Automatic pneumatic positioning perforating machine for perforating tail part of medical suture needle

A suture needle and punching machine technology, applied in the field of punching machines, can solve the problems of high processing difficulty, high loss rate, low efficiency, etc., and achieve high punching accuracy, fast punching speed, and improve quality and production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

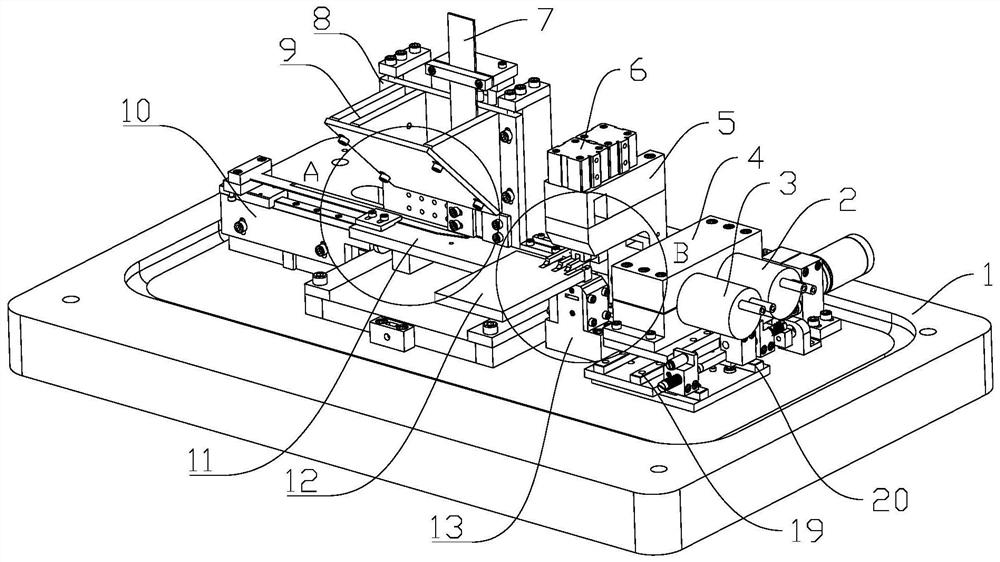

[0037] Please refer to figure 1 , figure 1 The schematic view of the embodiment of the present invention is shown in the present invention, and this embodiment provides a medical sewing needle 21 tail hole perforation, aperture, aperture, aperture, and a table 1, a fixing assembly, a positioning assembly 3, and a drilling assembly 2. The above table 1 can carry the fixing assembly, the positioning assembly 3, and the drilling assembly 2, facilitate the mounting of the components, positioning assemblies 3, and the drilling assembly 2. The fixing assembly is used to secure the suture 21 to prevent the suture 21 from sliding when drilling, resulting in a decrease in the drilling quality. The positioning assembly 3 is used to achieve the positioning of the tail opening point of the suture pin 21, and the opening position is accurate, avoiding the bias. The drilling assembly 2 described above is a direct drilling member, which is responsible for punching in the tail of the stitch 21.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com