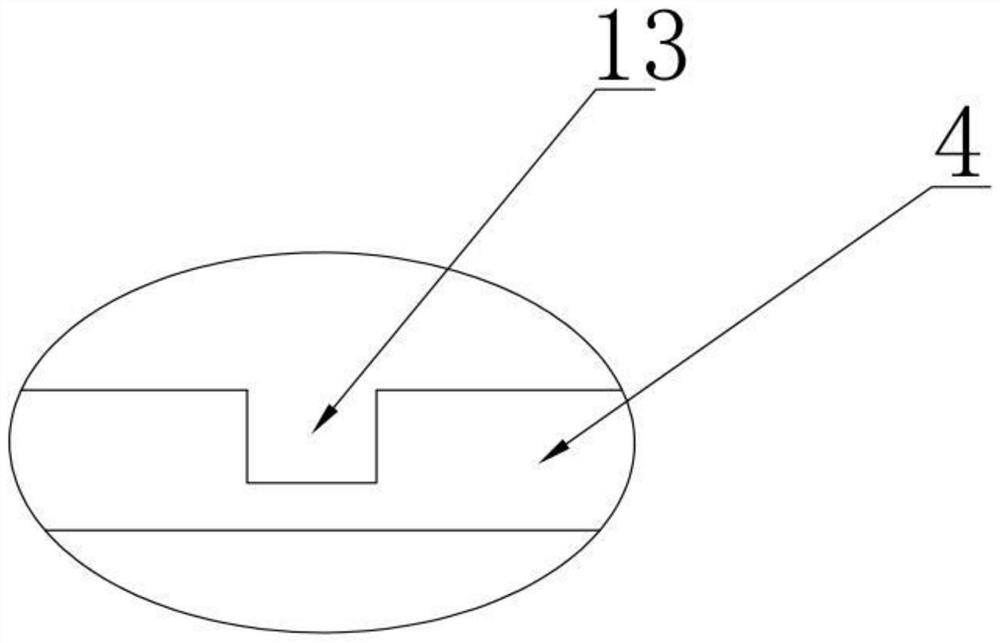

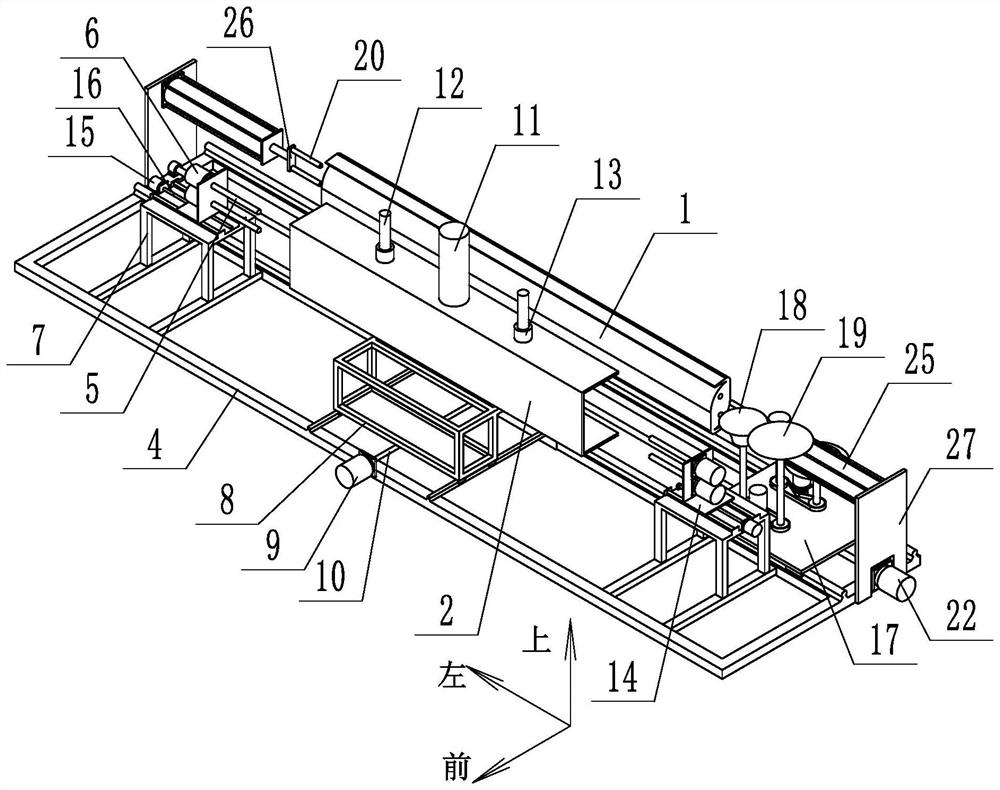

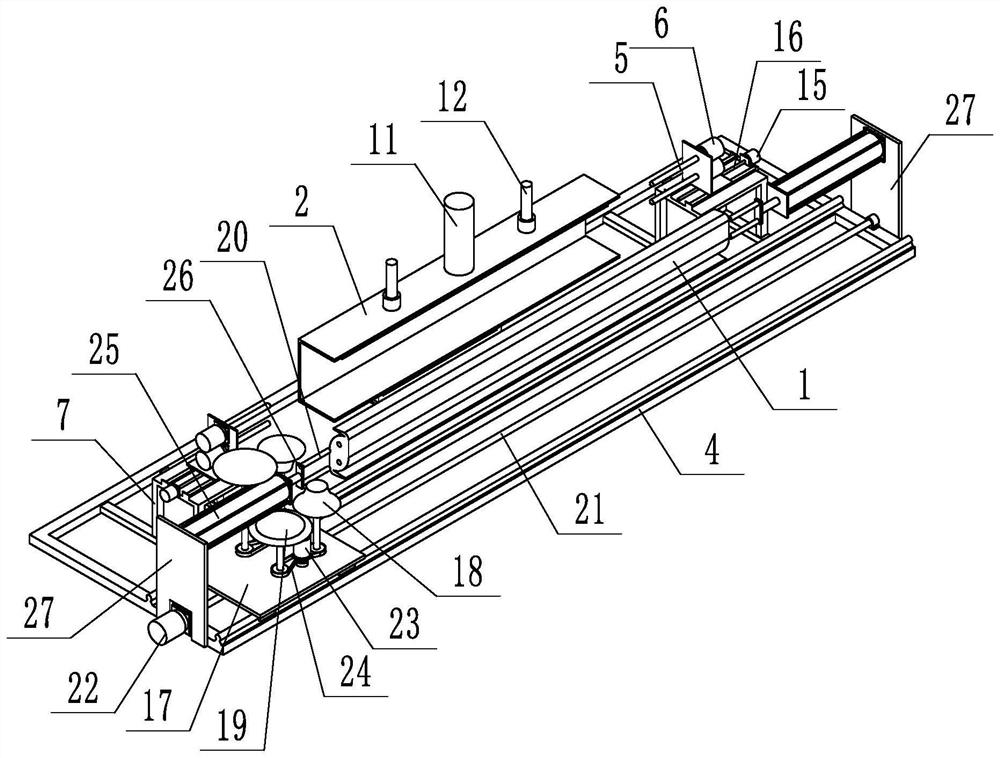

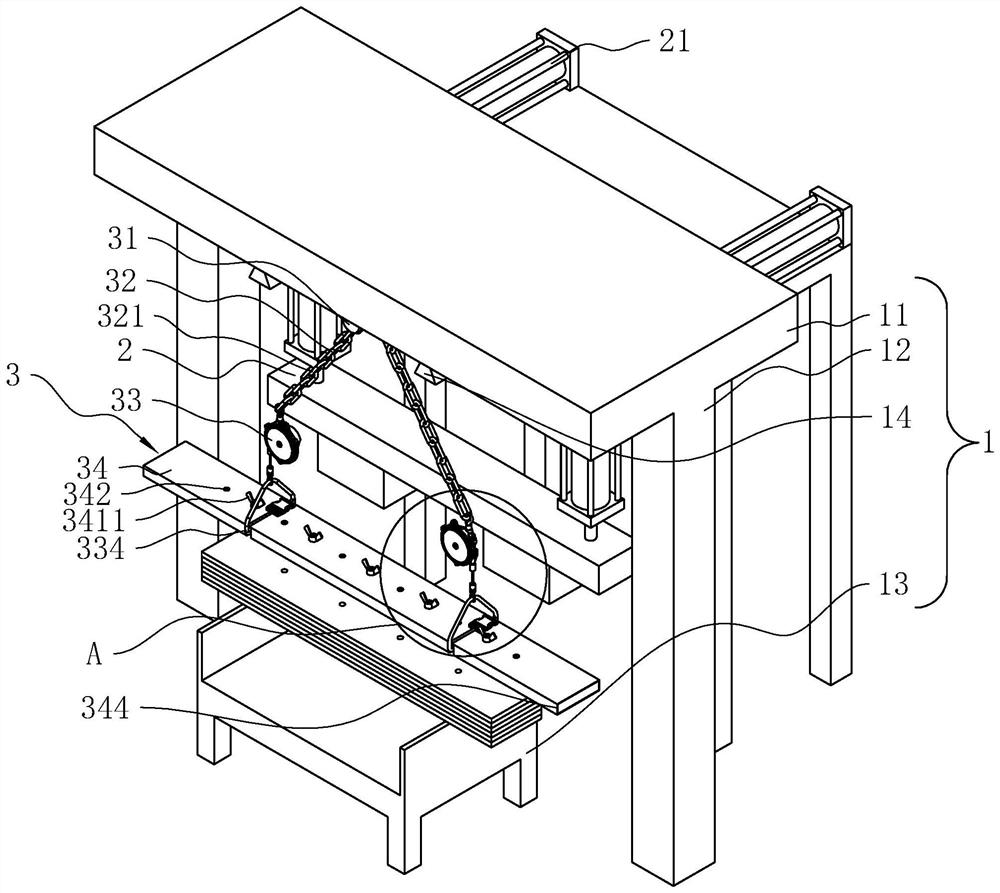

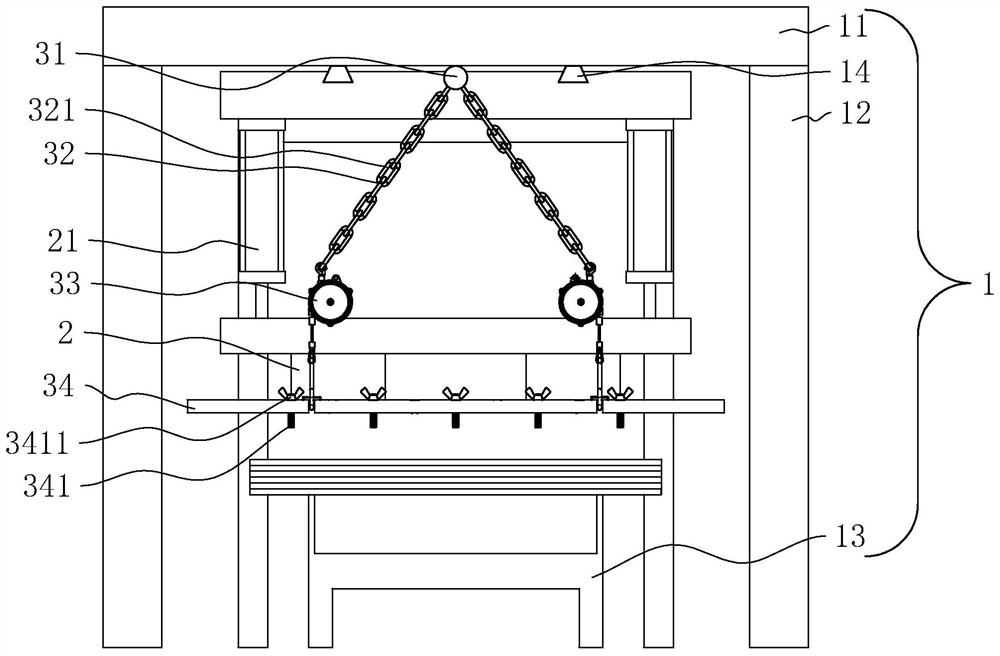

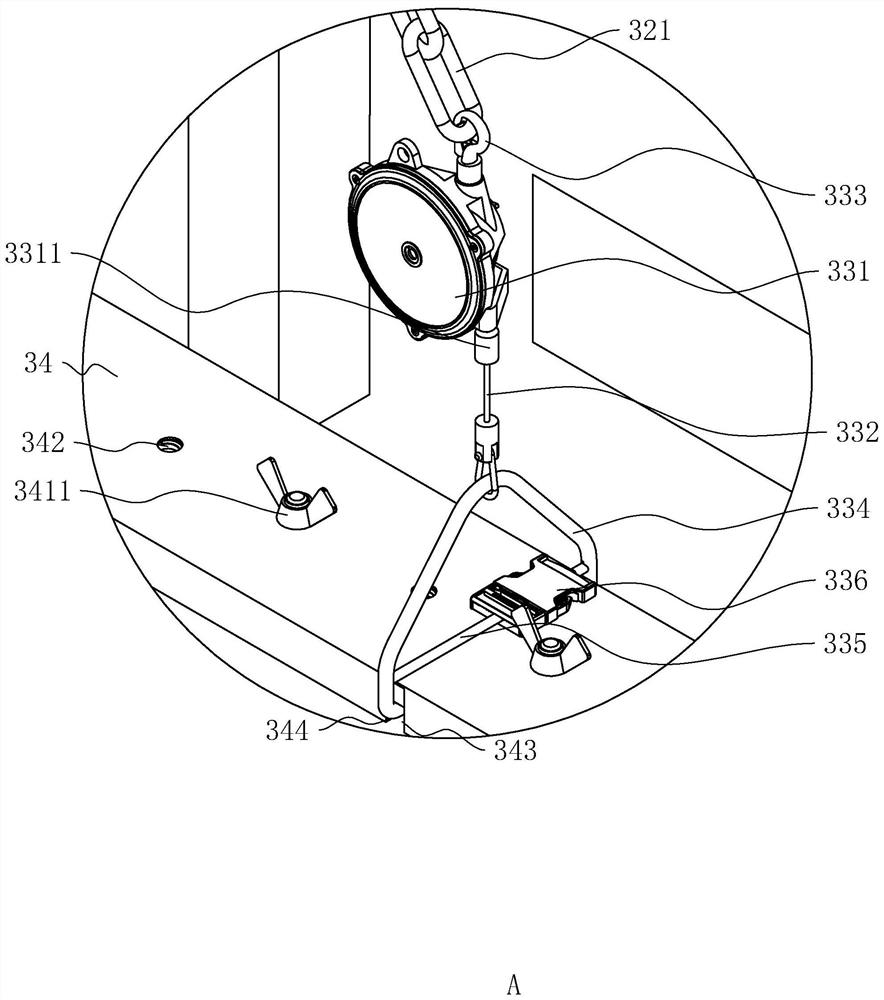

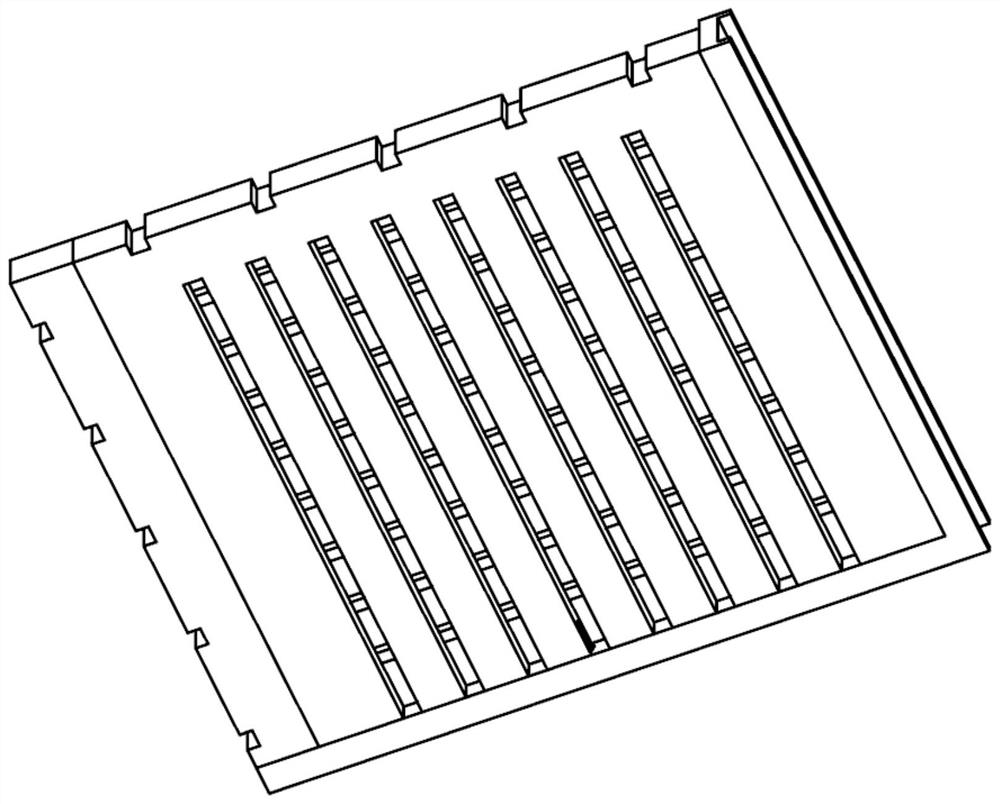

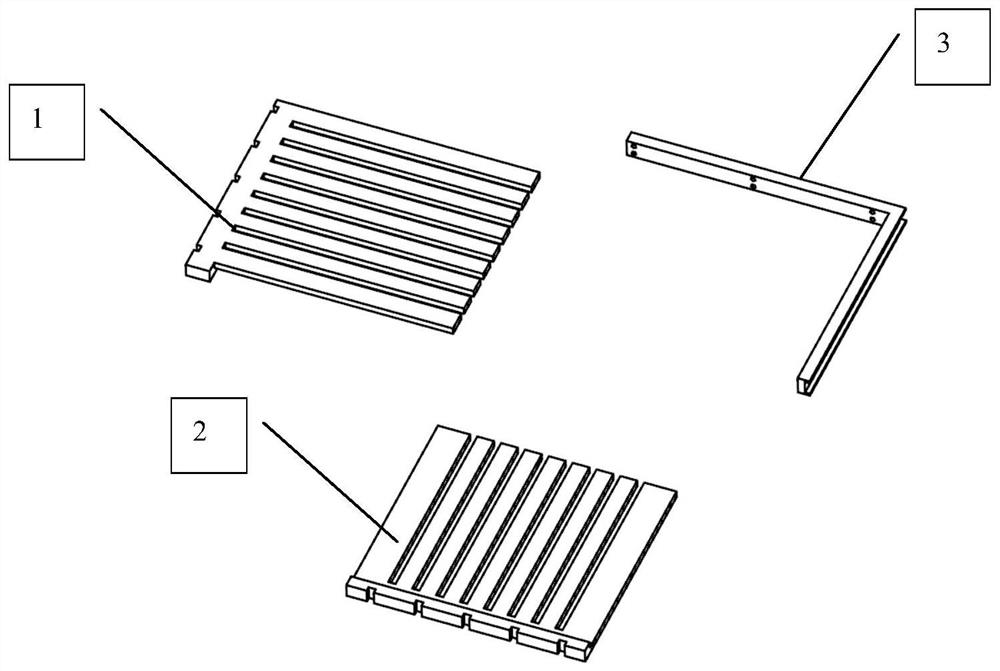

Automatic blade plate stacking device

PendingCN112850177AConvenient inspectionThe hole position is accurateStacking articlesRigid containersBlade plateClassical mechanics

The invention relates to the field of machining, in particular to an automatic blade plate stacking device which comprises a machine frame and a conveying assembly arranged on the machine frame. The machine frame comprises a cross beam, stand columns perpendicular to the cross beam and a containing frame fixedly arranged between the stand columns, and a positioning device is arranged on the cross beam in a hanging mode. The positioning device comprises connecting ropes and a positioning rod which are fixedly arranged on the cross beam, telescopic assemblies are arranged at the ends, away from the cross beam, of the connecting ropes, the ends, away from the cross beam, of the telescopic assemblies are arranged, and a plurality of positioning blocks are arranged on the positioning rod. In the process of machining and transporting blade plates, the blade plates are stacked in order, and follow-up machining is facilitated.

Owner:布莱凯特设备(苏州)有限公司

Radio frequency/microwave blind-mate connector array positioning method

PendingCN113872008ASimple structureEasy to installContact member assembly/disassemblyMicrowaveHigh density

A radio frequency / microwave blind-mate connector array positioning method disclosed by the invention is convenient to operate, reliable in positioning and low in cost. The method is realized through the following steps: preparing a finger-shaped clamp capable of limiting all radio frequency blind-mate connector array bidirectional plugs in a vertically and horizontally crossed finger insertion grid of two groups of positioning finger insertion plates; then, during assembly, inserting the longitudinal positioning finger insertion plate and the transverse positioning finger insertion plate into an array area of a radio frequency bidirectional plug in a crossed mode in the longitudinal direction and the transverse direction respectively, and forming crossed grids between matrix row and column interval channels of the radio frequency bidirectional plug through the longitudinal positioning finger insertion plate and the transverse positioning finger insertion plate which are stacked up and down; then, fixing rectangular right-angle sides formed by intersection of the longitudinal positioning finger insertion plates and the transverse positioning finger insertion plates through L-shaped angle square positioning pieces; and positioning the relative plane positions of all the radio frequency bidirectional plugs by virtue of the cooperation of the pore size of the crossed grid and the boundary dimension of the connector, so as to complete the overall positioning of the high-density bidirectional plugs of the radio frequency blind-mating connector array between the microwave components.

Owner:10TH RES INST OF CETC

Drilling device for motor blade cover

ActiveCN106424816BImprove work efficiencyThe hole position is accurateBoring/drilling componentsBoring/drilling machinesEngineeringFan blade

The invention relates to a motor blade cover drilling device. The motor blade cover drilling device comprises a workbench and further comprises a material bearing frame and drilling device bodies. The material bearing frame is in a cylinder shape of which the top surface is provided with an opening, and four through holes are formed in the same height position of the middle-lower portion of the material bearing frame in a circumference array mode. The material bearing frame is fixedly installed in the center of the workbench. Each drilling device body comprises a base, a linear guide rail, an air cylinder and a drilling power head. Each base is fixedly installed on the workbench. Each linear guide rail is fixed to the end, close to the material bearing frame, of the corresponding base and is parallel to the axis line of the corresponding through hole. Each drilling power head is slidably installed on the corresponding linear guide rail, and the axis line of each drilling power head is aligned to the axis line of the corresponding through hole. Each air cylinder is fixedly installed at the end, away from the material bearing frame, of the corresponding base. The top of each air cylinder is fixedly connected to the tail end of the corresponding drilling power head. The four drilling device bodies are fixed to the workbench around the material bearing frame and are aligned to the four through holes of the material bearing frame correspondingly. The working efficiency is greatly improved, and in addition, the hole positions are also accurate, so that substandard products are not produced.

Owner:浙江佳雪微特电机有限公司

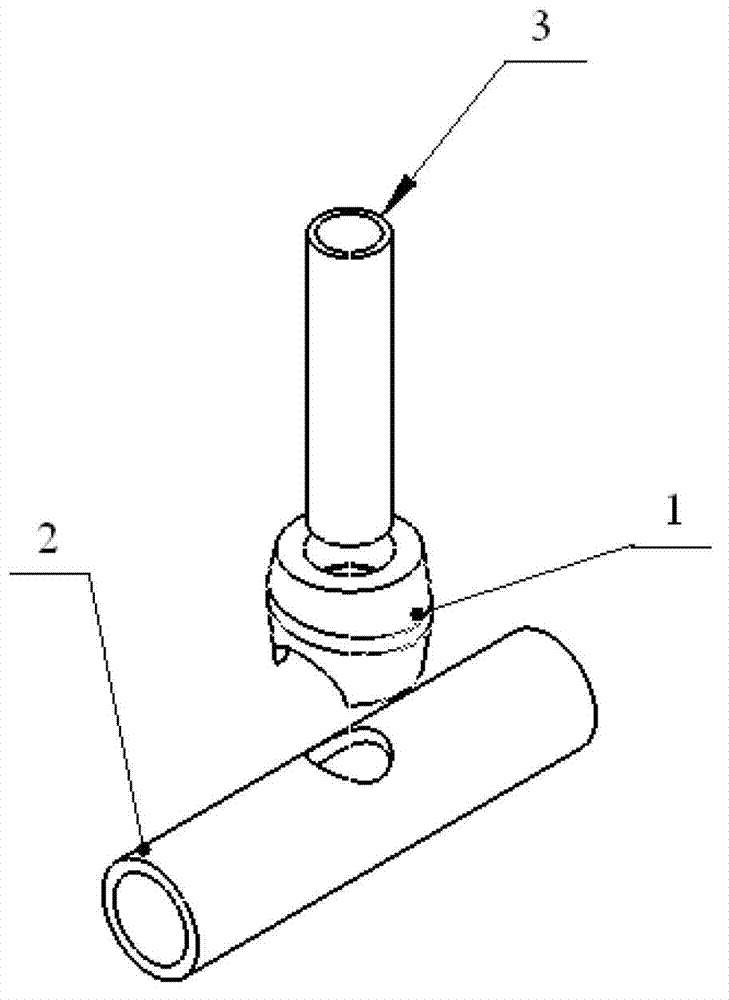

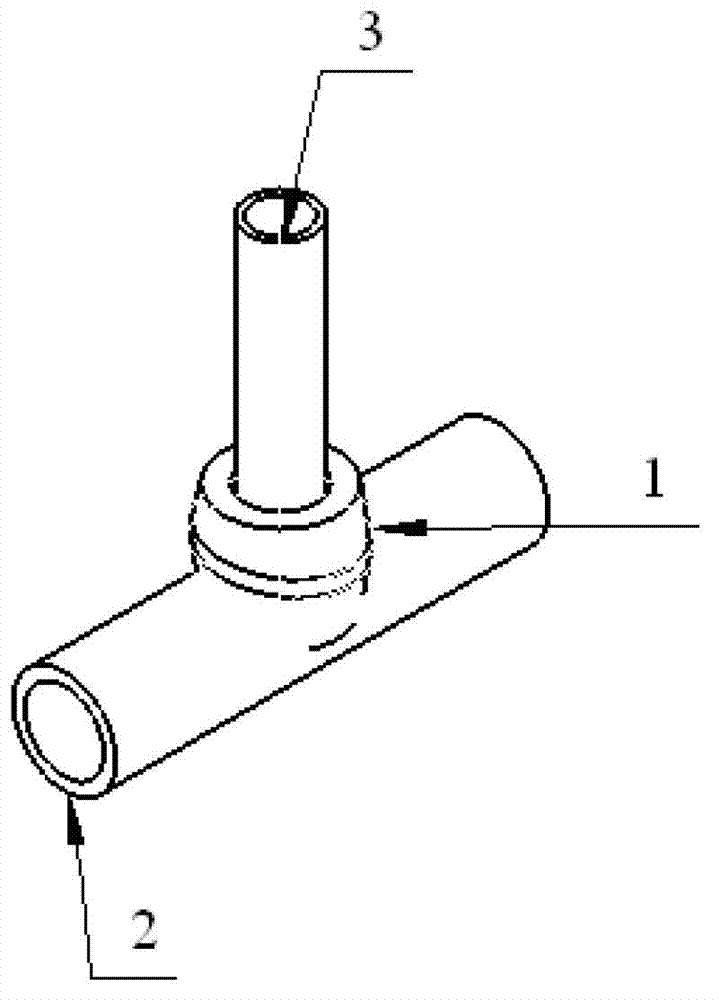

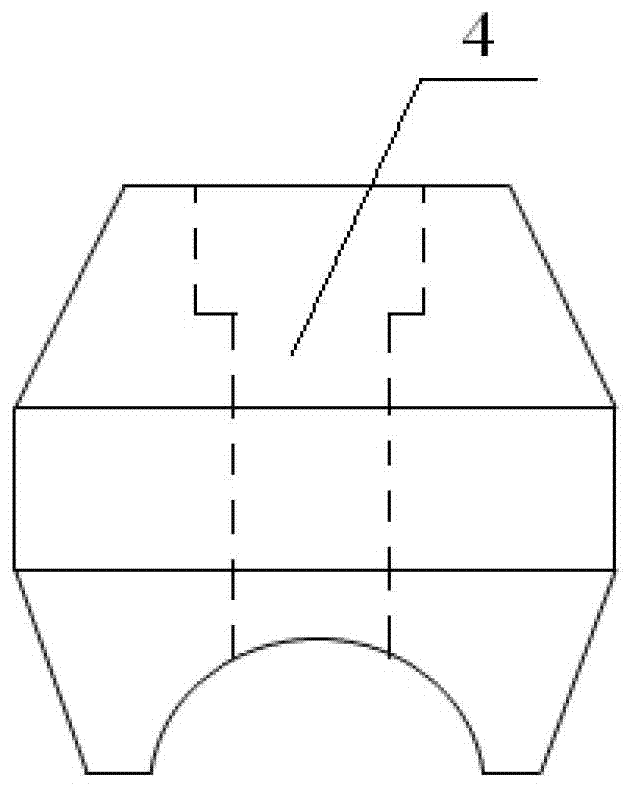

Tool and method for installing novel inserting opening of hydraulic pipeline

InactiveCN102825441AThe hole position is accurateLow skill level requiredArchitectural engineeringDrill bit

The invention discloses a tool and a method for installing a novel inserting opening of a hydraulic pipeline. The method comprises the following steps of (1) welding a sleeve at the installation position of a branch pipeline according to a technical document, placing a drill head of a magnetic drill at the inner part of the sleeve, providing a hole on a main pipeline, then removing the sleeve, and polishing the hole; (2) stretching a magnetic bar to the inner part of the main pipeline through the hole, and extracting iron fillings which are generated during the hole processing; (3) placing a bearing hydraulic connector which is processed and prepared at the position of the hole of the main pipeline, assembling and welding; and (4) placing the branch pipeline in an inserting hole of the bearing hydraulic connector, and welding. According to the method for installing the novel inserting opening of the hydraulic pipeline, disclosed by the invention, the branch pipeline and the hydraulic connector adopt bearing type welding, the requirement on the technical level of an operator is greatly reduced, and the construction quality is increased; the construction can be carried out in smaller space, and the requirement on the construction environment is greatly reduced; and by adopting the construction method, the welding work amount is reduced, the number of long flaw detection welded junctions is reduced, the construction period is saved, and the method is economic and practical.

Owner:TIANJIN 20 CONSTR

Automatic pneumatic positioning perforating machine for perforating tail part of medical suture needle

PendingCN112974893AImprove quality and efficiencyIncrease productivityFeeding apparatusMetal working apparatusSuturing needleSurgery

The invention provides an automatic pneumatic positioning perforating machine for perforating the tail part of a medical suture needle, and relates to the technical field of perforating machines. The automatic pneumatic positioning perforating machine for perforating the tail of the medical suture needle comprises a workbench, a fixing assembly, a positioning assembly and a drilling assembly, wherein the workbench can bear the fixing assembly, the positioning assembly and the drilling assembly, so that installation of the fixing assembly, the positioning assembly and the drilling assembly is facilitated. The fixing assembly is used for fixing the suture needle, so that the situation that the suture needle slides during drilling, and consequently the drilling quality is reduced is prevented. The positioning assembly is used for positioning a tapping point at the tail of the suture needle, so that the tapping position is accurate, and the problem of hole deviation is avoided. The drilling assembly is a direct drilling part and is responsible for drilling at the tail part of the suture needle. According to automatic pneumatic positioning perforating machine disclosed by the invention, automatic perforating of the tail part of the medical suture needle can be achieved, the perforating precision is high, the perforating speed is high, and the quality and production efficiency of the medical suture needle are greatly improved.

Owner:董松

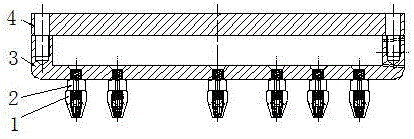

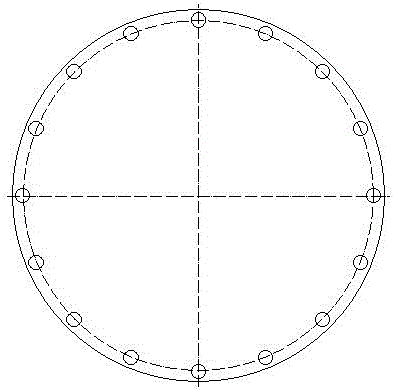

Forming device for drilling multiple holes in glassware bottom through one-time fire

ActiveCN106524158AAccurate locationThe hole position is accurateGaseous fuel burnerEngineeringMechanical engineering

The invention provides a forming device for drilling multiple holes in the glassware bottom through one-time fire. Rapidness is achieved, and the processing stability is good. Moreover, a guarantee is provided for subsequent product quality, and rupturing hidden danger is eliminated. The forming device for drilling multiple holes in the glassware bottom through one-time fire comprises a gun body and one or more gun heads. The gun body comprises a gun main body and a gun body cover plate which is detachably connected with the gun main body. A cavity is formed in the gun main body. The gun heads are uniformly distributed in the peripheral direction of the outer edge of the gun main body. Each gun head comprises a gun head inner core and a gun head outer shell. One end of each gun head inner core is connected to the gun body, and each gun head inner core is in threaded connection with the corresponding gun head outer shell.

Owner:SHANDONG LINUO TECHNICAL GLASS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com