Tool and method for installing novel inserting opening of hydraulic pipeline

An installation method and hydraulic pipeline technology, applied in the field of pipeline socket installation tools, can solve the problems of troublesome installation and construction of the socket, high strength, etc., and achieve the effect of reducing welding workload, accurate opening position, and lowering the technical level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings.

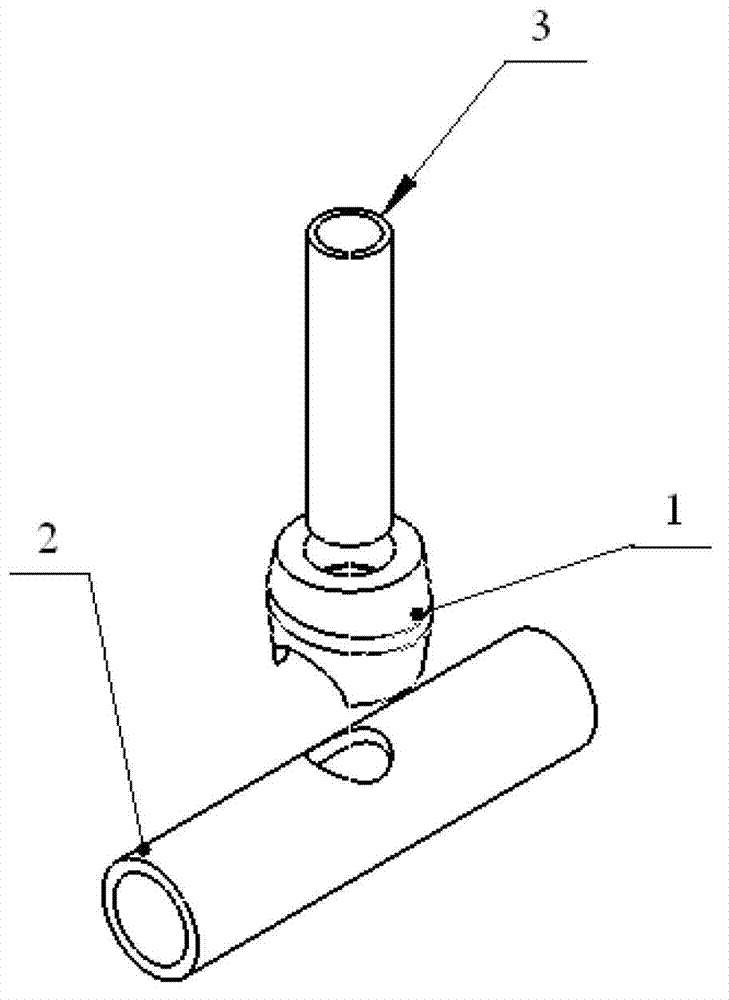

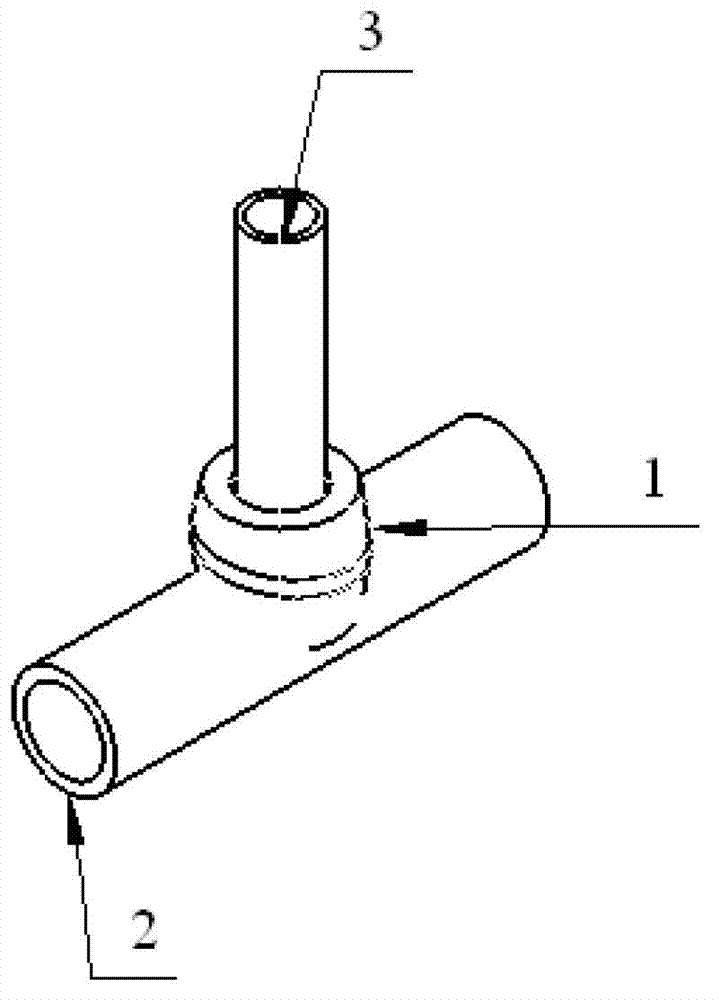

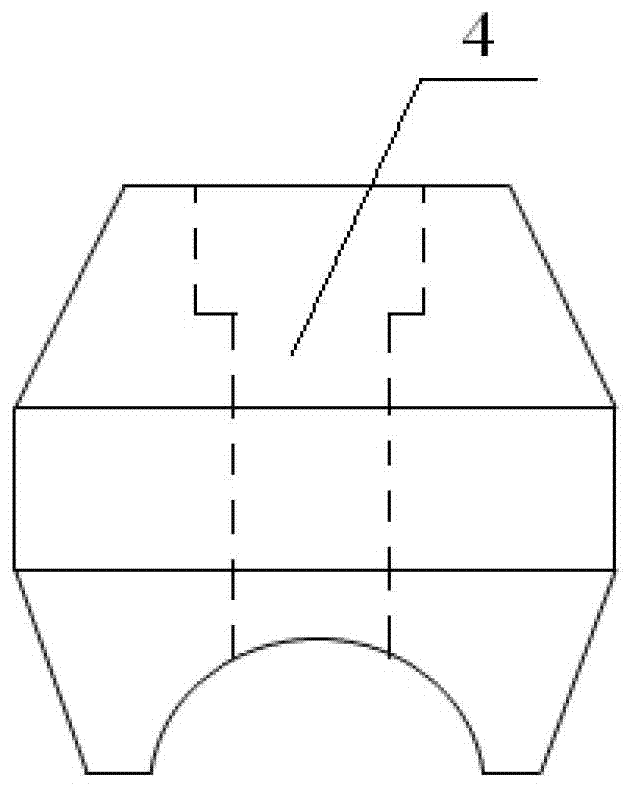

[0026] Such as image 3 The shown hydraulic joint 1 is made of 20# steel, and the upper part is conical, the middle part is cylindrical, and the lower part is conical. A through hole 4 is processed in the center of the hydraulic joint 1. The diameter of the upper part of the processed through hole 4 is slightly larger than the outer diameter of the branch pipeline 3 ( About 1 mm), it is convenient for the branch line 3 to be inserted into the hydraulic joint 1, and the length of the upper part of the through hole 4 is no more than the height of the top without the top cone. The diameter of the lower part is the same as the inner diameter of the branch pipeline 3, and the bottom of the hydraulic joint 1 is processed into an arc shape, which matches the outer diameter of the main pipeline 2, so that the hydraulic joint 1 can be placed on the main pipeline 2 for welding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com