Construction method and facilities of steel trestle bridge with percussion drilling limit hole implantation combined with crawler crane

A construction method and crawler crane technology, applied in bridge construction, infrastructure engineering, bridges, etc., can solve problems such as inability to ensure structural safety, achieve the effects of ensuring structural safety, reducing engineering costs, and ensuring safe construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

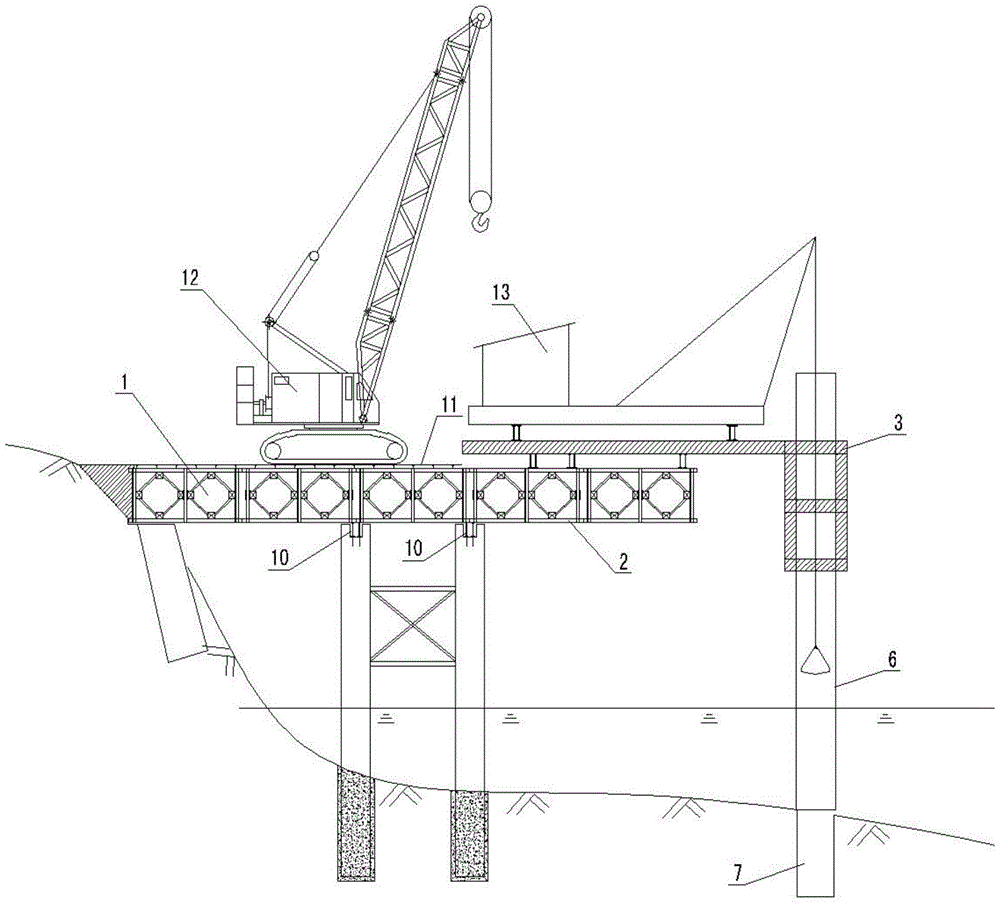

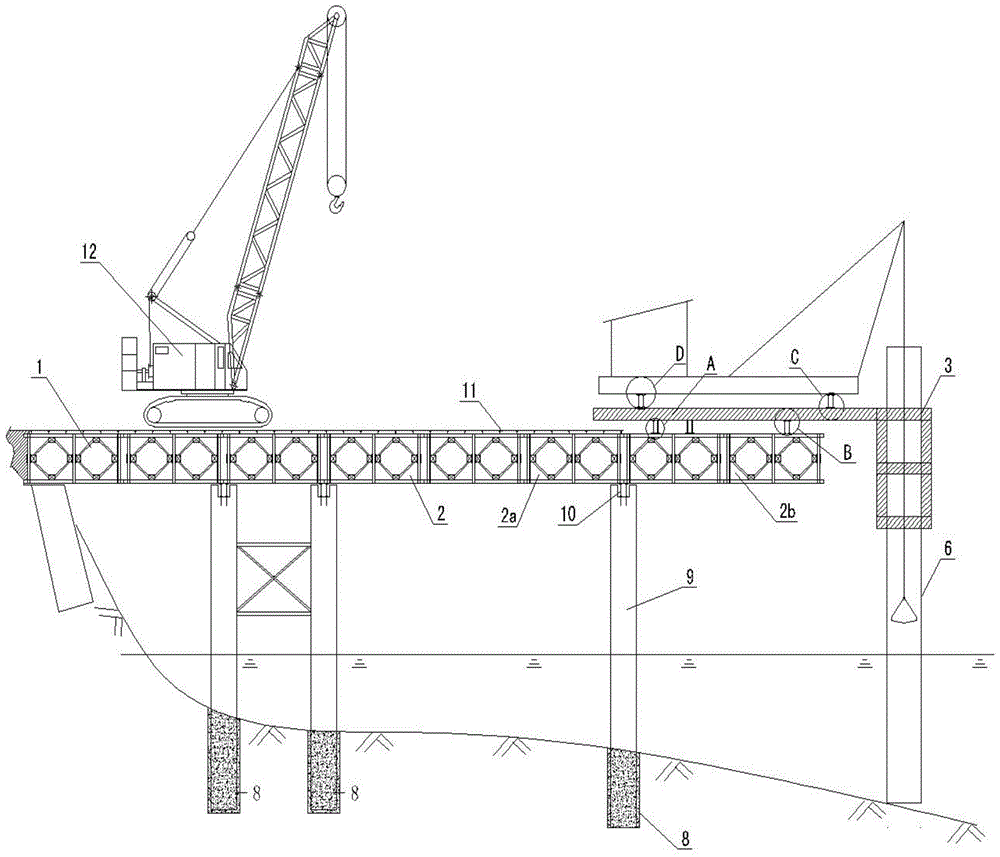

[0028] see figure 1 and figure 2 , in the present embodiment, the percussion drilling limit hole-forming method is implanted into the steel trestle bridge construction method combined with the crawler crane according to the following steps:

[0029] Step 1: construct the first-span steel trestle 1 on the shore, move the crawler crane 12 on the first-span steel trestle 1, and install the second-span cantilevered Bailey girder 2 with a length of 600cm on the first-span steel trestle 1.

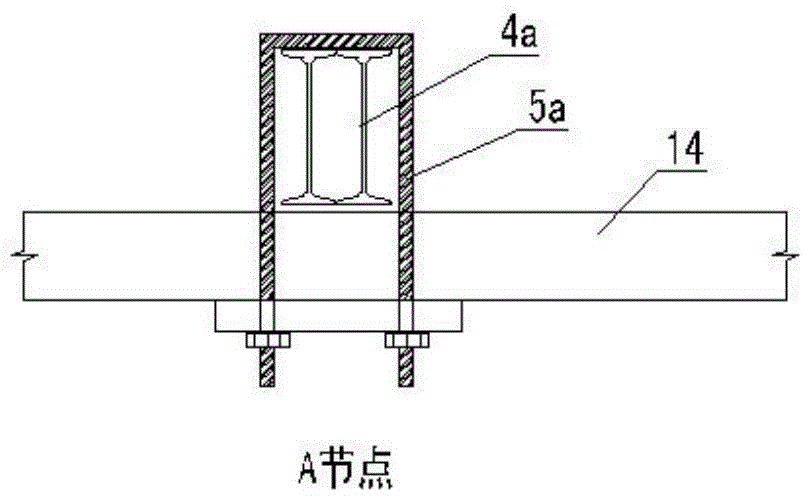

[0030] Step 2: Fix the limiting frame 3 and the percussion drilling rig 13 on the second-span cantilevered Bailey sheet beam 2 through double-button I-shaped steel and threaded steel U-shaped clips 5d, so that the cantilevered limiting frame The plane position of 3 is on the plane position of the second-span steel pipe pile; a steel casing 6 with a diameter of 1 m is placed in the limit frame 3, and a hammer head with a diameter of 0.8 m of the percussion drilling rig is placed in the steel ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com